Page 1

ASSEMBLY

VKC5.5,6,6H, 7,8,10 SERIES

Sealless Non-Metallic Vertical Pumps

Installation and Maintenance Instructions

Pat.No. 5,708,313

WARNING: Magnetic field hazard. This pump contains powerful

rare earth magnets. When the pump is disassembled (not

connected to a motor) and the magnets are exposed, these

magnets produce powerful magnetic fields. Individuals with

cardiac pacemakers, implanted defibrillators, other electronic

medical devices, metallic prosthetic heart valves, internal wound

clips (from surgery), metallic prosthetic devices or sickl cell

anemia must not handle or be in the proximity of the magnets

contained inside the pump. Consult a health care provider for

specific recommendations before working with this pump.

PUMPS WITH MOTORS

1. No assembly required. Simply unpack the pump and motor and examine for any signs of shipping damage. If damage is detected, save

the packaging and notify the carrier immediately.

2. Ensure that lock rings are securely snapped in place and did not loosen

during shipment.

3. To install the pump into the system, follow the installation instructions

provided.

PUMPS WITHOUT MOTORS

Note: Finish Thompson has added extra weight (Flywheel item 35 in

Figure 8) to several of our VKC Series Pumps to slow down motor start

up & prevent possible magnet decoupling. It is necessary to know

whether your pump was supplied with the flywheel. Flywheels are supplied with all VKC8 (54”- 60”) & All VKC10 pumps both 56C NEMA & 80

Metric frame motor adapters. If you are unsure whether your pump was

supplied with a flywheel please contact our Tech Service Department at

PH: 800-888-3743 or email techservice@finishthompson.com.

Note: motor assembly videos are available on line at http://www.Finishthompson.Com/downloads/maintenance-videos/

FOR 56C FRAME VKC5.5,6,6H, 7 AND 8 PUMP ADAPTERS

WITHOUT FLYWHEELS [12” - 48” (30-

122 cm)]. USE FIGURE 7.

1. Unpack the pump and any supplied accessories and examine for damage. If damage is detected, save the packaging and notify the carrier

immediately.

2. Prepare to assemble the pump onto the motor by placing the motor

on the fan cover on a suitable clean, level work surface.

3. Slide the supplied coupling half (metal half of item 27 in figure 7)

onto the motor shaft with the splined side facing the pump. Adjust the

coupling half so that the motor shaft is recessed 7/32” below the top

of the coupling. Insert the motor shaft key in the slot and tighten both

setscrews with a 1/8” Allen wrench to 70 in-lbs.

4. Install the coupling insert (yellow internally splined plastic sleeve)

onto the coupling half on the motor shaft. Carefully slide the motor

adapter (item 9 in figure 7) onto the motor making sure the pump shaft

coupling matches up with the plastic insert and seats properly. Make

sure rabbet on the motor is firmly seated into the motor adapter.

CAUTION: Pump assembly may be top heavy.

5. Rotate the pump discharge and mounting plate (if ordered) to the desired orientation. Align the holes in the mounting plate and the motor

adapter with the holes in the motor face. Secure the mounting plate

and motor adapter to the motor using (4) washers, lock washers, and

3/8” bolts (items 6,7,8) from the hardware package.

6. Ensure that lock rings are securely snapped in place and did not loosen

during shipment.

7. Install the pump into the system according to the installation instructions provided.

FOR 56C FRAME VKC8 [54”-60”(137-152

cm)] AND ALL VKC10 PUMP ADAPTERS

WITH FLYWHEELS (ITEM 35 IN FIGURE 8):

1. Unpack the pump and any supplied accessories and examine for damage. If damage is detected, save the packaging and notify the carrier

immediately.

2. Prepare to assemble the pump onto the motor by placing the motor

on the fan cover on a suitable clean, level work surface.

3. Install motor key into motor shaft key slot. Align the keyway slot on

the flywheel (item 35 in figure 8) and slide the flywheel onto the motor

shaft with the protruding boss towards the motor face. Align the keyway

slot in the coupling half and slide the coupling half on. Set coupling

half with the motor shaft recessed 7/32” and tighten both setscrews

with a 1/8” Allen wrench to 70 in-lbs.

4. Slide the flywheel forward so that it rests against the backside

of the coupling half. Tighten both setscrews.

5. Insert the coupling insert (yellow internally splined plastic sleeve) into

the coupling half on the motor shaft. Place coupling support (item

38A in figure 8) into center of coupling half with the short side facing

the motor. Carefully slide the motor adapter end (item 9 in figure 8)

of the pump assembly over the motor shaft until both coupling halves

are completely seated in the coupling insert. Make sure rabbet on the

motor is firmly seated into the motor adapter.

CAUTION: Pump assembly may be top heavy

6. Rotate the pump discharge and mounting plate (if ordered) to the

desired orientation. Align the holes in the mounting plate and the

motor adapter with the holes in the motor face. Secure the mounting

plate and motor adapter to the motor using (4) washers, lock washers

and 3/8” bolts (items 6, 7, 8) from the hardware package.

7. Ensure that lock rings are securely snapped in place and did not loosen

during shipment.

1

Page 2

8. Install the pump into the system according to the installation

instructions provided.

FOR 63, 71 AND 80 METRIC FRAME

ADAPTERS WITHOUT FLYWHEELS

(USE FIGURE 7)

1. Unpack the pump and any supplied accessories and examine for damage. If

damage is detected, save the packaging and notify the carrier immediately.

2. Prepare to assemble the pump onto the motor by placing the motor

on the fan cover on a suitable clean, level work surface.

3. Install the keyway into the motor shaft key slot. Align the keyway slot

in the coupling half, and slide the coupling half onto the motor shaft

with the splined side facing the pump. Set the coupling half with the

motor shaft recessed 11.1 mm. Tighten both setscrews with a 1/8”

Allen wrench to 7.9 N-m.

4. Install the metric motor adapter (item 2 in figure 7) onto the motor.

To aid in correct installation, the letters “A” and “B” are molded onto

opposite sides of the motor adapter. For 71 frame motors, using the

Figure A

correct hardware (items 3, 4, and 5 in figure 7), mount the adapter

with side B facing up. For 63 and 80 frame motors, using the correct

hardware (items 3, 4, and 5 in figure 7), mount the adapter with side

A facing up. See figures A and B.

