Firefly YASBP-56HL, YASBP-25HL, YASBP-38HL, YASBP-90HL User Manual, Installation & Operation

Page 1

Air Source Heat Pump

Applicable Models: YASBP-25HL

YASBP-38HL

YASBP-56HL

YASBP-90HL

Jan. 2012s V

Presented b y Ji mm y Zh an g

Than k yo u ve ry much f or p ur chasi ng o ur a ir sour ce h ea t pumps .

Plea se r ead this ma nu al c arefu ll y an d keep it f or f ut ure ref er en ce befo re i ns talling a nd u sing the he at p umps.

Page 2

Hot Water S eri es

CONTENTS

9. Maintenance and Trouble Shooting

9.1 Maintenance

9.2 Parameter Checking

9.3 Error Code

9.4 Trouble Shooting

7. Controller Operation

7.1 Keys Illustration

7.2 Illustration for LCD Display

7.3 Water Temperature Setting

7.4 Clock Setting

7.5 ON/OFF Time Setting

6. Commissioning

6.1 Preparation Before Commissioning

6.2 Commissioning

5. Installation

5.1 Heat Pump unit Installation

5.2 Water System Installation

5.2.1 Water Tank Installation

5.2.2 Water Piping Installation

5.3 Power Source Installation

4. Technical Data

4.1 Parameter Table

4.2 Dimension

4.3 Performance Curves

4.4 System Diagram

4.5 Components

1. Features/Benefits

2. Notes/Precautions

3. Model Number Nomenclature

8. Circuit Drawing

1

1

2

2

2

3

4

8

9

10

10

11

11

11

12

14

14

14

15

15

16

16

18

19

21

23

23

24

24

25

5.4 Wire Controller Installation

13

Page 3

1. Features/Benefits

Wide App lication Ran ges

Full Consi deration for Nois e Control

The Thermal Mas ter S eries is designed for

Compressor ru bbe r feet are specially select ed for

domestic hot wa ter f or a houses, as well as small

reducing vibr ati on. Specially, co mpressor sound

commercial bu ild ings such as small hotels, jacket is avail able for every unit. Well- balanced

offices, scho ols , hospitals, apartme nts e tc. The fans and fan moto rs, w ith the optimized fan

holder, contributes to the l ow no ise operation. The

hot water outle t ran ge is wide from 20 to 60 ,

cabinet insid e is insulated to reduce noise

meeting deman ds fo r most hot water project. The

transmissio n.

performance i s at wi de ambient temperature

range from -10~ 43 . Modular control system i s

Relia ble D esign and Strict Qu ality Control

available to me et th e demand of bigger hot water

Standard safe ty fe atures for the refrigeran t circuit

projects.

include high- pre ssure switch and low-pres sure

Assur ing You Get Gra nts from Governme nt

switch to detec t los s of refrigerant, as well as

Designed for hi gh ef ficiency performance ov er a

deficient wat er fl ow. Equipment safety feat ures

lifetime of ope rat ion. The annual average COP i s

include water l oop t emperature monitoring ,

up to 4.5. The wate r pip es and refrigerant pipes

voltage prote cti on, water coil freeze prote ction.

are well insula ted t o minimize the heat loss.

All safety feat ure s are tested and run at the facto ry

to assure prope r ope ration of all components an d

Durab le an d Long Life

safety switch es.

High efficien cy co mpressor for all units , wit h

All component s are c arefully designed and

durable featu res a gainst high temperature a nd

selected for en dur ance, durability, and carefree

high pressure f or lo ng life. The tube in shell heat

day-to-day operation. Ea ch un it is fully tested in

exchanger are d ura ble for anti-corrsion, ha rd

performance a nd sa fety before exit factory.

water, high pressure and une xpe cted freeze

caused by power c ut-off.

Simple Mai ntenance and Serv iceability

Full acce ss fo r maintenance or service is p rovided

Strong Cab inet

from the mainte nan ce panel, for better flexib ility in

Standard unit f abr ication consists of heavy g age

confined spac e. Ea sy removal of the control box

galvanized sh eet m etal cabinet constructi on th at

from the unit pro vid es access to all refrigeran t

provides maxi mum s trength. All interior she et

components. T he re frigerant circuit is easi ly

metal surface s are p owder-painted for maximum

tested and serv ice d though the use of high and

corrosion pro tec tion to ensure resilience f or long

low pressure po rts i ntegral to the refrigeran t

term vitality. Compact, stackable c abinets are

circuit.

designed to min imi ze installation spac e.

° °

C C

°

C

Hot Water S eri es

1

The installat ion , commissioning and wires are apart f rom h ot or moving parts [eg:

maintenance o f the s ystem should only be done compressor, f an] o f the system to avoid

by qualified pe rsonnel with adequate knowle dge damage to the wir es.

of the relevant s tan dards and local regulatio ns as

Anti-freezi ng me asures must be well done to

well as experie nce w ith similar systems.

avoid damage to t he wa ter system and the heat

pump water heat e xch anger.

Please make sur e the w ater flow is sufficient all

the time.

Please make sur e the l ifting and transportati on

are safely done a cco rding to the heat pump

All ground line c onn ections must be prepared in

size and weight .

accordance wi th re levant local regulation s.

It is very danger ous w ork done at the facility

To reduce the risk of electrical i nsulation faults,

without previ ous ly cutting off the electric ity from

you first make th e con nection of the protective

the main power so urc e.

conductor of th e hea t pump safe according to

local regulat ion s.

When installi ng th e system, please ensure tha t

no contaminan ts en ter the water cycle.

When installa tio n, mak e sure that the inside

2. Notes/Precautions

■

■

■

■

■

■

■

■

■

Page 4

Hot Water S eri es

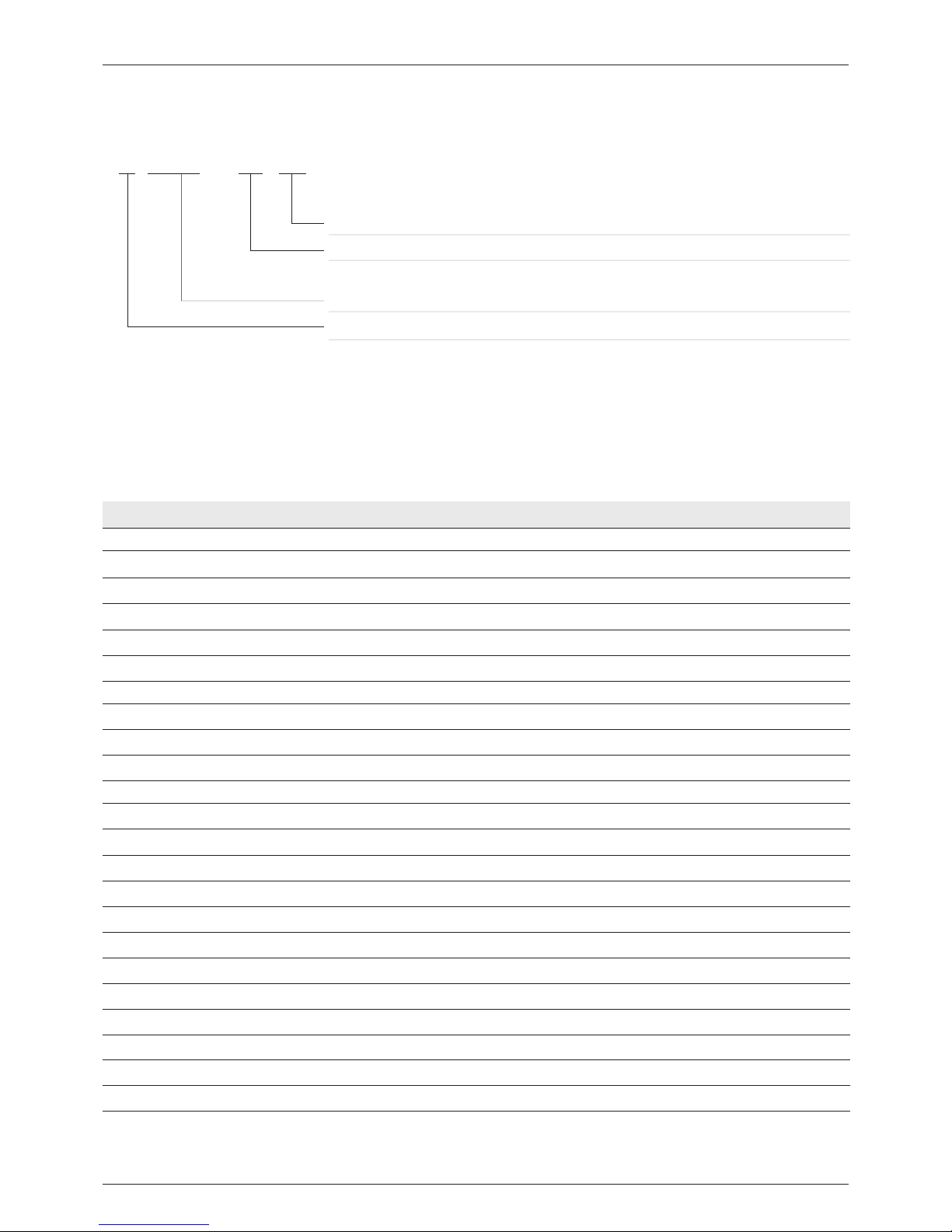

3. Model Number Nomenclature

Y ASBP - 25 HL

HL - Si ngle Phase; H S - 3 Phase s

25 - 1HP 38 - 1. 5HP 56 - 2HP 90 - 2.5HP

AS BP - Horizontal Fan; Y ASA - Ver tical Fan

FIREFLY

Po wer Supply

Case St ruc ture

Co mpany

Input Power

Running Current

Max. Input Power

Max. Running Current

Refrigerant

Compressor

Compressor Type

Compressor Quantity

Outlet Water Temp

Max. Outlet Water Temp

Hot Water Output

Water Flow

Condenser

Water Pressure Drop

Water Connection Tube

Noise

Electric Protection

Mechanical Protection

Power Supply

Heating Capacity

Net/Gross Weight

Dimension

Packing Dimension

3.91

0.8

3.64

1.2

5.57

R410a

Panasonic

Rotary

1

55

60

86

0.8

Tube in shell

20

3/4"

