Page 1

KC22/32 SERIES Sealless

Non-Metallic Centrifugal Pumps

Installation and

Maintenance Instructions

ASSEMBLY

Unpack pump from carton and check for shipping damage.

WARNING: Magnetic field hazard. This pump contains powerful rare

earth magnets. When the pump is disassembled (not connected to a motor)

and the magnets are exposed, these magnets produce powerful magnetic fields.

Individuals with cardiac pacemakers, implanted defibrillators, other electronic

medical devices, metallic prosthetic heart valves, internal wound clips (from

surgery), metallic prosthetic device or sickle cell anemia must not handle or be

in the proximity of the magnets contained inside the pump. Consult a health

care provider for specific recommendations before working with this pump.

ATEX COMPLIANT PUMPS

All assembly, installation, and maintenance instructions are the same as

standard pumps with the exceptions noted on page 3 under "Safety Precautions

for ATEX pumps."

PUMPS WITH MOTORS

Remove shipping plugs and insert from suction and discharge and proceed to

installation instructions.

PUMPS WITHOUT MOTORS

1. Remove wet end assembly from box.

CAUTION: Strong magnets present. Keep metal objects and

metallic chips/particles away from pump components.

2. Remove hardware package from box.

3. Install motor adapter (item 6) onto motor with labels at top

using items 10 and 11.

