Page 1

GP22/32 SERIES

Sealed Non-Metallic Centrifugal Pumps

Installation and Maintenance Instructions

ASSEMBLY

Unpack pump from carton and check for shipping damage.

PUMPS WITH MOTOR

No assembly required. Simply unpack the pump and motor and

examine for any shipping damage. If damage is detected, save the

packaging and notify the carrier immediately.

Remove the shipping plugs from the suction and discharge of the

pump and proceed to the “Installation Requirements” section of these

instructions.

PUMPS WITHOUT MOTORS

184JM MOTOR ADAPTER (STANDARD)

1. Unpack the pump and examine for any shipping damage. If damage

is detected, save the packaging and notify the carrier immediately.

2. Prepare to install the pump onto the motor.

a. Remove the protective shroud (Item #22) from the

Motor Adapter (item #6).

b. Install key (provided) on keyway of motor and coat with anti-

seize.

3. Align pump impeller shaft with the motor shaft and key, then push

pump onto the motor.

4. Pull the socket head bolt, impeller cap and impeller cap o-ring

(Items #4, 13, 16) from the hardware bag.

a. Install the socket head bolt through the suction of the pump with

a 5/16" hex key. Coat threads of socket head bolt with anti-seize

and tighten in a clockwise rotation. It may be necessary to hold

the motor fan blade with a screwdriver to keep motor shaft from

turning.

b. Install the impeller cap and impeller cap o-ring using a large flat

head screwdriver in a clockwise rotation.

IMPORTANT: Do not cross thread impeller cap or leakage could

occur.

5. Now install motor adapter bolts and washers (Items #12,19) and

tighten securely.

6. Verify back of impeller is not touching the housing cover by looking

into the discharge of the pump.

7. Reinstall protective shroud back onto the motor adapter.

8. Install pump according to installation instructions.

90,100/112 Motor Adapters (Metric)

1. Unpack the pump and examine for shipping damage. If damage is

detected, save the packaging and notify the carrier immediately.

2. Prepare to install the pump onto the motor.

a. Remove the protective shroud (Item #22) from the motor adapter

(item #6).

b. Install key (provided) on keyway of motor and coat with anti-

seize.

3. Align pump impeller shaft with the motor shaft and key, then push

pump onto the motor until it bottoms out.

4. Tighten the two (2) set screws (Item #25) on the motor shaft to 7.9

N•m (70 in•lbs).

5. Now install motor adapter bolts and washers (Items #12,19) and

tighten securely.

6. Verify back of impeller is not touching the housing cover by looking

into the discharge of the pump.

7. Reinstall protective shroud back onto the motor adapter.

8. Install pump according to installation instructions.

INSTALLATION

MOUNTING

Motor or base plate must be securely fastened.

PIPING

• Always support the piping near the pump to minimize stress and

strain on the pump’s casing.

• Minimize frictional losses by increasing the piping size by one

diameter.

• Use a minimal number of bends, keeping any bends at least a

distance of ten pipe diameters away from the pump.

• Install valves on the suction and discharge lines. Place the valves

within a minimum distance of ten pipe diameters away from the

pump.

• Ensure that the piping is leak free.

• Position the pump as close to the liquid source as possible.

• Maintain a flooded suction at all times.

PUMPS WITH COOLING (PRESSURE) COLLARS

A cooling collar provides a water flush to the pump’s seal. This is

necessary when pumping hot liquids or liquids that tend to build up or

crystallize around the seal faces. If your pump is supplied with a cooling collar, proper water flow and pressure are critical to the operation

of the pump.

1. Plumb a water supply to the cooling collar. Use the 1/8” NPT

threaded holes for the water inlet and drain lines. Either hard pipe

or flexible tubing is suitable.

2. Adjust the water flow and pressure of the flush/cooling water

BEFORE starting the pump.

• For pumps with bellows or multi-spring seals, supply

one to two gallons water flow per hour at 1 - 2 psi.

• For pumps with a double seal, supply one to two

gallons water flow per hour at 5 - 10 psi ABOVE the dis-

charge pressure of the pump.