<48

I

IPX4

220/1/50

YA SBP-2 5HL

38/43

770/300/490

820/325/520

kW

kW

A

kW

A

ºC

ºC

L/h

3

m /h

Kpa

mm

dB(A)

V/Ph/Hz

kg

mm

mm

5.1

1.214

5.31

1.7

7.75

R410a

Panasonic

Rotary

1

55

60

110

1.1

Tube in shell

20

<48

I

IPX4

220/1/50

YA SBP-3 8HL

51/56

940/360/550

985/390/590

3/4"

7.53

1.88

8.7

2.23

10.32

165

1.6

20

<48

220/1/50

YA SBP-5 6HL

58/63

940/360/550

985/390/590

R410a

Rotary

1

55

60

Panasonic

Tube in shell

3/4"

I

IPX4

Measu ring cond ition: Dry/wet bu lb te mp 20ºC/ 15ºC; Water outle t temp 15 ºC~55ºC.

4. Technical Data

4. 1 Parameter Table

2

Mo dle Typ e

9.05

2.61

11.86

3.99

18.12

210

2.1

20

<48

220/1/50

YA SBP-9 0HL

65/70

1010/370/615

1140/400/670

R410a

Rotary

1

55

60

Panasonic

Tube in shell

3/4"

I

IPX4

Page 5

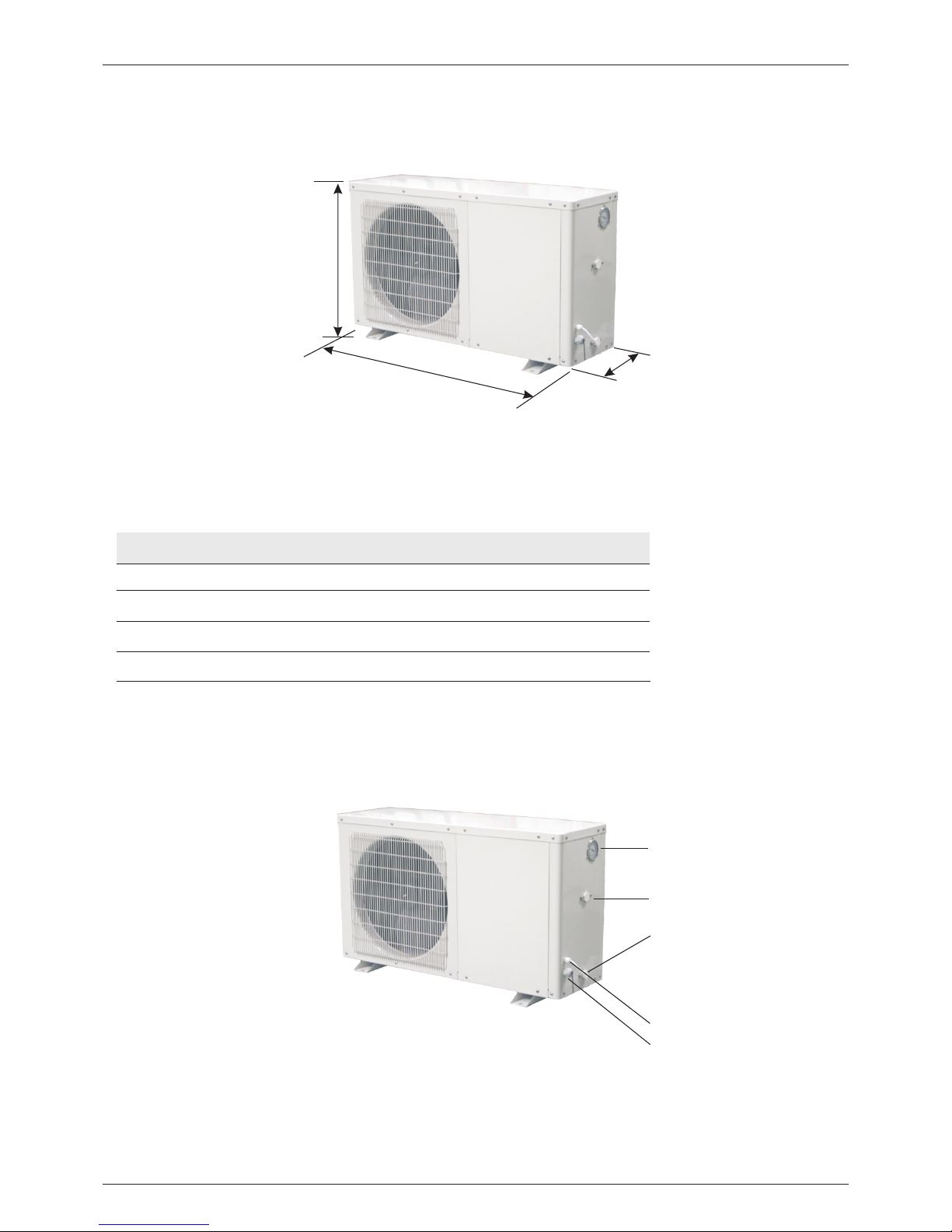

Water Outl et

Water Inle t

Power Su pp ly Cabl e Hole

Cont roller Ca ble Hol e

Hot Water S eri es

770

940

Length (mm)

300

360

Wide (mm)

490

550

Height (mm)

YASBP-25HL

YASBP-38HL

Model

4. 2 Dimension

3

L

H

W

High P ressu re G auge

940 360

550

YASBP-56HL

1010 370

615

YASBP-90HL

Page 6

Hot Water S eri es

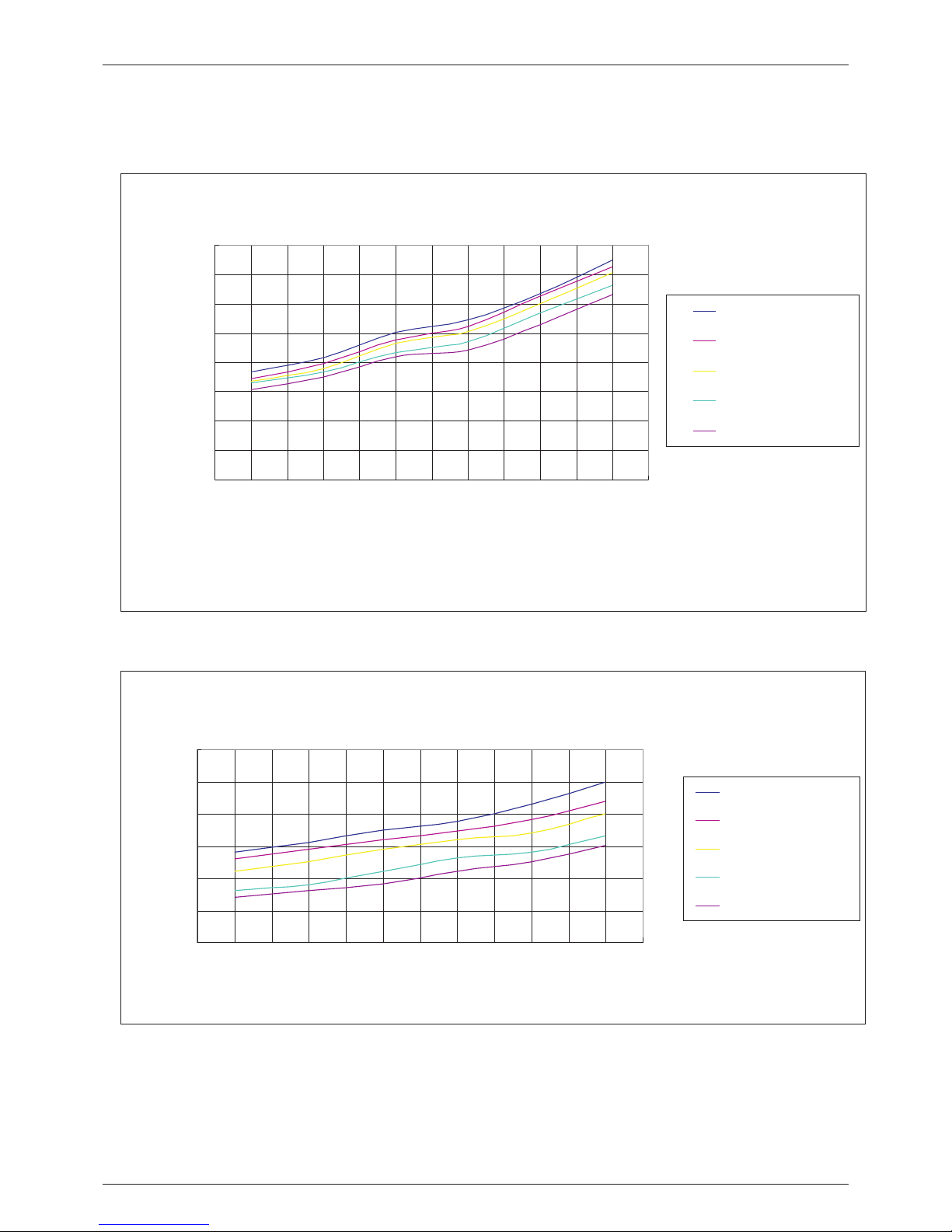

4.3 Performance Curves

Model: YASBP-25HL

4

KRS-35B/N2-S Heating Capacity Curves

0

500

1000

1500

2000

2500

3000

3500

4000

-10 -5 0 5 10 20

Ambient Temp. (℃)

