F B RM OPERAT RS I S RU TI NS

OVER & UNDER SHOTGUNS (covers Max Lion. Silver Lion. Light Lion. Ultra Mag

Lion. & Black lion Competition Models. 11 & 20 GAUGE)

SAFETY RULES

PLEASE READ THIS BEFORE HANDUNGYOUR FIREARM

The following safety rules are p!aced in this manual by Heckler & Koch, Inc. as

an important I'eminder that firearms safety is your responsibility, Firearms can

be dangerous and can potentially cause serious injury, damage to property or

death, If handled improperly.

.Never point a firearm at anyone, or in any direction other than a safe one,

I.e., downrange.

. Always treat all firearms as if they are loaded.

.Keep your finger off the trigger until your sights are on the target.

.Keep your finger off the trigger while loading or unloading the shotgun.

0

Be sure of your target and the back stop beyond,

.

Never give to or take the firearm from anyone unless the action is open,

0 Be sure the ammunition you are using is factory loaded and Is not damaged

In any way,

.

Before the days shooting, make certain the firearm is totally unloaded. on

Safe and the bolt locked to the rear. Check the bore of your unloaded

shotgun for any possible obstructions.

.

Before firing any firearm \.Infam iliar to you. make use you understand how it

functions.

.Before s hooti ng be su re th e gu n is closed. The top !ever must be in th e

frame extension and not out of it.

.-li;.

Assembly Instructions

The Over-&-Under Series of shotguns are packed with the barrels and forend

separated from the stock -r"ceiver (see figure I below).

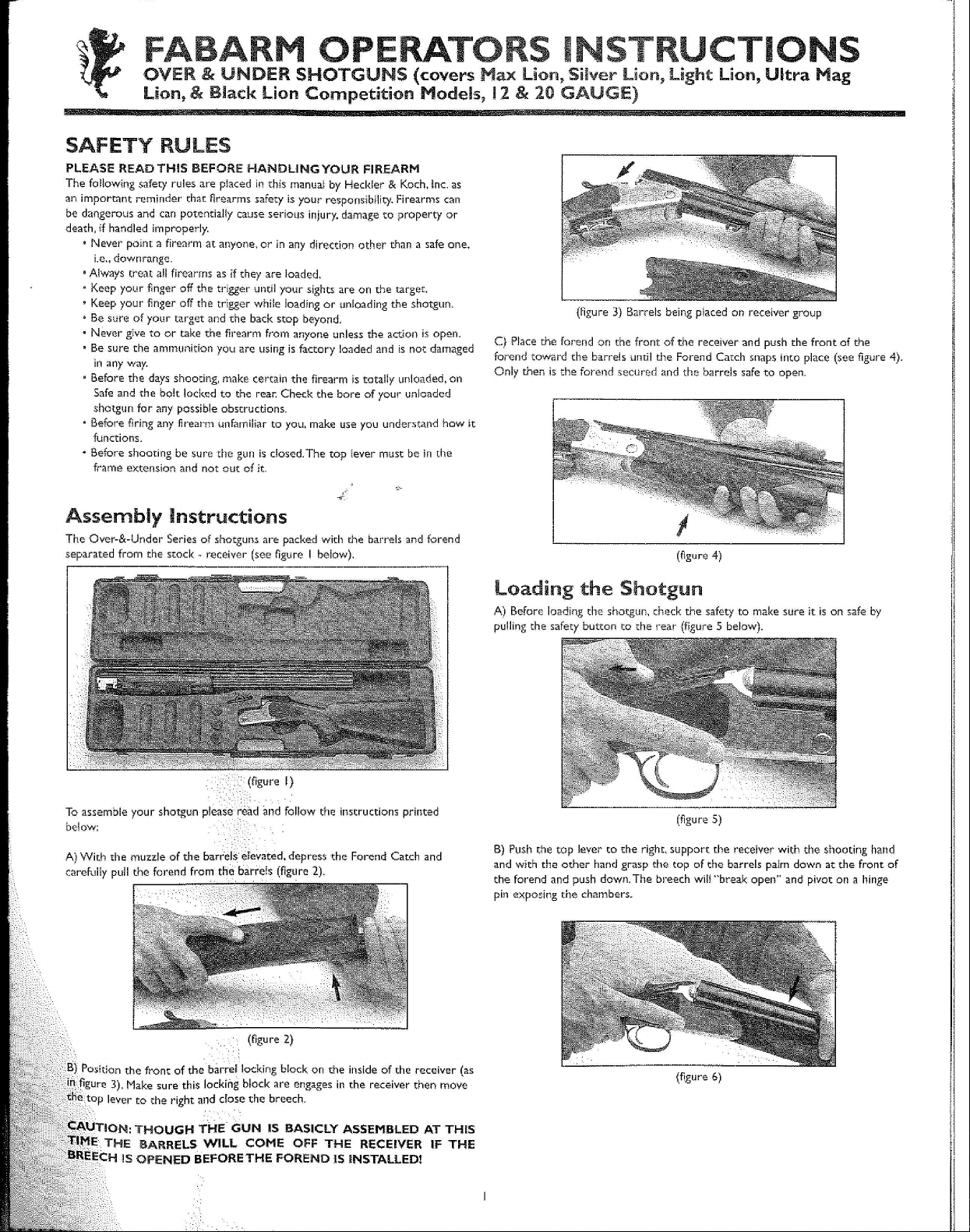

(figure 3) Barrels being piaced on receiver group

C) Place the forend on the front of the receiver and push the front of the

forend toward the barrels until the Forend Catch snaps into place (see figure 4).

Only then is the forend secured and the barrels safe to open.

(figure 4)

(figure I)

To assemble your shotgun please reid and follow the instructions printed

below:

A) With the muzzle of the barrels elevated, depress the Forend Catch and

carefully pull the forend from the barre!s (figure 2).

.

