Page 1

VKC22 Series

Sealless, Non-metallic

Vertical Mag Drive Centrifugal Pumps

Installation and Maintenance Instructions

Pat. No. 5,708,313

ASSEMBLY

WARNING: Magnetic field hazard. This pump contains

powerful rare earth magnets. When the pump is disassembled

(not connected to a motor) and the magnets are exposed, these

magnets produce powerful magnetic fields. Individuals with cardiac

pacemakers, implanted defibrillators, other electronic medical

devices, metallic prosthetic heart valves, internal wound clips (from

surgery), metallic prosthetic devices or sickle cell anemia must

not handle or be in the proximity of the magnets contained inside

the pump. Consult a health care provider for specific

recommendations before working with this pump.

PUMPS WITH MOTORS

1. Unpack the pump, the motor, and the mounting hardware

and examine for any signs of shipping damage. If damage is

detected, save the packaging and notify the carrier immediately.

2. The customer can chose to install the pump end into the tank

or lay it on its side prior to the motor installation. An overhead hoist of some sort may be needed to install the motor.

3. Install the coupling insert (item 11 onto the motor coupling

half on the motor shaft. Install the mounting plate o-ring

(item 14) into the o-ring groove on the mounting plate and

lubricate with a chemically compatible lubricant. Insert the

motor / motor adapter flange (items 1 and 3) into the top of

the pump. Note that the splines on the pump shaft coupling

half need to match up and seat into the coupling insert. Once

the coupling has seated, rotate the motor until it is oriented

correctly (avoid locating electrical box by the discharge piping). Insert and tighten the four bolts & washers (items 7, 8,

& 9) down through the motor adapter flange (item 3) into the

mounting plate.

4. Proceed to the “installation “ section of these instructions.

PUMPS WITHOUT MOTORS

1. Unpack the pump, the motor adapter flange, and the mounting hardware and examine for shipping damage. If damage is detected, save the packaging and contact the carrier

immediately.

2. The customer can chose to install the pump end into the

tank or lay it on its side prior to the motor installation. An

overhead hoist of some sort may be needed to install the

motor.

3. Install the motor coupling half (item 10 onto the motor

shaft so that the shaft is recessed below the face of the

coupling half. The correct recessed setting for 100/112

frame, 182/184 frame, and 215 frame motors is .170 plus

or minus .010. For 90 frame motors the recessed setting

is .100 plus or minus .010, and for 132 frame motors, it is

.125 plus or minus .010. Install the key into the key slot

and tighten the setscrews. Install the plastic coupling

insert (item 11 onto the coupling on the motor shaft.

4. Install the motor adapter flange o-ring (item 2) into the oring groove in the motor adapter flange (item 3) and lubricate it with a chemically compatible lubricant. Making sure

the o-ring stays in the groove place, situate the motor

adapter flange (item 3) onto the motor and bolt it down

with the correct hardware (items 4, 5, & 6).

5. Install the mounting plate o-ring (item 14) into the o-ring

groove in the mounting plate and lubricate it. Insert the

motor and motor adapter flange (items 1& 3) into the top

of the pump. Note, the splines on the pump shaft coupling half need to match up and seat into the coupling

insert. Once the coupling has seated, rotate the motor until

it is oriented correctly (avoid locating the electrical box by

the discharge piping). Insert and tighten the four bolts

and washers (item 7, 8, & 9) through the motor adapter

flange (item 3) into the mounting plate.

6. Proceed to the “installation” section of these instructions.

INSTALLATION

MOUNTING

The base plate must be securely fastened so that there is no

vibration when the pump is running.

PIPING TO AND FROM THE PUMP

• Always support the piping near the pump to minimize stress

and strain.

• Minimize frictional losses by increasing the piping size by

one diameter.

• Use a minimal number of bends, keeping any bends within

a distance of ten pipe diameters from the pump.

• Install valve on the discharge lines to control flow. Place

the valve within a distance of ten pipe diameters from the

pump.