Heating C apacity (W)

R eturn Water Temp.30

℃

R eturn Water Temp.35

℃

R eturn Water Temp.40

℃

R eturn Water Temp.50

℃

R eturn Water Temp.55

℃

YASB P-2 5HL Heati ng Ca pacit y

He

at

ing C

a

pa

cit

y (

W)

Ambi ent Temp . (℃)

COP Curves

0

1

2

3

4

5

6

-10 -5 0 5 10 20

Ambient Temp. (℃)

COP

Return Water Temp.30

℃

Return Water Temp.35

℃

Return Water Temp 40

℃

Return Water Temp.50

℃

Return Water Temp.55

℃

YASBP-25HL COP Curve

CO

P

Ambi ent Temp . (℃)

Page 7

Hot Water S eri es

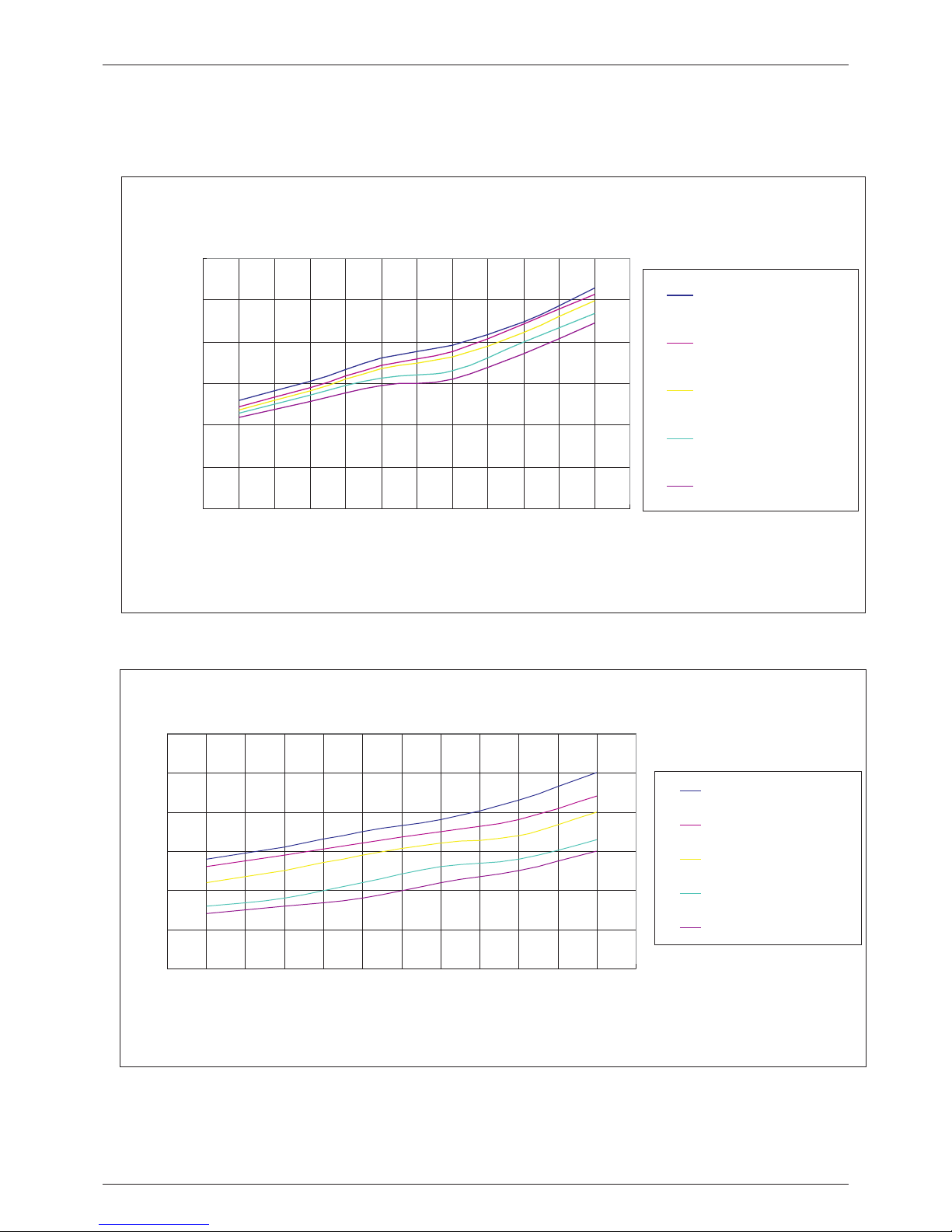

Model: YASBP-38HL

5

C OP C urves

0

1

2

3

4

5

6

-1 0 -5 0 5 10 2 0

Ambient Temp. (℃ )

COP

R eturn W a te r T e m p .3 0 ℃

R eturn W a te r T e m p .3 5 ℃

R eturn W a te r T e m p .4 0 ℃

R eturn W a te r T e m p .5 0 ℃

R eturn W a te r T e m p .5 5 ℃

YASBP-38HL COP Curve

C

O

P

Ambi ent Temp . (℃)

KRS-50B/N2-S Heating Capacity

0

1000

2000

3000

4000

5000

6000

-10 -5 0 5 10 20

Ambient Temp. (℃)

Heating C apacity(W)

Return Water Temp.30

℃

Return Water Temp.35

℃

Return Water Temp.40

℃

Return Water Temp.50

℃

Return Water Temp.55

℃

YASB P-3 8HL Heati ng Ca pacit y

He

at

i

ng Ca

pa

c

i

t

y (

W

)