loading the Shotgun

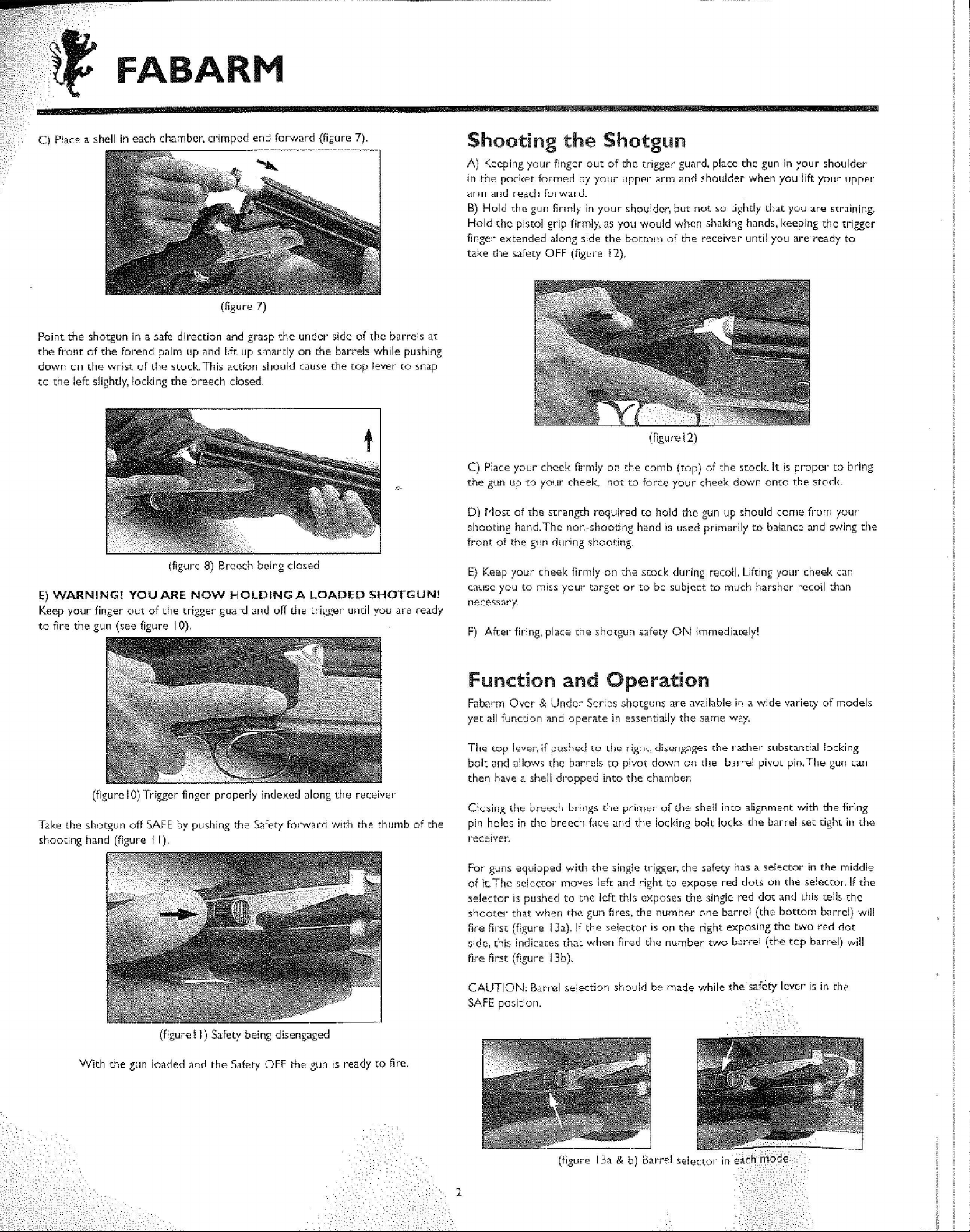

A) Before loading the shotgun. check the safety to make sure it is on safe by

pulling the safety button to the rear (figure 5 below}.

(figure

5)

B)

Push the top lever to the right, support the receiver with the shooting hand

and with th e other hand grasp the top of the barrels palm down at the front of

the forend and push down. The breech will "break open" and pivot on a hinge

pin exposing the chambers.

Position the front of the barrel locking block on the inside of the receiver (as

3). Make sure this locking block are engages in the receiver then move

lever to the right and close the breech.

THOUGH THE GUN IS BASICLY ASSEMBLED AT THIS

THE BARRELS WILL COME OFF THE RECEIVER IF THE

15 OPENED BEFORE THE FOREND IS INSTALLED!

(figure 6)

FABARM

C) Place a shell in each chamber, cl'imped end forward (figure 7).

(figu re 7)

Point the shotgun in a safe direction and grasp the under side of the barrels at

the front of the forend palm up and lift up smanly on the barrels while pushing

down on the wrist of the stock. This action should cause the top lever to snap

to the left slightly, locking the breech closed.

(figure 8) Breech being closed

E) WARNING! YOU ARE NOW HOLDING A LOADED SHOTGUN!

Keep your finger out of the trigger guard and off the trigger until you are ready

to fire the gun (see figure 10).

Shooting the Shotgun

A) Keeping your finger out of the trigger guard, place the gun in your shoulder

in the pocket formed by your upper arm and shoulder when you lift your upper

arm and reach fDrwal'd.

B) Hold the gun firmly in your shoulder, bUt nDt SD tightly that you are straining.

Hold the pistol grip firmly, as you would when shaking hands, keeping the tl'igger

finger extended along side the bouom of the receiver until you are ready to

take the safety OFF (figure 12).

(figure 12)

C) Place your cheek firmly on the comb (top) Df the stock. It is proper to bring

the gun up to your cheek, not to force your cheek down onto the stock.

D) Most of the strength required to hold the gun up should come from your

shooting hand. The non-shooting hand is used primarily to balance and swing the

front of the gun during shooting.

E) Keep your cheek firmly on the stock during recoil. Lifting your cheek can

cause you to miss your target or to be subject to much harsher recoil than

necessary.

F) After firing, place the shotgun safety ON immediately!