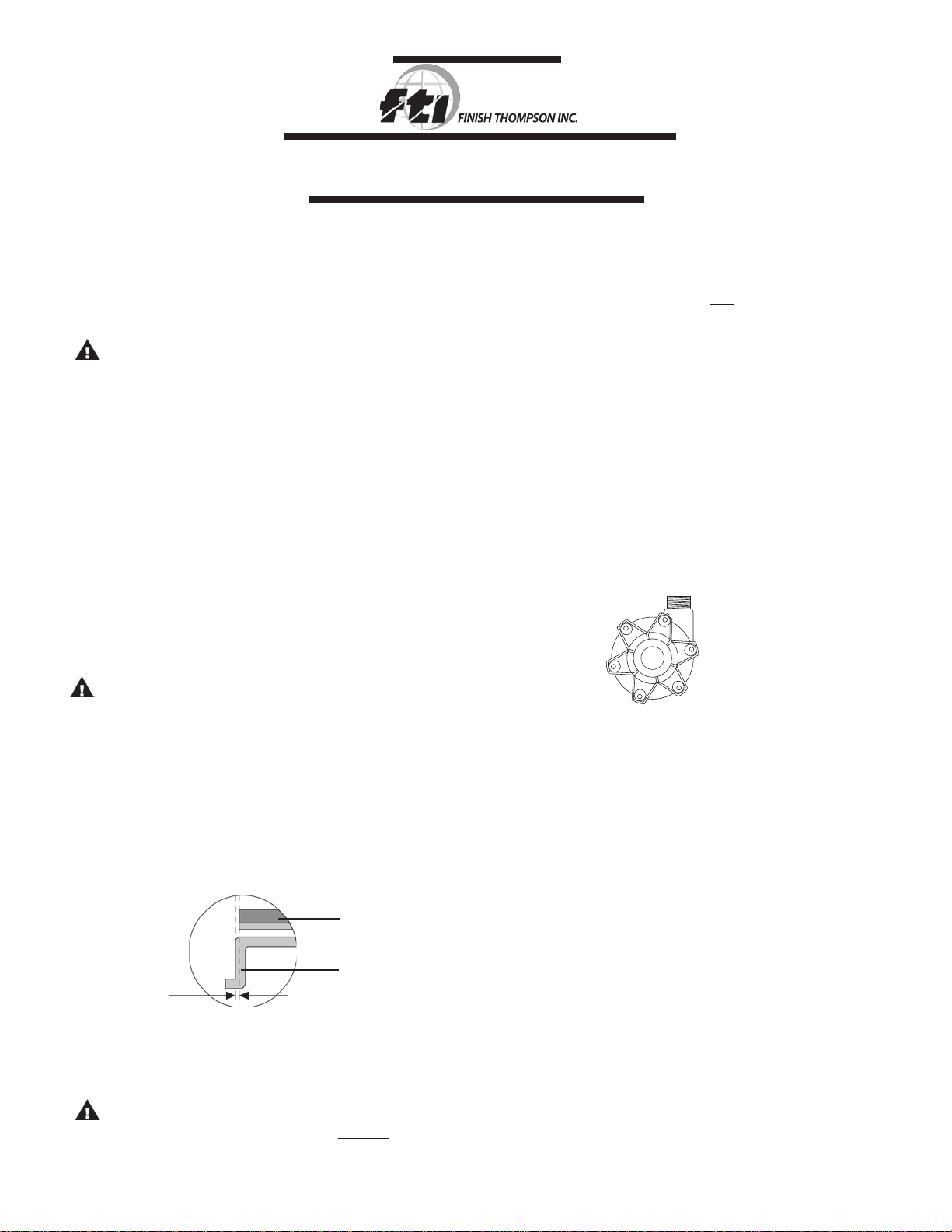

4. Remove drive mag assembly (item 5) from box and slide

assembly onto motor shaft making sure shaft key (item 12)

is in place. Installation dimension is .060 +/‑.010 inches as

shown in Figure 1. Tighten 2 set screws (item 5A) to 228

in‑lbs. (25.8 N‑m).

Item 5

Drive Magnet

Assembly

Item 6

Motor Adapter

.060 +/‑ .010

Figure 1

IMPORTANT: Verify the tightness of the set screws in the

drive magnet assembly prior to operation.

WARNING: Components can slam together from strong

magnets. Keep fingers away from area between housing

and motor adapter.

5. Gripping the discharge and the side of the impeller hous‑

ing (note above warning), carefully install the wet end into

the motor adapter. Note that the two housing studs (item

15) should be located at 3 and 9 o'clock (for 12 o'clock

discharge location) and will go through the motor adapter.

6. Install the 5/16 x 3/4 SS hex bolts (item 7), the 5/16 flat

washers (item 9), and the 5/16 hex nuts (item 8) and

tighten to 70 in‑lbs. of torque using the pattern shown in

figure 2.

7. Remove the two‑piece shipping plug from the suction.

8. Reach into the suction and spin the impeller to check if it

spins freely. If it does not, disassemble and recheck the

drive hub installation instructions in step 4.

9. Install pump into the system according to the following

installation instructions.

3

1

Figure 2

6

4

5

2

INSTALLATION

MOUNTING

Motor or base plate should be securely fastened.

PIPlNG

1. Support piping near the pump to minimize strain on pump

casing.

2. To minimize head loss due to friction:

a. Increase pipe size 1 diameter

b. Use minimal number of bends

3. Keep pipe bends a minimum of 10 pipe diameters from

suction and discharge. For example, if using 2" pipe, first

bend should be at least 20" from suction discharge.

4. Position pump as close to liquid source as possible.

5. Maintain a flooded suction.

6. Ensure that piping is leak proof.

7. Install valves on suction and discharge lines (minimum of

10 pipe diameters from pump).

8. For units in suction lift system, install appropriate piping in

discharge to allow priming of pump.

Page 2

9. The suction valve should be fully open to avoid restricting

suction flow.

IMPORTANT: To protect the pump if prime is lost, use one

of the following: (1 ) pressure switch on the discharge;

(2) vacuum switch on the suction; (3) a power monitor to

monitor motor current.

