Page 1

Page 2

LS Series “Little Still” Instruction Manual

Introduction

This LS Series solvent distillation system provides

safe, on-site reclamation of contaminated solvents.

Use of the Little Still can save money and conserve

the environment by reducing or eliminating the

disposal of these solvents.

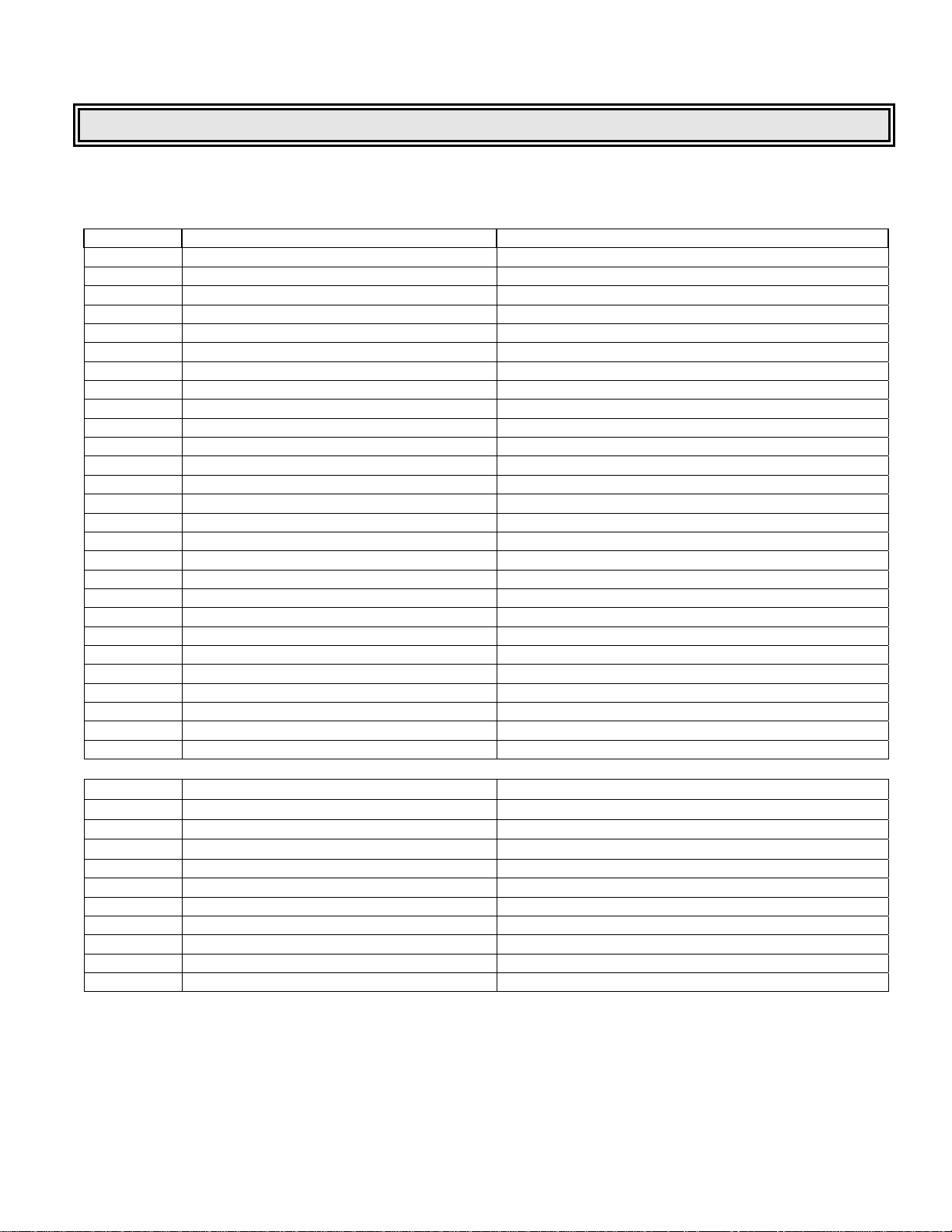

Table of Contents

Quality engineered and manufactured, the Little Still

requires minimal operator involvement. When

properly installed, operated, and maintained, this

equipment can provide years of trouble-free service.

Safety Precautions

Installation Requirements and Instructions

Assembly

Electrical Requirements

Grounding Requirements

Electrical Connections

Condenser Cooling Water Requirements

Quick Cool Requirements

Conventional Tap Water Supply

Instrumentation and Controls

Start-up and Operation

Maintenance Schedule

Service and Troubleshooting

Appendix

Common Spare Parts

Electrical Schematics

Warranty

2

3

3-4

5

5

6

7

8

9

10

14

18

20

27

27

29

31

For technical assistance call:

800-888-3743 or 814-455-4478

1

Page 3

Safety Precautions

WARNING:

READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND

OPERATING THIS EQUIPMENT. FAILURE TO FOLLOW THESE

PRECAUTIONS CAN RESULT IN SERIOUS INJURY OR DEATH.

Installation location and area must conform to requirements set by National Electric Code

Class 1, Division 1, Group D for hazardous locations.

Follow National Fire Protection Association guidelines for control of static electricity (NFPA

77, Recommended Practice on Static Electricity). This applies to the installation area,

equipment, personnel, and all transfer and receiving containers.

Ventilate all vapors from the processing area and distillation equipment according to National

Fire Protection Association guidelines (NFPA 91, Standard for the Installation of Blower and

Exhaust Systems for Dust, Stock, and Vapor Removal or Conveying).

Follow the National Fire Protection Association recommendations for safe storage and use of

flammable and combustible liquids (NFPA 30, Flammable and Combustible Liquids Code).

Electrical wiring should be performed by a qualified electrician and must conform to National

Electric Code Class 1, Division 1, Group D requirements for explosionproof equipment. Use

only electricals labeled explosionproof (boxes, receptacles, hard conduit, etc.) for the

installation and in the area.

Obtain approval of the installation area and installation from your insurance and/or fire

inspector.

Remove any ignition sources from the area such as flames (cigarettes, torches, furnace), or

sparks (grinders, non-explosionproof electrical switches and outlets, etc.).

Verify proper water flow before operation to prevent accumulation of hazardous vapors.

Wear proper eye and skin protection and an approved respirator when handling solvents and

working with this equipment.

Never process reactive solvents or materials such as gasoline, ethers, nitrocellulose, etc.

Never work on or with this equipment while it is hot. Never open a hot Still. Allow a minimum

of two hours or more cool-down time.

2

Page 4

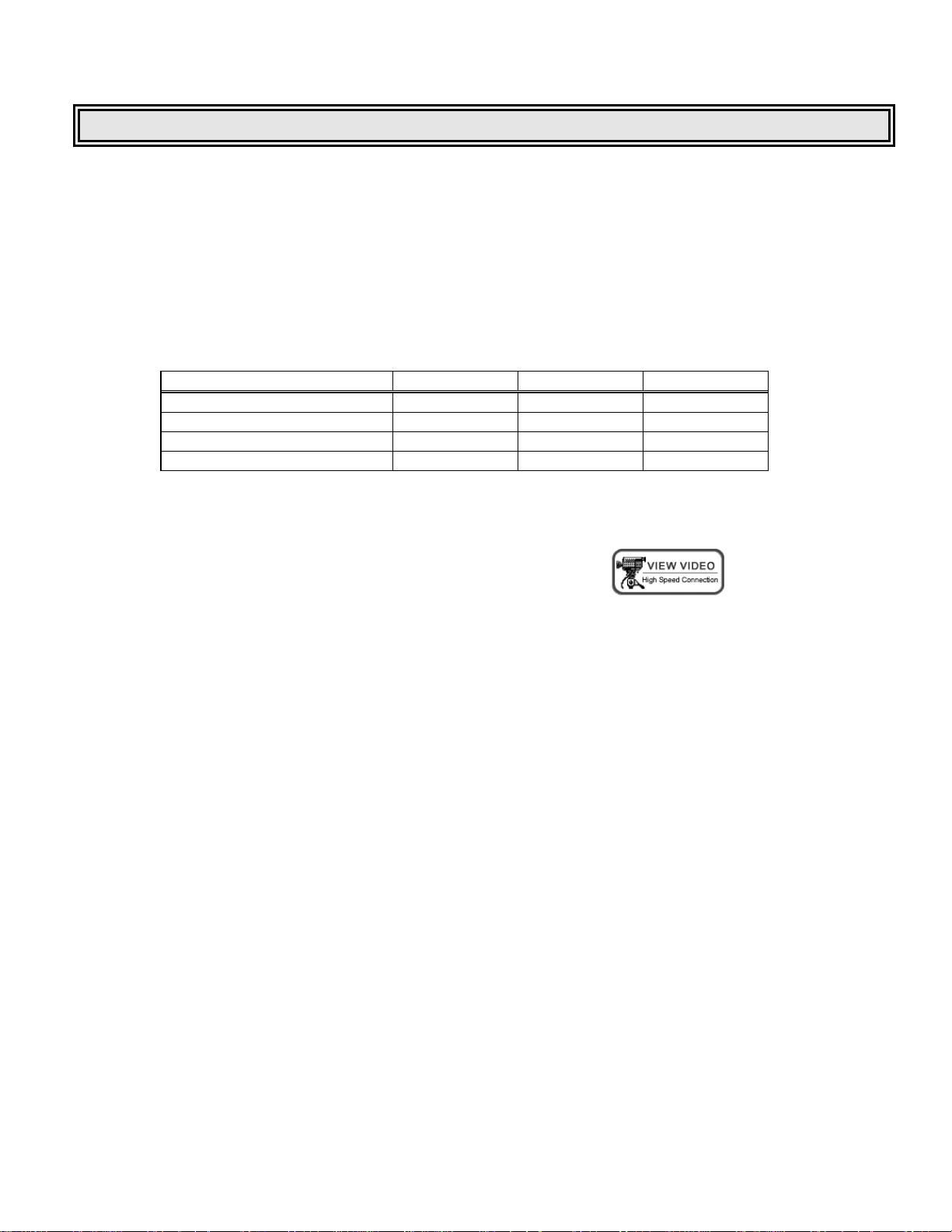

Installation Requirements and Instructions

PHYSICAL SPACE REQUIREMENTS:

See Safety Precautions for important information regarding the installation area.