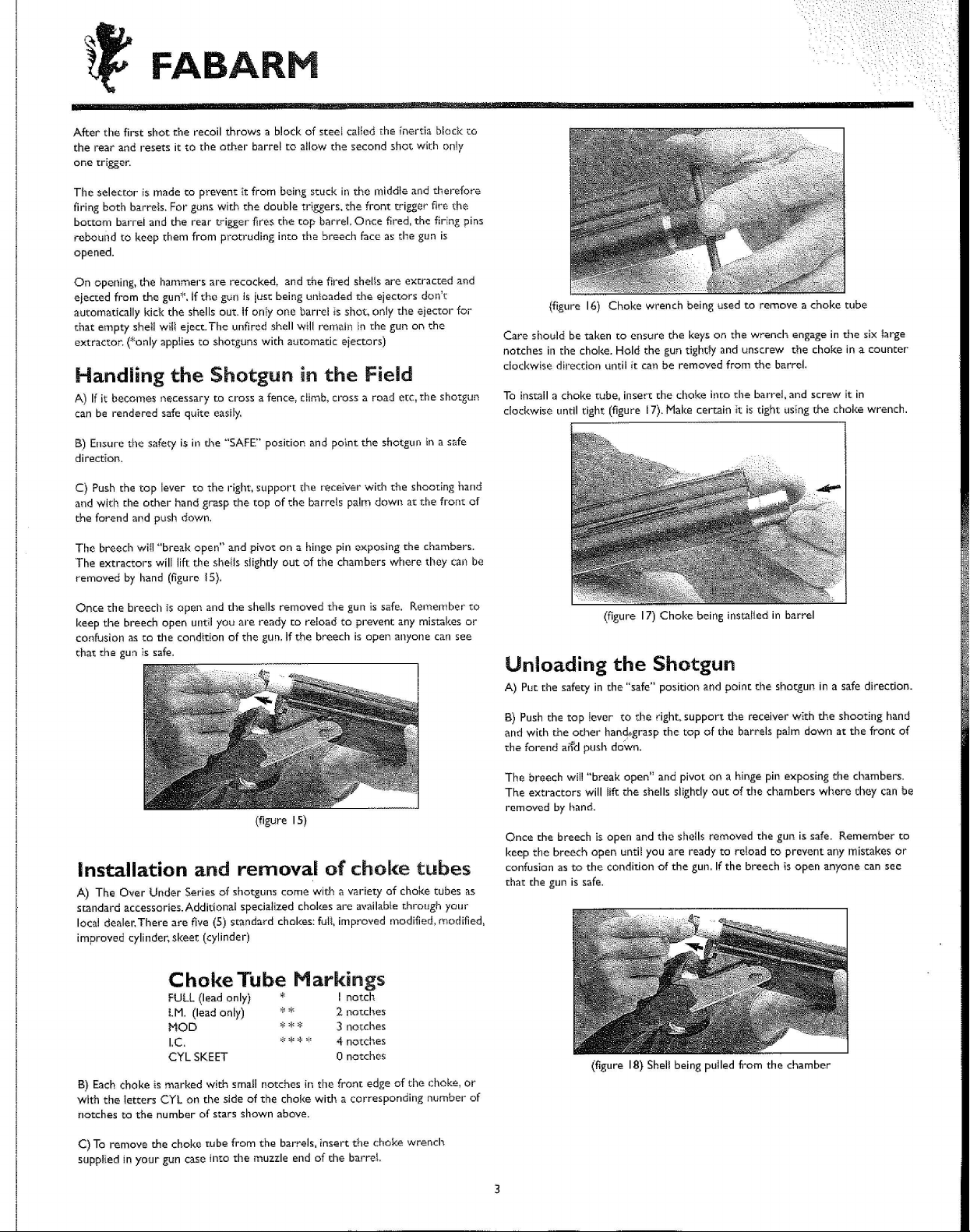

(figure 10)Trigger finger properly indexed along the receiver

Take the shotgun off SAFE by pushing the Safety forward with the thumb of the

shooting hand (figure

With the gun loaded and the Safety OFF the gun is ready to fire.

j

I).

(figure! I) Safety being disengaged

function and Operation

Fabarm Over & Under Series shotguns are available in a wide variety of models

yet all function and operate in essentially the some way.

The top lever, if pushed to the right, disengages the rather substantial locking

bolt and allows the barrels to pivot down on the barrel pivot pin. The gun can

then have a shell dropped into the chamber

Closing the breech brings the ptimer of the shell into alignment with the firing

pin holes in the breech face and the locking bolt locks the barrel set tight in the

receiver.

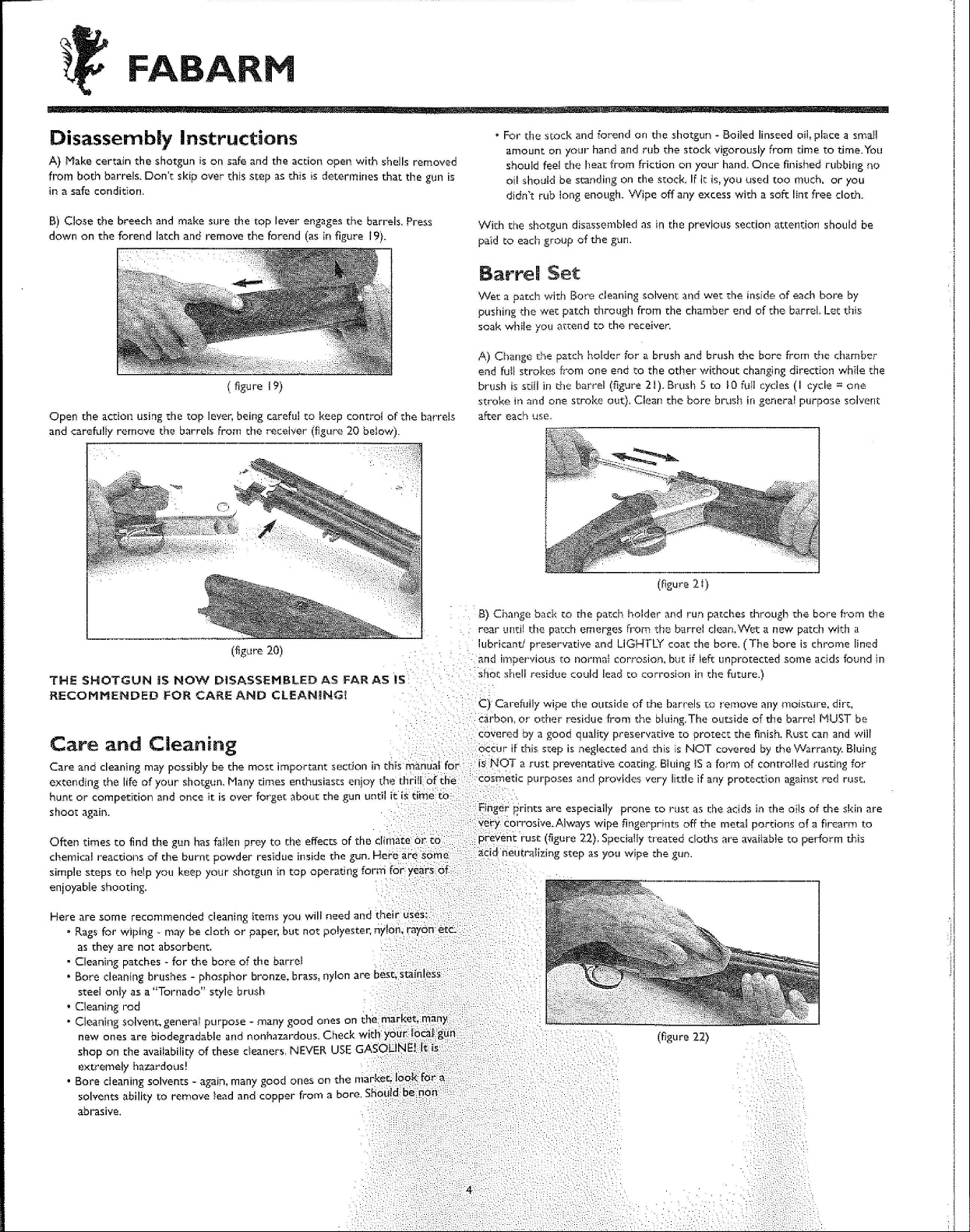

For guns equipped with the single trigger, the safety has a selector in the middle

of it-The selectal' moves left and right to expose red dots on the selector. If the

selector is pushed to the left thi, exposes the single red dot and this tells the

,hooter that when the gun fires, the number one barrel (the bottom barrel) will

fire first (figure 13a). If the selector is on the right exposing the two red dot

side, this indicates that when fil'ed the number two barrel (the tap barrel) will

fire first (figure 13h).

CAUTION: Bal'tel selection should be made while the safety lever is in the

SAFE position.

,

After the first shot the recoil throws a block of steel called the inertia block to

the rear and resets it to th e other barrel to allow the second shot with only

one trigger.