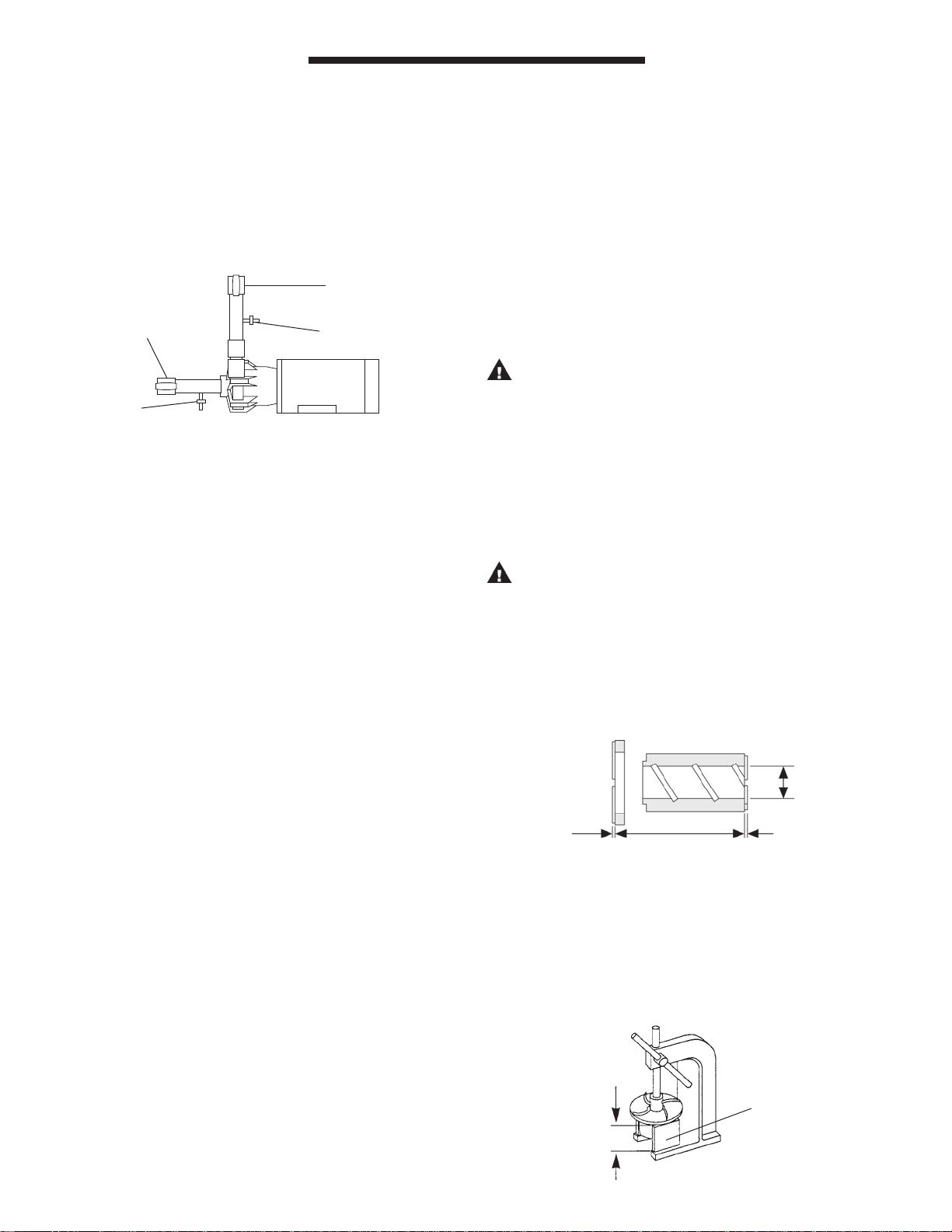

10. When pumping liquids which may solidify or crystallize, a

flush system should be added to the piping. See Figure 3.

Install water inlet and outlet valves as shown.

Discharge

Valve

Suction

Valve

Water Outlet

Valve

Figure 3

Water Inlet

Valve

ELECTRICAL

Install motor according to NEC requirements and local electrical

codes.

IMPORTANT: To verify correct motor rotation: (1) Install pump into system.

(2) Fully open suction and discharge valves. (3) Allow fluid to flow into the

pump. Do not allow pump to run dry (PTFE and ceramic bushings cannot be

run dry without damage to pump components). (4) Jog motor (allow it to run

for one or two seconds) and observe rotation of motor fan. Correct rotation is

clockwise as viewed from motor fan. Refer to directional arrow on pump.

OPERATION

START UP

1. This pump must be filled from a flooded suction tank

(gravity) or primed with liquid from an outside source. The

KC22/32 are not self‑priming.

2. Open the inlet (suction) and discharge valves completely

and allow the pump to fill with liquid.

3. Close the discharge valve.

4. Turn the pump on. Slowly open the discharge valve. Adjust

the flow rate and pressure by regulating the discharge

valve. Do not attempt to adjust the flow with the suction

valve.

5. Use of a power monitor is strongly recommended for

pumps with ceramic, PTFE or silicon carbide bushings.

The power monitor will stop the pump and help prevent

damage should the pump run dry. ATEX certified pumps

MUST use a power monitor.

SHUT DOWN

Use the following procedure to shutdown the pump.

1. Slowly close the discharge valve.

2. Turn off the motor.

3. Close the suction valve.

3. Connect drain hose to water outlet valve.

4. Open inlet and outlet valves, and flush system until pump

is clean (approximately 5 minutes).

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring and mounting

bolts to floor or base plate.

2. Close suction and discharge valves, and disconnect piping.

3. Remove bolts, nuts and washers (items 7, 8 and 9). Leave

the 2 housing studs (item 15) in place until the wet end is

removed.

4. Securely clamp or hold motor in place. Remove wet end

assembly by inserting both thumbs into pump suction and

pulling assembly straight out with a quick motion.