Ambi ent Temp . ( )℃

Page 8

Hot Water S eri es

6

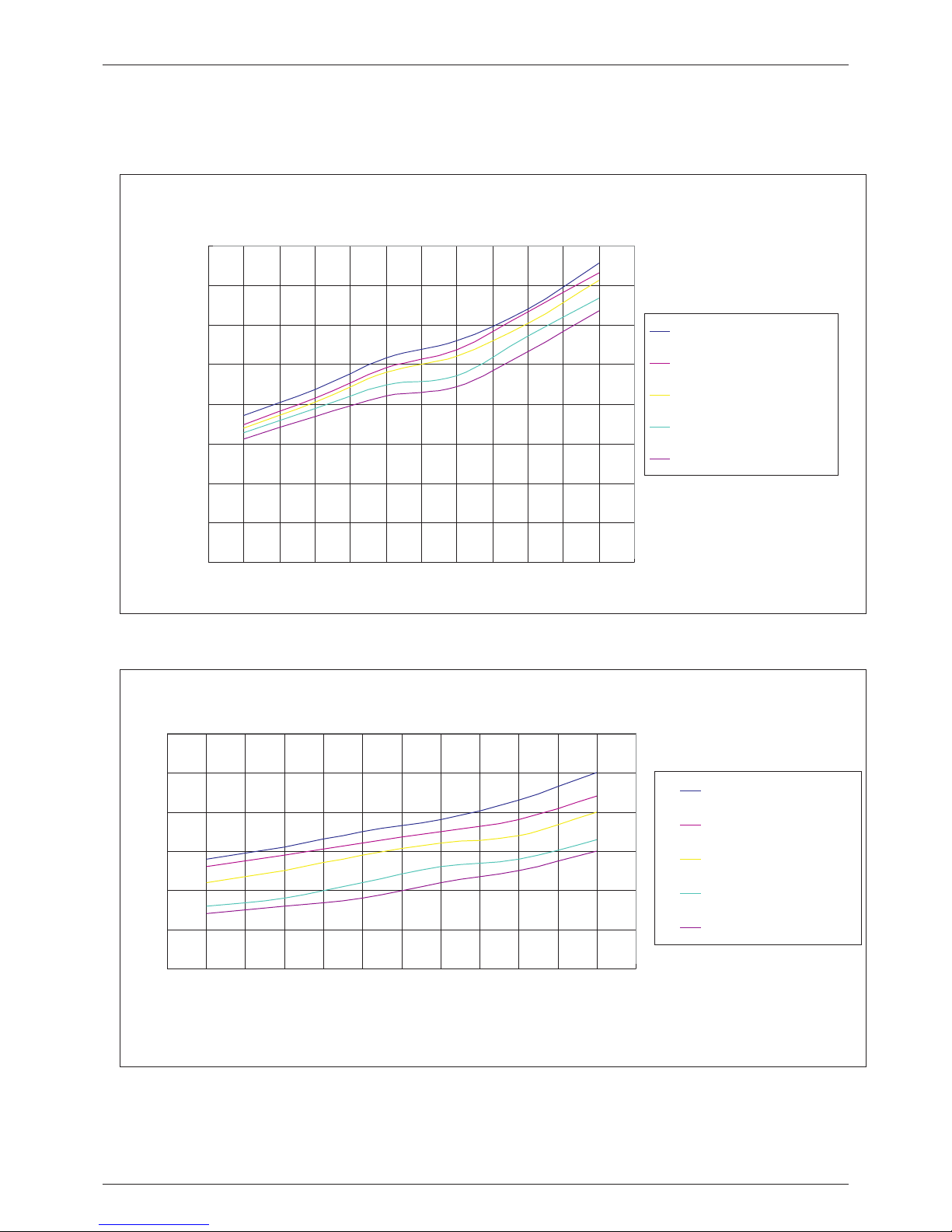

Model: YASBP-56HL

KR S -72 B /N2 -S Hea ting C a pac ity

0

1 0 0 0

2 0 0 0

3 0 0 0

4 0 0 0

5 0 0 0

6 0 0 0

7 0 0 0

8 0 0 0

-1 0 - 5 0 5 1 0 2 0

Am b ie nt T em p. (℃ )

HeatingCapacity(W)

R e tu r n W a te r T e m p .3 0

℃

R e tu r n W a te r T e m p .3 5

℃

R e tu r n W a te r T e m p .4 0

℃

R e tu r n W a te r T e m p .5 0

℃

R e tu r n W a te r T e m p .5 5

℃

YASB P-5 6HL Heati ng Ca pacit y

He

atin g Ca

p

a

cit

y (

W

)

Ambi ent Temp . (℃)

C OP C urves

0

1

2

3

4

5

6

-1 0 -5 0 5 10 2 0

Ambient Temp. (℃ )

COP

R eturn W a te r T e m p .3 0 ℃

R eturn W a te r T e m p .3 5 ℃

R eturn W a te r T e m p .4 0 ℃

R eturn W a te r T e m p .5 0 ℃

R eturn W a te r T e m p .5 5 ℃

YASB P-5 6HL COP Curve

C

OP

Ambi ent Temp . (℃)

Page 9

Hot Water S eri es

7

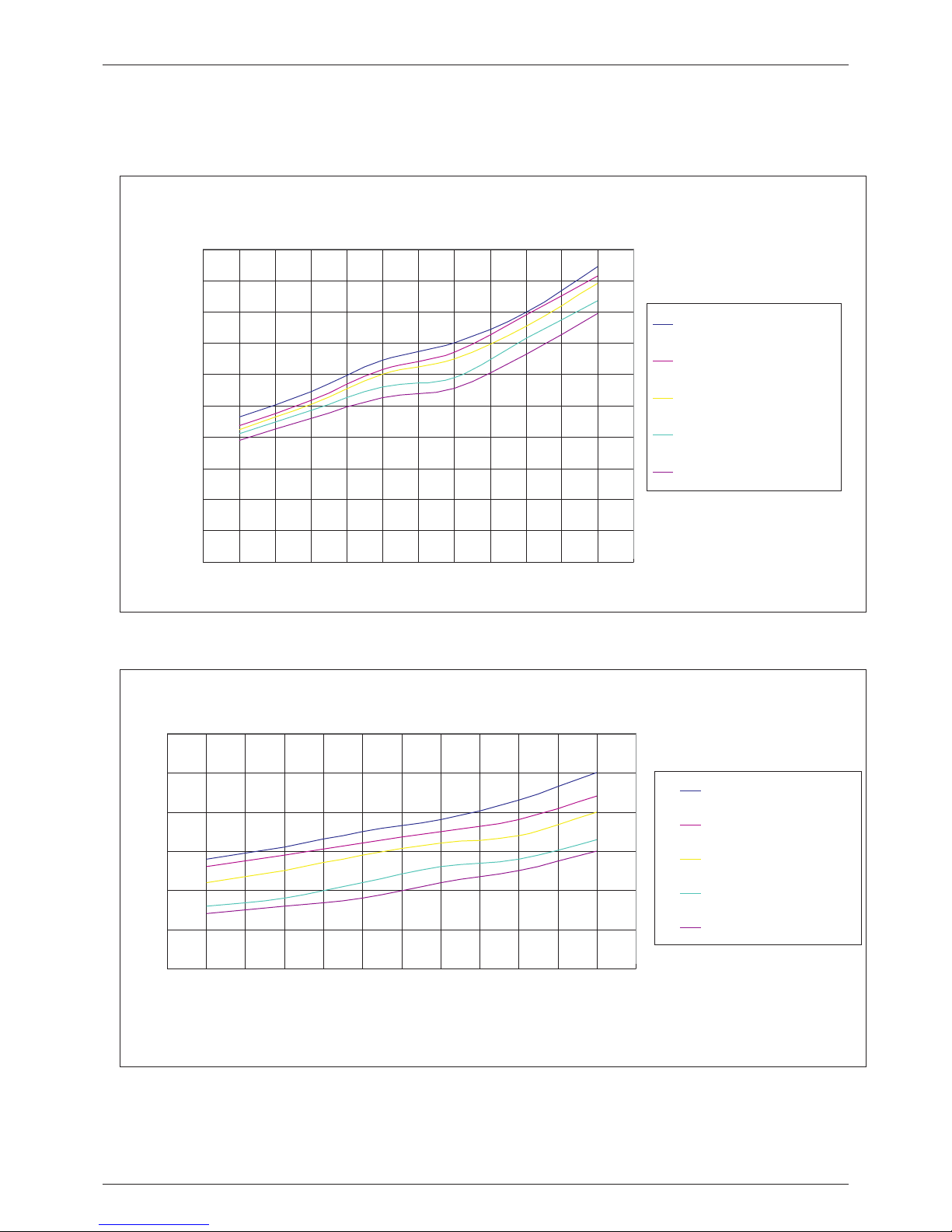

Model: YASBP-90HL

Ambi ent Temp . (℃)

KR S -90B/N2-S Heating Capacity

0

10 00

20 00

30 00

40 00

50 00

60 00

70 00

80 00

90 00

10 000

-10 -5 0 5 10 20

Ambient Temp. (℃ )

HeatingCapacity(W)

R e turn W ate r T e m p.30

℃

R e turn W ate r T e m p.35

℃

R e turn W ate r T e m p.40

℃

R e turn W ate r T e m p.50

℃

R e turn W ate r T e m p.55

℃

YASB P-9 0HL Heati ng Ca pacit y

H

e

a

t

i

ng C

a

pac

i

ty (W

)

C OP C urves

0

1

2

3

4

5

6

-1 0 -5 0 5 10 2 0

Ambient Temp. (℃ )

COP

R eturn W a te r T e m p .3 0 ℃

R eturn W a te r T e m p .3 5 ℃

R eturn W a te r T e m p .4 0 ℃

R eturn W a te r T e m p .5 0 ℃

R eturn W a te r T e m p .5 5 ℃

YASB P-9 0HL COP Curve

C

O

P

Ambi ent Temp . (℃)

Page 10

Hot Water S eri es

4.4 System Diagram

Heating Mode

Water inl et

Water inl et

Water out let

Water out let

Defrosting Mode

High pressure switch

High pressure switch

Low pressure switch

Low pressure switch

4 way valve

4 way valve

Suction accumulator

Suction accumulator

Compressor

Compressor

Condenser

(fin-tube)

(fin-tube)

Evaporator

Throttling

element

Evaporator

(Tub e in shell)

Condenser

(Tub e in shell)

8

Throttling

element

Page 11

Hot Water S eri es

4.5 Components

Compressor

The dependable hig h eff ici ency

compressor, with optimized

R410a system, can achie ve hi gh

water temperature up to 6 0De gC,

while ensures long l ife o f the

compressor.

4-Way valve

The reliable 4 wa y val ve can

avoid gas mixin g, and ensure

stable defros ting.

Condenser

The Tube in shell heat exchanger as

condenser, with bigger hea t

exchanging ar ea an d higher

efficiency.

Evaporator

The hydrophil ic fi n-tube heat

exchanger has b ig he at exchanging

area and ration al fi n distance, thus

significant ly improves heating and

defrosting ef ficiency.

Fan

The exterior mo tor f an, with multiple fan

blades, is stri ctly balanced. The multiple

fan blades run sl owe r, and mak e sur e

high air volume , thu s largely brings down

the noise.

Photo Features/AdvantagesComponents

Circulation pump

Fa mous German brand WI LO

ci rculation water pu mp used .

The main compon ent s are of famous brands and with g ood quality tested.

For examp le: Panasonic compressor, R410A gas, hig h eff iciency tube-in-shell h eat e xchanger etc.

Also, compone nts c an be replaced by customer’ s own r equirement.