• Ensure that the piping is leak free.

1

Page 2

Maintain a flooded suction at all times. Use a float switch to

turn off the pump at low level

CAUTION: Do not run the pump dry. This pump should

never be started without liquid in the casing as this could

damage the pump. The fluid being transferred by the pump

lubricates the pump components. Even short periods of

running the pump dry could damage the pump. It is

recommended that run dry protection be used. Optional

electrical power monitors are available to help protect

against run dry.

ELECTRICAL CONNECTIONS

1. Perform the motor wiring according to NEC requirements

and local electrical codes.

2. Wire the motor for clockwise rotation when facing the fan

end of the motor.

3. To verify correct motor rotation

a. Install the pump into the system

b. Fully open the discharge valve.

c. Allow fluid to flow into the pump. Do not allow the

pump to run dry, as this may damage to the pump com

ponents.

d. Jog the motor (allow it to run for one to two seconds)

and observe the rotation of the motor fan. Correct ro

tation is clockwise when viewed from the fan end of

the motor. Refer to directional arrow on the pump if

needed.

4. Remove the 4 bolts and washers from the bearing housing (item 12). Install two jackscrews (item 13) into two

jackscrew holes in top of bearing housing and screw them

in until the bolt heads bottom out. Grip the bearing housing firmly and pull straight out of the column assembly

(item 15). On extended length models, be sure to pull

straight up until the drive hub clears the mounting plate to

avoid damage to the lower bearing housing fingers.

5. Remove the bolts holding the mounting plate to the tank

and remove the pump from the tank. Gently place the pump

on the mounting plate (on a clean surface) with the pump

suction pointing straight up.

6. Remove the 6 housing bolts, loosen the discharge union ,

and remove the impeller housing . Remove the housing oring (item 18), and remove the impeller assembly (items

16 and 17).

