S-2A

Propane / CNG Fume Detector with Solenoid Valve Control

Installation and Operation Manual

MADE IN THE USA.

• Automatic Solenoid Control

• Dual Sensor Capability

• Microcomputer Operation

• Solid State Sensors

• Self Testing Circuitry

READ THIS MANUAL CAREFULLY AND

SAVE FOR FUTURE REFERENCE. KEEP

THIS MANUAL WITH THE S-2A.

Introduction

The S-2A vapor-monitoring system utilizes advanced technology for detection of propane (LPG)

fuel vapors as well as CNG (Compressed Natural Gas). The S-2A allows the connection of two

(2) sensors and has both visual and audible alarms. Test switches are provided for full checking

of all operations. System operation and correct sensor operation are continually monitored and

indicators are provided for fault detection. The S-2A has an internal relay for automatic control of

fuel solenoid. Read this owner’s manual completely before installation. Failure to read and follow

these instructions can result in damage to the unit voiding the warranty.

Components This Kit Includes

• One S-2A Display w/Bezel • Four screws for the display

• One SV-1 Solenoid Valve • Two screws for the sensor

• One 20 MS-2 Sensor

CAUTION: NO POWER ON/OFF SWITCH IS PROVIDED FOR THIS UNIT. TO

FUNCTION AS INTENDED, THE S-2A MUST BE CONNECTED TO A CORRECT

POWER SOURCE, AND FOR MAXIMUM EFFECTIVENESS, BE POWERED AT

ALL TIMES WHILE ABOARD. IF POWER IS ON AND LEFT UNATTENDED FOR AN

EXTENDED PERIOD OF TIME, BATTERY POWER MAY BE DIMINISHED.

P/N: 18122 Page 1 Rev. 1.0

Rev Date: 9/7/07

Tools Required and Hardware

• Screw Drivers (Slotted & Phillips) • Hole Saw 2-1/16” diameter

• Electrical Connector Crimping Tool • Two 1 Ampere Fuse

With Wire Stripper • Wire Nuts (#16 Gauge Wire)

• Power Drill • A Length of #16 Gauge Wire

• Electrical Tape • Tape Measure and Pencil

• Drill — 3/4 (19.05mm) Diameter • Crescent Wrench

• Drill — 1/8” (3-17mm) Diameter • 2 in-Line fuse Holder -

Manual Display Controls / Indicator

A - Solenoid Valve Indicator

B - Sensor #1 Indicator

C - Sensor #2 Indicator

D - Unit Fault Indicator

E - Solenoid Valve On/Off Switch

F - Sensor #1 Test Switch

C - Sensor #2 Test Switch

H - Horn Mute Switch

I - Audible Horn (Internal)

Indicator Definitions

Solenoid Indicator

Green = Solenoid Control on

Off = Solenoid Control off

Sensor #1 & #2

Green = Sensor active, no fumes detected Figure 1

Amber = Sensor failure

Red = Fumes detected! alarm condition

Flashing Green = Sensor warm up period

Off = No sensor detected on power-up

Unit Fault

Off = Unit Functional

Amber = Fault Detected, horn beeping

Display Installation

The S-2A should be mounted in a convenient location, preferably at the source of propane usage

(i.e. galley, heater, etc…) where the visual indicators may be readily seen. To install the display,

you must first remove the snap-on bezel by inserting a small, flat blade screwdriver into the slot

located on either side of the bezel and carefully prying up until the bezel snaps free. (See figure 5)

CAUTION: Do not attempt to remove the four (4) screws, which are now exposed which attach

the printed circuit panel to the frame. Doing so will void all warranties.

Next, drill a 2-1 /16” diameter hole into the panel. Slip the instrument through the hole and

secure, making sure that you have access to the terminals for solenoid valve connections, positive

and negative terminal connections and sensor(s) connections.

Plug in your sensor to connector one and make positive and negative connections for the display

and solenoid valve. Finish the installation by fastening to panel with four screws (provided) and

snapping bezel back into place.

