SCRUBBER-DRYER

ECOPRO40

USE AND MAINTENANCE MANUAL

EN

Translation of the original instructions

Revision: 1.1

Edition: 24/10/2016

Table of contents

1 GENERAL INFORMATION4

1.1 MANUFACTURER IDENTIFICATION DATA4

1.2 AIM OF THE MANUAL4

1.3 TERMINOLOGY AND SYMBOLS5

1.4 INTENDED USE AND UNINTENDED USE6

1.5 TECHNICAL MODIFICATIONS6

1.6 PRODUCT IDENTIFICATION6

2 SAFETY INFORMATION7

2.1 BASIC RECOMMENDATIONS7

2.2 TECHNICAL SUPPORT10

3 HANDLING INFORMATION11

3.1 DIMENSIONS AND WEIGHT OF PACKAGE11

3.2 LIFTING AND HANDLING THE PACKAGE11

3.3 INSPECTION UPON DELIVERY12

3.4 UNPACKING12

3.5 ASSEMBLING THE MACHINE13

4 TECHNICAL INFORMATION15

4.1 GENERAL DESCRIPTION OF COMPONENTS15

4.2 CONTROL PANEL16

4.3 DIMENSIONS AND TECHNICAL DATA16

5 USING THE MACHINE17

5.1 PREPARING THE MACHINE17

5.2 RECHARGING THE BATTERY18

5.3 FITTING AND REMOVING THE BRUSH18

5.3.1 BRUSH TYPES19

5.4 MOVING THE MACHINE20

5.5 FITTING AND REMOVING THE SQUEEGEE20

5.6 REPLACING THE SQUEEGEE BLADES21

5.7 FILLING AND EMPTYING THE SOLUTION TANK21

5.8 DRAINING THE RECOVERY TANK23

5.9 OPERATING THE MACHINE24

5.10 FLOOR CLEANING INSTRUCTIONS25

5.10.1 PREPARATION AND WARNINGS25

5.10.2 DIRECT WASHING OR FOR SLIGHTLY DIRTY SURFACES25

5.10.3 INDIRECT WASHING OR FOR VERY DIRTY SURFACES25

5.10.4 POST-CLEANING OPERATIONS25

6 MAINTENANCE26

6.1 TANKS26

6.2 DETERGENT SOLUTION TANK FILTER26

6.3 SUCTION HOSE26

6.4 SQUEEGEE27

6.5 VACUUM FILTER27

6.6 ACCESSORIES27

6.7 MACHINE BODY28

6.8 MAINTENANCE SCHEDULE28

6.9 EXTRAORDINARY MAINTENANCE29

6.10 RECOMMENDED SPARE PARTS29

7 TROUBLESHOOTING30

1 GENERAL INFORMATION

1.1 MANUFACTURER IDENTIFICATION DATA

Ing.O.Fiorentini s.p.a

administrative headquarters

50033 Piancaldoli (FI) via Piancaldoli 1896 Firenzuola tel +39 0558173610 - fax +39 055817144 50033

Pietramala (FI) via pietramala 70/B tel +39 055813447 - fax +39 055813504 40024

Castel San Pietro (BO) via Cà Bianca 231/C tel +39 051941743 - fax +39 0516942400

subsidiary

20132 Milano via Palmanova 211/A tel +39 0227207783 - fax +39 022592779 00012

Guidonia Montecelio ( Roma ) via Bruno Pontecorvo 20 tel +39 0774357184 - fax +39 0774353419

The manufacturer accepts no liability for damage or injury caused by:

The improper use of the machine or its use by unauthorised or unskilled personnel to carry out certain tasks

and/or during training courses.

The machine being used in a manner that does not conform to national safety and accident prevention

regulations.

The disabling or removal of safety devices installed on the machine.

The improper installation and / or connection to the intended power supplies (power supply defects).

The lack of or inadequate preventive maintenance.

Making modifications to or carrying out unauthorised work on the machine.

The use of non-original or unsuitable spare parts.

The total or partial failure to comply with the instructions provided.

Exceptional conditions.

1.2 AIM OF THE MANUAL

To make it easier to look up and read about the subjects of interest, refer to the table of contents at the beginning of

the manual.

This manual has been written by the manufacturer and is an integral part of the product. As such, it should be kept

safely for the entire service life of the machine until it is demolished.

The customer must make sure that operators have read or are familiar with the contents of this manual and that they

strictly follow the instructions provided.

The only way to obtain the best results in terms of safety, performance, efficiency and durability of your product is to

always comply with the instructions provided in this manual.

Failure to comply with these instructions may cause injury to persons or damage to the machine, the surface that is

being cleaned and to the environment. Under no circumstances can such injuries or damage be attributed to the

manufacturer.

