Page 1

Product Specification

RoHS-6 Compliant

10GBASE-LRM X2 Transponder

FTLX1341E2

PRODUCT FEATURES

Hot pluggable X2 MSA form factor

Total power consumption: 4.0 W maximum

RoHS-6 compliant (lead-free)

Temperature range 0°C to 70°C

Transmission distance up to 220m

Uncooled 1310 nm directly modulated

Fabry-Perot (FP) laser

Built In Advanced Electronic Dispersion

Compensation (EDC)

SC connector, multimode fiber

Full duplex transmission mode

Digital Optics Monitoring (DOM)

Power supply: +5.0 V, +3.3 V

Adaptable Power Supply (APS: +1.2 V)

XAUI electrical interface

- 4 x 3.125 Gb/s Ethernet

Management and control via MDIO

2-wire bus

70-pin connector

Separated signal/chassis ground

Mid Pak module variance for

front panel mounting

De-latch mechanism with low

extraction force

*

APPLICATIONS

IEEE 802.3aq-2006

10 Gb/s Ethernet transmission on

legacy multimode fiber.

The Finisar FTLX1341E2 transponder incorporates Electronic Dispersion Compensation (EDC)

which provides correction for the severe modal dispersion that may occur during propagation

through links up to 220m on legacy installed FDDI multimode fiber. The EDC device

incorporates a Feed Forward Equalizer (FFE) and a Decision Feedback Equalizer (DFE). The

EDC also contains sophisticated clock recovery architecture for extracting a robust clock from

extremely distorted signals.

PRODUCT SELECTION

FTLX1341E2

* Maximum reach as defined by IEEE. Longer reach possible depending upon link implementation.

