Page 1

f

y

b

n

f

d

by

r

b

p

g

t

y

g

a

d

N

y

N

g

t

Model LS-Jr.

Vacuum Attachment

Installation and Maintenance Instructions

INTRODUCTION

The LS-Jr. with vacuum attachment provides for safe in-house

reclamation of contaminated solvents with boiling points o

200° to 500°F (93° to 260°C). Most solvents conform easil

and safely to this thermal distillation process. However,

ecause most SOLVENTS ARE COMBUSTIBLE, EXTREME

CAUTION must be exercised when operating the unit. Whe

properly installed and operated, the LS-JrV provides long,

trouble-free service, reclaiming 3 to 4 gallons (11-15 liters) o

solvent in 6 to 8 hours. For your safe ty, reclamation is limite

design to this rate.

PRINCIPLES

The LS-JrV utilizes breakthrough technology to reclaim highe

oiling solvents. A unique v ertical solvent pump and JetVac are

immersed in a single reservoir and used to create a vacuum in

the distillation unit.

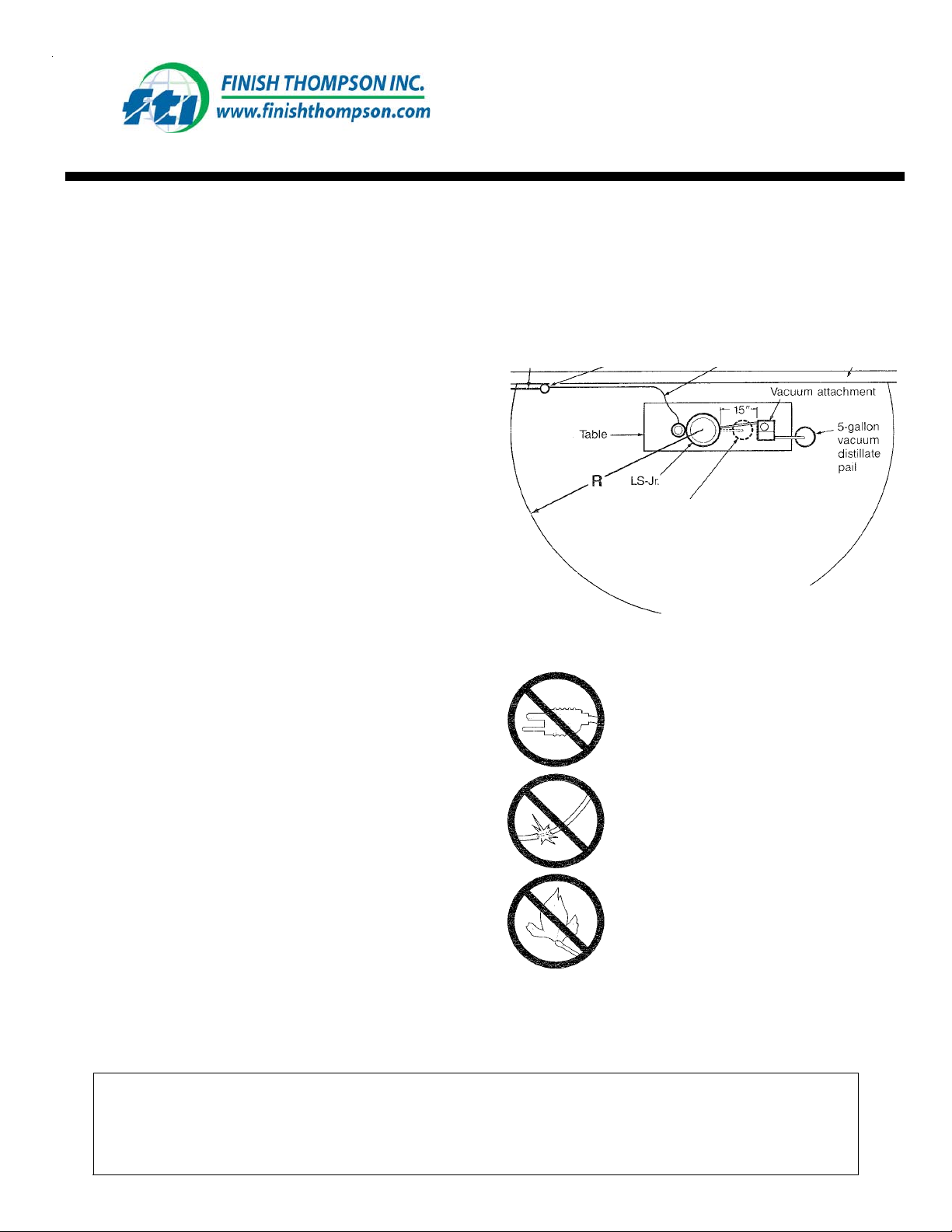

You must determine dimension R (see Figure 1). It illustrates

the larges t area where exp losive mixture s can be present. I n

well-ventilat ed area, R is of ten less than 10 ft. (3m). H owever,

R can also be more than 10 ft.

