Page 1

MAGPRIME CHAMBERMAGPRIME CHAMBER

MAGPRIME CHAMBER

MAGPRIME CHAMBERMAGPRIME CHAMBER

KC11 Series - Self Priming Option

Installation and Maintenance Instructions

INTRODUCTION

FTI’s MagPrime Chamber provides a self-priming feature

to the KC1145 sealless centrifugal pump. A state-of-theart, one piece modular design allows the MagPrime pump

to lift liquids up to 15 feet (4.57 meters) in two minutes.

HOW IT WORKS

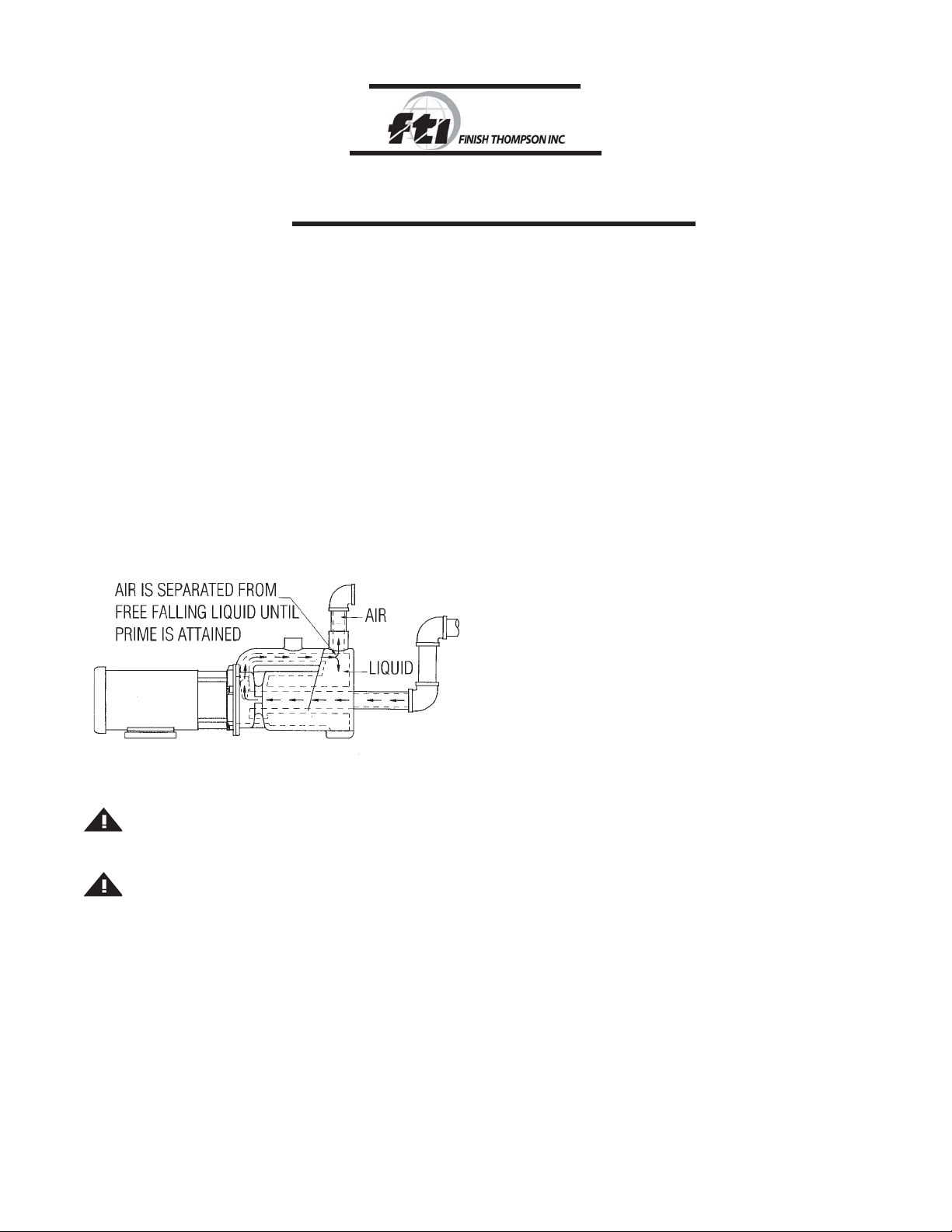

The MagPrime Chamber is initially filled with liquid. When

the pump is started, recirculating liquid creates a vacuum

in the suction line. This vacuum draws air from the suction line and releases it through the discharge outlet.

When the liquid in the suction line reaches the pump inlet, the pump is primed and normal operation begins (see

Figure 1).

Figure 1Figure 1

Figure 1

Figure 1Figure 1

SAFETY PRECAUTIONS

WARNING: Read this instruction manual com-pletely

before installing and operating this unit. Fail-ure to follow

these precautions can result in serious bodily injury.

WARNING: Magnetic field hazard. This pump contains

powerful rare earth magnets. When the pump is disassembled

(not connected to a motor) and the magnets are exposed,

these magnets produce powerful magnetic fields. Individuals

with cardiac pacemakes, implanted defibrillators, other

electronic medical devices, metallic prosthetic heart valves,

internal wound clips (from surgery), metalic prosthetic

devices or sickle cell anemia must not handle or be int he

proximity of the magnets contained

• Wear proper eye and skin protection when installing,

operating, and maintaining this equipment.

• All electrical wiring (e.g., motor) should be performed

by a qualified electrician.

• Never use this pump for flammables or combustibles.

• Verify chemical compatibility of the pump’s materials

