FIORI GROUP S.p.A.

Via per Ferrara, 7

41034 FINALE EMILIA (Modena Italia)

Tel. +39.0535.92357 - Fax +39.0535.90960

http://www.fi origroup.com

uk_EN

TRANSLATION FROM

ORIGINAL LANGUAGE

USE AND MAINTENANCE MANUAL

RIF. 9304444428 ed. 03

id.:

FIORI BATCH CONTROLLER

REV. 01 24/03/2015

3

REV. 00 02/01/2015

id.:

CONTENTS

1 WARNINGS ..................................................................................................................................................7

2 SYSTEM DESCRIPTION .............................................................................................................................9

2.1 SETTING UP ..........................................................................................................................................9

2.2 COMPONENTS ....................................................................................................................................10

2.3 KEY FUNCTIONS .................................................................................................................................11

2.4 PRINTER FUNCTIONS AND PAPER ROLL REPLACEMENT ............................................................ 12

2.5 TECHNICAL FEATURES .....................................................................................................................13

3 FBC MODE FUNCTIONS ..........................................................................................................................15

3.1 TURN ON .............................................................................................................................................15

3.2 ACCESSING THE FUNCTIONS ...........................................................................................................15

3.3 MAIN PAGE DESCRIPTION ................................................................................................................15

3.4 ADJUSTING THE DISPLAY BRIGHTNESS .........................................................................................15

3.5 TURNING OFF THE SYSTEM .............................................................................................................15

3.6 WATER MANAGEMENT ......................................................................................................................16

3.7 AUTOMATIC WATER LOADING .........................................................................................................16

3.8 MANUALLY LOADING A COMPONENT .............................................................................................16

3.9 LOADING COMPONENTS THROUGH WEIGHING ............................................................................17

3.10 LOADING PROGRESS INDICATORS .................................................................................................17

3.11 CANCELLING LAST WEIGHING .........................................................................................................17

3.12 TIP-OFF (DYNAMIC WEIGHING) ........................................................................................................18

3.13 BAG-COUNTING FUNCTION ............................................................................................................... 19

3.14 RESETTING MEASURED WEIGHTS ..................................................................................................19

3.15 COMPLETING WATER LOADING .......................................................................................................20

3.16 PRINT MENU .......................................................................................................................................20

3.17 HELP PAGE .........................................................................................................................................21

3.18 ALARMS PAGE ....................................................................................................................................21

3.19 CALIBRATING THE TARE ...................................................................................................................22

3.20 ADDITIONAL FUNCTIONS ..................................................................................................................24

3 CBV STANDARD MODE FUNCTIONS .....................................................................................................25

3.1 TURN ON .............................................................................................................................................25

3.2 ACCESSING THE FUNCTIONS .......................................................................................................... 25

3.3 MAIN PAGE DESCRIPTION ................................................................................................................25

3.4 ADJUSTING THE DISPLAY BRIGHTNESS .........................................................................................25

3.5 TURNING OFF THE SYSTEM ............................................................................................................25

3.6 SELECTING A RECIPE ........................................................................................................................26

3.7 MOISTURE OF AGGREGATES ...........................................................................................................26

3.8 SELECTING THE VOLUME .................................................................................................................27

3.9 AUTOMATIC WATER LOADING .........................................................................................................27

3.10 LOADING COMPONENTS THROUGH WEIGHING ............................................................................28

3.11 MANUALLY LOADING A COMPONENT .............................................................................................28

3.12 LOADING PROGRESS INDICATORS .................................................................................................29

3.13 CANCELLING LAST WEIGHING .........................................................................................................29

3.14 TIP-OFF (DYNAMIC WEIGHING) ........................................................................................................29

3.15 AUTOMATICALLY LOADING THE ADDITIVE .....................................................................................30

3.16 WATER LOADING ................................................................................................................................31

3.17 BAG-COUNTING FUNCTION ............................................................................................................... 32

4

REV. 00 02/01/2015

id.:

CONTENTS

3.18 VIEWING THE MIXING STATUS .........................................................................................................32

3.19 POURING THE MIX .............................................................................................................................33

3.20 RESETTING THE VALUES OF THE WEIGHTS MEASURED ............................................................33

3.21 PRINT MENU .......................................................................................................................................34

3.22 HELP PAGE .........................................................................................................................................36

3.23 ALARMS PAGE ....................................................................................................................................36

3.24 CALIBRATING THE TARE ....................................................................................................................36

3.25 WATER MANAGEMENT ......................................................................................................................38

3.26 FUNCTION MENU ................................................................................................................................38

3 CBV ADVANCED MODE FUNCTIONS .....................................................................................................41

3.1 TURN ON .............................................................................................................................................41

3.2 ACCESSING THE FUNCTIONS .......................................................................................................... 41

3.3 MAIN PAGE DESCRIPTION ................................................................................................................41

3.4 ADJUSTING THE DISPLAY BRIGHTNESS .........................................................................................41

3.5 TURNING OFF THE SYSTEM ............................................................................................................41

3.6 SELECTING A RECIPE ........................................................................................................................42

3.7 MOISTURE OF AGGREGATES ...........................................................................................................42

3.7.1 Manually enter the humidity percentage ................................................................................................42

3.7.2 Use of the Mikrolab ............................................................................................................................... 43

3.7.3 Use of the moisture probe .....................................................................................................................44

3.8 SELECTING THE VOLUME .................................................................................................................44

3.9 AUTOMATIC WATER LOADING .........................................................................................................44

3.10 LOADING COMPONENTS THROUGH WEIGHING ............................................................................45

3.11 MANUALLY LOADING A COMPONENT .............................................................................................45

3.12 LOADING PROGRESS INDICATORS .................................................................................................46

3.13 CANCELLING LAST WEIGHING .........................................................................................................46

3.14 TIP-OFF (DYNAMIC WEIGHING) ........................................................................................................46

3.15 AUTOMATICALLY LOADING THE ADDITIVE .....................................................................................47

3.16 WATER LOADING ................................................................................................................................48

3.17 BAG-COUNTING FUNCTION ............................................................................................................... 48

3.18 VIEWING THE MIXING STATUS .........................................................................................................49

3.19 POURING THE MIX .............................................................................................................................49

3.20 RESETTING THE VALUES OF THE WEIGHTS MEASURED ............................................................50

3.21 PRINT MENU .......................................................................................................................................50

3.22 HELP PAGE .........................................................................................................................................52

3.23 ALARMS PAGE ....................................................................................................................................52

3.24 CALIBRATING THE TARE ....................................................................................................................52

3.25 WATER MANAGEMENT ......................................................................................................................54

3.26 FUNCTION MENU ................................................................................................................................55

3.27 DATA SENT TO GPS AND GPRS SYSTEMS .....................................................................................56

4 FBC MODE FUNCTIONS FOR THE FOREMAN ONLY ............................................................................57

4.1 MENU SETTINGS ................................................................................................................................57

4.2 MENU FOREMAN ................................................................................................................................57

4.3 COMPONENTS AND RECIPES ...........................................................................................................58

4.4 SYSTEM CONFIGURATION ................................................................................................................59

4.5 DIAGNOSTICS .....................................................................................................................................59

4.6 SYSTEM DIAGNOSTICS .....................................................................................................................59

4.7 PASSWORD CHANGE ........................................................................................................................59

5

REV. 00 02/01/2015

id.:

CONTENTS

4.8 SETTING THE CLOCK .........................................................................................................................60

4.9 PRINTING THE PARAMETERS ...........................................................................................................60

4 CBV STANDARD MODE FUNCTIONS FOR THE FOREMAN ONLY ......................................................61

4.1 MENU SETTINGS ................................................................................................................................61

4.2 MENU FOREMAN ................................................................................................................................61

4.3 COMPONENTS AND RECIPES ...........................................................................................................62

4.3.1 Entering the components .......................................................................................................................62

4.3.2 Creating mixes .......................................................................................................................................63

4.3.3 Downloading components and recipes ..................................................................................................64

4.3.4 Uploading components and recipes ......................................................................................................64

4.4 SYSTEM CONFIGURATION ................................................................................................................65

4.5 MACHINE DIAGNOSTICS ...................................................................................................................65

4.6 SYSTEM DIAGNOSTICS .....................................................................................................................65

4.7 PASSWORD CHANGE ........................................................................................................................65

4.7 SETTING THE CLOCK .........................................................................................................................66

4.8 PRINTING THE PARAMETERS ...........................................................................................................66

4 CBV ADVANCED MODE FUNCTIONS FOR THE FOREMAN ONLY ......................................................67

4.1 MENU SETTINGS ................................................................................................................................67

4.2 MENU FOREMAN ................................................................................................................................67

4.3 COMPONENTS AND RECIPES ...........................................................................................................68

4.3.1 Entering the components .......................................................................................................................68

4.3.2 Creating mixes .......................................................................................................................................69

4.3.3 Downloading components and recipes ..................................................................................................70

4.3.4 Uploading components and recipes ......................................................................................................70

4.4 SYSTEM CONFIGURATION ................................................................................................................71

4.5 MACHINE DIAGNOSTICS ...................................................................................................................71

4.6 SYSTEM DIAGNOSTICS .....................................................................................................................71

4.7 PASSWORD CHANGE ........................................................................................................................71

4.8 SETTING THE CLOCK .........................................................................................................................72

4.9 PRINTING THE PARAMETERS ...........................................................................................................72

5 ALARM LIST ..............................................................................................................................................73

5.1 OPERATING ALARMS .........................................................................................................................73

5.2 SYSTEM DIAGNOSTICS ALARMS .....................................................................................................73

5.2 ALARM TABLE .....................................................................................................................................74

6

6 CBV STANDARD ADDITIVE FEEDER

.....................................................................................................

