WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

injury or property damage. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

All Weather Electronic Ignition System

(AWEIS)

Owner’s Manual

Installation and Operation

WARNING

Do not store or use gasoline or other flammable vapors and liquids in vicinity of

this or any other appliance.

An LP-cylinder not connected for use shall not be stored in the vicinity of this or

any other appliance.

DANGER

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, keep away from appliance and immediately call your

gas supplier or fire department.

WARNING

For Use with NATURAL or LP GAS Only

NO SOLID FUELS TO BE USED WITH THIS SYSTEM

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Installation must conform with local codes or, in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1 / NFPA 54, or International Fuel Gas Code.

The appliance, when installed, must be electrically grounded in accordance with local codes or, in

the absence of local codes, with the National Electric Code, ANSI/NFPA 70, if applicable.

www.FirebyDesign.com

Certified by

Lab Test Certification

Meets: ANSI Z21.97-2014

CSA 2.41-2014

CSA C22.2 No. 3-M1998 (R2014)

CARBON MONOXIDE HAZARD

This appliance can produce carbon monoxide which

has no odor.

Using it in an enclosed space can kill you.

Never use this appliance in an enclosed space such

as a camper, tent car or home.

WARNING

FOR OUTDOOR

USE ONLY

1

AVERTISSEMENT

Une installation, un ajustement, une modification, une réparation ou un entretien inapproprié peuvent

être la cause de blessures ou de dommages. Veuillez lire attentivement les instructions d'installation,

d'utilisation et d'entretien avant d'installer ou de réparer ce matériel.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l'essence ni d'autres vapeurs ou liquides inflammables dans le

voisinage de l'appareil, ni de tout autre appareil.

Une bouteille de propane qui n'est pas raccordée en vue de son utilisation, ne doit pas être entreposée

dans le voisinage de cet appareil ou de tout autre appareil.

DANGER

S'il y a une odeur de gaz:

1. Coupez l'admission de gaz de l'appariel.

2. Éteindre toute flamme nue.

3. Si l'odeur persiste, éloignez-vous de l'appareil et appelez immédiatement

le fournisseur de gaz ou le service d'incendie.

AVERTISSEMENT

Pour utilisation avec naturel ou propane ne gaz seulement

Aucun combustibles solides pour être utilisés avec ce système

MONOXYDE DE CARBONE

Cet appareil peut produire dumonoxyde de

carbone, un gaz inodore.

L’utililisation de cet appareil dans des espases clos

peut entrainer la mort.

Ne jamais utilizer cet appareil dans un espace clos

comme un vehicule de damping, une tente, une

automobile ou une maison.

AVERTISSEMENT

Pour utilisation

à l'extérieur seulement.

AVERTISSEMENT

Ne pas utiliser cet appareil s'il a été plongé, même partiellement, dans l'eau. Appeler un

technicien qualifié pour inspecter l'appareil et remplacer toute partie du système de

commande et toute commande qui a été plongée dans l'eau.

2

Table of Contents

Pilot Burner

Assembly

LP Air Mixer

(LP applications only)

Gas and Electrical Requirements

Page 4

Clearance from Combustibles

Page 4

Installation of AWEIS – Natural Gas

Page 5

Installation of AWEIS – Propane

Page 6

Acceptable Media for Fire Features

Page 8

Installation of Media in Fire Features

Page 8

Operation

Page 10

Maintenance

Page 11

Replacement Parts

Page 11

Troubleshooting

Page 12

Attachment 1: Automated Pool Controller Wiring Illustration

3

Gas Requirements

Pressure

Natural Gas

Propane

Minimum

3.5” W.C.

8.0” W.C.

Nominal

7.0” W.C.

11.0” W.C.

Maximum

½ psi (14.0” W.C.)

½ psi (14.0” W.C.)

WARNING

The All Weather Electronic Ignition System operates on 24 Volts AC power ONLY

DO NOT Attempt to Power using 110 Volts AC Power – Damage WILL RESULT

36 in.

8 ft.

Fuel Type – Before making gas connections ensure appliance being installed is compatible with the

available gas type. Check the label on the appliance to confirm appliance gas type requirement.

Gas Pressure – Proper input gas pressures are required for optimum appliance performance.