© Finisar Corporation – October 2008 Rev B Page 1

Page 2

FTLX1341E2 Product Specification – October 2008

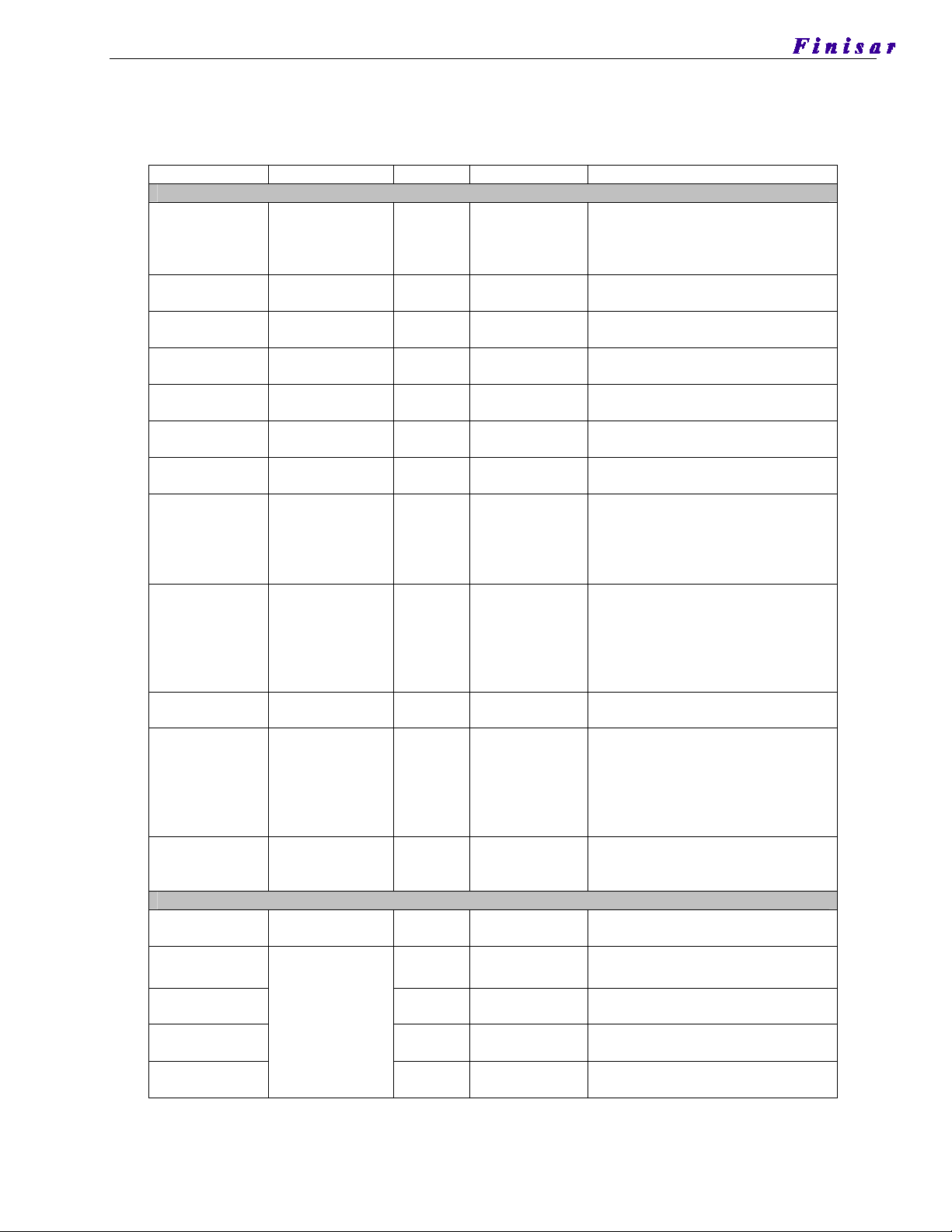

I. Pin Description

Signal Name Level I/O Pin No. Description

Management and Monitoring Ports

MDIO Open Drain

(output)

1.2V CMOS

(input)

MDC 1.2 V

CMOS

PRTAD4 1.2 V

CMOS

PRTAD3 1.2 V

CMOS

PRTAD2 1.2 V

CMOS

PRTAD1 1.2 V

CMOS

PRTAD0 1.2 V

CMOS

LASI Open Drain O 9 Link Alarm Status Interrupt Output.

RESET 1.2 V

CMOS

Vendor Specific 11,15,16,24 Vendor Specific Pins.

TX ON/OFF 1.2 V

CMOS

MOD DETECT O 14 Module Detect. Pulled low inside

Transmit Functions

Reserved

Reserved

TX LANE 3–

TX LANE 3+

TX LANE 2–

TX LANE 2+

TX LANE 1–

TX LANE 1+

TX LANE 0–

TX LANE 0+

I

AC-coupled,

Internally biased

differential

XAUI

I/O 17 Management Data I/O. Requires

external 10 - 22 kΩ pull-up to the

APS on host.

I 18 Management Data Clock Input

1 19 Port Address Input bit 4

I 20 Port Address Input bit 3

I 21 Port Address Input bit 2

I 22 Port Address Input bit 1

I 23 Port Address Input bit 0

Open Drain Compatible Output with

10 - 20 kΩ pull-up on host.

Logic high = Normal Operation

Logic low = Status Flag Triggered

I 10 Reset Input.

Open Drain Compatible Input with

22 kΩ pull-up to APS internal to

transponder.

Logic high = Normal Operation

Logic low = RESET

Leave unconnected when not used.

I 12 TX ON/OFF Input.

Open Drain Compatible Input with

22 kΩ pull-up to APS internal to

transponder.

Logic high = Transmitter On

Logic low = Transmitter Off

transponder through a 1 kΩ resistor

to Ground

68

I

I

I

I

I

I

I

I

I

67

65

64

62

61

59

58

56

55

Reserved For Future Use

Reserved For Future Use

Module XAUI Input Lane 3–

Module XAUI Input Lane 3+

Module XAUI Input Lane 2–

Module XAUI Input Lane 2+

Module XAUI Input Lane 1–

Module XAUI Input Lane 1+

Module XAUI Input Lane 0–

Module XAUI Input Lane 0+

© Finisar Corporation – October 2008 Rev B Page 2

Page 3

FTLX1341E2 Product Specification – October 2008

Receive Functions

Reserved

Reserved

RX LANE 0+

RX LANE 0–

RX LANE 1+

RX LANE 1–

RX LANE 2+

RX LANE 2–

RX LANE 3+

RX LANE 3–

DC Power

GND 0 V DC 1, 2, 3, 33, 34,

APS +1.2 V 7, 8, 28, 29 Input from Adaptive Power Supply

APS SENSE +1.2 V 27 APS Sense Output. Connected to the

APS SET 25 Feedback input from APS.