.....................................................................................................7777

6.1

6.1 TECHNICAL DATA

...............................................................................................................................

...............................................................................................................................7777

6.2

6.2 REFERENCES AND DESCRIPTIONS OF THE MAIN DEVICES

.......................................................

.......................................................7777

6.3

6.3 FILLING THE ADDITIVE T ANKS

..........................................................................................................

..........................................................................................................7878

6.4

6.4 SCHEDULED MAINTENANCE TABLE

................................................................................................

................................................................................................7878

6.5

6.5 CHECKING AND MAINTAINING

..........................................................................................................

..........................................................................................................7979

7

7 CBV ADVANCED DOUBLE ADDITIVE FEEDER

.....................................................................................

.....................................................................................8181

7.1

7.1 TECHNICAL DATA

...............................................................................................................................

...............................................................................................................................8181

7.2

7.2 REFERENCES AND DESCRIPTIONS OF THE MAIN DEVICES

.......................................................

.......................................................8181

7.3

7.3 FILLING THE ADDITIVE T ANKS

..........................................................................................................

..........................................................................................................8282

7.4

7.4 SCHEDULED MAINTENANCE TABLE

................................................................................................

................................................................................................8282

7.5

7.5 CHECKING AND MAINTAINING

..........................................................................................................

..........................................................................................................8383

REV. 01 24/03/2015

7

REV. 00 02/01/2015

id.:

WARNINGS

1

- Carefully read this manual for proper use of the system.

- Before cleaning the system, turn off the vehicle.

- Use only a clean moist cloth to clean the system. Do not use liquid products or aerosols.

- Do not spray water directly or indirectly onto the device with a hose or use pails of water or similar.

- Do not let the system come into direct contact with:

- Ammonia

- Acetone

- Benzene

- Hydrocarbons

- Perchlorethylene

- Trichlorethylene

- Methanol

- Dishwasher detergents

- Washing machine detergents

- Dichloromethane

- Ethyl ether

- Toluene

- Do not insert any objects in the system or the printer casing as they may damage some parts vital for proper

functioning.

- Do not operate on the system in any way except for the maintenance operations described in this manual.

- For any problem not indicated in this manual contact the supplier.

9

REV. 00 02/01/2015

id.:

SYSTEM DESCRIPTION

2

2.1 SETTING UP

The system is made up of one of the following modes; each version calls for a specifi c confi guration which is

described in the diagram in which we include all the available options.

A sensor kit is provided for each mode.

FBC Weighing

Component Archive Management

Setting up preset values

Print receipt

Water pump automatic management

Standard USB port (for software upgrade only)

CBV STANDARD Component Archive Management

Setting up preset values

Advanced weighing with angle compensation (proximity),

Recipe Archive Management and components ratio recalculation

Water compensation in hygroscopic components

Advanced USB port for upgrading the software, downloading receipts, and uploading/

downloading components and recipes.

Automatic management of the water pump and additive pump

Mixing quality control

CBV ADVANCED Component Archive Management

Setting up preset values

Recipe Archive Management and components ratio recalculation

Advanced weighing with angle compensation (tilt sensor),

Machine tilting safety check

Water compensation in hygroscopic components

Advanced USB port for upgrading the software, downloading receipts, and uploading/

downloading components and recipes.

Automatic management of the water pump and additive pump

Mixing quality control

Moisture Probe and Mikrolab management

Data transmission management towards a GSM/GPRS communication device

The system has been designed to operate on a concrete production vehicle.

It allows to set up different mix and visualize and record the quantity of components (cement, water, gravel,

sand, etc.) used

After storing the components and the recipes, the electronic system allows monitoring the correct quantity of

each component of each recipe during loading.

The recipe complete with a list and weight of the components can be printed using the printer unit FPR282

(optional) and stored in electronic format on a pendrive so that you have a record of the operations performed

and can keep track of the compositions made.

10

REV. 00 02/01/2015

id.:

SYSTEM DESCRIPTION

2

2.2 COMPONENTS

1 - Operating panel

2 - Display

3 - Keypad

4 - Printer connector

5 - System wiring connector

6 - USB

7 - Buzzer

8 - Printer

9 - Thermal paper roll

3 412

567

8

9

11

REV. 00 02/01/2015

id.:

SYSTEM DESCRIPTION

2

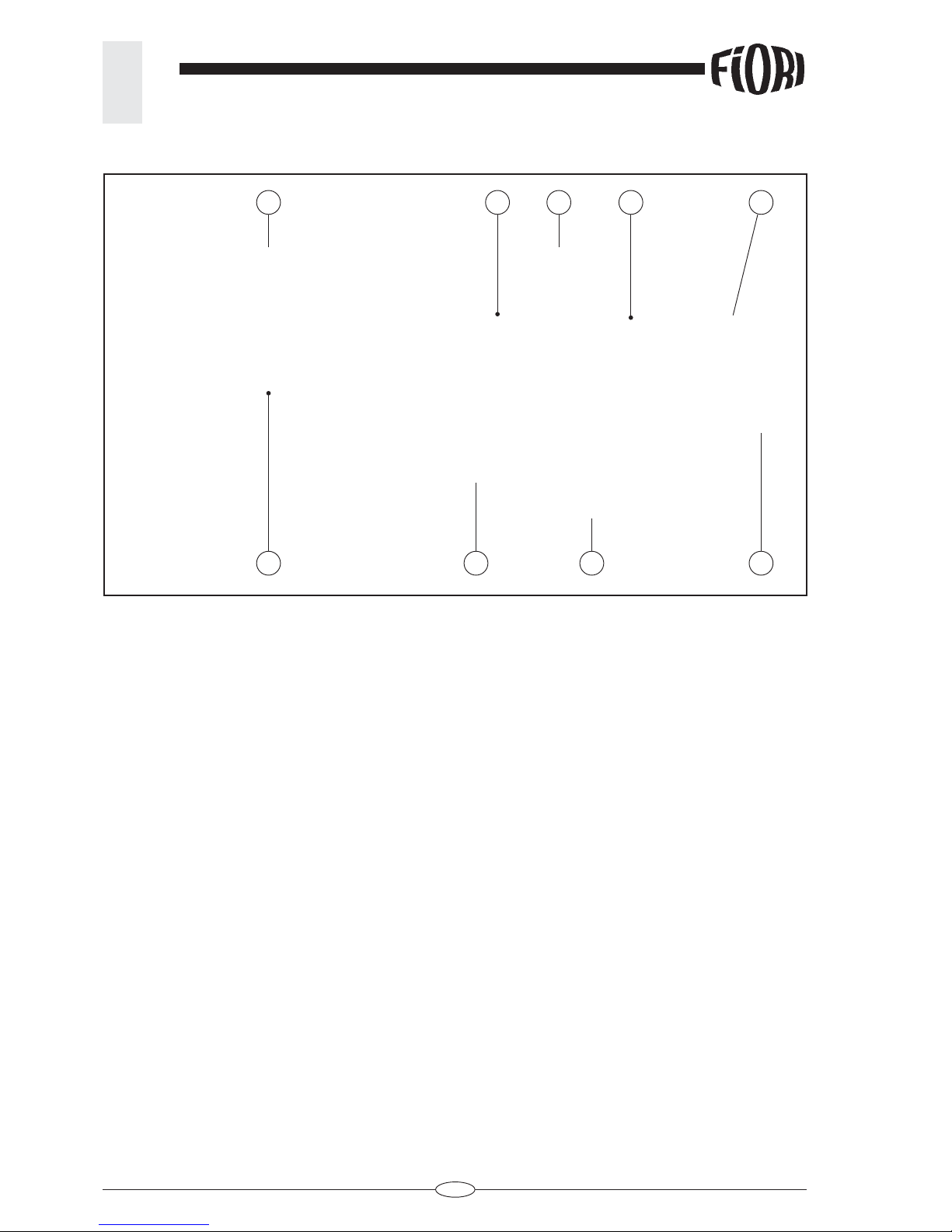

2.3 KEY FUNCTIONS

Key Function when weighing Function when editing

Print receipt Alphanumeric input

Access the mixing page Alphanumeric input

Start and stop (hold down for 3 secs.) Alphanumeric input

Alphanumeric input

Alphanumeric input

Access the “short manual” (hold down for 3 secs.) Alphanumeric input

Accessing the bag-counting function Alphanumeric input

Alphanumeric input

Access the diagnostics page

Activates the “reset weight” function (hold down for 3 secs.)

