Page 1

AK / AV 4 & 5 SERIES

Metallic Vertical Centrifugal Pumps

Installation and Maintenance Instructions

ASSEMBLY

PUMPS WITH MOTORS

1. No assembly required. Simply unpack the pump and motor

and examine for any signs of shipping damage. If damage is

detected, save the packaging and notify the carrier immediately.

2. To install the pump into the system, follow the installation

instructions provided.

PUMPS WITHOUT MOTORS

1. Unpack the pump and any supplied accessories and examine

for damage. If damage is detected, save the packaging and

notify the carrier immediately.

2. Lay the motor on its side. Install the slinger ring (item 2)

onto the motor shaft. After coating the motor shaft threads

with a thread lube, thread the pump shaft (item 8) onto the

motor shaft about 3 full turns. Install the four set screws

(item 6) in the motor end of the pump shaft, but do not

tighten.

3. Gently place the motor on the fan cover so the pump shaft

points straight up. Install the mounting plate (item 1) with

the four locating tabs (these are welded on one side of the

plate) facing the motor and locating on the raised motor face.

Slide column assembly (item 7) over the pump shaft and attach to the motor with the four mounting bolts, flat washers

and lock washers (items 5,3, 4) going through the column

flange and the mounting plate.

4. Lay the pump on its side and remove the fan cover from the

motor.

8. On AK/AV 4 models, spin the fan blade and visually check

to make sure all four impeller fins are not rubbing and are

straight in relationship to the back head section of the column

assembly. Gently adjust the fins if necessary.

9. Install the impeller housing (item 16) (without the o-ring) and

hold in place with your hand. Spin the fan blade while listening and feeling for impeller rubbing. Pump shaft adjustment

can be made if necessary.

10. Replace the motor fan cover and gently place the pump on the

motor fan cover.

11. Clean the o-ring sealing area on the back head section of the

column assembly and the impeller housing. Lubricate the

o-ring (item 10) with a compatible lubricant.

12. Install the impeller housing and v-clamp (item 11). Impeller

housings with the discharge attached need to be inserted into

the hole in the mounting plate and visually aligned with the

column assembly. Snug the nut on the v-clamp.

13. The alignment for the discharge can be adjusted by tapping

the impeller housing discharge left or right with a rubber mallet. Visually check that the discharge is parallel to the column

assembly and it goes through the mounting plate straight.

14. Once the discharge alignment is correct the v-clamp nut can be

tightened.

15. Insert a 1/2” socket into the suction and spin the impeller to

check clearances.

16. Install the pump into the system following the installation

instructions provided.

