Page 1

KC 5.5, 6, 6H, 7, 8, & 10 SERIES

Non-Metallic Centrifugal Pumps

Installation and Maintenance Instructions

ASSEMBLY

Unpack the pump, drive magnet assembly and hardware package

from carton and check for shipping damage.

WARNING: Magnetic field hazard. This pump contains powerful

rare earth magnets. When the pump is disassembled (not connected

to a motor) and the magnets are exposed, these magnets produce

powerful magnetic fields. Individuals with cardiac pacemakers,

implanted defibrillators, other electronic medical devices or sickle

cell anemia must not handle or be in the proximity of the magnets

contained inside the pump. Consult a health care provider for specific

recommendations before working with this pump.

ATEX COMPLIANT PUMPS

All assembly, installation, and maintenance instructions are the same

as standard pumps with the exceptions noted on page 4 under “Safety

Precautions for ATEX pumps.”

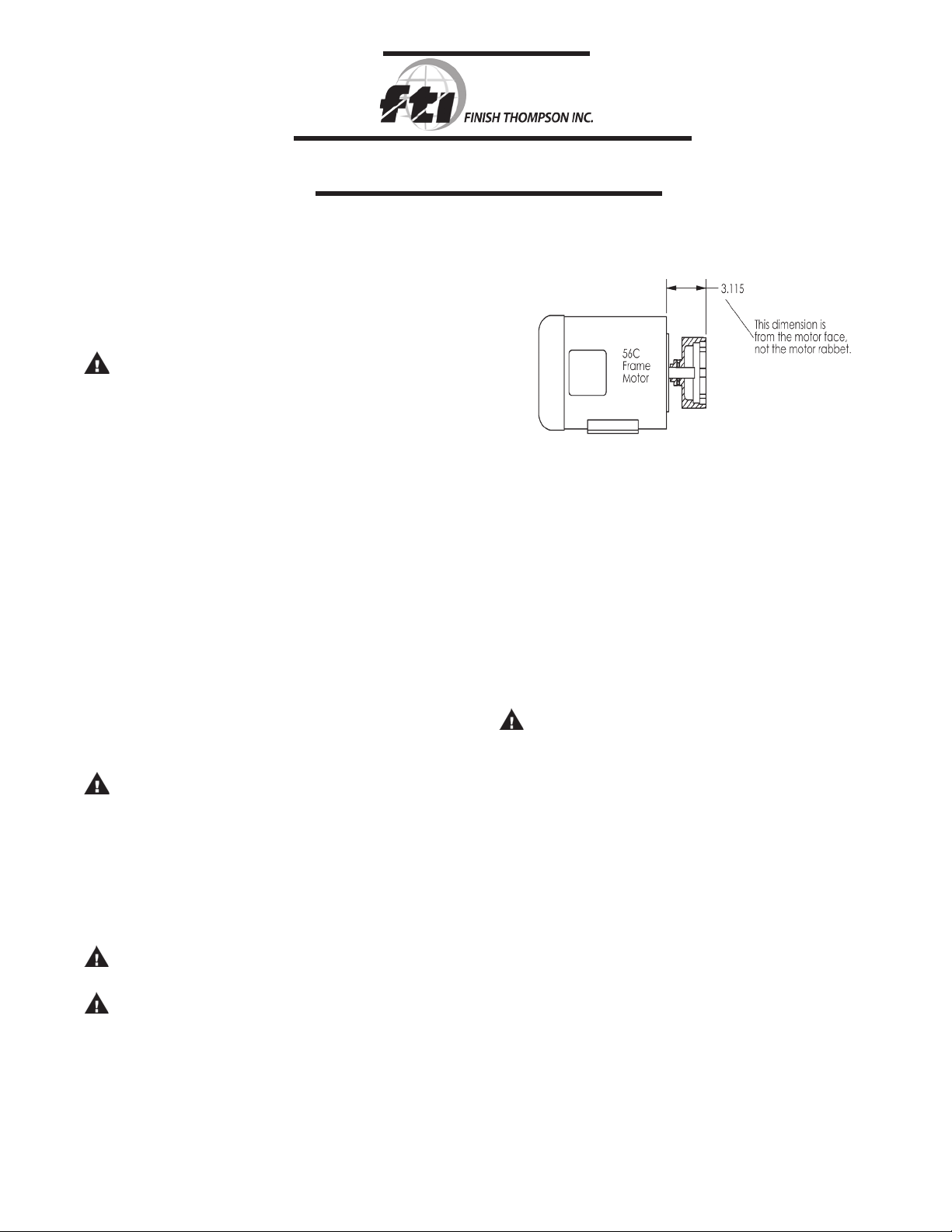

Figure 1

10A,10B, & 10C) from hardware package.