Activates the “boom calibration” function (hold down for 3 secs.) Alphanumeric input

Access the FUNCTIONS menu Alphanumeric input

Exit editing

Cancel the last weighing

Access the water management menu

Activates the tip-off mode Alphanumeric input

Activates the component manual loading selection Alphanumeric input

Confi rms selection

Navigation keys Navigation

Adjusts screen brightness Navigation

12

REV. 00 02/01/2015

id.:

SYSTEM DESCRIPTION

2

3

4

1

2

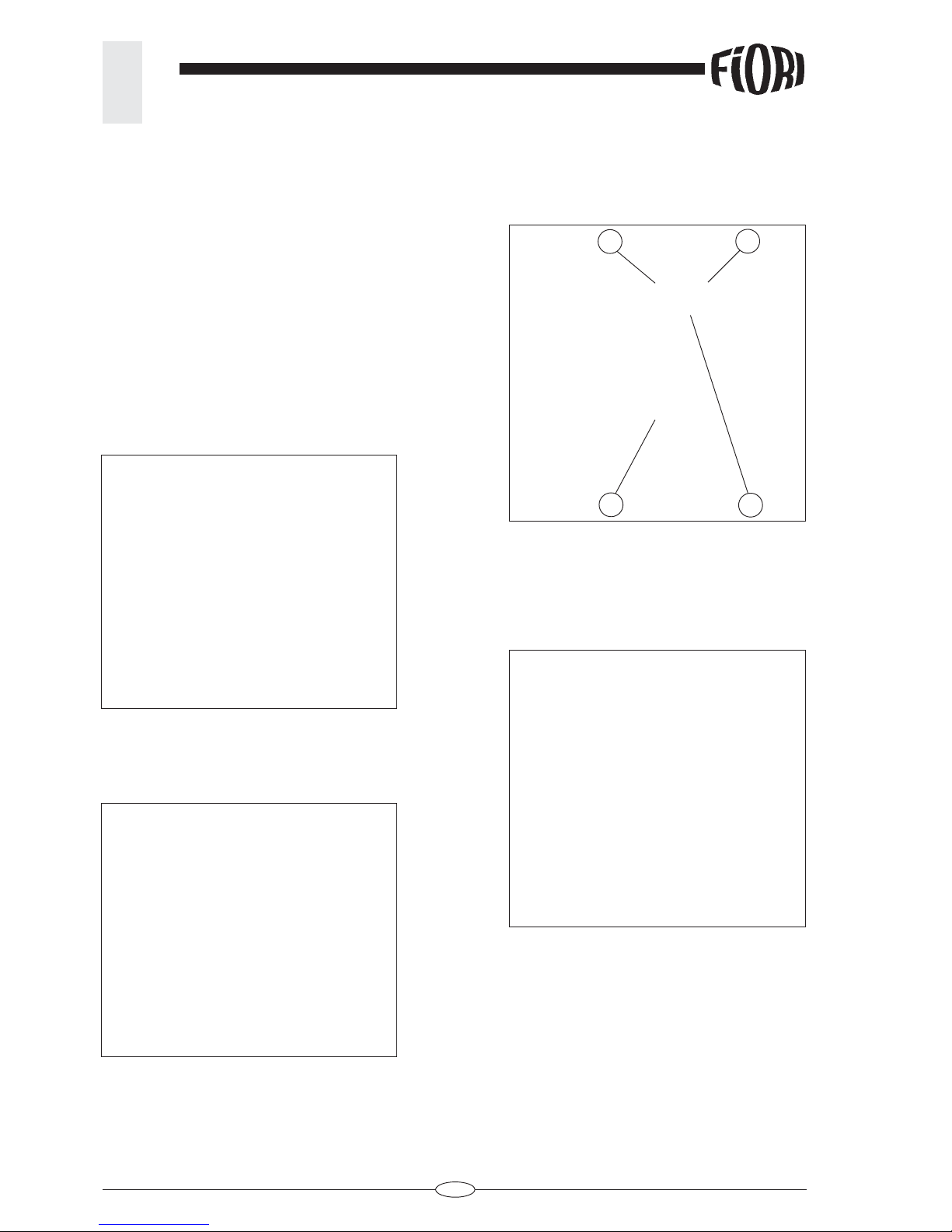

2.4 PRINTER FUNCTIONS AND PAPER ROLL REPLACEMENT

The printer is used to print the the record (of each single load).

1 Button to open the cover to replace the paper roll and a

status LED:

a - When it is on fi xed it means that there is no error.

b -

When it fl ashes slowly it means that the paper has run out.

c - When it fl ashes fast it means that there is an error

(head overheating or power supply fault).

2 FEED button (paper feed).

3 Paper outfeed.

4 Paper roll.

To replace the paper roll:

Press the key “1” to open the cover.

Remove the used paper roll and insert the new one (paper

width 57 mm)

Closing the cover insert the border of the paper roll in the

suitable opening “3”

13

REV. 00 02/01/2015

id.:

SYSTEM DESCRIPTION

2

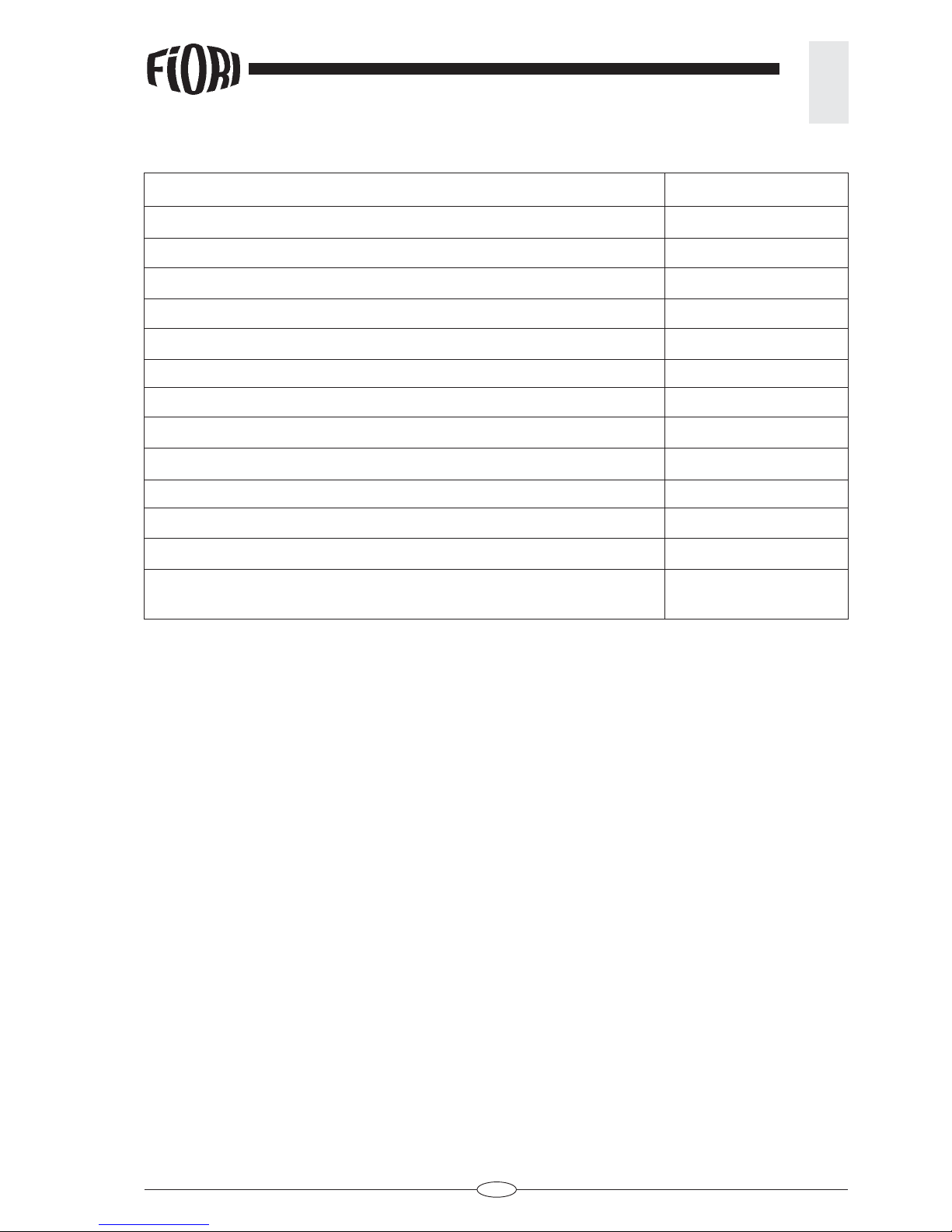

2.4 TECHNICAL FEATURES

Control unit dimensions 160 x 120 x 80 mm

Printer dimensions 120 x 120 x 80 mm

Supply voltage 10 ÷ 35 Vdc

Allowed ambient temperature during the operating phase -20°C) / +60°C

Allowed ambient temperature during the non-operating phase -30°C) / +80°C

Maximum front tilting (Y axis) of the machine during weighing (**) ± 10°

Paper type for printer Thermal

Maximum number of recipes (*) 16

Maximum number of components for each recipe 8

Maximum number of components available in the data storage 32

Languages 9

Selectable unit of measurement kg / lb

Water compensation in the components (*)

Compensation of the machine’s front tilting (Y axis)

during the weighing phase (*) within the ± 10° range

(*) not available in FBC mode

(**) ± 2.5° in FBC mode

15

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.1 TURN ON

Press and hold the key until the start page is displayed.

The start page is displayed for a few seconds,

3.2 ACCESSING THE FUNCTIONS

Enter the user identifi cation code (max. 4 digits).

Press the OK

key to confi rm.