of construction with the liquid being pumped.

o

• Maximum liquid temperature is 120

F (49oC).

INSTALLATION

The MagPrime Chamber comes complete with housing

gasket and hardware. The user must supply 1-1/2” rigid

suction piping and 1-1/4” discharge piping. The suction

inlet is located at the front of the priming chamber.

SECTION 1 - INSTALLATION OF MAGPRIME

CHAMBER FOR AN EXISTING KC11 PUMP

1. Remove any piping from the pump impeller housing.

2. Remove the (5) 1/4- 20 x 1” bolts and (4) Phillips pan

head screws from the impeller housing.

3. Gently tap the impeller housing’s discharge outlet

(using rubber mallet) to remove the impeller housing.

4. Save the impeller housing - DO NOT DISCARD. It is

necessary for pump assembly and disassembly.

5. Remove the old housing o-ring (item 7) from the pump

barrier (item 8) and discard.

6. Install the new housing o-ring (supplied with MagPrime Chamber) onto the pump barrier.

7. Verify that the white ceramic thrust washer is firmly

seated into the MagPrime Chamber.

8. Install the MagPrime Chamber by aligning the groove

in the MagPrime Chamber with the ridges on the

KC11 barrier. Press in place until firmly seated.

9. Install the (5) 1/4-20 x 1-3/4” hex bolts, washers and

nuts (supplied with the MagPrime Chamber). The

nuts will insert into the back tabs on the motor adapter

(item 13). Tighten each bolt to between 30 and 35

in.-lbs. (3.4 and 4.0 Nm) using star pattern sequence

(shown in Figure 2 of the KC11 Series Installation

and Maintenance Instructions). Do not overtighten.

NOTE: Periodic retightening of the bolts is required.

The bolts will loosen from vibration and the expansion/contraction of the plastic parts.

10. Firmly support the motor, prime chamber and piping.

Shim as necessary. Important: Failure to support

these items will result in damage to the pump.