INSTALLATION

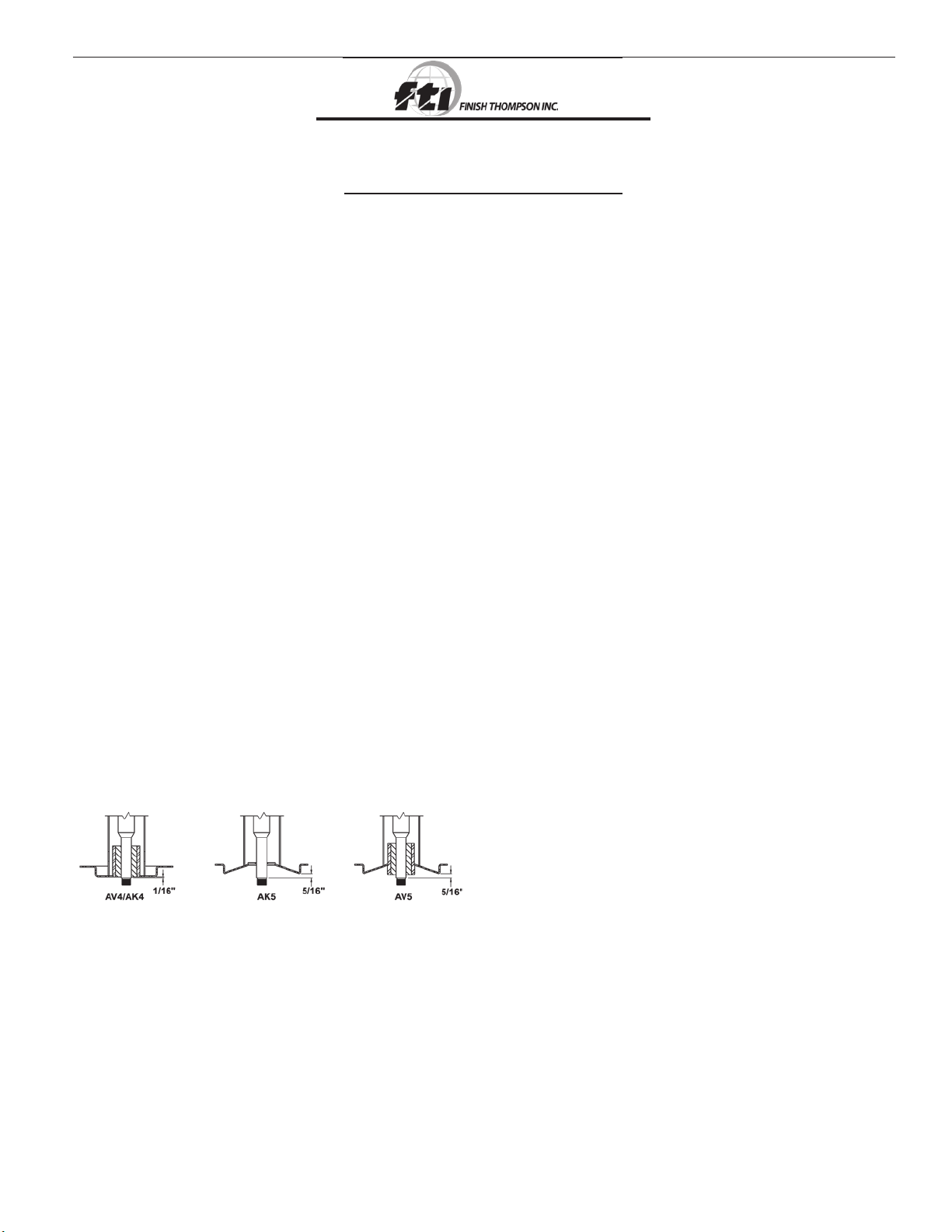

Figure 1

5. Holding the motor fan, adjust the pump shaft by threading

clockwise or counterclockwise until the pump shaft shoulder

is set correctly (see figure 1).

6. Tighten the setscrews in the pump shaft through the access

hole at the motor end of the column assembly.

7. After applying a thread lube, thread the impeller (item 12) on

until it bottoms out on the pump shaft shoulder. Install the

5/16 bolt, washer and lock washer (items 15, 13, 14) in the

impeller end of the pump shaft.

MOUNTING:

1. Base plate must be securely fastened so that there is no vibration

when the pump is running.

2. Align the piping with the pump ports. Do not connect the piping

until it is aligned properly and supported independently. Do not

pull the piping in line with the pump or support the piping with

the pump.

3. A valve should be installed in the discharge line. During initial

operation of the pump, determine the power consumed. If

necessary, throttle back the flow until the pump draws the

rated horsepower of the motor.

1

Page 2

PIPING TO AND FROM THE PUMP:

Figure 2

Always support the piping near the pump to minimize stress

and strain.

Minimize frictional losses by increasing the piping size by one

diameter.

Use a minimum number of bends, keeping any bends a mini-

mum distance of ten pipe diameters from the pump.

Install a valve on the discharge line to control the flow. Place

the valve within a distance of ten pipe diameters from the

pump.

Ensure that the pump is leak free.

Maintain a flooded suction at all times. Use a float switch to turn

off the pump at low level.

CAUTION: Suction prime must be maintained at all times.