CAUTIONS:

1) Never run a pump equipped with a cooling collar without

a proper water supply. Doing so will result in damage to

the pump. Use of a flow switch is recommended.

2) Do not over pressurize the cooling collar’s water supply.

Doing so can result in damage to pump components.

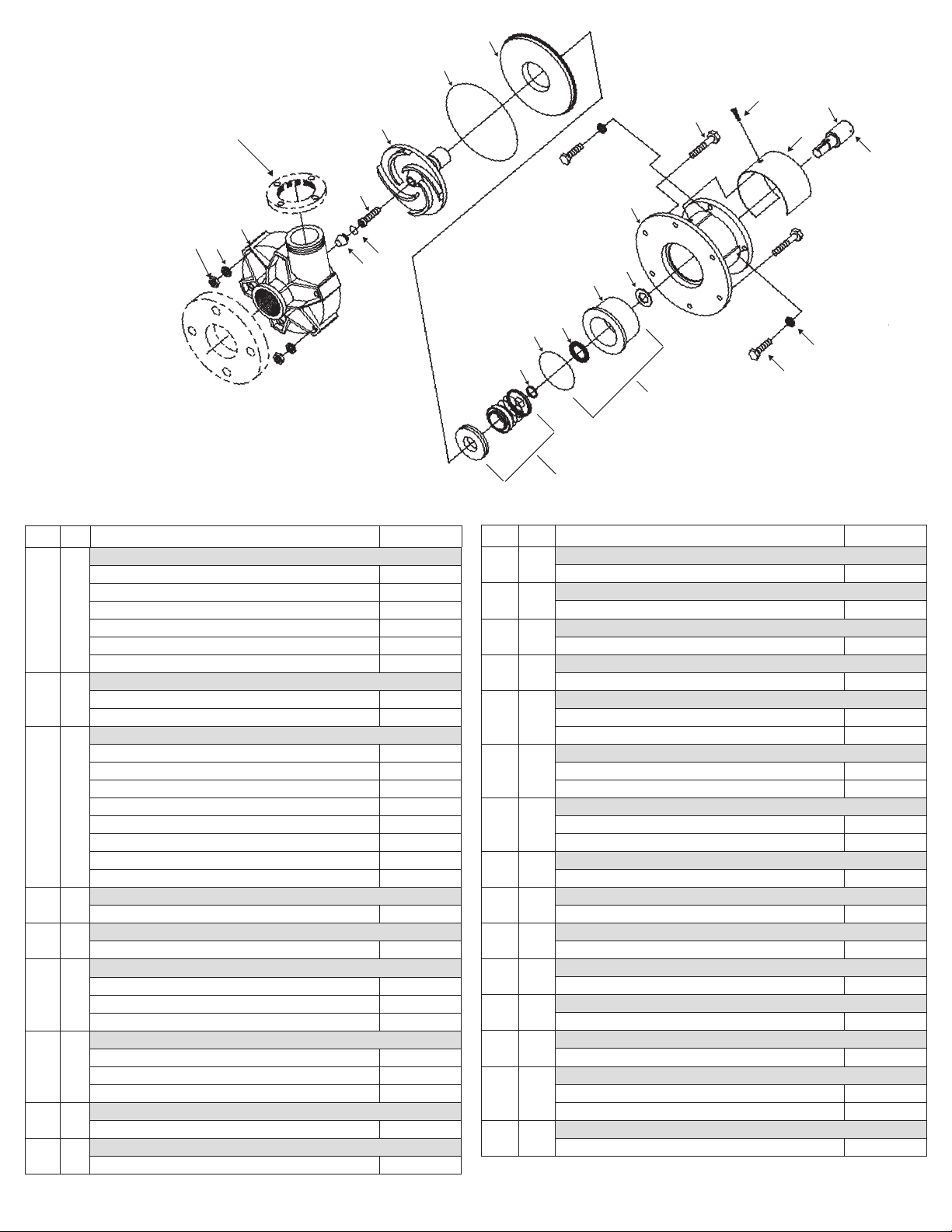

1

Page 2

2

14

GP-32 Flanges

Non-removable

1

11

10

Item Qty. Description Part No.