P/N: 18122 Page 2 Rev. 1.0

Rev Date: 9/7/07

Sensor Installation

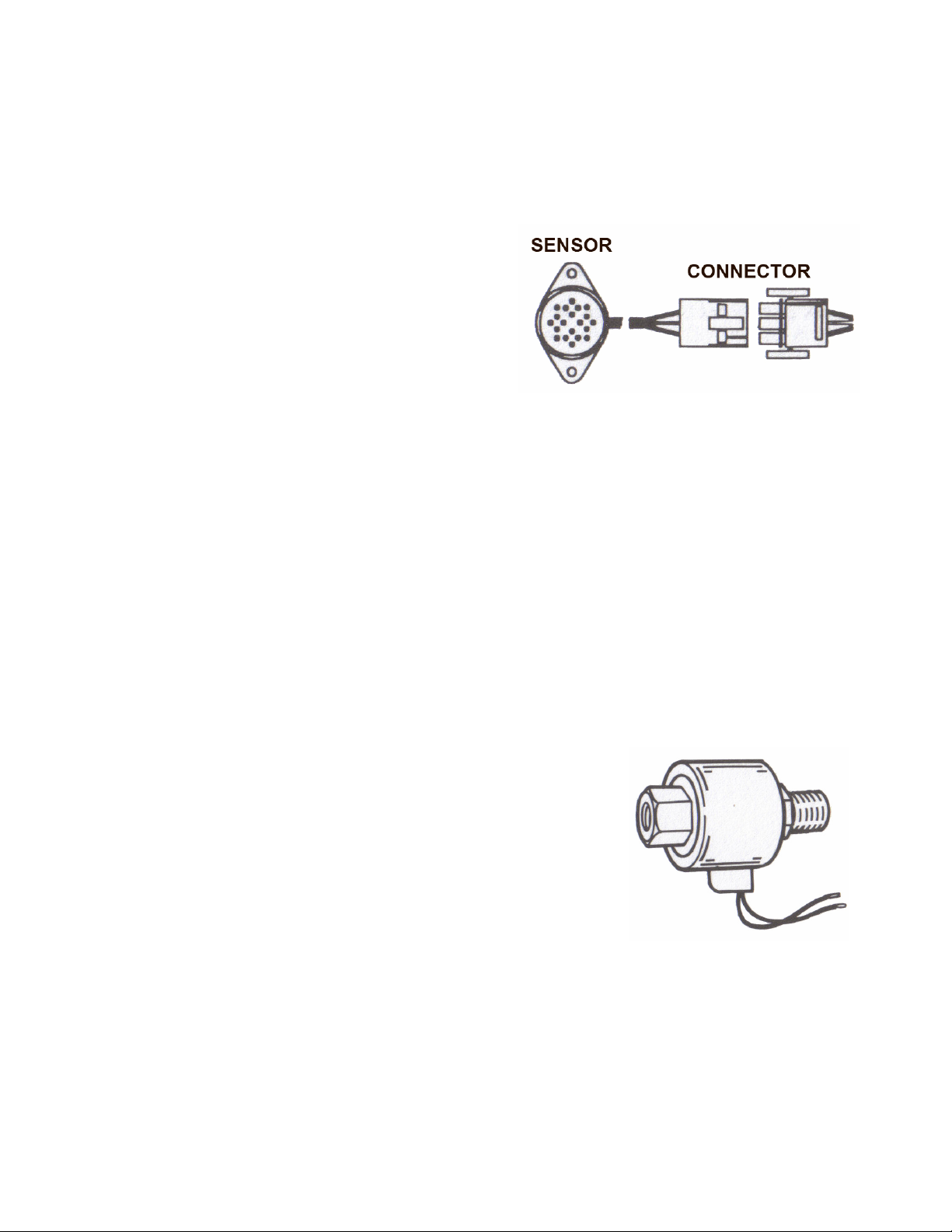

The sensor supplied with the S-2A includes a

standard 20 foot ( 8.29m) cable. If a longer cable

is desired contact your dealer or Fireboy-Xintex.

Coil excessive cable in a convenient location.