1.3 TERMINOLOGY AND SYMBOLS

For greater clarity and to adequately highlight the various aspects of the instructions described, specific terms and

symbols have been used. These are defined and illustrated below:

Term

Definition

Machine

This replaces the commercial name of the machine to which this manual refers.

Operator

A person who normally uses the machine and who is familiar with how to operate it, as well as

being familiar with the use of various types of detergent but who is not able to carry out work on

the machine that requires specific technical skills.

Technician

A person who has the necessary requisites (experience, technical skills and legislative and

regulatory knowledge) that allows him to carry out any type of work required and that has the

ability to recognise and avoid possible hazards during the installation, operation, handling and

maintenance of the machine.

Symbols and warnings

DANGER!

Symbol that draws attention to essential information to avoid serious (or extreme)

consequences that affect the health of persons, the integrity of the product and damage to

the environment in which it is used.

CAUTION

Symbol that accompanies information containing procedures and/or instructions that are

essential to understand and follow to avoid damage to the machine and to the environment

in which it is used.

NOTE:

Symbol used to highlight important information which if ignored, could cause damage to the

machine.

1.4 INTENDED USE AND UNINTENDED USE

The machine referred to in this manual (MIRA 40) is an operator-controlled hard floor scrubber-dryer. It must be

used to scrub and vacuum liquids on flat, hard, horizontal, smooth or moderately rough and uniform floors that are

free from obstacles in both civil and industrial environments.

DANGER!

Any other use is strictly prohibited!

Please read the safety information provided in this manual very carefully.

The scrubber-dryer distributes a quantity of a solution consisting of water and detergent (that can be regulated) onto

the surface to be cleaned, while the brushes remove any dirt from the surface.

The machine’s vacuum system, with the aid of the squeegee, completely dries the liquids and removes the dirt

removed by the front brushes in a single pass.

By matching the correct detergent with various types of brush (or abrasive disks), the machine can adapt to all the

various floor-dirt combinations.

1.5 TECHNICAL MODIFICATIONS

This machine was designed and built in accordance with the fundamental requirements for user health and safety

pursuant to the European directives. The CE mark was therefore placed on the rating label.

The European directives to which the appliance is compliant are referred to in the Certificate of Conformity, attached

to this manual. This certificate will cease to be valid if the appliance is modified in any way without the

manufacturer’s prior authorisation.

The manufacturer reserves the right to make technical modifications to the product without prior notice in order to

make technical upgrades or improvements.

For this reason, some details of your machine may be different from the information contained in the sales

catalogues or the illustrations shown in this booklet. Nevertheless, this will not affect safety or invalidate the

information provided regarding it.

1.6 PRODUCT IDENTIFICATION

Make sure that there is a rating label containing the serial number and the CE mark attached to the machine.

If there isn’t, please inform your dealer immediately.

The rating plate contains the following information:

Manufacturer’s identification data

CE mark

model

serial number

total power rating

year of construction

2 SAFETY INFORMATION

2.1 BASIC RECOMMENDATIONS

NOTE:

Read the “instructions manual” before starting up, using, or carrying out scheduled or unscheduled

maintenance or any other work on the machine.

CAUTION

Strictly comply with all the instructions provided in this manual and those regarding the

batteries and battery chargers (pay particular attention to safety warnings and danger notices).

The manufacturer declines all liability for injury or damage due to the failure to comply with the

above-mentioned instructions.

NOTE:

Before using the machine, make sure that all parts are in their correct position.

CAUTION

The machine must only be used by personnel who have been trained to use it, who have

proven their ability to use it and who have been expressly instructed to use it. To avoid

unauthorised use, when not in use, store the machine in a place that is not accessible by

unauthorised personnel.

Never allow minors to use the machine.

Never use this machine for any purpose other than for those for which it was specifically

designed. Consider the type of building in which it is to be used and comply fully with the

current rules and safety regulations of the building.

DANGER!

Never use the machine in poorly lit areas, in explosive environments, in the presence of dirt

that is hazardous to health (dust, gas etc.), on roads or public passageways and outdoors in

general.

CAUTION

The machine operating temperature range is +4°C to + 35°C. When not in use, store the

machine in a dry and non-corrosive environment in which the temperature is between +

10°C and + 50°C. The humidity range for the machine is between 30% and 95%, whatever

the conditions.

DANGER!

Never use or vacuum liquids, gases, dry dust, acids and solvents (e.g. paint thinners,

acetone etc.), even if diluted that are inflammable or explosive (e.g. petrol, fuel oil etc.).

Never vacuum objects that are on fire or incandescent.

CAUTION

Do not use the machine on slopes or ramps that are steeper than 2%. On sight slopes,

never use the machine sideways, always manoeuvre it with care and never reverse. When

transporting the machine on steep ramps or slopes, be very careful to prevent it tipping

over and/or accelerating uncontrollably. Use only the lowest speed! The machine should

only negotiate ramps and/or steps with the brush head and squeegee raised.