Press ESC

to skip.

3.3 MAIN PAGE DESCRIPTION

1 - Recipe components

2 - Preset weights

3 - Measured weights

4 - Displays loading progress of the selected com-

ponent

5 - Zoom of PRESET and MEASURE values of the

selected component

The yellow colour and the yellow arrow highlight the

selected component

Use the navigation keys to select the product

you want to upload

3.5 TURNING OFF THE SYSTEM

From the main page: press and hold the key until it turns off.

3.4 ADJUSTING THE DISPLAY BRIGHTNESS

From the main page press the indicated keys to increase or reduce the brightness.

12

3

4

55

16

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

Press the key to access the water management menu.

There are two different modes available for using the water:

A) Washing water

Normally used to wash the machine. The system does not count the amount of supplied water.

To activate the supply of washing water:

- Select “WASHING MODE”

- Press

or

To stop the water supply:

- Select “WASHING MODE”

- Press

again or

First stop threshold during the

water loading phase

B) Recipe water

You may set the threshold (%) at which the system will stop loading water during the fi rst loading phase.

3.6 WATER MANAGEMENT

3.7 AUTOMATIC WATER LOADING

Select the “WATER” component

Press OK

(a message is displayed)

Press OK

again to confi rm or ESC to

return to the previous step.

When the OK key is pressed, the water loading phase

starts; the loading progress is visible.

The water loading phase may be started through an

external device (Mix control); the device automatically

turns the pump off as soon as the preset value is

reached.

The water loading phase is carried out until the

set threshold is reached (e.g. 70%).

The remaining water will be loaded at the end of the loading phase by repeating the automatic water

loading operation.

3.8 MANUALLY LOADING A COMPONENT

Press the navigation keys to select the

desired component. Manually insert the

component in the drum .

Press the manual loading key.

A

B

17

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.9 LOADING COMPONENTS THROUGH WEIGHING

The required engine speed is 2000 revs/min

- Select the desired component

- Load the component into the bucket.

- Withdraw the bucket (A)

- Lift the bucket maintaining a constant speed.

- Repeat the operation until the preset value is reached.

During the fi rst weighing a lower

value has been reached and

therefore the operation

The preset value has been exceeded

The red bar indicates an overload

The following alarm message is displayed:

excessive load

3.11 CANCELLING LAST WEIGHING

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to cancel the weighing, then lower the bucket to pour some material and

repeat the loading operation of the component through weighing.

3.10 LOADING PROGRESS INDICATORS

The loading progress for each individual component is displayed by means of:

- loading progress bar (from 50% to 100%)

- progressive acoustic signal (from 50% to 100%)

A screen will be displayed, in which the user will input

the amount of material to be loaded: the number in

green represents the recipe PRESET, whereas the

number in yellow indicates the total amount of material

to be loaded. Input the desired amount and press OK

to confi rm.

A

18

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

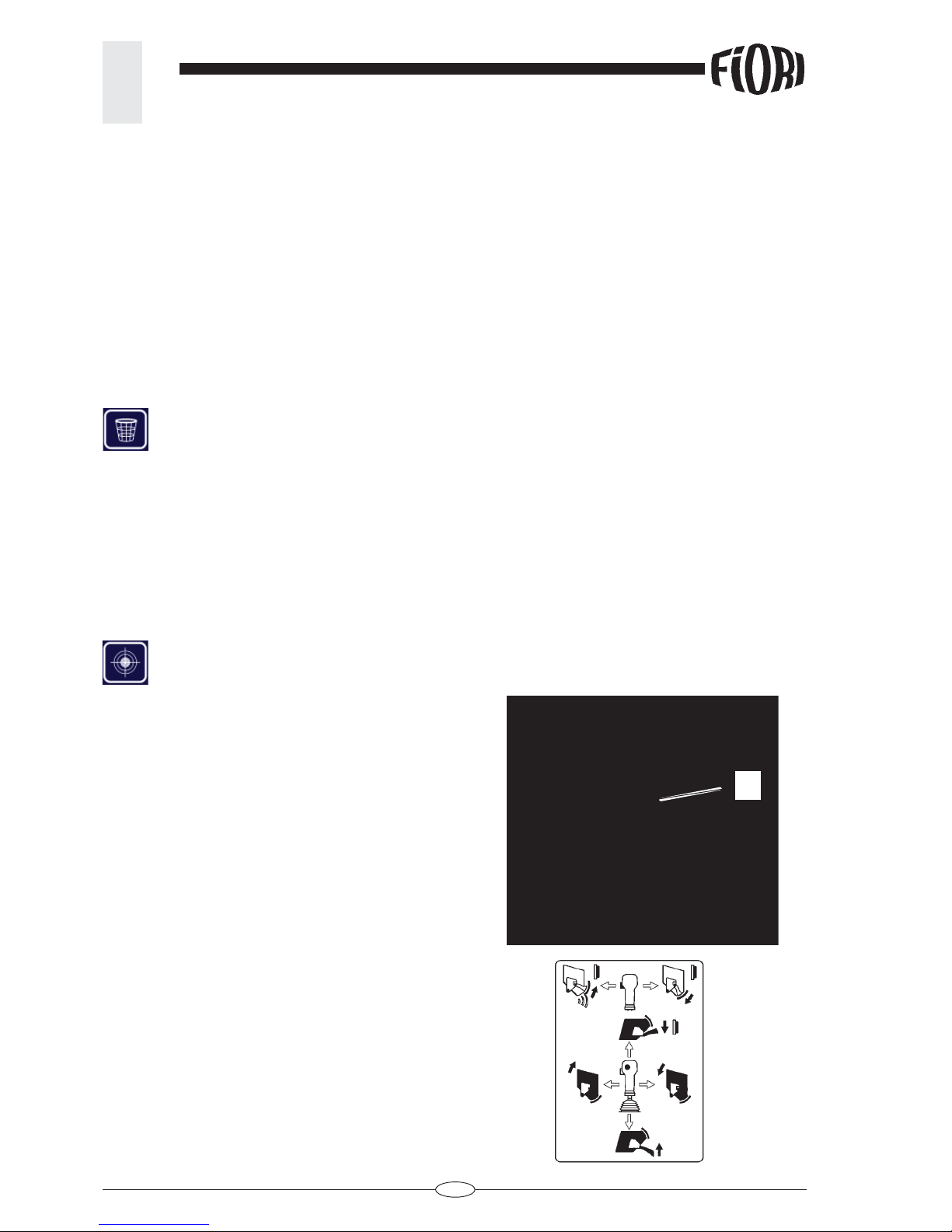

3.12 TIP-OFF (dynamic weighing)

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to shift to the dynamic reading, then open the pouring door located on the

bucket and pour the material until the preset value is reached.

Once the preset loading progress value is reached, as

long as it falls within the set tolerance limits, the bar

becomes green

press OK

to confi rm the end of the TIP OFF and pour the product from the drum.

Continue loading the other components by completing the recipe.

Complete the mixing of the fi nal product and pour it.

Press the button (A) on the joystick and shift it to the

left to open the hydraulic loader hatch and unload the

quantity of material necessary to reach the required

weight.

Shift the joystick to the right to close the hatch.

N.B.: Do not move the arm during tip-off; take into

account the weight shown in position ‘1’, always moving

the bucket to the same point where it was at the time of

activating the tip-off function.

N .B.: the precision of the weight in “Tip-Off” mode is

usually less than the one in standard conditions

A

19

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.13 BAG-COUNTING FUNCTION

Select the component CEMENT and press the key .

Lower the arm.

Lift the arm back up until the STOP signal is displayed.

Input the weight value of each single bag (25, 30, 42.5,

…...).

Press OK

.

The system will indicate the number of bags to be

loaded.

After reaching the number of bags indicated, press OK

and load the material.

Number of bags

to be loaded

Number of bags

loaded

3.14 RESETTING MEASURED WEIGHTS

To start a new recipe

Press and hold the C

key until the cancellation message is displayed.

Press OK

to reset

All values have been reset

You may now start loading the components for a new

recipe.

20

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.15 COMPLETING WATER LOADING

After loading all the recipe components, the water cycle needs to be completed by repeating the steps described

in paragraph 3.6.

3.16 PRINT MENU

Press 1 to access the print menu.

Press SELECT

to select the mixing you want to print.

Press 0

to deselect

press the SELECT

key + Arrows for multiple selections,

Press 0

+ arrows for multiple deselections,

select all items by pressing and holding down the SELECT

key,

deselect all items by pressing 0

and holding it down.

List of mixings performed: (Date and time of beginning

of mixing cycle)

The dot indicates that the recipe has not been printed

yet

Progressive number

Once you have selected the recipe you want to print,

press OK

or printing key 1 .

If multiple selections have been made, printing will be

performed in succession.

Press ESC

to return to the recipe page

21

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

1 - Machine code

2 - Operator code

3 - Recipe name

4 - Recipe data

5 - Component marker

OTHER MARKERS

*a: component with loaded weight outside the set tolerance limits

*b: component loaded despite the weighing error signalled by the device

*c: indicates that some components have been manually loaded

5

1

2

3

4

Key 6 to access the help page where all the

function keys are explained.

ESC

to return to the main page

3.18 ALARMS PAGE

If any alarms are present, they may be displayed by

pressing key 9

( refer to chapter “ALARM LIST”).