Explosionproof

conduit

Explosionproof

box

5-gallon

atmospheric

distillate pail

Explosionproof

wiring

Wall

Solvent in t he reservo ir tank is cir culated by th e solvent pu mp

through the high-velocity JetVac. This high-speed circulation

roduces a v acu um in the distill ation uni t. A co o ling c oil i n the

reservoir tank maintains solvent temperature. As additional

solvent is recovered and cooled, it is gravity fed from the

vacuum unit to a 5-

WARRANTY

When the LS-JrV is operated in strict accordance with these

instructions, it is guaranteed to recover h igher boiling solvents

See page 5 for detailed warranty information.

and is warranted 180 days from date of shipment agains

defects in materials and workmanship. All warranty claims

FOB Erie, Penns

allon distillate pail.

lvania.

INSTALLATION SITE

Install in a we ll-v entila ted area in a ccor dan ce with Artic les 5 00

and 501, Class I, Division 1, Group D of the National Electric

Code (explosion proof installation). Installation should be by a

qualified electrician and inspected by your insurance company.

The area surrounding the LS-JrV should be inspected carefully

to insure an explosionproof area. The LS-JrV must not be

installed in an area where open flame, sparks or electrical

are present.

arcin

Figure

Ignition of explosive mixtures can result from various items

causing "hot spots." Because of this, in the area defined by R,

the following are

Your qualified electrician can answer any questions you may

have for selecting the best LS-Jr. and vacuum attachmen

installation site and regard ing applicab le electrical codes.

1

ABSOLUTELY ESSENTIAL .

All electricals must be explosionproof har

conduit and explosion proof boxes.

o potential for sparks can be present (for

exam pie, non-explosion proof outlets and

electrical switches, coffeepots and other

appliances, static electricit

o flames can be present (for example,

torches, furnaces, ci

sources, etc.).

arettes, etc.).

WARNING:

The LS-Jr. is a boiling ve ssel, not a reactio n vessel . Chemi cal reactio ns with in the u nit mu st not be permit ted

to occur. The user must know the composition of the waste material to be processed. Most contaminated

solvents are recommended for the thermal distillation process. However, reactive materials must not be

processed in the LS-Jr. distilling unit. You must read and understand the caution printed on the lid of the unit

prior to operation, it reads

(example: lacquers with nitrocellulose) are processed."

:

"CAUTION: Dangerous health and safety problems will occur if reactive materials

Page 2

b

b

b

r

r

r

a

r

r

d

n

r

t

p

g

g

g

g

INSTALLATION

The LS-Jr. vacuum attachment should be installed on the distillate

discharge side of the LS-Jr. with 20 in. (51 cm) of clearance

ehind and 15 in. (38 cm) between the units. Enough clearance

must remain on floor level to the right of the vacuum unit for a 5gallon (19 liter) vacuum distillate receiving pail.

The LS-Jr. and vacuum attachment require 6 to 13 gallons (23-49

liters) of tap water per hour for cooling. Water enters and exits via

hoses on the rear of the units. Two valves are recommended

etween the water supply and the unit; one for on/off operation,

the other set to the desired flow rate. Water flow must be

confirmed prior to operation.