1

Page 2

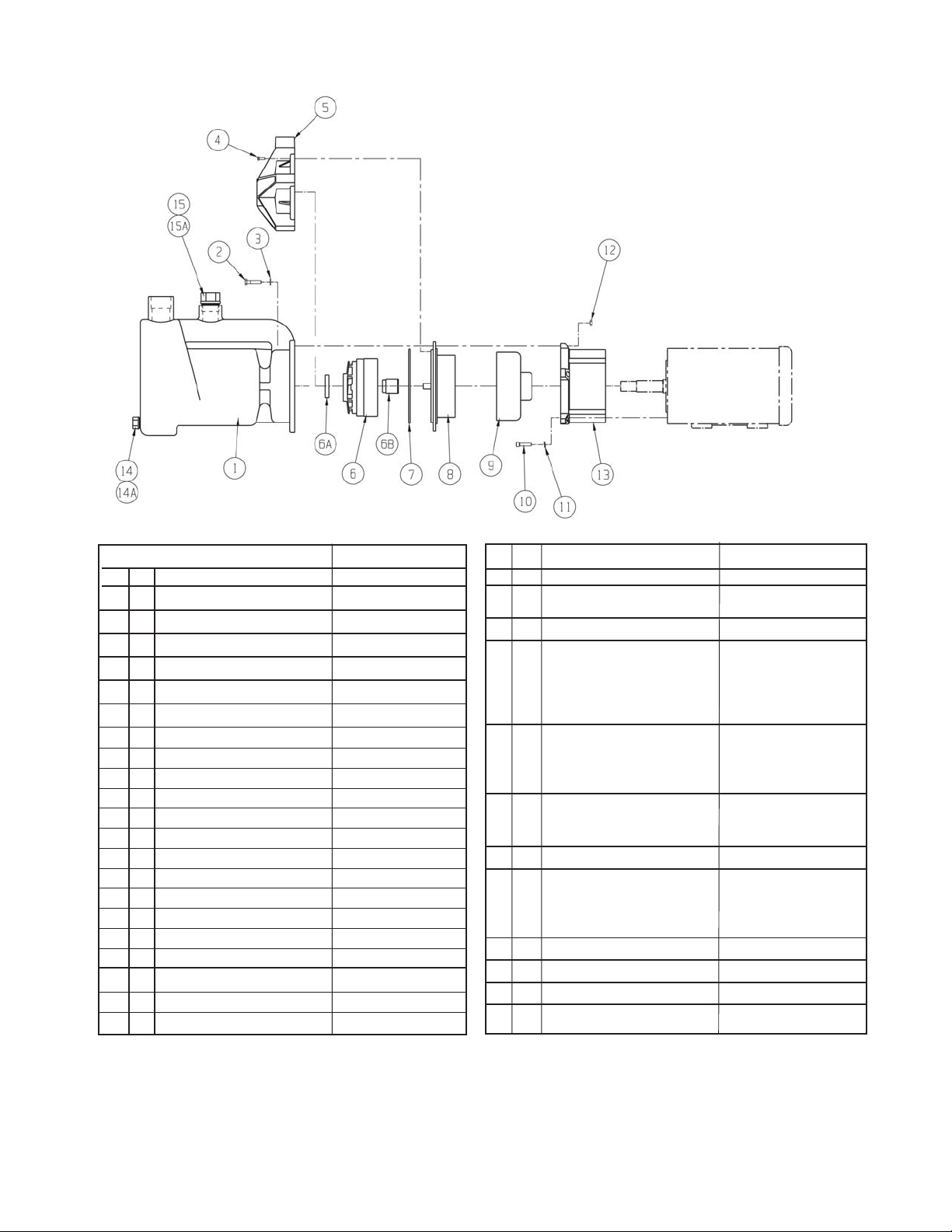

Pump Material

Item Qty Description Polypropylene CF PVDF

1 1 MagPrime Chamber Assembly A101556

2 5 SS Hex Head Cap Screw J102279

3 5 SS Flat Washer J100113

4 4 Phillips Head Screw J101020

5 1 KC11 Impeller Housing A101014-1 A101014-2

6 1 Impeller Hub w/carbon bushing -3” A101931 A101939

Impeller Hub w/PTFE bushing - 3” A101935 A101943

Impeller Hub w/ceramic bushing - 3” A103109 A103113

Impeller Hub w/carbon bushing - 3.5” A101930 A101938

Impeller Hub w/PTFE bushing - 3.5” A101934 A101942

Impeller Hub w/ceramic bushing - 3.5” A103108 A103112

Impeller Hub w/carbon bushing - 4.0” A101929 A101937

Impeller Hub w/PTFE bushing - 4.0” A101933 A101941

Impeller Hub w/ceramic bushing - 4.0” A103107 A103111

Impeller Hub w/carbon bushing - 4.5” A101928 A101936

Impeller Hub w/PTFE bushing - 4.5” A101932 A101940

Impeller Hub w/ceramic bushing - 4.5” A103106 A103110

6A 1 PTFE thrust ring J101606

6B 1 Carbon bushing only J100977

PTFE bushing only J100977-1

Ceramic bushing only J100977-2

Pump Material

Item Qty Description Polypropylene CF PVDF

7 1 Viton o-ring J102774

1 EPDM o-ring J102775

8 1 KC11 Barrier Assembly A101008-1 A101008-2

9 1 Drive Magnet Assembly

- fits 56C motors A101019-1

- fits 145TC motors A101019-2

- fits 80 frame motors A101019-3

- fits 90 frame motors A101019-4

10 4 SS Socket Head Cap Screws

- U.S. J101000

- Metric (80 frame) J101080

- Metric (90 frame) J101081

11 4 SS Lock Washers

- Metric (80 frame) J100672

- Metric (90 frame) J102282

12 4 SS Hex Nut J100321

13 1 Motor Adapter

- U.S. M101629-1

- Metric (80 frame) M101629-2

- Metric (90 frame) M101629-3

14 1 1/2” Pipe Plug J102183

