Page 1

FINOCAM A5

06260DE

Original FINO

Germany

Tischfräsmaschine

Table Milling Unit

Gebrauchsinformation•User Information•Mode d’emploi

Información sobre el uso•Informazioni d’uso

Gebruiksaanwijzing•Instrukcja stosowania

FINO

•der feine Unterschied•the fine difference•la fine différence•la fina diferencia•la fine differenza

Page 2

Version 1/2016. Read the User Manual prior to commencing work!

1. About this document 3

• Used symbols • Structure of safety notes

2. Safety instructions & regulations 3

• General safety instructions • Regulations

3. Machine description 6

• Connection panel• Front cover• Working chamber • Accessories container

• Air extraction concept • Manufacturing software and computer • Sound emission

• Technical data

4. Installing the machine 11

• Checking the scope of delivery • Choosing the installation site

• Machine installation (scheme) • Installing the pneumatics

• Installing the air extraction system • Establishing the electric connection

• Removing the transport lock • Connecting the manufacturing computer

• Testing the machine

5. Running the machine 18

• Starting up the machine • Job execution overview • Inserting/changing tools

• Inserting and removing workpieces • Executing jobs • Interrupting the job execution

• Operation interruption or abortion of job execution • Emergency release of the front cover

6. Machine maintenance and cleaning 25

• Definition of wear parts • Maintenance table • Inspection

• Cleaning the working chamber and measuring key • Cleaning the collet chuck

• Checking the hoses, cables and connections • Cleaning the housing

• Checking the service unit • Exchanging the main fuse • Calibrating the axes

• Replacing the tool changer inserts

7. Disposal 32

8. Troubleshooting 32

9. Index 36

CONTENTS

2

Page 3

1. About this document

1.1 Used symbols

Instructions

➤ General instruction

M Specific m

anual action

S Specific action in the manufacturing software

➡ Result

Additional symbols

➲ Cross reference

• List

Information to make work more efficient.

Important instructions without any danger

for people or objects.

Additional information

Structure of safety notes

Type and source of hazard

Further explanations and consequences when ignoring hazards.

➤ Instructions to avoid hazards.

The following signal words may occur in this document:

DANGER indicates a hazardous situation which will

result in death or serious injury.

WARNING indicates a hazardous situation which can

result in death or serious injury.

CAUTION indicates a hazardous situation which, if

not avoided, can result in minor or moderate injury.

NOTICE indicates a situation which can lead to physical damage of the product or in the surrounding

area(s).

SIGNAL WORD

DANGER

WARNING

CAUTION

NOTICE

2. Safety instructions & regulations

2.1 General safety instructions

Incorrect operation of the machine

➤ Read this document carefully before installing

and operating the machine.

➤ If it is unclear how to operate the machine in

any way, do not use the machine and contact

customer service.

➤ Make sure that every user has access to this

document.

➤ Instruct every user on safe and proper machine

handling.

Danger to life due to an electric shock

If you come into contact with electrically

charged parts, you can suffer from an elec tric shock. Water increases the risk significantly.

➤ Do not remove the housing of the machine.

➤ Only have qualified electricians work on any

electric equipment.

➤ Run power cables so that they cannot be dama-

ged by sharp edges.

➤ In the following cases, disconnect the

machine from the electrical source immediately and prevent it from being restarted:

• When machine connections, compressed air

hoses or electric cables are damaged

• Before you check or run electric cables

➤ Never perform any troubleshooting while the

machine is operating.

➤ Only have authorized service technicians repair

the machine.

➤ Replace damaged cables with original manu-

facturer’s spare parts.

➤ Install an operational Residual Current Device/

Ground Fault Circuit Interrupter on the electric

circuit of the machine.

➤ Do not touch the machine and especially the

cables with wet or damp hands.

➤ Remove any liquids near the machine imme -

diately.

DANGER

3

ENU

!

!

!

!

!

Page 4

Respiratory diseases when processing

harmful materials

If you inhale harmful materials during their processing, your respiratory tracts may be damaged.

➤ Only process materials when an air extraction

system is running.

➤ Avoid materials which can damage your health

during dry machining.

➤ Use a suction device with an extra-fine particle

filter.

Crushing hazard and risk of cutting injuries

through moving machine parts

Through the moving axes and the rotating spindle

you can suffer bruises and cuts.

➤ Only operate the machine when the front cover

is closed and the safety interlock is activated.

➤ Store the key for the emergency release in a

place where only authorised persons have

access.

➤ Do not circumvent or deactivate safety devices

of the machine.

➤ Check the machine regularly for damage,

especially the safety devices.

➤ Have damaged safety devices repaired by an

authorised service centre unless stated other wise in this document.

➤ Use only original manufacturer’s equipment and

original spare parts in the machine.

➤ Keep children and animals away from the

machine.

➤ Do not remove the housing of the machine.

Administrator mode: risk of cutting injuries

and bruises as well as hazards through

ejected debris

If you operate the machine in “Administrator mode”

with the front cover open, the risk of injury is increased significantly!

➤ Operate the machine in “User“ mode only unless

you have been authorised by FINO GmbH to use

other profiles.

➤ Even if you are an authorised user, use the

“Administrator mode” with the front cover open

only when necessary.

WARNING

!

➤ While in “Administrator mode”: Do not

reach into the working chamber while

the axes are moving or during machining.

➤ While in “Administrator mode”:

Everyone within reach of the machine

must wear protective eye wear.

Hearing damage due to loud noise

➤ In case of extraneous machining noise check the

working conditions: Ensure that the workpiece is

fixed properly, and verify the condition of the

tool and the material you are using.

➤ If loud noise cannot be avoided, wear

ear protection during processing.

Risk of injuries through loose pneumatic components under air pressure when connections

are open

Loose pneumatic components can move extremely

fast and unpredictably and may cause injury.

➤ Before you run the pneumatic hoses, close the

compressed air supply valve.

➤ Before you check the pneumatic hoses and

pneumatic connections, set the air pressure to a

minimum value.

➤ In case of defective machine connections

and pneumatic hoses, disconnect the

machine from the external compressed air

supply and the electrical source to prevent

it from being re started.

➤ Contact customer service if connections are

damaged or defective.

4

Page 5

Trip, fall and slipping hazards

➤ Keep the working environment and

installation site clean.

➤ Run cables in such a way that persons

cannot trip over them.

Risk of cutting injuries and burns

If you touch tools or sharp edges on workpieces or

the machine, you may suffer from cuts. If you touch

the hot spindle body or hot tools, you may suffer

from burns.

➤ Wear gloves when you perform manual work at

the machine or with workpieces/tools.

Reduced ability to act with insufficient lighting

In case of an insufficient lighting your judgement

and/or your precision may be reduced.

➤ Make sure that the lighting in your working

environment is sufficient.

Risk of injury in case of malfunctions caused

by insufficient maintenance

If you do not maintain the machine as often as is

required, malfunctions may occur which can lead to

injuries.

➤ Take note of the intervals and conditions mentio-

ned in the maintenance table in this document

and carry out the respective maintenance steps

accordingly.

Health risks through constant malpositioning

if your working environment is not sufficiently

ergonomic

Over the long run, an improper or one-sided positioning can be a risk to your health.

➤ Set up an ergonomic work environment.

➤ Ensure the seat height and monitor position is

ideal and the lighting is sufficient.

CAUTION

2.2 Regulations

If you violate the following regulations, you may lose

your entitlement for benefits. In addition, we cannot

be held liable for any damage resulting from such

violations.

2.2.1 Intended use

The FINOCAM A5 has been designed for easy to

medium machining work in the dental sector.

➤ Only process materials that you can select in

FINOCAM. Only use the machine commer cially.

➤ Before creating jobs, verify if the objects being

prepared may be utilized at the place of use

according to local and/or national regulations or

other authorized organisations or entities (e. g.

professional associations, health authorities). In

particular, verify if the material is approved for

the machined object type and if the object type

is designed in accordance with applicable regulations. Neither the manufacturing software nor

the CNC machine will inform you about possible

regulatory infringements, but will executes jobs

in accordance with the preferences and materials set by the user.

➤ Verify that each object type and each material in

your jobs are authorized to manufacturing materials. If mandated by local or national regula tions, obtain relevant authorization from the

responsible organisation or entities (e. g. professional associations, health authorities).

➤ Only manufacture objects which correspond to

the object types that you can select in the import

view in FINOCAM. While you can import/manufacture any other objects as well, neither the

manufacturing software nor the CNC machine

are designed for these other objects and should

not be used in this way.

➤ Do not manufacture implants or parts of objects

that are designed to have contact with implants.

These parts include parts of two-part abutments

which contain the connection geometry for the

implant. Do not manipulate the connection geometry of prefabricated abutments (“prefab abutments”) and you must always check finished

objects for accurate connection geometries (i.e.

that connection geometries of finished jobs have

not been damaged).

5

ENU

!

Page 6

2.2.2 Controlling the machine through

software

You control the CNC machine through specially

designed applications which are supplied with the

machine.

➤ Only use program versions that are officially

released for the machine.

➤ Always use the newest program versions that

are available for the machine.

➤ Before installing or operating the machine, be

sure to read the documentation for the applications.