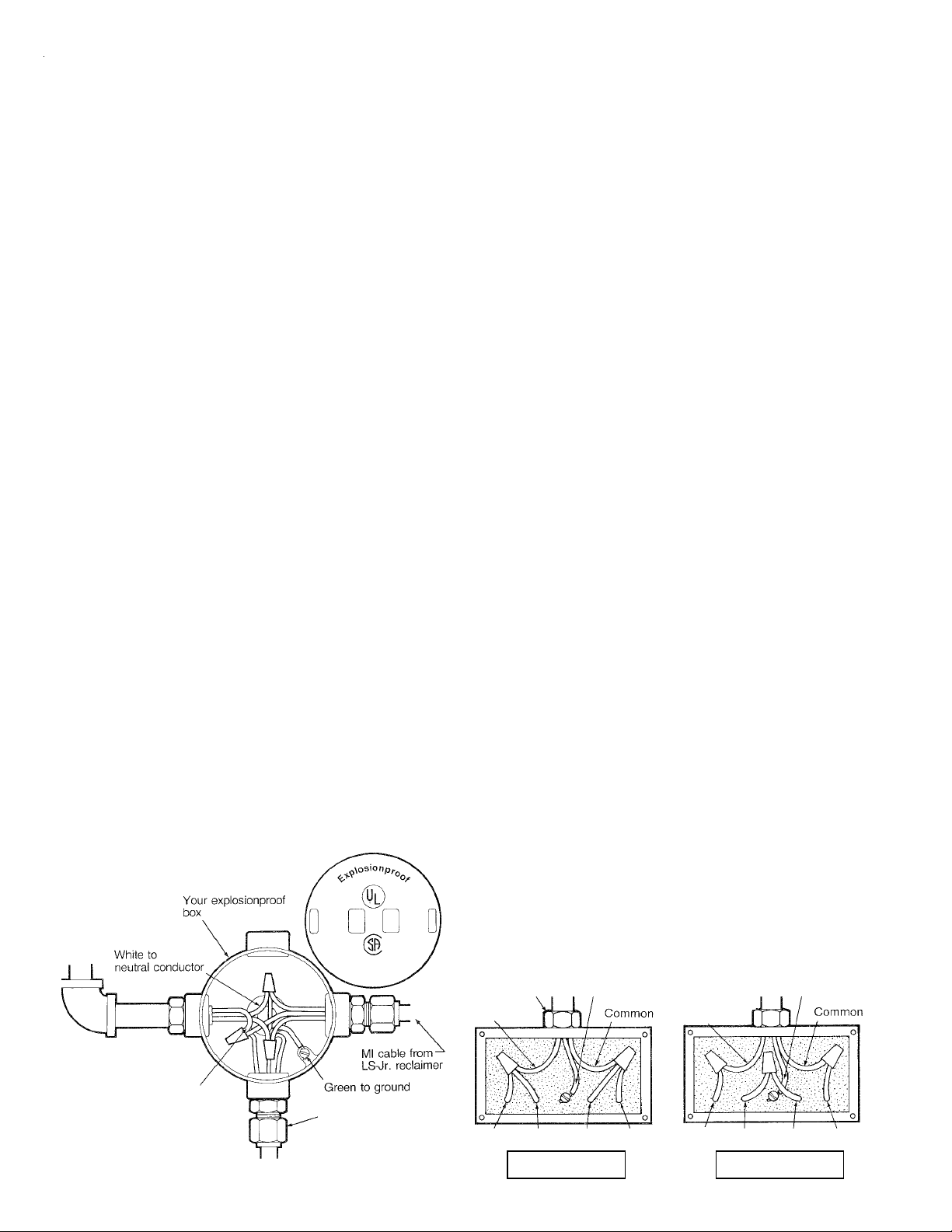

The LS-JrV requires an additional 115V, 1 phase, 60 Hz, 4 amps

with a separate ground or a 220V, 1 phase, 60 Hz, 2 amp

unit is available. All wiring must be connected to a suitable power

supply in accordance with the National Electric Code for Class I

installations (see Figure 2).

After installation, check the unit's ground. If the resistance

etween the unit and the transformer's earth ground exceeds

1 ohm, a separate ground must be installed from the unit to the

earth ground. The ground wire must be installed to insure safe

operation and to eliminate static spark hazard.

For simultaneous LS-Jr. and LS-Jr.V installation

Incoming water is supplied to the LS-Jr.V cooling wate

inlet (Item 14) on the rear of the vacuum unit. Connect

separate hose from the distillation unit cooling wate

discharge (Item 6) to a drain.

5. Install the cooling water connection hose between the

reclaimer and the vacuum unit. Slide one end of the hose

over the barbed fittings of the reclaimer's cooling wate

inlet (Item 5) and the other end to the vacuum unit's

cooling water discharge (Item 15).

6. Screw the vacuum distillate discharge hose (Item 10) into

the coupling (Item 24) provided on the side of the LS-JrV

reservoir tank. Place a receiving p ail next to the table an

cut the discharge hose to proper length.

7. Screw the flame-check assembly (Item 19) into the coupling provided on the back of the vacuum attachment reservoir tank.

8. Install a grounding cable (Item 23) between the distillatio

and vacuum units. To install, remove the bottom left screw

from the distillation unit hinge bracket, connect the

grounding cable and replace the screw. On the vacuum

unit, remove the screw between the cooling wate

discharge (Item 15) and the flame check (Item 19), connec

the grounding cable and replace the screw.

