Page 1

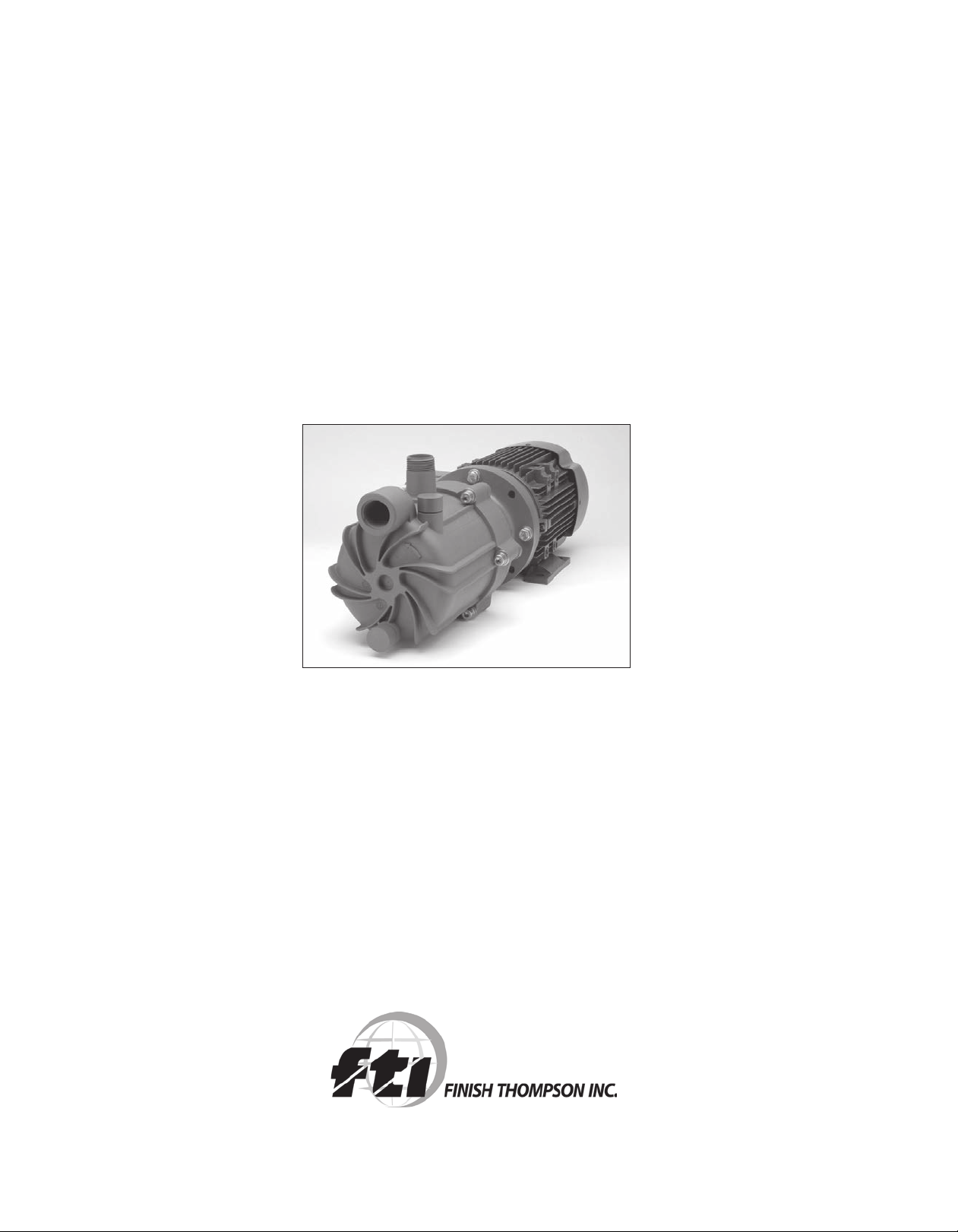

SP10 SERIES SELF-PRIMING PUMPS

ASSEMBLY, INSTALLATION AND

OPERATION MANUAL

Page 2

TABLE OF CONTENTS

Model Number/Serial Number ................................................3

Important Notice .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . 3

Chemical Reaction Disclaimer ................................................3

Safety Precautions ......................................................... 3-4

SP10 Capabilities........................................................... 4-5

Section I - Assembly ........................................................ 5-6

Section II - Installation ...................................................... 6-8

Motor/Electrical .....................................................8

Section III - Start-up and Operation. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . 8

Section IV - Shutdown . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . 8

Maintenance ........................................................ 9

Section V - Disassembly ....................................................9-12

Outer Drive Replacement ............................................13

Thrust Ring Replacement ............................................12

Bushing Replacement ...............................................12

Impeller Replacement................................................12

Section VI - Reassembly ...................................................12-13

Section VII - Troubleshooting. .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .14

Section VIII - Warranty . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .14

Section IX - Spare Parts......................................................15

Part Number Explanation ............................................15

Alternate Components ..............................................15

Spare Parts Diagram .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. .16

Spare Parts List ...................................................17-20

NOTE: Maintenance videos are now available online at www.nishthompson.com.

FTI Contacts:

Tech Service: 800-888-3743 or techservice@finishthompson.com

Order Fax: 814-459-3460 or 814-455-8518

Sales: 814-455-4478; 800-934-9384 (toll free U.S. & Canada)

2

Page 3

Model Number and Serial Number

Record the model number and serial number below for future reference. This is important information when ordering re-

placement parts or when technical assistance is required. The numbers are found on a label located on the motor adapter.

MODEL NUMBER = ________________________

SERIAL NUMBER = ________________________

IMPORTANT NOTICE

U.S. Export Administration Regulations, pursuant to ECCN 2B350, prohibit the export or reexport to certain enumerated countries of

sealless centrifugal pumps in which all wetted materials are constructed from fluoropolymers without first applying for and obtaining

a license from the U.S. Bureau of Industry and Security (BIS). This affects all Finish Thompson magnetic-drive pumps constructed from

PVDF or lined with ETFE. Please contact the BIS (www.bis.doc.gov) or Finish Thompson with questions regarding the Regulations or a

list of the countries to which they apply.

Chemical Reaction Disclaimer

The user must exercise primary responsibility in selecting the product’s materials of construction, which are compatible

with the uid(s) that come(s) in contact with the product. The user may consult Finish Thompson Inc. (manufacturer) and

a manufacturer’s representative/distributor agent to seek a recommendation of the product’s material of construction that

offers the optimum available chemical compatibility.

However neither manufacturer nor agent shall be liable for product damage or failure, injuries, or any other damage or

loss arising out of a reaction, interaction or any chemical effect that occurs between the materials of the product’s con-

struction and uids that come into contact with the product’s components.

Safety Precautions

WARNING: READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND OPERATING THIS UNIT. FAIL-

URE TO FOLLOW THESE PRECAUTIONS CAN RESULT IN SERIOUS INJURY OR DEATH.

WARNING: Magnetic eld hazard. This pump contains powerful magnets. Exposed magnets (pump not connected

to motor) produce powerful magnetic elds. Individuals with cardiac pacemakers, implanted debrillators, other elec-

tronic medical devices, metallic prosthetic heart valves, internal wound clips (from surgery), metallic prosthetic devices or

sickle cell anemia must not handle or be in the proximity of the magnets contained inside the pump. Consult a health care

provider for specic recommendations before working with this pump.

WARNING: Magnetic force hazard. This pump should only be disassembled and assembled using the recommend-

ed procedures. The magnetic attraction is powerful enough to rapidly pull the motor end and the wet end together. Do not

place ngers between the mating surfaces of the motor and wet ends to avoid injuries. Keep the drive magnet and impeller

assembly away from metal chips or particles, items with magnetic stripes like credit cards, and magnetic computer media

such as oppy discs and hard drives.