INSPECTION

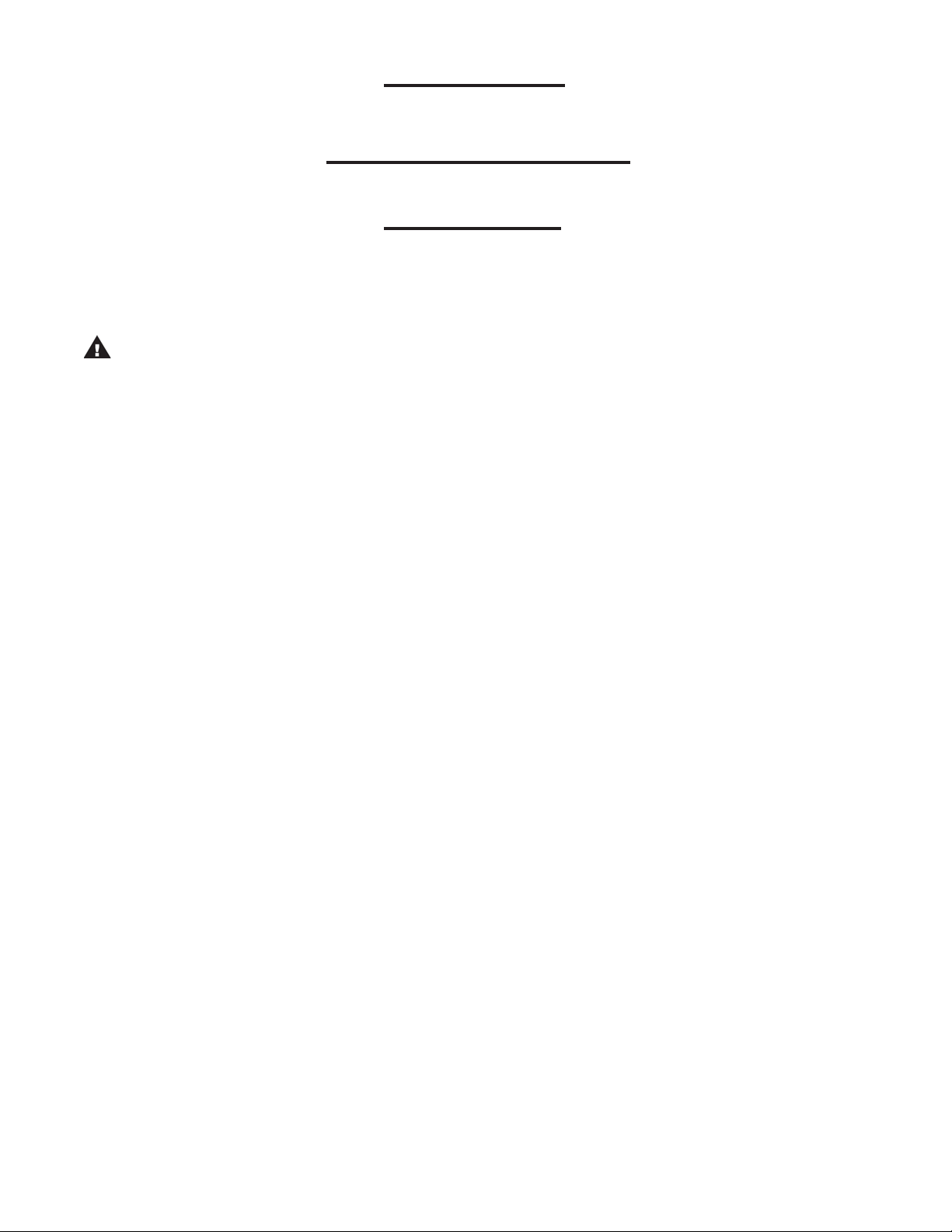

1. Check impeller drive bushing (item 16A) and impeller thrust

washer (item 17A). Replace if cracked, chipped, or scored.

If the minimum groove height in the slotted areas of the

drive bushing or the thrust washer is less than the minimum height recommended (.020), then replace them.

2. If the drive bushing’s inside diameter is more than .780,

then replace it. See figure 1.

.780 MAX.

Note: A pump running backwards will pump, but at a greatly

reduced flow and pressure.

OPERATION

1. Partially open the discharge valves.

2. Start the pump and verify liquid is flowing. If there is not

liquid flow, refer to the “Troubleshooting” section of these

instructions.

3. Adjust the flow rate and pressure by regulating the discharge valve.

MAINTENANCE

DISASSEMBLY

1. Disconnect the power and remove the electrical wiring.

2. Close the discharge valve and disconnect the piping.

3. Remove the 4 bolts and washers (items 7, 8 and 9), and

pull the motor and motor adapter flange (items 1 and 3)

from the pump. If the motor is to be replaced, remove the

4 bolts and washers (items 4, 5, and 6) from the motor

adapter flange (Item 3) and separate the flange from the

motor. Remove the motor adapter flange o-ring (item 2)

and the mounting plate o-ring (item 14).

.020 MIN.

Figure 1Figure 1

Figure 1

Figure 1Figure 1

3. Check for loose magnets on the drive hub.

4. Check for any signs of rubbing by the drive assembly inside the column assembly from the motor end, or signs of

rubbing inside the column assembly by the impeller assembly on the suction side. If there is any sign of rubbing,

contact the factory.

5. Check for bearing wear on the drive shaft (upper and lower

bearings on extended length models).