4. Manually rotate pump assembly to ensure that the pump

is not binding or rubbing on the drive magnet assembly.

5. Install the pump into the system according to installation

instructions.

PUMPS WITH MOTORS

Proceed to Installation Section.

PUMPS WITHOUT MOTORS

56C frame

1. Remove the pump, drive magnet assembly and hardware

package from box.

CAUTION: Keep away from metallic particles, tools and

electronics. Drive magnets MUST be free of metal chips.

2. Slide drive magnet assembly (item 6) onto the motor shaft

until it is between 3.110” and 3.120” as measured from the

motor face to the top of the drive magnet assembly. See

Figure 1. Align set screw (item 6B) with flat or key slot on

the motor shaft and tighten both setscrews with a 5/32” Al len wrench to 70 in.-lbs. (7.9 N-m ).

CAUTION: Do not operate/test the motor with the drive mag

net assembly exposed.

WARNING: Magnets are strong. To avoid damage and pinch-

ing fingers, tightly grasp pump assembly keeping finger tips

away from the area where the motor adapter and motor meet.

3. Carefully slide the pump assembly over the drive magnet

assembly. Orient the discharge port to either the 12 or

9 o’clock position. Make sure rabbet (step) on motor is fully

seated into the motor adapter (item 5). Align bolt holes in

motor adapter and motor. Install (4) bolts and washers (items

PUMPS WITHOUT MOTORS

63/B14, 71/B14 & 80/B14

1. Remove pump, drive magnet assembly and hardware

package from box.

CAUTION: Keep away from metallic particles, tools

and electronics.

2. Remove screws and washers (items 9A, 9B & 9C) from

impeller housing (item 1) and remove pump assembly

from motor adapter (item 5).

3. For 63 frame pumps - Adjust the single setscrew located in

the middle of the supplied shaft adapter so that it protrudes

slightly into the inside bore. Align that protruding setscrew

with the keyway or flat on the motor shaft and slide on the

shaft adapter until it bottoms out. Tighten the single set-

screw into the keyway, and then tighten the two setscrews

on the end of the adapter onto the motor shaft.

4. Install the motor adapter (item 5) onto the motor with the

access holes top and bottom. Secure with supplied hard-

ware (items 10A, 10B, and 10C). On 63 frame pumps,

from the motor side, insert the supplied gray spacer into the

base of the motor adapter and secure both to the motor.

5. For 63 frame pumps - Screw the cone point drive magnet

assembly setscrew (item 6B) in so that it protrudes

slightly into the drive bore. Align the protruding setscrew point

1

Page 2

.

with the key slot on the shaft adapter and slide the drive

magnet assembly (item 6) on. Adjust the drive magnet

assembly (item 6) so that it is 1.016 mm (.040 +/- .005)

below the face of the motor adapter (see figure 2) and

tighten both setscrews with a 5/32” Allen wrench to 7.9 N.m

(70 in. lbs.).