5. Install the coupling insert (yellow internally splined plastic sleeve) onto

the coupling half on the motor shaft. Carefully slide the motor adapter

(item 9 in figure 7) onto the motor making sure the pump shaft coupling

matches up with the plastic insert and seats properly. Make sure rabbet

on the motor is firmly seated into the motor adapter.

6. Rotate the pump discharge and the mounting plate if ordered to the

desired orientation. Align the bolt holes on the mounting plate with the

motor adapter (item 9) and the metric motor adapter flange (item 2).

Secure with the hardware provided.

CAUTION: Pump assembly may be top heavy.

7. Make sure that the locking rings are securely snapped in place and

did not loosen during shipping or the assembly process.

8. Install the pump into the system according to the installation instructions provided.

Figure B

4. Install the metric motor adapter (item 2 in figure 8) onto the motor. To

aid in correct installation, the letters “A” and “B” are molded on the

opposite sides of the metric motor adapter. For 80 frame motors using

the correct hardware (items 3,4 and 5 in figure 8) mount the adapter

with side “A” facing up. The metric motor adapter must be positioned

so that the adapter seats onto the motor rabbett. See figures A and B

above.

CAUTION: Improper positioning of the metric motor adapter can

cause premature coupling failure or cause the pump shaft to bottom

out before the pump is properly installed onto the motor adapter.

5. Install the flywheel (item 35 in figure 8) onto the flywheel adapter and

attach using four screws with lock washers (items 36 and 37 in figure

8). Tighten securely.

6. Insert the coupling insert (yellow internally splined plastic sleeve) into

the coupling half on the motor. Carefully slide the motor adapter end

(item 9 in figure 8) of the pump assembly over the motor shaft until

both coupling halves are completely seated in the coupling insert. Make

sure rabbet on the motor is firmly seated into the motor adapter.

7. Rotate the pump discharge and mounting plate if ordered to the desired

orientation. Align the boltholes on the mounting plate with the motor

adapter (item 9) and the metric motor adapter flange (item 2). Secure

with the hardware provided.

8. Make sure that the locking rings are securely snapped in place and

did not loosen during shipping or the assembly process.

CAUTION: Pump assembly may be top heavy.

Install the pump into the system according to the installation instruc-

tions provided.

FOR 80 FRAME METRIC MOTOR

ADAPTER WITH FLYWHEEL (ITEM 35

IN FIGURE 8):

1. Unpack the pump parts and any supplied accessories and examine

for damage. If damage is detected, save the packaging and notify the

carrier immediately.

2. Prepare to assemble the pump onto the motor by placing the motor on

the fan cover on a suitable clean, level work surface.

3. Install the keyway into motor shaft key slot. Align the keyway slot in

flywheel adapter / coupling half combination (item 34 and metal half of

item 27 in figure 8) and install on motor shaft with splined side facing the

pump. Note: These items are preassembled at the factory. Set coupling

half flush with the end of the motor shaft and secure with coupling support washer, lock washer and bolt (items 38B, 39 & 40). Tighten both

setscrews in coupling half with 1/8” Allen wrench to 7.9 N-m.

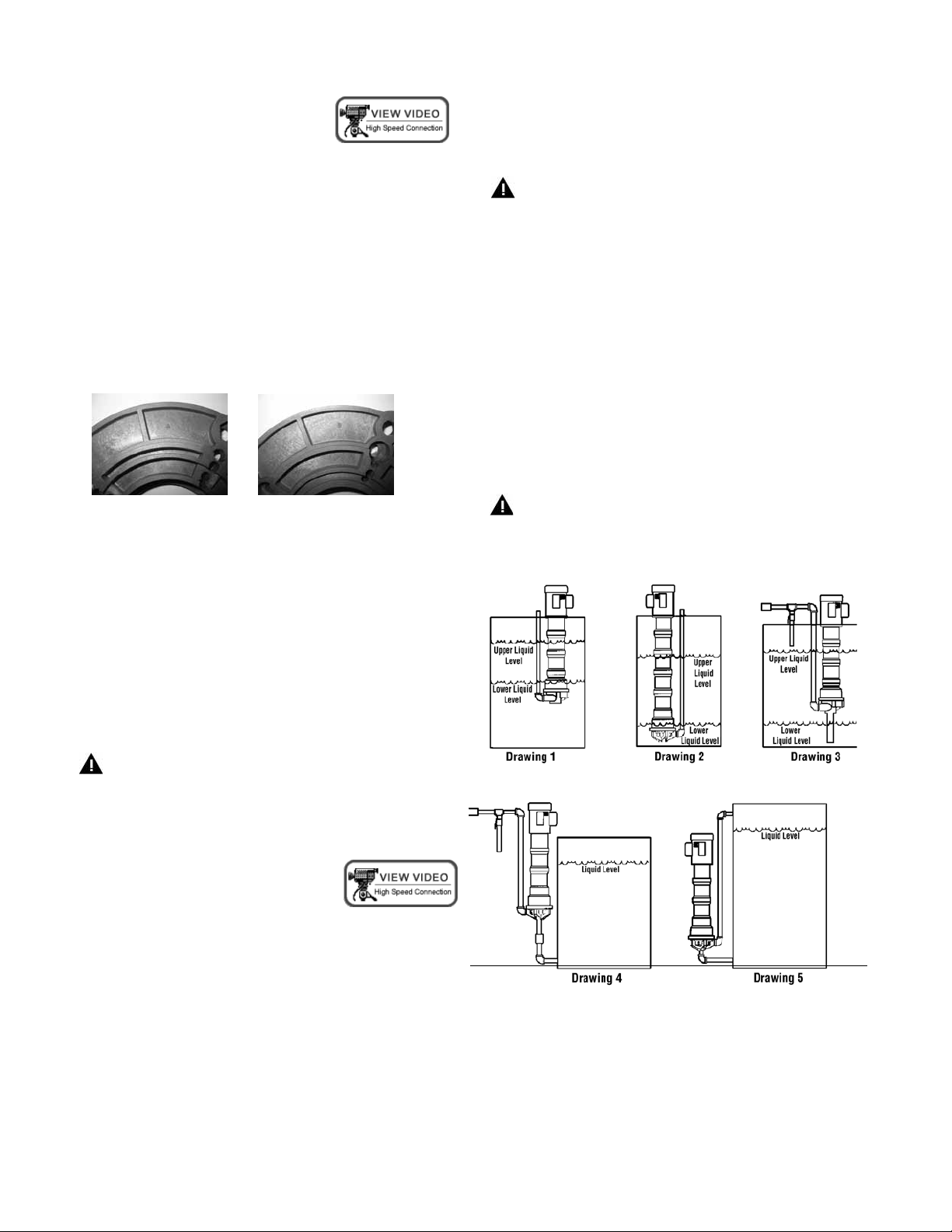

Figure 1

Drawing 1 shows drawing of pump mounted inside tank with suction off the bottom of the