2.2.3 Maintenance and cleaning

➤ Clean and maintain the CNC machine as

required. Only then can the machine reach a

long service life.

➤ Only carry out maintenance work which is de -

scribed in this document. Otherwise you risk

your health and may damage the machine.

2.2.4 Synchronous spindle SFK 300P

➤ Do not use unbalanced tools at high rotational

speeds. Such an imbalance puts a great strain

on the spindle’s ball bearings, which can cause

the bearings to be dam- aged.

➤ When working in the working chamber, do not

apply manual pressure against the spindle.

2.2.5 Unattended operation

➤ Unattended operation of the CNC machine

should only occur if the following conditions are

met:

• The national and local laws allow it.

• The working chamber of the machine is completely clean.

• Unauthorized users cannot access the machine.

• The room in which the machine is located has an

automatic fire detection system.

2.2.6 Transport ation and storage

Damaging of the machine if you transport the

machine without the transport lock

If you transport the machine without installing the

transport lock first, the machine may get damaged.

➤ Before every transport, install the transport lock

as it was installed at delivery

• Ambient temperature: between 10 °C and 35 °C

• Relative air moisture: max. 80 %, non-condensing

• For (un)packing and positioning two people are

required

• Weight of the machine: approx. 91 kg

➤ Always transport multiple machines

individually and do not stack them.

➤ Only trained transport personnel may transport

the machine to the installation site.

➤ Always transport the machine in an upright posi-

tion.

➤ Transport and position the machine only with a

closed accessories container.

➤ In case of overseas transport, take proper

measures against corrosion.

➤ To carry the machine, use the left and right grips

located on the bottom of the machine.

3. Machine description

Fig. 1: Front view of the FINOCAM A5

NOTICE

6

Page 7

1 Connection panel (➲ Fig. 2)

2 Front cover

3 View window to the working chamber

4 Recessed grip for opening

5 Accessories container

6 Opening for the air extraction system

With your FINOCAM A5 you can process workpieces

of different materials to create high quality objects

for the dental sector.

You can find a list of the materials which you can

process with the FINOCAM A5 in the FINOCAM

manufacturing software.

3.1 Connection panel

Fig. 2: The connection panel

1 Power connection 100 – 240 V AC, 50/60 Hz,

including glass fuse T6,3A L250V

2 Main power switch

3 Pneumatic connection

4 USB connection

5 Switching output for suction device

3.2 Front cover

The front cover locks the working chamber and

protects the user from injuries during operation.

Crushing hazard when opening or closing the

front cover

When you open or close the front cover, the moving

front cover may crush your fingers.

➤ When you open and close the front cover, use

one hand and keep the other hand away from the

machine.

➤ When you close the front cover, ensure your

hands do not get caught between the front cover

and the machine housing.

CAUTION

Damaging of the machine when opening the

front cover by force

When the CNC machine is not supplied with power or

when the axes are moving, the front cover remains

locked. If you open the locked front cover by force,

the machine may get damaged.

➤ Never open the front cover by force.

➤ Connect the machine to the electrical source

and switch it on first before opening the front

cover.

➤ To open the front cover, grasp the recessed grip

and pull the front cover upwards.

Fig. 3: The FINOCAM A5 with the front cover open

➤ To close the front cover, put your hand flat on

the upper edge of the front cover and push the

front cover downwards.

3.3 Working chamber

The machine processes all workpieces in the working

chamber.

Fig. 4: The working chamber of the FINOCAM A5

NOTICE

7

ENU

!

Page 8

1 Rotational axis B

2 Workpiece holder and rotational axis A

3 Fixing disc

4 Collet chuck for picking up tools

5 Spindle

6 Tool changer for up to 16 tools

Colours of the working chamber lighting

If the working chamber lighting is insufficient,

provide additional lighting.

Your FINOCAM A5 illuminates the working chamber

in different colours. The colour will change depending on the state of the machine. You will find the

colours and respective machine statuses in the following table:

3.4 Accessories container

In the accessories container below the working

chamber, you can store workpieces, tools, and the

spindle service set ready to hand.

➤ To access the accessories container, simply pull

it out of machine.

Fig. 5: Opening the accessories container

Colour Status

Green Machine is ready, front cover closed

White Machine is ready, front cover closed

Blue Machine is executing a job

Red A machine malfunction has occurred

8

Fig. 6: The open accessories container

(blanks and tools not provided)

➤ To close the accessories container, push it into

the machine until it is completely closed.

3.5 Air extraction concept

The air extraction concept consists of:

• Air that is emitted from the spindle and the

bellow

• The external air extraction system (suction

device, suction hose, optional switching unit)

• The vacuum sensor

During job execution, the machine constantly blows

air into the working chamber (➲ Fig. 7, upper arrows).

An external suction device that you connect to the

CNC machine with a suction hose extracts the

machining debris from the working chamber (➲ Fig.

7, lower arrow).

This concept decreases the soiling and wear of

sensitive machine parts.

The air extraction system does not replace the

regular cleaning of the machine. Without regular

cleaning, the machine life decreases signifi cantly.

Through the air extraction, a vacuum develops in the

working chamber which is constantly monitored by a

vacuum sensor (display in FINOCNC:

➲ chapter

4.9). If the vacuum is too weak, machining is not

possible. If the vacuum becomes too weak during a

running job, FINOCNC interrupts machining until the

vacuum is sufficient again (➲ chapter 5.7).

The current strength of the vacuum displays in

FINOCNC (➲ chapter 4.9 or in documentation for the

manufacturing software).

Page 9

Sound measurement

Measuring conditions:

• Processed material: CoCr

• Tool status: new

• Distance to sound source: 1 m

• Measurement according to ISO 3746,

engineering method 3

3.8 Technical data

Base system

• Dimensions (W/D/H):

approx. 450 x 530 x 630 mm

• Weight: approx. 91 kg

• Air pressure (min./max.): 6 bar/8 bar

• Recommended air pressure: 7 bar

• Air consumption: ca. 40 l/min at 6 bar,

approx. 50 l/min at 8 bar

• 5-axis mechanism;

positioning range (x/y/z): 165.5 x 108 x 93 mm

• Complete housing of the working chamber;

front cover with a safety contact and safety

interlock

• Vacuum sensor for monitoring the extraction

capacity

• Minimum extraction capacity: 2500 l/min

• Accessories container in drawer shape

• Working chamber lighting with different colours

to indicate the machine state

Rotary axes

• Rotation range: 360 ° (A) | ±35 ° (B)

• Exchangeable workpiece holder

Spindle

• Synchronous spindle rotating up to 60,000 RPM

• Nominal power under continuous load (S1):

300 Watts

• Maximal Power (Pmax): 500 Watts

• 4-fold bearing

• Hybrid ceramic ball bearing

• Pneumatic collet chuck ø 3 mm

• Cone cleaning and sealing air

Operating condition Maximum A-weighted

sound pressure level

Processing 71 dB(A)

All other operating

conditions (tool change,

movement of the axes

etc.)

<70 dB(A)

9

ENU

Fig. 7: Air extraction concept in the working chamber

3.6 Manufacturing software and

computer

To operate the machine, you must use a computer

running Windows®(“manufacturing computer“)

which should connect to the machine via the provided USB cable.

You can process manufacturing jobs with the manufacturing computer in 2 steps:

1. With FINOCAM you can create jobs with the

objects that you want to machine. FINOCAM

already contains all important parameters for the

different materials.

2. You can execute the jobs with the CNC software

FINOCNC. This application offers additional

maintenance and control functions for the

machine.

You must use a different computer together with

a scanner and suitable software to create 3D

models of the objects (not provided, sold by

specialist dealers).

3.7 Sound emission

The actual sound emission of the machine varies

heavily depending on the manufacturing material

and the machining conditions.

➤ If the machine is too loud, check the operating

conditions. Ensure that the workpiece is fixed

properly, check the condition of the tool and the

material in use.

➤ If loud noise cannot be avoided, wear ear pro-

tection during machining.

Page 10

10

Tool changer

• Automatic tool changer for 16 tools

• Maximum tool length: 40 mm

• Automatic tool length measurement and tool breakage monitoring via measuring key

• Compressed air monitoring for the automatic tool change

For additional information on tools see ➲ chapter 5.4.

Page 11

11

4. Installing the machine

4.1 Checking the scope of delivery

M Unpack the machine and ensure you have recei-

ved the following items:

ENU

1 1 CNC machine FINOCAM A5

2 1 spindle service set in the accessories container

3 1 power supply cord

4 1 USB cable

5 1 service unit for compressed air

6 1 torque wrench 1.5 Nm in the accessories container

7 1 drill bit (2.8 mm) for tool positions

8 1 calibration set: 1 micrometre, 3 blanks,

1 calibration tool

9 1 measuring pin

10 1 key for the emergency release of the front cover

11 1 Advanced Tool Board (ATB) in the accessories

container

12 1 pneumatic hose

13 2 tool changer inserts (as spare parts)

14 1 USB dongle

Without illustrations:

• This document

• Documentation for FINOCAM & FINOCNC

• 1 socket wrench in the accessories container

for replacing the measuring key (to be used

by the service technician)

• 4 screws for the workpiece fixation as spare

parts

➤ Please keep the machine packaging for future

transport.

