Page 1

AC 4 & 5 HORIZONTAL SERIES

Sealed Metallic Centrifugal Pumps

Installation and Maintenance Instructions

ASSEMBLY

PUMPS WITH MOTORS

1. No assembly required. Unpack the pump and motor and examine

for any signs of shipping damage. If damage is detected, save the

packaging and notify the carrier immediately.

2. Proceed to the “Installation” section of these instructions.

PUMPS WITHOUT MOTORS

Note: Do not remove shipping plug located in suction port of the

pump until the pump is completely assembled onto the motor.

1. Unpack the pump and examine for any signs of shipping damage.

If damage is detected, save packaging and notify the carrier immediately.

2. Place the motor on the fan cover. Align any set screw (item 9) with

key slot in motor shaft. Place the aluminum motor adapter (item

8) onto the motor rabbet. Position the slot (shaft sleeve set screw

access hole) in motor adapter with the top of the motor. Line up

the bolt holes in the motor adapter with the bolt holes in the motor

face. Install (4) bolts and lock washers (items 10,11). Securely

tighten.

3. Through the top and bottom access holes, tighten securely two of

the four set screws on the shaft adapter (item 6). You will need an

1/8” Allen wrench for this.

4. Remove the screw from the shipping plug and then remove the plug

from the suction port. Rotate the motor fan until you can tighten

the two remaining set screws on the shaft adapter.

5. Rotate the motor fan by hand and check for impeller rubbing. If

the impeller rubs loosen the shaft adapter set screws and adjust

the impeller accordingly. Retighten the shaft adapter set screws.

6. Proceed to the “Installation” section of these instructions.

INSTALLATION

MOUNTING

Motor or base plate must be securely fastened.

PIPING TO AND FROM THE PUMP

• Always support the piping near the pump to minimize stress

and strain on the pump’s casing.

• Minimize frictional losses by increasing the suction piping size

by one diameter.

• Use a minimal number of bends on suction piping. Keep

bends beyond a distance of ten pipe diameters from the pump.

• Install shut off valve on the suction line and flow control valve

in the discharge line. Place the valves beyond a distance of ten

pipe diameters from the pump.

• Ensure that the piping is leak free.

• Position the pump as close to the liquid source as possible.

• Maintain a flooded suction at all times or prime the pump and

maintain prime at all times.

CAUTION: Suction prime must be maintained at all times.

Running the pump dry will cause damage to pump components.

To protect the pump if prime is lost, use a pressure switch on the

discharge, a vacuum switch on the suction, or a motor minder to

monitor motor current draw.

PUMPING LIQUIDS THAT MAY SOLIDIFY OR CRYSTALLIZE:

Add a flush system to the pump’s piping to prevent accumulation of material

inside the pump. Install water inlet and outlet valves as shown in Figure 1.

Refer to the “Operation” section of these instructions for the flush procedure.

Figure 1

ELECTRICAL CONNECTIONS

1. Perform the motor wiring according to NEC requirements and local

electrical codes.

2. Wire the motor for clockwise rotation when facing the fan end of the

motor.

3. To verify correct rotation of the motor:

a. Install the pump into the system.

b. Fully open the suction and discharge valves.

c. Allow fluid to flow into the pump. Do not allow the pump

to run dry. Running the pump dry can damage internal parts.

d. Jog the motor (allow it to run for only 1-2 seconds) and

observe the rotation of the motor fan. Refer to the directional

on the arrow pump if needed.

NOTE: A pump running backwards will pump, but at a greatly

reduced rate.

OPERATION

FLOODED SUCTION SYSTEMS

1. Fully open the suction and discharge valves.

2. Start the pump and verify liquid is flowing. If there is no liquid

flow, refer to the “Troubleshooting” section of these instructions.

3. Adjust the flow rate and pressure by regulating the discharge valve.

CAUTION: Never attempt to adjust the liquid flow with the suction

valve. Limiting suction will damage pump components.

FLUSHING SYSTEMS EQUIPPED WITH FLUSH VALVES:

1. Fully close the suction and discharge valves.

2. Connect the water supply to the water inlet valve and connect a

drain hose to water outlet valve.