Impeller Housing

2"x2" NPT, polypropylene (GP22) M100870-1

2"x2" NPT, PVDF (GP22) M100870-2

1

1

2"x2" BSP, polypropylene (GP22) 105388

2"x2" BSP, PVDF (GP22) 105388-1

3"x2" flanged, polypropylene (GP32) A101230-1

3"x2" flanged, PVDF (GP32) A101230-2

Impeller Housing Cover

2

1

Polypropylene M100868-1

PVDF M100868-2

Impeller

6-1/8" - PVDF - bellows/multispring seal models only A101761-1

5" - PVDF - bellows/multispring seal models only A101761-3

5-1/2" - PVDF - bellows/multispring seal models only A101761-2

3

1

4-1/2" - PVDF - bellows/multispring seal models only A101761-4

6-1/8" - PVDF - double seal models only A101761-5

5-1/2" - PVDF- double seal models only A101761-6

5" - PVDF - double seal models only A101761-7

4-1/2" - PVDF - double seal models only A101761-8

4

5

6

7

8

9

Impeller Cap

1

PVDF M100130

Cooling/Press Collar Only

1

Polypropylene - use with double seal pumps M100132

Motor Adapter

NEMA 184JM frame M101569

1

IEC 90 frame M101570-2

IEC 100/112 frame M101570-1

Seals (standard options - call factory for additional options)

Bellows - C/R/V J100122

1

Multispring - C/RH/V J100123

Double - C/RH/V,C/RH/V J100124

Retaining Ring

1

Stainless steel J100125

Hex Head Cap Screw

6

5/16-3 stainless steel J101058

3

13

16

4

23

9

6

18

5

17

15

8

21

7

Item Qty. Description Part No.

10

11

12

13

14

15

16

17

18

19

21

22

23

24

25

Hex Nut

6

5/16-18 stainless steel J101257

Flat Washer

6

5/16 SAE stainless steel J101293

Lock Washer

4

3/8 stainless steel J100115

Hex Head Cap Screw

1

3/8-16 x 1/2 stainless steel J100129

Housing O-ring

1

FKM J101085

EPDM J101086

Cooling Collar O-ring

1

FKM J100118

EPDM J100119

Impeller Cap O-ring

1

FKM J100132

EPDM J100133

Cooling Collar Seal (for use w/ bellows & multispring seals)

1

Lip Seal J100134

Slinger Ring

1

Neoprene M100135

Hex Screw

4

3/8" x 16 x 1" stainless steel (4 required) J100114

Cooling Collar Assembly (for use w/ bellows & multispring seals)

1

w/ FKM o-ring & lip seal A100188

Protective Guard

1

For single seal M100851

Protective Shroud Screw

1

Stainless steel J102112

Shaft Adapter with Set Screws

1

IEC 90 frame A102047

IEC 100/112 frame A102048

Knurled Cup Point Set Screw

4

1/4-20 x 1/4 stainless steel J100220

24

22

25

12

19

2

Page 3

SPECIAL PIPING SITUATIONS

Suction Lift

1. Install a priming chamber on the feed side of the pump or appropriate piping on the discharge for priming the pump.

2. Install a foot valve on the bottom of the suction piping to maintain

a prime to the pump.

CAUTION: Suction prime must be maintained at all times. Running

the pump dry will cause damage to pump components. To protect

the pump if prime is lost, use a pressure switch on the discharge,

a vacuum switch on the suction, or a motor minder to monitor

motor current draw.