4.2 Choosing the installation site

➤ The installation site must meet the following

criteria:

• Firm and even surface, must carry the weight

of the machine

• Room temperature ideally between 18° Celsius

and 25° Celsius, maximum room temperature

32° Celsius

• Machine location must be dust-free

• Relative air moisture maximum 80 %,

non-condensing

• Alternating current source with 100-240 V

and 50/60 Hz

• Compressed air supply that meets the requirements of the machine (➲ chapter 4.4)

• Sufficient space at the sides of the machine

(➲ page 10)

Page 12

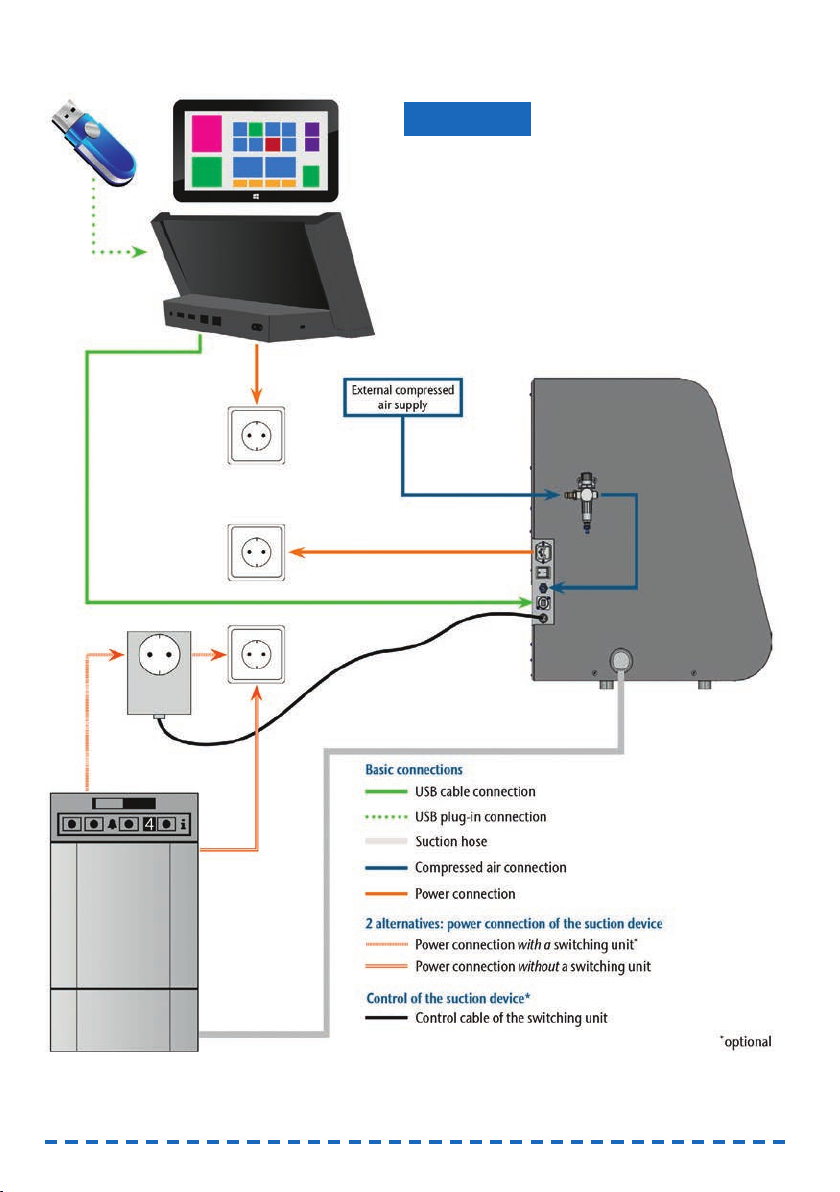

4.3 Machine installation (scheme)

12

Damage to the machine due to incorrect

installation

➤ Carry out the installation in the given order.

➤ Ensure to remove the transport lock before instal-

ling the manufacturing computer (➲ chapter 4.7).

NOTICE

Page 13

13

ENU

4.4 Installing the pneumatics

Risk of injuries through leaking compressed

air and lashing pneumatic hoses

Open or loose pneumatic connections can cause

severe injuries.

➤ Make sure that during installation and service

of the pneumatic hoses and of the service unit

compressed air is not running through the hoses

and connections.

➤ After installing the pneumatic hoses but before

running compressed air through the hoses and

connectors, check if the hoses are securely

inserted into the correct connectors and are not

damaged.

➤ Do not run compressed air through damaged

hoses and connectors.

The spindle may suffer bearing damage and

electrical damage if the compressed air is

contaminated

The incoming compressed air must be dry and oil-

free according to ISO 8573-1 because the service

unit only serves as an indicator for contaminated

air.

Air purity according to ISO 8573-1

Solid particles, Class 3,

Filtration degree better than 5 µm for solid particles

Water content, Class 4,

Maximum pressure dew point +3 °C

Residual oil content, Class 3,

Maximum oil content: 1 mg/m

3

➤ Ensure that the compressed air meets the above

requirements.

➤ Connect the machine to the compressed air

supply only via the provided service unit.

The spindle requires compressed air for the

following tasks:

• For the opening and closing of the collet chuck

during tool change.

• For the sealing air which prevents foreign bodies

from entering the spindle.

Air consumption of the machine:

• approx. 40 l/min at 6 bar

• approx. 50 l/min at 8 bar

WARNING

NOTICE

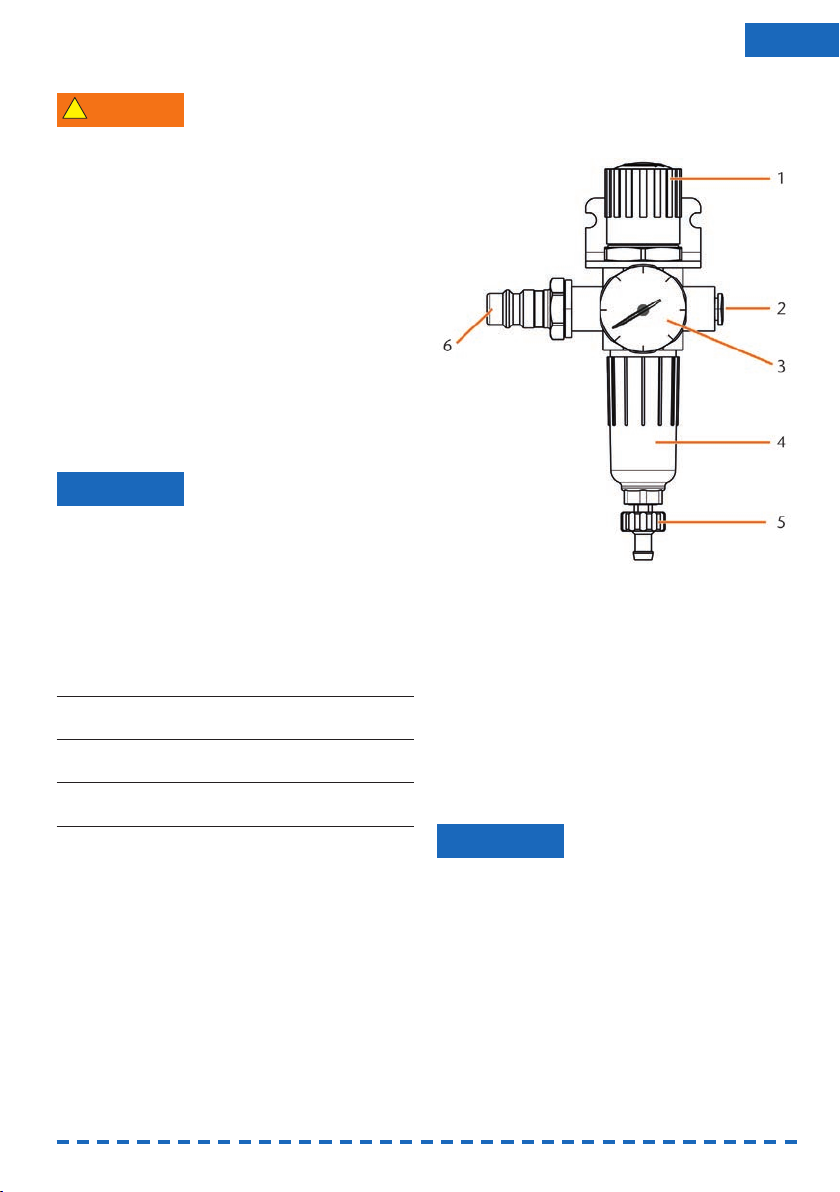

4.4.1 Overview service unit

Via the service unit you connect the CNC machine to

your compressed air supply and regulate the incoming pressure for the machine.

Fig. 8: The service unit:

Regulation and checking the air pressure

1 Rotary knob for pressure regulation

2 Pneumatic connection to the machine (ø 6 mm)

3 Manometer for monitoring the outgoing pressure

4 Water separator

5 Discharging screw

6 Pneumatic connection for external

compressed air supply

4.4.2 Mounting the service unit

on the CNC machine

Failure of the water separator caused by a

wrong alignment of the service unit

The service unit must always be mounted in an

upright position because otherwise the water

separator will not work.