3. Turn on the water supply and open the inlet and outlet valves. Flush

the system until the pump has been cleared of any material buildup

(usually approximately 5 minutes).

4. Close the water inlet and outlet valves and turn off water supply.

1

Page 2

MAINTENANCE

DISASSEMBLY

1. Disconnect power. Remove electrical wiring.

2. Close the suction and discharge valves and disconnect all piping.

3. Loosen and remove the nut on the V-clamp stud. Remove the Vclamp (item 2) and the impeller housing (item 1). Note V-clamp

stud and discharge spout location for reassemble alignment.

4. Remove the motor fan cover and fan. Secure the motor shaft to

prevent it from turning, and unthread the impeller.

NOTE: Shaft adapter threads are coated with Loctite Threadlocker

#262 to prevent the impeller from spinning off if the motor is inadvertently wired for incorrect rotation. If necessary follow Loctite’s

recommendations for loosening the threadlocker #262.

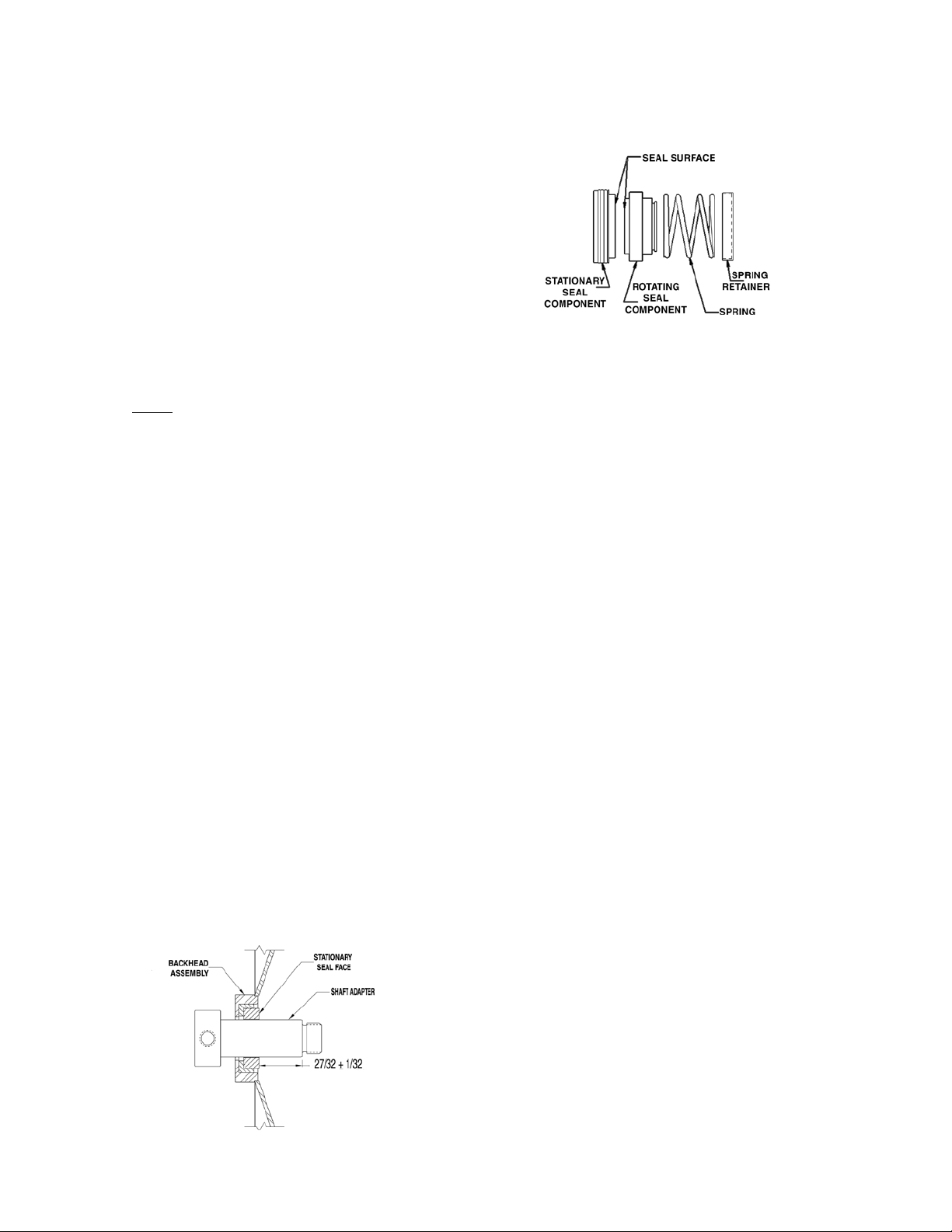

5. Remove the seal spring retainer, spring, and the rotating seal

component from the shaft adapter. Remove the backhead (item

7) from the pump. Remove the stationary part of the seal from

the backhead.

6. If the motor is being replaced, proceed to step 7. If the seal is being

replaced, do not loosen or remove the shaft adapter (item 6) from

the motor shaft. Proceed to step 3 of the reassembly instructions

7. Remove the four bolts holding the motor adapter/mounting plate

assembly (items 8 & 15) to the motor and remove the motor

adapter. Loosen all four setscrews and remove the shaft adapter.

8. Inspect all parts for wear and replace as required. Note the finish on the shaft adapter where the rotating seal boot is located. If

damaged or not smooth, replace the shaft adapter.

REASSEMBLY

1. Install the shaft adapter (item 6) onto the motor shaft. Be sure one

of the setscrews is protruding into the motor shaft keyway slot, but

do not tighten any setscrews yet.

2. Install the motor adapter/mounting plate assembly (8 & 15) with