tank and level fluctuating from near top of pump column to close to the bottom of the pump.

Drawing 2 shows drawing of pump suction near tank bottom and level fluctuating between

the top and bottom of the tank.

Drawing 3 shows drawing of pump with suction extension and the level fluctuating between

startup level and low level.

Drawing 4 shows drawing of pump mounted outside the tank.

Drawing 5 shows drawing of pump mounted outside the tank with the motor below the

liquid level.

2

Page 3

Mount pump in desired configuration. Securely fasten mounting

plate if used. Motor feet may also be used for mounting.

PIPING

1. Support piping near the pump to eliminate any strain on the pump

casings. Do not use suction or discharge piping to support the pump.

2. Do not overtighten the piping on the discharge on initial installation (i.e.,

down to the collar on NPT housings or the o-ring on BSP housings).

Damage to the discharge can occur. The o-ring on the BSP housing is

only used when the plastic threads are loose.

3. Do not place the pump suction directly on the bottom of the tank. Keep

the pump suction at least one pipe diameter off the bottom.

4. A suction extension tube of up to nine feet in length can be added.

5. To minimize head loss from friction:

a. Increase pipe size by 1 diameter.

b. Use minimal number of pipe bends.

6. If a check valve is installed in the discharge piping, an air bleed must

be installed in the discharge line to prevent air lock. This allows air

trapped in the pump internals to be removed on initial start-up. See

drawings 3 and 4 in Figure 1.

7. Maintain a flooded suction. Use a foot valve if necessary.

8. Ensure that the piping does not leak and suction is not prone to clogging. Use a strainer if necessary on the suction.

9. If flexible hose is preferred, use reinforced hose rated for the proper

temperature and pressure. This helps avoid collapse or kinks.

10. Install valves a minimum of 10 pipe diameters from the pump.

CAUTION: To stop the pump if prime is lost, use one of the

following: (1) pressure switch on the discharge or (2) motor

minder to monitor motor current.

1. Completely open discharge valve. On pumps equipped with a discharge

WET END INSPECTION / REPLACEMENT

1 Disconnect the power. Unwire the motor (mark the wires for correct

rotation upon reassembly). Close the suction and discharge valves,

and remove the pump from the installation. Remove any discharge

piping that will hinder the removal of the housing.

2. Place the pump on a clean work bench and secure the motor or

mounting plate. Gently tap the locking ring (item 11) towards the motor

until it is loose (the locking ring connects the column housing adapter

(item 15) to the next section). Using a strap wrench, unthread the

column housing section turning it counterclockwise. Grasping the

discharge and pump head, pull it straight off of the pump and place it

on the bench with the suction pointing straight up.

3. Make an alignment mark on the side of the impeller housing (item 21)

and the column housing adapter (item 15) to aid in alignment during

the reassembly process. Remove the six impeller housing mounting

screws (items 22). Remove the impeller housing (item 21) and o-ring

(item 16). Grasp the impeller and remove it from the column housing

adapter (item 15).

CAUTION: Keep the drive magnet assembly (item 14) and

impeller drive (item 18) away from metal chips or particles.

Note: Keep the impeller housing o-ring (item 16) with the

impeller housing to avoid mix up during reassembly.

Figure 2

INSTALLATION

The VKC Series is a versatile pump designed to be operated in a variety of mounting configurations. The pump can be mounted either

inside or outside of a tank or sump. See Figure 1.

Note: Drawings for illustration only. Pumps need to be properly

supported when installed.

ELECTRICAL

1. Install the motor according to NEC requirements and local

electrical codes. Motor should have an overload protection

circuit.

2. Wire the motor for clockwise rotation when facing the fan

end of the motor.

3. To verify the correct motor rotation:

a. Install the pump into the system

b. Fully open the suction and discharge valves

c. Allow fluid to run into the pump. Do not allow the pump

to run dry (PTFE and ceramic bushings can’t be run dry

without causing damage to internal parts).

d. Jog the motor (allow it to run for only one to two seconds)

and observe the rotation of the motor fan. Refer to the

directional arrow by the electrical box if needed.

Note: A pump running backwards will pump but at a greatly

reduced flow and pressure.