The selector is made to prevent it from being stuck in the middle and therefore

firing both barrels. For guns with the double triggers, the front trigger fire the

bottom barrel and the rear trigger fires the top barrel. Once fired, the firing pins

rebound to keep them from protruding into the breech face as the gun is

opened.

On opening, the hammers are recocked, and the fired shells are extracted and

ejected from the gun*. If the gun is just being unloaded the ejectors don't

automatically kick the shells out. If only one barrel is shot, only the ejector for

that em pty shell wi!! eject. The unfired shell will remai n in the gun on the

extractor. (*only applies to shotguns with automatic ejectors)

FABARM

Handling the Shotgun in the Field

A) If it becomes necessary to cross a fence, climb, cross a road etC, the shotgun

can be rendered safe quite easily.

B) Ensure the safety is in the "SAFE" position and point the shotgun in a safe

direction.

C) Push the top lever to the right, support the receiver with the shaming hand

and with the other hand grasp the top of the barrels palm down at the front of

the forend and push down.

(figure 16) Choke wrench being used to remove a choke tube

Care should be taken to ensure the keys on the wrench engage in the six large

notches in the choke. Hold the gun tightly and unscrew the choke in a counter

clockwise dil'ection until it can be removed from the barrel.

To install a choke tUbe, insert the choke into the barrel, and screw it in

clockwise until tight (figure 17). Make certain it is tight using the choke wrench.

The breech will "break open" and pivot on a hinge pin exposing the chambers.

The extractors will lift the sheHs slightly out of the chambers where they can be

removed by hand (figure 15).

Once the breech is open and the shells removed the gun is safe. Remember to

keep the breech open until you are ready to reload to prevent any mistakes or

confusion as to the condition of the gun. If the breech is open anyone can see

that the gu n is safe.

(figure 15)

Installation and removal of choke tubes

A) The Over Under Series of shotguns come with a variety of choke tubes as

standard accessories. Additional specialized chokes are available through your

local dealer. There are five (5) standard chokes: full, improved modified, modified,

improved cylinder, skeet (cylinder)

Choke Tube Markings

FULL (lead only)

I.M. (lead only)

MOD

I.c.

CYL

SKEET

B) Each choke is marked with small notches in the from edge of the choke, or

with the letters CYL on the side of the choke with a corresponding number of

notches to the number of stars shown above.

*

* *

***

* *

*

*

I notch

2 notches

3 notches

4 notches

0 notches

(figure 17) Choke being installed in barrel

Unloading the Shotgun

A) Put the safety in the "safe" position and point the shotgun in a safe direction.

B) Push the top lever to the right, support the receiver with the shooting hand

and with the other hanck.grasp the top of the barrels pai m down at the front of

the forend aifd push down.

The breech will "break open" and pivot on a hinge pin exposing the chambers.

The extractors will lift the shells slightly out of the chambers where they can be

removedbyhand.

Once the breech is open and the shells removed the gun is safe. Remember to

keep the breech open until you are ready to reload to prevent any mistakes or

confusion as to the condition of the gun. If the breech is open anyone can see

that the gun is safe.

(figure 18) Shell being pulled from the chamber

C) To remove the choke tUbe from the barrels, insert the choke wrench

supplied in your gun case intO the muzzle end of the barrel.

,

FABARM

Disassembly Instructions

A) Make certain the shotgun is on safe and the action open with shells removed

from both barrels. Don't skip over this step as this is determines that the gun is

in a safe condition.

B) Close the breech and make sure the top lever engages the barrels. Press

down on the forend latch and remove the forend (as in figure 19).

(figure 19)

Open the action using the top lever, being careful to keep control of the barrels

and carefully remove the barrels from the receiver (figure 20 below).

.For the stack and forend on the shotgun

amount on your hand and rub the stock vigorously from time to time. You

should feel the heat from friction on youl- hand. Once finished rubbing no

oil should be standing on the stock. If It is, you used too much, or you

didn't rub long enough. Wipe off any excess with a soft lint free cloth.

With the shotgun disassembled as in the previous section attention shouid be

paid to each group of the gun.

Boiled linseed oil, place a smail

-

Barrel Set

Wet a patch with Bore cleaning solvent and wet the inside of each bore by

pushing the wet patch through from the chamber end of the barrel. Let this

soak while you attend to the receiver.

A) Change the patch holder for a brush and brush the bore from the chamber

end full strokes from one end to the other without changing direction while the

brush is still in the barrel (figure 21). Brush 5 to 10 fuil cycles (I

stroke in and one stroke out). Clean the bore brush in general purpose solvent

after each use.

(figure 21)

cycle'" one

THE SHOTGUN IS NOW DISASSEMBLED AS FAR ASIS

RECOMMENDED FOR CARE AND CLEANING!

Care and Cleaning

Care and cleaning may possibly be the most important section in

extending the life of your shotgun. Many times enthusiasts enjoy the

hunt or competition and once it is over forget aboUL the gun until

shoot again.

Often times to find the gun has fallen prey to the effects of the

chemical reactions of the burnt powder residue inside the gun.

simple steps to help you keep your shotgun in top operating form

enj oyable shooti ng.

Here are some recommended cleaning items you will need and

.

Rags

for wiping. may be cloth or paper, but not polyester,

as they are not absorbent.

.Cleaning patches

.

Bore cleaning brushes

steel only as a "Tornado" style brush

. Cleaning rod

. Cleaning solvent, general purpose

new ones are biodegradable and nonhazardous. Check

shop on the availability of these cleaners.

extremely hazardous!

.Bore cIean ing solvents -

solvents abi lity to remove lead and copper from a bore.

abras ive.

for the bore of the barrel

-

phosphor bronze, brass, nylon are

-

many good ones on

-

again, many good ones on the

NEVER

USE

B) Change back to the patch holder and run patches through the bore from the

rear until the patch emerges kom the barrel clean. Wet a new patch with a

lubricant! preservative and LIGHTLY coat the bore. (The bore is chrome lined

.

and impervious to normal corrosion, but if left unprorected some acids found in

shot shell residue could lead to corrosion in the future.)

Carefully wipe the outside of the barrels to remove any moisture, dirt,

or other residue from the bluing. The outside of the ban-el MUST be

by a good quality preservative to protect the finish. Rust can and will

if chis step is neglected and this is NOT covered by the Warranty. Bluing

a rust preventative coating. Bluing IS a form of controlled rusting for

purposes and provides very little if any protection against red rust.

are especially prone to rust as the acids in the oils of the skin are

e.Always wipe fingerprints off the metal portions of a firearm to

(figure 22). Specially treated cloths are available to perform this

step as you wipe the gun.