setscrews access slots at 12 and 6 location, and tighten all four

bolts.

3. Lubricate the outer boot on the stationary part of the seal with a

chemically compatible lubricant, and press into the backhead (item

7) until it is fully seated. The polished seal surface should be facing

away from the motor.

NOTE: To keep the polished surface of the seal face clean, use a

piece of cardboard to protect the seal face during installation.

4. Insert the backhead (item 7) into the motor adapter (item 8) bore

and press into place.

If the shaft adapter was not loosened or removed, go to step 5. If

replacing the shaft adapter, firmly hold the backhead toward the

motor, and adjust the shaft adapter until the shoulder is .843 (27/32)

inches from the stationary seal face (see figure 2). Tighten all four

setscrews with a T wrench through the access slots in the motor

adapter.

Figure 2

5. Lubricate the inside of the rotating seal component with a chemically

compatible lubricant and carefully slide it over the shaft adapter

with a rotating face pointing at the motor (as shown in figure 3).

NOTE: Rotating seal must be completely seated against the station-

ary seal face.

Figure 3

6. Place the seal spring and spring retainer over the shaft adapter.

NOTE: To prevent spinning the impeller off in case the motor is

wired for incorrect rotation, it is recommended to coat the shaft

adapter threads with Loctite Threadlocker #262.

7. Holding the motor shaft firmly, thread the impeller onto the shaft

adapter until it stops at the adapter shoulder.

8. Lubricate the housing o-ring (item 3) with chemically compatible

lubricant, and install onto the backhead. Install the impeller housing (item 1), the V-clamp (item 2), and the nut onto the V-clamp

stud. Verify the V-clamp stud and housing discharge orientation

and tighten the V-clamp. Firmly tap the V-clamp to seat it in several

places and retighten the V-clamp nut.

9. Rotate the motor shaft by hand to verify there is no rubbing. Replace

the motor fan and fan cover. Reinstall the pump into the system.