OPERATION

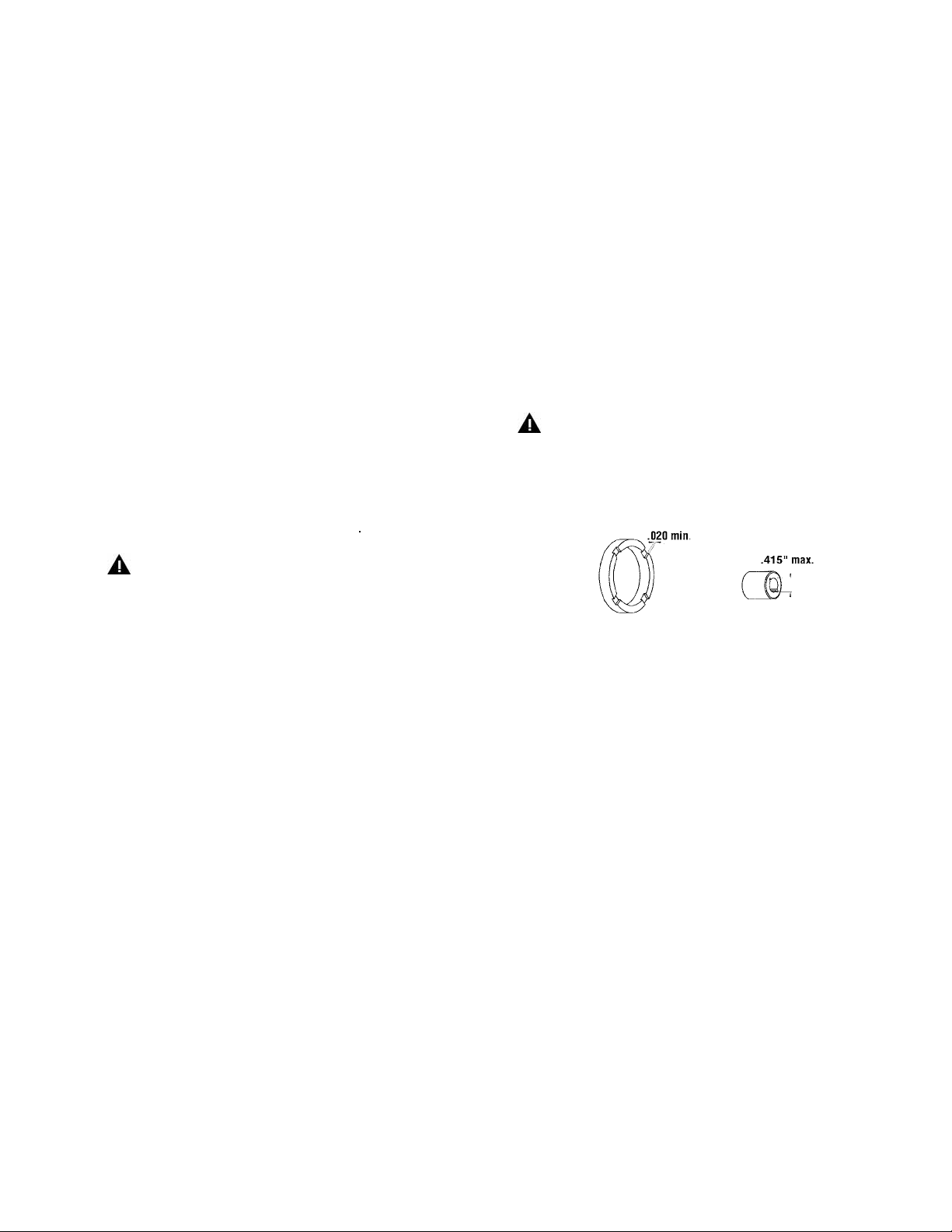

EXAMINATION

1. Check the impeller drive bushing (item 17), thrust ring (item 20), ceramic thrust ring and shaft for cracks, chips, scoring or excess wear.

See figure 2. Replace as required.

2. Check for loose magnets on the drive assembly or rubbed areas on

the impeller or column housing adapter assemblies. Contact your

distributor or FTI Technical Service if a problem is found.

BUSHING REPLACEMENT

1. To remove the bushing, insert 1/16” pin punch into balance hole (inner

circle of 4 holes) of impeller assembly (items 17,18,19,20). Gently

tap the bushing out of the back of the impeller assembly. The punch

may need to be moved to a different hole if the bushing is difficult to

remove.

2. To replace the bushing, clean the impeller bore. Insert the new bushing

into the back of the impeller assembly by aligning the bushing with

the impeller bore. Press gently until the bushing bottoms out (use a

block of wood and mallet if necessary).

MOTOR REPLACEMENT

Remove the four bolts and washers (items 6, 7, and 8) securing the

motor adapter (item 9) to the motor. Carefully pull the pump away

from the motor face. Loosen the two setscrews on the coupling

half (located on the motor shaft). Remove the coupling half. Install

motor shaft coupling half onto a new motor following the assembly

instructions on page one for 56C or metric frame pumps. Make

sure the coupling insert meshes. Install pump onto the new motor.

3

Page 4

DRIVE MAGNET ASSEMBLY, SHAFT BEARING

OR COLUMN SECTION REPLACEMENT

1. The drive magnet assembly (item 14) is locked in place with a left

hand threaded 5/8-18 jam nut (item 32). Loctite Thread Locker #262

is used to secure the jam nut and may require some heat to loosen

the bond for removal. Secure the pump shaft using the flats located

on the motor side of the drive magnet assembly, and remove the jam

nut. Unthread the drive magnet assembly (left hand thread) from the

shaft.

2. Loosen the two setscrews on the shaft bearing (item 28). Gently tap

the next locking ring (item 11) toward the motor until it is loose. Using

a strap wrench, unthread and remove the column extension (item 30).

Repeat step two for each section removed.

3. When you are down to the motor adapter section (item 9), remove the

four bolts holding the adapter (and mounting plate if you have one) to

the motor. Mark the flange on the motor adapter / mounting plate and

the motor face for correct orientation when reassembling. Remove

the mounting plate, and pull the motor adapter from the motor face.

4. 12” models will have two bearings in the motor adapter section. If

further disassembly is necessary, loosen the two setscrews on the

pump side bearing, and gently press the shaft and the second bearing toward the motor end until it loosens. If the bearing or the shaft

need replacement, loosen the setscrews and remove the pump shaft

coupling half. Loosen the setscrews on the bearing and slide it off the

shaft. On models 18” or longer, just loosen the setscrews on the pump

shaft coupling half and remove it.

5. Spin all of the bearings and visually inspect for binding or corrosion.

To replace, remove the four screws and washers (items 29 and 33).

Gently tap the bearings toward the pump end of each section until they

are loose.

6. Inspect the drive magnet assembly, each column section, all of the bearings, shaft, and o-rings for wear or damage. Replace as needed.