3.3 V +3.3 V DC 5, 6, 30, 31 DC Power Input, +3.3 V DC,

5.0 V +5.0 V DC 4, 32 DC Power Input, +5.0 V DC,

Reserved 26 Reserved for APD.

Reserved 13 Reserved.

O

O

AC-coupled,

Internally biased

differential

XAUI

O

O

O

O

O

O

O

O

38

39

41

42

44

45

47

48

50

51

35, 36, 37, 40,

43, 46, 49, 52,

53, 54, 57, 60,

63, 66, 69, 70

Reserved For Future Use

Reserved For Future Use

Module XAUI Output Lane 0+

Module XAUI Output Lane 0–

Module XAUI Output Lane 1+

Module XAUI Output Lane 1–

Module XAUI Output Lane 2+

Module XAUI Output Lane 2–

Module XAUI Output Lane 3+

Module XAUI Output Lane 3–

Ground connection for signal ground

on the module

APS input inside transponder.

Connected to GND through a 1180Ω

resistor inside the transponder.

Nominal

Nominal

© Finisar Corporation – October 2008 Rev B Page 3

Page 4

FTLX1341E2 Product Specification – October 2008

Electrical Pad Layout

Figure 1- X2 Transponder Electrical Pad Layout

II. Absolute Maximum Ratings

Limit Values

Parameter Symbol

min. max.

Unit

Storage Temperature1) TS -40 85 °C

Supply Voltage +5.0 V V5 0 6 V

Supply Voltage +3.3 V V3 0 4 V

Supply Voltage APS V

0 1.5 V

aps

Static Discharge Voltage, All Pins2) STd 500 V

Average Receive Optical Power RxP

Notes:

1) Non-condensing

2) HBM

1.5 dBm

max

Stresses in excess of the absolute maximum ratings can cause permanent damage to the device.