The unit must be installed on a level concrete pad/floor and protected from the weather and freezing temperatures.

Approximate overall dimensions/space requirements are listed below. Additional space is required around and

above the equipment for loading and unloading, storage drums, access for maintenance, etc.

Equipment model(s) Width Depth Height

LS-15E/15IIE 51 in. (1.3 m.) 27 in. (0.7 m.) 42 in. (1.1 m.)

LS-15E/15IIE + JetVac 108 in. (2.7 m.) 27 in. (0.7 m.) 48 in. (1.2 m.)

LS-55E/55IIE 75 in. (1.9 m.) 40 in. (1.0 m.) 60 in. (1.5 m.)

LS-55E/55IIE + JetVac 131 in. (3.3 m.) 40 in. (1.0 m.) 60 in. (1.5 m.)

IMPORTANT: If using a Little Cooler closed-loop cooling system with the Little Still, the Little Cooler must be

located outside of the hazardous area. Refer to the Little Cooler Instruction Manual for further details.

ASSEMBLY: See Parts Location Diagram for additional information.

Remove the unit from the shipping containers and inspect for damage. If damage is detected, save all packaging

and immediately report any exterior or interior damage to the freight carrier.

Remove all accessories from the inside of the Still (and the JetVac’s cabinet, if applicable).

Install the pressure relief valve assembly into the top of the Still’s lid. Face the elbow towards the rear of the unit

(away from the occupied area).

Attach the supplied grounding cables/clamps to the ground block on the right side of the Still.

Thread the discharge hose into the discharge pipe on the right side of the Still. Omit this step if installing a JetVac

(see below).

SPECIAL ASSEMBLY FOR LS-15IIE AND LS-55IIE: “System II” Stills have additional features for

automatic operation. Explanations of these features are discussed in the Instrumentation and Controls section.

Install the vapor temperature gage into the control panel on the front of the Still (this gage is a delicate instrument

and is packed separately to prevent damage). Attach the white wire to the positive (+) terminal and the red wire to

the negative (-) terminal. Mount the gage using the two nuts provided.

3

Page 5

SPECIAL ASSEMBLY FOR INSTALLATIONS WITH A JETVAC: When

installing a JetVac attachment to a Little Still, the system is installed and assembled in a

way that allows the system to operate either with or without the JetVac. Use pipe tape on

all threaded connections to prevent vacuum leaks.

Set the JetVac to the right of the Still, with approximately 24 inches of space between the units.

Thread the discharge hose with sightglass into the JetVac’s distillate port (on the left side, towards the front of the

cabinet). Also thread the Y-strainer into the JetVac’s vacuum port (on the left side, centered).

Thread a male quick-connect onto the JetVac’s metal braided hose female side. Thread a female quick-connect

into the discharge of the Still (on the right side, centered in the cabinet). Thread the metal braided hose into the

previously installed .

Adjust the distance between the Still and JetVac until the metal braided hose quick-connects to the Still. Secure

the Still and JetVac to the floor once positioned.

Attach the other male quick-connect to the Still’s discharge hose. This allows this discharge hose to attach

directly to the Still (after disconnecting the metal braided hose) for processing without the JetVac.

INSTALLATION OF THE FLAME ARRESTER TO JETVAC:

The flame arrestor is designed to prevent flame from entering the distillation system through the vent pipe.

Proper installation and location of the flame arrester is essential to effective operation.

Installation must be inspected and approved by your insurance and/or fire inspector.

Connection is made at the vent on the backside of the JetVac unit (see pg. 9 for location).

The flame arrester must be piped so the arrow on the flame arrestor body points away from the distillation system

and must be connected to the end of the vent pipe.

Using FTI supplied piping, screw the ½” nipple into the coupling on the back of the JetVac, attached a 90º elbow

to the nipple and a customer supplied connect a length of pipe to allow venting to a safe area (to the outside or

other safe area as determined by your insurance or other qualified inspector). Make sure that the piping is properly

supported and the flame arrestor is attached to the end of the vent pipe. Do not use pipe larger than ½” diameter.

If venting unit to the outside, a gooseneck can be installed on the end of the flame arrestor to prevent rain from

entering the vent piping through the flame arrestor. The gooseneck must be ½” pipe, be installed at the end of the

flame arrestor and be no more that 5” long.

4

Page 6

ELECTRICAL REQUIREMENTS:

CAUTION:

A qualified electrician should perform electrical connections. Improper electrical wiring can result in damage to

components.

See Safety Precautions for important information regarding the electrical connections.

Electrical power requirements to the control panel are 240 volts, 1 phase, 50/60 hertz from a protected circuit and

earth ground. If the incoming voltage is 208 volts, processing time will increase. The equipment will not operate

with incoming voltages (under load) less than 208 volts.

Electrical connections are made on the rear of the Still. Attach a customer supplied explosionproof circuit box to

the Still’s electrical conduit.

If a JetVac and/or Little Cooler are used with an LS-15E/55E still, they must be wired independent of the still and

manually started/stopped.

Note: Customer must supply a switch to control a Little Cooler in this case. See the Little Cooler Instruction

Manual for more details.

System II stills can be electrically connected for automatic operation of a JetVac and/or a Little Cooler, if using a

Little Cooler, a 10-amp contactor (customer supplied) must be used. See electrical connections below!

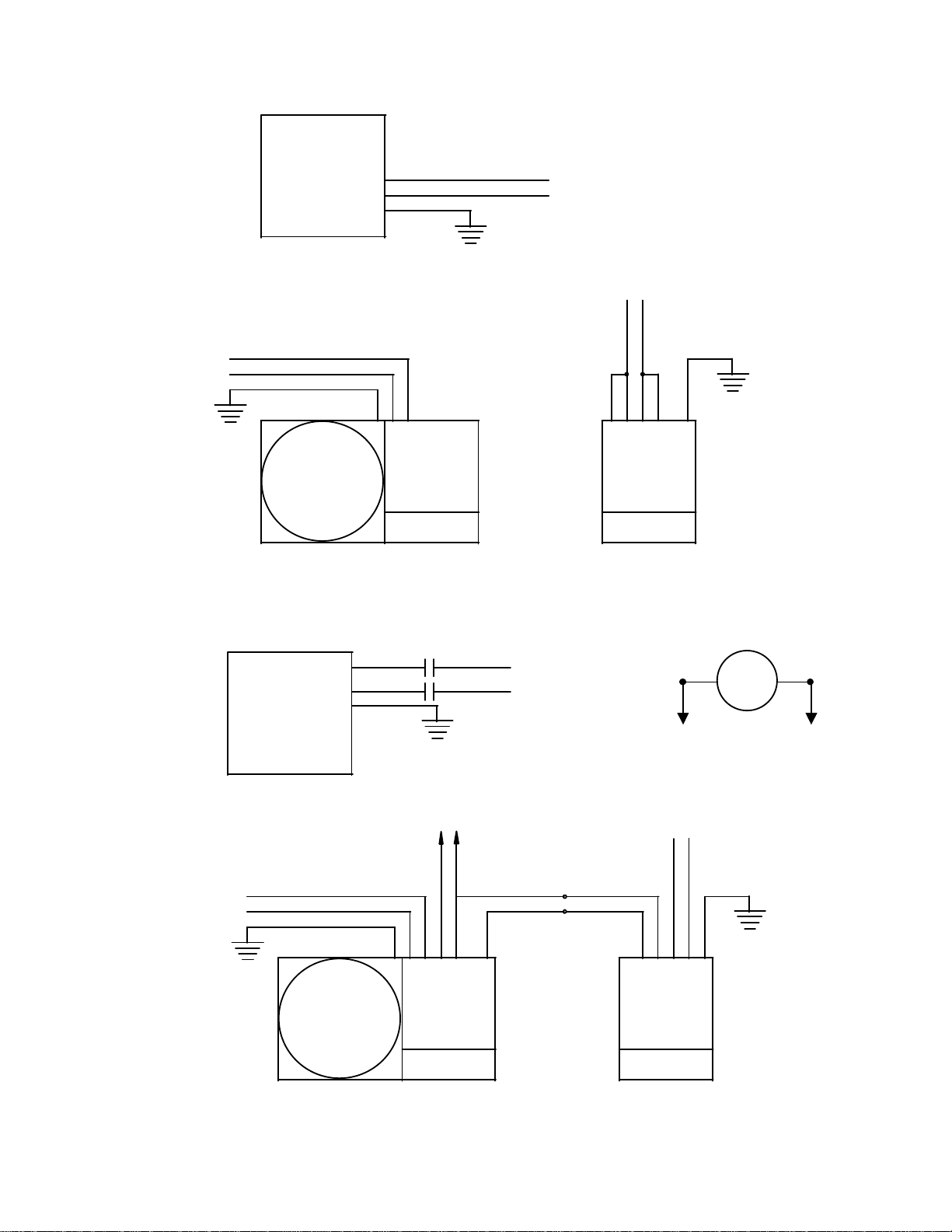

Make the connections per the diagrams following:

LSEII – wiring for units without JetVac or Little Cooler

LS15E/55IIE – wiring with JetVac and Little Cooler

LS15E/55IIE – wiring with JetVac

LS JetVac – wiring for LS15E and LS55E

LSJetVac – wiring for LS15IIE and LS55IIE

GROUNDING REQUIREMENTS:

See Safety Precautions for important information on static grounding.