:

ASSEMBLY

Assembly of the vacuum attachment and connection to the LSJr. reclaimer requires a f ew simple steps. Proper assembly and

connection is necessary for operation. The following steps and

Figures 4 and 5 serve as as sembly guidelines.

1. Remove the discharge hose and fitting from the reclaime

(Item 8). Do not loosen or remove the connecting distillate pipe

from the unit.

2. Screw the quick-disconnect coupling onto the reclaimer

distillate pip e .

3. Screw the discharge hose and fitting (removed in Step 1)

onto the nipple assembly provided for future

atmosphe r ic distillation .

4.

For LS-Jr.V installation to an existing LS-Jr.:

Remove

the cooling water inlet hose (Item 5) from the back of the

reclaiming unit and connect to the vacuum unit cooling wate

discharge (Item 15).

Explosionproof cover-----

Your rigid

explosionproof

conduit

..

OPERATION

The LS-Jr.V requires minimal operator attention. The following

steps serve as operation guidelines.

For atmospheric distillation:

Atmospheric distillation allows reclamation of solvents with

boiling points to 300°F (149°C). To distill solvents atmos-

herically, connect the short distillate discharge hose to the

reclaimer unit with the quick-disconnect coupling. Then follow

Steps 1-11 in the LS-Jr. Installation and Operating Instructions

(F86-180-QP).

For vacuum distillation:

Vacuum d istillation allows r eclamation of solv ents with boiling

points with a minimum temperature of 200°F (93°C) and a

maximum temperature of 500°F (260°C). To distill solvents in

this temperature range under a vacuum:

1. Ground all filling and receiving containers, wiring static

ground clamps provided (Items 2 and 17).

Vacuum attachment

Incoming Power

(115V, 1 phase, 60 Hz,

with separate ground)

Entrance for

Ri

id Conduit

Ground

motor

wiring

Incoming Power

(220V, 1 phase, 60 Hz,

with separate ground)

Entrance for

Ri

id Conduit

Hot

Ground

Black to

fused conductor

Your explosionproof wiring

from LS-JrV (MI cable

Figure 2

orhard conduit)

#1 #3 #2 #4

For 115V Wirin

#1 #2 #3 #4

For 220V Wirin

Page 3

b

p

p

d

b

2. Install a STILGASKET for each batch processed, following

procedures in the LS-Jr. Installation and Operating

Instructions. If an optional STILBAG is used, carefully

insert bag, making sure no air pockets are present. Positon

the retainer ring prior to filling.

3. Pump or pour 3 to 4 gallons (11-19 liters) of contaminated

solvent from a grounded container into the reclaimer unit's

oiling vessel. Stamp ings on the inside wall of th e boilin g

chamber indicate fill lines. Some solvents may expand and

"foam over" during the distillation process. Ex

will dictate largest batch size to be processed.

4. Carefully position the reclaimer unit lid, lifting approximately 30° to avoid touching the STILGASKET. When in

osition, lower th e lid slowly, matching flange to flange.

Secure the spring release latch.

5. Insert the vac uum distillate hose (It em 25 ) in to th e qui ck

disconnect coupling (Item 8) on the reclaimer unit lid.

6. Remove the access lid (Item 18) on the vacuum unit and fill

tank with 3 gallons (11 liters) of clean solvent. Clean

solvent should be the same as solvent to be reclaimed.

Replace access lid on the vacuum unit tank.

7. Place a five-gallon pail on the floor beneath the vacuum

unit distillate discharge hose. Ground receiving vessel with

static ground clam p.

8. Turn on condenser water. (Operation experience will

determine proper adjustment of cooling water flow rate.

Generally it can be reduced until distillate temperature

increases.)

9. Push dist illation unit (Item 1) start/stop button. Red light

turns on.

10. Turn on vacuum unit motor (Item 20). After approximately

11/2 hours, solvent should be flowing through the

discharge hose into the receiving pail. When distillate flow

stops, the material has been reclaimed.

11. Push distillation unit start/ stop button. Red light turns off.

12. Remove vacuum-connection discharge hose from the

quick-disconnect coupling. Vacuum pressure should return

to 0 on vacuum gauge. (Note: Failure to disconnect

vacuum-connection hose will result in reclaimed solvent

being drawn into the distillation unit.)

13. Turn off vacuum motor.

14. After approxim ate l y half an hour, turn off cooli ng wat er .

15. Allow unit to cool overnight. Unsecure lid and slowly lift

30° vertically to break seal. Swing lid to back of unit.