Alarm warnings are signalled as following:

- alarm triangle on the right upper part of the screen

- acoustic alarm

3.17 HELP PAGE

22

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.19 CALIBRATING THE TARE

It is a test that needs to be performed daily in order to

ensure the proper functioning of the weighing system.

TEST/CALIBRATION

To perform the device calibration

- Press 0

, hold it down for a few seconds then

press OK

or select TEST/CALIBRATION from the FUNCTIONS

menu.

- The “CAUTION....” message is displayed

operate as follows:

The maximum machine tilting must be <0.5° (frontal

axis) The engine speed must be 2000 rpm

TEST

1) Slowly lower the boom

2) Withdraw the bucket (A)

3) Lift the boom back up at a constant speed.

If the value displayed differs from zero (60 in this

instance), then the tare needs to be calibrated.

- Press OK

to shift to the calibration mode

TARE CALIBRATION

A

23

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

Step 1/3

- Ensure that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom at a constant speed

Step 2/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

Step 3/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

If during calibration the device detects any faults, it will ask to repeat the 3 calibration steps.

24

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS

3

3.20 ADDITIONAL FUNCTIONS

More functions may be accessed from the recipe page:

Press the specifi ed key to access the function

menu:

PRINT DATA

To access the list of receipts corresponding to the

recipes stored;

from the menu you can select the print function or press

ESC

to return to the previous page

RESET WEIGHT

Is equivalent to the “C” key in the main page; to reset

weights

EDIT COMPONENT

For the foreman only; password required (par. 4.3)

PRINT DAILY REPORT

To print a daily report indicating the weights of the

components loaded during the current day;

press OK to print

Machine ID code

Date

Time

Weights of the components loaded during the day

SYSTEM INFO

To view system information

HTS code

Serial number

Firmware version

USB fi rmware version

INSTRUMENT DATA

Hours of operation

Weighings performed

Schedule of next calibration (hours)

Schedule of next calibration (weighings)

Press ESC several times to return to the main working page.

par. 3.19

25

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

The system is set to operate on various recipes, with

water compensation in the hygroscopic components. It

can also monitor the quality of the mixing and manage

automatically both the water and additive pumps.

3.1 TURN ON

Press and hold the key until the start page is displayed.

The start page is displayed for a few seconds,

3.2 ACCESSING THE FUNCTIONS

Enter the user identifi cation code (max. 4 digits).

Press the OK

key to confi rm.

Press ESC

to skip.

3.3 MAIN PAGE DESCRIPTION

1 - Selected recipe

2 - Volume to be produced

3 - Mixing time

4 - Column of the recipe components

5 - Column of the preset values calculated based

on the volume to be produced

6 - Column of the values measured for each indi-

vidual component

7 - Line of total amounts (total weight to be pro-

duced and total weight measured)

8 - Selected component

9 - Loading progress bar

10 - Preset value of the selected component

11 - Measured value of the selected component

The yellow colour and the yellow arrow highlight the

selected component

Use the navigation keys to select the product

you want to upload

3.4 ADJUSTING THE DISPLAY BRIGHTNESS

From the main page press the indicated keys to increase or reduce the brightness.

3.5 TURNING OFF THE SYSTEM

From the main page: press and hold the key until it turns off.

12

3

4

5

6

7

8

9

10 11

26

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.6 SELECTING A RECIPE

Press the “select” key

select “SELECT MIX”

Press OK

: Recipe 1 is displayed

Use the UP/DOWN arrow keys to display all set recipes

Select the recipe and press OK

to confi rm.

3.7 MOISTURE OF AGGREGATES

Once the recipe has been selected, the system asks you to defi ne the humidity of the hygroscopic

aggregates.

This data will determine a compensation in the volume of the components involved

Press OK

to go to the HUMIDITY page

Enter the humidity percentage in the fi eld, ranging from 0% to +20%.

Press OK

to confi rm.

Press ESC

to return to the recipe and start loading the components

27

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

3.8 SELECTING THE VOLUME

From the “FUNCTION” menu select “SETUP VOLUME”

Press OK

to edit the volume

Enter the volume you want to produce

Press OK

to confi rm and return to the

“FUNCTION” menu

press ESC

from the “FUNCTION” menu to go

back to the main page (recipe)

To set up the volume to produce from

the selected recipe

Vehicle limits

Once the humidity percentage has been

entered, the device recalculates the hygroscopic

components and water values

3.9 AUTOMATIC WATER LOADING

Select the “WATER” component

Press OK

(a message is displayed)

Press OK

again to confi rm or ESC to

return to the previous step.

When the OK key is pressed, the water loading phase

starts; the loading progress is visible.

The water loading phase may be started through an

external device (Mix control); the device automatically

turns the pump off as soon as the preset value is

reached.

The water loading phase is carried out until the

set threshold is reached (e.g. 70%).

The remaining water will be loaded at the end of the loading phase by repeating the automatic water

loading operation.

Select the next component (e.g. CEMENT)

28

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.11 AUTOMATIC WATER LOADING

Press the navigation keys to select the

desired component. Manually insert the

component in the drum, until you reach the

quantity defi ned in the PRESET fi eld.

Once the 20% of the WATER-CEMENT loading

value is reached, the mixing timer starts.

Press the manual loading key.

A screen will be displayed, in which the user will input

the amount of material to be loaded: the number in

green represents the recipe PRESET, whereas the

number in yellow indicates the total amount of material

to be loaded. Input the desired amount and press OK

to confi rm.

3.10 LOADING COMPONENTS THROUGH WEIGHING

The required engine speed is 2000 revs/min

- Select the desired component

- Load the component into the bucket.

- Withdraw the bucket (A)

- Lift the bucket maintaining a constant speed.

- Repeat the operation until the preset value is reached.

- If the loaded value exceeds the PRESET value, the

procedure described in “cancel last weight” “Tip Off”

may be followed.

During the fi rst weighing a lower value has

been reached and therefore the operation

The preset value has been exceeded

The red bar indicates an overload

The following alarm message is displayed:

excessive load

A

29

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

3.13 CANCELLING LAST WEIGHING

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to cancel the weighing, then lower the bucket to pour some material and

repeat the loading operation of the component through weighing.

3.14 TIP-OFF (dynamic weighing)

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to shift to the dynamic reading, then open the pouring door located on the

bucket and pour the material until the preset value is reached.

Press the button (A) on the joystick and shift it to the

left to open the hydraulic loader hatch and unload the

quantity of material necessary to reach the required

weight.

Shift the joystick to the right to close the hatch.

N.B.: Do not move the arm during tip-off; take into

account the weight shown in position ‘1’, always moving

the bucket to the same point where it was at the time of

activating the tip-off function.

N .B.: the precision of the weight in “Tip-Off” mode is

usually less than the one in standard conditions

3.12 LOADING PROGRESS INDICATORS

The loading progress for each individual component is displayed by means of:

- loading progress bar (from 50% to 100%)

- progressive acoustic signal (from 50% to 100%)

A

30

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.15 AUTOMATICALLY LOADING THE ADDITIVE

The additive is loaded by means of the automatic

management of the relevant pump, in a similar manner

than water loading.

Select “ADDITIVE” Press OK

.

A warning message is displayed

Press OK

to confi rm.

The device will automatically start the additive pump.

The device will automatically stop the additive pump as

soon as the preset value is reached.

Once the preset loading progress value is reached, as long as it falls within the set tolerance limits, the bar

becomes green

press OK

to confi rm the end of the TIP OFF and pour the product from the drum.

Continue loading the other components by completing the recipe.

Complete the mixing of the fi nal product and pour it.

31

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

3.16 COMPLETING WATER LOADING

Once all recipe components have been loaded, the water loading needs to be completed.

Select “WATER”.

Press OK

(a warning message is displayed).

Press OK

to confi rm.

The water pump is started and loading completion is performed.

The mix. is complete.

When the device detects the start of the mixing

phase, the START MIXING DETECT message

is displayed.

The start of the mixing phase is detected only after all

components required by the recipe have been loaded.

32

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.18 VIEWING THE MIXING STATUS

Press key 2

N.B. If the values are displayed in yellow, it means that the mix is not ready yet.

The RPM fi eld may be displayed in three different

colours:

Green: speed is suitable

Yellow: speed is too slow

Red: speed is too fast

Revolutions performed by

the drum during the mixing

phase

Number of revolutions to be performed

Maximum mixing

pressure

Drum rotation

speed

Mixing revolutions

progress

Differential progress of last mixing revolution

Drum rotation

direction (mixing/ pouring)

3.17 BAG-COUNTING FUNCTION

Select the component CEMENT and press the key .

Lower the arm.

Lift the arm back up until the STOP signal is displayed.

Input the weight value of each single bag (25, 30, 42.5,

…...).

Press OK

.

The system will indicate the number of bags to be

loaded.

After reaching the number of bags indicated, press OK

and load the material.

Number of bags

to be loaded

Number of bags

loaded

33

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

3.19 POURING THE MIX

Set the drum rotation in the pouring position; the

following message is displayed

Beginning of the pouring phase has

been detected

when the device detects the end of the pouring phase,

the following message is displayed

End of pouring phase message

Press ESC to return to the recipe page

3.20 RESETTING THE VALUES OF THE WEIGHTS MEASURED

Press and hold the C

key until the cancellation

message is displayed.