A positive earth ground must be provided to help avoid static ignition and must be attached to all equipment,

filling and receiving containers, tanks, personnel, etc. All transfer devices such as piping, hoses, and pumps must

also be grounded.

Several ground lugs are provided on the right side of the Still and several grounding clamps are provided.

USE THEM.

5

Page 7

LITTLE

COOLER

L1

INCOMING POWER

(SWITCHED)

L2

INCOMING

POWER

INCOMING

POWER

L1

L2

COOLER

L1

A

LS-15E/55E

STILL

Electrical connections for an LS-15E/55E

CC1

L1

CC2

LITTLE

INCOMING

POWER

L2

L2

1L2

JETVAC

CUSTOMER SUPPLIED

CONTACTOR

C.C.

B1L2

TO “CUSTOMER SUPPLIED” CONTACTOR

COIL FOR LITT LE COOLER

INCOMING

POWER

L2

L1

INCOMING

1L2

POWER

B

1L2

1L2

L1

L2

A

A

LS-15IIE

or

JETVAC

LS-55IIE

Electrical connections for a “System II”

6

Page 8

CONDENSER COOLING WATER REQUIREMENTS:

WARNING:

Improper cooling water supply can result in the accumulation of hazardous vapors (refer to Safety

Precautions for ventilation information).

CAUTION:

Do not allow the cooling water supply to freeze. Damage to components can occur. Do not exceed 85 psi

inlet water pressure.

Cooling water can be supplied via “tap water” or from a closed-loop cooling system (e.g., a Little Cooler or

cooling tower).

Cooling water supply and return connections are ½” NPT female pipe and are located on the rear of the Still and

JetVac.

Minimum cooling water flow required for the condenser is ½ gallon per minute for the LS-15E/15IIE,

and 1½ gallons per minute for the LS-55E/55IIE. Minimum requirements increase by a ½ gallon a minute when

using any still in conjunction with a JetVac.

Cooling water temperature must be less than 80° F or 50° F below the lowest boiling point of the solvent being

processed—whichever is lower (determine solvent boiling point under vacuum, if applicable).

If using a “hard” water supply, treatment is required to prevent mineral deposit or scale accumulation within the

vapor condensers and cooling coils of the cooling system. If water contains particulate, install an appropriate

filter before the Still.

IMPORTANT: Follow these guidelines when using a Little Cooler closed-loop cooling system. Refer to the Little

Cooler Instruction Manual for further information.

The Little Cooler is designed only for condenser cooling. Do not attach it to the quick-cool coil (use tap water

for the quick-cool).

Depending on the physical distance, height, and type of plumbing used between the Still and the Little Cooler, it

may be necessary to bypass the condenser water solenoid valve. Simply remove the hose from the inlet of the

solenoid valve and connect it to the water inlet of the condenser (lower connection on the condenser).

There will be a slight delay before the Still will turn on when using a Little Cooler (until the cooling water begins

to circulate).