WARNING: Not Recommended for Pumping Flammable or Combustible Liquids. During the priming process the

internal pump atmosphere can become very dangerous should the pump fail to prime and overheat.

The SP Series pumps can be used to pump non-ammable or non-combustible liquids in a hazardous area. It is important

to follow these guidelines:

1. Select the Ns (non-sparking) bronze bump ring option. The non-sparking ring is pressed into the clamp ring or motor

adapter and prevents sparking should the motor bearings fail and the outer mag drive assembly runs out of round.

2. Select an FTI explosionproof motor or provide your own.

WARNING: Hot surfaces. This pump is capable of handling liquids with temperatures as high as 220º F (104º C).

This may cause the outer areas of the pump to become hot as well and could cause burns.

WARNING: Rotating Parts. This pump has components that rotate while in operation. Follow local safety standards

for locking out the motor from the power supply during maintenance or service.

WARNING: Chemical Hazard. This pump is used for transferring many types of potentially dangerous chemicals.

Always wear protective clothing and eye protection, and follow standard safety procedures when handling corrosive or

personally harmful materials. Proper procedures should be followed for draining and decontaminating the pump before

disassembly and inspection of the pump. There may be small quantities of chemicals present during inspection.

WARNING: Never run pump at less than minimum ow or with the discharge valve closed. This could lead to pump

failure.

3

Page 4

WARNING: The pump and associated components are heavy. Failure to properly support the pump during lifting and

movement could result in serious injury or damage to the pump and components.

CAUTION: This pump should never be started without the 0.6 US gallon /77 oz. ( 2.7 liters) of priming uid in the

housing. If the pump has a PTFE, ceramic or silicon carbide bushing, IT CANNOT BE RUN DRY WITHOUT CAUSING

DAMAGE TO THE PUMP. However, the pump can operate without liquid in the housing if the pump has a carbon bushing.

The exact length of time the pump can operate dry with a carbon bushing varies with operating conditions and environment.

CAUTION: Never start or operate with a closed suction valve.

WARNING: Operation without priming or against a closed discharge valve can result in high temperatures that can

result in injury or damage to pump components.

CAUTION: Always provide adequate NPSHa (net positive suction head available). It is recommended to provide at

least 2 feet (61 cm) above the NPSHr (net positive suction head required).

CAUTION: If pump is used on variable speed drive, do not exceed 60 Hz.

SP10 Capabilities

Maximum Working Pressure: 80 psi (5.5 bar)

Maximum Temperature: Polypropylene: 180º F (82º C); PVDF: 220º F (104º C)

NOTE: Maximum temperature is application dependent. Consult a chemical resistance guide

or the chemical manufacturer for chemical compatibility and temperature limits.

Maximum Lift: 25 feet (7.6 meters) with 4.18” and 4” diameter impellers. See the chart below for maximum lift

for other impeller diameters.

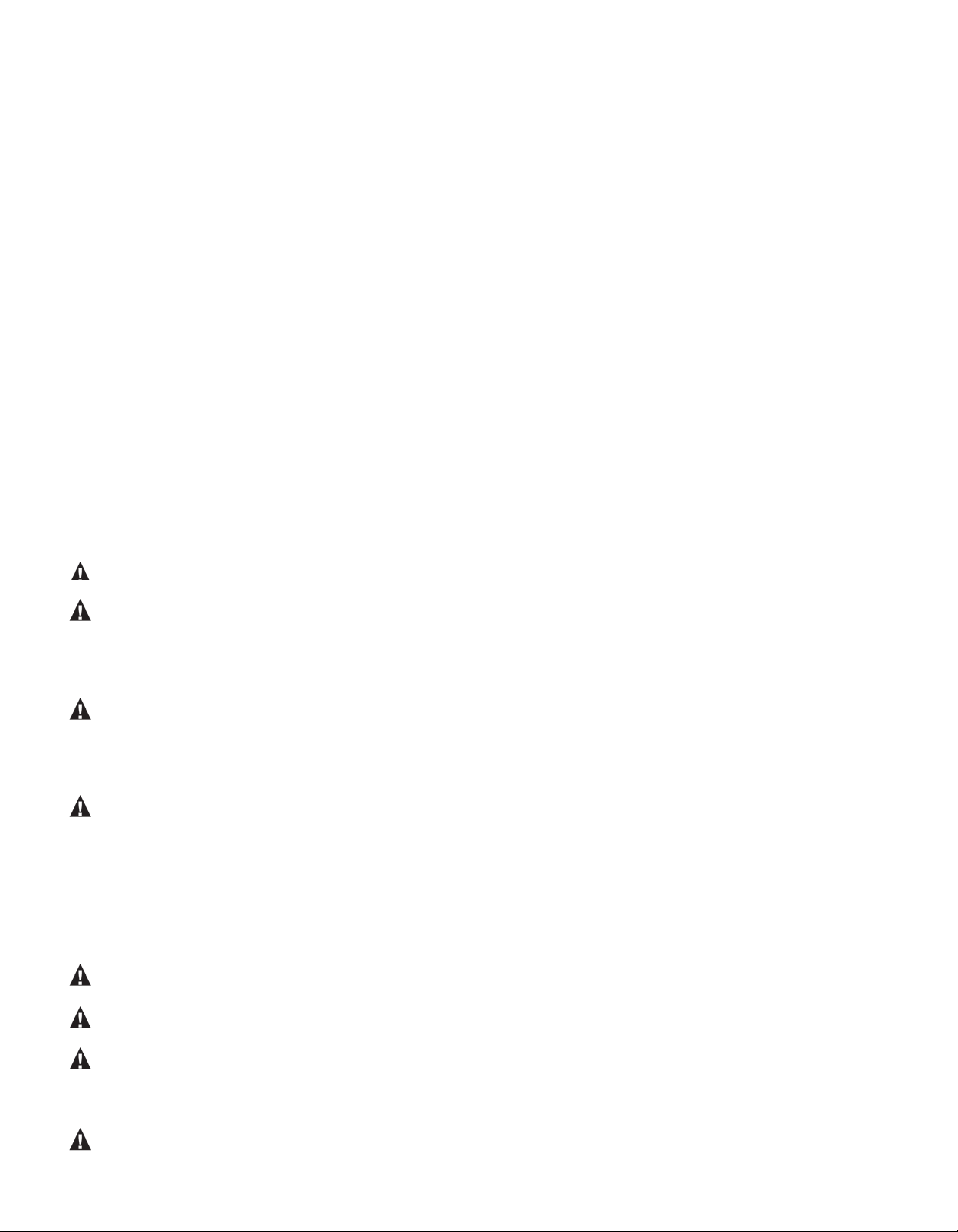

SP10 Maximum Lift Chart

1” (25.4 mm) Suction

Piping

Impeller Diameter Max. Lift

@ 3450 rpm

4.18” (106.2 mm) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M)

4.00” (101.6 mm) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M) 20’ (6.1 M)

3.75” (95.3 mm) 20’ (6.1 M) 20’ (6.1 M) 20’ (6.1 M) 15’ (4.6 M)

3.5” (88.9 mm) 20’ (6.1 M) 15’ (4.6 M) 15’ (4.6 M) 10 (3.1 M)

3.25” (82.6 mm) 15’ (4.6 M) 10 (3.1 M) 15’ (4.6 M) 10 (3.1 M)

3” (76.2 mm) 10’ (3.1 M) 5’ (1.5 M) 10’ (3.1 M) 5’ (1.5 M)

NOTE: Lift was determined on fresh, cold water with 1” and 1 ½” Schedule 40 pipe. Specific

gravity affects lift capability. Divide maximum lift from chart above by the specific gravity to

determine equivalent maximum lift.