Gas Pressure Requirements

Electrical Requirements

Acceptable Input Voltages to Supplied 24 Volt AC Transformer

110 / 210 / 220 / 240 / 480 Volt AC

(Supplied 24 Volt AC Transformer compatible with all voltages listed above)

(Read label on supplied transformer for proper connection information)

Recommended Wire Size

12 gauge wire for all installations

Clearance from Combustibles

WARNING – FIRE RISK

Provide Adequate Clearance from Combustibles as shown below

4

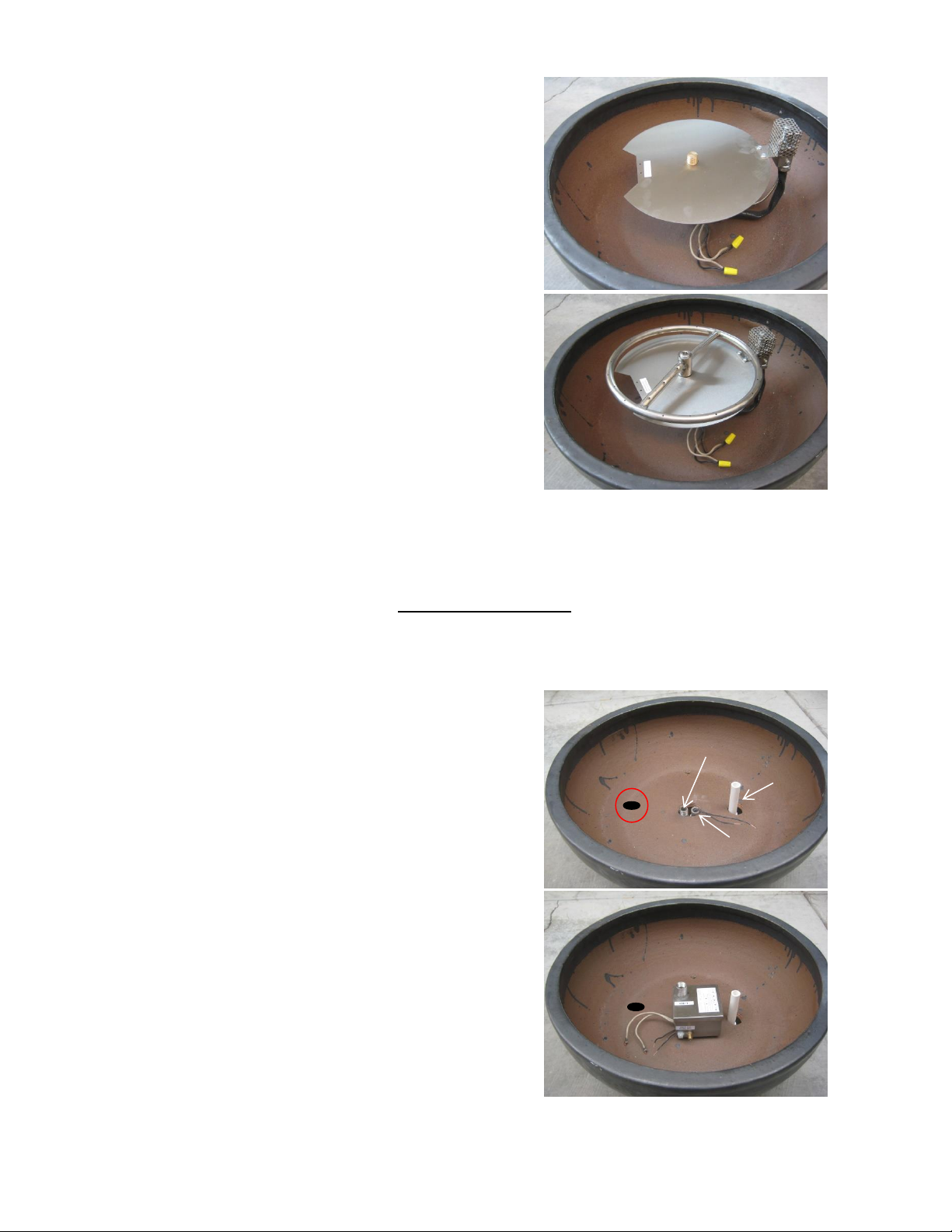

1. In the photo at right there is a bowl with both a gas

riser and an electrical conduit stubbed up inside the

bowl. In this photo the gas riser is centered whereas the

electrical is off center. It is preferred to stub the gas

riser centered in order to ensure the fire ring is centered

in the bowl once installation is complete.

NOTE: Drainage MUST be provided in the bottom of

the bowl. Drainage can be obtained by making a simple

hole as shown at right or providing a drain line next to

the gas and electrical conduit.