Running the pump dry will cause damage to the pump

components. To protect the pump if prime is lost, use a

pressure switch on the discharge or a motor power monitor

to monitor motor current draw.

Note: AK4 & AK5 can be run dry without damage since they have no

lower bushing.

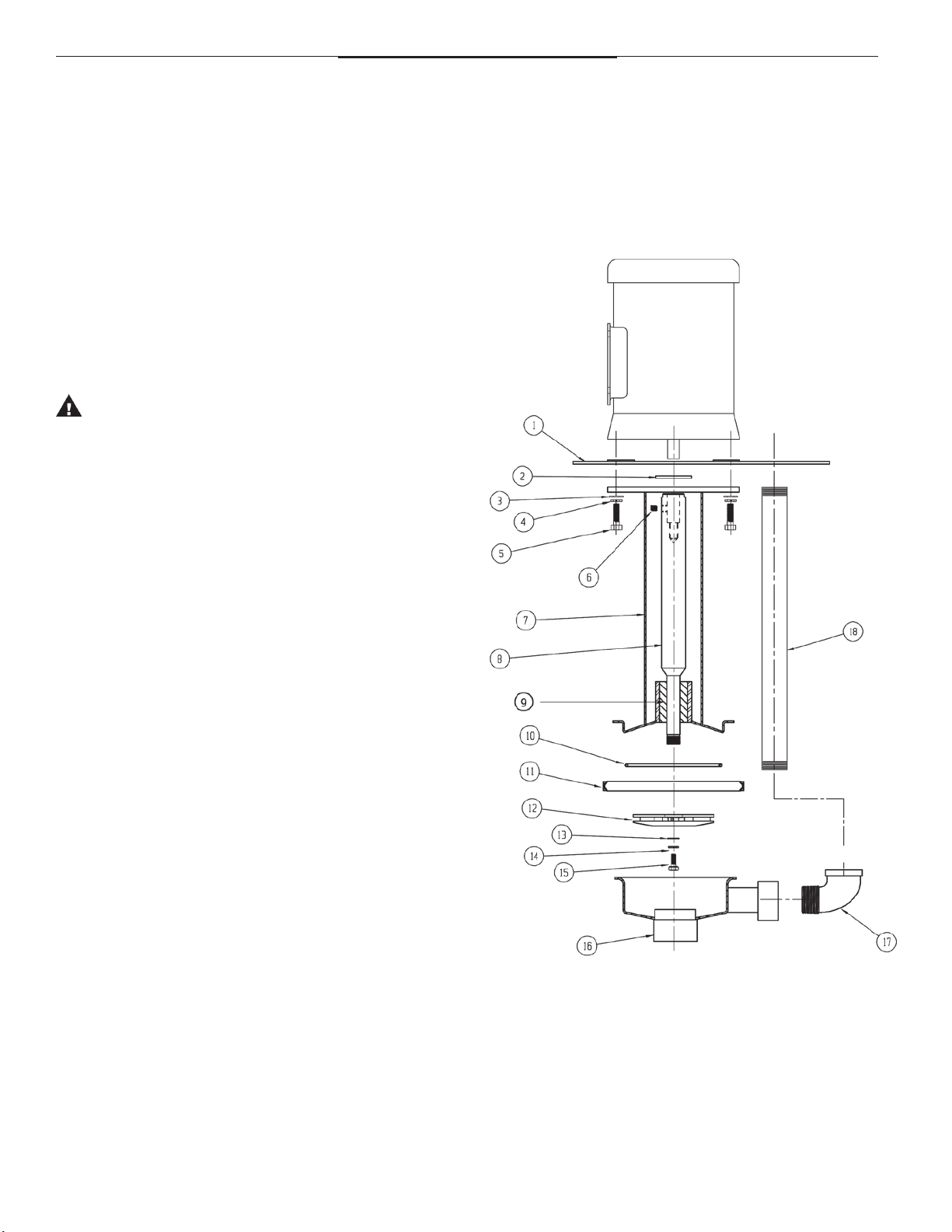

AK/AV Parts Drawing

ELECTRICAL CONNECTIONS:

1. Perform the motor wiring according to NEC requirements and

local electrical codes.