Max. Lift

@ 2900 rpm

1.5” (38.1 mm) Suction

Piping

Max. Lift

@ 3450 rpm

Max. Lift

@ 2900 rpm

Solids: Maximum particle size is 100 microns for slurries and 1/64” (.4 mm) for infrequent particles.

Maximum hardness is 80 HS. Maximum concentration is 10% by weight. If solids are being

pumped, it is

recommended the pump has either ceramic or, for best results, silicon carbide components.

Pumping solids may lead to increased wear.

NOTE: While the pump is capable of being used in sump applications, it is NOT a trash pump. Care must be taken to ensure that debris

and foreign objects do not enter the pump or damage may result. Suggest using a 1” strainer basket with 1/32” (.8 mm) perforations

or 1 1/2” strainer basket with 1/8” (3.2 mm) perforations. Regular strainer basket maintenance is required to prevent plugging and

decrease in NPSHa so not to starve and damage the pump.

Minimum Allowable Flow Rate

Do not allow the flow rate to drop below the minimum flow rate listed in the chart below.

Model 3450 rpm 2900 rpm

SP10 ½ gpm (1.9 lpm) 1.9 lpm (½ gpm)

Maximum Sound Level:

69 dBA (pump only)

4

Page 5

Maximum Allowable Motor Power

• Do not exceed the maximum power rating for the pump coupling.

• Standard coupling for the SP10 is 10-pole & maximum 2 HP (1.5 kW).

Priming Liquid Volume

Initial filling (or refilling after maintenance) of the pump housing requires 0.6 US gallon / 77 oz. (2.7 liters) of liquid.

Unpacking and Inspection

Unpack the pump and examine for any signs of shipping damage. If damage is detected, save the packaging and notify the carrier

immediately.

SP10 Assembly, Installation and Operation

Section I - Assembly

Tools Required:

Metric socket or wrench set, 9/16” socket or wrench, 8 mm

Allen wrench, and 3/16” Allen wrench (NEMA motors

only) and pliers (for ll/drain plugs).

Pumps with Motors

Proceed to “Installation” Section II.

Pumps Without Motors

1. Remove the pump, drive magnet assembly and hard-

ware package from the carton.

CAUTION: Keep away from metallic particles, tools

and electronics. Drive magnets MUST be free of metal

chips.

WARNING: Keep the drive magnet away from the

open end of the motor adapter and barrier. Strong mag-

netic attraction could allow the drive hub to enter the

motor adapter resulting in injury or damage.

2. Place motor on the fan end. See gure 1.

NOTE: For 56C/145TC frame motors go to step 4.

3. For Metric motors install the motor adapter ange

(item18) on the motor face using bolts, lock washers

and at washers (items 31,32 & 33). See gure 2.

Torque bolts to the following:

• 63 frame (M4) = 30 in-lb (3.4 N-m)

• 71 frame (M5) = 90 in-lb (10.2 N-m)

• 80 frame (M6) = 90 in-lb (10.2 N-m)

NOTE: 63/71 B14 adapter ange is reversible. Install

63/71 B14 adapter so that proper motor ange size is

facing motor.

NOTE: Apply anti-seize compound on the threads of

the bolts.

4. Coat the motor shaft with anti-seize compound. Insert

the key supplied with the motor into the keway on the

motor shaft. See gure 3.

Note: Make sure the motor shaft is clean & free of

burrs. The outer drive is precision machined and has a

bore tolerance of +.0005/-0 inch.

Figure 1

Figure 2 Figure 3

5

Page 6

5. Slide the outer drive magnet assembly (item 17) onto

the motor shaft until the motor shaft contacts the snap

ring in the bore of the drive. See gures 4 & 5.

Figure 4 Figure 5

6. Secure the drive on the motor shaft.

WARNING: Be careful, magnets will try to attract tools.

Metric Motors: Secure the drive to the motor shaft us-

ing bolt, lock washer and at washer (items 25, 26, 27).

Thread the bolt into the end of the motor shaft (while

holding the outer drive to prevent it from turning).

See gure 6.

Tighten the bolt to the following:

• 63 frame (M4) = 15 in-lb (1.7 N-m)

• 71 frame (M5) = 30 in-lb (3.4 N-m)

• 80 frame (M6) = 90 in-lb (10.2 N-m)

• 90 frame (M8) = 130 in-lb (14.7 N-m)

NEMA Motors: Install (2) 3/8” set screws (item 17B)

into threaded holes on the side of the outer drive magnet

assembly. Using a 3/16” Allen wrench, tighten to 228

in-lbs (25.8 N-m). See gure 7.

assembly.

8. Secure the pump to the motor with (4) 3/8” bolts, lock

washers and at washers (items 28, 29 & 30) using a

9/16” socket or wrench. Tighten to 240 in-lb (27.1

N-m). See gures 8 and 9.

Figure 8

Figure 9

9. Rotate the motor fan to ensure that there is no binding

in the pump.

10. Proceed to Installation Section

Section II - Installation

Mounting

Motor feet should be securely fastened to a solid foundation.

Note: Shims are required for the motor feet on ALL 63, 71

and 80 frame motors and 90 frame B5 motors.

Piping

Figure 6 Figure 7

7. Install the pump end on the motor/drive magnet as-

sembly. With the motor/outer drive magnet assembly in

a horizontal position, securely clamp to the workbench.

NOTE: If the pump has the optional o-ring sealing op

tion (available on 56C and 145TC frame pumps only),

in stall the o-ring (item 16) in the groove in the motor

adapter (motor end).

Carefully slide the pump onto the drive magnet as sembly. The last couple of inches (5 cm) before the

pump reaches the motor will have STRONG magnetic

attraction between the pump and outer drive magnet

6

Page 7

CAUTION: The NPSH available to the pump must be

greater than the NPSH required. The amount of lift,

frictional pipe loss, and vapor pressure must be calcu lated into the application. NPSH available should be 2

feet (.6 meters) greater than NPSH required.

• Total suction lift including pipe friction loss and

corrections for specic gravity must not exceed value

shown in chart below.

SP10 Maximum Lift Chart

1” (25.4 mm) Suction

Piping

Impeller Diameter Max. Lift

@ 3450 rpm

4.18” (106.2 mm) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M)

4.00” (101.6 mm) 25’ (7.6 M) 25’ (7.6 M) 25’ (7.6 M) 20’ (6.1 M)

3.75” (95.3 mm) 20’ (6.1 M) 20’ (6.1 M) 20’ (6.1 M) 15’ (4.6 M)

3.5” (88.9 mm) 20’ (6.1 M) 15’ (4.6 M) 15’ (4.6 M) 10 (3.1 M)

3.25” (82.6 mm) 15’ (4.6 M) 10 (3.1 M) 15’ (4.6 M) 10 (3.1 M)

3” (76.2 mm) 10’ (3.1 M) 5’ (1.5 M) 10’ (3.1 M) 5’ (1.5 M)

Max. Lift

@ 2900 rpm

1.5” (38.1 mm) Suction

Piping

Max. Lift

@ 3450 rpm

Max. Lift

@ 2900 rpm

NOTE Maximum suction lift is reduced by 1.13 feet

(.34 meters) for every 1,000 feet (304 meeters) of

altitude.