2. Apply pipe dope to the gas stub and thread the

AWEIS onto the gas riser as shown in the photo at right.

NOTE: Leak Test – it is highly recommended to

perform a gas leak test at this point in the install. Turn

on the gas supply and then, using a soapy water solution

spray the bottom of the AWEIS where it is connected to

the gas line to ensure no leaks exist.

3. Electrical Connections / Orifice Install. In the photo

at right the wires protruding from the AWEIS have been

connected to the two wires from the electrical conduit

using appropriate sized wire nuts.

In addition a short pipe nipple and the Natural Gas

Orifice (supplied) are installed using either Teflon tape

or gas plumbing pipe dope.

4. On the side of the AWEIS there are two connections

for the Pilot Burner Assembly as shown in the photo at

right. The white ‘quick connect’ is the electrical

connection and the brass plumbing fitting is the gas

connection. There is a label next to these connections,

“Attach Pilot Burner Here”.

5. The photo at right shows the AWEIS after the Pilot

Burner Assembly has been connected.

NOTE: The electrical connection for the Pilot Burner

Assembly is a shaped connection thereby ensuring it can

only be connected the correct way. On the Pilot Burner

Assembly side of the connection there is a locking clip

on the quick connect that will ‘lock’ the connection in

place. Therefore after making the connection lightly tug

on the connection to ensure it is in fact ‘locked’ in place.

1” Drain

Hole

Gas Stub

Electrical

Conduit

Installation – Natural Gas

Note: Installation should be done by a qualified service technician that is locally licensed.

Natural Gas

Orifice

5

7. Install Fire Ring using either Teflon tape or gas plumbing

pipe dope. Holes in the Fire Ring MUST FACE UP.

6. Install the Heat Deflector Shield. Notice the heat shield has

a notch on one side. Position the Pilot Burner in the notch

ONLY when using either a 6” or 18” fire ring. For all other

burner sizes attach the Pilot Burner to the heat shield on the

opposite side of the notch as shown in photo at right. Use the

two screws that came with the heat shield to attach the Pilot

Burner to the heat shield.

1” above ring

Arrow

Installation – Propane

Note: Installation should be done by a qualified service technician that is locally licensed.

1. In the photo at right there is a bowl with a gas riser, electrical

conduit and air line stubbed up inside the bowl. In this photo the

gas riser is centered, the electrical conduit is off center slightly and

the air line is off set center by 5”. It is preferred to stub the gas

riser centered in order to ensure the fire ring is centered in the

bowl once installation is complete.

NOTE: Drainage MUST be provided in the bottom of the bowl.

Drainage can be obtained by making a simple hole as shown at

right or providing a drain line next to the gas and electrical

conduit.

1” Drain

Hole

Gas Stub

Electrical

Conduit

Air Line

(5” Off Center)

2. Apply pipe dope to the gas stub and thread the AWEIS onto

the gas riser as shown in the photo at right.

NOTE: Leak Test – it is highly recommended to perform a gas

leak test at this point in the install. Turn on the gas supply and

then, using a soapy water solution spray the bottom of the

AWEIS where it is connected to the gas line to ensure no leaks

exist.

6

3. Electrical Connections / Air Mixer Install. In the photo at

right the wires protruding from the AWEIS have been

connected to the two wires from the electrical conduit using

appropriate sized wire nuts.

In addition the fitting in the photo at far right is to be installed

in the outlet of the AWEIS using either Teflon tape or gas

plumbing pipe dope. This fitting is made up of an Air Mixer

(brass), ½” Stainless Steel coupling and a ½” close nipple.

4. On the side of the AWEIS there are two connections for the Pilot

Burner Assembly as shown in the photo at right. The white ‘quick

connect’ is the electrical connection and the brass plumbing fitting is

the gas connection. There is a label next to these connections,

“Attach Pilot Burner Here”.

5. The photo at right shows the AWEIS after the Pilot Burner

Assembly has been connected.

NOTE: The electrical connection for the Pilot Burner Assembly is a

shaped connection thereby ensuring it can only be connected the

correct way. On the Pilot Burner Assembly side of the connection

there is a locking clip on the quick connect that will ‘lock’ the

connection in place. Therefore after making the connection lightly

tug on the connection to ensure it is in fact ‘locked’ in place.

6. Install the Heat Deflector Shield. Use the two screws that came

with the heat shield to attach the Pilot Burner to the heat shield.