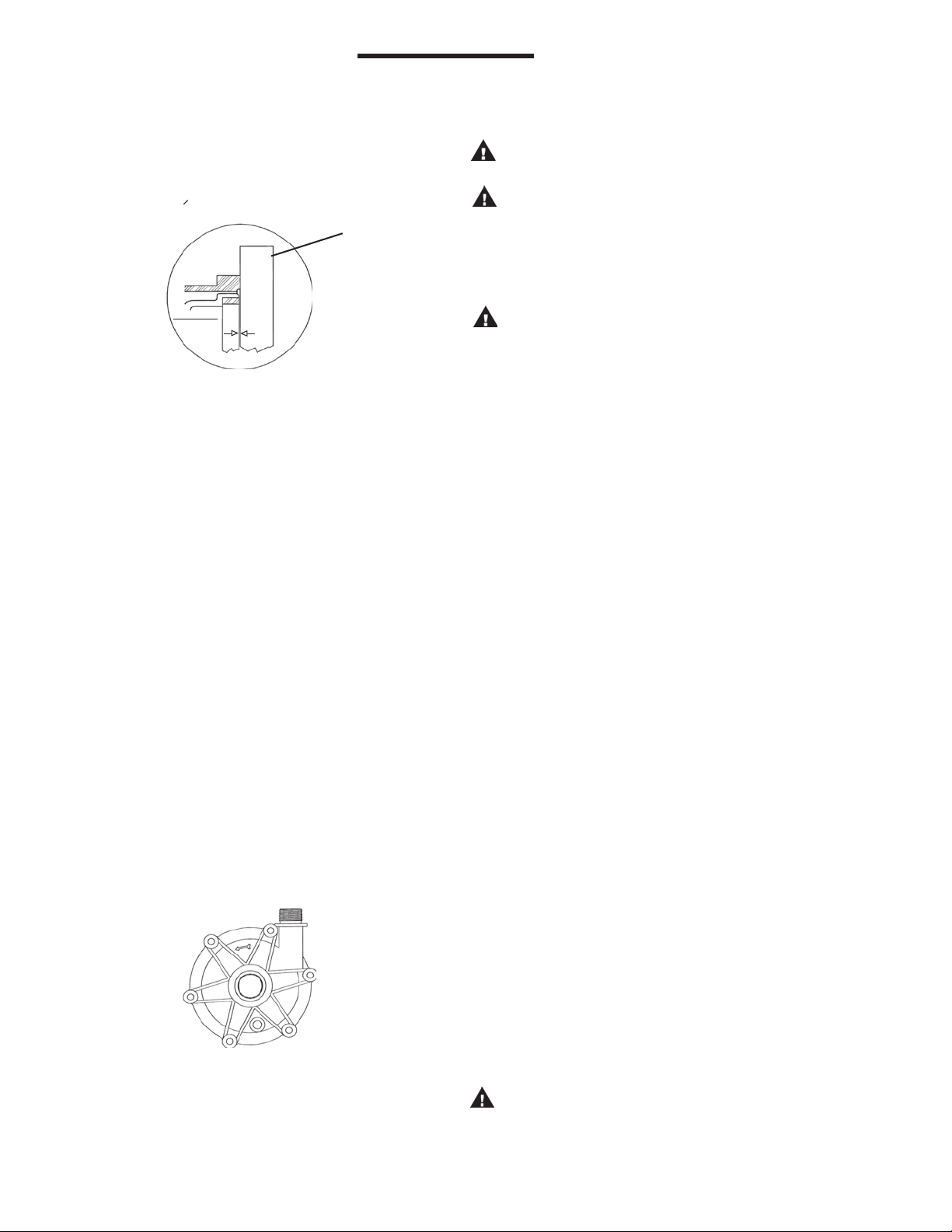

STRAIGHT

EDGE

DRIVE

MAGNET

ASSY.

.040

Figure 2

For 71 and 80 frame - Align the cone point set screw (item

6B) on the motor shaft and slide the drive magnet assembly

(item 6) onto the motor shaft. Adjust the drive so that it is

1.016 mm (.040 + or -.005) below the face of the motor

adapter (see figure 2). Tighten both setscrews with a 5/32”

Allen wrench to 7.9 N-m (70 in-lbs.).

6. Place the impeller assembly (comprised of items 2 and 3) in

barrier (item 4). Grasping the barrier at opposite bolt tabs,

carefully lower the barrier assembly into the motor adapter/

drive assembly. Line up the tabs of the barrier between the

tabs on the motor adapter to avoid pinching fingers. Once

seated, rotate the barrier until bolt holes line up.

7. Install the o-ring (item 7) on the barrier. Lubricate the o-ring

with a compatible lubricant to facilitate installation.

8. Place the impeller housing (item 1) on the barrier being

careful not to dislodge the o-ring.

9. Align mounting holes and install 6 mounting screws and

washers (items 9A, 9B & 9C) from hardware package. Hand-

tighten screws using pattern shown in Figure 3.

Manually rotate the pump assembly to ensure that the pump

is not binding or rubbing on the drive magnet assembly.

10. Install pump into the system according to installation

instructions.

CAUTION: Do not operate/test the motor with the drive magnet

assembly exposed.

CAUTION: Drive magnets MUST be free of metal chips.

Note: Prior to start-up, double check the two set screws to assure that they are firmly tightened. Failure to do so could result

in internal damage. Rotate to assure clearance with the motor

adapter.

WARNING: Magnets are strong. To avoid damage and

pinching fingers, tightly grasp pump assembly keeping

finger tips away from the area where the housing and

motor adapter meet.

INSTALLATION

MOUNTING

Motor should be securely fastened.