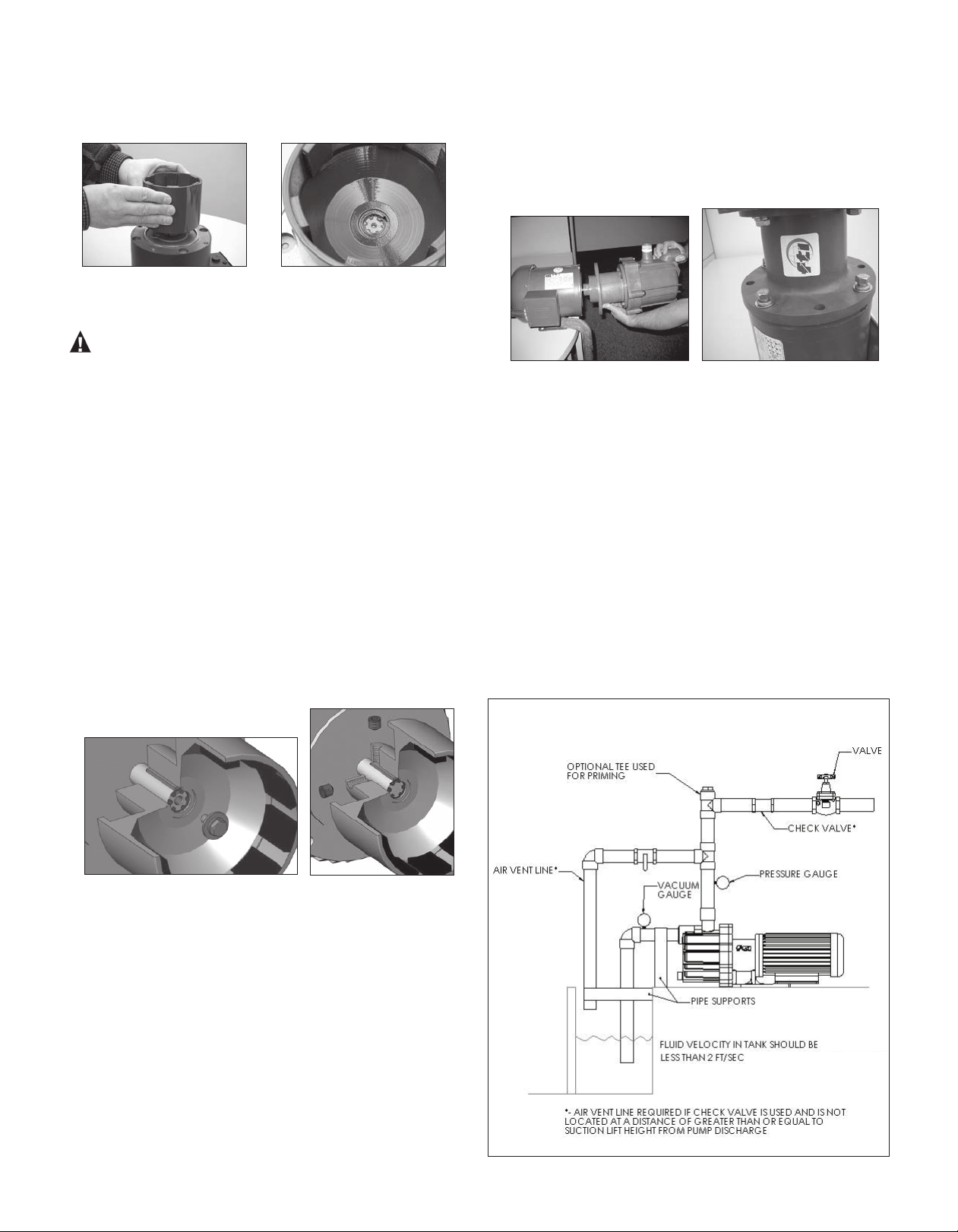

• Install the pump as close to the suction source as

possible.

• SP Series pumps are designed to operate in a horizontal

position only with discharge on the top.

• SP Series pumps self-priming capability is due to its

ability to create a vacuum in the suction piping. The

suction piping MUST be airtight at ttings and

connections.

• Support the piping independently near the pump to

eliminate any strain on the pump casing. In addition,

the piping should be aligned to avoid placing stress on

the pump casing.

• The suction side of the pump should be as straight and

short as possible to minimize pipe friction.

• The suction line should not have any high spots. This

can create air pockets that can reduce pump perfor mance. The suction piping should be level or slope

slightly upward to the pump.

• The suction pipe should be 1” (25.4 mm) or 1½” (38

mm). Larger suction piping will affect priming ability.

Smaller piping affects NPSH available and pump per formance. See SP10 performance curve book or on-line

at www.nishthompson.com.

• Provide for adequate suction submergence. Excessive

submergence will reduce pump performance.

• The end of the pipe should be at least 2” (5.08 cm) for

1” pipe & 3” (7.6 cm) for 1½” pipe above the bottom

of the suction tank.

• If debris is in the suction tank, a strainer can be in stalled to help prevent foreign matter from entering

the pump. The strainer must be periodically cleaned to

prevent restriction.

• It is recommended that a vacuum/pressure gage be

installed in the suction piping.

• For faster priming on installations with high lift, a foot

valve is recommended.

• Check and control valves (if used) should be installed

on the discharge line. The control valve is used for

regulating ow. Isolation valves on the suction and

discharge are used to make the pump accessible for

maintenance. The check valve helps protect the pump

against damage from water hammer. This is particularly

important when the static discharge head is high.

NOTE: If a check valve is used in the discharge line, it

must be placed at a distance at least equal to the maxi mum suction lift from the pump. If this cannot be done,

an air vent must be provided in the discharge line.

• If exible hose is preferred over pipe, use a vacuum

rated reinforced hose for the proper temperature, pres sure and is chemically resistant against the uid being

pumped.

• The suction valve must be completely open to avoid

restricting the suction ow.

• When installing pumps with anges, we recommend

use of low seating stress gaskets such as Gore-Tex or

Gylon (expanded PTFE).

• It is advisable to install a ush system in the piping to

allow the pump to be ushed before the pump is re moved from service.

NOTE: The pump is provided with a 1/2” BSPP drain

in the impeller housing.

• A “tee” can be installed in the discharge piping as an

alternative location for lling the housing with uid

before pump operation.

• “Filling” is dened as lling the housing with 0.6 US

gallon / 77 oz. (2.7 liters) of liquid

• “Priming” is dened as evacuating all the air from the

suction piping/pump and replacing it with uid. See

Priming chart on next page.