TROUBLESHOOTING

NO OR INSUFFICIENT FLOW

1. Pump not primed.

2. Closed valve.

3. Viscosity too high.

4. Air leaks in suction piping.

5. Discharge head higher than anticipated.

6. Suction lift too high or insufficient NPSH.

7. Check for clogged suction line.

8. Motor wired for wrong rotation.

INSUFFICIENT PRESSURE

1. Air or gas in liquid.

2. Impeller diameter too small.

3. Discharge head higher than anticipated.

4. Motor speed insufficient (too low) or motor rotation incorrect.

LOSS OF PRIME

1. Leaking suction line.

2. Foot valve or suction opening not submerged enough.

3. Foot valve too small or leaking.

4. Air or gas in liquid.

5. Foreign matter in impeller.

EXCESSIVE POWER CONSUMPTION

1. Head lower than rating. Excessive flow.

2. Specific gravity or viscosity of liquid is too high.

EXCESSIVE VIBRATION

1. Loose piping or bolts.

2. Pump cavitating from improper suction or feed.

2

Page 3

AC4 EXPLODED VIEW

11

8

10

15

2

9

6

3

7

5

4

1

12

14

13

AC5 EXPLODED VIEW

17

8

16

12

11

Item Qty Description

Impeller Housing

AC4 3/4” x 1/2” A102106-1*

1 1

2 1

3 1

4 1

**To order a housing with BSP threads, substitute the number following the dash with the number in parentheses.

*Universal FNPT & BSP

AC5 1 1/4” x 3/4” A102113-1(2) A102112-2(4)

AC5 1 1/2” x 1 1/4 A102112-1(3) A102133-3(4)

AC5 2” x 1 1/2” A102133-1(2)

AC5H 1/2” x 1/4” (high head) A102120-1(2)

V-Clamp

O-Ring

FKM J 102946 J102960 J102960

EPDM J103004 J103003 J103003

Buna (FDA compliant) 108213 108214 108214

PTFE J103042 J103043 J103043

Impeller

AC4/AC5R 3” A102105-1 A102105-1

AC4 3 1/4” A102105-2 A102105-2

AC4/AC5R 3 1/2” A102105-3 A102105-3

AC5R 3 3/4” A102105-4

AC5R 4 1/2” A102105-5

AC5 4” x 3/8” vane A102114-9

AC5 4 1/4” x 3/8” vane A102114-10

AC5 4 1/2” x 3/8” vane A102114-11

AC5 4 3/4” x 3/8” vane A102114-12

AC5 4” x 1/4” vane A102114-1

AC5 4 1/4” x 1/4” vane A102114-2

AC5 4 1/2” x 1/4” vane A102114-3

AC5 4 3/4” x 1/4” vane A102114-4

AC5H 4 3/4” x 1/8” vane (high head) A102183

AC4 Part

J102947 J102947 J102947

14

Number

15

9

6

13

10

FNPT (BSP)**

3

4

5

7

AC5 Part Number

AC5S

1

2

AC5R

FNPT (BSP)**

3

Page 4

Item Qty Description

Seal

3/4” Carbon/Ceramic/FKM Seal J102957-1 J102957-1 J102957-1

3/4” Carbon/Ceramic/EPDM Seal J102957-2 J102957-2 J102957-2

5 1

6 1

7 1

8 1

9 4

10 4

11 4

12 1

13 4

14 4

15 1

16 1

17 4

3/4” Carbon/Ceramic/Buna Seal (FDA compliant) 108073 108073 108073

3/4” Carbon/Ceramic/Kalrez Seal J103081 J103081 J103081

3/4” Silcarb./Silcarb./FKM Seal J103066 J103066 J103066

3/4” Silcarb./Silcarb./EPDM Seal J103067 J103067 J103067

Shaft Adapter w/ Set Screws

56C Frame A102895 A102895 A102895

71-B14 Frame A102896 A102896 A102896

80 Frame A102897 A102897

90 Frame A102898 A102898

Backhead

Motor Adapter

56C Frame M102049-1 M102049-1 M102049-1

71-B14 Frame M102049-2 M102049-2 M102049-2

80 Frame M102049-3 M102049-3

90 Frame M102049-4 M102049-4

1/4-20 x 1/4” Cup Point Set Screw

Hex Head Cap Screw

3/8-16 x 1” (56C Frame) J100114 J100114 J100114

M6 x 25 mm (71-B14 & 80 Frame) J103456 J103456 J103456

M8 x 40 mm (90 Frame) J102760 J102760

Lock Washer

3/8” (56C) J100115 J100115 J100115

5/16” (90 Frame only) J101282 J101282

1/4” (71-B14 & 80 Frame) J100672 J100672 J100672

Slinger Ring

56C Frame M102064-1 M102064-1 M102064-1

71-B14 Frame M102064-2 M102064-2 M102064-2

80 Frame M102064-3 M102064-3

90 Frame M102064-4 M102064-4

Cap Screw Fillister Head (all)