PIPING

1. Support piping near the pump to eliminate any strain on

the pump casings.

2. Do not overtighten the piping on the discharge on initial

installation (i.e., down to the o-ring). Damage to the

discharge can occur. The o-ring is used only when there

is wear and the plastic threads are loose.

3. To minimize head loss from friction:

a. Increase pipe size by 1 diameter.

b. Use minimal number of pipe bends.

4. Keep bends and valves a minimum of 10 pipe diameters from

the suction and discharge.

5. Position pump as close to the liquid source as possible.

6. Maintain a flooded suction (liquid above pump prior to

being primed).

7. Ensure that the piping does not leak and suction is not

prone to clogging.

8. If flexible hose is preferred, use a reinforced hose rated for the

1

3

6

5

proper temperature and pressure. This helps avoid collapse or

kinks.

9. Install valves on suction and discharge lines (a minimum of 10

pipe diameters from the pump).

10. For units in a suction lift system, install appropriate piping in

the discharge to allow priming of the pump.

2

Figure 3

4

11. The suction valve should be completely open to avoid

restricting suction flow.

CAUTION: To stop the pump if prime is lost, use one of the

following: (1) pressure switch on the discharge, (2) vacuum

switch on the suction, (3) a motor minder to monitor motor

current.

2

Page 3

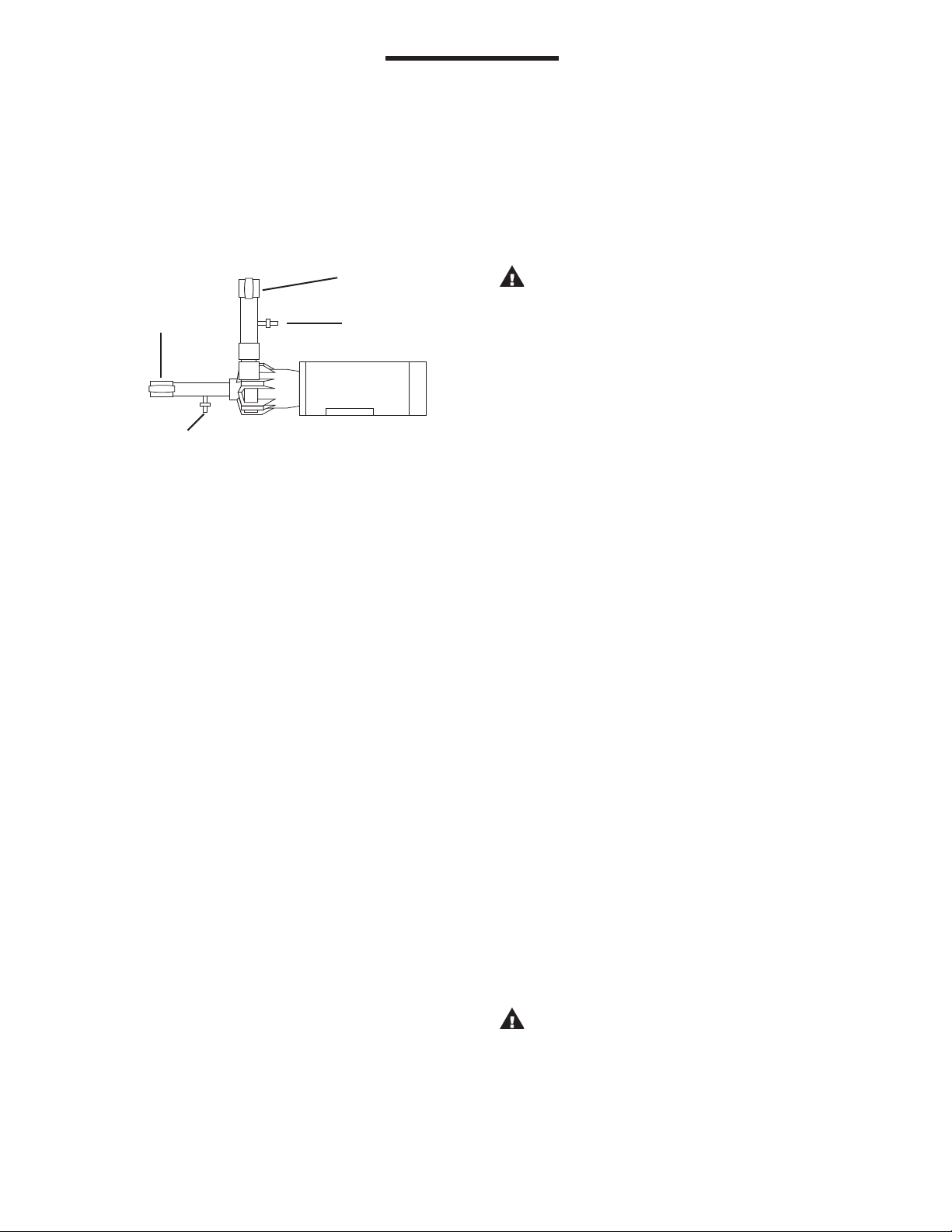

12. When pumping liquids that may solidify or crystallize, a

flush system should be added to the piping. See Figure 4.

Install water inlet and outlet valves as shown.

Note: This pump is provided with a provision for a customer

installed 1/4” NPT drain in the impeller housing. See Drain

Installation Section for details.

SUCTION LIFT SYSTEM

1. Prime the system by filling the priming chamber and/or

suction line with a liquid. Allow time for trapped air to

work its way out.

2. If priming via filling the suction line, close the discharge

valve prior to returning the suction line to the tank.

Figure 4

Discharge Valve

Suction

Valve

Water

Outlet

Valve

Water Inlet Valve

ELECTRICAL

1. Install the motor according to NEC requirements and local

electrical codes. The motor should have an overload protection

circuit.

2. Wire the motor for clockwise rotation when facing the fan

end of the motor.

3. To verify correct rotation of the motor:

a. Install the pump into the system.

b. Fully open the suction and discharge valves

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry (PTFE and ceramic bushings can’t be run dry

without damage to pump components).

d. Jog the motor (allow it to run for only one to two

seconds) and observe the rotation of the motor fan.

Refer to the directional arrow on the pump if needed.

Note: A pump running backward will pump but at a