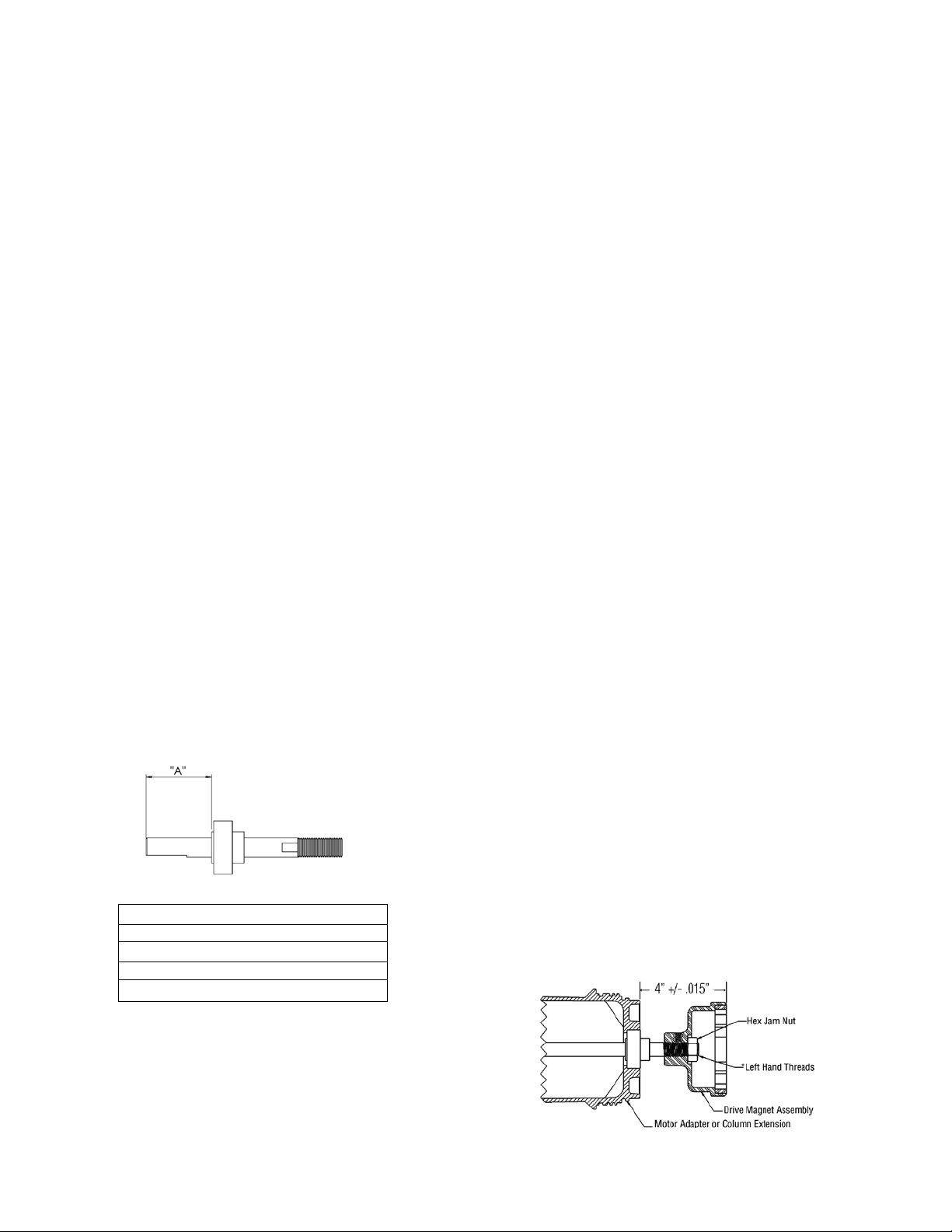

REASSEMBLY

1. If the shaft, or the first bearing on a 12” model was replaced, you will

need to slide the new bearing onto the shaft with the setscrew side

facing away from the motor. Adjust the bearing to the correct setting

in Figure 3, and tighten both setscrews.

Figure 3

Pump Motor Frame Dim. A”

VKC6/8/10 56C 0.95”

VKC6/8/10 80 2.41”

VKC6/8/10 71 2.19”

VKC6/8/10 63 2.40”

bearing into the machined recess making sure to use the outer bearing

race as the point of contact.

For models 18” or longer, insert the threaded end of the pump shaft

up through the bearing already in place in the pump end of the motor

adapter. Leave the bearing setscrews loose.

4. For metric frame pumps, install the metric motor adapter flange (item

2) per instructions in step 4 of “Pumps Without Motors (Metric Frame)

from page 1.

5. Install the coupling insert onto the pump shaft coupling half. Place

motor on its fan cover on a flat clean area. Make sure the coupling

splines mesh with the insert. Install the motor adapter and pump shaft

onto the motor face. Verify the motor adapter seats completely onto

the motor rabbet (or metric motor adapter flange on metric pumps).

Install the mounting plate (if one is used) and align the marks on the

motor, the motor adapter flange and the mounting plate for correct

orientation. Install the four bolts and tighten to the motor face.

6. For 12” models, go to step 8. For models 18” or longer, rotate the

pump shaft and press down to insure complete coupling engagement.

While holding the shaft snugly down, tighten the bearing setscrews.

7. If column o-rings (item 12) were removed or need replacement,

lubricate the o-rings with a compatible lubricant and install them in

the o-ring grooves. If the bearing (item 28) was removed, press the

new bearing (only making contact with the outer bearing race) into

the recess with the extended race (setscrews) facing away from the

motor. Install the four retaining screws and washers (items 29 and 33).

8. Lubricate the motor adapter o-rings (item 12) with a compatible lubricant. Place the locking ring (item 11) (with the smaller inside diameter

side toward the motor) over the end of the column section and slide

it toward the motor. Install the column extension (item 30) by aligning

the threaded end of the shaft through the bearing and sliding it down

to the top of the motor adapter. Secure the motor and mounting plate

to the table. Using a strap wrench, thread the column extension onto

the motor adapter. Tighten the section until there is no gap between the

sections and the flats are parallel. Tighten the two bearing setscrews

into the pump shaft. Pull the locking ring (item 11) toward the pump

end until it snaps into place locking the two sections together.

9. Repeat step eight until all column extensions are installed. If the pump

is a 24” model or longer, you may need a second strap wrench to hold

the previous section in place while tightening the new one.

Note: It may be possible to slightly overtighten these sections. Simply

back off slowly until the flats are aligned and the lock ring snaps into

place.