➤ Mount the service unit in an upright position

(➲ Fig. 8). On the left side of the CNC machine

are two drilled holes which you can use to mount

the service unit on the machine.

NOTICE

!

Page 14

14

M1. Remove the two blind screws in the drilled holes.

M2. Mount the service units with the provided lens

head screws in an upright position.

Fig. 9: Mounting the service unit on the machine

4.4.3 Installing the pneumatic hoses

to the service unit

Fig. 10: Installation of the service unit (scheme)

M1. Close the external compressed air supply valve.

M2. Use the provided pneumatic hose to connect the

right pneumatic connection of the service unit

[Fig. 8, 2] with the pneumatic connection of the

machine.

M3. Connect the external compressed air supply with

the left pneumatic connection of the service unit

[Fig. 8, 6].

M4. Check the installation carefully for errors and

damage. Do not run compressed air through

damaged or loose hoses and connections!

M5. Open the external compressed air supply.

M6.Check the air pressure on the manometer

[Fig. 8, 3]. If it does not lie between 6 bar and

8 bar, adjust it with the service unit (➲ chapter

4.4.4)

4.4.4 Adjusting the air pressure with

the service unit

Setting the air pressure is only necessary if the air

pressure shown by the manometer does not lie

between 6 bar and 8 bar.

M1. Check if the service unit is correctly connected

to the machine and the compressed air supply

(➲ chapter 4.4.2 onwards).

M2. Pull the rotary knob on top of the service unit

slightly upwards.

M3. Turn the rotary knob in the desired direction until

the pressure lies between 6 bar and 8 bar

(recommended: 7 bar):

• Turning it towards “+“ you increase the

pressure

• Turning it towards “–“ you decrease it

M4. Push the rotary knob down again.

➡ The knob is locked and cannot be changed

inadvertently.

Fig. 11: Setting the air pressure

4.5 Installing the air extraction system

How the air extraction system works:

➲ chapter 3.5

Available components of the air extraction system:

• Suction device including suction hose

•

Switching unit for switching the suction device

on and off via the CNC machine

• Hose connection for suction hose: if the suction

hose does not fit into the machine

Which components are required and how you can

combine them is listed in the following table.

Page 15

You obtain the switching unit via customer service if

necessary.

4.5.1 Requirements for the suction

device

➤ Use a suction device with the following

properties

only:

• Designed for the commercial use in the

dental sector

• Equipped with a filter of the filter class M

• Suitable for the operating site of the CNC

machine

• Equipped with safety devices which protect

you from static discharges (e. g. through an

anti-static suction hose)

• Minimum extraction capacity: 2500 l/min

4.5.2 Absauggerät anschließen

➤ Before the installation of the suction device read

the documentation for the device and have the

documentation always ready at hand.

M1. Check if the connection of the suction hose has

an outer diameter of 45 mm. If the diameter is

different, use the optional hose connection

(➲ chapter 4.5.3.)

M2. Insert the suction hose of the suction device into

the opening for the air extraction of the CNC

machine. Make sure that the suction hose is

firmly connected.

Fig. 12: Inserting the suction hose into the machine

Component Source Required? Prerequisite

Suction device Customer service,

specialist dealers

Yes –

Switching device Customer

service

Nein –

Hose connection Customer

service

If the suction

hose does

not fit

Ask customer

service

M3. If you want the machine to automatically switch

the suction device on and off, install the

switching unit (➲ chapter 4.5.4. If you require a

switching unit, contact customer service.

M4. Continue with the installation of the suction devi-

ce as described in the documentation for the

device.

4.5.3 Connecting the suction hose with

the optional hose connection

If you can connect the suction hose of your

suction device directly to the CNC machine, you

do not need the hose connection.

M1. Obtain the hose connection via customer ser-

vice.

M2. Turn the thread of the hose connection counter-

clockwise until the connection is completely

open. If the thread gets detached from the hose

connection, place it onto the connection again

and turn it clockwise once so that it is screwed

to the connection again.

M3.

Insert the suction hose of the suction device

completely into the hose connection on the side

of the thread.

Abb. 13: Inserting the suction hose

into the hose connection

M4. Turn the thread of the hose connector clockwise

up to the stop.

➡ The suction hose is firmly attached to the hose

connection.

M5. Insert the hose connection into the opening for

the air extraction system of the machine. Ensure

it is firmly connected.

15

ENU

Page 16

Fig. 14: Inserting the hose connection into

the opening for the air extraction system

➡ The installation of the suction hose with the

optional hose connection is complete.

4.5.4 Installing the switching unit

M1. Connect the power cable of the suction device to

the switching unit.

M2. Connect the control cable of the switching unit

to the switching output at the connection panel

of the CNC machine.

M3. Plug the switching unit into a power socket.

Fig. 15: Connecting the switching unit to

the suction device and the machine

4.6 Establishing the electric connection

Damaging of the machine through heavy

voltage fluctuations

Heavy voltage fluctuations can disrupt the control

unit and can cause system failure.

➤ Plug the machine’s power cord in a dedicated

circuit current or ensure that no devices are

conn ected that can cause heavy voltage fluctuation when switched on.

NOTICE

Damaging of the machine if the transport lock

and the manufacturing computer are installed

When you connect the machine to the electrical

source and the manufacturing computer is connected, the machine starts referencing. During this

process, the transport lock which is installed at delivery can damage the mechanics of the machine.

➤ Do not connect the machine to the electrical

source if the manufacturing computer and the

transport lock are installed.

➤ If the transport lock is installed, disconnect the

USB connector between the machine and the

manufacturing computer before connecting the

machine to the electrical source.

M1. Plug the provided power cord into the power

connection at the connection panel of the CNC

machine.

M2. Put the plug of the cord into a socket that is pro-

tected by a Residual Current Device/Ground

Fault Circuit Interrupter.

4.7 Removing the transport lock

Before operating the machine for the first time, you

must remove the transport lock. The transport lock

prevents the spindle from getting damaged during

transport.

M1. Disconnect the USB connector between the ma -

chine and the manufacturing computer.

M2. Connect the machine to the electrical source.

M3. Switch on the machine via the main power

switch.

Fig. 16: Turning on the main power switch

M4. Open the front cover.

NOTICE

16

Page 17

Fig. 17: Removing the transport lock

1 Upper part of the transport lock

2 Bottom part of the transport lock

M5. Carefully pull the bottom part of the transport

lock (2) towards you and out of the working

chamber.

M6. Carefully lift the upper part of the transport lock

(1) out of the workpiece holder. Pull it towards

you and out of the working chamber.

M7. Clean the working chamber from parts of the

transport lock that may have broken off.

M8. Store the transport lock safely to use it for future

transports.

4.8 Connecting the manufacturing

computer

The transport lock must not be installed when

you connect the manufacturing computer to the

machine (➲ chapter 4.7).

M1. Switch on the machine.

M2. Close the front cover.

M3.

Start the manufacturing computer.

M4. Use the provided USB cable to connect a USB

port of your computer or docking station with

the connection panel of your CNC machine.

M5. Insert the dongle into a USB port of the manu-

facturing computer or docking station.

S6. Install the newest version of FINOCAM and

FINOCNC that is released for the machine. For

more information on this, read the documenta -

tion for the applications.

S7. Start FINOCNC and click on the de -

picted icon in the icon bar.

S8. Click on the depicted icon in the lower

icon bar.

➡ The application settings view displays.

S9. Click on the depicted icon beside the

text Port number.

➡ FINOCNC will try to establish a connection to the

CNC machine. If this is successful, the application will display the port number beside the icon

and the machine references.

The machine will not reference if the front cover

is open.

M10.If the front cover was open at step S9, close it. If

the machine does not reference as a result, quit

FINOCNC and restart the application.

M11.If FINOCNC did not determine the port number,

read how to determine the port number manually

in the documentation for the application.

4.9 Testing the machine

After the first installation or after a re-installation, for

example after a transport, you should test the basic

functions of the machine.

M1. Switch on the machine.

M2. Close the front cover.

➡ The machine starts up. The working chamber is

illuminated in white.

M3. Open the compressed air supply valve.

S4. Start the manufacturing computer and start

FINOCNC.

➡ The machine will reference and the working

chamber will illuminate in green. The machine is

now in

default position

.

S5. In the upper icon bar, click on the

depicted icon.

M6. Switch on the suction device and select the

necessary extraction level.

S7. If the machine controls the suction

device via a switching unit, click on the

depicted icon.

➡ The suction device is operating and a vacuum

develops in the working chamber.

M8. With the value bars and icons depicted below,

verify that the compressed air and the vacuum in

the working chamber are sufficient.

17

ENU

Page 18

18

➡ The icons display in blue when the compressed

air and the vacuum are sufficient.

Fig. 18: Top: Value bar and icon for compressed air

Bottom: Value bar and icon for the vacuum

S9. Move the spindle to the cleaning posi-

tion by clicking on the depicted icon.

➡ The spindle should move through the working

chamber at constant speed.

S10. Move the spindle from the cleaning

position back to the default position by

clicking on the depicted icon.

➡ The spindle moves to the default position at

constant speed.

S11. If the machine controls the suction devi-

ce, click on the depicted icon.