Remove the paper covering the adhesive backing

on the sensor-mounting surface and press the

sensor into position on a previously cleaned

surface. Install with two (2) screws provided.

CAUTION: Do not attempt to use any other

manufacturer’s sensor or previously installed

sensors.

Figure 2

Sensor Location

CAUTION: Propane is heavier than air and will

settle. Therefore it is important that a location be

selected that is as low as practical and as near the

appliance as is possible. Keep sensor dry.

CNG (Compressed Natural Gas) is lighter than air and will rise. Therefore, it is important that a

location be selected that is within nine (9”) inches (22.86cm) of the ceiling height. Do not locate

sensor directly over cooking or heating appliances. Keep sensor dry.

Solenoid Installation

Propane (LPG) — Mount the solenoid in-line on the tank

side of the LPG regulator as close to the tank as is practical.

The tank itself should be mounted outside the cabin or

crew quarters to avoid the possibility of gas accumulation

due to a leak between the tank and the solenoid valve.

CNG — Because of the high tank pressure of CNG, the

solenoid valve MUST be installed after the CNG regulator

and as close to the regulator as practical. The tank

and regulator should be mounted outside the cabin or

crew quarters to avoid the possibility of gas accumulation

due to a leak between the tank and the solenoid valve,

NOTE: DO NOT over-tighten fittings. Doing so will cause

the solenoid valve to malfunction. After installation, check

all fittings for leaks with a soapy water solution - NEVER Figure 3

use flame to check for leaks. Use 2 wrenches when tightening

connections to avoid twisting the valve and causing damage.

P/N: 18122 Page 3 Rev. 1.0

Rev Date: 9/7/07

Wiring the S-2A

Connect a length of 16-gauge wire from the control panel positive to the +12 VDC terminal on

the S-2A display through a 1-amp fuse. Connect a length of 16-gage wire from the control panel

buss bar ground to the negative terminal on the S2A display.

If you are supplying your own solenoid valve, disconnect solenoid valve from current system and

wire solenoid valve to S-2A display using figure 6 on page 4.

If you choose to use the valve provided in the carton, which is non-polarized, wire solenoid valve

to S-2A display using figure 6 on page 4.

Quick Disconnect Style Sensor with 20’ sensor cable is included. The disconnect/connector plug

is located 12” from the red sensor. In the event you need to replace the red sensor, simply

disconnect it at the plug and remove. When reattaching the sensor, make sure the connector

“snaps” into place by pushing the side locks in. This ensures a watertight seal. No need to reroute

or replace the 20’ sensor cable. NOTE: If longer sensor length is necessary, contact your retailer

or our factory for lengths 25’ through 100’.

Sensor Connection

Plug sensor #1 provided with the S-2A into the connector on the backside of display labeled #1. If

installing the optional second sensor, plug sensor #2 into the other connector.

Figure 5

P/N: 18122 Page 4 Rev. 1.0

Rev Date: 9/7/07

Overall Wiring Diagram

Figure 6

Terminal Strip Connections

- 12V = Display Ground (negative)

+ 12V = Display Positive

+ V = Solenoid Valve Positive

- V = Solenoid Valve Ground (negative)

Operation

When first turning the unit on, the S-2A goes through an audio/visual cycle of all indicators and

the audible horn. Beginning with sensor #1, the indicators will cycle green, amber, and red. This

will then continue with sensor #2. If optional sensor #2 is not installed the indicator light will turn

off. The unit fault indicator will then illuminate, and then the horn will beep.

The sensor lights may flash green during the warm-up period. This flashing will occur only if a

sensor is connected. Warm-up time will vary depending upon usage of the unit. Long periods of

inactivity will require long warm-up periods. After the warm-up period, the indicator will change

to green. It a sensor is not installed the sensor indicator will turn off. The solenoid control may be

tested by pressing the solenoid switch. Pressing this switch again will turn the solenoid off.

CAUTION: Be certain solenoid switch is on! Gas will not flow through the system.

Should either of the sensors detect propane or CNG fumes, the corresponding indicator #1 or #2

will change to red and the audible horn will sound. The indicator will remain red as long as fumes

are detected. The solenoid control will turn off. Do NOT consider the area clear until the indicator

light returns to green.