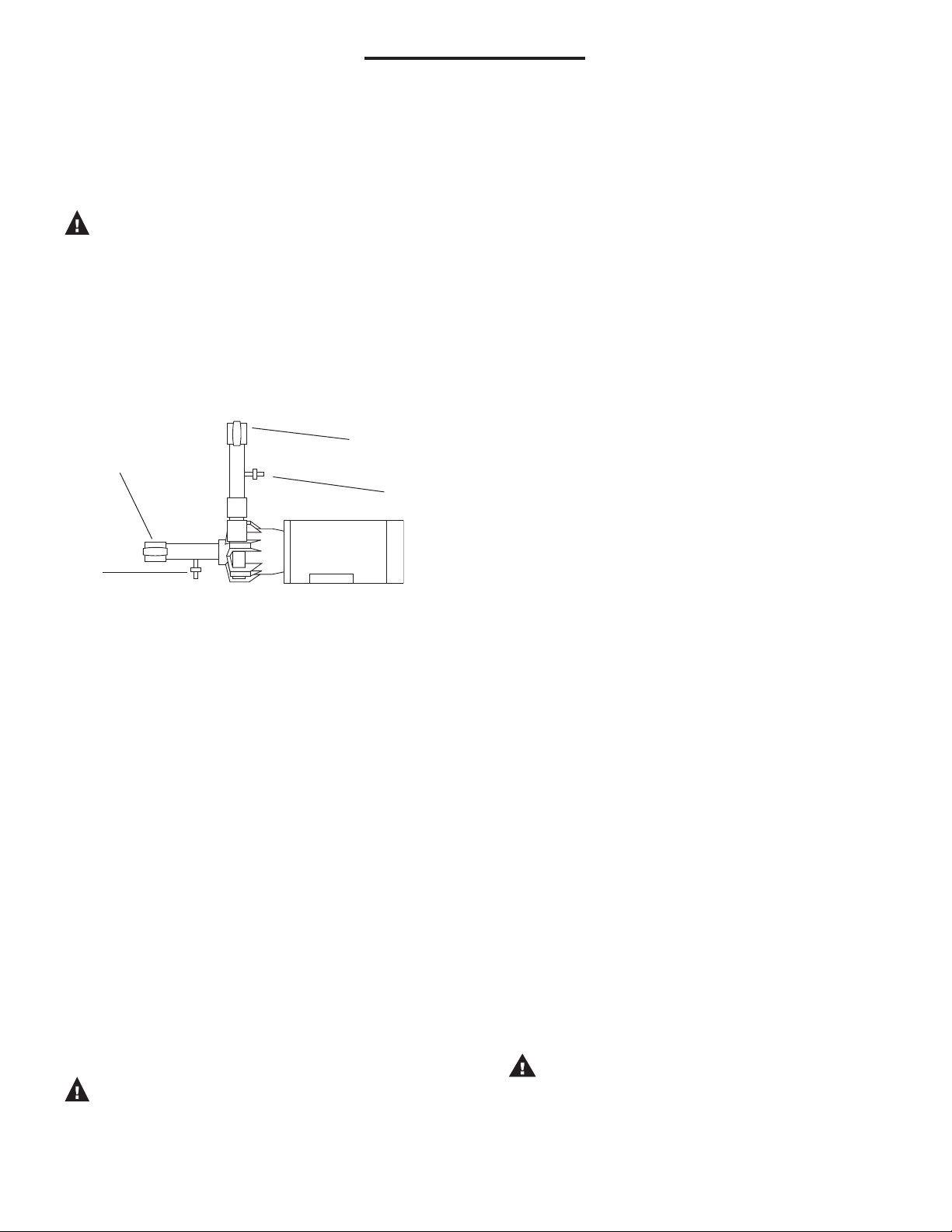

PUMPING LIQUIDS WHICH MAY SOLIDIFY OR CRYSTALLIZE

Add a flush system to the pump’s piping to prevent accumulation of

material inside the pump. Install water inlet and outlet valves as shown

in Figure 1. Refer to the “Operation” section of these instructions for

the flush procedure.

Discharge Valve

Suction Valve

Water Inlet Valve

Figure 1

ELECTRICAL CONNECTIONS

1. Install the motor according to NEC requirements and local electrical

codes. Motor should have an overload protection circuit.

2. Wire the motor for clockwise rotation when facing the fan end of

the motor.

3. To verify correct rotation of the motor:

a. Install the pump into the system.

b. Fully open the suction and discharge valves.

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry.

d. Jog the motor (allow it to run for only one to two seconds)

and observe the rotation of the motor fan. Refer to the

directional arrow on the pump if needed.

NOTE: A pump running backward will run but at a greatly reduced

flow and pressure.

OPERATION

FLOODED SUCTION SYSTEMS

1. Fully open the suction and discharge valves.

2. If a cooling collar is used, turn on the cooling water.

3. Start the pump and verify liquid is flowing. If there is no liquid

flow, refer to the “Troubleshooting” section of these instructions.