7. Install Fire Ring using either Teflon tape or gas plumbing pipe

dope. Holes in the Fire Ring MUST FACE UP.

7

Acceptable Media for Fire Features

Close Up View of Pilot Burner

Filler Material

(material used below the fire ring)

There are a couple options when it comes to adding filler material to a fire

feature. For ‘shallow’ features such as the bowl at right it is recommended to

use landscape lava rock (3/4” chunk size) up to the level of the fire ring. This

lava rock is very inexpensive and is available at local hardware/nursery stores.

For ‘deep’ features it is recommended to first build a fake ‘floor’ in the feature

prior to adding the filler material described above. This will cut down on the

amount of filler material needed.

Notice in the photo at far right the top half of Pilot Burner

is elevated above the Filler Material – this is important.

Topping Material

(Large Chunk Lava Rock)

There are several options when it comes to topping material for a fire feature;

large chunk lava rock, fireglass and fire stones. In the photo at right we used

large chunk lava (2” to 3”) to cover the fire ring. This lava rock hides the

components of the fire feature while at the same time allowing plenty of

oxygen to mix with the gas coming from the fire ring. This lava rock is more

expensive than the “filler’ lava rock but is still fairly inexpensive and readily

available in the BBQ section of most hardware stores.

Notice in the photo at far right the Pilot Burner is

Concealed by the lava rock but NOT completely buried.

Close Up View of Pilot Burner

Pilot Burner

WARNING

Do not use any other material as filler/topping media inside fire features other than those listed below.

Using improper media inside a fire feature could result in damage to property or

injury to persons nearby due to media ‘popping’ or ‘exploding’ due to heat

List of Acceptable Media for Fire Features

Lava Rock (or other Igneous Rock) NO LARGER THAN 2” in diameter

Fireglass approved for use in fire features

Manmade stone for use in fire features (Refractory Material)

Installation Note

The use of media inside fire features is recommended due to the fact it enhances the look of the fire

feature but also improves its performance by forcing the gas emanating from the burner to mix as it

passes through the media. This ‘mixing’ of gases creates an even flame throughout the feature and

helps spread the flame from the Pilot Burner throughout the burner quicker than when there is no

media. Recommended thickness of the media above the burner element is NO MORE than 2”.

Due to the fact the Pilot Burner must be partially exposed to oxygen in order to ignite the pilot flame

during startup DO NOT COMPLETELY COVER THE PILOT BURNER. When installation of the

media is complete the top of the Pilot Burner Protective Cover should be visible.