7

Page 9

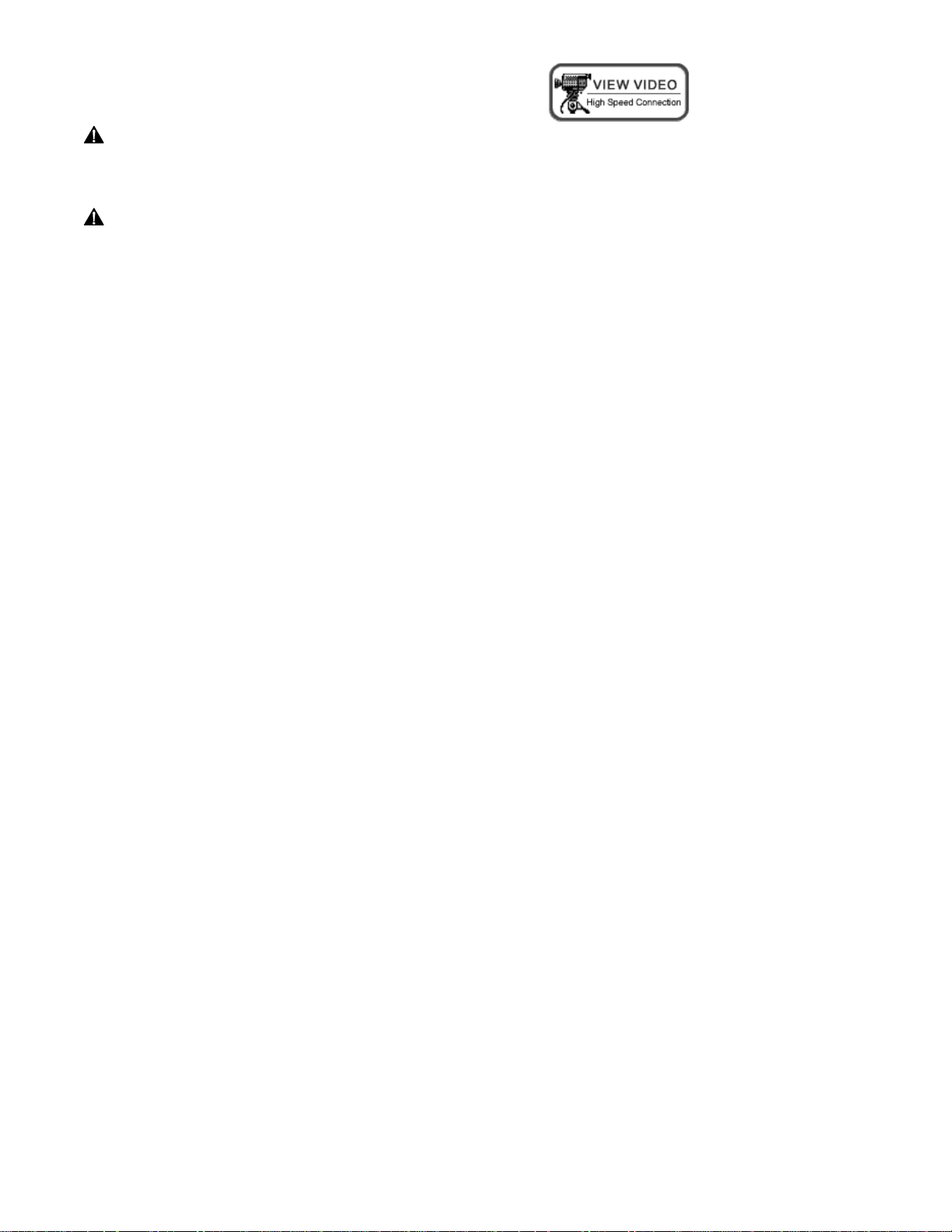

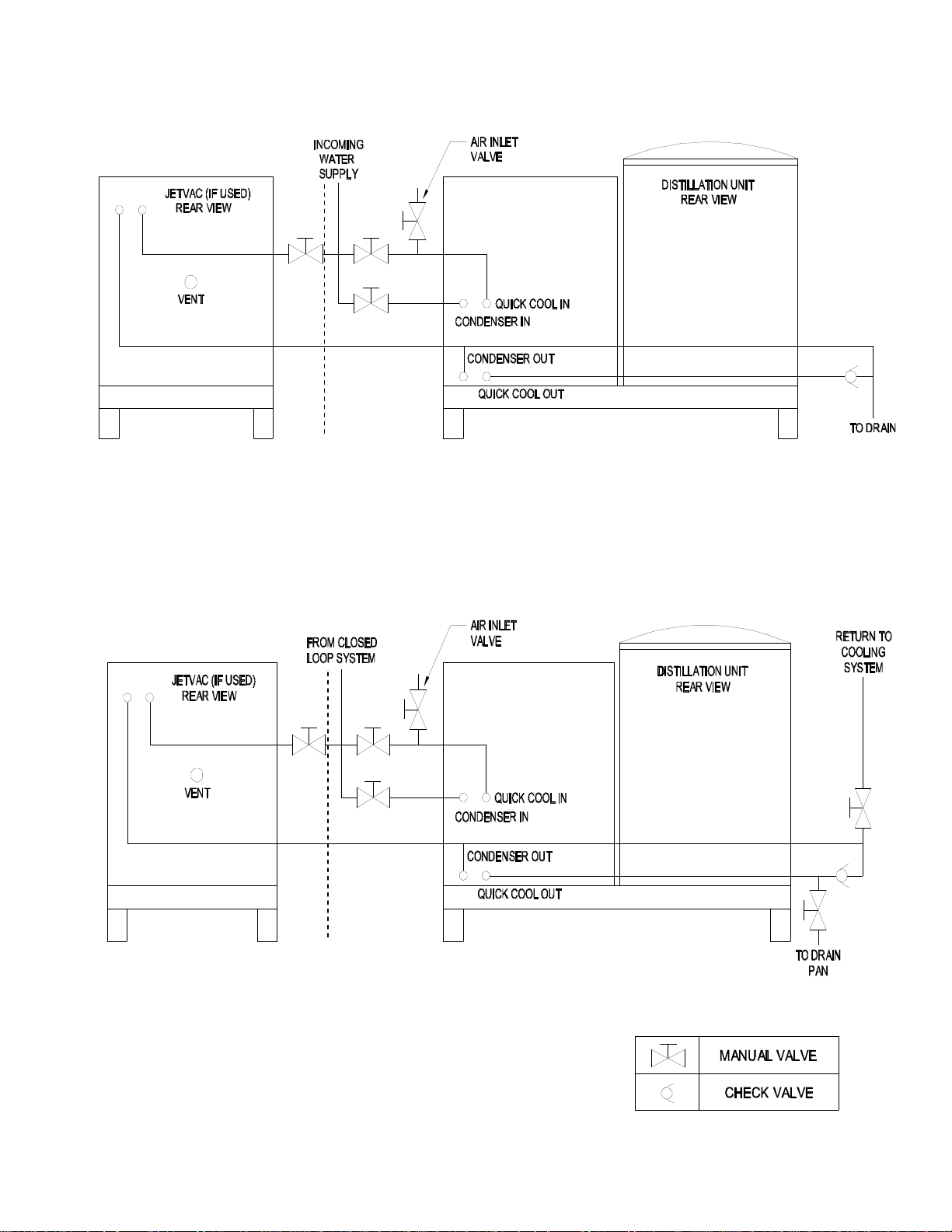

QUICK COOL REQUIREMENTS

NOTE:

The Quick Cool is standard in the LS-15E/15IIE units. The main purpose of the quick cool coil is to rapidly cool

down the distillation tank after a cycle is complete, which allows the user to run multiple shifts each day. If the user

does not intend to run multiple shifts, FTI recommends not plumbing the quick cool coil.

The Little Cooler is designed only for condenser cooling. Do not attach it to the quick-cool coil (use tap water

for the quick cool).

Plumb the quick cool coil with hard piping only.

An air inlet valve must be installed to properly vent the system. This allows the line to be adequately drained after

each use (see cooling diagram). Always completely drain the quick cool coil after each use or the next cycle will

be prolonged and/or possible damage to the unit may occur.

A check valve should be installed on the outlet side of the quick cool to prevent backpressure or back flow into the

system from down steam (see cooling diagram), which will hinder the cycle time of the next cycle.

Minimum cooling water flow required for the quick cool is 1-3 gallons per minute for the LS-15E/15IIE and 2-5

gallons per minute for the LS-55E/55IIE.

8

Page 10

CONVENTIONAL “TAP” WATER SUPPY:

Use with optional JetVac.

ATMOSPHERIC

. CLOSED-LOOP COOLING WATER SUPPLY: Refer to Little Cooler Instruction Manual when

connecting a Little Cooler.

Use with optional JetVac.

ATMOSPHERIC

IMPORTANT:

Quick cool must be drained completely before each run.

An air inlet valve is required to drain quick-cool coil.

9

Page 11

Instrumentation and Controls

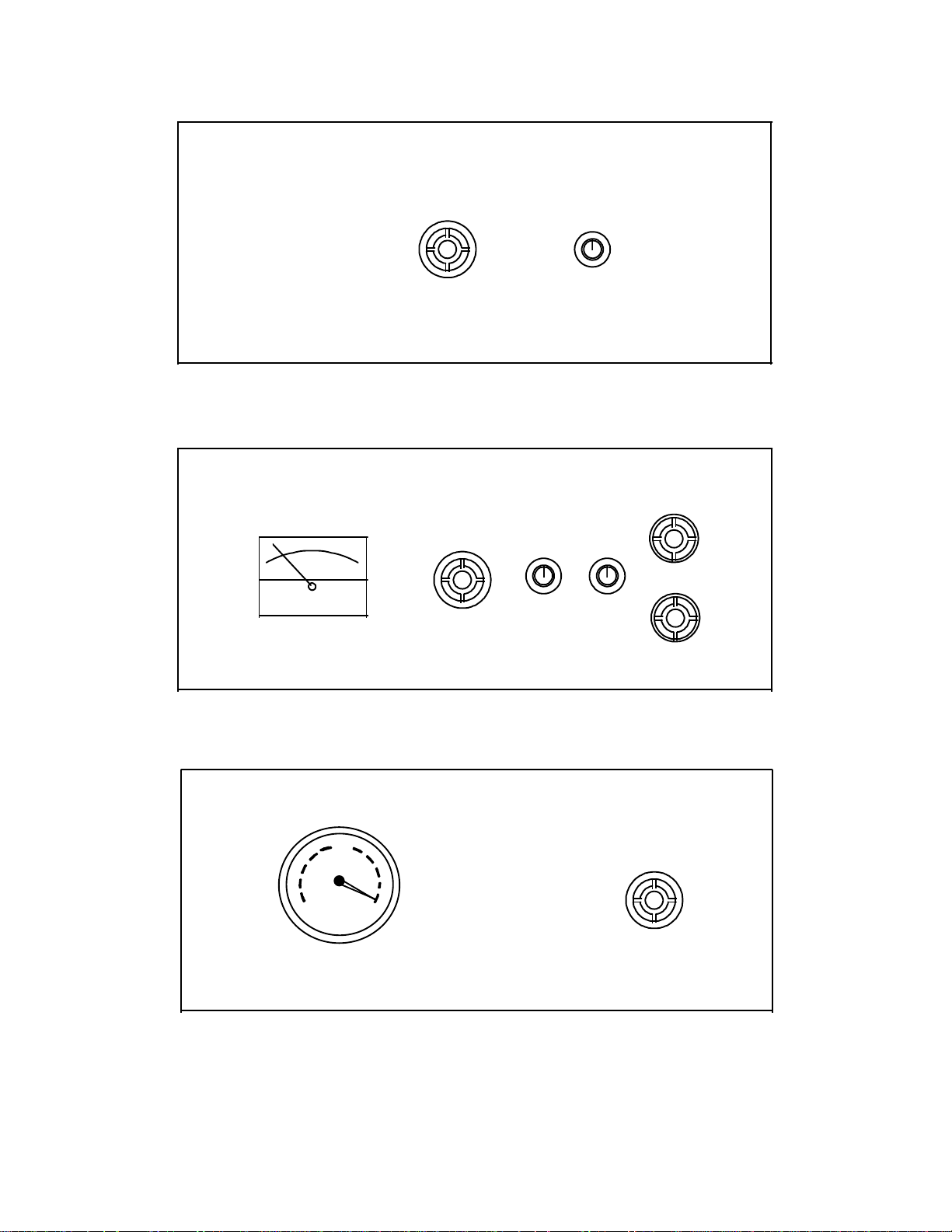

LS SERIES STILLS (ALL MODELS):

STOP/START - An illuminated push-button switch. Pull to activate the Still, push to terminate all functions. A

green light indicates that the Still is operating within the processing cycle.

IMPORTANT: The STOP/START push-button switch must be left pushed in the STOP position for a minimum of

five (5) seconds before pulling on. This allows the controls to electrically reset themselves. Failure to do so will

prevent the heater from operating.