Press OK

to reset the recipe data; by doing this

you may perform the same recipe again or perform

other recipes in the data storage.

All values have been reset

34

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.21 PRINT MENU

Press 1 to access the print menu.

Press SELECT

to select the mixing you want to print.

Press 0

to deselect

press the SELECT

key + Arrows for multiple selections,

Press 0

+ arrows for multiple deselections,

select all items by pressing and holding down the SELECT

key,

deselect all items by pressing 0

and holding it down.

List of mixings performed: (Date and time of beginning

of mixing cycle)

Letter “X” indicates that the recipe has been selected

for printing

The dot indicates that the recipe has not been printed

yet

Progressive number

Once you have selected the recipe you want to print,

press OK

or printing key 1 .

If multiple selections have been made, printing will be

performed in succession.

Press ESC

to return to the recipe page

35

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

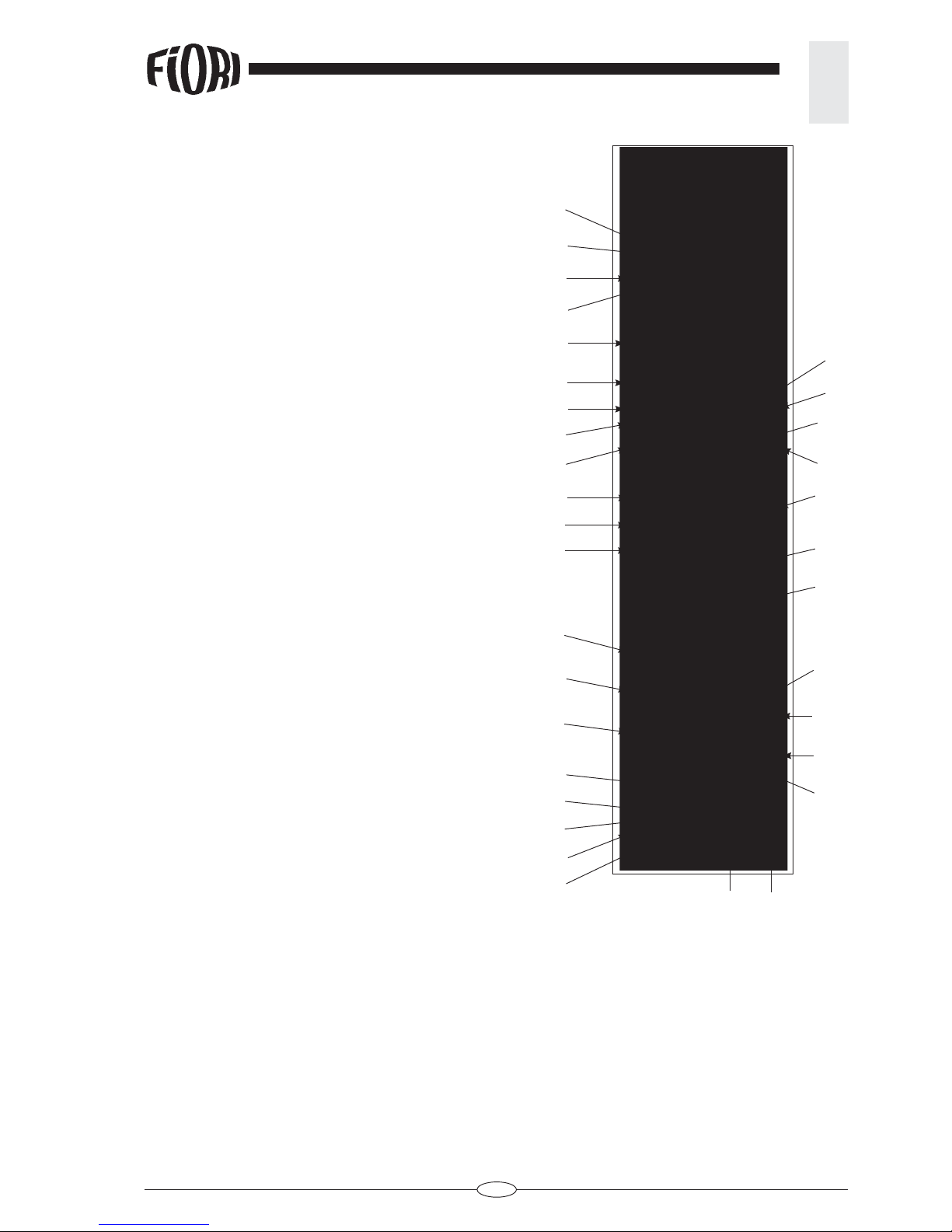

1 - Machine code

2 - Operator code

3 - Recipe name

4 - Recipe volume

5 - Start time and date of mixing cycle

6 - End time and date of mixing cycle

7 - Mixing revolutions

8 - Performed

9 - Preset

10 - Mixing time

11 - Stabilized pressure

12 – Pressure

13 - Mixing revolutions at which pressure has stabilized

14 - End time and date of pouring phase

15 - Pouring revolutions

16 - Cycle time

17 - Recipe data

18 - Component marker

19 - Specifi c weight of the additive

20 - Component typical absorption

21 - Water amount in SSA (SSD - Saturated Surface Dry)

22 - Hygroscopic aggregate data

23 - Component name

24 - Moisture %

25 - Water contained in the component

26 - Mix data

27 - Total loaded water

28 - Total hygroscopic components (SSA)

29 - Total weight

30 - Water/cement ratio

31 - Column of data set by recipes

32 - Data column

OTHER MARKERS

*a: component with loaded weight outside the set tolerance limits

*b: component loaded despite the weighing error signalled by the device

*c: indicates that some components have been manually loaded

17

26

27

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

22

23

20

21

28

29

30

31 32

18

24

25

36

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

Key 6 to access the help page where all the

function keys are explained.

ESC

to return to the main page

3.23 ALARMS PAGE

If any alarms are present, they may be displayed by

pressing key 9

( refer to chapter “ALARM LIST”).

Alarm warnings are signalled as following:

- alarm triangle on the right upper part of the screen

- acoustic alarm

3.22 HELP PAGE

3.24 CALIBRATING THE TARE

It is a test that needs to be performed daily in order to

ensure the proper functioning of the weighing system.

TEST/CALIBRATION

To perform the device calibration

- Press 0

, hold it down for a few seconds then

press OK

or select TEST/CALIBRATION from the FUNCTIONS

menu.

- The “CAUTION....” message is displayed

operate as follows:

The maximum machine tilting must be <0.5° (frontal

axis) The engine speed must be 2000 rpm

37

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

TEST

1) Slowly lower the boom

2) Withdraw the bucket (A)

3) Lift the boom back up at a constant speed.

If the value displayed differs from zero (60 in this

instance), then the tare needs to be calibrated.

- Press OK

to shift to the calibration mode

TARE CALIBRATION

Step 1/3

- Ensure that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom at a constant speed

Step 2/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

Step 3/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

If during calibration the device detects any faults, it will ask to repeat the 3 calibration steps.

A

38

REV. 00 02/01/2015

id.:

CBV STANDARD

MODE FUNCTIONS

3

3.26 FUNCTION MENU

Vehicle limits

Press “SELECT” from the recipe page

PRINT DATA

To access the list of receipts corresponding to the

recipes stored;

from the menu you can select the print function or

press ESC

to return to the previous page.

RESET WEIGHT

Is equivalent to the “C” key in the main page; to reset

weights.

SETUP VOLUME

To set up the volume to produce from the selected

recipe.

par. 3.6

par. 3.24

Press the key to access the water management menu.

There are two different modes available for using the water:

A) Washing water

Normally used to wash the machine. The system does not count the amount of supplied water.

To activate the supply of washing water:

- Select “WASHING MODE”

- Press

or

To stop the water supply:

- Select “WASHING MODE”

- Press

again or

First stop threshold during the

water loading phase

B) Recipe water

You may set the threshold (%) at which the system will stop loading water during the fi rst loading phase.

3.25 WATER MANAGEMENT

A

B

39

REV. 00 02/01/2015

id.:

3

CBV STANDARD

MODE FUNCTIONS

PRINT DAILY REPORT

To print a daily report indicating the weights of the

components loaded during the current day;

press OK

to print.

DOWNLOAD

select one or more fi elds

Press OK

Insert the USB memory stick

A message is displayed confi rming that the USB

memory stick has been detected and therefore the

download will start showing the transfer progress

status from 0 to 100%

Remove the USB memory stick and carefully put the

cap back in place to ensure the system protection IP

levels.

Esc to return to the FUNCTION menu.

SYSTEM INFO

To view system information

Print daily report

Machine ID code

Date

Time

Weights of the components loaded

during the day

Print all the components loaded during the day

HTS code

Serial number

Firmware version

USB fi rmware version

INSTRUMENT DATA

Hours of operation

Weighings performed

Next programming

calibration (hours)

Next programming

calibration (weighings)

41

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

The system is set to operate on various recipes, with

water compensation in the hygroscopic components. It

can also monitor the quality of the mixing and manage

automatically both the water and additive pumps.

It provides information on the front and lateral tilting of

the carriage.

It sends the data to external GPS/GPRS devices.

3.1 TURN ON

Press and hold the key until the start page is displayed.