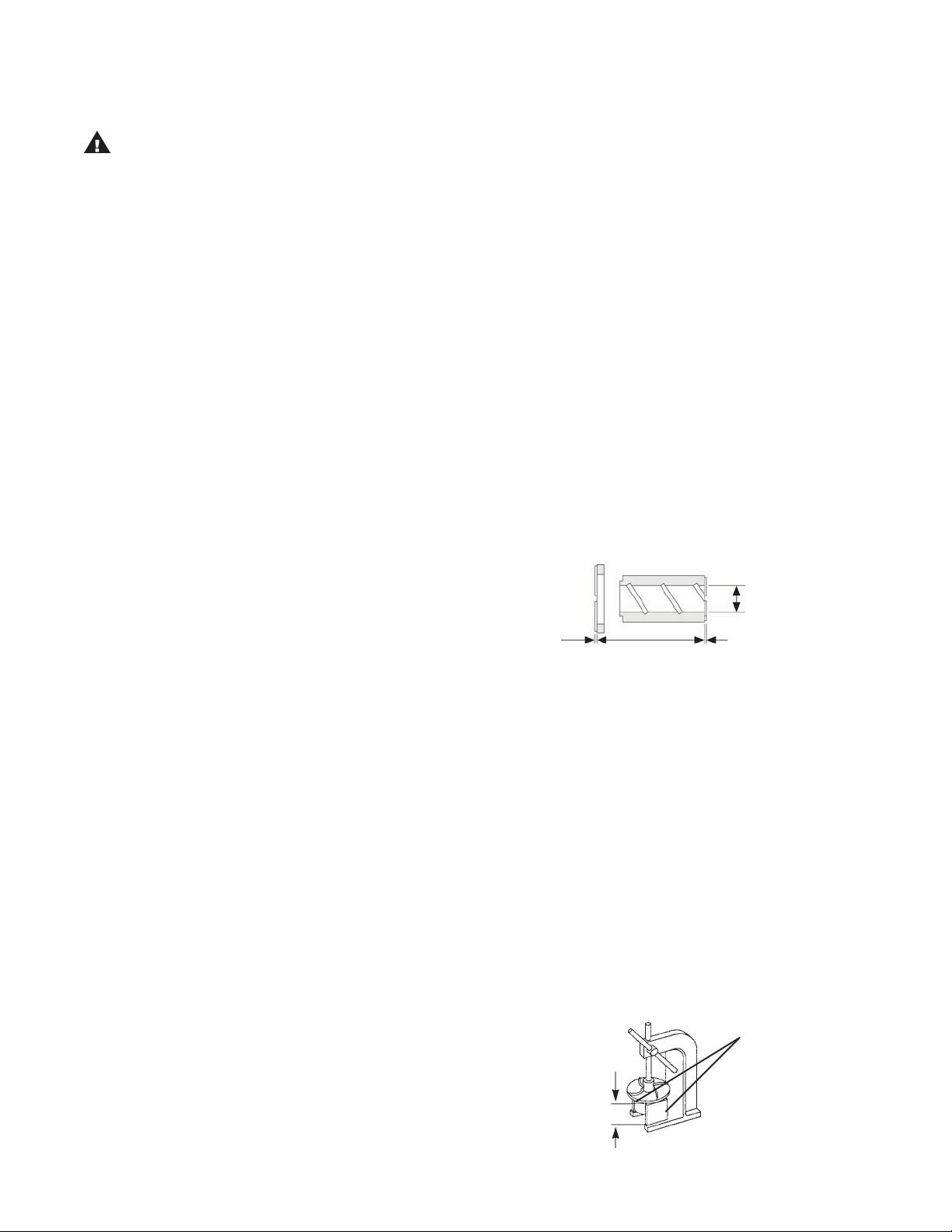

IMPELLER DISASSEMBLY

1. To separate the impeller drive (item 16) from the impeller

(item 17), support the impeller in an arbor press using two

5-inch minimum spacer blocks

2. Insert a 1-1/2” diameter plastic or wooden shaft into the

eye of the impeller and press the impeller drive out of the

impeller. See figure 2.

Support

5” MIN.

Figure 2Figure 2

Figure 2

Figure 2Figure 2

2

Page 3

3. If an arbor press is not available, use two slotted screwdrivers to pry the impeller apart from the impeller drive.

There are two slots located 180° apart in the top of the

impeller drive. Insert the screwdriver tips into the slots

and pry them apart.