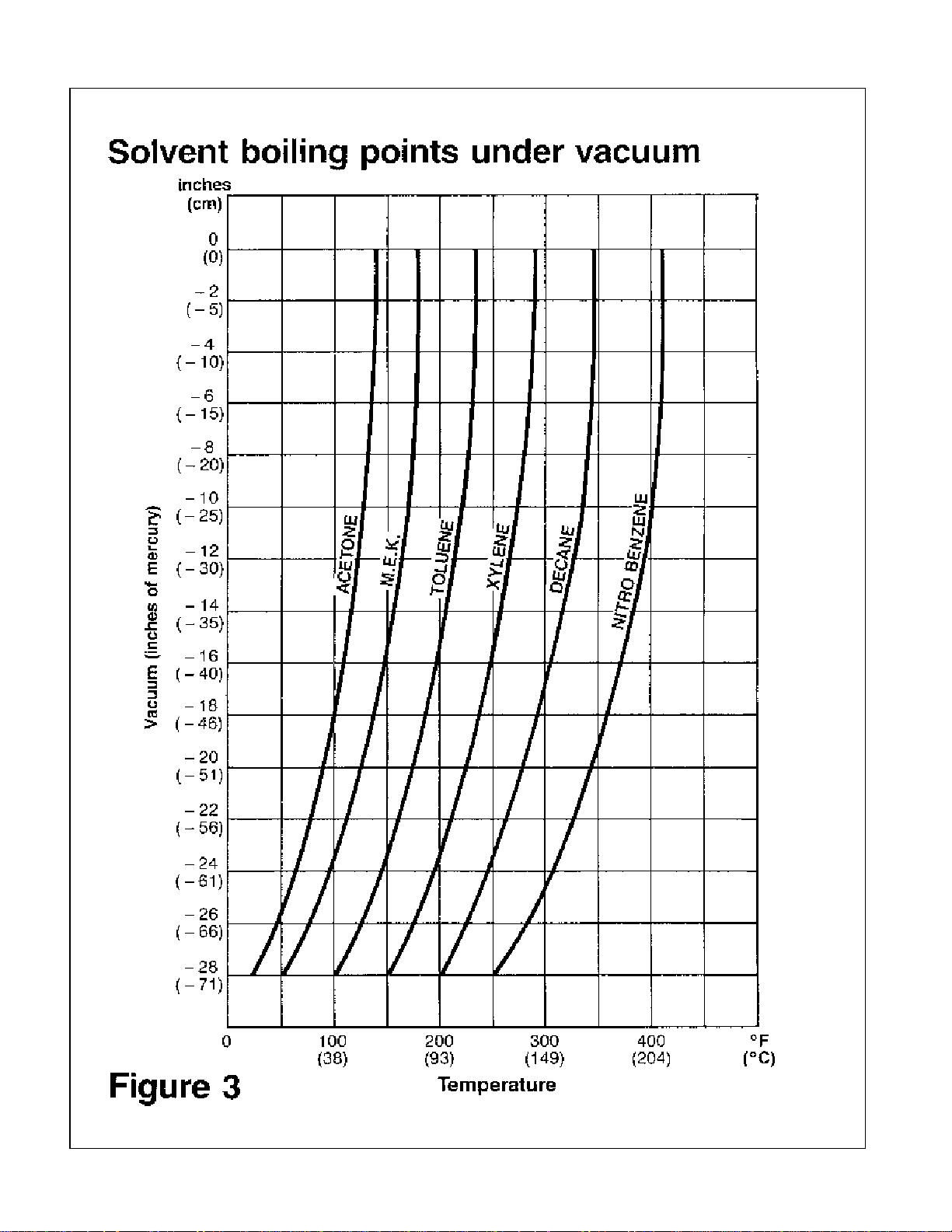

CYCLE TEMP - Controls the temperature that will be maintained in the area of the heater. Turn the dial to set the

temperature at least 50° to 100°F above the boiling point of the solvent being processed.

IMPORTANT: Determine the solvent boiling point under vacuum, if applicable. See Solvent Boiling Points

Under Vacuum for additional information.

LS SERIES “SYSTEM II” STILLS:

CYCLE TIMER - This setting determines the total duration of the cycle. Turn the dial to the desired amount of

time, depending on your particular solvent. If unsure as to the time required for your solvent, start at 8 hours, then

observe the results. Adjust up or down, as necessary until the optimum time is determined.

IMPORTANT: The minimum setting (full counter-clockwise) allows the still to process for 10 minutes, then

activates the cool-down mode for 1 hour. The maximum setting (full clockwise) allows the still to process for 16

hours, then activates the cool-down mode for 1 hour. The accuracy of the timer is approximately ±15%.

COOLING WATER - White indicator light. When illuminated, this light indicates that the cooling water supply to

the condenser is flowing at or above the proper rate. Adjust your incoming water flow until the light stays on

without flickering. If the white light does not illuminate, this may indicate that the water flow to the unit is

inadequate, or the condenser cooling system or flow switch requires maintenance.

HEAT - Amber indicator light. This light indicates the heater element is ON. During normal operation, this light

will remain illuminated for approximately the first hour of the process, then will cycle ON and OFF to indicate that

the heating system is cycling to maintain the temperature set on the Cycle Temp dial.

VAPOR TEMP - Indicates the temperature of the solvent vapor before being condensed into liquid. This gage is

for informational purposes only, and controls no functions.

10

Page 12

JETVAC ATTACHMENT:

STOP/START - An illuminated push-button switch. Pull to ready the JetVac’s operation, push to terminate all

JetVac functions. A green light indicates that the JetVac is operating within the processing cycle.

IMPORTANT: The STOP/START push-button switch should remain ON (pulled) when wired for automatic

operation. In this mode, the Still will automatically turn on and off the JetVac depending on the status of the Still’s

operation. If vacuum operation is not required for a particular process, simply push STOP/START to the STOP

position.

VACUUM GAGE - A gage that indicates the level of vacuum, measured in inches of mercury being generated by

the JetVac measured in inches of mercury (0” to -30” Hg.). An increase in vacuum level decreases the boiling point

of the solvent being processed. The vacuum level can be adjusted turning the nuts on the vac adjust valve located

inside of the JetVac’s cabinet.

11

Page 13

LS-15E/55E CONTROLS

VAPOR TEMPERATURE

PUSH TO

STOP

PUSH TO

STOP

PULL TO

START

PULL TO

START

CYCLE TEMP

ºF

CYCLE TEMP

ºF

CYCLE TIMER

HOURS

COOLING WATER

HEAT

LS-15IIE/55IIE CONTROLS

15

30

VACUUM GAUGE

PUSH TO

0

STOP

PULL TO

START

JETVAC CONTROLS

12

Page 14

13

Page 15

Start-up and Operation

The LS Series equipment requires minimal operator involvement. Once set up and started, the unit can operate

virtually unattended until the process is complete. See Safety Precautions before operating this unit. Explanation of

each control and setting can be found in Instrumentation and Controls.

CAUTION:

Only process neutral waste solvents with a pH between 6 and 9. Solvents outside of this safe pH range can

cause damage to your LS Series equipment that is not covered under its warranty. Some solvents can

become acidic or basic once heated. Periodically test the dirty solvent as well as the distillate and residue

to verify a safe pH. If your pH is not in the “safe zone,” it must be neutralized. Consult your solvent

supplier for recommendations on testing the pH and pH correction.

LS-15E/55E MODELS:

1. Open the lid and remove any residues from a previous run. Make sure that the inside of the boiling chamber is

clean and free of debris.

CAUTION:

When cleaning, use only plastic or other non-metallic utensils to avoid scratching the boiling chamber

when scraping out residues. Scratching the non-stick coating results in permanent damage and voids the

warranty.

2. Install a Stilbag or a Stilpan (if used, see Installing a Stilbag). If using a JetVac attachment, prepare the JetVac

for operation (see Start-up and Operation: JetVac).

3. Fill the boiling chamber (ground all transfer equipment, containers, and personnel, see Safety Precautions). Do

not overfill. Close the lid, make sure the lid is centered on the gasket, and secure the lid clamps. Place a clean,

grounded receiving drum under the discharge hose of the Still (or JetVac, if applicable).

4. Verify that the quick-cool water supply is off and that all cooling water is drained from the quick-cool coil by

opening the drain valve and breather valve.

5. Turn on the condenser’s water supply. If using a Little Cooler, prepare the Little Cooler for operation (refer to

the Little Cooler Instruction Manual).

6. Set the CYCLE TEMP dial to the desired temperature.

7. Pull the Still’s STOP/START switch to the START position.

8. Adjust the condenser’s water supply until the safety flow switch is satisfied (until the green light on the

STOP/START button stays on).

9. Allow system to operate until solvent is no longer processing or until desired time has elapsed. Push the

STOP/START switch to the STOP position. Allow the condenser cooling water to run for an additional hour (to

condense any remaining vapors) before turning the condenser water off.

10. If using the quick-cool feature, turn on the quick-cool water supply for one hour, or until the Still has reached

the desired temperature (100°F or less), turn water supply off and drain quick-cool before starting next cycle.

14

Page 16

LS-15IIE/55IIE MODELS:

1. Open the lid and remove any residues from a previous run. Make sure that the inside of the boiling chamber is

clean and free of debris.

CAUTION:

When cleaning, use only plastic or other non-metallic utensils to avoid scratching the boiling chamber

when scraping out residues. Scratching the non-stick coating results in permanent damage and voids the

warranty.

2. Install a Stilbag or a Stilpan (if used, see Installing a Stilbag). If using a JetVac attachment, prepare the JetVac

for operation (see Start-up and Operation: JetVac).

3. Fill the boiling chamber (ground all transfer equipment, containers, and personnel, see Safety Precautions). Do

not overfill. Close the lid, make sure the lid is centered on the gasket, and secure the lid clamps. Place a clean,

grounded receiving drum under the discharge hose of the Still (or JetVac, if applicable).

4. Verify that the quick-cool water supply is off, and that all cooling water is drained from the quick-cool coil by

opening the drain valve and breather valve.

5. Verify that the condenser water supply is on to the Still. If using a Little Cooler, prepare the Little Cooler for

operation (refer to the Little Cooler Instruction Manual).

6. Set the CYCLE TEMP dial to the desired temperature.

7. Set the CYCLE TIME dial to the desired length of time.

8. Pull the Still’s STOP/START switch to the START position. If the switch is pulled out from a previous run,

push the switch in, wait 5 seconds, then pull the switch to the START position.

9. Adjust the condenser’s water supply until the safety flow switch is satisfied (until the white light stays on).

10. Allow system to operate until the desired time has elapsed, or the solvent has finished processing (a drop in

temperature on the VAPOR TEMP gage indicates near completion of the process). The green light on the

STOP/START switch and the amber light will go out indicating the system is in cool-down mode (this allows

the condenser cooling water to run for an additional hour (to condense any remaining vapors) before

automatically turning the condenser water off.

WARNING:

Never push the STOP/START switch to the STOP position to terminate a process early. Instead, set the

CYCLE TIMER to the 10 MIN position (full counter-clockwise). This will automatically terminate the cycle

in ten minutes, and allows the cool-down mode to engage to help prevent the release of hazardous

vapors.