WARNING: Components can slam together from strong

magnets. Keep fingers away from area between housing

and motor adapter.

5. Disassemble wet end by removing 2 housing studs and

nuts (items 16) which attach barrier (item 4) to impeller

housing (item 1). Remove and discard o‑ring (item 13).

6. Remove drive magnet assembly by inserting a 3/16" hex

wrench into access hole in side of motor adapter and

loosening 2 set screws (item 5A). Grasp inside of magnet

assembly and pull off of motor shaft.

CAUTION: Strong magnets present. Keep metal objects and

metallic chips/particles away from pump components.

EXAMINATION

1. Check impeller drive bushing (item 3A) and impeller thrust

washer (item 2A). If cracked, chipped or scored, then

replace. Replace if minimum groove height is less than the

minimum height recommended. See Figure 4.

2. Check for loose magnets.

.780 MAX.

.020 MIN.

Groove Height

IMPELLER DISASSEMBLY

1. To separate impeller body (item 2) from the impeller drive

(item 3), support the body in an arbor press using two 5"

minimum spacer blocks.

2. Insert a 1‑1/2" diameter plastic or wooden shaft into the

impeller eye, and push the drive out of the body. See

Figure 5.

5” MIN.

Diameter

Figure 4

FLUSH SYSTEM

1. Fully close suction and discharge valves.

2. Connect water supply to water inlet valve.

Support

Figure 5

2

Page 3

Note: On closed impellers, use two screwdrivers in slots provided to pry

apart impeller and impeller drive.

BUSHING AND THRUST RING REPLACEMENT

1. To remove the bushing, place the impeller assembly (items

2 and 3) in an arbor press. Insert a 1" diameter plastic or

wooden shaft through the impeller and press bushing out.

Refer to Figure 6.

Figure 6

SAFETY PRECAUTIONS FOR ATEX PUMPS

CAUTION: Proper o‑ring material must be chosen for the fluid being

pumped. Improper material selection could lead to swelling and be a possible

source of leaks. This is the responsibility of the end user.

WARNING: The pump must be checked for leaks on a regular basis. If

leaks are noticed, the pump must be repaired or replaced immediately.

WARNING: The pump must be cleaned on a regular basis to avoid dust

buildup greater than 5 mm.

WARNING: ATEX pumps must use a power monitor, flow switch, pressure

switch or similar device to help protect against dry running, closed discharge

valve and decoupling. Any of these conditions could lead to a rise in surface

temperature of the pump.

TEMPERATURE CLASSIFICATION

2. To replace bushing, place the impeller assembly (items

2 and 3) on a flat surface with the thrust ring face down

(item 2A). Insert the bushing (item 3A), slotted face out,

into impeller assembly. Gently push until bushing bottoms

out. Bushing should be flush with impeller eye.

3. Impeller thrust ring (item 2A) can be removed from impel‑

ler body (item 2) by gently pulling ring from impeller nose.

Note: The thrust ring on the closed impeller must be

removed by grasping with a pliers and twisting. Once

removed, a new thrust ring is required.

4. To replace thrust ring, align ring (grooved side up) with

the inside of the impeller assembly (item 2), and press into

place.

Note: Protect face with wood or plastic and avoid tilting

ring.

REASSEMBLY

1. Insert impeller assembly (items 2 and 3) into barrier (item

4). Make sure impeller is free of metal chips. Install new

O‑ring (item 13) onto lip of barrier (item 4).

2. Install impeller housing (item 1 ) onto barrier (item 4). In‑

sert 2 housing studs and washers (items 15 &16) long end

into back of barrier (item 4) and push through the impeller

housing (item 1) until threads are exposed. Install nut and

washer (items 8 & 9) and tighten. On the other end of the

stud you will find a threaded housing nut (item 16). This

nut can be tightened using a pliers or crescent wrench. It

is important to leave about 3/4" of thread exposed so nuts

and washers can be installed on motor adapter side.

3. Complete reassembly following steps 5, 6, 7 and 8 of

“Pumps Without Motors” section on page 1 of these

instructions.

CAUTION: If item numbers 14, 9 and 8 are removed from

the motor adapter (item 6), it is very important to place a

small amount of “Loc‑Tite” removable thread locker‑242

onto the threads of the socket head cap screw (item 14)

before installing back into the nut (item 8). The above pro‑

cedure is only necessary for the U.S. adapters 184 TC and

213 TC and prevents the parts from working loose during

normal operation. Failure to comply may cause damage to

the pump!