7

Page 8

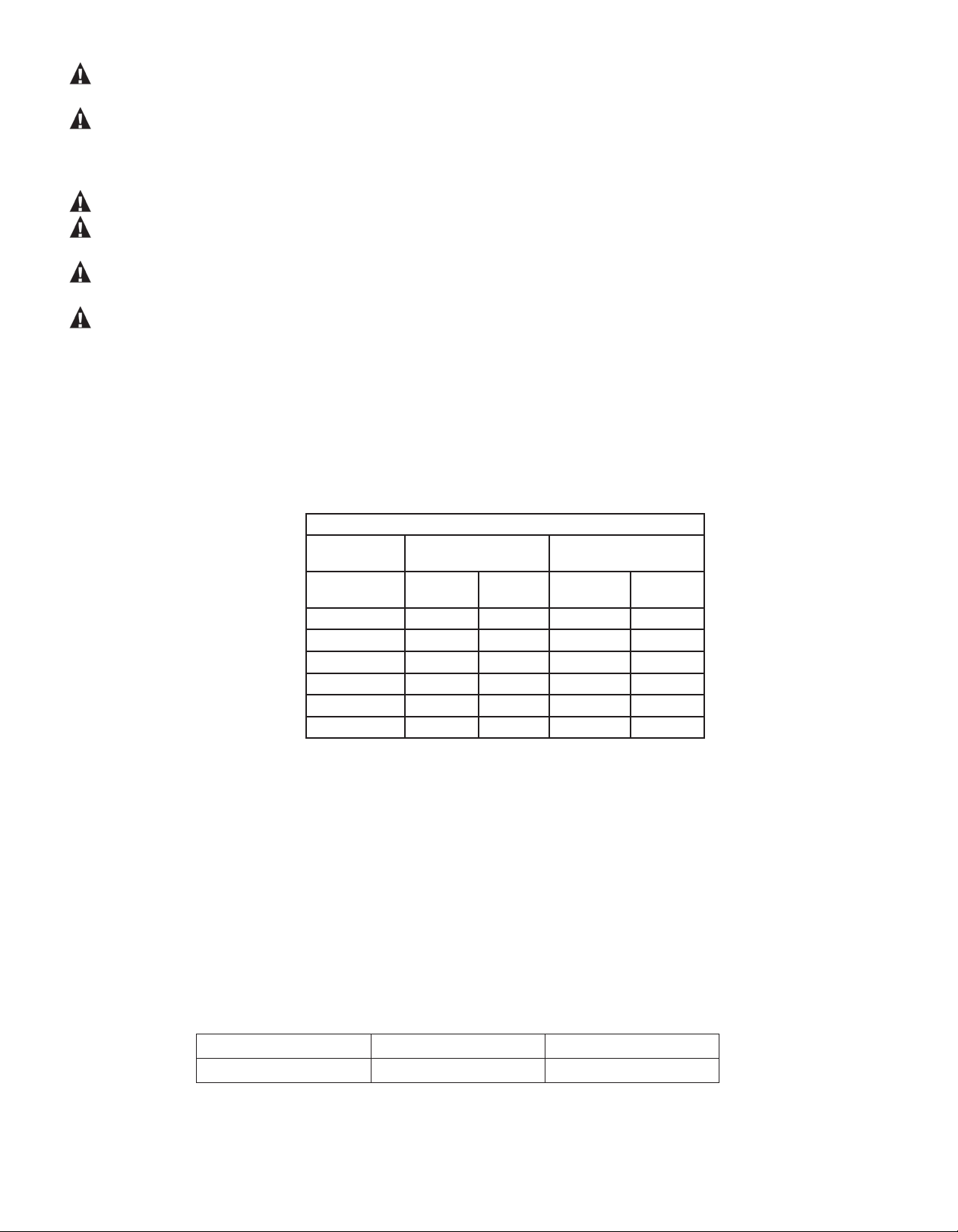

SP10 Priming Time Chart

1” (25.4 mm) Suction Piping 1.5” (38.1 mm) Suction Piping

Impeller

Diameter

in. (mm) 5 10 15 20 25 1.5 3.1 4.6 6.1 7.6 5 10 15 20 25 1.5 3.1 4.6 6.1 7.6

4.18 (106.2) 10 35 65 100 140 10 40 80 160 240 25 60 100 150 210 30 75 145 255 455

4.00 (101.6) 12 37 68 130 310 20 50 90 200 320 28 60 100 180 280 35 80 150 360

3.75 (95.3) 15 45 72 155 30 45 135 30 70 110 275 40 95 240

3.5 (88.9) 20 50 75 185 35 75 225 35 80 150 60 120

3.25 (82.6) 25 60 145 37 150 40 88 240 85 225

3 (76.2) 27 115 60 55 165 120

NOTE: Times shown are guidelines only. Times will vary based on system and piping setups.

3450 RPM 2900 RPM 3450 RPM 2900 RPM

Feet of Lift (sec.) Meters of Lift (sec.) Feet of Lift (sec.) Meters of Lift (sec.)

Motor Speed Motor Speed

Motor/Electrical

Install the motor according to NEC requirements and local

electrical codes. The motor should have an overload protec-

tion circuit.

Wire the motor for clockwise rotation when facing the fan

end of the motor.

CAUTION: Do not operate the pump to check rotation

until the pump is full of liquid.

Check all electrical connections with the wiring diagram

on the motor. Make sure the voltage, frequency, phase, and

amp draw comply with the supply circuit.

To verify correct rotation of the motor:

1. Install the pump into the system.

2. Remove the ll plug (items 2 & 2A) and ll the hous -

ing with 0.6 US gallon / 77 oz. (2.7 liters) of the service

liquid or water. Replace ll plug and tighten until the

o-ring is seated.

NOTE: Use a exible spout funnel or a “tee” in the

discharge piping to ll the housing on pumps equipped

with anges.

3. Fully open the suction and discharge valves.

4. Jog the motor (allow it to run for 1-2 seconds) and ob serve the rotation of the motor fan. Refer to the direc tional arrow molded into the front of the housing if

necessary.

NOTE: An SP pump running backwards may not

prime.

Section III - Start-up and Operation

2. Open the inlet (suction) and outlet (discharge) valves

completely.

3. Turn the pump on. Wait for discharge pressure and ow

to stabilize (could take several minutes depending

upon suction lift). Adjust the ow rate and pressure by

regulating the discharge valve. Do not attempt to adjust

the ow with the suction valve.

Section IV - Shutdown

Turn off the motor.

NOTE: When the pump is stopped without a check valve

in the piping, liquid will ow through the pump returning

to the suction source. The SP design allows enough liquid

to be retained in the housing to allow repriming without

having to rell with liquid.

Flush Systems

CAUTION: Some uids react with water; use compat-

ible ushing uid.

1. Turn off the pump.

2. Completely close the suction and discharge valves.

3. Connect ushing uid supply to ush inlet valve.

4. Connect ushing uid drain to ush drain valve.

5. Open ushing inlet and outlet valves. Flush system

until the pump is clean.

NOTE: The drain can be used as the ushing drain

valve using appropriate customer supplied ttings. Us ing the drain helps to promote superior ushing and

draining results.

1. Be sure the housing (item 1) has been lled with 0.6

US gallon / 77 oz. (2.7 liters) of service liquid and the

ll plug (item 2 & 2A) has been installed and tightened

until the o-ring is seated.

8

Page 9

Maintenance

Recommended maintenance schedule

The recommended maintenance schedule depends upon the

nature of the uid being pumped and the specic applica-

tion. If the pump is used on a clean uid, it is recommended

that the pump be removed from service and examined after

six months of operation or after 2,000 hours of operation.

If the pump is used on uids with solids, high temperatures

or other items that could cause accelerated wear, this initial

examination should be sooner.

After the initial examination of the internal components and

wear items are measured, a specic maintenance schedule

can be determined. For best results, it is recommended that

the pump be removed from service annually for examination.

washers (items 28, 29 & 30) securing the pump to the

motor. See gure 10.

Section V - Disassembly

Tools Required:

Metric socket or wrench set, 13mm socket or wrench,

3/16” Allen Wrench (NEMA motors only), pliers (for ll/

drain plugs), and (2) Flat Head screwdrivers.

WARNING: Rotating Parts. This pump has compo-

nents that rotate while in operation. Follow local safety

standards for locking out the motor from the power

supply during maintenance or service.

WARNING: Chemical Hazard. This pump is used for

transferring many types of potentially dangerous chem-

icals. Always wear protective clothing, eye protection,

and follow standard safety procedures when handling

corrosive or personally harmful materials. Proper Pro cedures should be followed for draining and decontam inating the pump before disassembly and inspection of

the pump. There may be small quantities of chemicals

present during inspection.

WARNING: Magnetic force hazard. This pump should

only be disassembled and assembled using the recom mended procedures. The magnetic attraction is power-

ful enough to rapidly pull the motor end and the wet

end together. Do not place ngers between the mating

surfaces of the motor and wet ends to avoid injuries.

Keep the drive magnet and impeller assembly away

from metal chips or particles.

1. Stop the pump, lock out the motor starter, close all the

valves that are connected to the pump, and drain/decon-

taminate the pump.