2. Wire the motor for clockwise rotation when facing the fan end

of the motor.

3. To verify correct motor rotation:

a. Install the pump into the system.

b. Fully open the suction and the discharge valves.

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry, as this will cause damage to pump components.

d. Jog the motor (allow it to run for only one to two seconds)

and observe the rotation of the motor fan. Refer to the

directional arrow on the pump if needed.

Note: A pump running backwards will pump, but a greatly reduced

flow and pressure.

OPERATION

1. Partially open the discharge valves.

2. Start the pump and verify liquid is flowing. If there is no liquid

flow, refer to the “Troubleshooting” section of these instructions.

3. Adjust the flow rate and pressure by regulating the discharge

valve.

2

Page 3

AK/AV 4 & 5 PARTS LIST

3

Page 4

TROUBLESHOOTING

NO OR INSUFFICIENT FLOW:

1. No liquid in the sump

2. Closed valve.

3. Viscosity too high.

4. Discharge head higher than anticipated.

5. Suction too close to the bottom of the sump.

INSUFFICIENT PRESSURE:

1. Air or gasses in liquid.

2. Discharge head higher than anticipated.

EXCESSIVE POWER CONSUMPTION:

1. Head lower than rating.

2. Specific gravity or viscosity of liquid is too high.

EXCESSIVE VIBRATION:

1. Loose piping or bolts.

2. Suction too close to the bottom of the sump.

WARRANTY

Finish Thompson, Inc (manufacturer) warrants this pump product to be

free of defects in materials and workmanship for a period of180 days

from date of purchase by original purchaser. If a warranted defect,

which is determined by manufacturer’s inspection, occurs within this

period, it will be repaired or replaced at the manufacturer’s option,

provided (1) the product is submitted with proof of purchase date and

(2) transportation charges are prepaid to the manufacturer. Liability

under this warranty is expressly limited to repairing or replacing the

product of parts thereof and is in lieu of any other warranties, either

expressed or implied. This warranty does apply only to normal wear of

the product or components. This warranty does not apply to products

or parts broken due to, in whole or in part, accident, overload, abuse,

chemical attack, tampering, or alteration. The warranty does not apply

to any other equipment used or purchased in combination with this

product.

The manufacturer accepts no responsibility for product damage or

personal injuries sustained when the product is modified in any way. If

this warranty does not apply, the purchaser shall bear all cost for labor,

material and transportation.

Manufacturer shall not be liable for incidental or consequential damages

including, but not limited to process down time, trans-portation costs,

costs associated with replacement or substi-tution products, labor

costs, product installation or removal costs, or loss of profit. In any

and all events, manufacturer’s liability shall not exceed the purchase

price of the product and/or accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the product’s

materials of construction, which are compatible with the fluid(s) that

come(s) in contact with the product. The user may consult Finish

Thompson, Inc. (manufacturer) and a manufacturer’s representative/

distributor agent to seek a recommendation of the product’s material of

construction that offers the optimum available chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising out

of a reaction, interaction or any chemical effect that occurs between

the materials of the product’s construction and fluids that come into

contact with the product’s internals.

ORDERING SPARE PARTS

Spare parts can be ordered from your local distributor. Always refer

to the pump model number to avoid error.

OTHER FINISH THOMPSON PRODUCTS

Finish Thompson manufactures a diverse range of pumps including

drum/barrel fluid transfer, plastic or metallic magnetic drive and

plastic or stainless steel mechanical sealed centrifugal pumps. For

more information on these products visit our web site at www.

finishthompson.com or contact your local distributor.

Call our Technical Service Hot Line, 1-800-888-3743, if you have any

questions regarding product operation or repair.

SERVICE 800-888-3743

J103017, Rev7, 4.30.12

4

Loading...

Loading...