Installation of Media in Fire Features

8

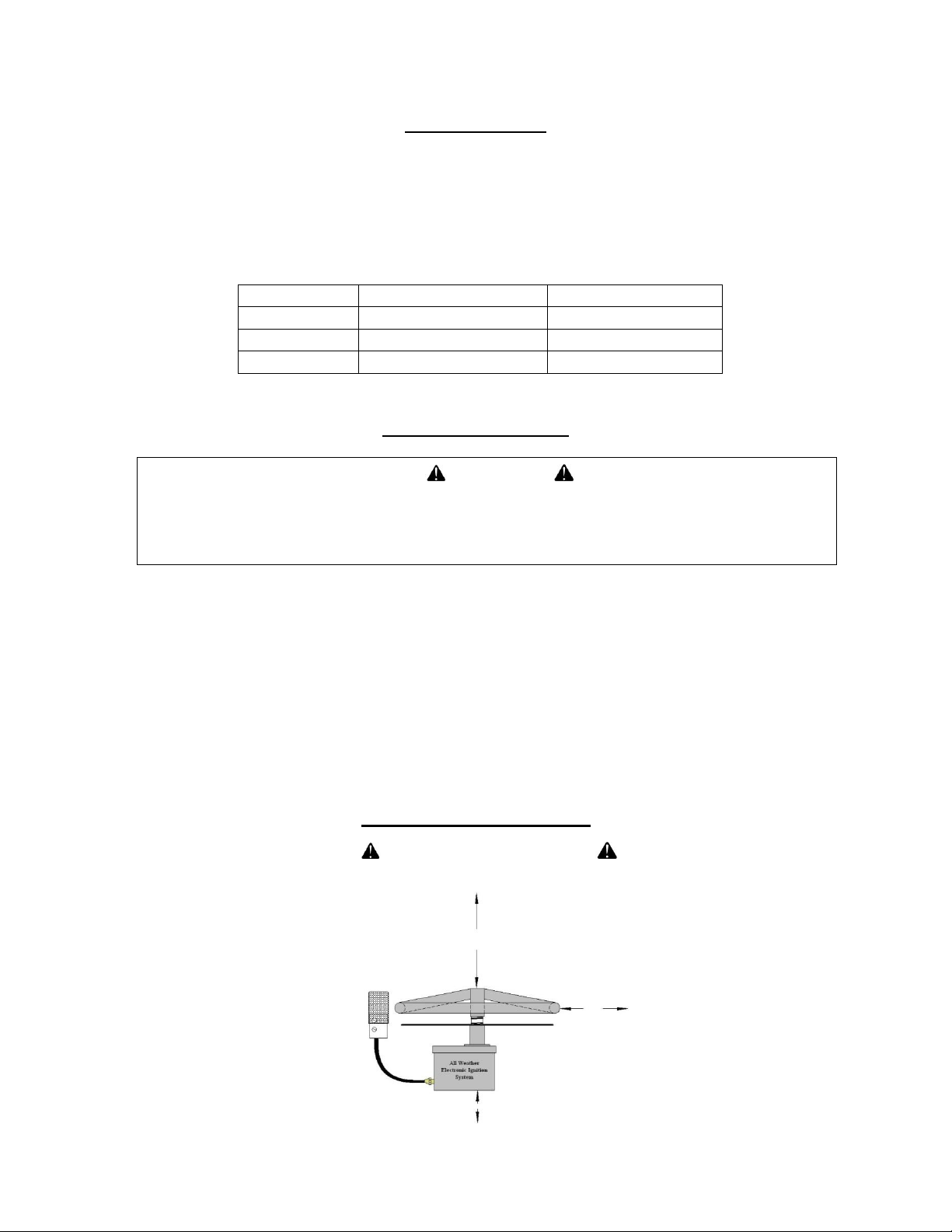

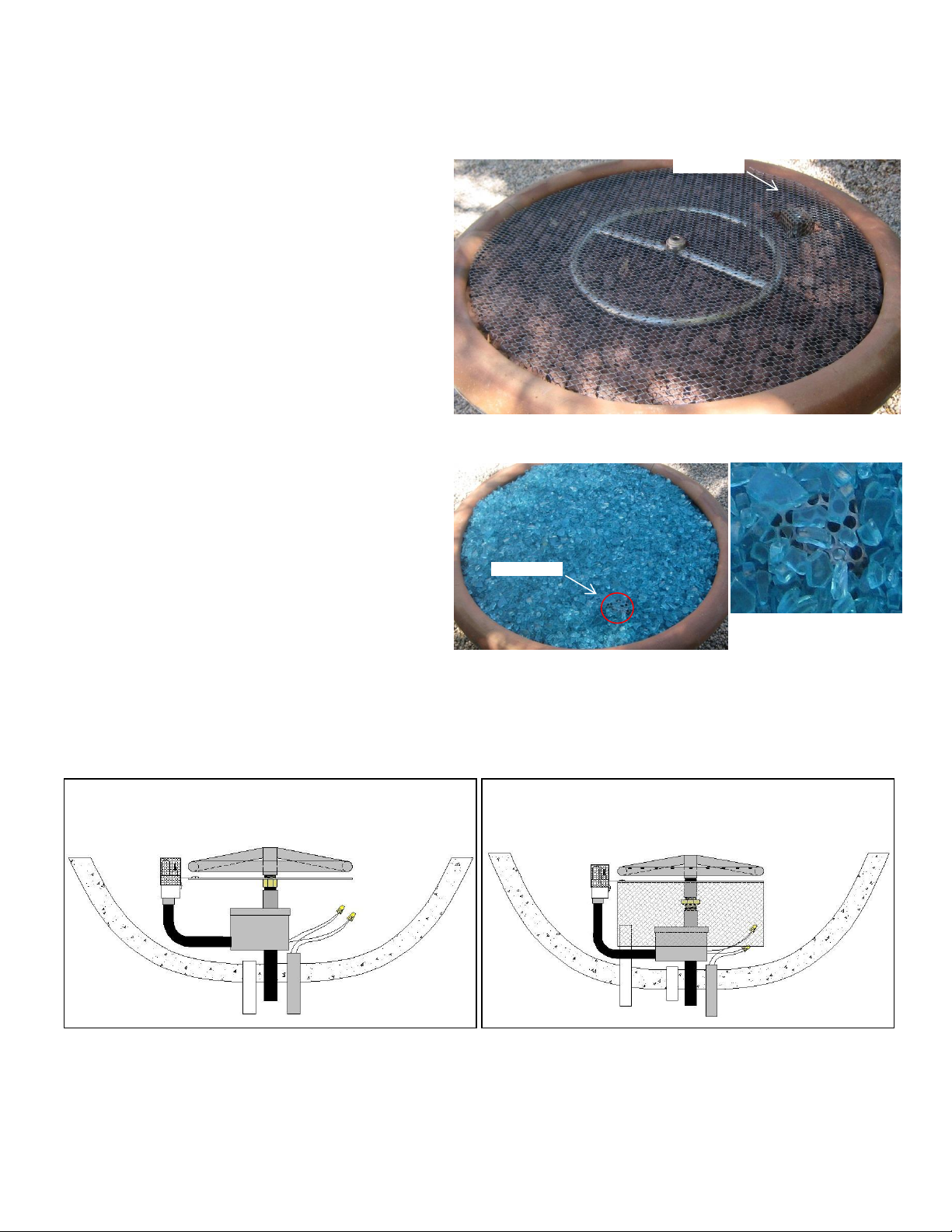

Illustrations showing the Finished Installs

Topping Material

(Fireglass - Preparation)

Fireglass is an acceptable fire feature topping material. Due to its expense

(much more expensive than lava rock) it is recommended you only purchase

enough to put a 2” thick layer on top of the fire ring. (Refer to our website to

determine how much fireglass you need to accomplish this). Prior to installing

the glass we recommend installing a galvanized screen mesh as shown at right.

This mesh is available in the stucco section of most hardware stores. This

mesh will ensure the fireglass stays on top and does not mix with the

underlying lava rock.

Notice in the photo at right the top half of Pilot Burner

is elevated above the screen mesh – this is important.

Pilot Burner

Pilot Burner

Topping Material

(Fireglass - Installation)

Once the screen mesh is in place simply pour the fireglass on top of the

mesh. Spread the fireglass to achieve an even layer of glass.

IMPORTANT: The top of the Pilot Burner should be level with the

top of the Fireglass.

NOTE: If after installing the fireglass you notice the Pilot Burner is

having difficulty igniting, remove some of the fireglass over the top of

it. Continue to remove glass and try turning the fire feature on until

you are able to achieve ignition every time you turn the fire feature on.

This part requires some experimenting on your part to determine ‘how

much’ glass you can have on top of the Pilot Burner.

Close Up View of Pilot Burner

Fire Ring

(Level with Top of Bowl - Holes pointed skyward)

Pilot Burner

Assembly

Heat Shield