14A 1 O-ring J102280

15 1 1” Pipe Plug J102187

15A 1 O-ring J102281

2

Page 3

11. Plumb the pump into your system. Use only 1-1/2”

rigid piping on the suction side. Important: Suction

piping must be raised approximately 7” (18 cm) above

the center line of the suction inlet on the MagPrime

Chamber (see Figure 2). This ensures proper priming

and pump operation.

Figure 2Figure 2

Figure 2

Figure 2Figure 2

12. Install 1-1/4” rigid piping on the discharge of the

MagPrime Chamber. Important: If the MagPrime

Chamber mounting and piping are not extremely rigid,

leakage can occur and possible pump damage.

TROUBLESHOOTING

If pump does not prime and begin to pump within three

minutes (specific gravity of 1.0 - higher specific gravities

require longer prime times), verify the following:

• No air leaks in suction plumbing.

• Priming chamber filled to proper level.

• The liquid’s specific gravity is not greater than 1.4.

• The impeller is a 4” or 4-1/2” version.

• The motor is at least 2900 rpm and rotating in the

proper direction.

For further troubleshooting, consult the factory.

MAINTENANCE

DISASSEMBLY

1. Drain MagPrime Chamber into an appropriate con-

tainer. Remove the 1/2” pipe plug from front of

MagPrime Chamber. Reinstall plug after draining.

SECTION 2 - INSTALLATION USING NEW KC11 AND

CUSTOMER SUPPLIED MOTOR

1. Install the KC11 pump (not MagPrime Chamber) in

accordance with “KC11 Series Installation and Maintenance Instructions: Assembly Section - steps 1 - 7.”

2. Follow installation steps 2 - 12 from Section 1 of this

manual.

SECTION 3 - INSTALLATION USING NEW KC11

WITH FACTORY SUPPLIED MOTOR

Follow installation steps 2 - 12 from Section 1 of this

manual.