© Finisar Corporation – October 2008 Rev B Page 4

Page 5

FTLX1341E2 Product Specification – October 2008

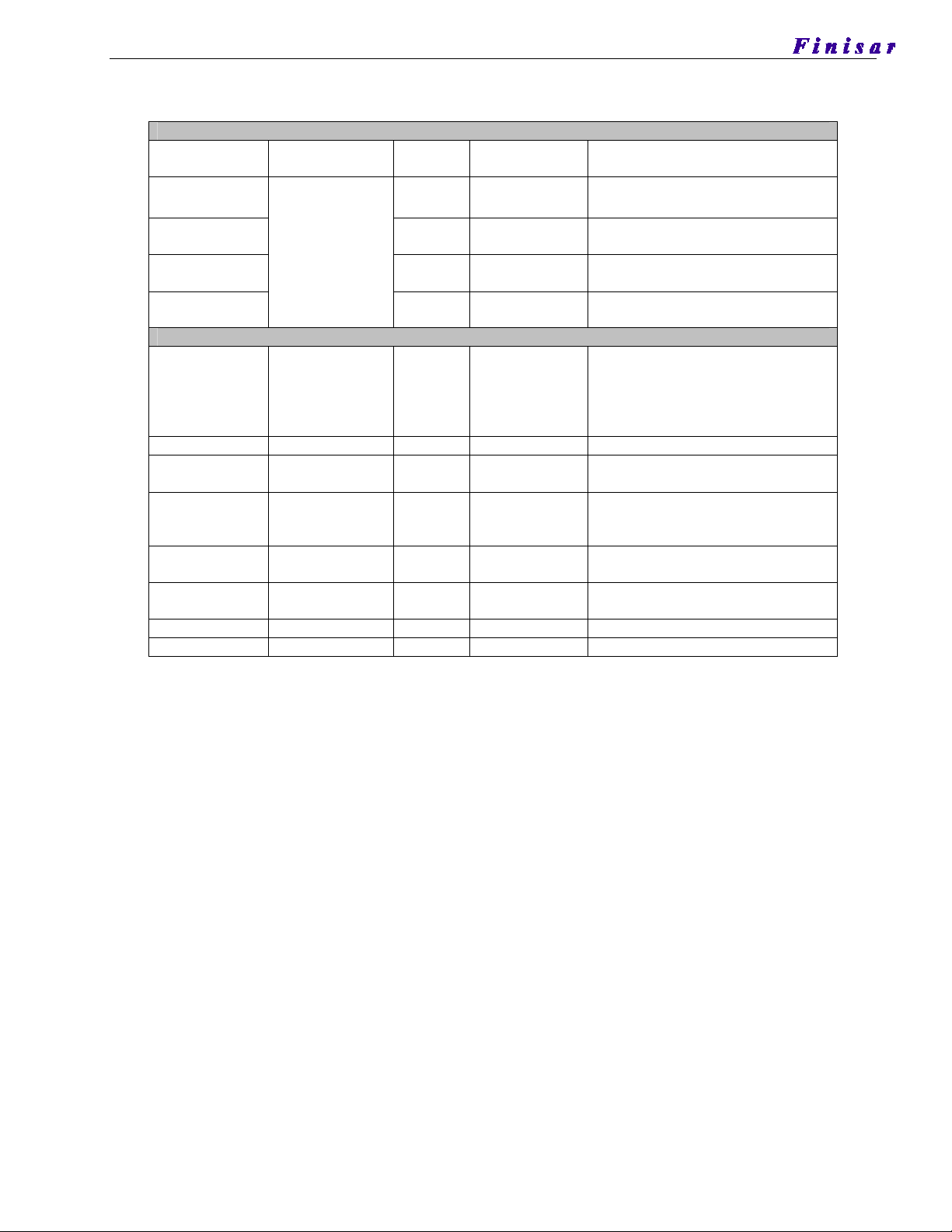

III. Electrical Characteristics

Recommended Operating Conditions

Values

Parameter Symbol

min. typ. max.

Unit

Operating Case Temperature1) TC 0 70 °C

Transponder Total Power

P 4 W

Consumption

Supply Voltage +5.0 V V

Supply Current +5.0 V I

Supply Voltage +3.3 V V

Supply Current +3.3 V I

Supply Voltage APS V

Supply Current APS I

1)

Measured at reference thermal location, see Figure 3.

See also Environmental Performance.

4.75 5.0 5.25 V

CC5

10 mA

CC5

3.14 3.3 3.47 V

CC3

830 mA

CC3

1.152 1.2 1.248 V

CC aps

850 mA

CC aps

Electrical DC Characteristics

(V

= 4.75 V to 5.25 V, V

CC5

= 3.14 V to 3.47 V, V

CC3

= 1.152 V to 1.248 V, TC = 0°C to 70°C)

CC aps

Values

Parameter Symbol

min. typ. max.

1.2 V CMOS (1.8 V CMOS Compatible1)) I/O DC Characteristics

(PRTAD; LASI; RESET; TX_ONOFF)

External Pull-up Resistor for Open Drain R

10 22 kΩ

pullup

Output High Voltage2) Voh 1 V

Output Low Voltage2) Vol 0.15 V

Input High Voltage Vih 0.84 1.5 V

Input Low Voltage Vil 0.36 V

Input Pull-down Current3) Ipd 20 120 µA

MDIO I/O Characteristics (MDIO; MDC)

MDIO Data Hold Time t

10 ns

HOLD

MDIO Data Setup Time tSU 10 ns

Delay from MDC Rising Edge to MDIO

t

300 ns

DELAY

Data Change

MDC Clock Rate ƒ

2.5 MHz

MAX

Output Low Voltage5) VOL –0.3 0.2 V

Output Low Current IOL 20 mA

Input High Voltage VIH 0.84 1.2 1.5 V

Input Low Voltage VIL –0.3 0.36 V

Pull-up Supply Voltage VPU 0.84 1.2 1.5 V

Input Capacitance CIN 10 pF

Load Capacitance C

External Pull-up Resistance R

470 pF

LOAD

200 Ω

LOAD

Power-On Reset AC Characteristics

Power-On Reset and TX_ONOFF

Characteristics

1)

For 1.8 V CMOS V

2)

R

= 10 kΩ to 1.8 V.

pull-up

3)

V

= 1.8 V.

in

4)

AC coupled.

5)

I

= 100 µA.

OL

© Finisar Corporation – October 2008 Rev B Page 5

= 1.65 V min., V

oh

= 0.15 V max., V

ol

According to XENPAK MSA Issue 3.0 Draft 4.0, 2002-9-9

= 1.17 V min., V

ih

= 0.63 V max.

il

Unit

Page 6

FTLX1341E2 Product Specification – October 2008

Electrical AC Characteristics

(V

= 4.75 V to 5.25 V, V

CC5

= 3.14 V to 3.47 V, V

CC3

= 1.152 V to 1.248 V, TC = 0°C to 70°C)

CC aps

Values

Parameter Symbol

min. typ. max.