10. Install the left hand threaded drive magnet assembly (item 14) onto

the drive shaft (item 13) until it is set at 4.00 +/- .015 as measured

from the top of the motor adapter/column extension to the top of the

drive magnet assembly. See Figure 4. Apply a small amount of Loctite

Thread Locker #262 to the inside threads on the 5/8-18 left hand jam

nut (item 32) and the outside threads on the drive shaft. Thread the

jam nut on until it makes contact with the drive. Hold the drive magnet

assembly still and tighten it to 50 ft. pounds. Recheck the drive magnet

setting after the jam nut is tight to ensure it did not move.

2. Install the key into the keyway cut in the motor end of the pump shaft

(item 13). Align the coupling half keyway slot and install the coupling

half with the splines pointing toward the motor end. For 56C frame, set

the coupling with the shaft end recessed .218”. Tighten the setscrews.

For 63 and 71 frames, set the coupling with the shaft end recessed

.437” and tighten the setscrews. For 80 frame, set the coupling with

the shaft recessed .250 and tighten the setscrews.

3. For 12” models - from the motor side, insert the threaded end of the

shaft up through the center of the motor adapter (item 9) . Press the

Figure 4

4

Page 5

11. Reassemble the wet end by placing the impeller (items 18 and 19) onto

the ceramic shaft in the column housing adapter (item 15). Install the

housing o-ring (item 16), and lubricate with a compatible lubricant.

Align the marks made on the housing (item 21) and the column housing adapter (item 15) during disassembly. Install the impeller housing

(item 21) onto the column housing adapter taking care not to dislodge

the o-ring. Align the bolt holes and install the six mounting screws

(item 22). Use a PTFE thread lubricant on the PVDF screws. Following

the pattern in Figure 5, carefully tighten using a screwdriver. Do not

over- tighten the screws (recommended maximum torque is 25 in-lbs.)

Reach into the suction and spin the impeller with your finger to verify

it is not rubbing or binding.

Figure 5

12. Slide the locking ring over the end of the column extension with the

smaller inside diameter side toward the motor. Lubricate the column

rings (item 12) with a compatible lubricant and install the “wet end”

by threading it on until the flats line up. Pull the locking ring toward

the pump end and snap it in place locking the two sections together.

Rotate the motor fan by hand to verify nothing is rubbing or binding. Reinstall

13.

the pump into the system according to the installation instructions.

7. The pump will contain various numbers of shaft bearings (item 28)

based on the length of the pump as follows:

12” pump = (2) shaft bearing

18” pump = (2) shaft bearings

24” pump = (3) shaft bearings

30” pump = (4) shaft bearings

36” pump = (5) shaft bearings

42” pump = (6) shaft bearings

48” pump = (7) shaft bearings

54” pump = (8) shaft bearings

60” pump = (9) shaft bearings

8. Due to the hermetically sealed design, the pump will displace liquid

as follows:

12” pump = approximately 1 gallon (3.78 liters)

Add approximately 1 quart (.95 liter) per column section.

E.G. 24” pump = 1-1/2 gallons (4.73 liters)

9. 12” pumps do not have column extensions.

GENERAL NOTES

1. Do not pump liquids containing metal fines.

2. If magnets decouple, stop the pump immediately. The rare earth

magnets used in this pump are more resistant to demagnetization,

but operating the pump with the magnets decoupled will eventually

weaken the magnets.

3. Plastic pumps will expand and contract with temperature so periodically

check and hand tighten screws.

4. Use a chemically compatible thread lubricant on threads of column

sections.

5. The setting of the drive magnet dimension is critical. Failure to properly set the dimension may result in decoupling or damage to pump

components.

6. An information sticker is attached to the motor adapter section. The

first line is the model number, the second is the serial number. See

Figure 6.

Figure 6

5

Page 6

VKC SERIES WITHOUT FLYWHEEL

VKC5.5, 6, 6H, 7 and 8

[12-48” (30 cm - 122 cm)]

56C, 63, 71, and 80 Frames

Figure 7

1

27

2

3

4

31

10

5

12B

9

33

29

32

6

7

8

15

18

12A

28

13

14

11

16

17

20

21

19

22

23

R100581

6

Page 7

VKC SERIES WITH FLYWHEEL

VKC8 [54” - 60” (137 cm - 152 cm)]