4. Adjust the flow rate and pressure by regulating the discharge valve.

CAUTION: Never attempt to adjust the liquid flow with the suction

valve. Limiting the suction will result in damage to the pump's

components.

Water

Outlet Valve

SUCTION LIFT SYSTEMS

1. Fully open suction and discharge valves.

2. If a cooling collar is used, turn on the cooling water.

3. Prime the pump by filling the priming chamber. Allow time for any

trapped air in the suction piping to escape.

4. Start the pump. Adjust the flow rate and pressure by regulating

the discharge valve.

CAUTION: Never attempt to adjust the liquid flow with the suction

valve. Limiting the suction will result in damage to pump components.

FLUSH SYSTEMS

1. Fully close the suction and discharge valves.

2. Connect the water supply to the water inlet valve and connect a

drain hose to water outlet valve.

3. Turn on the water supply and open the inlet and outlet valves. Flush

the system until the pump has been cleared of any material buildup

(approximately 5 minutes).

4. Close the inlet and outlet valves and turn off water supply.

SEALS

SEAL REMOVAL AND INSPECTION

1. Disconnect the piping and electrical power from the pump.

2. Disassemble the pump from the motor adapter.

a. Remove the six hex-head cap screws from the impeller

housing. The impeller housing will loosen if gently tapped at

the discharge outlet.

b. Remove the protective shroud from the motor adapter.

c. While preventing the motor shaft from moving (insert a screw-

driver into the motor’s fan), unscrew the impeller cap with o-ring

and socket head bolt (Items #4,16 and 13) in a counterclockwise

rotation. Use large flathead screw driver and 5/16" hex key.

Remove the impeller, seal, cooling collar (if applicable) and

housing cover as one assembly from the motor shaft.

Note: For pumps using 90, 100/112 motor adapters, leave the

shaft adapter secured to the motor shaft.

3. Remove the seal for inspection.

a. Lubricate the impeller’s shaft with a rubber lubricant emul-

sion or soapy water to allow the seal to slide easier.

Note: Never use a petroleum product for lubrication.

Doing so will effect the seal elastomer’s performance

after reassembly.

b. If no cooling collar is present, carefully remove the retaining

ring that holds the rear of the seal. If equipped with a

cooling collar, carefully slide the cooling collar off of the

impeller’s shaft.

• With single bellows or multi-spring seals, a retain-

ing ring holds the seal in place. Carefully remove

the retaining ring. Loosen the four (4) set screw on

the multi-spring seal.

• With double seals, the cooling collar holds the seal

in place.

CAUTION: The seal’s spring is compressed and under

pressure. Use care when removing.

c. Remove the seal’s spring. Grasp the rotating head of the

seal by hand and twist to remove from the impeller’s shaft.

d. Remove the housing cover from the impeller.

e. Press the ceramic stationary seat portion of the seal out of

the housing cover.

3

Page 4

4. Visually inspect all parts for damage. Replace any parts that appear

worn or damaged.

• Look for scoring of the seal’s ceramic face.

• Inspect the rotating seal face for wear.

• Check for degradation or chemical attack of any

elastomers and other seal components.

• Look for signs of heat damage (melted plastic) to the

housing cover and impeller’s shaft.

SEAL INSTALLATION AND PUMP REASSEMBLY

Single Bellows Seal

1. Install the stationary seal face.

a. Lubricate the stationary face’s o-ring with a rubber lubricant

emulsion or soapy water. Keep the polished surfaces of the

seal face clean.

Note: Never use a petroleum product for lubrication.

Doing so will effect the seal elastomer’s performance

after reassembly.

b. Carefully press the stationary face into the housing cover (use

a piece of cardboard to protect the seal while pressing

against the stationary face). The smoothest side of the station ary face should be facing outward.

2. Install the rotating face.

a. Lubricate the impeller’s shaft with a rubber lubricant emulsion

or soapy water.

b. Carefully slide the housing cover over the impeller’s shaft.

The side of the housing cover with the pressed-in seal face

should be away from the impeller.

c. Separate the rotating head of the seal from the large spring.