3

1

5

6

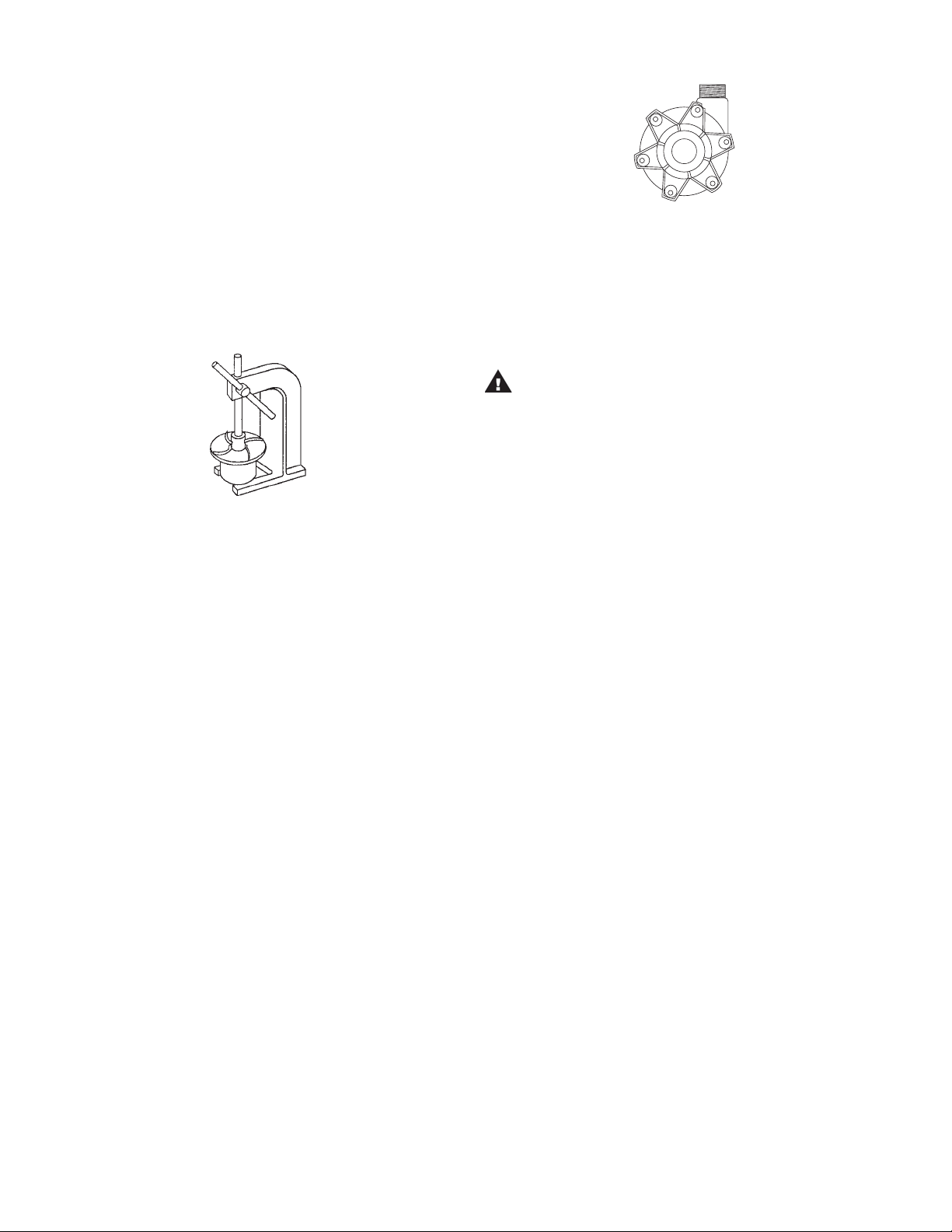

BUSHING AND THRUST RING REPLACEMENT

1. To remove the bushing (item 16A), place the impeller drive

in an arbor press with the slotted end of the bushing facing down. Insert a 1” diameter plastic or wooden shaft

through the impeller eye and press the bushing out. See

figure 3.