All VKC10 56C and 80 Frames

Figure 8

1

34

For 80 frame only

For 80 frame only

For 80 frame only

10

37

36

38A

2

3

4

5

9

33

32

27

29

28

38B

39

40

12B

12A

13

35

31

For 80 frame only

14

6

7

8

15

18

19

20

21

22

7

17

23

11

16

R100581

Page 8

Item Qty Description Part Number

IEC 63/71 frame M101947

IEC 80 frame M101947-2

1/4" stainless steel J100113

1/4" stainless steel J100672

IEC 63 frame J103226

IEC 71/80 frame J103228

3/8" stainless steel J100128

3/8" stainless steel J100115

3/8-16 x 1-3/4” hex head - all 56C models w/ mounting plate J103161

3/8-16 x 1” hex head - all 56C models w/out mounting plate J100114

3/8-16 x 2-1/4” hex head - all 63/71/80 models w/ mounting plate J103227

3/8-16 x 1-1/2” hex head - all 63/71/80 models w/out mounting plate J103207

Polypropylene - 18" to 60" length models M101981-1

Polypropylene - 12" length models A103377-1

PVDF - 18" to 60" length models M101981-2

PVDF - 12" length models A103377-2

VKC 5.5, 6, 6H 105612

VKC 7, 8, 10 105611

Polypropylene M101984-1

PVDF M101984-2

FKM J103306

EPDM J103308

FKM J103307

EPDM J103309

12” 56C frame M102119-9

12” 63/80 frame M102119-19

12” 71 frame M102119-10

18” 56C frame M102119-1

18” 63/80 frame M102119-20

18” 71 frame M102119-5

24” 56C frame M102119-2

24” 63/80 frame M102119-21

24” 71 frame M102119-6

30” 56C frame M102119-3

30” 63/80 frame M102119-22

30” 71 frame M102119-7

36” 56C frame M1012119-4

36” 63/80 frame M102119-23

36” 71 frame M102119-8

42” 56C frame M102119-11

42” 63/80 frame M102119-24

42” 71 frame M102119-15

48” 56C frame M102119-12

48” 63/80 frame M102119-25

48” 71 frame M102119-16

54” 56C frame M102119-13

54” 63/80 frame M102119-26

54” 71 frame M102119-17

60” 56C frame M102119-14

60” 63/80 frame M102119-27

60” 71 frame M102119-18

VKC 5.5, 6, 6H, 7, 8, 10 SERIES SPARE PARTS

1

Motor

2

Metric Motor Adapter

3

Flat Washer

See Motor Section on page 11

1

1

4

Lock Washer

5

Socket Head Cap Screw

6

Flat Washer

7

Lock Washer

8

Motor Mounting Cap Screw

Motor Adapter

9

4

1

Motor Adapter/Column O-Ring

PVC Mounting Plate 9-1/2” x 14-3/4” (Optional)

11

Lock Ring

12A

Motor Adapter/Column O-Ring

10 1

13

Drive Shaft

1

12B

4

4

4

4

4

8

Page 9

Item Qty Description Part Number

6 pole A101989-17

8 pole A101989-18

10 pole A101989-19

12 pole A101989-20

Polypropylene A102271-1

PVDF A102271-2

FKM J102389

EPDM J102585

Carbon J102387

PTFE J102790

Ceramic J103617

6 pole - polypropylene with carbon bushing A102746-1

6 pole - polypropylene with PTFE bushing A102746-10

6 pole - polypropylene with ceramic bushing A102746-20

6 pole - PDVF with carbon bushing A102746-2

6 pole - PVDF with PTFE bushing A102746-13

6 pole - PVDF with ceramic bushing A102746-21

8 pole - polypropylene carbon bushing A102746-4

8 pole - polypropylene with PTFE bushing A102746-11

8 pole - polypropylene with ceramic bushing A102746-22

8 pole - PVDF with carbon bushing A102746-5

8 pole - PVDF with PTFE bushing A102746-14

8 pole - PVDF with ceramic bushing A102746-23

10 pole - polypropylene with carbon bushing A102746-7

10 pole - polypropylene with PTFE bushing A102746-12

10 pole - polypropylene with ceramic bushing A102746-24

10 pole - PVDF with carbon bushing A102746-8

10 pole - PVDF with PTFE bushing A102746-15

10 pole - PVDF with ceramic bushing A102746-25

12 pole - polypropylene with carbon bushing A102746-16

12 pole - polypropylene with PTFE bushing A102746-17

12 pole - polypropylene with ceramic bushing A102746-26

12 pole - PVDF with carbon bushing A102746-18

12 pole - PVDF with PTFE bushing A102746-19

12 pole - PVDF with ceramic bushing A102746-27

3.00” polypropylene VKC5.5 A101983-10

3.19” polypropylene VKC6 A101983-1

3.88” polypropylene VKC6H A101983-13

3.19” polypropylene VKC7 A101983-15

3,50” polypropylene VKC8 A101983-2

3.88” polypropylene VKC10 A101983-3

3.00” PVDF VKC5.5 A101983-11

3.19” PVDF VKC6 A101983-4

3.88” PVDF VKC6H A101983-14

3.19” PVDF VKC7 A101983-16

3,50” PVDF VKC8 A101983-5

3.88” PVDF VKC10 A101983-6

VKC5.5,6 J102388

VKC6H

J104045

VKC7

J103893

VKC 8,10

J101606

20 1

PTFE Thrust Ring

18 1

Impeller Drive Assembly

19 1

Impeller with Thrust Ring

16 1

Impeller Housing O-ring

17 1

Impeller Bushing

14 1

15 1

VKC 5.5, 6, 6H, 7, 8, 10 Spare Parts - cont.