NEVER leave the machine on a slope.

NOTE:

Never leave the machine unattended without first making sure that it cannot move accidentally and that

it is disconnected from the power supply.

DANGER!

When using the machine, pay attention to other people, especially children in the area

where the machine is being used.

CAUTION

Do not use the machine to transport persons / things or to tow things. Do not tow the

machine.

NOTE:

Do not for any reason use the machine as a support for any amount of weight.

Do not obstruct the ventilation and heat discharge vents.

CAUTION

Do not remove, modify or bypass the safety devices.

Operators should always use personal protective equipment (both when using the

machine and when carrying out maintenance on it):

apron or overalls

non-slip waterproof footwear

rubber gloves

goggles and ear protectors

breathing mask

Before starting to use the machine, remove jewellery, watches, ties and other items that

could potentially cause serious injury.

Never insert hands between moving parts.

NOTE:

Do not use detergents other than the ones intended and follow the instructions on the relative safety

data sheets.

Detergents should be kept in a place that is inaccessible to children. In case of contact with the eyes,

rinse immediately with copious amounts of water. If swallowed, consult a doctor immediately.

Make sure that the power outlets used for the battery charger are connected to an efficient earthing

system and that they are protected by magneto thermal and differential circuit breakers.

DANGER!

Do not place tools on top of the batteries: they may cause a short-circuit or an explosion.

In the presence of particularly strong magnetic fields, asses the possible effect they may have

on electronic control devices.

Never clean the machine using water jets.

NOTE:

The fluids that are recovered contain detergents, disinfectant and water together with organic and

inorganic substances collected whilst the machine is in use. They must be disposed of according to the

current applicable legislation.

NOTE:

Before each use, check the machine. In particular, check that the battery charging cable and connector

are in good condition and safe for use.

If they are not in perfect condition, do not use the machine for any reason until repairs have been

carried out by an authorised technician.

NOTE:

Turn off the vacuum motor immediately if you notice any foam or liquid leaking from the appliance.

Do not use the machine on textile floor coverings such as rugs, carpets etc.

The use of wax, foaming detergents or dispersions may cause serious damage to the machine or clog

the hoses.

CAUTION

If the machine breaks down and/or malfunctions, turn it off immediately (unplug it from the

electric power supply or the batteries) and do not tamper with it.

Contact one of the manufacturer’s technical support centres.

2.2 TECHNICAL SUPPORT

DANGER!

All maintenance work or the replacement of accessories must be carried out in areas with

adequate lighting and only after having disconnected the machine from the power supply by

unplugging the battery connector.

NOTE:

All work on the electrical system and all maintenance and repair work (especially work not specifically

described in this manual) should only be carried out by skilled personnel with experience in the field

and knowledge of the relevant safety regulations.

Only ORIGINAL SPARE PARTS, supplied exclusively by the manufacturer, should be used. Only

these parts can provide the assurance that the appliance will work safely and efficiently.

Do not use parts that have been removed from other machines or other kits as replacement parts.

Do not wait until the components are worn out; replacing a component at the right time means that the

machine will perform better and at the same time savings will be made by avoiding further damage.

The manufacturer provides its customers with a Technical Support Service to help resolve any issues there may be

regarding the use and maintenance of the machine.

Any requests for assistance must be made after having carefully assessed the problems and their causes.

When making a written request, please specify the following:

Machine model

Serial number

Details of the problem

The checks carried out

Any adjustments made and their effect

Any other information you think may be useful

Send the request to the manufacturer using the following e-mail address:

3 HANDLING INFORMATION

3.1 DIMENSIONS AND WEIGHT OF PACKAGE

Weight:

38 kg

Volume:

0.22 m3

A

1250 mm

B

510 mm

C

520 mm

3.2 LIFTING AND HANDLING THE PACKAGE

CAUTION

When lifting or transporting the machine, make sure that the packaged machine is securely

anchored to prevent it from tipping over or falling accidentally.

Vehicle loading and unloading operations must be carried out with adequate lighting.

The packaged machine must be handled using suitable equipment. Care must be taken not to damage/hit any part

of the packaging, not to tip it over and to be careful when placing it on the ground.

Symbols used on the packaging

Fragile, handle with care.

Indicates that the contents of the package are fragile and must be

handled with the utmost care.

Keep dry

Indicates that the package should be kept in a dry place.

This way up.

Indicates that the package must be stored the right way up.

3.3 INSPECTION UPON DELIVERY

When the goods are delivered (machine, battery or battery charger) by the carrier, carefully check the condition of

the packaging and its contents. If the contents have been damaged, inform the carrier immediately and reserve the

right, in writing (select the “accepted with reserve” item on the document), to submit a claim for compensation before

accepting the goods.