greatly reduced flow and pressure.

OPERATION

FLOODED SUCTION SYSTEM

1. Completely open suction and discharge valves

2. Start the pump and check liquid flow. If there is no flow,

see the Troubleshooting section.

3. Adjust the flow rate and pressure by regulating the dis-

charge valve. Do not attempt to adjust the flow with the

suction valve.

FLUSH SYSTEMS

CAUTION: Some liquids react with water.

1. Completely close suction and discharge valves.

2. Connect water supply to water inlet valve.

3. Connect drain hose to water valve.

4. Open inlet and outlet valves. Flush system until pump is

clean (approximately 5 minutes).

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring and motor

mounting bolts.

2. Close suction and discharge valves. Disconnect piping.

3. Securely hold or clamp the motor in place.

4. For metric pumps, skip to step 5. For 56C frame pumps,

remove the four motor adapter bolts (items 10A, 10B, &

10C) and pull the pump end straight off of the motor

face. Place the pump end on the table with the adapter

flange on the table and the suction pointing straight up.

5. Remove the six housing bolts (item 9A, 9B, & 9C) from

the pump.

6. Using a thin bladed screwdriver, gently separate the im-

peller housing (item 1) from the barrier (item 4). Re-

move the housing o-ring (item 7). Gently separate the

barrier from the motor adapter (item 5). On metric

pumps, carefully separate and rotate the barrier tabs so

that they are located in between the motor adapter bolt

holes. Gripping the tabs, pull the barrier and impeller

assembly from the pump. Remove the impeller assembly

(items 2 and 3) from the barrier.

7. Remove the drive magnet assembly (item 6) using a 5/

32” hex wrench on the two set screws. Metric pumps

have access holes in the motor adapter to loosen set

screws.

CAUTION: Keep the drive magnet and impeller assem-

blies away from metal chips or particles.

EXAMINATION:

1. Check impeller drive bushing (item 3A), thrust ring, ce-

ramic thrust ring and shaft for cracks, chips, scoring or

excess wear. See Figure 5. Replace as required.

3

Page 4

2. Check for loose magnets on drive assembly or rubbed

areas on impeller or barrier assemblies. Contact your

distributor or FTI Technical Service if a problem is found.

3. If you did not remove the drive magnet assembly, check

the set screws for tightness before reassembly.

.020” min.

2. For metric pumps - Follow assembly instructions for metric

pumps on page 1, steps 3 through 10.

Note: Plastic pumps will expand and contract with tem-

perature, so periodically check and hand tighten screws.

This pump is designed to accept an o-ring on the discharge

flange and inlet chamfer as a backup to the NPT or BSP

threads to ensure leak-free operation after temperature

cycling.