The surface temperatures of the KC ATEX Series pumps depend

upon the temperature of the fluid being pumped. The chart below

lists different fluid temperatures and the corresponding pump

surface temperatures.

Maximum Allowable

Fluid Surface Temperature Surface

Temperature Temperature Class Temperature

80oF (27oC) 122oF (50oC) T6 85oC

185oF (85oC) 192oF (89oC) T4 135oC

220oF (104oC) 248oF (120oC) T3 200oC

3

Page 4

KC 22/32 PARTS DIAGRAM

3A

3

2

1

2A

15

16

7

9

4

13

Figure 7

5A

12

10

6

11

8

9

5A

5

14

4

Page 5

Item Qty. Description Part No.

Housing w/ Ceramic Thrust Ring

KC22 ‑ polypropylene ‑ NPT A101231‑1

KC22 ‑ PVDF ‑ NPT A101231‑2

1

1

KC22 ‑ polypropylene ‑ BSP w/ discharge o‑ring A101231‑3

KC22 ‑ PVDF ‑ BSP w/ discharge o‑ring A101231‑4

KC32 ‑ polypropylene ‑ flanged A102721‑5

KC32 ‑ PVDF ‑ Flanged (ATEX where applicable) A102721‑7

1A

Housing Thrust Ring Only (not pictured)

1

Ceramic J101847

Impeller

6.0” ‑ Polypropylene A101235‑1

6.0” ‑ PVDF A101235‑5

Open

Impeller

Style

5.5” ‑ Polypropylene A101235‑2

5.5” ‑ PVDF A101235‑6

5.0” ‑ Polypropylene A101235‑3

5.0” ‑ PVDF A101235‑7

4.5” ‑ Polypropylene A101235‑4

4.5” ‑ PVDF A101235‑8

2

1

6.37” ‑ Polypropylene 105569‑1

6.37” ‑ PVDF 105569‑6

6.0” ‑ Polypropylene 105569‑2

Closed

Impeller

Style

6.0” ‑ PVDF 105569‑7

5.5” ‑ Polypropylene 105569‑3

5.5” ‑ PVDF 105569‑8

5.0” ‑ Polypropylene 105569‑4

5.0” ‑ PVDF 105569‑9

4.5” ‑ Polypropylene 105569‑5

4.5” ‑ PVDF 105569‑10

PTFE Thrust Ring

2A

1

For open impeller J101460

For closed impeller J103899

Impeller Drive with Bushing

Polypropylene ‑ carbon bushing A101944

Open

Impeller

Style

3

1

Polypropylene ‑ PTFE bushing A101945

Polypropylene ‑ ceramic bushing A103231

PVDF ‑ carbon bushing A101946

PVDF ‑ PTFE bushing A101947

PVDF ‑ ceramic bushing A103232

Polypropylene ‑ carbon bushing* 105563

Closed

Impeller

Style

Polypropylene ‑ ceramic bushing* 105565

Polypropylene ‑ PTFE bushing* 105564

PVDF ‑ carbon bushing* 105566

PVDF ‑ PTFE bushing* 105567

PVDF ‑ ceramic bushing* 105568

Impeller Bushing

Carbon ‑ for open impeller J101701‑1

PTFE ‑ for open impeller J101701‑2

Ceramic ‑ for open impeller J101701‑3

Carbon ‑ for closed impeller J103917‑1

PTFE ‑ for closed impeller 106757

Ceramic ‑ for closed impeller J103917

3A

1

Open

Impeller

Style

Closed

Impeller

Style

Barrier with Spindle

4

1

Polypropylene A101147‑1

PVDF A101147‑2

Drive Magnet Assembly

184TC frame A101141‑5

5

1

213TC frame A101141‑6

90 frame A101141‑8

100/112 frame A101141‑7

Item Qty. Part No.

5A

Set Screw

2

Stainless steel J101084

Motor Adapter Assembly

90 frame A103249

90 frame ATEX (PVDF) A103249‑1

6

1

184TC frame A102045

213TC frame A102046

100/112 frame A101788

100/112 frame ATEX (PVDF) A101788‑1

7

8

9

Hex Bolt

4

Stainless steel (4 required) J101357

Hex Nut

12

Stainless steel (12 required) J101257

Flat Washer

18

Stainless steel (18 required) J101293

Bolts

184TC frame ‑ U. S. hex bolt J101359

10

4

213TC frame ‑ U. S. hex bolt J101858

90 frame ‑ metric cap screw J103931

100/112 frame ‑ metric cap screw J103234

11

Flat Washer

4

Stainless steel J101360

Shaft Key

12

1

US 184TC ‑ 1/4” M101675

100/112 frame ‑ 8mm M101749

Housing O-ring

13

1

FKM J101085

EPDM J101086

14

15

16

*NOTE: If you have a pump that requires these parts, and the pump serial number is between

31848G01 and 44905 G04, please call the factory for correct part number confirmation.