The package contains the following:

1

Scrubber-dryer

2

Squeegee

3

Battery

4

Graduated container

5

Battery charger

6

Brushes

3.4 UNPACKING

To unpack the machine, proceed as follows:

1) Remove the graduated container 4

2) Remove the top packaging insert B

3) Grip the machine by the handle and bring it into an upright position

4) Remove the machine from the box.

5) Remove the box A

NOTE:

We recommend that you keep all packaging materials because they may be useful in the future to

protect the machine and accessories when transporting it to an authorised service centre.

If you do not wish to keep the packaging materials, they should be disposed in accordance with current

waste disposal legislation.

3.5 ASSEMBLING THE MACHINE

DANGER!

All the operations described below must be carried out in areas having adequate lighting and

only when the battery has been removed from the machine.

After unpacking the machine, it must be assembled as described below (refer to the relevant sections in Chapter 5

for a detailed description of these procedures):

1) Fit the brushes

2) Fit the squeegee and make sure that it is securely fastened and connected to the suction hose.

3) Fill the solution tank.

4) Place the battery into the compartment and connect the connector.

o how to move & transport condition.

With the machine in POWER OFF, pressing and rotating the front lever A, The machine will rest on the three wheels

and lifts the brushes OFF the floor.

In this position it is possible to move the machine by maneuvering it as in the working phase without blocking the

handle.

To store the machine, lower the handle locking/unlocking lever, make sure that the machine rest on the three wheels

(not on the brushes) and that thelever “A” is in a horizontal position as when moving the machine.

ATTENTION

Do not store the machine with the brushes resting on the floor, the weight may deform the bristles,

reducing their performance.

4 TECHNICAL INFORMATION

4.1 GENERAL DESCRIPTION OF COMPONENTS

1

ON/OFF switch

2

Power indicator light

3

Brush / Brush+Water switch

4

Vacuum motor switch

5

Handle

6

Recovery tank fastening clip

7

Suction hose

8

Battery

9

Squeegee

10

Brushes

11

Solution tank

12

Wheels

13

Drain plug

14

Vacuum motor fan

15

Filler plug

16

Handle lock/release lever

17

Recovery tank

18

Vacuum filter

19

Graduated container

20

Battery charger

4.2 CONTROL PANEL

1.

Power button

Turning the machine ON or

OFF

2

Suction

command

button

Activate or deactivate the suction

function.

3

Brush speed

adjustment

buttons

Pressing the + or – buttons

increases or decreases the speed

of the brushes.

4

Water flow

adjustment

buttons

Pressing the + or the – buttons

increase or decreases the volume

of water solution.

5

Battery charge

indicator

display.

The display indicates the battery

charge level.

o SUCTION POWER ADJUSTMENT

CONTROL

Pressing for 5 second simultaneously, buttons 1 and 2, on

the display 5, the word Vacuum appears, bellow the sector

indicating the battery charge level.

By pressing the button 3 it is possible to increase (pressing

+) or decrease (pressing -) the suction power of the

machine; this adjustment is signaled on the display 5.

To set the selected power level , press the main power

button 1 switching OFF the machine.

Pressing ON the main power button (button1) the stored

setting of suction power level is indicated on the display 5.

There is 8 different setting possibility indicated on the

display (1/8, 2/8, 3/8....until 8/8).

4.3 DIMENSIONS AND TECHNICAL DATA

Description

Units

Value

Power supply

V

36

Performance

m2/h

1200

Cleaning width

cm

400

Squeegee blade width

cm

450

Brush diameter

mm

2 x 200

Brush speed

rpm

210

Brush pressure

Kg

22

Brush motor power

W

2 x 36/120

Vacuum motor power

W

36/300

Solution/recovery tank capacity

lt

3/5

Noise Level

dB

66

Measurements are in centimetres.

5 USING THE MACHINE

5.1 PREPARING THE MACHINE

DANGER!

All maintenance work or the replacement of accessories must be carried out in areas with

adequate lighting and only after having disconnected the machine from the power supply by

unplugging the battery connector.

CAUTION

Before starting, put on non-slip shoes, gloves and any other personal protection equipment

indicated by the supplier of the detergent or required by the environment in which the machine

is to be used.

NOTE:

Carry out the checks described below before you start to use the machine (refer to the relative sections

for a detailed description of these procedures).

1) Fit the brush or pad driver (with abrasive pad) that is suitable for the surface and the work to be performed.

2) Fit the squeegee and make sure that it is securely fastened, connected to the suction hose and that the

blades are not excessively worn.

3) Fill the solution tank with a mixture of clean water and a suitable amount of non-foaming detergent (using the

graduated container provided).

4) Check the battery charge level and charge if necessary.

NOTE:

To avoid hazards, we recommend that you become familiar with the machine movements by

experimenting on a large surface that is free from obstacles.

To obtain the best results in terms of cleanliness and the service life of the appliance, you should follow a few

simple, but important procedures:

Identify the work area and remove all possible obstacles that may get in the way. If the surface is very large,

work in contiguous and parallel rectangular areas.