Figure 3Figure 3

Figure 3

Figure 3Figure 3

Note: The slotted end of the bushing is always located on

and installed from the “bottom” of the impeller drive. The

recessed, splined end that the impeller is inserted into is

the “top” of the impeller drive.

2. To replace the bushing, place the impeller drive with the

recessed splined end(the top) face down on a clean flat

surface. Match up the flat on the bushing side with the

flat in the eye of the impeller drive and insert the bushing,

slotted face up, into the impeller drive. Gently push until

the bushing bottoms out. The bushing should be flush

with the impeller eye on the “top” side.

3. If replacement is necessary, the impeller thrust ring (item

17A) on the open impeller can be removed by gently pulling the ring out of the impeller. The thrust ring on the

closed impeller must be removed by grasping the ring

with pliers and twisting the ring out.

4. To replace the thrust ring, match up the corresponding

flats on the thrust ring and the top of the impeller and

press into place.

Note: Protect the face of the thrust ring during installation with wood or plastic, and avoid tilting the ring.

REASSEMBLY

1. Align splines on the impeller into the impeller drive and

press together (protect the face of the thrust ring during

assembly).

2. With mounting plate down and the column section facing up, carefully install the impeller assembly onto the

barrier spindle (white ceramic post).

3. Install and lubricate the housing o-ring (item 18), and

place the impeller housing onto the pump. Align the discharge and start the discharge union (do not tighten yet).

Using the correct hardware, bolt the housing to the col-

4

Figure 4Figure 4

Figure 4

Figure 4Figure 4

2

umn section and tighten to 70 in-lbs. of torque using the pattern shown in figure 4. For pumps with PVDF hardware, a

®

Teflon

thread lubricant must be used on all plastic threads

before each use. Insert the 5/16-18 x 3-1/4 PVDF bolts through

the housing and barrier. Install PVDF nut. Tighten the nuts

onto the bolts using the pattern shown in figure 4.

CAUTION: Do not tighten more than maximum torque of 25

inch pounds on all PVDF hardware.

Next install the three 5/8-11 x 4-3/4 PVDF bolts using the

same maximum torque setting. Tighten the discharge pipe

union nut.

4. Clamp or somehow secure the mounting plate (item 21) to a

table with the pump end down. Making sure the jackscrews

(item 13) are threaded all the way into the bearing housing

(item 12), carefully set the drive hub into the column assembly

until the jackscrews touch. Extended length models require

lowering the drive hub and lower bearing mount straight down

into the column section until the jackscrews make contact. To

be centered correctly, the four fingers on the lower bearing

mount must seat inside locating bore in base of the column.

Avoid pinching your fingers by gripping the top flange of the

bearing housing and keeping fingers away from the jackscrews.

Use the jackscrews to slowly lower the bearing housing into

the column section and remove the jackscrews. Install and

tighten the four bolts and washers that secure the bearing

housing to the column assembly.

5. If the motor was replaced, install and lubricate the motor adapter

flange o-ring (item 2) and bolt the flange (item 3) onto the motor using the correct hardware (items 4, 5, & 6). Install the

coupling half onto the motor shaft (see instructions on page 1,

step 3, under “Pumps Without Motors”).

6. The customer can choose to either lay the pump end on its

side and then install the motor, or place the pump end into the

tank prior to the motor installation. An overhead hoist of some

sort may be needed to install the motor.

7. Install the plastic coupling insert (item 11) onto the motor

coupling half on the motor shaft. Install the mounting plate oring (item 14) into the o-ring groove on the mounting plate

and lubricate with a chemically compatible lubricant. Insert the

motor / motor adapter flange (items 1 & 3) into the top of the

pump. Note that the splines on the pump shaft coupling half

need to match up and seat into the coupling insert. Once the

coupling has seated, rotate the motor until it is orientated correctly (avoid locating electrical box by the discharge piping).