The start page is displayed for a few seconds,

3.2 ACCESSING THE FUNCTIONS

Enter the user identifi cation code (max. 4 digits).

Press the OK

key to confi rm.

Press ESC

to skip.

3.3 MAIN PAGE DESCRIPTION

1 - Selected recipe

2 - Volume to be produced

3 - Mixing time

4 - Column of the recipe components

5 - Column of the preset values calculated based

on the volume to be produced

6 - Column of the values measured for each indi-

vidual component

7 - Line of total amounts (total weight to be pro-

duced and total weight measured)

8 - Selected component

9 - Loading progress bar

10 - Preset value of the selected component

11 - Measured value of the selected component

The yellow colour and the yellow arrow highlight the

selected component

Use the navigation keys to select the product you want to upload

3.4 ADJUSTING THE DISPLAY BRIGHTNESS

From the main page press the indicated keys to increase or reduce the brightness.

3.5 TURNING OFF THE SYSTEM

From the main page: press and hold the key until it turns off.

12

3

4

5

6

7

8

9

10 11

42

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.6 SELECTING A RECIPE

Press the “select” key

select “SELECT MIX”

Press OK

: Recipe 1 is displayed

Use the UP/DOWN arrow keys to display all set recipes

Select the recipe and press OK

to confi rm.

3.7 MOISTURE OF AGGREGATES (see section 4.3.1)

3.7.1 Manually enter the humidity percentage

Once the recipe has been selected, the system asks you to defi ne the humidity of the hygroscopic

aggregates.

This data will determine a compensation in the volume of the components involved

Press OK

to go to the HUMIDITY page

Enter the humidity percentage in the fi eld, ranging from 0% to +20%.

Press OK

to confi rm.

Press ESC

to return to the recipe and start loading the components

43

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.7.2 Use of the Mikrolab

If you set the use of the Mikrolab and the recipe con-

tains SAND MP1...... SAND MP6 type hygroscopic

components

Press OK

to go to the HUMIDITY PAGE.

Connect the Mikrolab to the system.

Insert the selected component into the Mikrolab.

Press OK

to confi rm.

The system automatically acquires the moisture percentage.

Press ESC

to return to the recipe and start loading the components.

Once the humidity percentage has been entered, the device recalculates the hygroscopic

components and water values

Once the humidity percentage has been

entered, the device recalculates the

hygroscopic components and water values

44

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.7.3 Use of the moisture probe

If you set the use of the moisture probe, you do not need to enter the humidity value; the system will automatically

detect it during weighing

3.8 SELECTING THE VOLUME

From the “FUNCTION” menu select “SETUP VOLUME”

Press OK

to edit the volume

Enter the volume you want to produce

Press OK

to confi rm and return to the

“FUNCTION” menu

press ESC

from the “FUNCTION” menu to go

back to the main page (recipe)

To set up the volume to produce from

the selected recipe

Vehicle limits

3.9 AUTOMATIC WATER LOADING

Select the “WATER” component

Press OK

(a message is displayed)

Press OK

again to confi rm or ESC to

return to the previous step.

When the OK key is pressed, the water loading phase

starts; the loading progress is visible.

The water loading phase may be started through an

external device (Mix control); the device automatically

turns the pump off as soon as the preset value is

reached.

The water loading phase is carried out until the

set threshold is reached (e.g. 70%).

The remaining water will be loaded at the end of the loading phase by repeating the automatic water

loading operation.

Select the next component (e.g. CEMENT)

45

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.11 AUTOMATIC WATER LOADING

Press the navigation keys to select the

desired component. Manually insert the

component in the drum, until you reach the

quantity defi ned in the PRESET fi eld.

Once the 20% of the WATER-CEMENT loading

value is reached, the mixing timer starts.

Press the manual loading key.

A screen will be displayed, in which the user will input

the amount of material to be loaded: the number in

green represents the recipe PRESET, whereas the

number in yellow indicates the total amount of material

to be loaded. Input the desired amount and press OK

to confi rm.

3.10 LOADING COMPONENTS THROUGH WEIGHING

The required engine speed is 2000 revs/min

- Select the desired component

- Load the component into the bucket.

- Withdraw the bucket (A)

- Lift the bucket maintaining a constant speed.

- Repeat the operation until the preset value is reached.

- If the loaded value exceeds the PRESET value, the

procedure described in “cancel last weight” “Tip Off”

may be followed.

During the fi rst weighing a lower value has

been reached and therefore the operation

The preset value has been exceeded

The red bar indicates an overload

The following alarm message is displayed:

excessive load

A

46

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.13 CANCELLING LAST WEIGHING

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to cancel the weighing, then lower the bucket to pour some material and

repeat the loading operation of the component through weighing.

3.14 TIP-OFF (dynamic weighing)

If the preset weighing value is exceeded, before pouring the material you may:

Press the indicated key to shift to the dynamic reading, then open the pouring door located on the

bucket and pour the material until the preset value is reached.

Press the button (A) on the joystick and shift it to the

left to open the hydraulic loader hatch and unload the

quantity of material necessary to reach the required

weight.

Shift the joystick to the right to close the hatch.

N.B.: Do not move the arm during tip-off; take into

account the weight shown in position ‘1’, always moving

the bucket to the same point where it was at the time of

activating the tip-off function.

N .B.: the precision of the weight in “Tip-Off” mode is

usually less than the one in standard conditions

3.12 LOADING PROGRESS INDICATORS

The loading progress for each individual component is displayed by means of:

- loading progress bar (from 50% to 100%)

- progressive acoustic signal (from 50% to 100%)

A

47

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

Once the preset loading progress value is reached, as long as it falls within the set tolerance limits, the bar

becomes green

press OK

to confi rm the end of the TIP OFF and pour the product from the drum.

Continue loading the other components by completing the recipe.

Complete the mixing of the fi nal product and pour it.

3.15 AUTOMATICALLY LOADING THE ADDITIVE

The additive is loaded by means of the automatic

management of the relevant pump, in a similar manner

than water loading.

Select “ADDITIVE” Press OK

.

A warning message is displayed

Press OK

to confi rm.

The device will automatically start the additive pump.

The device will automatically stop the additive pump as

soon as the preset value is reached.

48

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.16 COMPLETING WATER LOADING

Once all recipe components have been loaded, the water loading needs to be completed.

Select “WATER”.

Press OK

(a warning message is displayed).

Press OK

to confi rm.

The water pump is started and loading completion is performed.

The mix. is complete.

When the device detects the start of the mixing

phase, the START MIXING DETECT message

is displayed.

The start of the mixing phase is detected only after all

components required by the recipe have been loaded.

3.17 BAG-COUNTING FUNCTION

Select the component CEMENT and press the key .

Lower the arm.

Lift the arm back up until the STOP signal is displayed.

Input the weight value of each single bag (25, 30, 42.5,

…...).

Press OK

.

49

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.18 VIEWING THE MIXING STATUS

Press key 2

N.B. If the values are displayed in yellow, it means that the mix is not ready yet.

The RPM fi eld may be displayed in three different

colours:

Green: speed is suitable

Yellow: speed is too slow

Red: speed is too fast

Revolutions performed by

the drum during the mixing

phase

Number of revolutions to be performed

Maximum mixing

pressure

Drum rotation

speed

Mixing revolutions

progress

Differential progress of last mixing revolution

Drum rotation

direction (mixing/ pouring)

3.19 POURING THE MIX

Set the drum rotation in the pouring position; the

following message is displayed

Beginning of the pouring phase has

been detected

when the device detects the end of the pouring phase,

the following message is displayed

End of pouring phase message

Press ESC to return to the recipe page

Number of bags

to be loaded

Number of bags

loaded

The system will indicate the number of bags to be

loaded.

After reaching the number of bags indicated, press OK

and load the material.

50

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.20 RESETTING THE VALUES OF THE WEIGHTS MEASURED

Press and hold the C

key until the cancellation

message is displayed.

Press OK

to reset the recipe data; by doing this

you may perform the same recipe again or perform

other recipes in the data storage.

All values have been reset

3.21 PRINT MENU

Press 1 to access the print menu.

Press SELECT

to select the mixing you want to print.

Press 0

to deselect

press the SELECT

key + Arrows for multiple selections,

Press 0

+ arrows for multiple deselections,

select all items by pressing and holding down the SELECT

key,

deselect all items by pressing 0

and holding it down.

List of mixings performed: (Date and time of beginning

of mixing cycle)

Letter “X” indicates that the recipe has been selected

for printing

The dot indicates that the recipe has not been printed

yet

Progressive number

Once you have selected the recipe you want to print,

press OK

or printing key 1 .

If multiple selections have been made, printing will be

performed in succession.

Press ESC

to return to the recipe page

51

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

1 - Machine code

2 - Operator code

3 - Recipe name

4 - Recipe volume

5 - Start time and date of mixing cycle

6 - End time and date of mixing cycle

7 - Mixing revolutions

8 - Performed

9 - Preset

10 - Mixing time

11 - Stabilized pressure

12 – Pressure

13 - Mixing revolutions at which pressure has stabilized

14 - End time and date of pouring phase

15 - Pouring revolutions

16 - Cycle time

17 - Recipe data

18 - Component marker

19 - Specifi c weight of the additive

20 - Component typical absorption

21 - Water amount in SSA (SSD - Saturated Surface Dry)

22 - Hygroscopic aggregate data

23 - Component name

24 - Moisture %

25 - Water contained in the component

26 - Mix data

27 - Total loaded water

28 - Total hygroscopic components (SSA)

29 - Total weight

30 - Water/cement ratio

31 - Column of data set by recipes

32 - Data column

OTHER MARKERS

*a: component with loaded weight outside the set tolerance limits

*b: component loaded despite the weighing error signalled by the device

*c: indicates that some components have been manually loaded

17

26

27

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

22

23

20

21

28

29

30

31 32

18

24

25

52

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

Key 6 to access the help page where all the

function keys are explained.