M12.If you control the suction device manually,

switch it off. The suction device stops operating.

M13.Open and close the front cover.

➡ The front cover can be opened and closed

easily.

M14.If a result did not occur as described, check the

following depending on the error:

• The USB connection & USB driver installation

(➲ chapter 4.8 & documentation for the manu-

facturing software)

• The compressed air supply (➲ chapter 4.4)

• The set extraction capacity of the suction device

• The installation of the air extraction system

(➲ chapter 4.5)

M15.If you cannot solve a problem that occurred,

contact customer service.

5. Running the machine

5.1 Starting up the machine

M1. Close the front cover.

M2. Switch on the machine and the manufacturing

computer.

➡ The machine and manufacturing computer start

up. When the machine has started up, the working chamber is illuminated in white.

M3. If machine controls the suction device, switch on

the device and select the necessary extraction

level.

➡ The suction device is not running.

If you control your suction device manually, you

switch on the device immediately before job

execution.

S4. Start FINOCNC.

➡ The machine references. Afterwards the working

chamber is illuminated in green. The machine is

now ready for use.

The machine will not reference if the front cover

is open.

M5. If the working chamber is illuminated in red,

switch the machine off and on again. If the wor-

king chamber is still illuminated in red, contact

customer service.

M6. If the front cover was open at step S4, close it.

S7.

If the machine does not reference as a result,

quit FINOCNC and restart the application.

5.2 Job execution overview

Damaging of the machine when using

damaged tools or workpieces

If tools or workpieces are damaged, parts can break

off and damage the machine during job execution.

➤ Check the workpieces and tools thoroughly for

damage before every job execution.

Carrying out a typical job with the FINOCAM A5 is as

follows:

1. Create a job in FINOCAM

2. Insert the tools into the machine

3. Insert the workpieces into the machine

4. Execute the job in FINOCNC

The steps in the manufacturing software are described in the corresponding documentation. The following text describes how to perform manual work with

the CNC machine.

NOTICE

Page 19

19

ENU

5.3 Inserting/changing tools

Damaging of the spindle or the tool positions

if you use improper tools

Improper tools can damage the collet chuck of the

spindle and/or the tool positions.

➤ Only use tools with a sufficiently large chamfer

at the tool shank.

➤ Install a retaining ring as a stop ring according to

DIN 471-A3.

➤ Only insert tools with a maximum diameter of

3 mm at the thickest part into the collet chuck.

➤ Only insert tools with a maximum cutting edge

diameter of 2.6 mm into the tool changer.

We recommend original tools as they are desig-

ned especially for the designated jobs.

You can insert up to 16 tools into the tool changer.

The machine can change tools automatically during

machining so that it executes jobs without your interference.

Fig. 19: Tool changer positions in the working chamber of

the machine (marked orange)

You can equip the tool changer in two ways:

• Via the spindle – you insert a tool into the collet

chuck and the spindle will deposit the tool in the

tool changer. This function is described in the

documentation for the manufacturing software.

• By inserting the tools into the tool changer

manually. This is described below.

You insert the tools manually as follows:

S1. Start FINOCNC.

S2. Call up the job execution view and select the job

that you want to execute from the job list.

➡ FINOCNC displays the tools that are assigned to

the job in the lower part of the application win -

dow.

M3. Open the front cover.

NOTICE

M4. Insert the tools into the tool positions of the tool

changer:

• Insert the tools straight into the tool positions

and push them in until the ring touches the

rubber (➲ Fig. 20).

• The positions of the tools in the tool changer

must match the tool positions in FINOCNC

(➲ Fig. 21).

If the positions of the tools in the tool changer

do not match the tool positions in FINOCNC, the

machine will use the wrong tool(s) during job

execution and the job result will become unusable.

Fig. 20: Inserting tools straight into the tool position

Page 20

Fig. 21: Top: tool positions 1 – 16 in the tool changer

Bottom: tool positions 1 – 16 in FINOCNC

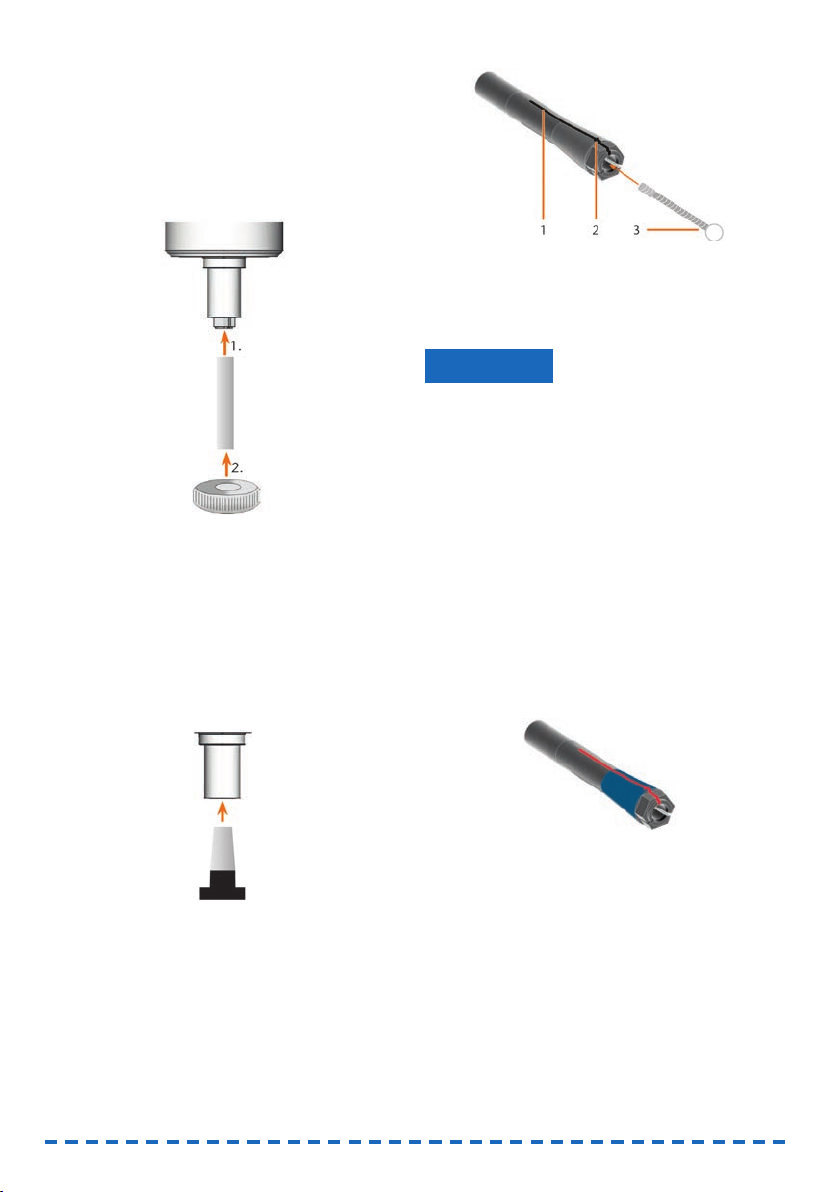

5.4 Inserting and removing workpieces

On delivery, your FINOCAM A5 processes blanks

with a diameter of 98.5 mm.

5.4.1 Inserting blanks

You put blanks into the workpiece holder and immobilize them with a fixing disc.

Fig. 22: The fixing disc (blue) is attached to the workpiece

holder (grey) with 4 screws (orange)

M1. Open the front cover.

M2. Unscrew the 4 screws which attach the fixing

disc to the workpiece holder.

M3. Remove the fixing disc and the blank in the

workpiece holder (if any).

M4. Place the blank into the workpiece holder.

Fig. 23: Placing the blank into the workpiece holder

M5. Place the fixing disc onto the workpiece holder

on top of the blank.

20

Page 21

21

ENU

M6. Screw down the fixing disc with the screws you

unscrewed in step M2.

Tighten the screws firmly. If workpieces move

or vibrate during processing, the result may

become unusable.

Fig. 24: Attaching the blank with the fixing disc

5.4.2 Removing blanks

M To remove a blank, unscrew the 4 screws of the

fixing disc and remove the fixing disc and the

blank.

5.4.3 Mounting the FINOCAM block

holder

You can obtain the optional FINOCAM block

holder via customer service.

The FINOCAM block holder allows you to grind workpieces in block shape with your FINOCAM A5. You

can attach the FINOCAM block holder to the built-in

workpiece holder and then secure the blocks into the

block holder.

Fig. 24: The FINOCAM block holder for the FINOCAM A5

1 Positioning aid for the FINOCAM block holder

2 Positioning pins for blocks

3 Drilled holes for inserting blocks

4 Fixing pins for blocks

M1. Open the front cover.

M2. Remove the fixing disc and blank from the wor-

king chamber (➲ chapter 5.4.1, page 21).

M3. Place the FINOCAM block holder so that the 2

positioning aids (1) lie in the

left

outer roundings

of the workpiece holder (➲ Fig. 25). Hold the

FINOCAM block holder in place with one hand.

Fig. 25: Positioning the FINOCAM block holder

Page 22

M3. Insert the shaft of the block into the desired

position in the FINOCAM block holder until it is

completely and firmly seated.