Choose a straight work trajectory and start working from the area furthest away to avoid going over areas

that have already been cleaned.

BLOCKING / UNLOCKING SQUEEGEE LIFTING

Lifting the squeegee off the floor from plate “1” activate the snap lock “2”which allows the squeegee to remain lifted

from the floor.

To bring the squeegee back to the floor, lift the latch “2” releasing it.

5.2 RECHARGING THE BATTERY

1) Connect the battery extension cable 1 to the

plug of the battery charger 2.

2) Plug the battery charger into a mains socket

and charge the battery as long as the red

LED on the battery charger 2 remains on.

3) When the green LED on the battery charger

2 lights up it means that it is fully charged.

4) Disconnect the plug of the battery charger 2

from the battery extension cable 1.

5.3 FITTING AND REMOVING THE BRUSH

CAUTION

Only use the machine if the brushes or pad drivers, together with abrasive disk, are installed

properly.

Assembly procedure:

1) Lock the handle using the locking lever.

2) Grip the handle and, using it as a lever to lift

the front of the machine, rotate it (A)

backwards.

3) Insert (B) the brushes onto the appropriate

pins and press (C) all the way down.

To remove them, follow the procedure

indicated in point 3 in reverse.

NOTE:

Follow the same procedure to fit /

remove the pad driver.

CAUTION

REPLACE the brushes / abrasive discs before the length of the bristles or the thickness of the

abrasive discs become less than 1 cm.

Working with brushes that are excessively worn, or abrasive discs that are excessively thin,

may damage the machine and the floor.

Regularly check the wear on these parts before starting to use the machine.

BRUSH TYPES

Four different types of brush are supplied with the machine. Their characteristics differ according to their composition

and abrasiveness. Their use depends on the type of floor or the specific application.

N.

Picture

Brush name

Description

1 PPL 06 BRUSH

Can be used for cleaning hard surfaces such as cement, tiles,

clinker, porphyry etc.

2 PAD DRIVER

Covered with Velcro and a sponge disc (pad). The

abrasiveness of the sponge varies according to its colour:

white (soft) to black (very abrasive).

Choose the type of sponge according to the type of floor, for

example:

parquet - white or yellow

PVC - blue or red

wax removal or cement - brown or black.

3 P.E.S. BRUSH

Fibre bush with bristles of various diameters (from 0.1 to 0.6

mm).

Can also be used without detergent on treated surfaces or

wood. Its mixture of bristles means it can also be used just to

polish treated floors.

4 TYNEX BRUSH

Made of carbon fibre, it can be used only for heavy duty

cleaning applications. For example on tiles in industrial

kitchens, production departments with machine tools,

foundries etc.

When used with a suitable detergent, it can be used to

remove sludge or dirt consisting of lime deposits or of plant or

animal origin (grease).

Warning: The Tynex brush MUST NOT be used on delicate

flooring materials (such as parquet, marble, PVC etc.).

5.4 MOVING THE MACHINE

To move the machine when not in operation, proceed as follows:

1) Switch the machine off using the main switch on the control panel.

2) Lock the handle using the locking lever.

3) Raise the squeegee using the appropriate lever.

4) Grip the handle and using it as a lever to lift the front of the machine,

rotate it (A) backwards until it is resting completely on its wheels.

5) Keeping the machine in this position, push it to where it needs to be

used or stored.

CAUTION

Do not use the wheels to support the machine when moving it up or down flights of stairs. It

should be lifted (it requires at least 2 people) using the carrying handle.

5.5 FITTING AND REMOVING THE SQUEEGEE

Assembly procedure:

1) Position the squeegee support 1 so that it is facing upwards A

2) Insert the squeegee 2 onto the holes X in the support 1.

3) Tighten the knobs 3 securely to fasten the squeegee 2 to the support 1.

4) Insert the suction hose 4 into the sleeve 5.

Removal procedure:

1) Position the squeegee support 1 so that it is facing upwards A

2) Disconnect the suction hose 4 from the sleeve 5.

3) Loosen the knobs 3 that fasten the squeegee 2 to the support 1.

4) Remove the squeegee 2.

5.6 REPLACING THE SQUEEGEE BLADES

1) Remove the squeegee A from its support (see previous section).

2) Completely unscrew the rear knobs 1 and remove the pins 2.

3) Remove the squeegee blade 4-6 clamping strips 3-7.

4) Remove the rubber blades 4-6 from the body 5 of the squeegee by pulling from one end.

5) To replace the rubber blade, follow the same procedure in reverse starting from the rear blade 6.

6) Fit the rectangular holes on the blades into the seats on the body 5 of the squeegee.

7) Replace the blades 4-6 and the clamping strips 3-7

8) Insert the pins 2 and fasten the whole unit using the knobs 1.