FABARM

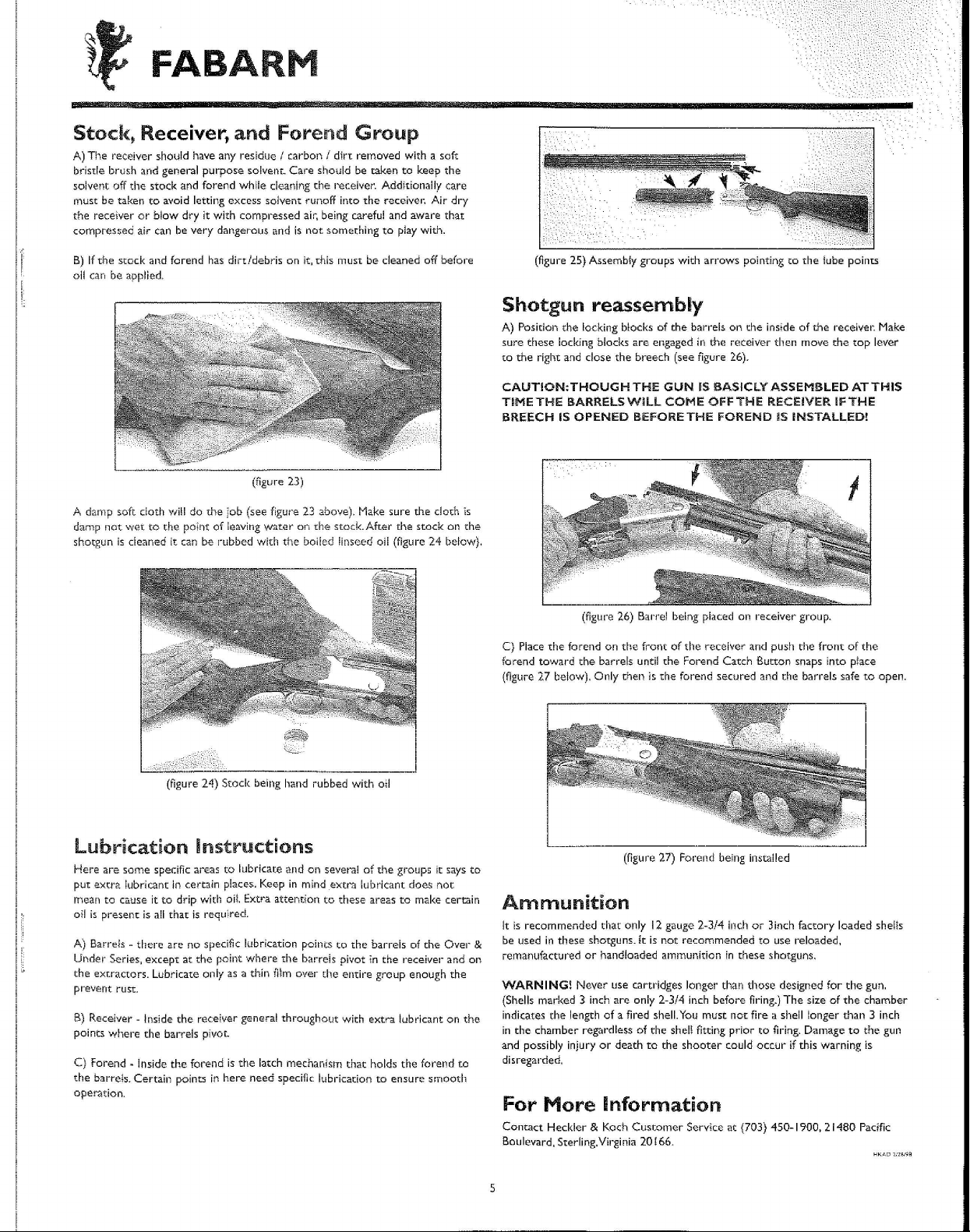

Stock, Receiver, and Forend Group

A) The receiver should have any residue / carbon / dirt removed with a soft

bristle brush and general purpose solvent. Care should be taken to keep the

solvent off the stock and forend wh ile cleaning the I'"ceiver. Additionally care

must be taken to avoid letting excess solvent runoff into the receiver. Air dry

the receiver or blow dry it with compl'i~ssed ai1',being careful and aware that

compressed air can be very dangerous and Is not something to play with.

"'.?ISL

--

B) If the stock and forend has dirt/debris on it, this must be cleaned off before

oil can be applied.

(figure 23)

A damp soft cloth will do the job (see figure 23 above). Make sure the cloth is

damp not wet to the point of leaving water on the stock.After the stock on the

snocgun is cleaned it can be rubbed with the boiled linseed oil (figure 24 below).

(figure 25) Assembly groups with arrows pointing to the lube points

Shotgun reassembly

A) Position the locking blocks of the barrels on the inside of the receivel~ Make

sure these locking blocks are engaged in the receiver th en move the top lever

to the right and close the breech (see figure 26).

CAUTION:THOUGHTHE GUN IS BASJCLY ASSEMBLED AT THIS

T!METHE BARRELS WILL COME OFF THE RECEIVER IFTHE

BREECH IS OPENED BEFORE THE FOREND IS INSTALLED!

(figure 26) Barrel being placed on receiver group.

C) Place the fa rend on the front of the receiver and push the front of the

fa rend toward the barrels until the Forend Catch Button snaps into place

(figure27 below).Only then is the forend secured and the barrels safe to open.

(figure 24) StOck being hand rubbed with oil

lubrication Instructions

Here are some specific areas to lubricate and on several of the groups it says to

put extra lubricant in certain places. Keep in mind extra lubricant does not

mean to cause it to drip with oi!. Extra attention to these areas to make certain

oil is present is all that is required.

A) Barrels

Under Series, except at the point where the barrels pivot in the receivel" and on

the extractors. Lubricate only as a thin film over the entire group enough the

prevent rust.

B) Receiver

points where the barrels pivot.

C) Forend .Inside the forend is the latch mechanism that holds the forend to

the barrels. Certain points in here need specific lubrication to ensure smooth

operation.

there are no specific lubrication points to the barrels of the Over &

-

Inside the receiver general throughout with extra lubricant on the

-

(figure 27) Forend being installed

Ammunition

It is recommended that only 12 gauge 2-3/4 inch or 3inch factory loaded shells

be used in th ese shotgu ns. It is not recommended to use reloaded,

remanufactured or handloaded ammunition in these shotguns.

WARNING! Never use cartridges longer than those designed for the gun.

(Shells marked 3 inch are only 2-3/4 inch before firing.) The size of the chamber

indicates the length of a fired shell.You must not fire a shell longer than 3 inch

in the chamber regardless of the shell fitting prior to firing. Damage to the gun

and possibly injury or death to the shooter could occur if this warning is

disregal'ded.

For More Information

Contact Heckler & Koch Customer Service at (703) 450-1900, 21480 Pacific

Boulevard, Sterling,Vil'ginia 20 I66.