Column Housing Adapter

Drive Magnet Assembly

9

Page 10

VKC5.5, 6, 6H - polypropylene NPT

A101981-1

VKC5.5, 6, 6H - polypropylene BSP with FKM discharge o-ring

A101982-3

VKC5.5, 6, 6H - polypropylene BSP with EPDM discharge o-ring

A101982-7

VKC5.5, 6, 6H - PVDF NPT

A101981-3

VKC5.5, 6, 6H - PVDF BSP with FKM discharge o-ring

A101982-4

VKC5.5, 6, 6H - PVDF BSP with EPDM discharge o-ring

A101982-8

VKC7, 8, 10 - polypropylene NPT

A101981-7

VKC7, 8, 10 - polypropylene BSP with FKM discharge o-ring

A101982-11

VKC7, 8, 10 - polypropylene BSP with EPDM discharge o-ring

A101982-15

VKC7, 8, 10 - PVDF NPT

A101981-9

VKC7, 8, 10 - PVDF BSP with FKM discharge o-ring

A101982-12

VKC7, 8, 10 - PVDF BSP with EPDM discharge o-ring

A101982-16

PVDF J103149

Titanium J103524

Hastelloy C J103535

FKM (VKC5.5, 6, 6H) J102390

EPDM (VKC5.5, 6, 6H) J102712

FKM (VKC7, 8, 10) J102391

EPDM (VKC7, 8, 10) J102713

VKC 5.5, 6, 6H - 1” x 3/4” polypropylene J103158

VKC 5.5, 6, 6H - 1” x 3/4” PVDF J103153

VKC7, 8, 10 - 1-1/2” x 1” polypropylene J103160

VKC7, 8, 10 - 1-1/2” x 1” PVDF J103159

VKC5.5,6,6H polypropylene - 90° x 1” J103167

VKC5.5,6,6H PVDF - 90° x 1” J103168

VKC7,8,10

polypropy

lene - 90° x 1-1/2” J103165

VKC7,8,10 PVDF - 90° x 1-1/2” J103166

Available in polypropylene & PVDF, 18" to 60" Contact FTI for pricing

Coupling - 56C frame A102485

Coupling - 63 frame A102486

Coupling - 71 frame A102487

Coupling - 80 frame A102488

Coupling - 80 frame w/ flywheel 105464

J103157

Phillips head M5 x 16mm J103175

Polypropylene M101982-1

PVDF M101982-2

3/8” -16 for metric adapter plate J100135

Left hand threads J103515

#10 stainless steel J103638

80 frame only - VKC8 (54" & 60" lengths only) & VKC10 all lengths 105442

56C Frame - VKC8 (54" & 60" lengths only) & VKC10 all lengths 105462

IEC 63 B14 frame N/A

IEC 71 B14 frame N/A

IEC 80 B14 frame VKC8 (54" & 60" lengths only) & VKC10 all lengths 105443

10-32 x 1-1/4” - VKC8 (54" & 60" lengths only) & VKC10 all lengths J100023

#10 (80 frame ONLY) J103637

56C Frame 105463

IEC 63 B14 frame N/A

IEC 71 B14 frame N/A

27 1

Coupling

31 4

Hex Nut

28

Shaft Bearing

32 1

Jam Nut

29

Bearing Retaining Screw

30

Column Extension

33 4

Flat Washer

34 1

Flywheel Adapter

35 1

Flywheel

36 4

Socket Head Bolt (80 Frame Only)

37 4

Lock Washer

38A

Coupling Support

25

1

Elbow

26 1

Discharge Piping (Optional)

Discharge O-ring

Hex Reducer Bushing

22 6

Impeller Housing Mounting Screw

23

1

24

1

21

VKC 5.5, 6, 6H, 7, 8, 10 Spare Parts - cont.

Item Qty Description

Part

Number

1

Impeller Housing with Thrust Ring

10

Page 11

Item Qty Description Part Number

IEC 80 B14 frame 105444

1/4" - VKC8 (54" & 60" lengths only) & VKC10 all lengths J100672

M6 Hex Head - VKC8 (54" & 60" lengths only) & VKC10 all lengths J102759

Lock Washer (80 Frame Only)

VKC 5.5, 6, 6H, 7, 8, 10 Spare Parts - cont.

40 4

Bolt (80 Frame Only)

*Note: If a VKC 5.5/6/8/10 drive magnet assembly replacement part is needed and the pump does not have a threaded shaft (serial numbers

below #25318), then the following parts must be ordered to convert to the threaded drive magnet design: drive magnet assembly, pump shaft,

and hex jam nut.

38B 4

Coupling Support (80 Frame Only)

39 4

11

Page 12

TROUBLESHOOTING

NO DISCHARGE

Pump not primed.

Air lock in pump.

Discharge head too high.

Closed valve.

Viscosity or specific gravity too high (magnets un-

coupled).

INSUFFICIENT DISCHARGE

Discharge head higher than anticipated.

Clogged suction line, foot valve or crimp in hose.

Foot valve too small.

Foot valve or suction opening not submerged enough.

Incorrect pump rotation

INSUFFICIENT PRESSURE

Air or gasses in liquid.

Impeller diameter too small.

Discharge head higher than anticipated.

Incorrect pump rotation.

LOSS OF PRIME

Leaking discharge line.

Suction lift too high or insufficient NPSHA. Should be 2

feet above NPSHR.

Foreign matter in impeller.

Leaking valve.

Malfunctioning level sensor or control.

EXCESSIVE POWER CONSUMPTION

System head lower than rating. Pumps too much liquid.

Specific gravity or viscosity of liquid being pumped is too

high or higher than defined in application.

Binding pump parts.

(2) transportation charges are prepaid to the manufacturer. Liability

under this warranty is expressly limited to repairing or replacing the

product or parts thereof and is in lieu of any other warranties, either

expressed or implied. This warranty does apply only to normal wear of

the product or components. This warranty does not apply to products

or parts broken due to, in whole or in part, accident, overload, abuse,

chemical attack, tampering, or alteration. The warranty does not apply to any other equipment usedor purchased in combination with

this product. The manufacturer accepts no responsibility for product

damage or personal injuries sustained when the product is modified

in any way. If this warranty does not apply, the purchaser shall bear

all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to process down time, transportation

costs, costs associated with replacement or substitution products,

labor costs, product installation or removal costs, or loss of profit.

In any and all events, manufacturer’s liability shall not exceed the

purchase price of the product and/or accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the

product’s materials of construction, which are compatible with the

fluid(s) that come(s) in contact with the product. The user may

consult Finish Thompson, Inc. (manufacturer) and a manufacturer’s

representative/distributor agent to seek a recommendation of the

product’s material of construction that offers the optimum available

chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising out

of a reaction, interaction or any chemical effect that occurs between

the materials of the product’s construction and fluids that come into

contact with the product’s internals.

Call our toll free Technical Service Hot Line, 1-800-888-3743, if you

have questions regarding product operation or repair.

VIBRATION/NOISE

Excess bearing wear.

Drive magnet uncoupled.

Loose magnet.

Pump cavitating.

Motor or piping not properly secured.

Foreign object in impeller.

Set screws on motor shaft coupling loose.

Drive magnet assembly may not be properly set or secured.

WARRANTY

Finish Thompson Inc. (manufacturer) warrants this pump product to

be free of defects in materials and workmanship for a period of one

year from date of purchase by original purchaser. If a warranted defect,

which is determined by manufacturer’s inspection, occurs within this

period, it will be repaired or replaced at the manufacturer’s option,

provided (1) the product is submitted with proof of purchase date and

ORDERING SPARE PARTS

Spare parts can be ordered from your local distributor. Always refer

to pump model number to avoid error.

OTHER FINISH THOMPSON PRODUCTS

Drum Transfer Pumps, available in sanitary construction, stainless

steel, polypropylene, PVDF, and CPVC, are capable of flows to 40

gpm, discharge heads to 300 feet and viscosities to 100,000 cP.

Portable Mixers for turbine mixing and blending handle viscosities

to 1,000 cP with gentle, non-vortexing circulation. Available in 316

stainless steel.

Centrifugal Pumps, in polypropylene, PVDF, 316 stainless steel, and

cast ductile iron are offered in mag drive sealless or mechanical seal

models. Pumps are capable of 330 gpm, up to 325 feet discharge

head, and 220

Service 800-888-3743

P/N J103242, Rev. 17

Literature ID No. FT97-645O, 1-31-11

o

F (104oC) maximum.

12

Loading...

Loading...