M4. Fixate the block with the corresponding fixing

pin. Tighten the pin firmly.

Fig. 28: Inserting blocks into the FINOCAM block holder

5.5 Executing jobs

Do not move the machine during job execution,

otherwise the results may become imprecise.

M1. Make sure that the following requirements are

met before job execution:

• You created the job that you want to execute in

FINOCAM and transferred it to FINOCNC.

•

All required tools are assigned to the job in

FINOCNC.

• The required tools are in the right positions in

the tool changer of the machine.

• All required workpieces of the correct material

are inserted.

• The compressed air supply is set correctly.

M2. Close the front cover.

M3. Switch on the suction device and set it to the

required level.

S4. Start the job execution in FINOCNC.

➡ The CNC machine begins with the job execution.

The working chamber is illuminated in blue.

5.6 Interrupting the job execution

S Click on the depicted icon to interrupt

the job execution. The icon only displays during job operation.

22

M4. With the other hand, lay the fixing disc above the

FINOCAM block holder into the workpiece holder

and screw it down with the provided torque

wrench.

➡ The FINOCAM block holder is ready for use.

Fig. 26: Immobilizing the FINOCAM block holder

with the fixing disc

5.4.4 Attaching blocks into the

FINOCAM block holder

You can attach up to 3 blocks with round shafts into

the FINOCAM block holder.

The material, number and position of the blocks

must correspond to the job in DentalCAM.

M1. Loosen the fixing pins at the position where you

want to insert the blocks.

M2. Position the block so that the positioning pin at

the FINOCAM block holder lies in the groove in

the block shaft.

Fig. 27: Positioning pin (left marking) must lie

in the groove in the shaft (right marking)

Page 23

5.7.3 How to proceed in case of a tool

breakage

If a tool breaks during machining, the machine will

not recognize this immediately and the spindle will

continue until the next tool change. Only upon measuring the broken tool will the job execution be cancelled and FINOCNC will display a corresponding

message.

A tool breakage can be caused by the following:

• The tool was damaged or worn.

• The tool was put into the wrong tool changer

position or was inserted into the spindle manually at the wrong time. As a consequence, it was

not suitable for the processing step.

• The distribution of the objects in the workpiece

(“nesting”) was not sufficiently adapted to the

material.

M1. Open the front cover.

M2. Remove all parts of the broken tool from the

working chamber.

M3. If the spindle picked up the tool from the tool

changer, check if the tool was inserted into the

correct position. Insert a spare tool into the correct position in the tool changer (➲ chapter 5.3).

M4. If you inserted the tool into the collet chuck

manually, check if the broken tool corresponds

to the initial tool type in which FINOCNC prompted. Have a correct spare tool ready.

M5. Close the front cover and execute the job again.

If tools break regularly, you can find additional

information in the chapter on troubleshooting

(➲ chapter 8).

23

ENU

5.7 Operation interruption or abortion

of job execution

An operation interruption can occur because the

compressed air supply or the vacuum in the working

chamber is not sufficient. An

interrupted

job will

normally be resumed automatically after the error is

corrected.

The job execution is

aborted

in the following cases:

• In case of a machine malfunction

• In case of a tool breakage

• In case of a power failure

If a job was

aborted

, you have to execute it again in

FINOCNC.

5.7.1 How to proceed in case of

an operation interruption

If the job execution was interrupted, FINOCNC

displays a corresponding message.

M1. If FINOCNC prompts that the compressed air is

insufficient, check the following:

• The manometer of the service unit

The installation of the pneumatic hoses

• Your compressor

M2. If FINOCNC prompts that the vacuum in the wor-

king chamber is insufficient, check the suc tion

hose and your suction device.

You will find additional information in the chapter

on troubleshooting (➲ chapter 8).

5.7.2 How to proceed in case of a

machine malfunction

A machine malfunction is recognized by the internal

control unit in case of a critical event. The working

chamber will be illuminated in red. FINOCNC

displays the error message and error code that was

sent by the control unit.

M1. Disconnect the machine from the electrical

source and prevent it from being restarted.

M2. Record the error message and error code that is

displayed in FINOCNC.

M3.Contact customer service. Have the error

message and error code from FINOCNC readily

available.

M4.To remove a workpiece from the working

chamber, unlock the front cover with the key for

emergency release (➲ chapter 5.8).

Page 24

5.7.4 Procedure in case of a power

failure

As long as the machine is not powered, the front

cover will remain locked.

➤ After a short power failure turn on the machine

again and follow the on-screen prompts so that

the machine can reference.

➤ In case of a longer power failure use the provi-

ded key for the emergency release of the front

cover.

5.8 Not-Entriegelung der Frontklappe

➤ Only use the emergency release of the front

cover to remove a workpiece from the working

chamber if the front cover is permanently locked.

Crushing hazard and cutting injuries while

running the machine with the front cover open

If the safety lock is not reactivated after the emergency release, the user will be able to operate the

machine with the front cover open. In this case the

front cover will not protect the user from bruises

caused by machine movements and from cutting

injuries caused by the rotating tool.

➤ Activate the safety interlock immediately after

completing your work in the working chamber.

➤ Never operate the machine with the front cover

open. h Perform the emergency release only if

you are authorised to do so and if you have

received training on its usage.

➤ Store the key for the emergency release in a

place where only authorised persons can access

it.

➤ Report every emergency release to customer

service.

Cutting injuries when touching a rotating tool

If a power failure or a machine malfunction occurs

during processing, the spindle including the inserted

tool keeps rotating. If you touch the rotating tool,

you will suffer from cutting injuries.

➤ Wait until the spindle has stopped rotating befo-

re carrying out an emergency release.

There is an opening for the emergency release at the

right side of the machine.

WARNING

CAUTION

Fig. 25: Opening for the emergency release

M1. Switch off the machine at the main power switch

and disconnect the machine from any electrical

source and the compressed air supply.

M2. Remove the protective cap from the emergency

release opening (➲ Fig. 26, top).

M3. Insert the key for the emergency release of the

front cover through the opening (➲ Fig. 26,

middle).

M4. Deactivate the safety interlock of the front cover

by turning the key counter-clockwise by 90°

(➲ Fig. 26, bottom).

➡ You can open the front cover.

M5. Carry out your work in the working chamber.

M6. Close the front cover.

M7. Reactivate the safety interlock of the front cover

by turning the key for the emergency release

clockwise by 90° (➲ Fig. 26, bottom).

M8. Check if the front cover actually is locked.

➡ If you can still open the front cover, repeat the

steps M6–M8.

24

!

!

Page 25

Fig. 26: Using the key for the emergency release

Top: Remove cap

Middle: Insert key

Bottom: Turn the key

M9. Close the opening for the emergency release

again with the protective cap.

6. Machine maintenance and cleaning

6.1 Definition of wear parts

The CNC machine and the extra equipment are warranted for a period of 24 months or 2000 operating

hours, whatever comes first. The warranty covers

defects in materials or fabrication as long as the

regulations for using the machine in all documents

are followed.

Of course, the warranty also covers wear parts as

long as their failure cannot be attributed to the

function-related abrasion. The wear parts that are

mentioned below can already wear down within the

warranty period due to their normal function. The

average useful life of the wear parts can be seen in

the following table.

Use these values to determine operating costs, to

plan your spare part stock as well as to create individual maintenance and service plans.