WARNING: The pump must be thoroughly ushed of

any hazardous materials and all internal pressure re-

lieved prior to opening the pump. Allow the pump to

reach ambient temperatures prior to performing

maintenance.

2. Securely clamp the motor to the bench. Remove the

(4) 3/8” motor adapter bolts, lock washers and at

Figure 10

3. Firmly grab the pump and pull straight back to disen-

gage the motor and pump.

4. Place pump on bench with housing (item 1) facing up.

Using a 13mm socket or wrench, remove (6) 8M hous-

ing bolts, lock washers and at washers (items 19, 20

& 21). See gure 11.

Figure 11

5. Remove the housing by carefully inserting two at

head screwdrivers at the locations shown in gure

12. Slide the screwdrivers in at the bolt holes between

the metal clamp ring (item 13) and the housing until

they stop. Applying equal pressure, gently pry both

screwdrivers in an upward motion away from the work

bench (to avoid damaging sealing surface on the hous ing). See gure 12A. Housing is tight due to o-ring

seal on the internal “gooseneck.” NOTE: Do not twist

the screwdrivers or damage may occur to the housing.

Lift the housing straight up to remove.

9

Page 10

Insert one screwdriver under this bolting location.

Insert approximately 3/4”

(19 mm) until it hits the

barrier.

Insert one screwdriver

under this bolting

location.Insert approximately 3/4” (19

mm) until it hits the

barrier.

Figure 12

Figure 12A

6. Inspect housing for signs of wear or damage. Inspect

“gooseneck” for cracks. Inspect suction and discharge

for cracks. See gure 13. Inspect ll and drain plug

o-rings (item 2 & 2A) for chemical attack, swelling,

brittleness, cuts, etc.

7. Pull the separator plate (item 6) off the inner volute

(item 7). See gure 14. Inspect for damage and cracks.

9. Pull the inner volute straight off. Be careful since the

impeller shaft may come out with the inner volute. See

gure 17.

Figure 17

10. Remove impeller/inner drive assembly (items 8, 8A,

9 & 9A). Inspect impeller and drive for signs of wear

or damage. See gure 18. Check the impeller thrust

ring and bushing for wear. See gure 19.

Figure 18

Figure 13

Figure 14

8. To remove the inner volute (item 7), pull back the (3)

snap t prongs one at a time so that the hook portion

falls into the channel on the inner volute. See gures 15

& 16.

Figure 15

Figure 16

Figure 19

11. Remove the impeller shaft (item 10) from the barrier

(item 11) and check for signs of cracking, chipping,

scoring or wear. See gure 20.

Figure 20

10

Page 11

12. Pull on one of the 3 prongs to remove the barrier (item

11) from the clamp ring and motor adapter (items13 &

15). NOTE: Prongs are sharp. Use a glove or rag for

better grip. Motor adapters have an o-ring seal between

the barrier and adaptor so t may be snug. See gure

21. Inspect the inside and outside of the barrier for

signs of rubbing.

Figure 21

Thrust Ring Replacement

1. The thrust ring (item 8A) is held in-place with a snap t

with a ridge. Using a razor, knife, or side cutters, cut

a notch out of the thrust ring. Pull ring up and out of

the holder. See gures 23 & 24.

13. Remove the o-ring (item 4) from the barrier and inspect

for chemical attack, swelling, brittleness, cuts, etc.

14. Visually inspect the outer drive (item 17) for rubbing,

damage, corrosion, or loose magnets.

Outer Drive Replacement

1. Remove the setscrews (item 17B) from the side of the

drive (NEMA motors) or the bolt, lock washer and at

washer (items 25, 26 & 27) from the center of the drive

(metric motors).

WARNING: Be careful, tools will want to be attracted

to the magnets.

2. Remove the drive magnet from the motor shaft by gen-

tly prying up from the bottom of the drive. See gure 22.

3. To reinstall the drive or a new drive, follow the instruc-

Figure 23

Figure 24

2. To reinstall, align the two ats on the thrust ring with

the ats in the bore of the impeller. Using a piece of

wood, press into place using an arbor press until the

thrust ring is completely seated in the impeller.

Bushing Replacement

To remove the bushing, place the impeller/inner drive as-

sembly in an arbor press. Insert a 7/16” diameter plastic or

wood shaft through the eye of the impeller and press the

bushing out.

To replace the bushing (item 9A), place the top of the

impeller on an arbor press with the thrust ring face down.

Insert the front of the bushing (see gure 25) into the center

of the impeller/inner drive magnet assembly. Press into

place until the bushing reaches the shoulder molded into

the inner drive. See gures 26 & 27.

Figure 22

tions from Section I – Assembly, Pumps without

Motors, Steps 4-6.

Figure 25

Figure 27

11

Figure 26

Page 12

Impeller Replacement

To remove the impeller from the inner drive magnet, gently

pry off by hand or lightly

tap on the back of the im-

peller. See gure 28.

To install a new impel-

ler, place the inner drive

magnet assembly face up.

Line up the patterns on the

impeller with the ones on

the inner drive magnet so

Figure 28

they match and press into place by hand. An arbor press can

also be used to press the impeller on the inner drive. Place

a piece of wood over the top of the impeller thrust ring and

push down on the impeller until it is completely seated in

the inner drive.

4. Install barrier into motor adapter/clamp ring assembly.

NOTE: If removed, reinstall the o-ring (item 12), lubri-

cate with a chemically compatible lubricant, and install

in the groove in the clamp ring before installing the

barrier. See gure 33A. Lubricate the back of the bar-

rier with a chemically compatible lubricant and push it

straight down into place. See gure 33B. Note: Barrier

can only be installed in one position. The barrier prongs

should be placed in the 11:00, 2:00 and 5:00 o’clock

positions. See gure 33 for correct orientation. Line up

the 5:00 o’clock prong with the bottom bolt hole in the

motor adapter. See gure 33C.

Section VI Reassembly

1. Place motor adapter (item 15)

so the large ange is on the

bench. Rotate the adapter so

the four holes in the smaller

ange are in the horizontal

position. See gure 29. If re moved, reinstall the o-ring

(item 14) in the groove on the

face of the motor adapter.

Lubricate the o-ring with chemically compatible lubri cant. This will help to hold it in place. See gure 29.

2. Install clamp ring. Note: The discharge tting must

be in the vertical position for all SP series pumps to

work properly – Install the clamp ring (item 13) on the

motor adapter so NO clamp ring bolt holes are in 12:00

or 6:00 position (see gure 30). Align the (4) bolt holes

with the bolt holes in the motor adapter & push straight

down. This will properly seat the o-ring to prevent

vapors from entering this area during pump operation.

3. Install (4) at washers, lock washers and M8 bolts

(items 22, 23, 24). Tighten evenly using a star pattern.

Tighten to 60 in-lbs (6.8 N-m). See gure 31.

Figure 29

Figure 33A

Figure 33

Figure 33B

Figure 33C

5. Install o-ring (item 4) in groove in the barrier making

sure it is tucked in all the way around.

6. Install impeller shaft (item 10) into barrier by aligning

the ats on the shaft with the ones in the barrier. Make

sure it is completely seated.

7. Carefully install the impeller/inner drive assembly

(items 8, 8A, 9 & 9A) by sliding it over the impeller

shaft in the barrier. It is normal for the impeller/inner

drive to pop up a slight amount due to magnetic forces

with the metal clamp ring. See gures 34 & 35.

Figure 30

Figure 31

12

Page 13

Figure 34

Figure 35

9. Install the separator plate (item 6) by lining up the

bottom opening of the inner volute with the opening in

the plate. Line up the slots in the separator plate with

the notches in the inner volute. See gure 38.

10. If the inner volute o-ring was removed previously,

lubricate the inner volute o-ring (item 5) with a chemi-

cally compatible lubricant, and install it in the groove

on the round suction nozzle in the center of the inner

volute. See gure 39.