CAUTION

The front rubber blade is different from the rear blade as it has notches through which water

can pass.

The clamping strips are identical.

5.7 FILLING AND EMPTYING THE SOLUTION TANK

NOTE:

The temperature of the water or the detergent added should never exceed 50°C.

Always empty the recovery tank every time you fill the solution tank.

CAUTION

Use only products suitable for the floor and for the dirt that has to be removed.

Filling procedure:

1) Remove the filler plug 1.

2) Pour the required quantity of the chemical product into the tank, considering the percentage (%) indicated by

the supplier, according to the full tank capacity indicated on the product sheet.

3) Using the graduated container, pour water into the filling inlet 2.

4) Close the tank with the plug 1.

CAUTION

Always use non-foaming detergents (low foam).

The use of other chemical products (such as sodium hypochlorite, oxidisers, solvents or

hydrocarbons) may damage or cause irreparable damage to the machine.

The machine has been designed for use with

non-foaming and biodegradable detergents that

are specific for scrubber-dryers.

Follow the safety regulations indicated in the

relative section and on the detergent

container.

NOTE:

For a complete list of suitable detergents available, please contact the machine manufacturer.

Emptying procedure:

1) Unscrew the drain plug 3, together with the filter 4,

located in the lower part of the tank.

2) Wait for the tank to empty completely.

3) Screw the drain plug back on tightly 3.

5.8 DRAINING THE RECOVERY TANK

1) Move the machine to a suitable place in which to empty the dirty water, preferably close to a drain

(comply with national regulations regarding the disposal of waste water).

2) Release the fastening clips 1

3) Remove the tank 2

4) Disconnect the hose 3 from its seat.

5) Unscrew the lower plug 4

6) Pour the recovered water into the drain until the tank is completely empty 2.

7) Screw the lower plug back on 4

8) Insert the hose 3 into its seat, taking care to position it properly as shown in the picture.

9) Pace the tank 2 back onto the handle 5.

10) Secure it with the fastening clips 1

5.9 OPERATING THE MACHINE

1) Check that all the switches (1, 2 and 3) on the control panel

A are in the O position.

2) Lower the squeegee.

3) Lift the lever 4 to release the handle 5.

4) Switch on (position ) the machine using the ON/OFF

switch 1 (the LED 6 lights up).

5) Start the brushes and the dispensing of the solution (water

+ detergent) using switch 2 (position ).

6) Turn on the vacuum using the switch 3 (position ).

7) Wash the floor by moving slowly forwards and follow the

machine as it progresses due to the movement of the

brushes.

CAUTION

Remember to raise the squeegee before reversing in order to avoid damaging it.

NOTE:

The machine is fitted with a motor overload protection system that stops the motor in the event that the

ON/OFF switch is pressed repeatedly at short intervals.

The machine must be restarted in order to resume normal operation.

5.10 FLOOR CLEANING INSTRUCTIONS

PREPARATION AND WARNINGS

Remove any loose solid residues from the surface to be treated (using suitable equipment such as vacuum cleaners,

sweepers, etc.) If this is not done, the solid dirt could prevent the squeegee from working properly and prevent the

floor from being dried correctly.

This machine must only be used by trained personnel.

CAUTION

Do not obstruct the motor cooling fan grille.

DIRECT WASHING OR FOR SLIGHTLY DIRTY SURFACES

Scrubbing and drying in a single pass.

Prepare the machine and use it as described in section Errore. L'origine riferimento non è stata trovata..

NOTE:

Never use the machine without a detergent solution as it may damage the floor.

INDIRECT WASHING OR FOR VERY DIRTY SURFACES

Scrubbing and drying in multiple passes.

Prepare the machine and use it as described in section Errore. L'origine riferimento non è stata trovata..

First step:

Wash the floor as described in section Errore. L'origine riferimento non è stata trovata. without drying it.

Give the detergent solution time to act on the dirt, as indicated in the instructions of the detergent used.

Second step:

Proceed as explained in the previous section and also dry the floor.

NOTE:

Never use the machine without a detergent solution as it may damage the floor.

POST-CLEANING OPERATIONS

1) Turn off the detergent dispensing function.

2) After having completely dried the surface of any traces of water, wait a few seconds, then raise the

squeegee and turn off the vacuum motor.

3) Go to a suitable place where to drain the tanks.

4) Empty and clean the tanks (see sections Errore. L'origine riferimento non è stata trovata. and

Errore. L'origine riferimento non è stata trovata.).

5) Turn off the machine using the ON / OFF switch

6) Lock the handle using the locking lever.

7) Charge the battery, if necessary.

6 MAINTENANCE

DANGER!

All maintenance work or the replacement of accessories must be carried out in areas with

adequate lighting and only after having disconnected the machine from the power supply by

unplugging the battery connector.