ESC

to return to the main page

3.23 ALARMS PAGE

If any alarms are present, they may be displayed by

pressing key 9

( refer to chapter “ALARM LIST”).

Alarm warnings are signalled as following:

- alarm triangle on the right upper part of the screen

- acoustic alarm

3.22 HELP PAGE

3.24 CALIBRATING THE TARE

It is a test that needs to be performed daily in order to

ensure the proper functioning of the weighing system.

TEST/CALIBRATION

To perform the device calibration

- Press 0

, hold it down for a few seconds then

press OK

or select TEST/CALIBRATION from the FUNCTIONS

menu.

- The “CAUTION....” message is displayed

operate as follows:

The maximum machine tilting must be <0.5° (frontal

axis) The engine speed must be 2000 rpm

53

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

TEST

1) Slowly lower the boom

2) Withdraw the bucket (A)

3) Lift the boom back up at a constant speed.

If the value displayed differs from zero (60 in this

instance), then the tare needs to be calibrated.

- Press OK

to shift to the calibration mode

TARE CALIBRATION

Step 1/3

- Ensure that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom at a constant speed

Step 2/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

Step 3/3

- Check that the bucket is empty

- Slowly lower the boom

- Withdraw the bucket (A)

- Lift the boom back up

If during calibration the device detects any faults, it will ask to repeat the 3 calibration steps.

A

54

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

Press the key to access the water management menu.

There are two different modes available for using the water:

A) Washing water

Normally used to wash the machine. The system does not count the amount of supplied water.

To activate the supply of washing water:

- Select “WASHING MODE”

- Press

or

To stop the water supply:

- Select “WASHING MODE”

- Press

again or

First stop threshold during the

water loading phase

B) Recipe water

You may set the threshold (%) at which the system will stop loading water during the fi rst loading phase.

3.25 WATER MANAGEMENT

A

B

55

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

3.25 FUNCTION MENU

par. 3.6

par. 3.24

Press “SELECT”

from the recipe page

PRINTING DATA

To access the list of receipts corresponding to the recipes stored;

from the menu you can select the print function or press

ESC

to return to the previous page

RESET WEIGHTS

Is equivalent to the “C” key in the main page; to reset

weights

SET UP VOLUME

To set up the volume to produce from the selected

recipe

DAILY REPORT

To print a daily report indicating the weights of the components loaded during the current day;

press OK

to print

Machine limits

Print daily report

Machine ID code

Date

Time

Weights of the

components loaded

during the day

56

REV. 00 02/01/2015

id.:

CBV ADVANCED

MODE FUNCTIONS

3

DOWNLOAD

Select one or more fi elds

Press OK Insert the USB memory stick

A message is displayed confi rming that the USB mem-

ory stick has been detected; the download will start

showing the transfer progress status from 0 to 100%

Remove the USB memory stick and carefully put the

cap back in place to ensure the system protection IP

levels.

Esc

to return to the FUNCTION menu.

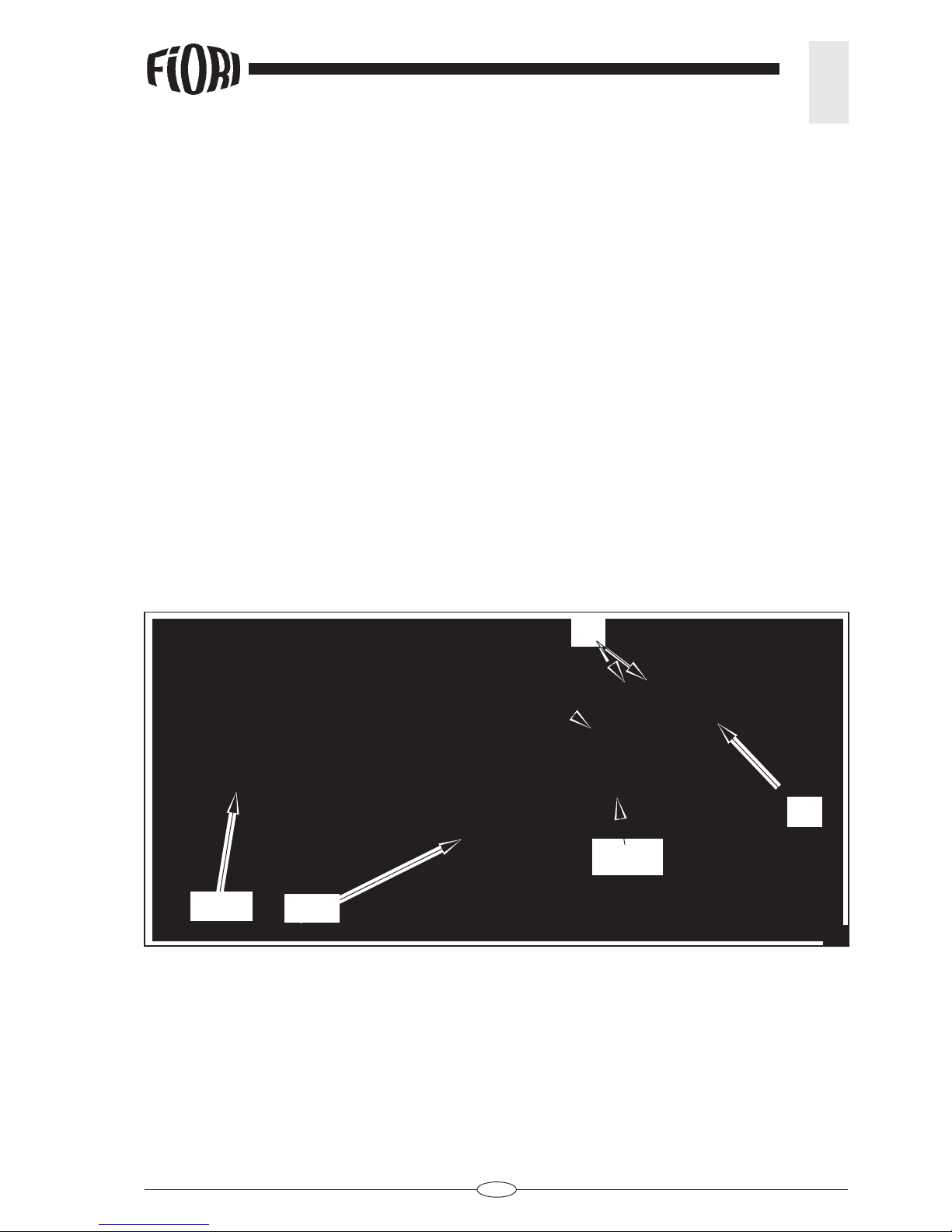

DETECTING THE MACHINE TILTING

Select the “MACHINE TILTING” fi eld

Press OK

; the tilting graphic page is displayed.

COLOURS:

green = values within tolerance

yellow = Next to the machine overturning danger

threshold

red = danger of machine overturning

N.B: the yellow and red signals are accompanied by a

progressive acoustic alarm depending on the level of

danger.

SYSTEM INFO

To view system information

left tilting

back tilting

Tilting values

FR= front LA= lateral

Print all the components loaded during the day

HTS code

Serial number

Firmware version

USB fi rmware version

INSTRUMENT DATA

Hours of operation

Weighings performed

Schedule of next

calibration (hours)

Schedule of next

calibration (weighings)

3.27 DATA SENT TO GPS AND GPRS SYSTEMS

The following data are sent:

- The receipt printing data, each time that a recipe processing cycle is completed.

- General alarms

- drum rotation pressures.

57

REV. 00 02/01/2015

id.:

4

FBC

MODE FUNCTIONS FOR THE FOREMAN ONLY

4.1 MENU SETTINGS

- Go to the main page (recipe)

- Press and hold the arrow key (>)

and then

the SELECT

key.

In the SETTING page you may change:

- Language

- unit of measurement (kg) or pounds (lbs)

Select the “FOREMAN” fi eld and then press OK

.

Enter the foreman password (the default password is 0, it may be changed at a later time).

4.2 MENU FOREMAN

58

REV. 00 02/01/2015

id.:

FBC

MODE FUNCTIONS FOR THE FOREMAN ONLY

4

4.3 COMPONENTS AND RECIPES

To set or modify the list of components to be used in the recipe.

Some components are preset by the manufacturer, however all components may be set or modifi ed.

Up to 32 components may be set

In the main page (used by the operator) only the components with weight

different from zero will be displayed .

The fi rst component must always be WATER

component type:

Water = water,

---- = generic

progressive index

component name

value (kg) to be loaded to run the

recipe)

To write or change the name of a component

- Use the arrow

keys to select the component

- Press C

several times to delete the name and then write it again.

- Press OK

to confi rm