Cap Screw

4

Stainless steel J101361

Housing Stud

2

Stainless steel M101299

Housing Nut

4

Stainless steel J103119

5

Page 6

TROUBLESHOOTING

NO FLOW

1. Pump not primed.

2. Discharge head too high. Insufficient NPSH.

3. Suction lift too high.

4. Closed valve.

5. Viscosity too high (magnets uncoupled).

INSUFFICIENT DISCHARGE

1. Air leaks in suction piping.

2. Discharge head higher than anticipated.

3. Suction lift too high or insufficient NPSH. Check also for

clogged suction line or clogged foot valve.

4. Foot valve too small.

5. Foot valve or suction open or not submerged enough.

INSUFFICIENT PRESSURE

1. Air or gases in liquid.

2. Impeller diameter too small.

3. Discharge head higher than anticipated.

LOSS OF PRIME

1. Leaking suction line.

2. Suction lift too high or insufficient NPSH.

3. Air or gases in liquid.

4. Foreign matter in impeller.

5. Leaking foot valve.

EXCESSIVE POWER CONSUMPTION

1. Head lower than rating. Pumps too much liquid.

2. Specific gravity or viscosity of liquid pumped is too high or

higher than that defined in application.

VIBRATION

1. Excess bushing wear.

2. Drive magnet uncoupled.

3. Loose magnet.

4. Pump cavitating.

WARRANTY

Finish Thompson, Inc. (manufacturer) warrants this pump

product to be free of defects in materials and workmanship for a

period of one year from date of purchase by original purchaser.

If a warranted defect, which is determined by manufacturer’s

inspection, occurs within this period, it will be repaired or replaced

at the manufacturer’s option, provided (1) the product is submitted

with proof of purchase date and (2) transportation charges are

prepaid to the manufacturer. Liability under this warranty is

expressly limited to repairing or replacing the product or parts

thereof and is in lieu of any other warranties, either expressed

or implied. This warranty does apply only to normal wear of the

product or components. This warranty does not apply to products

or parts broken due to, in whole or in part, accident, overload,

abuse, chemical attack, tampering, or alteration. The warranty

does not apply to any other equipment used or purchased in

combination with this product. The manufacturer accepts no

responsibility for product damage or personal injuries sustained

when the product is modified in any way. If this warranty does

not apply, the purchaser shall bear all cost for labor, material and

transportation.

Manufacturer shall not be liable for incidental or consequential

damages including, but not limited to process down time,

transportation costs, costs associated with replacement or

substitution products, labor costs, product installation or removal

costs, or loss of profit. In any and all events, manufacturer’s

liability shall not exceed the purchase price of the product and/or

accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the

product’s materials of construction, which are compatible with

the fluid(s) that come(s) in contact with the product. The user

may consult Finish Thompson, Inc. (manufacturer) and/or

a manufacturer’s representative/distributor agent to seek a

recommendation of the product’s material of construction that

offers the optimum available chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising

out of a reaction, interaction or any chemical effect that occurs

between the materials of the product’s construction and fluids that

come into contact with the product’s internals.

ORDERING OF SPARE PARTS

Spare parts can be ordered from your local distributor. Always

refer to pump model number to avoid error.

OTHER FINISH THOMPSON PRODUCTS

Drum Transfer Pumps are available in sanitary construction,

stainless steel, polypropylene and CPVC. Flows to 40 gpm,

discharge heads to 80 feet and viscosities to 100,000 cP.

Portable Mixers for turbine mixing and blending handle

viscosities to 1,000 cP with gentle, non‑vortexing circulation.

Available in 316 stainless steel construction.

Centrifugal Pumps in 316 SS, ETFE lined cast iron,

polypropylene and PVDF come with a wide variety of sealing

materials. Flows to 330 gpm, discharge heads to 130 feet and

temperatures to 220°F (104°C).

For more information, contact Finish Thompson Inc.

ORDER FAX 814-459-3460

J102309, Rev. 21, 7/15/2014

Literature I.D. Number- FT95-541S

6

Loading...

Loading...