24 vac

Power

Drain

Line

Electrical

Conduit

Gas

Line

Illustration of Properly Installed AWEIS

(Natural Gas)

Natural Gas

Orifice

AWEIS

Fire Ring

(Level with Top of Bowl - Holes pointed skyward)

Pilot Burner

Assembly

Heat Shield

24 vac

Power

Drain

Line

Electrical

Conduit

Gas

Line

Illustration of Properly Installed AWEIS

(Propane)

Air

Line

AWEIS

Propane

Air Mixer

9

Operation

WARNING

Do NOT use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the appliance and to replace

any part of the control system and any gas control which has been under water.

WARNING

HOT – DO NOT TOUCH - SEVERE BURNS MAY RESULT - CLOTHING IGNITION MAY RESULT

- CAREFULLY SUPERVISE children in same area as the appliance.

- Alert children and adults to hazards of high temperatures.

- Clothing or other flammable materials should not be hung from the appliance or placed on or near the

appliance.

WARNING

The appliance should be inspected before use and at least annually by a qualified service technician.

Any guard or protective device removed for servicing must be replaced prior to operation.

Keep the appliance area clear and free from combustible materials, gasoline and other flammable vapors and liquids.

WARNING

If fire feature fails to turn off completely (small flames still visible)

Turn off gas supply using the manual gas shutoff.

1. Prior to turning appliance on visually inspect fire feature to ensure debris such as leaves or other

combustible material has not collected inside the feature which could burn and emit embers once the

fire feature is turned on. Also ensure any person standing close to the fire feature is aware you will be

turning the fire feature on prior to actually turning it on.