5

HKAD

,-,'U.19~

f

FABARM

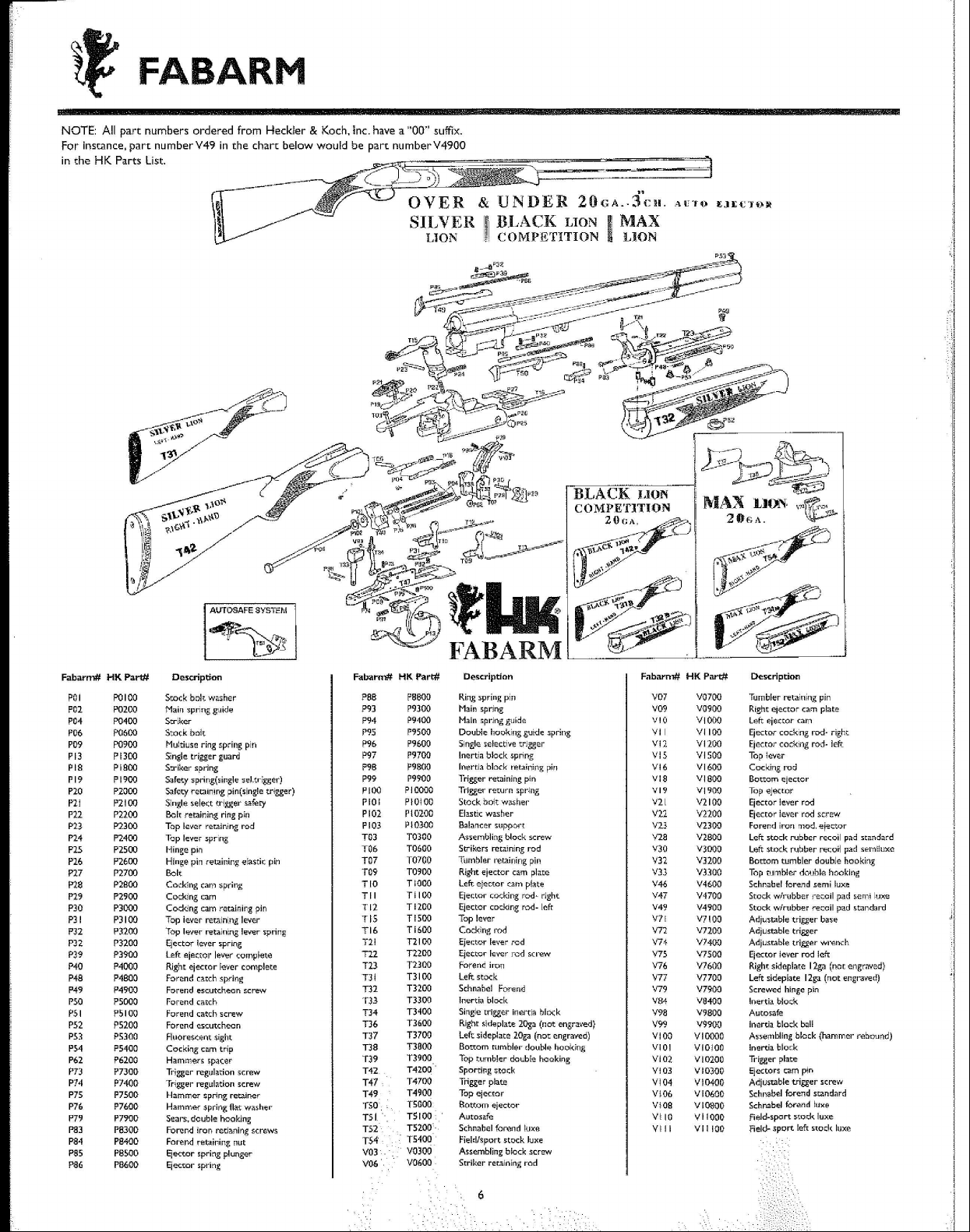

NOTE: All part numbers ordered from Heckler & Koch, Inc. have a "00" suffix.

For instance, part number V49 in the chart below would be part number V4900

in the HK Parts List.

~'-=i

'1

\'

\.\o't'i

S.\-1.~~.1l

~~~"J

\_;r.'ii-

AUTOSAFE SYSTEM

~~.

Fabarm# HK part#

POI POIOO

P02

1'0200

P04 P0400

P06

1'0600

P0900 Mukiusering

P09

PI300

PI3

PIB PI800

PI9 PI900

P20 P2000

P21 P2100

P2200

P22

P23 P2300

PH

P2400

P2S

P2500

P26 P2600

1'2700

1'27

P2BOO

P28

P29

1'2900

P30 P3000

P31 P3100

P3200

1'32

P32

1'3200

P39 P3900 Left ejectOr

NO

1'4000

?48 P4800 Forend c~tch spring

P49 P4900 Forend escutch.eon s-crew

PSO P5000 Forend couch

PSI

P5100 Forend catch screw

PS2

P5200

PS3 P5300

PS4

P5400

P62 P6200

P73

P7300

P74

P7400

P7S00

P75

P76

P7600 Hammer spring flat w~~her

P79 P7900

P83 P8300

1'8400 Forel'ld rat~ining nut

1'84

P8S00

P85

P8600

P86

Descripdon

Stock bDIt washer

Main sprlflg g\Jide

Strlker

Stack

bQIt

Single trigger guard

Striker spring

Safety spring(single seLtdgger)

Safety retaining pin(sing!e trJgg€!r)

Single $elact trigger 1i<3:fety

Bol'Cretaining ring

Top lever retairbing rod

Top lever spring

Hinge pin

Hinge pin re~ining e!3sr;i( pin T07

Bolt

CockJng cam :5pring

Cocking eam TII

Cocking eam retaining pin TI2

Top lever rer..ainlnglever

Top lever retaJntng lever spring

Ejector ~everspring

Right ejec'COr ~evercomplete

Forend escutcheon

FluQre«eot 'ight

Cocking carn trip

Hammers spac-er

Trigger regul<l.tion screw

Trigger regulation screw T47

Hammer spr~ng retainer

Sears, doubl€! hooking

Forend iron reti"'ning :;crews

Ejector spring plunger

Ejector ~pring

$pring pin

lever

complf:!te

p~n

:.,~ If

OVER & UNDER 20GA..:fcu.

SILVER

Fabatm# HK Part#

PB8 PB800

P9300

P93

P9400

P94

P9S

P9500 Double hooking gu~de spdng

P96

P9600

P97 P9700

P9800

P98

P99 P9900

PI

PlOD

PIOI PIOIOO

PI02

PI03

TO]

T06

T09

TIO

TIS

TI6

T21

T22

T23

T31

T32

T33

T34

T36

T37

T38

T39

T42

T49

TSO

TSI

TS2

TS4

V03

V06

0000

PI0200 Elasttc

PI0300 Balancer supporr

T0300

T0600

T0700

T090D

TIOOO Left €jector eam plate

TIIOO

T1200

T1500

T1600

T2100

T2200 Ejector lever rod s.crew

T230D

T3100 Left stock

T3200

T3300 Inertia block

T3400

T3600

T3700 Leftside

T3600 Bottom rumbler doubl~ hQokillg

T3900

T4200

T4700

T4900

TSOOO BottQm -ejector

TSIOO Autosafe

TS200 Schnabel forend ~uxe

T5400

V0300 Assembling b~ock screw

V0600

LION

BLACK LION

I!i'

l

I!;, COMPETITION Ii LION

m MAX

BLACK UON

COMPETJTION

20G,\,

~---- - ~---- -

De!Ocription

Ring spring pin

Main spring V09 V0900

Main sprJng guide

Single selective trJgger

Inertia block sprijng

InertJa

block retaining pin

Trigger retaining

Trigger return sprjng

Stock bok w~;>;her

Assembling block screw

Strikers retaining rod

Tumbler retaillillg pin

Right ejector

Ejector cocking rod~ dght

Ejector cockjl1g rod- left

Top lever

Cockingrod

Ejector lever rad

Forecid iron

Schnabel Forend

Singje trigger inertia bkKk

Right'idepl.te 20ga(nQtengraved)

TQPtumbler dQubl. hQQking

.

Sporting ~tod(

Trigger plate

Top ejector

Field/sport stock luxe

Striker rcrajn~ng rod

pin

washer V22 V2200

carn

plate

plate

20ga (nQt

"ngraved) VI 00

Fabarm# HK Part#

.~ U'ft) E.H:C'JOII