25

ENU

Page 26

26

6.2 Maintenance table

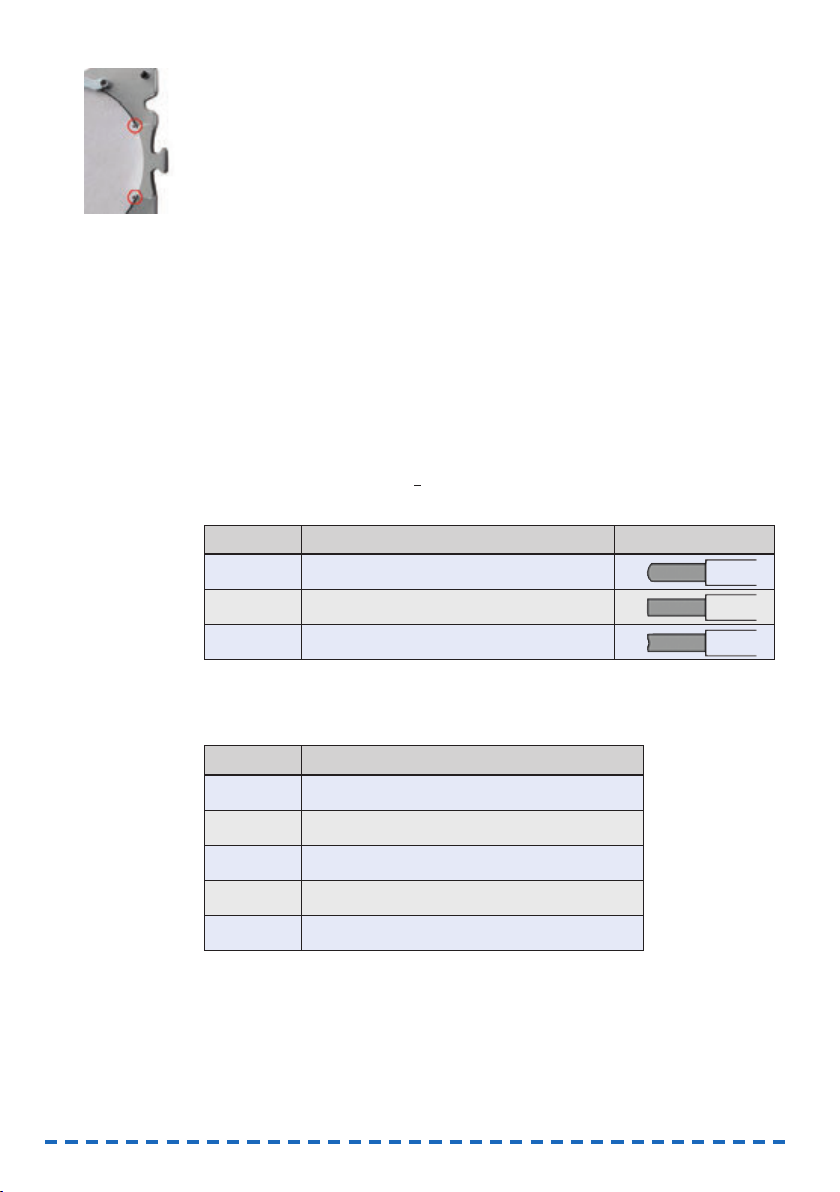

Task Recommended interval Procedure/Parts Spare part illustration

Cleaning the working

chamber & the measuring

key (➲ chapter 6.4)

Cleaning the collet chuck

(➲ chapter 6.5)

Checking the hoses,

cables & connections

(➲ chapter 6.6)

Cleaning the housing &

accessories container

(➲ chapter 6.7)

Service unit:

a) Checking for

contamination

b) Cleaning/exchanging

the filter cartridge

(➲ chapter 6.8)

Exchanging the main fuse

(➲ chapter 6.9)

Calibrating the axes

(➲ chapter 6.10)

Inspection by a service

technician (➲ chapter 6.3)

Wear parts

Exchanging wear parts

Exchanging the tool

changer inserts

(➲ chapter 6.11)

Exchanging the collet chuck

Exchanging the spindle

bearings (requires spindle

exchange by service

technician)

1 x per day, more often if the

chamber is very dirty

1 x per week, in case of

rotational imperfections,

in case of bad machining

results

1x per week

As necessary

a) Necessarily every day

b) In case of visible contami-

nation or every 2 years

In case of a defective fuse

in the power supply of the

machine

Only if necessary

After 2000 operating hours*

or every 2 years*

Average useful life

After 500 operating hours*

After 1000 operating hours*

After 2000 operating hours*

or every 2 years*

Vacuum cleaner, brush,

dry cloth, never use

compressed air

Spindle service set

Visual inspection

Cloth, water,

possibly a mild cleaner

A new filter cartridge

if necessary

Replacement fuse of the

type T6,3A L250V

Calibration specimen,

micrometre, calibration tool

Procedure/Parts

Replacement inserts,

drill for drilling the tool

positions, screwdriver

Performed by service

technician

* These are recommendation guidelines. Depending on the processing material and how well the machine is cleaned, these values may differ.

Spare part illustration

Page 27

6.3 Inspection

We recommend having a service technician perform

an inspection regularly.

➤ In addition, have an inspection carried out when -

ever the machine is being repaired.

6.4 Cleaning the working chamber and

measuring key

Breathing difficulties caused by processing

dust

Processing dust that gets into your lungs can cause

breathing difficulties.

➤ Clean the machine only if the air extraction

system is properly installed and activated.

➤ Wear a face mask of class FFP2 during the entire

cleaning.

Damaging of the linear guides or the spindle

when cleaning with compressed air

If you clean the working chamber with compressed

air, material chips can reach the linear guides or the

spindle bearings.

➤ Clean the interior of the machine exclusively

with a vacuum cleaner, a brush and a cloth and

never with compressed air.

M1. Have ready:

• A vacuum cleaner

•A

dry

cloth

•A

mild

cleaner (optional)

• A wet brush

M2. Switch on the machine and start FINOCNC.

S3. In the upper icon bar, click on the

depicted icon.

S4. Move the spindle to the cleaning posi-

tion by clicking on the depicted icon.

➡ The spindle will move to the cleaning position

and the sealing air will be activated.

M5. Open the front cover.

M6. Suck up the coarse dirt in the working chamber

with the vacuum cleaner.

M7. Clean the whole interior thoroughly with the dry

cloth. Use a mild cleaner if necessary.

CAUTION

NOTICE

M8. Thoroughly clean the workpiece holder including

all screws, pins and clamping mechanisms as

well as all openings from the processing dust.

M9. Clean the measuring key with a brush.

Fig. 27: Measuring key on top of the tool changer

(marked orange)

M10.Close the front cover of the machine.

S11. Move the spindle from the cleaning

po si tion back to the default position by

clicking the depicted icon.

6.5 Cleaning the collet chuck

Damaging of the spindle when cleaning with

compressed air

If you clean the collet chuck with compressed air, the

spindle bearings may get damaged.

➤ Clean the collet chuck exclusively with the

appropriate service set.

Fig. 28: Components of the spindle service set

1 Collet grease

2 Cleaning brush

3 Knurled nut

4 Cleaning cone

NOTICE

27

ENU

!

Page 28

M1. Close the front cover of the machine.

S2. Open the collet chuck with the “Release tool”

function of FINOCNC and remove the tool from

the spindle if necessary.

M3. Insert the measuring pin into the collet chuck

and keep holding it with one hand. With the

other hand put the knurled nut to the spindle.

Fig. 29: Unscrewing the collet chuck

M4. Loosen the collet chuck with the knurled nut and

unscrew the collet chuck with your hand or with

the knurled nut.

M5.Remove the measuring pin from the collet

chuck. Then put it aside within reach together

with the knurled nut.

M6. Clean the inner cone of the spindle with the

cleaning cone of the service set.

Fig. 30: Cleaning the inner cone of the spindle

M7. Clean the collet chuck with the brush of the

service set. Make sure that the 3 buffers in the

collet chuck do not fall out during cleaning.

Fig. 31: Cleaning the collet chuck

1 Longitudinal slot

2 Buffer

3 Cleaning brush

Damaging of the spindle when using the wrong

grease or applying the grease in a wrong way

If you use grease that is unsuitable for the spindle or

if grease gets into the longitudinal slots of the collet

chuck, the spindle may get damaged.

➤ Ensure that no grease gets into the longitudinal

slots of the collet chuck.

➤ Only use a very small, about pinhead-size

amount of the grease.

➤ Only use the provided collet grease of the ser-

vice set.

M8. Put a small amount of the collet grease on the

index finger and smear it with the thumb.

M9. Apply the smeared collet grease to the flanks of

the collet chuck.

Fig. 32: Greasing the collet chuck; surface to grease is

marked in blue; Slot that may not be greased is

marked in red

M10.Insert the measuring pin into the collet chuck

with one hand and keep holding it. Screw the

collet chuck with the knurled nut in your other

hand

tightly

into the spindle.

In any case, turn the knurled nut up to the stop

so that the collet chuck is properly seated in the

spindle. Otherwise rotational imperfections can

occur during operation which will worsen your

processing results.

NOTICE

28

Page 29

29

ENU

M11.Remove the measuring pin from the collet chuck

and store it together with the other components

of the spindle service set.

M12.Close the front cover.

6.6 Checking the hoses, cables and

connections

M1. Disconnect the machine from the electrical sour-

ce and the compressed air supply.

M2. Check the hoses and cables that are connected

to the machine.

M3. In case of damages prevent the machine from

being restarted. Replace the damaged cables

and hoses immediately with original replace-

ment cables. Contact customer service.

M4. Verify all connections on the connection panel

(e.g. loose connections).

M5. Re-insert loose cables and hoses tightly into the

corresponding connections. In case of damaged

connections cease use of the machine immedia-

tely. Contact customer service.

6.7 Cleaning the housing

Damaging of the housing when using

a nonrecommended cleaner

If you use an unsuitable cleaner for cleaning the

machine housing, the surface or the adhesive foil can

get damaged.

➤ Avoid contact of the powder coating with alkaline

or acid substances. Especially metallic powders

show a highly sensitive reaction.

➤ Take care of the glued symbols so that they do

not peel off. The adhesive foil is especially sensi-

tive to rubbing and strong detergents.

➤ If the usage of a special cleaner is necessary to

eliminate certain dirt, we recommend checking

the suitability of the cleaner at a hidden place of

the part first.

M1. First, clean the powder coated surface with a

soft, dry cloth.

M2. If some dirt cannot be removed this way, moisten

the cloth. Use a pH neutral cleaner if necessary.

NOTICE

6.8 Checking the service unit

Damaging of the machine when compressed

air is contaminated

Compressed air that does not fulfil the guidelines for

purity according to ISO 8573-1 can damage the

machine.

➤ Check the water separator of the service unit

daily for contamination.

➤ Never use the machine if there is water, oil or

solid particles in the water separator.

6.8.1 Checking the water separator for

condensate

Condensate in the separator usually points to compressed air not being dry enough.

M1. Check if water, oil or solid particles piled up in

the water separator.