11. If using the quick-cool feature, turn on the quick-cool water supply for one hour, or until the Still has reached

the desired temperature (100°F or less), turn water supply off and drain quick-cool before starting next cycle.

12. Once all lights have gone out, push the STOP/START switch to the STOP position.

15

Page 17

JETVAC ATTACHMENT:

CAUTION:

Do not process solvents with boiling points below 200º F with the JetVac. Release of hazardous vapors and

damage to the equipment may result.

1. Lift the top panel of the JetVac’s cabinet and prop it open with the supplied prop bar (attached under the top

panel). If changing the solvent or cleaning the reservoir, the “old” solvent can be drained through a ball-valve

located on the right side of the JetVac’s cabinet.

2. Locate the pump reservoir, unscrew the two wing-nuts, lift the reservoir lid, and set the lid to the side.

3. Fill the pump reservoir with clean solvent (the same type of solvent that is being processed). Ground all transfer

equipment, containers, and personnel (see Safety Precautions). Replace and secure the pump reservoir’s lid.

4. Start the system by turning on the Still (and pulling the STOP/START switch of the JetVac to the START

position). Allow the JetVac to generate vacuum (as indicated on the vacuum gage). When the vacuum level no

longer rises, use the vacuum adjust valve to adjust to desired vacuum level, then close the top panel.

5. IMPORTANT: On new installations, it may be necessary to tape the Still’s lid with the supplied pipe tape for

the first few runs, or until the Still’s lid gasket compresses and seals properly.

6. At the end of the process, the JetVac will shut down automatically (when wired in the automatic mode). In

automatic mode, the STOP/START switch can remain in the START position, and operation will be controlled

by the Still. When the JetVac stops, the vacuum will be relieved through a vacuum relief solenoid (atmospheric

vent).

NOTE: For processing atmospherically (without vacuum) with a JetVac attached to the Still, simply push the

JetVac’s STOP/START switch to the STOP position, disconnect the metal braided hose at the Still with the quickconnector, connect the Still’s red discharge hose to the discharge of the Still, and place the grounded receiving drum

under the Still’s discharge hose. Follow the operation instructions for the Still.

16

Page 18

INSTALLING A STILBAG:

WARNING

Proper installation of a Stilbag is critical. Improper installation can result in

dangerous pressurization of the boiling chamber. Never disable the Stilbag venting

system.

1. Unroll the Stilbag and expand it open. Gather the top opening of the Stilbag, trapping air

inside to form a “ball”.

2. Insert the Stilbag into the boiling chamber, taking care to line the bottom seam of the

Stilbag from side to side and in line with the Stilbag vent (located on the inside right side

of the boiling chamber). If using a Liftrack, place it into the boiling chamber before

inserting the Stilbag.

3. Flatten the Stilbag along the bottom and sides to help prevent air pockets under the

Stilbag.

4. Install the Stilbag retaining ring. Compress the ring by placing your thumb and finger

into the loops and squeezing them together. Place the ring inside the Stilbag and allow it

to expand into the groove on the inside of the boiling chamber, holding the Stilbag in

place. Position the Stilbag retaining ring so that the Stilbag vent is between the opening

of the retaining ring.

5. Re-adjust the Stilbag, if needed, in order to get a close fit to the boiling chamber and to

further eliminate air pockets from under the Stilbag.

IMPORTANT: A Stilbag is designed for a single use only. The bag can become brittle and

burst if used for more than one cycle. Some applications require the use of high temperature

Stilbags. Other applications may be incompatible with the Stilbags material and require the

use of a Stilpan.

Note: Lift bar (standard on LS-55E/IIE) maximum weight limit is 250 lbs.

17

Page 19

~ Maintenance Schedule ~

CAUTION:

Always wear eye protection, protective clothing, gloves and an approved respirator when working on or with this

unit. Never work on or with this equipment while it is hot. Never open a hot Still. Allow a minimum of two

hours or more cool-down time.

EACH USE:

CLEAN THE BOILING CHAMBER - Remove any waste residues from the boiling chamber and Stilbag

venting system. If necessary, gently scrape the sides with an approved scraper (see Common Spare Parts). Also

keep the underside of the lid’s lip clean for proper sealing, as well as clearing the opening to the pressure relief

valve.

CAUTION:

When cleaning, use only plastic or other non-metallic utensils to avoid scratching the boiling chamber

when scraping out residues. Scratching the non-stick coating results in permanent damage and voids the

warranty.

WEEKLY:

VERIFY FLOW SWITCH - Test the operation of the cooling water flow switch. Start the system, and reduce

the water flow to the condenser to verify that the indicator light goes out (the JetVac will also shut off, if used). If

the flowswitch operates incorrectly, verify proper condenser water flow, and clean the flowswitch according to

Maintenance: Semi-annually. If this does not solve the problem, replace the flow switch.

WARNING:

Do not attempt to operate the Still when the cooling water flow switch is not operating correctly. Doing

so can result in the accumulation of hazardous vapors.

CHECK GROUNDING CABLES - Inspect all grounding cables and clamps for deterioration or damage.

Replace any suspect parts.

INSPECT GASKETS - Check the lid gasket on the boiling chamber and the JetVac reservoir for debris, cracks,

voids, etc. Replace any damaged gaskets.

IMPORTANT - Do not attempt to remove the Still gasket for inspection. A used gasket is compressed and will

not easily re-install onto the boiling chamber.

18

Page 20

SEMI-ANNUALLY OR AS REQUIRED:

ADJUST LID CLAMPS - Make sure that all of the Still’s lid clamps hold tightly. Adjust any loose clamps, and

replace clamps that appear weak.

CLEAN JETVAC PUMP RESERVOIR - If using a JetVac attachment, drain the pump reservoir and clean and

remove all dirt and debris. Inspect parts for corrosion, and replace any suspect parts.

CLEAN Y-STRAINERS - The Still’s Y-strainer is located inside of its cabinet. The JetVac’s Y-strainer is

located on its left side, in line with the metal braided hose. Remove the screen and clean out the debris. If

mineral deposit or scale is detected, also remove and clean inside the condenser cooling water jacket as well.

CLEAN THE CONDENSER - Remove the condenser and inspect it for scale or residue on both the water and

solvent side. Clean or replace if necessary.

LID LIFT BAR - On LS-55E/55IIE, units grease the lid’s lift bar (located at the rear of the unit) using the two

supplied grease fittings.

CLEAN THE FLOW SWITCH - The flow switch is

located inside of the Still’s cabinet.

1. Disassemble the flow switch by loosening the large

bonnet nut and pulling the body of the flow switch

free.

2. Clean the shuttle assembly, spring, magnet,

plunger, and body of the flow switch.

3. Place the spring, magnet, and plunger onto the

shuttle assembly, then gently push the body onto

the shuttle assembly. Take care not to damage the

shuttle’s O-ring.

4. Test the operation of the flow switch (see

Maintenance: Weekly).

SHUTTLE

ASSEMBLY

BONNET NUT

SPRING

MAGNET

PLUNGER

19

Page 21

Service and Troubleshooting

In the event the Little Still does not appear to operate correctly, use the following tips to diagnose common

problems. If these suggestions do not pinpoint the cause of your problem, contact FTI’s toll-free “Tech Service

Hotline” between the hours of 8 a.m. to 5 p.m. EST.

Tech Service Hotline - 800-888-3743

WARNING:

Never electrically trouble shoot or operate this equipment in the hazardous area when electrical

components are exposed (e.g., the explosion-proof control box is opened). Doing so can provide an ignition

source for hazardous vapors, resulting in serious injury or death. Any electrical tests should be performed

by a qualified electrician.

CAUTION:

Always wear eye protection, protective clothing, gloves and an approved respirator when working on or

with this unit. Never work on or with this equipment while it is hot. Never open a hot Still. Allow a

minimum of two hours or more cool-down time.

LS SERIES STILLS: BASIC TROUBLESHOOTING TIPS

PROBLEM: Still appears to be operating, but nothing is processing.

POSSIBLE CAUSES:

Turn up the cycle temperature to a higher temperature.

Solvent’s boiling point is too high. Use a JetVac attachment for solvents with boiling points between 300°F and

500°F.

Cooling water left in quick-cool coil. Verify that the water supply to the quick-cool coil is off, and all water has

been evacuated from the coil.

Residue build-up. Clean any accumulation of residues from the bottom of the boiling chamber. A build-up of

material will act as an insulator and make it difficult to transfer heat into the solvent.

Too high of solids in waste solvent. Process the solvent when it is less contaminated. Solids level should not

exceed 20% for best results.

PROBLEM: Odor of solvent vapors around the LS units.

POSSIBLE CAUSES:

Normal occurrence. During the process, very small amounts of vapors can escape from the lid and from the

receiving drum. Proper ventilation in the area should evacuate these vapors.

Lid ajar. Verify that the gasket for the lid of the Still and/or JetVac pump reservoir is not damaged and the lid is

properly seated.

Condenser is plugged with mineral deposits or scale. Replace the condenser; treat the cooling water supply to

prevent re-occurrence.

Cooling water temperature too high. Cooling water temperature must be less than 80° F or 50° F below the lowest

boiling point of the solvent being processed—whichever is lower (determine solvent boiling point under vacuum,

if applicable).

Faulty flow switch not detecting low water flow. Test the operation of the flow switch and service if necessary.