9

Page 12

Hot Water S eri es

5. Installation

5.1 Heat Pump Installation

10

Se lect ion of i nsta llat ion si te

1. Installation must be simple and allow easy access for later work.

2. If the unit is to be installed on the floor, its undercarriage should be heightened, to avoid

ingression of acculated water in rainy season. In snowy areas, it is important to prevent

accumulated snow from blocking up the air-out.The recommended height is 20cm to 30cm.

3. Drain ditch or other facilities should be arranged under the outdoor unit, to avoid the

environment influence because of water discharge.

4. To install the unit at balcon or top of building, the installation site must meet the

Allowable bearing capacity of building structure, without affecting the structural safety.

5. Ensure the unit is well ventilated, direction of air exhaust is kept away from windows of

neighboring buildings, and the exhaust air cannot flow back. Moreover, adequate service

clearance should be kept around the unit.

6. The unit sould not be installed at places accompanied with oil, Inflammable gas, corrosive

compents, e.g. Sulfur compound, or high-frequency equipment.

7. The unit must be installed on reliable base or framework. Weight capacity of framework

should be 3 times of the body weight, and safeguard measures should be taken to avoid

malfunction of fastenings.

8. The unit should not be installed at sites with typhoon/earthquake hazards. Midair

installation should be avoided as much as possible as machine falling down may result in

Severe accident.

9. Do not install the heat pump close to a road or path to avoid mud splashing on the unit.

10. Keep, wherever possible, the unit out of reach of children.

Installation in some exceptional circumstances (mm):

3 5 0

2 0 0

3 5 0

4 0 0

3 5 0

3 5 0

2 0 0

No obstacl e in front of the heat pu mp Ob stacle above the he at pump

Sever al he at pumps insta lle d in a row

Page 13

Hot Water S eri es

5.2 Water System Installation

5.2.1 Water Tank Installation

5.2.2 Water Piping Installation

1. The water tank s hou ld be put in a place where suggeste d to in stall the heat pump, the wate r

ambient tempe rat ure is more higher. tank and the ci rcu lation pump at the same level .

Besides, the he igh t difference between the he at

2. It can be instal led e ither outdoors or on the

pump and the wate r tan k should be no more than

roof-to p (some elements such as the si ze of

2 meters, when wa ter t ank position is higher than

water tank and th e bea ring capability of the

that of the heat pu mp.

building shou ld be considered). Instal lat ion on

roof-to p should be based on suppo rt su ch as 4. Do not install t he wa ter tank in a pollutive or

crossbeam or pi lla r. corrosive are a.

3.The water tan k sho uld not be installed lower

than the founda tio n of the heat pump; It is

1. Drainpi pe an d overflow pipe should be carried out for t he wa ter supply valve and the

installed nea r the g utter or the sinkhole for stop valve of the s yst em (according to local

draining wate r mor e efficiently. Di scharge valve ambient temperatu re) f or avoiding icing of the

is necessary on t he dr ainpipe. water supply pi pe an d the valves.

2. Service valv e needs to be installed befor e the 6. Keep the water pipes straigh t and t he pipeline

magnet-valves on the sy ste m pipeline for further allocation rea son able; Reduce pipe turning s as

inspection. many as possibl e to reduce water resistance.

3. The pressure o f the water outlet should be 7. Prevent the pi peline and the connectors from

between 0.3MPa an d 0.6MPa. water leakage .

4. It is recommen ded to use metal pipeline suc h 8. The water p res sure bearing capability o f each

as stainless st eel p ipes, internal-pla sti c pipes, part of the pipin g system should be tested after

internal stai nle ss steel pipes or copper pipe s the installatio n is fi nished; Drainage should b e

etc; Telescopic issue of the pip eline between done to create a cl ean i nterior system.

heat pump unit an d wat er tank should be

9. Measures of he at preservation for the hot

considered if p lastic pipeline such as PPR p ipe

water pipelin e nee d to be conducted after

and ABS pipe etc. is used.

assuring no wat er le akage.

5. In winter, heat preservat ion may need to be

11

Wate r

Tan k

Wate r

Tan k

Page 14

Hot Water S eri es

Heat pump Installation

Shut Off Valve

Solenoid Valve

Check Valve

Elec Heater

Water Pump

Y-Shape Filter

12

Flow Switch

Heat Pump

Controller

Heat Pump

Dinning Hall

Filter

Filter

Flow Switch

(can omit)

Guest Room

Sauna Room

Drainage

Water Tank

Check Valve

Water tank

temp. sensor

5.3 Power Source Installation

Recommended w ire s pecification

2

3x1.5mm

Po wer Cable

LC D controller

Se nsorMo del Wa ter Pump

YA SBP-25HL

YA SBP-38HL

YA SBP-56HL

2

3x1.5mm

2

3x2.5mm

2

3x0.75mm

2

3x0.75mm

2

3x0.75mm

2

3x0.35mm

2

3x0.35mm

2

3x0.35mm

2

2x0.35mm

2

2x0.35mm

2

2x0.35mm

NOTE: the ab ove s pecification is the lowes t one w e recommend. Please choos e bigger wires if additiona l

power is requir ed un der installation.

YA SBP-90HL

2

3x2.5mm

2

3x0.75mm

2

3x0.35mm

2

2x0.35mm

NOTE:

Before instal lin g the heat pump unit, please re ad this manual carefully and kee p it for future reference.

Page 15

M

SE

T

M

SET

5.4 Wire Controller Installation

The wired controller is originally fixed on the maintenance door of the mac hine; please refer t o bel ow

steps if you want t o ins tall it on the wall:

1.Take do wn the controller from the ma chi ne. Pleas e pay attention that th e communi cat ion wire is

connected wit h the c ircuit board, separate th em fr om where they match.

2.Use a scre wdr iver to open the clip as pictur e 1, separate the controller as 2 pa rts, as picture 2

3.On the w all that you are going to install th e controller, drill 2 hole s at a level para lle l to the sight li ne as

picture 3.

The hole distan ce is 6 0mm, diameter is 8mm.

4.Place the plastic screws of th e enclos ure into the hole, and use the tapping screw (ST4*16 D- 1)

enclosed to fix t he ba ck cover of controller on the w all , as picture 4.

5.Match th e fro nt and back covers perfectl y, as picture 5, make sure t hat it is fixed firmly on the wal l.

6.Connec t the c ommunication wire well.

1 2

5

6

The front cover

6

0

mm

Φ8

3 4

Outl et of the comm unicatio n wire

Attention :

Please don't use ke en-edged things to hit the contro ller face and keys, or it may cause dam age .

When the contr oller is fixed on the wall, don't pull the c ommunication wire, or it may caus e poor contact.

The back cover

Hot Water S eri es

13

Page 16

6. Commissioning

6.1 Preparation Before Commissioning

6.2 Commissioning

Check the heat pump Check the piping system

Check if the outside case and the inside check if the water piping system,

system of the heat pump have been including water supply pipe, return

damaged during the transportation. water pipe, pressure gauge,

Check if there is still air inside the water

thermometer, valves, water level switch

system. If yes, use the air vents on the

are installed correctly. Please open all

water system and the circulation pumps,

the valves which should be opened, and

to discharge the air out.

close all that should be closed before

the commissioning.

Check the power source system

Make sure the heat preservation of the

Make sure the power source is

water system is in good condition.

accordance with the specification in the

manual or on the heat pump nameplate.

Make sure all power connections and

control circuit are in place. Make sure

the wiring , grounding and all terminals

are strong and reliable.

The commissioning should be carried down the power supply and adjust the

out by profession. phase-order. Make sure the compressor

current is in normal range, without

Comprehensive inspection of the entire abnormal sound.

system should be identified as meeting

the requirements, and the water level Check the circulation pump and all other

inside the tank is higher than the cycling parts meet the requirement. The whole

heating outlet and the water outlet, system can be put into use after the prebefore the commissioning. operation for a period of time.

After power on the electricity, turn on the

heat pump by pressing the on/off key on

the wire control panel. Please check if

the fan and the circulation pump are

running in the right direction. If not, shut

Hot Water S eri es

14

Page 17

ON/OFF

Mode se lec tion

Up and Do wn

Clock Ti me Se tting

ON/OFF Timi ng Setting

7.1 Key Illustration

Pres s it to s witch o n or off he at pump.

Pres s it to s elect t he mo de. The sequen ce is: co oli ng-he ati ng.

Long p res s it for mo re th an 6 seco nds ,heat p ump w ill com e to de frost ing .

Duri ng pa ramet er se tting , pre ss it to ad jus t param ete rs;

Duri ng cl ock and t ime r setti ng, p ress it t o cho ose the h our v alue or m inu te valu e.

Pres s the m to adju st th e value o f wat er temp era ture, c loc k, time r, paramete rs; During f ailure che cking and

para met er chec kin g, pres s any o f them to e xit c hecki ng.

Long p res s them fo r a few s econd s can l ock and u nlo ck the ke ys.

Pres s it to s et cloc k tim e.

Set th e cor rect lo cal t ime by us ing U p and Dow n key.

Pres s it to s et auto O N/O FF time o f the h eat pum p.

The al rea dy set ON /OF F timin g is me moriz ed ev en the he at pu mp is pow er- off.