NOTE:

All work on the electrical system and all maintenance and repair work (especially work not specifically

described in this manual) should only be carried out at authorised service centres or by skilled

personnel with experience in the field and knowledge of the relevant safety regulations.

Carrying out regular maintenance on the machine, carefully following the manufacturer’s instructions

ensures better performance and a longer machine service life.

6.1 TANKS

Drain the two tanks as described in the relative sections Errore. L'origine riferimento non è stata trovata. and

Errore. L'origine riferimento non è stata trovata..

Remove any solid dirt by filling and draining the tanks until all dirt has been eliminated.

Do this using a hose or similar item and only wash the inside of the tank.

CAUTION

Water temperatures in excess of 50°, high-pressure washers or excessively powerful sprays

can damage the tanks and the machine.

Leave the plugs of the tanks open (only while the machine is not being used) so that the tanks

can dry and prevent the formation of unpleasant odours.

6.2 DETERGENT SOLUTION TANK FILTER

1) To clean the detergent solution filter, remove the

plug 1 and the filter element 2.

2) After cleaning, place the filter element 2 back into

its seat and screw the plug back on 1.

6.3 SUCTION HOSE

1) Disconnect the suction hose 1 from the squeegee

2.

2) The hose 1 can now be cleaned and any

obstructions removed.

3) After cleaning, insert the hose 1 firmly onto the

squeegee body 2.

6.4 SQUEEGEE

CAUTION

Do not handle the squeegee with bare hands: wear gloves and any other protective clothing

that may be necessary.

Remove the squeegee from the machine and clean it under running water using a sponge or brush.

Check the effectiveness and the wear of the rubber blades that are in contact with the floor.

They are designed to scrape the detergent-water film on the floor and to isolate that area of the surface to help the

vacuum motor reach the maximum vacuum pressure: this ensures that the machine will dry the floor completely.

Working like this continuously causes the sharp edge of the blade to become round or to wear, thereby reducing its

drying efficiency. The squeegee blades must therefore be replaced fairly often.

If necessary, turn the blades in order to use the other sharp edges or to install new ones (see section Errore.

L'origine riferimento non è stata trovata.).

6.5 VACUUM FILTER

1) Release the fastening clips 1

2) Remove the tank 2

3) Remove the filter 3 from its seat and clean it under running water.

4) After cleaning, replace the filter 3 in its seat

5) Put the tank 2 back into the handle.

6.6 ACCESSORIES

Remove and clean the brush or pad driver (see section Errore. L'origine riferimento non è stata trovata.).

Check that the brushes work evenly on the surface (check for any irregular wear on the brushes or abrasive disks).

CAUTION

To avoid damaging the floor and the machine, make sure that no foreign objects, such as

metallic parts, screws, chippings, string or similar items, have become caught in the brushes.

NOTE:

Only use accessories recommended by the manufacturer:

Using products that are non-compliant may affect safety and damage the machine.

6.7 MACHINE BODY

Use a sponge or a damp cloth to clean the outside of the machine and if necessary, use soft brush to eliminate

stubborn dirt.

The machine’s impact resistant surface is rough to make it harder to see scratches produced during use. However,

this does not make it easy to remove stubborn stains from its surface.

CAUTION

Never use steam cleaners, hoses with running water or high-pressure washers.

6.8 MAINTENANCE SCHEDULE

NOTE:

For all the operations described here, refer to the detailed instructions and warnings given in the

relative sections.

The frequency with which the routine maintenance is carried out is determined by the number of complete machine

discharge cycles.

The machine has an autonomy of approximately 1 hour. Each cycle is considered to be 1 working hour.

Cycles

Description

1

Clean the squeegee (see section Errore. L'origine riferimento non è stata trovata.)

5

Clean the solenoid valve filter (see section Errore. L'origine riferimento non è stata trovata.).

Clean the vacuum filter (see section Errore. L'origine riferimento non è stata trovata.).

Clean the recovery tank seals 1 and 2 using a damp cloth.

10

Clean the bottom plate 3 and particularly the clean water nozzles 4 using a damp cloth or abrasive sponge.

6.9 EXTRAORDINARY MAINTENANCE

Even though the machine has been carefully built and conforms with the most stringent quality tests, the electrical

and mechanical components are inevitably subject to wear and ageing after long periods of use.

In order for the machine to provide safe and trouble-free service, it is recommended that your machine be thoroughly

inspected every year at a service centre authorised by the manufacturer (or by someone specialised in the field who

has the proper skills and who is familiar with all the relevant safety regulations contained in this manual).

This may need to be done more frequently if the machine is used in particularly harsh conditions and / or if it has not

been properly maintained.

6.10 RECOMMENDED SPARE PARTS

To get the most out of your machine, it is recommended that you always keep a stock of the common consumables

and to schedule routine and extraordinary maintenance

Contact your dealer for a list of these spare parts.