Testing Display Mode

Internal operation of the display mode may be tested using the corresponding TEST switch.

Pressing the test buttons will simulate the above alarm conditions.

P/N: 18122 Page 5 Rev. 1.0

Rev Date: 9/7/07

Functional Testing of the Sensor

WARNING: DO NOT use a gasoline soaked rag or a container partially filled with gasoline to

test sensor. The raw gas could ignite resulting in serious injury. In addition, the isolated high

concentration of fumes may damage the sensor and render it inoperative.

To TEST SENSOR use butane lighter with the striker wheel removed. Hold the lighter to the

sensor and press down on the lever to release the Butane. In three to four seconds the warning

light will come on. In about ten seconds the alarm horn will sound. Remove lighter from the

sensor. Mute the alarm horn and within several seconds the warning light will shut off.

Whenever the S-2A alarms, the horn may be muted with the “MUTE” button, but THE

PROBLEM SHOULD NOT BE CONSIDERED CLEARED UNTIL THE ALARM LIGHT

GOES OUT

Sensor Fault Detection

Should the unit determine that either of the sensors is faulty or disconnected, the corresponding

indicator will change to amber and the horn will sound, Check that the sensor is connected and

that wiring has not been frayed or cut. Should this condition persist, the sensor has been damaged

and must be replaced.

Unit Fault Detection

Should an internal failure occur, the unit fault light will display amber and the horn will sound.

Should this occur, return the display to the manufacturer for repair.

Nuisance Alarms

The sensor used for the S-2A is sensitive to hydrocarbons- an alarm may be triggered by the use

of other chemicals such as cleaners, paint, polish, etc… The sensors will also detect hydrogen

fumes from an overcharged battery. If no gasoline fumes are present, check for recent use of

cleaners, fiberglass repairs, strong adhesives, etc… If none of these are present, the sensor may

have been damaged and will need replacement.

WARNING:

The S-2A has been designed to alarm nominally at 20% of the LEL (Lower Explosive Limit) of

Propane/CNG. Implement immediately the following procedures in the event of an alarm. Shut

down all appliances. Manually shut oft the source of Propane/CNG. Turn off all electrical circuits

EXCEPT circuits, which operate blowers and/or exhaust fans. Remove all personnel from the

area. Ventilate the area; turn on exhaust fans and open windows, hatches, etc… Carefully check

all fuel lines, tanks and fittings to locate the leak. Have the problem repaired by qualified

personnel.

Maintenance

The S-2A requires very little maintenance. Periodically examine the sensors for contamination or

damage. Check that sensor wires are not frayed, pinched, or cut. Test the operation of both

sensors and display frequently. Do NOT expose sensors to liquids or chemicals.

When cleaning, seal off the sensor(s) with a plastic covering. Harsh chemicals may damage the

sensor. Keep sensor(s) sealed until the compartment has been completely ventilated.

CAUTION: DO NOT FORGET TO REMOVE SENSOR COVERINGS OR THE S-2A WILL

NOT OPERATE CORRECTLY.

P/N: 18122 Page 6 Rev. 1.0

Rev Date: 9/7/07

Specifications

Voltage ………………………………………… +12VDC Nominal (10VDC min to

18VDC max)

Current ………………………………………… 150 mA per sensor / 300 mA max

(solenoid off)

Alarm ………………………………………… 20% Lower Explosive Limit (LEL)

Horn ………………………………………… 75dB @ 10cm 3kHz frequency

Solenoid Control ……………………………… 1 amp max

Solenoid Valve ………………………………… 312 PSI maximum

Current Draw (SV-1) ………………………… 800mA holding

Options

MS-2 Propane Sensor

SV-1 Solenoid Control Valve

CNV 12-1 12V Converter for 24/32 volt systems

All Options are available from Fireboy-Xintex. Contact the Customer Service Department at 866350-9500. Visa. Mastercard, or C.O.D accepted.