~~~-

.JpJ~

MAX UON

20&'\,

!

/"~

I

cy

V07 V0700

VIO

VIOOO

VII VIIOO

VI2 VI200

VIS VI500

VI600

VI6

VI8 VI800

VI9

VI900

V21

V2100

V23 V2300

V2800

Y28

V30 V3000

V32 V3200 Bottom tumbler doubje hooking

V33

V3300

V46 V4600 Schnabel foreJ1d semi luxe

V47 V4700 Stock w/rubb€r f€coil pad semi ~uxe

V49

V4900

V71

V7100

V72 V7200

V74

V7400 Adiustabl~ trigger wren(h

V7S

V7500

V76 V7600

V77 V7700

V79

V79DO

V84 V6400

V98 V9800 AutOsi3ife

V99

V9900 Inartia block bal!

VI DODO

VIOl

VIOIOO

VI02

VI0200

VI03 VI0300

VI04

YI0400

Vi06

V 10600

ViOB

V 10800

V! 10

YIIOOO

VIII VIIIOO

Tumbler ret~i\lf\lg

Right

Left ejectOr (am

Ejector cocking rodMright

Ejector cocktng rod-

Top

Cocking rod

Bottom ejectQr

TQP ojeCtQr

Ejector lever rod

Ejector lever rod screw

Forend iron mod. -ej-ectQr

Len: stock

Left $totk rubber rf;L~oiipad 1iemtJuxe

Toptumbler double hooking

Stock w/rubher -recoil pad s.tandard

Adi~slAble trigger bas~

Adjustable trigger

Ejector Jever rod !eft

Right 'ideplate 12ga (nm engraved)

Left sideplate 12ga(not engraved)

Screwed hinge pin

lo~rtia block

Assembling blQck (hammer rebQund)

Inertia blo\:;k

Trigger plate

Ejectors earn pin

Adjustable trigger screw

Schrlabel forend standard

Schnabel forend ~uxe

field-sportstQckluxe

Field~ sport !eft:s'Coc:k luxe

'''~.o,

~

Descripdon

ejector

eam plat~

1ever

rubber recoil pad standard

pin

left

tt

FABARM

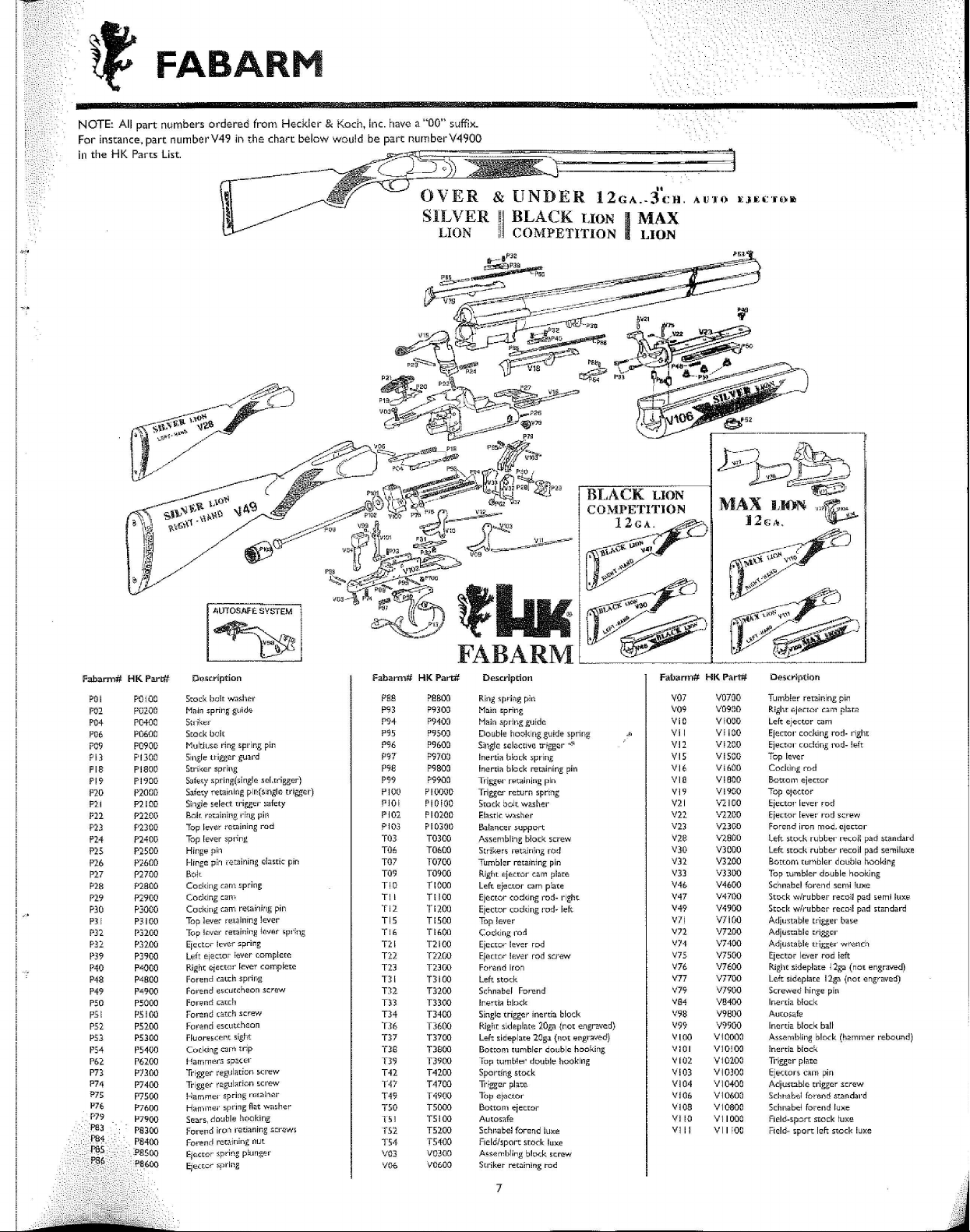

NOTE: All part numbers ordered from Heckler & Koch, Inc. have a "00" suffix.