2. Turn fire feature on by turning on the electrical device used to power the fire feature.

Sequence of Operation during Ignition

- Power is applied

- Hot Surface Igniter (Glow Plug) becomes hot and 4 seconds later the Pilot Gas Valve opens

- Within 10 seconds of power application Pilot Flame should be visible (at night only)

- Within 10 seconds of Pilot Flame Ignition burner (fire ring/burner bar) should ignite

1. Turn fire feature off by turning off the electrical device used to power the fire feature.

Fire Feature Start Up

Fire Feature Shutdown

10

Maintenance

WARNING

Maintenance should be done by a qualified service technician.

The appliance should be inspected before use and at least annually by a qualified service technician.

WARNING

Ensure gas and power are shut off and appliance is cool before servicing.

WARNING

Any guard or protective device removed for servicing must be replaced prior to operation.

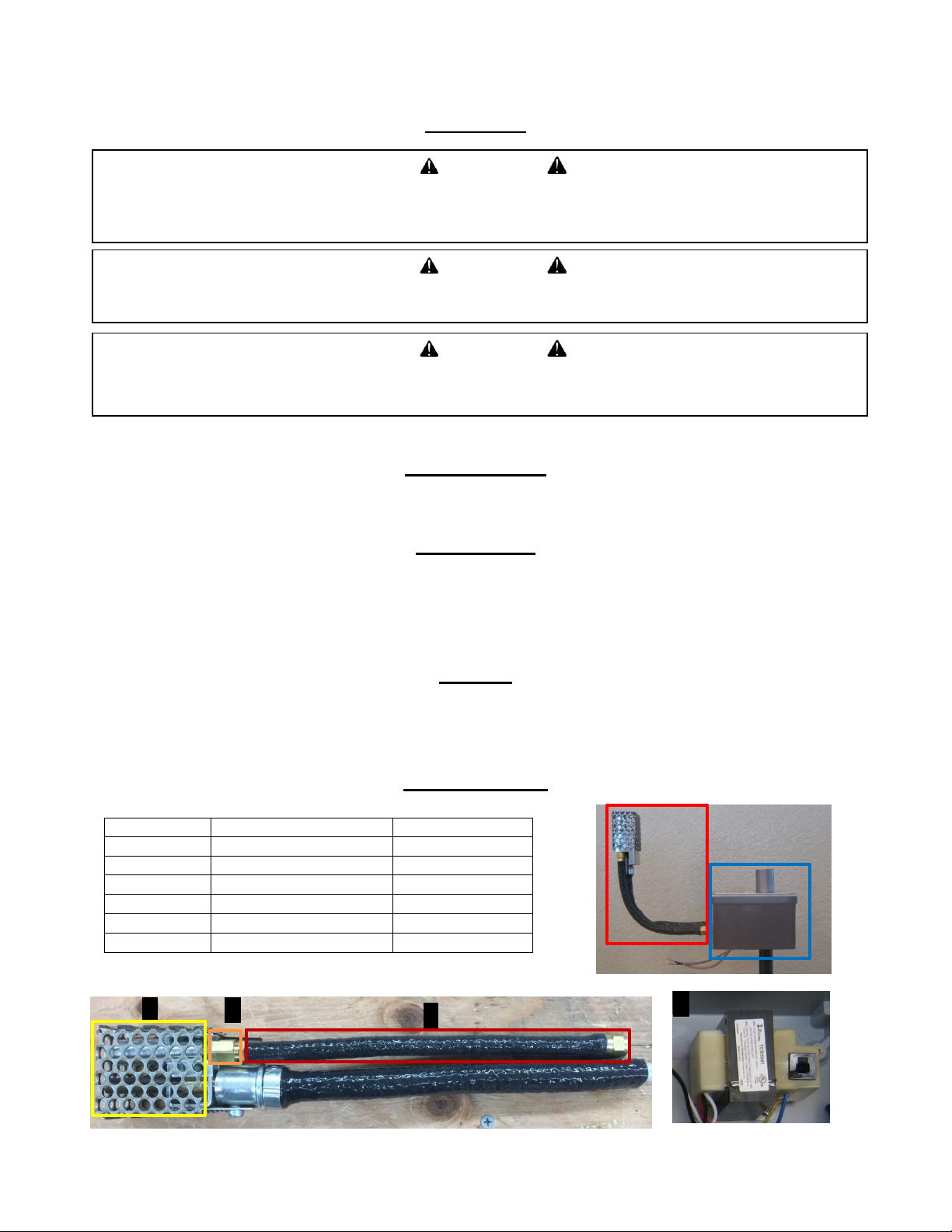

Item Letter

Part Name

Part #

A

Pilot Burner Assembly

PBA

B

Ignition Control Box

ICB

C

Pilot Burner Cage

PBC

D

Pilot Burner Gas Line

PBG

E

Pilot Burner Orifice

PBO

F

24 Volt AC Transformer

24VAC

A

B

F C E

D

Prior to Each Use

1. Inspect for debris in Fire Feature – remove debris prior to use

Semi-Annually

1. Visually inspect Pilot Burner for debris/insect infestation (spider webs)

2. Visually inspect burner holes for debris/insect infestation

3. Clean either of the above as necessary using compressed air.

Annually

1. Visually inspect Pilot Burner for excess corrosion due to heat and moisture.

2. Turn fire feature on to ensure proper operation.

Replacement Parts

11

Troubleshooting

I installed the Electronic Ignition System, turned it on and nothing happened

When this occurs it is usually due to an electrical wiring / power issue. Check all your electrical connections thoroughly to

ensure all wires at the transformer and inside the fire feature are connected properly. If it appears all wiring is connected

properly, disconnect the wires at the fire feature, attach a Multimeter to the wires to confirm a minimum of 24 volts when

the fire feature is turned on. If you determine that you do not have a minimum of 24 volts at the fire feature conduct the

same test at the transformer to ensure the transformer is in fact producing a minimum of 24 volts. If you do have a

minimum of 24 volts at the fire feature contact us for further assistance.

I installed the Electronic Ignition System, turned it on and I can see the glow plug glowing

orange and I can hear gas flowing but it will not ignite.

There are two possible causes to this problem; Air in the Gas Line or not enough Electrical Current to the fire feature.

Air in the Gas Line. If a new gas line was installed and the air was never purged from it prior to installing the Electronic

Ignition System then it may take several times of turning the fire feature on and off before the air is purged from the gas

line. Here is how our system works; after you turn it on the glow plug will come on first followed by the Pilot Gas Valve