7. Controller Operation

Hot Water S eri es

15

ON/OFF

LCD dis pla y

Mode se lec tion Up D own

Param ete r setting

Clock a nd ti mer

Time

Defro sti ng Mode

Heati ng Mo de

Curre nt Wate r Temp.

Temp. Set

Page 18

Middle area

Outllet wat er temperatur e symbol, the fig ure under is the te mperature val ue.

Failure sym bol.

Bottom area

Turning o n timer symbol. It appears when setting turn on timer.

Turning o ff ti mer symbol. It ap pears when sett ing turn off tim er.

Auto ON/OFF timing setting .

ON

OFF

7.2 Illustration for LCD Display

Top area

Circu lat ion pump runni ng.

Cooli ng mo de symbol / Defr ost ing symbol (fl ash ).

Heati ng mo de symbol.

Auxil iar y heat source st art .

Parameter n umber symbol, t he figure under i s the parameter n umber .

Water tan k temperature s ymbol, the figu re under is the temperature value.

Clock time se tting symbol.

Parameter v alue symbol, th e figure under is t he parameter va lue.

This symbol m eans heat pump ha s two compresso rs.

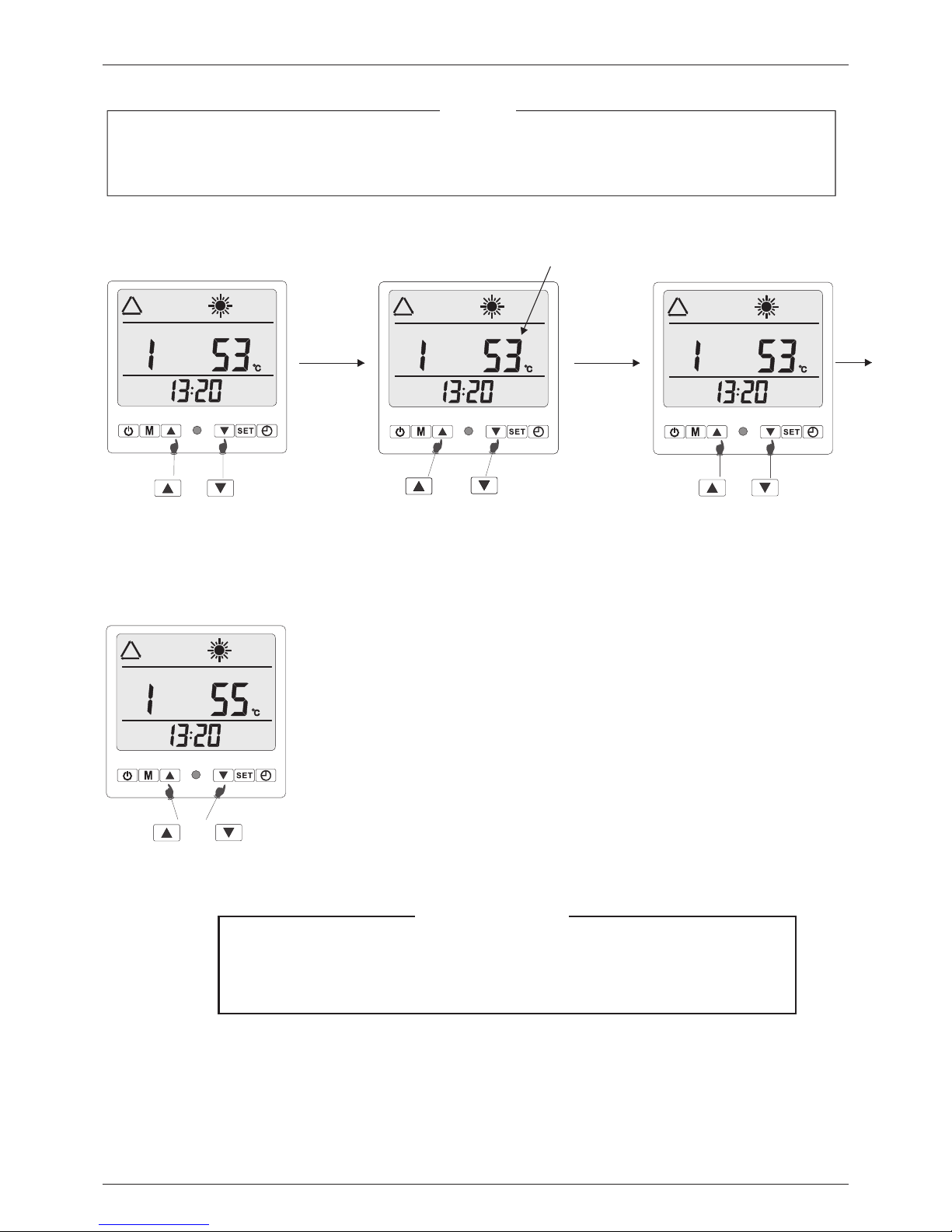

7.3 Water Temperature Setting

When the heat p ump is switched o n, just press or to check the pa rameter.

Initi al st ate

For exa mpl e

press or

“1" mea ns pa rameter of wat er ta nk temperatu re.

Hot Water S eri es

16

Press “ up” a nd “down” key fo r 3~5 s econds, “Bee ~~! !” sound is hear d and the keys are lock ( vice versa).

Page 19

3

1

Set the w ate r outlet tempe rat ure as follows :

Hot Water S eri es

17

Press and fo r 3~5 seconds

till “B ee~ ~!!” sound hea rd; a nd the

tempe rat ure value flas hes .

Press or to ad just

the wat er ou tlet tempera tur e.

Flashing

Press and fo r 3~5 seconds

to save the se tting.

Press or to ch eck the

param ete r, please choos e “1"

(0~11) for water tank t emp erature

setti ng (s ee “1" on the abov e

pictu re) .

NOTICE

Durin g par ameter setti ng, i f no operation f or mo re than 8 second s, th e interface of t he co ntroller pan el

will au tom atically bac k to th e main view.

Press ON/O FF key and Mode ke y wil l defrost forc edl y.

The wat er ou tlet tempera tur e of the domesti c hot w ater heat pump s is se t

with 55 ~60℃ b efore delive ry in f actory.

It is sugges ted to be 55℃ for exp and ing the workin g lif e of the compres sor

and who le sy stem.

IMPORTANT

Page 20

3

1

7.4 Clock Setting

Set the syst em time accord ing t o the local time a s fol lows:

Step 1

Step 2

Press to sta rt clock setting.

Press agai n to start

setti ng ho ur value. The h our

value f las hes.

Step 4

Flas hi ng

Step 5

Flas hi ng

Step 3

Flas hi ng

Flas hi ng

Step 6

Flas hi ng

Press or to ad just

the hou r val ue.

Press to sel ect minute and

the min ute v alue flashes .

Press or to ad just

the minute va lue.

Press to con firm the value

and ret urn t o main interfa ce.

Main In ter face

The cur ren t time is adjust ed fr om 13:20 to 15:3 0.

Hot Water S eri es

18

NOTICE

At the first t ime, the time shoul d be defined acc ord ing to local tim e zon e; otherwise , the accuracy of

“Timer on/Timer off” would be infl uen ced.