Re-lubricate the impeller’s shaft, then carefully slide the rotating

head of the seal over the impeller’s shaft using a twisting

motion. The carbon side of the rotating face should be toward

and pressed against the stationary head of the housing cover.

CAUTION: The carbon portion of the seal is easily

damaged. Take care not to apply uneven force or crack

the carbon while installing.

3. Install the seal’s spring and spring retainer. Compress the spring and

snap the retaining ring (item #8) into the groove on the impeller’s

shaft.

4. Install the assembled seal, impeller and housing cover onto the

motor bracket.

a. If a cooling collar is being used, slide it onto the impeller’s

shaft at this time. Take care to align the water connections

so they are accessible.

b. Install the impeller socket head bolt and cap with o-ring in a

clockwise rotation.

c. Make certain that the housing cover’s o-ring is in place.

d. Place the impeller housing into position and install the hard-

ware. Tighten the six hex-head cap screws to 90 in•lbs.

Multi-Spring Seal

The basic installation procedure for a multi-spring seal is the same as

for the single bellows seal. The exception is that a multi-spring seal has

four (4) set screws which need to be tightened on the impeller shaft.

Double Seal

1. Remove the motor adapter from the motor’s face (it is assumed

that the pump has previously been removed).

2. Install the stationary seal faces.

a. Lubricate the stationary faces’ o-rings with a rubber lubri-

cant emulsion or soapy water. Keep the polished surfaces

of the seal face clean.

Note: Never use a petroleum product for lubrication. Do

ing so will affect the seal elastomer’s performance after

reassembly.

b. Carefully press the stationary faces into the housing cover and

the cooling collar (use a piece of cardboard to protect the seal

while pressing against the stationary face). The smoothest side

of the stationary faces should be facing outward.

Note: If using a special seal material, it is vital that the

special stationary seal face is pressed into the housing cover.

3. Install the rotating faces and cooling collar to the motor adapter.

a. Carefully slide the housing cover over the impeller’s shaft.

The side of the housing cover with the pressed-in seal face

should be away from the impeller.

b. Separate the rotating head of the seal from the spring.

Note: If using a special seal material, it is vital that the

special seal face mates against the housing cover’s sta tionary face.

c. Lubricate the impeller’s shaft, and then carefully slide the

rotating face of the seal over the impeller’s shaft using a

twisting motion. The carbon or special side of the rotating

face should be toward and pressed against the stationary face

of the housing cover.

CAUTION: The carbon or special portion of the seal is

easily damaged. Take care not to apply uneven force or crack

the carbon or special material while installing.

d. Place the seal’s spring into position on top of the installed

rotating face.

e. Re-lubricate the impeller’s shaft and then carefully slide the

second rotating face of the seal over the impeller’s shaft

using a twisting motion (the carbon side of the second

rotating face should be facing away from the other rotating

face). This will require some compression of the seal’s

spring.

f. Place the cooling collar’s o-ring into position. Slide the

cooling collar onto the impeller’s shaft, with the stationary face

in the cooling collar pressed against the second rotating face.

Continue to slide the cooling collar until it mates against the

housing cover. Hold the cooling collar in this position. Take

care to align the water connections so they are accessible.

Notes:

1) The seal’s spring must be compressed further in order to

mate the cooling collar and housing cover.

2) Take care not to pinch the cooling collar’s o-ring. If

the o-ring is not properly seated, the cooling collar will leak.

4. Place the pump components onto the motor adapter. While holding

the cooling collar against the housing cover, install the assembly

into the motor adapter. The motor adapter will hold the cooling

collar in place. It will now be necessary to hold the impeller to

keep the seal’s spring compressed.

5. Carefully place the assembly in position to the motor’s face.

a. In a clockwise rotation, install the impeller socket head bolt and

cap with o-ring. It may be necessary to hold motor’s fan with a

screwdriver to keep the motor shaft from turning.

b. Align the motor adapter so that the access hole is straight up.

c. Install and tighten the impeller’s set screws through the access

hole in the motor adapter (it will be necessary to turn the impeller

to expose the holes in the impeller’s shaft).