8. Install the inner volute (item 7) by lining up the prongs

of the barrier with the channels in the inner volute.

Press down evenly until the prongs snap onto the sur-

face of the inner volute. See gures 36 and 37.

Figure 36

Figure 37

Figure 38

Figure 39

11. After lubricating inside of gooseneck, install the hous ing (item 1). Line up the tab on the top of the separator

plate with the notch in the housing (located inside the

front of the housing near the discharge port). Using uni

form pressure, press the housing into place until it is

ush with the motor adapter. See gure 40. Install the

housing bolts, lock washers and at washers (items 19,

20 & 21). Tighten all bolts evenly using a star pattern.

Tighten to 5 foot-lbs (6.8 N-m). Note: If bolt holes do

not line up, it may be necessary to tap the housing into

place with a rubber mallet. If still unable to line up the

bolt holes, then disassemble the pump down to the

barrier and start over from step 4.

Figure 40

12. Reinstall the pump on the motor/drive magnet follow ing instructions found in “Assembly, Pumps Without

Motors,” steps 7-10.

13

Page 14

Section Vii - Troubleshooting

General Notes:

• Cold water can contain dissolved air. Under high lift ap plications, the air can come out of solution blocking

suction passages. This can lead to lack of priming, slow

priming, or low ow rates.

• Do not pump liquids containing ferrous metal nes.

• If magnets decouple, stop pump immediately. Operat ing the pump with the magnets decoupled will eventu-

ally weaken the magnets.

• Do not use mismatched drive magnet assemblies (dif ferent number of magnets on inner and outer drive mag-

net assemblies).

• Contact our Technical Service Department by phone at

800-888-3743 or by e-mail at techservice@nishthomp-

son.com if you have any questions regarding product

operation or repair.

No or Insufcient Discharge

• Air leaks in suction piping

• Housing not lled with priming uid

• Suction pipe smaller than 1”

• Suction pipe contains high spots causing trapped air

pockets

• Suction pipe excessively long (ow drops as suction

pipe gets longer)

• System head higher than anticipated

• Closed valve

• Viscosity or specic gravity too high

• Motor too large for magnet coupling rating (magnets

uncoupled)

• Clogged suction line, suction strainer (if used), or impel-

ler vanes

Insufcient Pressure

• Air or gas entrained liquid

• Impeller diameter too small

• System head lower than anticipated

• Motors speed insufcient (too low) or motor rotation

incorrect (correct rotation when viewed from the fan end

is clockwise)

Won’t Prime

• Did not ll housing with uid before initially starting

pump

• Closed discharge valve (valve should be open or open air

vent line)

• Leak in suction piping

• Suction pipe not submerged enough (causing a vortex or

exposing the end of the suction pipe)

• Lift exceeds pump ability (see Capabilities section)

• Suction pipe diameter too large

• Specic gravity or local atmospheric pressure (altitude/

elevation) not accounted for in lift calculations

• Mis-match of inner volute and impeller diameter

• Inner volute o-ring chemically attacked, cut, brittle, etc.

• Motor rotation incorrect (correct rotation when viewed

from the fan end is clockwise)

• Check valve installed too close to the pump

Primes Slowly

• Mismatch of inner volute and impeller diameter

• Suction pipe diameter too large (larger than 1” or 1½”)

• Closed discharge valve (valve should be open)

• Inner volute o-ring chemically attacked, cut, brittle, etc.

Excessive Power Consumption

• Head lower than rating

• Excessive ow

• Specic gravity or viscosity too high

Vibration/Noise

• Loose magnet

• Drive magnet rubbing

• Pump cavitating from improper suction or feed

• Motor or piping not properly secured

• Foreign object in impeller

Section VIII - Warranty

Finish Thompson, Inc (manufacturer) warrants this pump

product to be free of defects in materials and workmanship

for a period of ve years from date of purchase by origi-

nal purchaser. If a warranted defect, which is determined

by manufacturer’s inspection, occurs within this period, it

will be repaired or replaced at the manufacturer’s option,

provided (1) the product is submitted with proof of pur-

chase date and (2) transportation charges are prepaid to the

manufacturer. Liability under this warranty is expressly

limited to repairing or replacing the product or parts thereof

14

Page 15

and is in lieu of any other warranties, either expressed or implied. This warranty does not apply to normal wear of the

product or components. This warranty does not apply to products or parts broken due to, in whole or in part, accident,

overload, abuse, chemical attack, tampering, or alteration. The manufacturer accepts no responsibility for product dam-

age or personal injuries sustained when the product is modied in any way. If this warranty does not apply, the purchaser

shall bear all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to process down time,

transportation costs, costs associated with replacement or substitution products, labor costs, product installation or remov-

al costs, or loss of prot. In any and all events, manufacturer’s liability shall not exceed the purchase price of the product

and/or accessories.

Ordering Spare Parts

Spare parts can be ordered from your local distributor. Consult FTI’s web site, www.nishthompson.com, to nd the nearest local

distributor. Always refer to the pump model to avoid error.

Section IX - Spare Parts

1. Select base model (e.g. SP10P)

2. If standard components are not

suitable, enter symbol(s) of

alternative components in any

order.

Base Model - - - -

SP10P E - Ff - 14

SP10P-E-Ff-14 is a SP10 poly propylene construction with EPDM

o-ring, fiberglass flanges and

145TC motor adapter.

3. Where standard components aren’t

suitable, add the alternative com ponent code letter after the base

model number to substitute

components. (See adjacent list of

alternative components.)

The model number appears on the serial number label located on the motor

adapter. The model number contains a

base model that features certain standard

components. Compare the model number

on the pump to the adjacent chart to determine if the pump contains any alternate

components. Model numbers containing

“P” have primary components molded

from polypropylene. Model numbers

containing “V” have primary components

molded from PVDF.

Base model numbers are: SP10P and

SP10V.

Bushing Graphite Carbon

O-Ring Viton

Connection NPT

Impeller

Magnet 10-pole only

Motor

Adapter

Specials

Motor Not Standard Select Motor Reference Number from SP Series Price Book.

BASE MODEL

COMPONENTS

1

56C NEMA

SS hardware,

PTFE/ceramic thrust

rings, ceramic shaft,

Buna o-ring vapor

protection kit option

(NEMA only)

Model Number Explanation

ALTERNATIVE COMPONENTS Code

PTFE T

Alumina Ceramic R

EPDM E

BSP Threads B

Union U

Steel enforced flange Fs

Fiberglass enforced flange Ff

2 3 4 5 6

No alternatives available. A 10-pole will handle up to a

2 Hp motor.

145TC NEMA 14

IEC 63/B14 64

IEC 71/B14 74

IEC 80/B14 84

IEC 90/B14 94

IEC 63/B5 65

IEC 71/B5 75

IEC 80/B5 85

IEC 90/B5 95

SiC bushing, thrust ring, shaft Si

Hastelloy shaft Hs

Titanium hardware Ti

Viton o-ring vapor protection kit (NEMA only) Vv

EPDM o-ring vapor protection kit (NEMA only) Ve

Non-sparking ring Ns

15

Page 16

16

Page 17

SP10 Spare Parts List

Item Qty Description

Housing

NPT Threads 106564 106564-1

1 1

2 2

2A 2

3 1

4 1

5 1

6 1

7 1

8 1

8A 1

BSP Threads 106564-2 106564-3

Steel Flanges 106964-1 106964-3

Fiberglass Flanges 106964 106964-2

Unions 106965 106965-1

Fill/Drain Plug

Fill Plug O-Ring

EPDM 106154

FKM 106155

Discharge O-Ring (BSP Housings Only)