Page 21

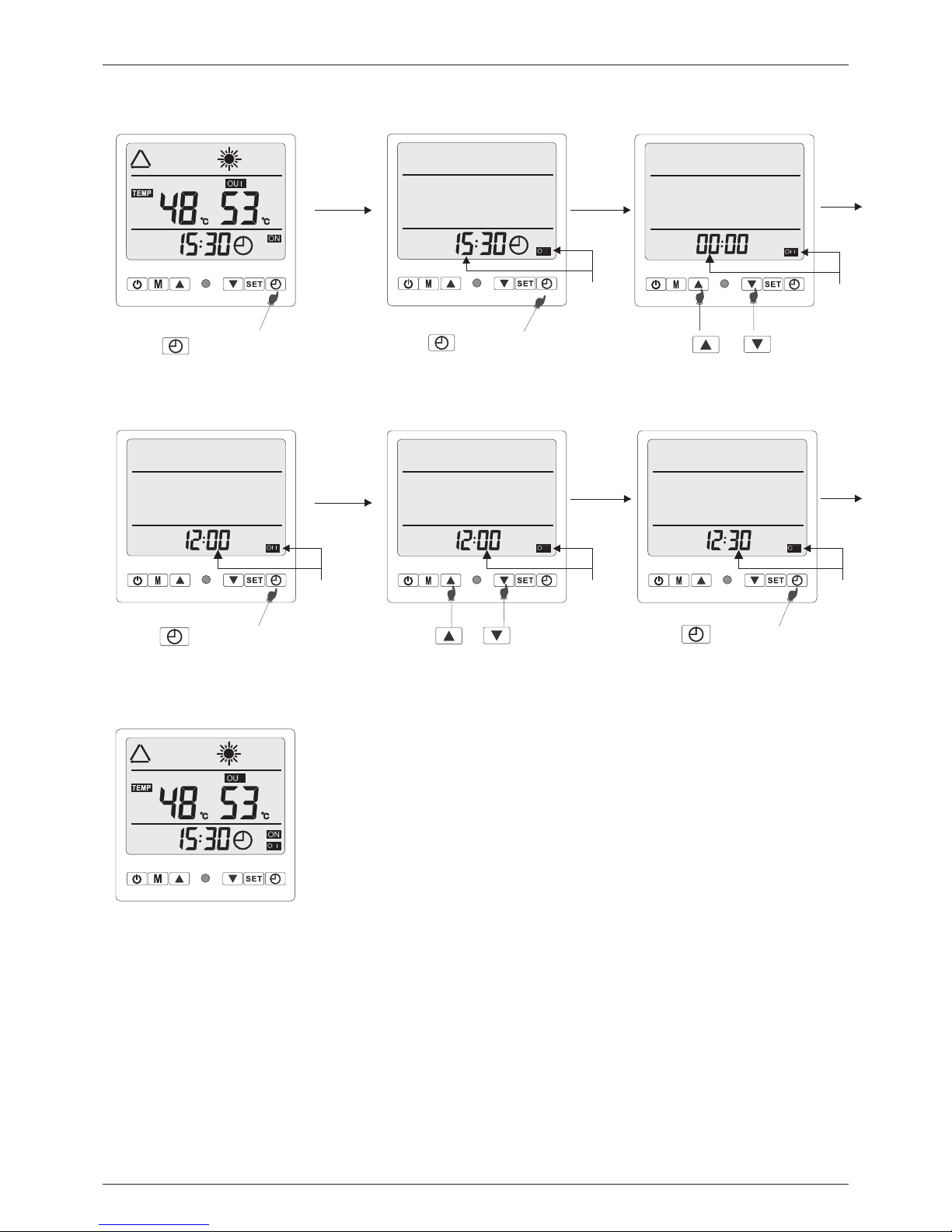

7.5 ON/OFF Timing Setting

With t his f uncti on, t he heat p ump c an turn o n or tu rn off auto mat icall y at th e set tim e.

When t he ti me poin t of “Timer o n” is arrive d, the heat pu mp starts; t hereafte r, the “ON /OF F” coul d be co ntrol led

auto mat icall y bas ed on the s ett ing tem per ature .

When the time po int o f “Timer off” is a rrive d, th e hea t pump is shut down; sub seq uentl y, the machin e cou ld no l onger be

cont rol led automati cally based on the setting temp erature; it will be restart ed u nti l th e ne xt t ime poi nt o f “Timer on” is

arri ved o r the key i s pre ssed.

Belo w exa mples s how h ow to set t he he at pump t o swi tch on at 9 :10 a nd swit ch off at 1 2:30.

Step 2

Flash

Flash ing

Flash ing

Step 3

Step 4

Flash ing

Step 5

Flash ing

Step 6

Step 1

Press to sta rt ON time

setting.

Press agai n to select hour

and the h our v alue flashes .

Press or to ad just

the hou r val ue.

Press or to ad just

the min ute v alue.

Press to con firm the value and

turn to n orm al display.

Press to sel ect minute and

the min ute v alue flashes .

pleas e tur n to

the nex t pag e

Hot Water S eri es

19

Totall y 1 ON/ OFF tim ers c an be set . And th ey can be a ppl ied to us e for e very da y or only one da y.

In timer se tting stat us, t he figure be low N O. repr ese nts the time r seq uence . If it s hows “--:- --“ o n botto m, it m eans

time r inv alid.

To cance l the t imer, pl eas e refer t o the i nstru cti on for ti mer s ettin g and set it to be “ ---:---“

NOTICE

Page 22

Step 8

Flash ing

Flash ing

Step 9

Flash ing

Step 10

Flash ing

Step 11

Flash ing

Step 12

Refer t o the p revious page o r bro ught forward ( b.f .)

Press to sel ect hour and

the hou r val ue flashes.

Press or to ad just

the hou r val ue.

Press to sel ect minute and

the min ute v alue flashes .

Press or to ad just

the min ute v alue.

Step 7

Press to sta rt OFF time

setting.

Main In ter face

Press to con firm the value

and tur n to ma in interface .