4

Page 5

d. Bolt the motor adapter to the motor using the hex-head cap

screws and lock-washers.

e. Double check the alignment of the water connection holes in the

cooling collar.

6. Install the impeller housing.

a. Install the housing cover’s o-ring.

b. Place the impeller housing into position and install the

hardware. Tighten the six hex-head cap screws to 90 in•lbs.

c. Look through the discharge of the pump to verify proper

spacing between the impeller and the housing cover.

TROUBLESHOOTING

NO OR INSUFFICIENT FLOW

1. Pump not primed.

2. Closed valve.

3. Viscosity too high.

4. Air leaks in suction piping.

5. Discharge head higher than anticipated.

6. Suction lift too high or insufficient NPSH. Check also for clogged

suction line.

INSUFFICIENT PRESSURE

1. Air or gasses in liquid.

2. Impeller diameter too small.

3. Discharge head higher than anticipated.

LOSS OF PRIME

1. Leaking suction line.

2. Foot valve or suction opening not submerged enough.

3. Foot valve too small or leaking.

4. Air or gasses in liquid.

5. Foreign matter in impeller.

EXCESSIVE POWER CONSUMPTION

1. Head lower than rating. Excessive flow.

2. Specific gravity or viscosity of liquid is too high.

EXCESSIVE VIBRATION

1. Loose piping or bolts.

2. Pump cavitating from improper suction or feed.

WARRANTY

Finish Thompson, Inc (manufacturer) warrants this pump product to be

free of defects in materials and workmanship for a period of one year

from date of purchase by original purchaser. If a warranted defect, which

is determined by manufacturer’s inspection, occurs within this period, it

will be repaired or replaced at the manufacturer’s option, provided (1) the

product is submitted with proof of purchase

charges are prepaid to the manufacturer. Liability under this warranty is

expressly limited to repairing or replacing the product of parts thereof

date and (2) transportation

and is in lieu of any other warranties, either expressed or implied. This

warranty does apply only to normal wear of the product or components.

This warranty does not apply to products or parts broken due to, in

whole or in part, accident, overload, abuse, chemical attack, tampering,

or alteration. The warranty does not apply to any other equipment used

or purchased in combination with this product. The manufacturer accepts

no responsibility for product damage or personal injuries sustained when

the product is modified in any way. If this warranty does not apply,

the purchaser shall bear all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential damages

including, but not limited to process down time, transportation costs,

costs associated with replacement or substitution products, labor costs,

product installation or removal costs, or loss of profit. In any and all

events, manufacturer’s liability shall not exceed the purchase price of

the product and/or accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the product’s

materials of construction, which are compatible with the fluid(s) that

come(s) in contact with the product. The user may consult Finish

Thompson, Inc. (manufacturer) and a manufacturer’s representative/

distributor agent to seek a recommendation of the product’s material of

construction that offers the optimum available chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising out of

a reaction, interaction or any chemical effect that occurs between the

materials of the product’s construction and fluids that come into contact

with the product’s internals.

Call our toll free Technical Service Hot Line, 1-800-888-3743, if you

have any questions regarding product operation or repair.

ORDERING SPARE PARTS

Spare parts can be ordered from your local distributor. Always refer to

pump model number to avoid error.

OTHER FTI PRODUCTS

Drum Transfer Pumps are available in sanitary construction, stainless

steel, polypropylene and CPVC. Flows to 40 gpm, discharge heads to

80 feet and viscosities to 100,000 cP.

Portable Mixers for turbine mixing and blending handle viscosities to

1,000 cP with gentle, non-vortex circulation. Available in 316 stainless

steel construction.

Sealless Mag Drive Centrifugal Pumps in polypropylene and CF PVDF.

Ansi-dimensional mag drives in ETFE lined ductile iron. Flows to 330

gpm and discharge heads to 325 feet. Handle temperatures up to 220°F

(104°C) and have run-dry capability. Mount to standard frame motors.

For further information, contact FTI or your local distributor.

TECH SERVICE 1-800-888-3743

P/N J102611, Rev. 13, 3-26-13

Lit. ID No. FT95-574J

5

Loading...

Loading...