For instance, part number V49 in the chart below would be part number V4900

in the HK Parts List.

~--:.

'I

~1

AUTOSAFE SYSTEM

OVER & UNDER 12GA..3'cH.

SILVER !II'

Pll

~.,

LION Ii! COMPETITION LION

~,

BLACK LION

I

BLACK LION

COMPETITION

II

12cA.

MAX

A Ul'O I:,JI:C'fI)1I!

MAX LION

J2{;,\.

,'"

'''~~''

II

I,

Fabarm# HK Part#

POI POIOO

P020D

P02

P0400 Str,k~l"

P04

P0600

P06

P09 P0900

PI3 PI300

PIS PISM

PI900

PI9

nODO

P20

P21 P2100

P22 P2200

P2300

P23

P24 PHOO

P2500

P2S

P2600

P26

P2700

PH

P28

P2BOO

P29 P2900

P3000

P30

P31 P3100

P32 P3200

P32 P3200

P39 P3900

P40 P4000

P48 NBOO

P49 P4900

PSO P5000

PSI PSIOO

PS200

PS2

PS300

PS3

PS400

PS4

P62

P6200

P73

P7300

P74

P7400

P75

P7S00 Hammer spring retainer T49 T4900

P76

P7600

P79

P7900

P8300

P8400

Deficription

StOck b-olt wa:;h~r

Main spring gujd€

Stock bDI,

Mu~tiLJ$ering spring pin

Sfngle trigger gUJrd P97 P9700

Str~ker spring P98 P9800

S~fe:tyspring(singJe sel.trigge:r) P99 P9900

Safety r€taining pil1(s~ngletrigger)

Sing!e selel:t rl"iggei"

Bolt retaining rrng pin

Top lev-er retaining rod

Top lever spring

Hinge p~n T06 T0600

Hinge p~n r\?:t3iningelast~{;pin

Bolt

Cocking Lam spdng

Cocking c:.an<

Cockiog C.3ntretaining pir)

Top je:ve~-retaining Jever

Top !aver retaining javBIL 1;pl'Ellg

Ejector !~vcr spring

Ldt e~ec:tOr kwer complere T22

Righr ejector lever complete

Forend Gitch sprirlg

Forend e';i(urcheon screw

Forerid catch

Forend I;:atch :sc~--ew T34

Forend es-cutt.heon

Fluorescent

Cocking earn trip

HammErs spacf;r

Trfgger t-e,gulations.crew

TriggecL ~-egul(l,[1on s.crew

H~rnme-r

Sears, double hooking

Forend iron retianing screws

Forend rct.-i.inEognut

Eje;ctor :=.pringp~ung€r

Eje(:tQi

safety PIOI

sight

5-pring fI<J:twlisher-

~pring

Fabarm# HK Part#

PBS PSBOO

P93 P9300 Ma!n spring

P<J4

P9400 Main sprJng gutde

P95

P9500

P<J6

P9600

PlOD PIOOOO

PIOIOO

PI02 PI0200

PI03 PI

T03 T0300

T07 T0700 Tumbler retaining pin

T09

TIO TIOOO

TII

TI2

TIS

TI6 TI600

121 12100

123 12300

T31 T3100 Left sto<:k

T32 T3200

T33 T3300 Inerti~ block

T36

T37 T3700

T38

T39

T42

T47 T4700

TSO

T51

TS2

TS4

V03

V06 VD600

0300

T0900

TIIOO

TI200

TISOO

T2200

T3400

T3600

T3S00

T3900

T4200

TSOOO

TSIOO

TS200 Schnabelforend

TS400 Field/sport stock luxe

V0300

FABARM

Description Fabarm# HK Part#

Ring spring pil1

Double hookillg gu!de sprillg

Single selecwle tr~gger"'f'o

Inertia b!ock .)pring

Inertia block retalrling pin

Trigger retaining pin VI8

Trigger return spdng

StOck bok washer

Elastic

w<'!sher

Bal,mcer .)upport

AssembHng block screw

Str!ker~ retainrng rod

Right ejeLtor c<:Im pl:J:t:e V33 V3300

Left ejec.1:.orcam pfate

Ejecwr cockjng rod- right

Ejector cockillg rod- left

Top lever

Cocking rod

Ejector lever rod

Ejector !e.v-errod screw

Fon;:nd iron V76 V7600

Schnabel Fo~-end

Sing~etrigger inertia block

Righr 'Idepl.to

Lofr ,idoplaro 20ga (not engraved)

Bottom tumbler

Toptumble!'double

Sport!ng

1dgger plate

Top e!t:!aor

Bottom ejectOr

AutQs<lfe

As:;emb1ing block suew

Stdker reti1in1ng

stock

7

20g. (nor ongravod)

double hooking

hooking

luxe VIII

rod

V07

V09 VD9DO

VIO VIOOO Left ejector cam

$,

VII VIIOO

VI2

VIS

VI6

VI9

V21 V2100

V22 V2200

V23 V2300

V28

V30

V32 V3200

V46 V4600 Schnabel

V47

V49

V71

vn

V74

V7S

V77 V7700

V79 V7900 Screwed

V84

V98 V9800

V99

VIOO

VIOl VIOIOO

VI02 VI 0200

VI03

VI04 VI0400

VI06 VI0600

VI OS

VIIO VI 1000

Description

V0700

Vl200

VI500

V1600

VIBOO

V1900

V2S00

V3000

V4700

V4900

V7100

vnoo

V7400

V7S00

V8400

V9900 Inertia block ball

VI

V10300

VI0800

VIIIOO Field~

Tumbler

reraining pin

Right:ejeCtor eam plat€

Ejector cocking rod- right

Ejector c:oc:kir\grod-

Top lever

Co~kjlEg md

Bottom ejeCtor

Top ejector

Ejecto1"lever rod

Eiec:tor lev-er rod :screw

Forend iron mod- ejector

Left

5to<:-krubber

Left stock rubber recoil pad semiluxe

Bottom rumbler double hooking

Top tUmbler double hooking

forend

Sto<:k w/rubber recoil pad semi luxe-

Stock wlrubber recoH pad standard

Adju~table trigger ba5=e

Adjustable crigger

Adju:;table triggar wrench

Ejector lever

Right :skieplilt€

Leftsidep!ate 12g~(not

hinge pin

Inertia block

Auto5~fl;"

As:;embjlng block (h~mmer rebound)

0000

!r1t~rtia

block

li'~gger pl;\te

Ejector~ (am pin

AdjusubJe

trigger screw

Schnabe1 (orand $ldndard

Sc:hnabdforend luxe

Field-sport stock ~uxe

sport left stock luxe

left

p3d $taridard

~-:-oH

semi !uxe

rod left

j

2ga (not el1graved)

engraved)

Loading...

Loading...