EPDM 106304

FKM 106303

Housing O-Ring

EPDM 106299

FKM 106298

Inner Volute O-Ring

EPDM 106976

FKM 106975

Separator Plate

Inner Volute (Select Appopriate Impeller Diameter)

4.18" (#1) impeller w/ standard alumina ceramic ring 106568-2 106568-3

4.00" (#2) impeller w/ standard alumina ceramic ring 106568-4 106568-5

3.75" (#3) impeller w/ standard alumina ceramic ring 106568-6 106568-7

3.50" (#4) impeller w/ standard alumina ceramic ring 106568-8 106568-9

3.25" (#5) impeller w/ standard alumina ceramic ring 106568-10 106568-11

3.00" (#6) impeller w/ standard alumina ceramic ring 106568 106568-1

4.18" (#1) impeller w/ optional silicon carbide ring 106963-2 106963-3

4.00" (#2) impeller w/ optional silicon carbide ring 106963-4 106963-5

3.75" (#3) impeller w/ optional silicon carbide ring 106963-6 106963-7

3.50" (#4) impeller w/ optional silicon carbide ring 106963-8 106963-9

3.25" (#5) impeller w/ optional silicon carbide ring 106963-10 106963-11

3.00" (#6) impeller w/ optional silicon carbide ring 106963 106963-1

Impeller Assembly

4.18" (#1) impeller w/ standard PTFE thrust ring 106352 106352-1

4.00" (#2) impeller w/ standard PTFE thrust ring 106352-2 106352-3

3.75" (#3) impeller w/ standard PTFE thrust ring 106352-4 106352-5

3.50" (#4) impeller w/ standard PTFE thrust ring 106352-6 106352-7

3.25" (#5) impeller w/ standard PTFE thrust ring 106352-8 106352-9

3.00" (#6) impeller w/ standard PTFE thrust ring 106352-10 106352-11

4.18" (#1) impeller w/ optional silicon carbide thrust ring 106353 106353-1

4.00" (#2) impeller w/ optional silicon carbide thrust ring 106353-2 106353-3

3.75" (#3) impeller w/ optional silicon carbide thrust ring 106353-4 106353-5

3.50" (#4) impeller w/ optional silicon carbide thrust ring 106353-12 106353-13

3.25" (#5) impeller w/ optional silicon carbide thrust ring 106353-8 106353-9

3.00" (#6) impeller w/ optional silicon carbide thrust ring 106353-10 106353-11

Impeller Thrust Ring Only

PTFE 106257

SiC 106257-1

Pump Material

Polypropylene PVDF

106143 106143-1

106563 106563-1

17

Page 18

SP10 Spare Parts - continued

Item Qty Description

Impeller Drive

6-pole w/ carbon bushing 106361 106361-3

8-pole w/ carbon bushing 106361-1 106361-4

10-pole w/ carbon bushing 106361-2 106361-5

6-pole w/ sIlicon carbide bushing 106361 106362-3

8-pole w/ sIlicon carbide bushing 106362-1 106362-4

9 1

10-pole w/ sIlicon carbide bushing 106362-2 106362-5

6-pole w/ alumina ceramic bushing 106363 106363-3

8-pole w/ alumina ceramic bushing 106363-1 106363-4

10-pole w/ alumina ceramic bushing 106363-2 106363-5

6-pole w/ PTFE bushing 106364 106364-3

8-pole w/ PTFE bushing 106364-1 106364-4

10-pole w/ PTFE bushing 106364-2 106364-5

Impeller Bushing Only

Carbon J102387

9A 1

PTFE J102790

Ceramic J103617

SiC J103617-1

Impeller Shaft

10 1

Ceramic 106293

SiC 106293-1

Hastelloy C 106293-2

11 1

Barrier

With silicon carbide thrust washer 106235-6 106235-7

Barrier O-ring (NEMA motors only)

12 1

Buna 106572

EPDM 106550

FKM 106551

Clamp Ring

Painted cast iron (Standard) 106246 106246-1

13 1

Painted cast iron with non-sparking ring 106521 106521-1

Stainless steel 108599 108599

Stainless steel with non-sparking ring 108599-1 108599-1

Clamp Ring O-ring (NEMA Motors only)

14 1

Buna 106548

EPDM 106372

FKM J103954

15 1

Motor Adapter

Motor Adapter O-ring (NEMA Motors only)

16 1

Buna 106549

EPDM 106373

FKM 106374

Pump Material

Polypropylene PVDF

106248 106248-1

18

Page 19

SP10 Spare Parts - continued

Item Qty Description

Drive Magnet Assembly with Retaining Ring (56C frame also includes set screws)

56C frame, 6-pole 106283

56C frame, 8-pole 106283-1

56C frame, 10-pole 106283-2

143/145TC frame, 8-pole 106283-4

143/145TC frame, 10-pole 106283-5

63 frame, 6-pole 106289

17 1

63 frame, 8-pole 106289-1

63 frame, 10-pole 106289-2

71 frame, 6-pole 106286

71 frame, 8-pole 106286-1

71 frame, 10-pole 106286-2

80 frame, 8-pole 106292-1

80 frame, 10-pole 106292-2

90 Frame, 10-pole 106292-5

Retaining Ring Only

56C frame 105708

143/145TC frame 105709

17A 1

63 frame 106310

71 frame 106309

80 frame 105711

90 frame 105712

17B 2

Set Screws

NEMA Motors Only J101084

Motor Adapter Flange (IEC Motors Only)

63/71 frame w/ B14 106271 106271-1

80 frame w/ B14 105724-1 105724-2

18 1

90 frame w/ B14 105725-1 105725-2

63 frame w/ B5 106272 106272-1

71 frame w/ B5 106273 106273-1

80/90 frame w/ B5 106274 106274-1

Pump Material

Polypropylene PVDF

19

Page 20

Hardware - All SP10 Models

Item Qty Description Stainless Steel Titanium

19 6

20 6

21 6

22 4

23 4

24 4

25 1

26 1

27 1

28 4

29 4

30 4

31 4

32 4

33 4

34 4

Housing Bolt

J102789 106308

Housing Lock Washer

J102282 J103847

Housing Flat Washer

105767 105768

Clamp Ring Flatwasher

105767 105768

Clamp Ring Lockwasher

J102282 J103847

Clamp Ring Bolt

105770 105770

Drive Bolt (IEC Only)

63 Frame

71 Frame

106314 106315

106312 106313

80 Frame 105765 105766

90 Frame

105770 105771

Drive Lock Washer (IEC Only)

63 Frame

71 Frame

80 Frame

90 Frame

106322 106323

106320 106321

J100672 J104203

J102282 J103847

Drive Flat Washer (IEC Only)

63 Frame

71 Frame

80 Frame

90 Frame

106318 106319

106316 106317

105767 105768

105722 105773

Motor Adapter Bolt

J100114 106311

Motor Adapter Lock Washer

J100115 J104206

Motor Adapter Flat Washer

J100128 J104207

Motor Adapter Flange Bolt (IEC Only)

63 Frame

71 Frame

80 Frame

106348 106349

105765 105766

105765 105766

90 Frame 105770 105771

Motor Adapter Lock Washer (IEC Only)

63 Frame J103637 106350

71 Frame

80 Frame

90 Frame

J100672 J104203

J100672 J104203

J102282 J103847

Motor Adapter Flat Washer (IEC Only)

63 Frame

71 Frame

80 Frame

90 Frame

J103638 106351

J100113 J104204

J100113 J104204

J101293 J103845

Motor Adapter Nut (IEC Only)

63 & 71 Frame with B14 Flange 108141 n/a

Part Number 107009, R11, 2/14/2014

Order fax: 814-459-3460

Tech Service: 800-888-3743

20

Loading...

Loading...