Pressure relief valve is activating. Check for obstructions.

20

Page 22

LS SERIES STILLS: BASIC TROUBLESHOOTING TIPS CONTINUED…

PROBLEM: Stilbags break or melt during a cycle or while lifting out residue.

POSSIBLE CAUSES:

Temperature too hot. The standard temp Stilbags will become brittle if overheated. Try the hi-temp Stilbags.

Stilbag used too long. The Stilbag is designed for a maximum of up to 16 hours and for a single use only.

Chemical incompatibility. The Stilbags are made of “Nylon 6” and “Nylon 66.” Check compatibility with your

solvent supplier.

Acid or caustic attack. The Stilbags are designed for use with solvents/residues with a pH between 6 and 9.

Residue too heavy. The dirty/waste solvent should contain no more than 20% solids.

PROBLEM: Unit(s) will not turn on (no lights come on).

POSSIBLE CAUSES:

No power to the Still. Verify the electrical power/connections to the Still.

Blown fuse inside the Still’s control box (System II units only). Replace fuse. This would indicate an electrical

power surge or other problem with the circuitry (consult factory).

Flow switch not engaged (LS-15E and LS-55E only). Verify proper condenser water supply. Clean or service the

flow switch.

Controls have not reset (LS-15E and LS-55E only). Push the STOP/START switch to the STOP position for at

least five (5) seconds before pulling the switch back out.

PROBLEM: Only the green light comes on (System II only). Still not heating.

POSSIBLE CAUSES:

Flowswitch not engaged. Verify proper condenser water supply. Clean or service the flowswitch.

PROBLEM: Only the white light comes on when the STOP/START switch is pulled (System II only).

POSSIBLE CAUSES:

Controls have not reset. Push the STOP/START switch to the STOP position for at least five (5) seconds before

pulling the switch back out.

21

Page 23

JETVAC ATTACHMENT TROUBLESHOOTING TIPS:

PROBLEM: JetVac will not turn on.

POSSIBLE CAUSES:

JetVac is improperly wired. Verify the electrical power and connections to the JetVac and Still. When wired for

automatic mode, the Still must be operating for the JetVac to operate.

Improper cooling water flow to the condenser. If the flow switch in the Still is not engaged, the JetVac will not

operate (when wired in automatic mode).

PROBLEM: Low vacuum readings.

POSSIBLE CAUSES:

1. Air Leak – Disconnect the vacuum from the still. Place a hand over the end of the stainless steel hose and turn

on the vacuum. If you get good vacuum, check for:

Leaks around the lid of the Still. Check the Still’s lid gasket, and/or tape the lid to seal.

Leaks at the quick-connector. Inspect the gasket inside of the female quick-connector on the metal braided

hose. Replace the gasket if damaged.

Loose fitting on the unit.

2. If vacuum is still low, check:

The pumps reservoir for low liquid level. Top off the liquid level in the JetVac’s pump reservoir with clean

solvent.

3. Debris carried over during the distillation cycle can block:

The Y-strainer, check valve, aspirator, or pump causing a loss of vacuum. Look for signs of debris in the

pump reservoir. If debris is found, the aspirator may be clogged. Suction 4 - 5 gallons of clean solvent

through the stainless steel hose.

4. An O-ring failure on the vacuum adjustment valve.

5. Chemical attack of the internals in the vacuum relief solenoid.

6. Loose compression fittings in the system.

22

Page 24

Advanced Troubleshooting Tips: LS-15E / LS-55E

WARNING:

Qualified electrical personnel must perform all electrical tests and work. There is a potential for sparks when the

electrical control box is open. The unit must be removed to a location outside the hazardous area before any

electrical work can be done on live circuits.

PROBLEM: No heat. Green light not on.

1. Verify that cooling water is properly supplied to the condenser. The unit requires at least 1-1/2 gallons per

minute for the LS-55 and 1/2 gallon per minute for the LS-15. Make sure this volume of water is passing

through the unit. If the water supply is not adequate the unit will not turn on.

2. Verify that the flow switch (FLS) is performing properly. Check for voltage between wire lL2 (on the on/off

switch) and wire 5 on pin 15 on the temp board. If no voltage exists, turn off your water supply and service the

flow switch (see pg. 17). It is located down low inside the front panel of the still (it is brass colored and labeled

"Gems" on it).

3. If after cleaning the flow switch (and turning the water supply back on) the voltage still is not present between

wire 1L2 and wire 5, temporarily bypass the flow switch by connecting a jumper wire between pin 21 and pin

15 (on the temp board) to see if the heater contactor engages. If the heater contactor engages with the flow

switch bypassed, replace the flow switch.

PROBLEM: No heat. Green light is on.

The thermisters are metal rods that are inserted into the heater casting and wired to the temp board.

Their job is to tell the heater when to cycle on and off, using a temperature / resistance relationship.

Follow these instructions to test the thermisters (1 TC and 2TC) to verify proper specs.

1. Disconnect the power to the unit.

2. Check each thermister individually by disconnecting their wires (22 gauge black and white twisted pairs) from

the temp board. One set is on pins 1 and 3, and the other set is on pins 2 and 4. Measure the resistance between

the black and white wires. The following values should be obtained;

Ambient Temperatures

(Degrees)

60°F (l6°C).

77ºF (25 °C).

100°F (38º C)

240°F (115°C)

If one or both of the readings do not fall within this range, the thermister(s) should be replaced. If they both

fall within acceptable ranges, continue with the troubleshooting tips.

Resistance

(kilo - ohms)

13 6 kΩ

90 kΩ

52.5 kΩ

3.9 kΩ

23

Page 25

Advanced Troubleshooting Tips: LS-15E / LS-55E continued…

3. Verify that the K2 relay on the temp board is closing (when unit is turned on) by measuring for voltage between

wire IL2 (on the on/off switch) and wire 6 on pin 14 (on temp board). If no voltage is present, K2 may be faulty

and the temp board must be replaced. If 240V is present, K2 has closed and it is all right to continue with

troubleshooting tips.

4. Verify that KI relay on the temp board is closing (when the unit is turned on) by measuring for voltage between

wire lL2 (on the on/off switch) and wire 7 on pin 11 (on temp board). If no voltage is present, and all previous

tests check out, K I may be faulty and the temp board must be replaced. If 240V is present, Kl is closed and the

temp board is alright. If the temp board checks out, call the factory for further information.

5. This set of troubleshooting tips will verify a faulty temp board. Most heating problems lie within the water

supply or the flow switch. It is common for scale and other debris to build up in this switch causing the

symptoms you are experiencing. A Y-strainer should be used on the incoming water supply to help prevent

problems.

If you have any questions, please contact our Technical Service Hotline at 800-888-3743.

24

Page 26

Advanced Troubleshooting Tips: LS15IIE I LS55IIE

Warning: Qualified electrical personnel must perform all electrical tests/work. There is a potential for

sparks when the electrical control box is open. The unit must be removed to a location outside the hazardous

area before any electrical work can be done on live circuits.

PROBLEM: Only green light comes on / still

1. With the on/off switch in the ON position (pulled out), opening the solenoid valve (sol-1) controls the water

flow. If 240 V.A.C. is present at the solenoid valve and the water is still not flowing, the solenoid valve is

defective and should be cleaned or replaced. If voltage is not present, check fuses FUI and FU2. If the fuses are

good, verify power from the power supply. There should be 24 V.D.C. between wires #7 (pos.) and #11 (neg.).

If there is not, then replace the power supply. If the power supply checks out all right and the solenoid valve still

does not power up, timer 2 (TIM-2) is probably defective and should be replaced.

2. Verify that the cooling water is properly supplied to the condenser. The units require at least 1/2 gallon per

minute for the LS-I5IIE and 1-1/2 gallons per minute for the LS-55IIE. Make sure this amount of water is

passing through the unit. If the water supply is inadequate, the unit will not turn on.

3. Verify that the flow switch IFLS is performing properly. Check for 24 V.D.C. between wire # 11 and wire # 8

on pin 15 on the temp board. If no voltage exists, turn off your water supply and service the flow switch (see pg.

7). It is located down low inside the front panel of the still (it is brass colored and labeled "Gems" on it).

4. If after cleaning the flow switch (and turning the water supply back on) the voltage is still not present between

wire #11 and wire #8, temporarily bypass the flow switch by connecting a jumper wire between pin 21 and pin

15 (on the temp board) to see if the heater contactor engages. If the heater contactor engages with the flow

switch bypassed, replace the flows witch.

PROBLEM: Green light on / White light on / Amber light is not on

5. Disconnect the power to the unit.

Check each thermister individually by disconnecting their wires (22 gauge black and white twisted pairs) from

the temp board. One set is on pins 1 and 3, and the other set is on pins 2 and 4. Measure the resistance between

the black and white wires. The following values should be obtained:

Ambient Temperature Resistance

(degrees) (kilo-ohms)

60°F (16° C) 136 kΩ

77°F (25°C) 90 kΩ

100°F (38°C) 52.5 kΩ

240°F (115°C) 3.9kΩ

If one or both of the readings do not fall within this range, the thermister(s) should be replaced.

25

Page 27

Advanced Troubleshooting Tips: LS 15IIE I LS55IIE CONTINUED…

6. Verify that power is getting to the temp board. There should be 24 V.D.C. between wires # 3 (pos.) pin 21 on the

temp board and wire # 11 (neg.) pin 23 on the temp board. If this is not the case, than the cycle timer could be

defective. The timer can be bypassed by jumping a wire between wire #7 pin 2 on TIM-l and wire #3 pin 1 on

TIM-I. If this works, then replace the cycle timer.