opening 4 seconds later. For the next 180 seconds (3 minutes) the glow plug will cycle on and off every 30 seconds while

the Pilot Gas Valve will remain on the entire time. Therefore if you are attempting to purge air from the gas line, turn the

system on and leave it on for approximately 3 minutes. Then turn it off and then back on (no need to wait to turn it back

on). Let the system run for another 3 minutes. Usually when purging air from a new gas line you will need to cycle the

power several times as described above before gas begins to flow. If at any point you smell gas but still don’t have

ignition, attempt to light the Pilot flame with a handheld lighter. If the flame ignites when you light it by hand, go to the

section below, “Electrical Current”.

Electrical Current. If you have determined that air in the gas line is not the problem then most likely the failure to ignite

is due to the fact the glow plug is not getting hot enough to ignite the gas. The reason a glow plug will not get hot enough

is due to the fact it is not getting enough ‘amps’. Often times when troubleshooting electricians will check the electrical

power and when they see they have a minimum of 24 volts they think everything is fine electrically so there must be a

problem with the Electronic Ignition System. The problem is not due to the volts but rather the amps. The number of amps

reaching the fire feature is heavily dependent on the gauge wire used between the transformer and the fire feature. Our

Install Instructions require no less than 12 gauge wire be run for all fire features. Often times we learn that in many cases

less than 12 gauge wire has been used and herein lies the cause of the problem.

Here is how you check to determine if enough Electrical Current (amps) are getting to the fire feature:

1. CAUTION: Turn off the gas supply prior to the next step.

2. Using a clamp on ammeter, clamp the ammeter around one of the wires providing power to the Electronic

Ignition System.

3. Turn the fire feature on.

4. The amps you should see will range between 1.4 to 1.6 amps initially. Four seconds after being turned on the

amps will jump to approximately 2.0 amps.

If you do not see the amps listed above AND the wire gauge used was less than 12 gauge wire – change the wiring.

Otherwise contact us for further assistance.

I turned the Fire Feature off but I still see small flames emanating from the fire feature.

Turn the fire feature on, let the main fire ring light and then turn it off again – do this several times. Small pieces of debris

from the gas line can get caught in the main or pilot valve thereby preventing it from closing all the way. This will

sometimes happen with a new gas line. By cycling power you can often times dislodge the debris. If cycling power does

not rectify the problem, turn the gas off using the manual gas shutoff and contact us for further assistance.

12

Attachment 1

Automated Pool Controller Wiring

13

Loading...

Loading...