Hot Water S eri es

20

Page 23

Hot Water S eri es

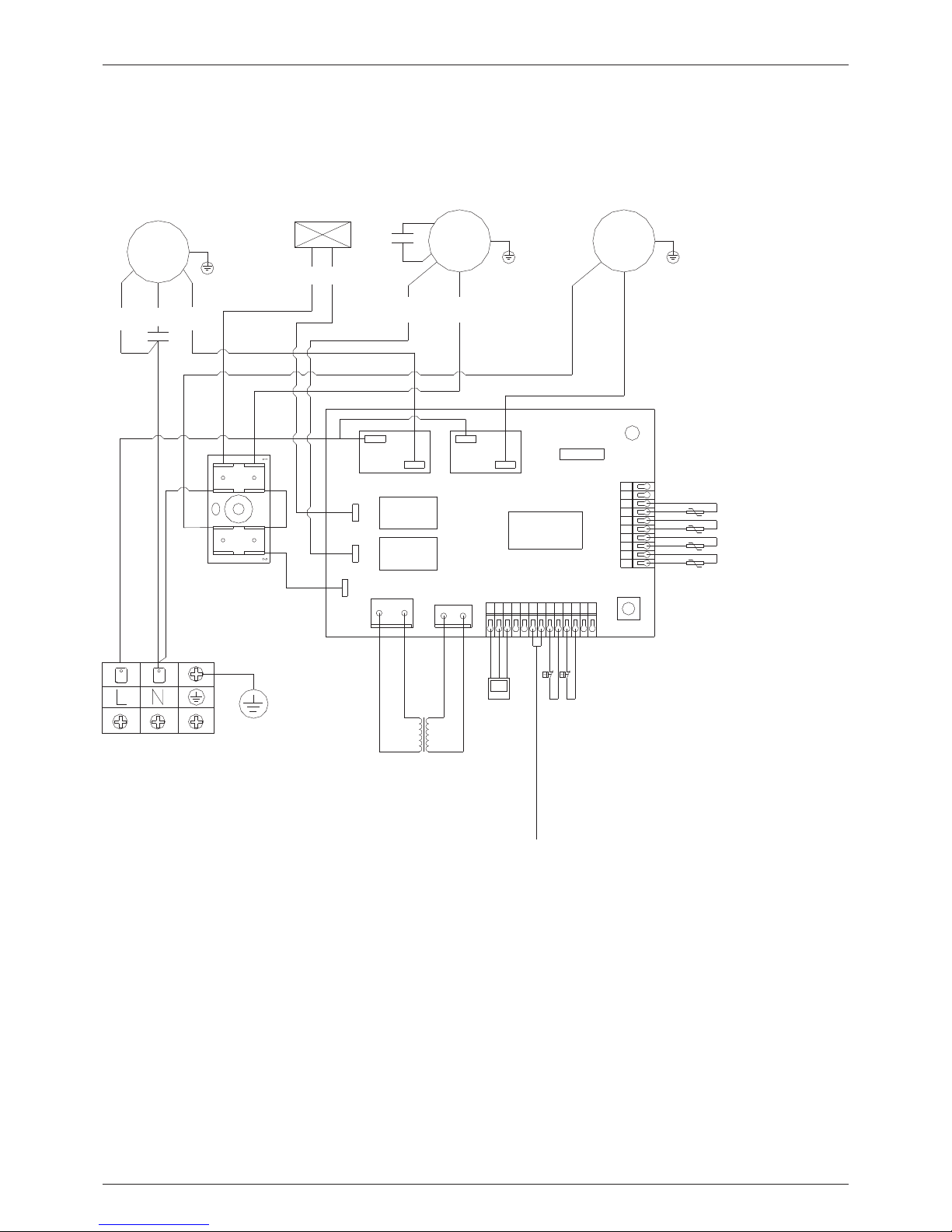

8. Circuit drawing

Model: YASBP-25HL

21

4

3

4

3

123

4

567 8

9

0

1

1

2

3

4

5

6

7

98

1

0

1

1

2

1

13

Compressor

4-Way Valve

BR

Fan

FAN

BL BL

OR

BK WH

REBLBK

CM

R

S

C

Pump

GND

T.S

A.S

C.S

GND

GND

GND

R.S

Tank Temp. Sensor

Ambient Temp. Sensor

Coil Temp. Sensor

Exhaust Air Temp. Sensor

MCU

AC - L

AC - N

CQC

250VAC

2.5mm *2

N

High Pressure Switch

Low Pressure Switch

LCD Controller

GND

GND

GND

GND

GND

GND

OB

H-P.S

L-P.S

F.S

NET

12V

OB

LP

HP

Flow Switch Must be Installed Here

220V/AC 12V/AC

Transformer

220V/1Ph/50Hz AC

PUMP

Page 24

Hot Water S eri es

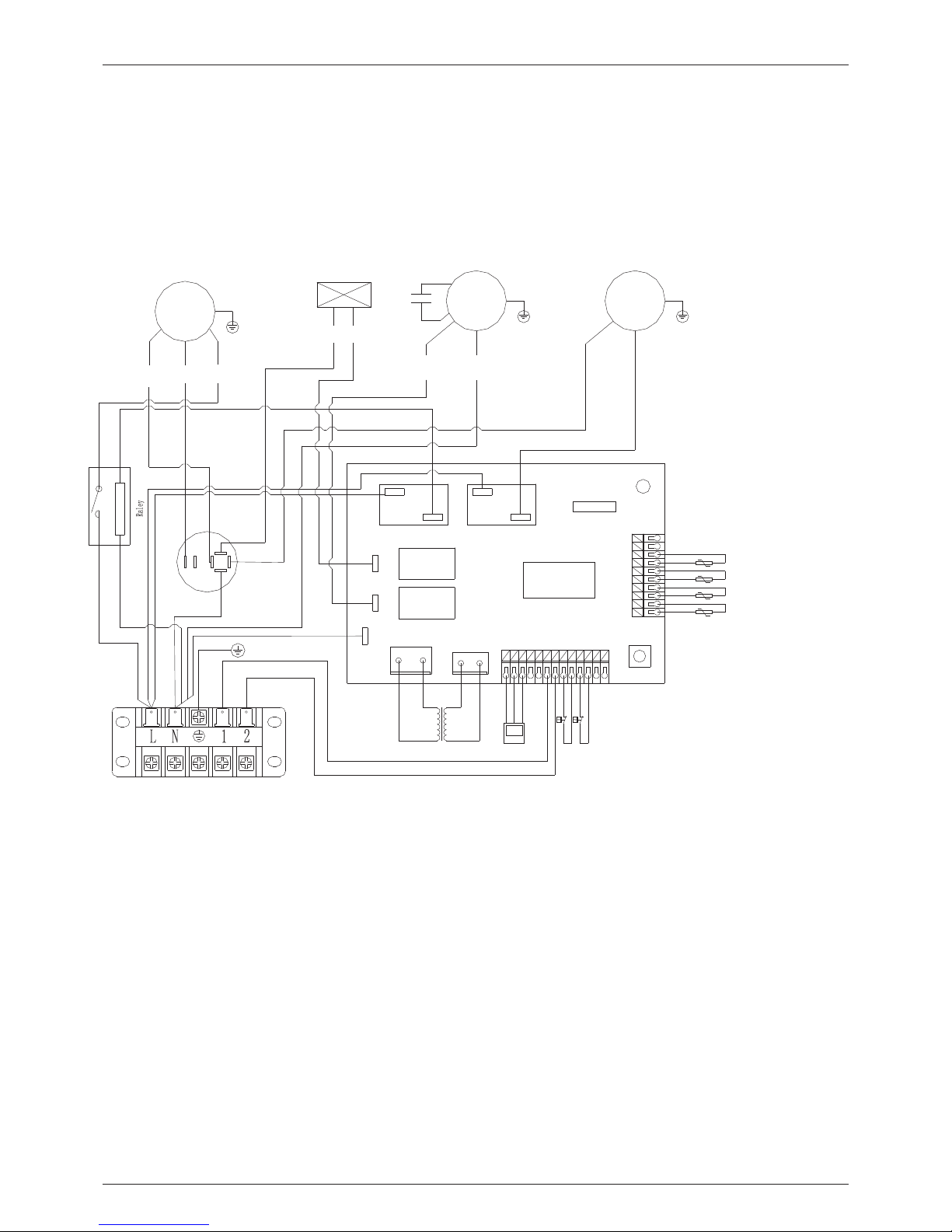

Model: YASBP-38HL, YASBP-56HL, YASBP-90HL

22

4

3

4

3

CM FAN PUMP

4-Way Vale

Fan Pump

4-Way Vale

Tank Temp. Sensor

Ambient Temp. Sensor

Coil Temp. Sensor

Exhause Air Temp. Sensor

AC 220V/1Ph/50Hz Flow Switch

Transformer LCD Controller

220V/AC 12V/AC

AC - N

AC - L

MCU

BK

RE

BL

BL BL

OR

BK WH

BR

R C

S

COM

NO

COM

OCC

GND

HP

LP

High Pressure Switch

Low Pressure Switch

Page 25

Hot Water S eri es

9. Maintenance and Trouble Shooting

9.1 Maintenance

The heat pump wat er he ater is an advanced leakage from connec tor s.

Keep t he su rrounding of the heat pump dr y,

equipment wit h hig h automization. The

clean and venti lat ed. Regularly clean the

reliability a nd op eration life of the heat pump c an

evaporator to k eep h igh heat exchanging

be expectedly g urr anteed and even increased b y

efficiency.

regular inspe cti on and effective maintena nce.

Check the insid e pip e connectors and refriger ant

The external wa ter f ilter should be cleaned

service port is d irty with oil. Make sure there is no

regularly to en sur e the cleanness of the water in

refrigerant l eak age.

the system and av oid d amage caused by

blockage in the f ilt er.

Before stoppi ng th e heat pump for long time,

drain out all wat er in t he pipes, and shut off the

All protectiv e set tings in the unit have been set

power supply, and put it into a shield. Full

before ex-factory. Users must not adjust it when

inspection of t he sy stem is required before nex t

the heat pump uni t is in u se.

operation.

Regular inspe cti on is required for the power

Users should ca ll th e installer or the seller eve ry

source and the wi rin g connection of the electri c

time when there i s an er ror on the heat pump

system. Loose w iri ng connection and electri c

controller.

components sh oul d be repaired in time.

Clean the conde nse r with phosphoric acid of

The water suppl y sys tem, relief valve of the wate r

15% consisten ce un der temperature of 50C -60C.

tank, water lev el co ntrol device and air discha rge

Run the circula tio n pump for 3 hours, and then

device need to be c hec ked regularly in case of

flush with fres h wat er for 3 times. When installi ng

low circulati on wa ter volume caused by air

the pipes, add a 3 wa y val ve on the pipes and

entering the sy ste m, to ensure enough capacit y

closed on outle t of it , for cleaning use. Corrosi ve

and reliabili ty of t he heat pump.

washing liqui d is forbidden to clean the

Check the water p ump a nd the valves on the

condenser.

pipes if they wor k wel l, and make sure there is no

23

Page 26

9.2 Parameter Checking.

Hot Water S eri es

24

Digit Meaning Range Default

Adjust(yes/no)

0

Tank set temperature hysteresis

0-30℃ 5℃

yes

1

Water tank temperature setting

8-55℃ 55℃

yes

2

Defros t Cycle

30-90Min 40Min

yes

3

The time point to enter defrosting in

heating

0-30℃ -5℃

yes

4

Exit defros t temperature

2-30℃ 15℃

yes

5

Exit condition of defrost time

1-12Min 8Min

yes

6

Water tank temperature setting

range (55/65)

0-1 0

yes

7

Res erved

yes

8

Com pensation(yes /no)

0-1 1

yes

9

Cyclic heating(yes/no)

0-1 1

no

A

Heater / pump selection

0-1 1

yes

B

Target superheat / 10

-F--F 0

no

C

Start tem perature

10-55 47

no

D

Exhaust temperature

-9--99℃

ajdus ted by technicians

E

Pipe temperature

-9--99℃

ajdus ted by technicians

F

Res erved

-9--99℃

ajdus ted by technicians

10

Ambient temperature

-9--99℃

ajdus ted by technicians

11

The actual num ber of steps / 10

0-40

no

Running time

0-9999h

ajdus ted by technicians

Protection / Failure Remote Controller

Water tank temp. sensor fault F0

Coil temp.sensor fault F1

Flow switch malfunction F2

Ambient temperature sensor fault F3

Protection of the exhaust temperature is too high F4

High voltage protection of the system F5

System voltage protection F6

Exhaust temperature sensor fault F7

The second time freezing protection in winter F8

Wired remote communication failure F9

Defrost Defrost display

9.3 Error Code.

Page 27

Hot Water S eri es

9.4 Trouble Shooting

Users should contact with the professional maintenance staff when there is a

problem with the heat pump. Maintenance stuff may need to refer to the following

table for troubleshooting.

Malfunction Possible Problems Disposing Methods

Heat pump unit is

out of operation.

1. Power source fault.

2. Loose connection of

power wire.

3. Power fuse burnt out.

4. Low water level switch is

not on.

1. Cut off the power source

and check.

2. check the power wire

connection.

3. Check the fuse.

4. Supply water until the

water level switch is on.

Water pump is

running but no

water circulation or

much noise made by

water pump

1. Few water in the system.

2. Air exists in the water

system.

3. Some valves are not

opened.

4. The water filters is

blocked up.

1. Fill water into the water

supply system.

2. Discharge air from the

water system.

3. Open all the valves in the

system.

4. Clean the water filter.

Low heating

capacity.

1. Lack of refrigerant.

2. Bad water system heat

preservation.

3. Low evaporator heat

transferring.

4. Low water flow volume.

1. leakage hunting and fix it,

discharge all the refrigerant

and inject the right amount.

2. improve the heat

preservation.

3. Wash the evaporator.

4. Clean the water filter.

Heavy frosting, low

heating capacity.

1. The evaporator is too

dirty.

2. Defrost sensor fault.

3. The 4 way valve can not

change direction.

4. Over long defrosting

duration.

1. Wash the evaporator.

2. Change a new defrost

sensor.

3. Check the solenoid if it is

energized.

4. Change the temperature

for entering defrost and the

duration.

High noise of

compressor.

1. Liquid refrigerant into

the compressor.

2. Interior component of

the compressor is faulty.

1. Check if the thermostatic

expansion valve is faulty.

2. Change the compressor.

25

Loading...

Loading...