➡ In this case switch the machine off immediately

and proceed as follows:

M2. Check the compressed air supply and make sure

that the compressed air fulfils the requirements

for air purity according to ISO 8573-1. Do not use

the machine until the compressed air fulfils this

requirement!

M3. Drain the water separator by turning the dischar-

ging screw counter-clockwise.

➡ The condensate is blown out downwards under

pressure.

M4. Close the discharging screw again by turning it

clockwise.

Fig. 33: Opening/closing the discharging screw

at the service unit

NOTICE

Page 30

M4. Remove the defective fuse and replace it with a

new fuse of the type T6,3A L250V.

If you do not have a replacement fuse ready,

take the replacement fuse from the right side of

the fuse cover and put it into the left side of the

fuse cover.

M5. Remount the fuse cover.

6.10 Calibrating the axes

Deterioration of machining results caused by

an incorrect calibration

The machine is already calibrated at delivery. As

long as your machining results are without flaw, a

new calibration is not necessary. A calibration takes

much time and can deteriorate the machining results

in the worst case if it is not done correctly.

➤ In case of inaccurate machining results, try

adjusting the working conditions first: check the

fixation of the workpiece, the state of the tool or

of the processing material.

➤ Before calibrating the machine, contact custo-

mer service.

➤ Be very careful when measuring and entering

data during calibration. When in doubt, stop the

calibration.

With test and calibration specimens you can measure and, if possible, improve the machining results of

the CNC machine

The documentation for the manufacturing soft-

ware contains all information on calibrating the

machine. Therefore, you will only find infor mation specific to the FINOCAM A5 in this document.

Your FINOCAM A5 is delivered with a calibration set.

It contains the following parts:

•

Calibration blanks which you use

to mill calibration and test specimens

•

A tool for milling the calibration or

test specimens

• A micrometre for measuring the

machining precision

NOTICE

30

6.8.2 Exchanging/cleaning the

contaminated filter cartridge

You have to clean or exchange the filter cartridge in

the water separator in case of strong contamination.

A strongly contaminated cartridge can lead to a

pressure loss.

If the compressed air fulfils the requirements for air

purity according to ISO 8573-1, the filter cartridge

usually does not have to be changed.

➤ If the filter cartridge is contaminated, check the

purity of your compressed air.

You exchange or clean the filter cartridge as

follows:

M1. Disconnect the machine from the compressed

air supply.

M2.

Unscrew the bowl of the water separator.

M3. Untighten the filter screw below the filter cart -

ridge.

M4. Pull out the filter cartridge and clean it if neces-

sary.

A new filter cartridge is available as spare part

from customer service.

M5. Insert the new or cleaned filter cartridge and

reassemble the water separator.

6.9 Exchanging the main fuse

Only use fuse type T6,3A L250V as a replace-

ment fuse.

The internal power supply of the FINOCAM A5 has a

main fuse that is accessible from the outside and

can be replaced if necessary.

A new main fuse is available as spare part from

customer service.

M1. Turn off the machine at the main power switch

and dis- connect the machine from any electrical

source and the compressed air supply.

M2. Remove the power cord from the connection

panel.

M3.

Remove the cover of the fuse.

Fig. 34: Cover of the fuse (marked orange)

Page 31

31

ENU

Tool breakage or incorrect results caused by

loose screws

If the workpiece is screwed into the workpiece holder

too loosely, the measurement results may become

incorrect or the tool may break during calibration.

➤ Tighten the screws of the fixing disc firmly.

M1. Insert a calibration blank into the workpiece

holder.

S2. Mill the calibration/test specimen as described

in the documentation for the manufacturing

software.

➡ After milling the calibration/test specimen looks

as follows:

Fig. 35: A milled calibration/test specimen

for the FINOCAM A5

M3. Remove the calibration/test specimen from the

machine.

S4. Follow the instructions on calibration in the

documentation for the manufacturing software.

M5. After the calibration, remove the calibration tool

from the machine and keep all parts of the

calibration set for further use.

6.11 Replacing the tool changer inserts

When the tool changer inserts are worn, they should

be replaced. Afterwards you must drill the tool positions into the new inserts with the CNC machine.

• Your CNC machine comes with tool changer

inserts as spare parts and with the drill tool.

• Additional inserts and drill tools are available via

customer service.

NOTICE

➤ Always replace

both

inserts together even if only

one of the inserts is worn. The machine will

always drill the tool positions for

both

inserts.

The documentation for the manufacturing

software contains step-by-step instructions for

drilling the inserts. Below you find a description

of how to replace the tool changer inserts in the

machine.

M1.

Have 2 tool changer inserts ready as spare

parts.

M2. Open the front cover.

M3.

Remove all tools from the tool changer.

M4. Loosen the 4 screws on the upper side of the

tool changer and lift the cover (➲ Fig. 36).

M5. Remove the 2 existing tool changer inserts and

replace them with 2 new ones (➲ Fig. 37).

M6. Put the cover back onto the tool changer and

screw it down with the screws that you untightened in step M4.

S7. Follow the instructions in the documentation for

the manufacturing software and drill the tool

positions in the new inserts.

Fig. 36: Loosening the screws and lifting the cover

Page 32

Fig. 37: New tool changer inserts (right, without drill

positions) replace old inserts (left, with drill positions)

7. Disposal

We will dispose of the machine at no cost. The owner

will bear the costs for disassembly, packaging and

transport.

➤ Before sending in the machine for disposal,

contact customer service.

➤ If you dispose the machine yourself, abide by

the national and local laws of the disposal

location.

8. Troubleshooting

Danger to life due to improper troubleshooting

In case of improper troubleshooting, you may suffer

from severe or deadly injuries caused by, for example, electric shocks, axis and spindle movements,

loose pneumatic components and pneumatic hoses.

In addition, your machine may get damaged.

➤ Do not remove the housing of the machine.

➤ Before you check or run pneumatic hoses,

close the external compressed air supply valve.

➤ Before you check or run electric cables or

power connectors, disconnect the machine from

the electrical source and prevent it from being

restarted.

➤ Do not perform any troubleshooting while the

machine is operating.

➤ Wear safety gloves throughout the troubleshoo-

ting process.

DANGER

32

➤ If you are unsure of how to perform certain steps

during troubleshooting or cannot solve the

problems, abort the troubleshooting and contact

customer service.

Additional symbols in this chapter

Problem/question

Solution/answer

Frequently Asked Questions (FAQ)

The suction hose of my suction device

does not fit into the opening for the air

extraction system of the CNC machine.

Is the suction hose equipped with a hose connection?

M1. Unscrew the hose connection from the suction

hose.

M2. Try to insert the suction hose into the opening

for the air extraction system.

M3. If the suction hose still does not fit, contact

customer service and obtain a suitable hose

connection.

M4. Install the suitable hose connection to the suc -

tion hose.

➲ Chapter 4.5.3

Did the suction hose come without a hose

connection?

M1. Contact customer service and obtain a suitable

hose connection.

M2. Install the suitable hose connection to the suc -

tion hose.

➲ Chapter 4.5.3

I cannot open the front cover.

Is the machine operating? While the axes are

moving, the front cover stays locked.

M Wait until the machine has finished and the

working chamber lighting shines green.

Without electricity, the front cover remains

locked.

Has a power failure occurred at the installation

site of the machine?

M Depending on the duration of the power failure,

restart the machine or use the key for the emergency release.

➲ Chapter 5.7.4

!

Page 33

Is electricity available at the installation site of

the machine?

M1. If you have not removed the transport lock from

the working chamber yet, disconnect the machine from the manufacturing computer.

M2. Connect the machine to the electrical source

and switch it on via the main power switch.

M3. If the working chamber lighting does not illumi-

nate, check if the power cable is properly seated

in machine and to the power source.

M4. Try connecting the machine to a different socket.

➲ Chapter 3.2

I have installed all components, started

FINOCNC but the machine does not refe-

rence.

Is the front cover open? The machine does not

reference with the front cover open.

M Close the front cover.

Is the USB cable connected properly?

M Check if the USB cable is properly seated in the

connector and is undamaged. If possible, use

the provided cable.

Is the correct port specified in FINOCNC?

Without the correct port, the application will not

establish a connection with the machine.

S1. Start FINOCNC.

S2. Try to have the application determine the correct

port in the application settings.

S3. If the application cannot determine the correct

port, enter the port manually. For this, follow the

instructions in the documentation for the manu-

facturing software.

➲ Chapter 4.8

My machine does not execute any jobs alt-

hough FINOCNC displays that there is a

connection between the manufacturing

computer and the machine.

Is the front cover open? The machine does not

move the axes if the front cover is open.

M Close the front cover.

➲ Chapter 3.2

The machining results are not satisfactory

and/or tools keep breaking.

Do the tool positions in FINOCNC correspond to

the tools in the tool changer of the machine? If

not, the machine uses the wrong tools during job

execution.

S1. Call up the job execution view in FINOCNC.

S2. Compare the tool positions in the application to

the tools in the tool changer.

M3. Replace the wrong tools in the tool changer with

the correct ones.

➲ Chapter 5.3

Is the workpiece attached properly?

M Ensure that all screws, pins and clamping

mechanisms fixate the workpiece firmly.