7. Verify that K2 contactor on the temp board is closing (when the unit is turned on) by measuring for voltage

between wire #11 and wire #9 on pin 14 (temp board). If no voltage is present, K2 may be faulty and the temp

board must be replaced. If 24 V.D.C. is present, K2 is closed and all right.

8. Verify that Kl contactor on the temp board is closing (when the unit is turned on) by measuring for voltage

between wire #11 and wire #10 on pin 11 on the temp board. If no voltage is present, and all previous tests

check out, than Kl may be faulty and the temp board must be replaced. If 24 V.D.C. is present and K1 is closed,

then the temp board is all right. If the temp board checks out, call the factory for further information.

9. This set of troubleshooting tips will help verify a faulty temp board. Most problems lie within the water supply

system or the flow switch. It is common for scale and other debris to build up in this switch, causing the

symptoms you are experiencing. A Y-strainer should be used on the incoming water supply to help prevent these

problems.

26

Page 28

......

Appendix

SPARE PARTS - MECHANICAL:

Part # Description Notes

A100619 Aspirator, brass, JetVac Attaches to discharge of pump. Standard brass material.

A101047 Aspirator, stainless steel, JetVac Optional aspirator material. 316 SS construction.

J100634 Condenser, LS-15 Standard CuNi construction.

A100413 Condenser, LS-15 stainless steel Condenser with 316 SS construction.

J102937 Condenser, LS-55 Standard CuNi construction.

A100431 Condenser, LS-55 stainless steel Condenser with 316 SS construction.

A101126 Discharge hose Red Nycoil tubing with brass fitting.

A100416 Discharge hose with sightglass Nycoil hose, brass sightglass and swivel fitting.

J100205 Flame check-valve, JetVac Attached to rear of JetVac for venting of solvent vapors.

J100216 Heat resistant tape Tape used to help seal Still’s lid for better vacuum.

M100182 Lid Gasket, LS-15 Gortex rope for lid seal.

M100188 Lid Gasket, LS-55 Gortex rope for lid seal.

A100423 Lid toggle clamp Holds down lid.

A100439 Liftrack, LS-55 SS rack with handles used to help remove Stilbags.

J100221 Plastic Stilscraper For scraping the residues from vessel walls.

A100628 Pressure relief valve assy. - LS-15 Mounts in lid, rated for 1/2 psi.

A100587 Pressure relief valve assy. - LS-55 Mounts in lid, rated for 1/2 psi.

A100444 Pump reservoir, JetVac Stainless steel reservoir - tank only.

J100211 Quick connector, female Attach to Still for easy connection of braided hose.

J100210 Quick connector, male Attach to braided hose for easy connection to Still.

A101436 Quick-cool tube assy. Internal PTFE tubing and fittings for Q-cool. 2 req’d.

M100184 Reservoir lid gasket, JetVac Gortex gasket for sealing pump reservoir cover.

M100115 Seal, JetVac motor shaft Lip seal used on pump motor to protect bearings.

A100445 SS cooling coil, JetVac Includes mounting plate, and gasket. Three required.

A100576 Static ground clamp (6’) Braided wire with alligator-type clip and ring connector.

M101055 Stilbag ring, LS-15 Holds Stilbag in place.

A100438 Stilbag ring, LS-55 Holds Stilbag in place.

M101831 Stilbags, LS-15 hi temp, per doz.

M101830 Stilbags, LS-15 reg. temp, per doz.

M101833 Stilbags, LS-55 hi temp, per doz.

M101832 Stilbags, LS-55, reg. temp, per doz.

A100427 Stilpan, LS-15 Non-stick coated pan for residue removal without bags.

A100440 Stilpan, LS-55 Non-stick coated pan for residue removal without bags.

A100414 Thermowell for standard condenser. Threads into condenser for vapor temperature gage.

J100212 Vacuum gage Measures vacuum level in inches of Hg.

J100209 Vacuum hose, metal braid, JetVac Hose between JetVac and discharge of still.

A100442 Vacuum pump assembly Includes housing, impeller assy., and center bearing.

M100176 Vapor temperature gage Measures vapor temp at condenser.

Rated for temperatures up to 430F (blue).

Rated for temperatures up to 400F (clear).

Rated for temperatures up to 430F (blue).

Rated for temperatures up to 400F (orange).

.

27

Page 29

SPARE PARTS - ELECTRICAL:

Item # Part # Description Notes

C1 J101486 Contactor Controls heater in Still or pump in JetVac

CTRL1 J102795 Temp control board, LS-15E/55E Controls cycle temperature from 100°F to 392°F.

CTRL1 J102734 Temp control board, LS-15IIE/55IIE Controls cycle temperature from 100°F to 392°F.

FS1 J100914 Flowswitch, LS-55E/55IIE Rated for 1½ gallons per minute.

FS2 J100913 Flowswitch, LS-15E/15IIE Rated for ½ gallons per minute.

FUSE1 J102735 Fuse, System II Protection for controls. Type 3AG 2A.

FUSE2 J102919 Fuse, System II (600 mA) Protection for Power Supply. 250 volt 5 x 20mm

LT2 J102736 Indicator light, white, System II Cooling water indicator.

LT3 J102737 Indicator light, amber, System II Heat on indicator.

MOV1 J102738 MOV, System II For surge protection.

MTR1 J103298 Motor, JetVac pump X-proof, 3450 rpm, 56C, 208-230V/1 Ph, 60 Hz.

PB1/LT1 J100323 STOP/START switch, LS-15E/55E/JV Pull on, push off switch with green light.

PB1/LT1 J102739 STOP/START switch, LS15IIE/55IIE Pull on, push off switch with green light.

POT1 J102139 Potentiometer, System II cycle temp

POT2 J102740 Potentiometer, System II cycle time

PS1 J102741 Power supply, System II Power supply converts 240 VAC to 24 VDC.

RC1/RC2 J101699 RC network assembly RC network, crimp connectors.

SOL1 J100889 Solenoid valve, System II water Controls the cooling water supply to the condenser.

SOL2 J102249 Solenoid Valve, JetVac relief Vacuum relief valve. Opens when JV is off.

SSR1/SSR2 J102742 Relay, solid state, System II For heater control and JetVac control.

TC1 J101157 Thermistor Temperature sensing probe for Still (Controlled by

TC2 J101157 Thermistor

TIM1 J102743 Timer relay, System II cycle time 16 hour timer for cycle time

TIM2 J102744 Timer relay, System II cool-down 1-hour timer for condenser water.

Note: Heater for LS-15E/15IIE is 1650 watts. Heater for LS-55E/55IIE is 6200 watts

For adjusting the cycle temperature, 450.

For adjusting the cycle time, 1 M.

POT 1 - 100F to 392F ) K1 is its contact.

Overtemp sensing probe for still (412F) K2 is its

contact.

28

Page 30

ELECTRICAL SCHEMATIC - LS-JETVAC:

C1-2

SOL -2

ELECTRICAL SCHEMATIC - LS-15E/55E:

“NORMALLY OPEN”

29

Page 31

ELECTRICAL SCHEMATIC - LS-15IIE/55IIE:

Note: When start button is pulled on, both timers are energized, but timer # 2 does not start timing

until timer #1 times out.

Note: If using a Little Cooler, connect control wires to the coil of the customer supplied contactor.

(refer to the Little Cooler manual).

30

Page 32

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the product's material of construction, which are

compatible with the fluid(s) that come(s) in contact with the product. The user may consult Finish Thompson, Inc.

(manufacturer) and a manufacturer's representative/distributor agent to seek a recommendation of the product's

material of construction that offers the optimum available chemical compatibility.

However neither Manufacturer nor agent shall be liable for product damage or failure, injuries, nor any other

damage or loss arising out of a reaction, interaction or any chemical effect that occurs between the materials of the

products construction and fluids that come into contact with the product's internals.

WARRANTY

Finish Thompson, Inc (manufacturer) warrants this product to be free of defects in materials and workmanship for a

period of 3 years plus a lifetime warranty on the LS Heater, with the exception of the PTFE vessel coating which

carries a 1 year warranty, from date of purchase by original purchaser. If a warranted defect, which is determined by

manufacturer's inspection, occurs within this period, it will be repaired or replaced at the manufacturer's option,

provided (1) the product is submitted with proof of purchase date and (2) transportation charges are prepaid to the

manufacturer. Liability under this warranty is expressly limited to repairing or replacing the product of parts thereof

and is in lieu of any other warranties, either expressed or implied. This warranty does apply only to normal wear of

the product or components. This warranty does not apply to products or parts broken due to, in whole or in part,

accident, overload, abuse, chemical attack, tampering, or alteration. The manufacturer accepts no responsibility for

product damage or personal injuries sustained when the product is modified in any way. If this warranty does not

apply, the purchaser shall bear all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to process down

time, transportation costs, costs associated with replacement or substitution products, labor costs, product

installation or removal costs, or loss of profit. In any and all events, manufacturer’s liability shall not exceed the

purchase price of the product and/or accessories.

Tech Service Hotline 800-888-3743

Part Number J102856-4, Rev21, 3-5-15

31

Lit ID No. FT01-829J, 1/6/2012

Loading...

Loading...