Insert and tighten the four bolts & washers (items 7, 8, and 9)

down through the motor adapter flange (item 3) into the mounting plate.

8. Refer to the “installation” section in this manual if needed.

3

Page 4

VKC 22 EXPLODED VIEW

4

Page 5

VKC22 SPARE PARTS LIST

5

Page 6

VKC22 SPARE PARTS LIST (continued)

6

Page 7

GENERAL NOTES

WARRANTY

1. Do not pump liquids containing metal fines.

2. If magnets decouple, stop the pump immediately. The rare

earth magnets used in this pump are more resistant to demagnetization, but operating the pump with the magnets

decoupled will eventually weaken the magnets.

3. Plastic pumps will expand and contract with temperature so

the plastic column sections.

4. Always use a chemically compatible lubricant on any o-ring.

5. An information sticker is attached to the mounting plate. The

first line is the model number and the second line is the serial

number.

TROUBLESHOOTING

NO OR INSUFFICIENT FLOW:

1. No liquid in sump.

2. Air lock in pump.

3. Closed valve.

4. Viscosity or specific gravity too high

5. Discharge head higher than anticipated.

6. Suction too close to the bottom of the sump.

INSUFFICIENT PRESSURE:

1. Air or gasses in liquid.

2. Clogged suction

EXCESSIVE POWER CONSUMPTION:

1. Head lower than rating. Excessive flow.

2. Specific gravity or viscosity of liquid is too high.

EXCESSIVE VIBRATION:

1. Loose piping or bolts.

2. Suction too close to the bottom of the sump

Finish Thompson, Inc (manufacturer) warrants this product to

be free of defects in materials and workmanship for a period of

one year from date of purchase by original purchaser. If a

warranted defect, which is determined by manufacturer’s

inspection, occurs within this period, it will be repaired or

replaced at the manufacturer’s option, provided (1) the product

is submitted with proof of purchase date and (2) transportation

charges are prepaid to the manufacturer. Liability under this

warranty is expressly limited to repairing or replacing the

product of parts thereof and is in lieu of any other warranties,

either expressed or implied. This warranty does apply only to

normal wear of the product or components. This warranty does

not apply to products or parts broken due to, in whole or in

part, accident, overload, abuse, chemical attack, tampering, or

alteration. The manufacturer accepts no responsibility for

product damage or personal injuries sustained when the product

is modified in any way. If this warranty does not apply, the

purchaser shall bear all cost for labor, material and

transportation.

Manufacturer shall not be liable for incidental or consequential

damages including, but not limited to process down time,

transportation costs, costs associated with replacement or

substitution products, labor costs, product installation or

removal costs, or loss of profit. In any and all events,

manufacturer’s liability shall not exceed the purchase price of

the product and/or accessories.

Call our toll free Technical Service Hot Line, 1-800-888-3743, if you

have any questions regarding product operation or repair.

ORDERING SPARE PARTS

Spare parts can be ordered from your local distributor. Always

refer to pump model number to avoid error.

OTHER FINISH THOMPSON PRODUCTS

Drum Transfer Pumps, available in sanitary construction,

stainless steel, polypropylene, PVDF, and CPVC are capable of

flows to 40 gpm, discharge head to 80 feet and viscosities to

100,000 cps.

Portable Mixers for turbine mixing and blending handle

viscosities to 1,000 cps with gentle, non-vortexing circulation.

Available in 316 stainless steel.

Centrifugal Pumps in corrosion resistant materials are

offered in magnetic drive sealless or mechanical seal models.

Pumps are capable of330 gpm, up to 325 feet discharge

head, and 220

o

F (104oC) maximum.

For more information, contact Finish Thompson Inc.

Toll Free Service 1-800-888-3743

Part Number J104161, Rev. 5

FT02-851E, 6-21-06

7

Loading...

Loading...