#10 Lock Washer (all)

Mounting Plate

Metric Motor Adapter (90 Frame only)

Flat Washer - 5/16” (90 Frame only)

AC4 Part

Number

A102110-1 A102121-1 A102121-1

J100220 J100220 J100220

J100932 J100932 J100932

J100824 J100824 J100824

J103389-1 J103389-1 J103389-1

AC5S Part

Number

AC5R Part

Number

M102129

J101293

SAFETY PRECAUTIONS FOR ATEX PUMPS

WARNING: Proper materials of construction must be chosen for the fluid being pumped. Improper material selection could lead to pump

failure and leakage. This is the responsibility of the end user.

WARNING: ATEX pumps must have a power monitor, flow switch, pressure switch or similar device installed to protect against running

dry, closed discharge valve, major leaks, and possible sources of ignition due to motor bearing failure. Any of these conditions could lead

to a rise in surface temperature of the pump. The device must be set to stop the pump within three seconds of a fault.

WARNING: The pump must be checked for leaks on a regular basis. If leaks are detected, the pump must be repaired or

replaced immediately.

WARNING: The pump must be cleaned on a regular basis to avoid dust buildup greater than 5mm.

TEMPERATURE CLASSIFICATION

Pump temperature is completely dependent on operating conditions. Pump will transfer heat from the piping system, motor, and fluid.

These items must be considered as a system when assessing an ATEX application.

4

Page 5

WARRANTY

Finish Thompson, Inc (manufacturer) warrants this pump product

to be free of defects in materials and workmanship for a period of

one year from date of purchase by original purchaser. If a warranted defect, which is determined by manufacturer’s inspection,

occurs within this period, it will be repaired or replaced at the

manufacturer’s option, provided (1) the product is submitted with

proof of purchase date and (2) transportation charges are prepaid

to the manufacturer. Liability under this warranty is expressly

limited to repairing or replacing the product of parts thereof and

is in lieu of any other warranties, either expressed or implied.

This warranty does apply only to normal wear of the product or

components. This warranty does not apply to products or parts

broken due to, in whole or in part, accident, overload, abuse,

chemical attack, tampering, or alteration. The warranty does not

apply to any other equipment used or purchased in combination

with this product.

The manufacturer accepts no responsibility for product damage

or personal injuries sustained when the product is modified in

any way. If this warranty does not apply, the purchaser shall bear

all cost for labor, material and transportation.

Manufacturer shall not be liable for incidental or consequential

damages including, but not limited to process down time, transportation costs, costs associated with replacement or substitution

products, labor costs, product installation or removal costs, or

loss of profit. In any and all events, manufacturer’s liability shall

not exceed the purchase price of the product and/or accessories.

CHEMICAL REACTION DISCLAIMER

The user must exercise primary responsibility in selecting the

product’s materials of construction, which are compatible with the

fluid(s) that come(s) in contact with the product. The user may

consult Finish Thompson, Inc. (manufacturer) and a manufacturer’s

representative/distributor agent to seek a recommendation of the

product’s material of construction that offers the optimum available

chemical compatibility.

However neither manufacturer nor agent shall be liable for product

damage or failure, injuries, or any other damage or loss arising out

of a reaction, interaction or any chemical effect that occurs between

the materials of the product’s construction and fluids that come into

contact with the product’s internals.

Call our toll free Technical Service Hot Line, 1-800-888-3743, if you

have any questions regarding product operation or repair.

Tech Service: 800-888-3743

P/N J103334, Rev. 17, 3/5/13

Lit. I.D. No. FT98-718O

5

Loading...

Loading...