OPERATION

Remove the fill port plug (located on the top of the

MagPrime Chamber). Use approximately 3 quarts (3 liters) of the liquid being pumped to fill the MagPrime

Chamber to capacity. Replace the fill port plug.

CAUTION: Do not allow MagPrime Chamber to overflow.

2. Remove the piping from the suction and discharge

on the MagPrime Chamber.

3. Remove the (5) 1/4-20 x 1- 3/4” bolts from the MagPrime Chamber.

4. Remove the MagPrime Chamber.

CAUTION: Some fluid may leak out when the

chamber is removed.

5. Reinstall the KC11 housing (saved from step 4 in

Section 1 of this manual). Using (4) Phillips pan

head screws, secure the housing to the barrier.

NOTE: Reinstalling the housing allows the impeller

and barrier to be easily and safely removed from the

motor adapter.

6. Remove the impeller and barrier in accordance with

“KC11 Series Installation and Maintenance Instructions: Maintenance Section - Disassembly,” step 4.

7. Follow the steps outlined in the “KC11 Series Installation and Maintenance Instructions: Maintenance

Section - Examination” to check for worn parts.

Replace parts as necessary.

Start the pump. Check all pump components and piping

for leaks.

NOTE: It is critical that the suction piping is air tight. Any

leaks, no matter how small, will prevent the pump from

priming properly.

8. Reassemble following the steps outlined in the “KC11

Series Installation and Maintenance Instructions:

Maintenance Section - Reassembly,” steps 1 - 4.

9. Install wet end following steps outlined in the “KC11

Series Installation and Maintenance Instructions:

Assembly Section,” step 6.

10. Reinstall the MagPrime Chamber following installation steps 2 - 12 from Section 1 of this manual.

3

Page 4

WARRANTY

OTHER FTI PRODUCTS

Finish Thompson, Inc (manufacturer) warrants this product to be free of defects in materials and workmanship for

a period of 180 days from date of purchase by original

purchaser. If a warranted defect, which is determined by

manufacturer’s inspection, occurs within this period, it will

be repaired or replaced at the manufacturer’s option, provided (1) the product is submitted with proof of purchase

date and (2) transportation charges are prepaid to the

manufacturer. Liability under this warranty is expressly

limited to repairing or replacing the product of parts thereof

and is in lieu of any other warranties, either expressed or

implied. This warranty does apply only to normal wear of

the product or components. This warranty does not apply

to products or parts broken due to, in whole or in part,

accident, overload, abuse, chemical attack, tampering,

or alteration. The manufacturer accepts no responsibility

for product damage or personal injuries sustained when

the product is modified in any way. If this warranty does

not apply, the purchaser shall bear all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to process

down time, transportation costs, costs associated with

replacement or substitution products, labor costs, product installation or removal costs, or loss of profit. In any

and all events, manufacturer’s liability shall not exceed

the purchase price of the product and/or accessories.

Drum Transfer Pumps, available in sanitary construction, stainless steel, polypropylene, PVDF, and CPVC,

are capable of flows to 40 gpm, discharge head to 80

feet and viscosities to 100,000+ cps.

Portable Mixers for turbine mixing and blending handle

viscosities to 1,000 cps with gentle, non-vortexing circulation. Available in 316 stainless steel.

Centrifugal Pumps, in polypropylene, PVDF, 316 stainless steel, and cast iron are offered in mag drive sealless

or mechanical seal models. Pumps are capable of 330

gpm, up to 325 feet discharge head, and 220oF (104oC)

maximum.

For more information, contact Finish Thompson Inc. or

your local distributor.

Call our toll free Technical Service Hot Line, 1-800888-3743, if you have any questions regarding product operation or repair.

ORDERING SPARE PARTS

Spare parts can be ordered from your local distributor.

Always refer to the pump model number to avoid error.

Toll Free Service 800-888-3743

Part Number J103057-1, Rev. 4

FT00-779B, 6/22/06

4

Loading...

Loading...