OPTIONAL DRAIN INSTALLATION SECTION

1. Remove the impeller housing from the pump assembly.

Figure 5

.415” max.

BUSHING REPLACEMENT

1. To remove the bushing, insert a 1/16” pin punch into bal-

ance hole (inner circle of 4 holes) of impeller assembly

(items 2 & 3). Gently tap the bushing out of the back of the

impeller assembly. The punch may need to be moved to

a different hole if the bushing is difficult to remove.

2. To replace the bushing, clean the impeller bore. Insert

the new bushing into the back of the impeller assembly

by aligning the bushing with the impeller bore. Press

gently until the bushing bottoms out (use a block of wood

and mallet if necessary).

REASSEMBLY

1. 56C pumps - Insert the barrier (item 4) into the motor

adapter (item 5). Align the barrier tabs with the motor

adapter bolt holes and press/pop into place. Install the

impeller assembly (items 2 and 3) into the barrier. Lubricate

the housing o-ring (item 7) with a chemically compatible

lubricant and install. Carefully place the impeller housing

(item 1) onto the barrier, lining up the discharge with a set

screw access hole (top) in the motor adapter. Be careful not

to dislodge the o-ring. Install the six bolts and washers

(items 9A, 9B, and 9C) and hand tighten the screws follow ing the pattern shown in figure 3.

After verifying the setting and setscrews tension on the

drive magnet assembly, grip the pump end by the dis charge and the opposing front edge of the motor adapter

and install the pump end on to the motor. Secure to the

motor with correct hardware (items 10A, 10B, and 10C).

CAUTION: Do not allow fingers between the motor face

and the motor adapter.

2. Clamp the impeller housing to a drill press table.

3. Using a 7/16” drill and the molded boss as a guide, drill

completely through the molded boss into the interior of

the impeller housing. De-burr the hole on the inside of

the impeller housing. See Figure 6.

CAUTION: Do not tap too deep or the impeller housing

may be damaged.

4. Using a 1/4” NPT tap, tap the hole in the molded boss to

the appropriate depth.

5. Install drain plug or valve, being careful not to overtighten.

Figure 6

Drain fitting molded boss.

Use as a guide for drill ing

and tapping 1/4” NPT.

SAFETY PRECAUTIONS FOR ATEX PUMPS

CAUTION: Proper o-ring material must be chosen for the fluid

being pumped. Improper material selection could lead to swelling

and be a possible source of leaks. This is the responsibility of the

end user.

WARNING: The pump must be checked for leaks on a regular

basis. If leaks are noticed, the pump must be repaired or replaced

immediately.

WARNING: The pump must be cleaned on a regular basis to

avoid dust buildup greater than 5 mm.

WARNING: ATEX pumps must use a power monitor, flow

switch, pressure switch or similar device to help protect against

dry running, closed discharge valve and de-coupling. Any of these

conditions could lead to a rise in surface temperature of the pump.

4

Page 5

TEMPERATURE CLASSIFICATION

Maximum

Maximum Allowable

The surface temperatures of the KC ATEX Series pumps depend upon the temperature of the fluid that is being pumped.

Fluid Surface Temperature Surface

Temperature Temperature Class Temperature

The following chart lists different fluid temperatures and the

corresponding pump surface temperatures:

80oF (27oC) 122oF (50oC) T6 85oC

185oF (85oC) 192oF (89oC) T4 135oC

220oF (104oC) 248oF (120oC) T3 200oC

KC5.5, 6, 6H, 7, 8, 10 EXPLODED VIEW

5

Page 6

KC 5.5, 6, 6H, 7, 8, 10 Spare Parts

Item Description Part Number

Impeller Housing with Thrust Ring

KC5.5, 6, 6H NPT - polypropylene A101981-1

KC5.5, 6, 6H NPT - PVDF A101981-3

KC5.5, 6, 6H BSP - polypropylene with FKM o-ring A101982-3

KC5.5, 6, 6H BSP - PVDF with FKM o-ring A101982-4

KC5.5, 6, 6H BSP - polypropylene with EPDM o-ring A101982-7

1

2

2A

3

KC5.5, 6, 6H BSP - PVDF with EPDM o-ring A101982-8

KC7, 8,10, NPT - polypropylene A101981-7

KC7, 8,10, NPT - PVDF A101981-9

KC7, 8,10, BSP - polypropylene with FKM o-ring A101982-11

KC7, 8,10, BSP - PVDF with FKM o-ring A101982-12

KC7, 8,10, BSP - polypropylene with EPDM o-ring A101982-15

KC7, 8, 10, BSP - PVDF with EPDM o-ring A101982-16

Impeller Head Assembly with Thrust Ring

KC5.5 polypropylene - 3.00” A101983-10

KC5.5 PVDF - 3.00” A101983-11

KC6 polypropylene - 3.19” A101983-1

KC6 PVDF - 3.19" A101983-4

KC6H polypropylene - 3.88" A101983-13

KC6H PVDF - 3.88" A101983-14

KC7 polypropylene - 3.19" A101983-15

KC7 PVDF - 3.19" A101983-16

KC8 polypropylene - 3.50" A101983-2

KC8 PVDF - 3.50" A101983-5

KC10 polypropylene - 3.88" A101983-3

KC10 PVDF - 3.88" A101983-6

PTFE Thrust Ring

KC5.5, 6 J102388

KC6H J104045

KC7 J103893

KC8, 10 J101606

Impeller Hub with Bushing

6 pole - polypropylene with carbon bushing A102746-1

6 pole - polypropylene with PTFE bushing A102746-10

6 pole - polypropylene with ceramic bushing A102746-20

6 pole - PDVF with carbon bushing A102746-2

6 pole - PVDF with PTFE bushing A102746-13

6 pole - PVDF with ceramic bushing A102746-21

8 pole - polypropylene carbon bushing A102746-4

8 pole - polypropylene with PTFE bushing A102746-11

8 pole - polypropylene with ceramic bushing A102746-22

8 pole - PVDF with carbon bushing A102746-5

8 pole - PVDF with PTFE bushing A102746-14

8 pole - PVDF with ceramic bushing A102746-23

10 pole - polypropylene with carbon bushing A102746-7

10 pole - polypropylene with PTFE bushing A102746-12

10 pole - polypropylene with ceramic bushing A102746-24

10 pole - PVDF with carbon bushing A102746-8

10 pole - PVDF with PTFE bushing A102746-15

10 pole - PVDF with ceramic bushing A102746-25

12 pole - polypropylene with carbon bushing A102746-16

12 pole - polypropylene with PTFE bushing A102746-17

12 pole - polypropylene with ceramic bushing A102746-26

12 pole - PVDF with carbon bushing A102746-18

12 pole - PVDF with PTFE bushing A102746-19

12 pole - PVDF with ceramic bushing A102746-27

6

Page 7

KC 5.5, 6, 6H, 7, 8, 10 Spare Parts - cont.

Item Description Part Number

Impeller Bushing

3A

Carbon J102387

PTFE J102790

Ceramic J103617

Barrier with Ceramic Shaft & Silicon Carbide Thrust Washer

4

PP A101703-1

PVDF A101703-2

Motor Adapter

56C frame A101991-3

63 frame A101991-8

5

63 frame ATEX (PVDF) A101991-11

71 frame A101991-1

71 frame ATEX (PVDF) A101991-10

80 frame A101991-2

80 frame ATEX (PVDF) A101991-9

Drive Magnet Assembly

6 pole - 56C frame A101990-3

6 pole - 63 frame A101990-11

6 pole - 71 frame A101990-1

6 pole - 80 frame A101990-2

8 pole - 56C frame A101990-6

8 pole - 63 frame A101990-12

6

8 pole - 71 frame A101990-4

8 pole - 80 frame A101990-5

10 pole - 56C frame A101990-7

10 pole - 71 frame A101990-8

10 pole - 80 frame A101990-9

12 pole - 56C frame A101990-15

12 pole - 63 frame A101990-16

12 pole - 71 frame A101990-13

12 pole - 80 frame A101990-14

6A

6B

Set Screw

5/16" knurled J104219

Set Screw

5/16" cone point J104220

Housing O-ring

7

FKM J102389

EPDM J102585

Discharge O-ring

KC5.5, 6 - BSP - FKM J102390

8

KC5.5, 6 - BSP - EPDM J102712

KC7, 8,10 - BSP - FKM J102391

KC7, 8,10 - BSP - EPDM J102713

9A

9B

9C

Impeller Housing Bolts

Stainless steel J102484

Impeller Housing Lock Washers

Stainless steel J100672

Impeller Housing Flat Washers

Stainless steel J100113

Motor Adapter Bolts

10A

56C frame J100114

71, 80 frame J102884

63 frame J103198

Motor Adapter Lock Washers

10B

56C frame J100115

71, 80 frame J100672

63 frame J100672

7

Page 8

KC 5.5, 6, 6H, 7, 8, 10 Spare Parts - cont.