7 TROUBLESHOOTING

CAUTION

The content of this chapter is not exhaustive but it aims to provide information regarding the

most common problems in order to help the user to troubleshoot faults.

The instructions under the heading “SOLUTION” in the table below DO NOT AUTHORISE work

to be carried out that can affect safety.

Please anyway refer to the corresponding section in this manual for details of the type of action to take.

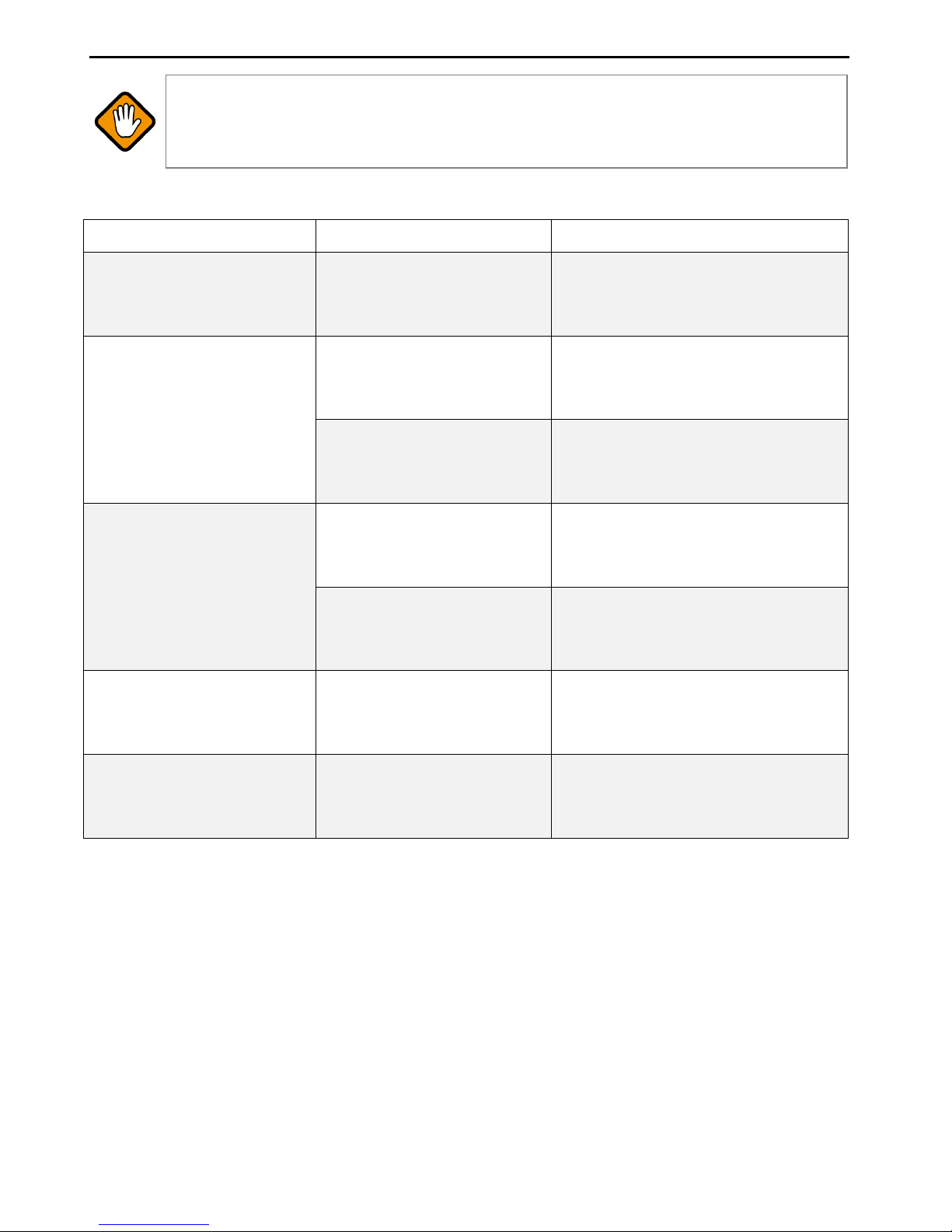

PROBLEM

CAUSE

SOLUTION

THE MACHINE DOES NOT

SWITCH ON

Low battery

Check the battery connection.

Check the battery charge level.

Replace the battery.

The brush doesn’t rotate

Low battery

Check the battery connection.

Check the battery charge level.

Replace the battery.

Electronic cards are in standby

Turn the machine off and then on again.

The vacuum motor doesn’t start

Low battery

Check the battery connection.

Check the battery charge level.

Replace the battery.

Electronic cards are in standby

Turn the machine off and then on again.

The vacuum motor does not

remove the water

Suction hose and / or filter

clogged

Clean the suction hose and / or filter

The water does not reach the

brushes

The water tank is empty or the

internal filter is clogged

Remove the tank drain plug and clean the

filter.

Loading...

Loading...