16. Remove residue using STIL SCRAPER or similar plastic

utensil. (If optional STILBAG is used, remove retainer

ring and take out residue-filled STILBAG.)

erience

Solvent

Pressurizes recycled solvent from the reservoir tank to provide

a primary (motive) fluid to the JetVac pump.

pump

JetVac pump

Creates a vacu um in the distillatio n unit by combining a high velocity primary jet stream of solvent with a secondary stream

of leak- air a n d co n d ensate from t he d ist ill at io n unit. The JetVac

pump also elevates solvent vapors to near-atmospheric conditions and assists in the condensing process.

Check valve

Used for short intervals, the check valve prevents reclaimed

solvent from re-entering the reclaimer unit.

Y-strainer

Prevents plugging of the vacuum unit should a carry-over occur

by trapping large particles. After every 40-60 hours of operation, clean the screen within the V-strainer by removing an

rinsing

.

Cooling coils

Water circulation within the cooling coils cools solvent and

removes heat from compression, condensation and fluid

friction.

Flame-check

Prevents possible back-flash of flame into the reservoir tank.

Vacuum rel i e f

Allows adjustment to the vacuum, if nece ssary. Adjustment is

rarely necessary and factory settings will usually be

satisfactory. To adjust, loosen nuts to decrease vacuum, tighten

nuts to increase vacuum. During adjustment. vacuum pressure

is indicated on the vacuum gauge

valve

.

INSTRUMENTATION AND MAINTENANCE

Solvent reservoir tank

Contains clean solvent, cooling coils, a solvent pump and a

JetVac pump. An overflow pipe carries reclaimed distillate to a

receiving pail. Each co mponent in th e re se rvoir tank is u se d f or

either creating the required vacuum or condensing reclaimed

solvent.

After every 40-60 hours of operation, clean the inside of the

reservoir tank. Drain solvent from the tank and clean the tank

y wiping with a clean, dry cloth. Refill the reservoir tank with

3 gallons (11 liters) clean solvent.

c.

Page 4

18

17

4

1

13

9 16

22

3

20

4

Figure 4. Front View

5

6

21

15

11

3

7

2

Figure 5. Rear View

Item Description Item Description

1 Vacuum unit on/off switch 14 Vacuum unit cooling water inlet

2 Grounding cable for waste solvent container 15 Vacuum unit cooling water discharge (to No.5)

3 Grounding cable between units 16 Vacuum gauge

4 Distillate hose coupling 17 Grounding cable for vacuum distillate pail

5 Cooling water inlet to condenser (from No. 15) 18 Reservoir access door

6 Cooling water discharge to drain 19 Flame check

7 Grounding cable for atmospheric distillate pail 20 Receiving pail for atmospheric distillation

8 Quick-disconnect coupling 21 Receiving pail for vacuum distillation

9 Adjusting valve 22 Lighted start/stop button (LS-Jr.)

10 Vacuum distillate discharge hose

11 V-strainer

12 Explosionproof motor with on/off switch

13 Vacuum-connection hose

Page 5

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the product’s materials of construction, which are compatible with the fluid(s) that come(s) in contact with the product. The user may consult Finish Thompson, Inc. (manufacturer) and a manufacturer’s representative/distributor agent to seek a recommendation of the product’ s material

of construction that offers the optimum available chemical compatibility .

However neither manufacturer nor agent shall be liable for product damage or failure, injuries, or any other damage

or loss arising out of a reaction, interaction or any chemical effect that occurs between the materials of the product’ s

construction and fluids that come into contact with the product’s internals.

WARRANTY

Finish Thompson, Inc (manufacturer) warrants this product to be free of defects in materials and workmanship for a

period of 3 years plus lifetime on the LS heater from date of purchase by original purchaser. If a warranted defect,

which is determined by manufacturer’s inspection, occurs within this period, it will be repaired or replaced at the

manufacturer’s option, provided (1) the product is submitted with proof of purchase date and (2) transportation

charges are prepaid to the manufacturer . Liability under this warranty is expressly limited to repairing or replacing

the product of parts thereof and is in lieu of any other warranties, either expressed or implied. This warranty does

apply only to normal wear of the product or components. This warranty does not apply to products or parts

broken due to, in whole or in part, accident, overload, abuse, chemical attack, tampering, or alteration. The manufacturer accepts no responsibility for product damage or personal injuries sustained when the product is modified in

any way . If this warranty does not apply, the purchaser shall bear all cost for labor , material and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to process down

time, transportation costs, costs associated with replacement or substitution products, labor costs, product installation or removal costs, or loss of profit. In any and all events, manufacturer’s liability shall not exceed the purchase

price of the product and/or accessories.

Service 1-800-888-3743

Part Number J100962, Rev 2

Literature ID Number FT03-878A

Loading...

Loading...