Item Description Part Number

10C

10C

11

Motor Adapter Flat Washer

3/8" stainless steel J100128

Flat Washer

1/4" stainless steel J100113

Plug

For motor adapter J102878

8

Page 9

TROUBLESHOOTING

GENERAL NOTES:

1. Do not pump liquids containing metal fines.

2. Orient the discharge port to either 12 or 9 o’clock position.

3. If magnets de-couple, stop the pump immediately. The rare

earth magnets used in this pump are more resistant to

demagnetization than ceramic magnets, but operating the

pump with the magnets de-coupled will eventually weaken

the magnets.

4. Plastic pumps will expand and contract with temperature so peri odically check and hand-tighten screws. This pump is designed

to accept an o-ring on the discharge flange and inlet chamfer

as a backup to the NPT or BSP threads to ensure leak-free

operation after temperature cycling.

5. Fitting o-rings on discharge flange and inlet chamfer is

possible.

NO DISCHARGE

1. Air leaks in suction piping.

2. Pump not primed.

3. Discharge head too high.

4. Suction lift too high or insufficient NPSHA. Suction lift should

be 2 feet above NPSHR.

5. Closed valve.

6. Viscosity or specific gravity too high (magnets uncoupled).

INSUFFICIENT DISCHARGE

1. Air leaks in suction piping.

2. Discharge head higher than anticipated.

3. Suction lift too high or insufficient NPSHA. Suction lift should be

2 feet above NPSHR.

4. Clogged suction line, foot valve or crimp in hose.

5. Foot valve too small.

6. Foot valve or suction opening not submerged enough.

7. Incorrect pump rotation.

INSUFFICIENT PRESSURE

1. Air or gasses in liquid.

2. Impeller diameter too small.

3. Discharge head higher than anticipated.

4. Incorrect pump rotation.

LOSS OF PRIME

1. Leaking suction or discharge line.

2. Suction lift too high or insufficient NPSHA. Should be 2 feet

above NPSHR.

3. Air or gasses in liquid.

4. Foreign matter in impeller.

5. Leaking valve.

EXCESSIVE POWER CONSUMPTION

1. System head lower than rating. Pumps too much liquid.

.

2. Specific gravity or viscosity of liquid pumped is too high or

higher than that defined in application.

3. Binding pump parts.

VIBRATION/NOISE

1. Excess bearing wear.

2. Drive magnet uncoupled.

3. Loose magnet.

4. Pump cavitation.

5. Motor or piping not properly secured.

6. Foreign object in impeller.

WARRANTY

Finish Thompson Inc. warrants this pump product to be free of defects

in materials and workmanship for a period of one year from date of

purchase by original purchaser. If a warranted defect occurs, which

is determined by manufacturer’s inspection, within this period, it will

be repaired or replaced at the manufacturer’s option, provided (1) the

product is submitted with proof of purchase date and (2) transportation charges are prepaid to the factory. Liability under this warranty is

expressly limited to repairing or replacing the product or parts thereof

and is in lieu of any other warranties, either expressed or implied. This

warranty applies only to normal wear of the product or components.

This warranty does not apply to products or parts broken due to, in

whole or in part, accident, overload, abuse, chemical attack, tampering, or alteration. The warranty does not apply to any other equipment

used or purchased in combination with this product. The manufacturer

accepts no responsibility for product damage or personal injuries

sustained when the product has been modified or altered in any way. If

this warranty does not apply, the purchaser shall bear all costs for labor,

material, and transportation.

Manufacturer shall not be liable for incidental or consequential damages including, but not limited to, process down time, transportation

costs, costs associated with replacement or substitution products, labor

costs, product installation or removal costs, or loss of profit. In any and

all events, manufacturer’s liability shall not exceed the purchase price of

the product and/or accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the product’s materials of construction, which are compatible with the fluid(s)

that come(s) in contact with the product. The user may consult Finish

Thompson, Inc. (manufacturer) and a manufacturer’s representative/

distributor agent to seek a recommendation of the product’s material of

construction that offers the optimum available chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising out

of a reaction, interaction or any chemical effect that occurs between

the materials of the product’s construction and fluids that come into

contact with the product’s internals.

Service 800-888-3743

J102714, Rev.16, 7./15/2014

FT96-606N

Loading...

Loading...