WARNING

The S-2A is a propane/CNG (Compressed Natural Gas) detector ONLY. This device is

meant to serve as a supplement warning only. It is NOT intended to replace standard

safety practices which should be carried out around explosive gases (i.e. inspect all

rooms and compartments, check all gas fittings and connections, smell for

propane/CNG gas fumes, etc…) To function properly the S-2A must be powered at all

times while aboard. Do not install this outdoors. Before installing in applications which

may appear different than those outlined in this manual, contact Fireboy-Xintex 866350-9500. This device is not intended for use in aircraft.

There are no user or field serviceable parts in this product. The S-2A must be returned

to the manufacturer for any repair or trouble shooting beyond what is recommended in

this manual. Installation shall be done by qualified personnel authorized to do so by the

authorities having jurisdiction for the particular application in which the product is

being used. Electrical wiring shall be in accordance with applicable codes. Improper

wiring, including all wire connections, may render the unit inoperable, damage

components, or cause a fire, and will void all warranties

More Safety Products from FIREBOY/XINTEX

• Clean Agent Automatic Fire Extinguishers

• Clean Agent Manual / Automatic Fire Extinguishers

• M-1 / M-2A Gasoline Fume Detectors

• MB-1 / MB-2 Gasoline Fume Detectors with Blower Control

• CMD-4M Carbon Monoxide Detectors

P/N: 18122 Page 7 Rev. 1.0

Rev Date: 9/7/07

Seller warrants title, materials, and workmanship on Fireboy equipment and assigns,

the original manufacturer’s warranty on those components manufactured by others,

as permitted. Seller’s warranty shall be for a period of (1) one year from the date of

sale to the ORIGINAL CONSUMER Fireboy-Xintex, Inc. does not assume the

costs of removal and/or installation of the product or any other incidental costs

which may arise as a result of any defect in materials or workmanship. Any nonconforming equipment returned to the Seller at Buyer’s expense and risk shall be

repaired or replaced at Seller’s option, provided that: (a) the product has not been

subjected to abuse, contamination, neglect, accident, incorrect wiring not our own,

improper installation or servicing, or used in violation of the instructions furnished

by Fireboy-Xintex, Inc. (b) the product has not been repaired or altered by anyone

other than Fireboy-Xintex, Inc. (c) the serial number has not been removed,

defaced, or otherwise changed (d) the product is determined to contain defective

materials or workmanship: and (e) use of the product is discontinued upon

discovery of detective materials or workmanship and Fireboy-Xintex Inc. is notified

immediately.

ANY WARRANTY IMPLIED BY LAW, INCLUDING WARRANTIES OF

MERCHANTABILITY OF FITNESS, IS IN EFFECT ONLY FOR THE

DURATION OF THE EXPRESS WARRANTIES, OR TO ASSUME FOR

FIREBOY/XINTEX, INC., ANY OTHER LIABILITY IN CONNECTION WITH

THE SALE OF ITS PRODUCTS. FIREBOY/XINTEX, INC. SHALL BE NOT

LIABLE FOR THE LOSS OF USE, REVENUE, PROFIT, INJURY OR ANY

OTHER CONSEQUENTIAL OR INCIDENTAL DAMAGES. BUYER IS NOT

RELYING ON SELLER’S JUDGEMENT REGARDING BUYERS

PARTICULAR REQUIREMENTS, AND HAS HAD AN OPPORTUNITY TO

INSPECT THE PRODUCT TO BUYER’S SATISFACTION.

Shipping Address: O-379 Lake Michigan Drive NW, Grand Rapids, MI USA 49534

This Warranty is in lieu of all other express or implied warranties.

Mailing Address: PO Box 152, Grand Rapids, MI USA 49501-0152

Website: www.fireboy-xintex.com

One (1) Year Limited Warranty

FIREBOY-XINTEX, Inc.

Phone (616) 735-9380 Fax (616) 735-9381

Email: fireboy@fireboy-xintex.com

TOLL FREE: 1-866-350-9500

P/N: 18122 Page 8 Rev. 1.0

Rev Date: 9/7/07

P/N: 18122 Page 9 Rev. 1.0

Rev Date: 9/7/07

Loading...

Loading...