Unit

XAUI Input AC Characteristics (TXLANE[0..3])

Baud Rate

Ethernet

Baud Rate Tolerance R

Differential Input Impedance Z

R

XAUIIN

3.125

–100 100 ppm

TOLXAUI

80 100 120 Ω

INXAUI

Gbit/s

Differential Return Loss1) |S11| 10 dB

Input Differential Skew2) t

Jitter Amplitude Tolerance3) J

75 ps

SKEWIN

0.65 UI

XAUITOL

p-p

XAUI Output AC Characteristics (RXLANE[0..3])

Baud Rate

Ethernet

Baud Rate Variation R

R

XAUIOUT

XAUIVAR

Gbit/s

3.125

–100 100 ppm

XAUI Eye Mask (far-end) According to IEEE 802.3ae

Output Differential Impedance Z

80 100 120 Ω

OUTXAUI

Differential Output Return Loss1) |S22| 10 dB

1)

100 MHz to 2.5 GHz.

2)

At crossing point.

3)

Per IEEE Std 802.3ae.

IV. Optical Characteristics

RMS Spectral Width Mask

Figure 2-Transmitter Maximum RMS Spectral Width

© Finisar Corporation – October 2008 Rev B Page 6

Page 7

FTLX1341E2 Product Specification – October 2008

Optical Specifications

Parameter Symbol Min Typ Max Unit Ref.

Transmitter

Optical Modulation Amplitude (OMA) P

Average Launch Power P

Peak Launch Power P

Optical Wavelength

@1260nm

λ

Spectral Width

1260nm-

1300nm

λ

1300nm-

OMA

MAX

λ

rms

AVE

λ

rms

@

-4.5 +1.5 dBm

-6.5 +0.5 dBm

+3 dBm

1260 1355

See Figure

@

rms

nm

2.4 1

2

nm

4

1355nm

Optical Extinction Ratio ER

3.5 dB

Optical Eye Mask Margin 0 % 2

Transmitter Waveform Dispersion

Penalty

Average Launch Power of OFF

Transmitter

Uncorrelated Jitter [rms]

Relative Intensity Noise RIN20OMA

Encircled Flux

TWDP 4.7

P

OFF

Tx

j

<5μm

<11μm

-30

0.033

-128 dB/Hz

30

81

dB 3

dBm

UI

%

Tramsmitter Reflectance -12 dB

Receiver

Overload in OMA +1.5 dBm 4

Comprehensive Stressed Receiver

Sensitivity (OMA) @ 10.3125Gb/s

Optical Center Wavelength

Precursor -6.5

Symmetrical -6.0

Postcursor

λ

C

dBm

-6.5

1260 1355

nm

Receiver Reflectance Rrx -12 dB

Signal Detect Deassert Level P

Signal Detect Assert Level P

Signal Detect Hysteresis P

Notes:

1)

Maximum RMS spectral width as specified by Figure 68-3 in IEEE802.3aq -2006

2)

Optical eye mask per IEEE802.3aq -2006.

3)

TWDP is calculated using the Matlab code provided in clause 68.6.6.2 of IEEE802.3aq -2006

4)

Receiver overload specified in OMA and under the worst comprehensive stressed condition.

SDD

SDA

SDH

-14.4 dBm

-25.0 dBm

0.5 1.5 dB

V. General Specifications

Optical Interface Standard Specifications

Fiber Type 850nm OFL Bandwidth Symbol Distance

62.5μm

“FDDI” 160MHz/km 220

OM1 200MHz/km

Lmax

[1]

220

Units

m

400MHz/km 100

50μm

OM2 500MHz/km 220

OM3 2000MHz/km

Notes:

1)

Operating range as defined by IEEE standards. Longer reach possible depending upon link implementation.

© Finisar Corporation – October 2008 Rev B Page 7

Lmax

220

m

Page 8

FTLX1341E2 Product Specification – October 2008

Environmental Performance

Operating case temperature: 0°C to +70°C

Operating humidity: 0% -95% RH non-condensing

Fibers and Connectors

The transponder has SC receptacles for both Tx and Rx. The transponder is designed for multimode

SC cables, 0° polished endface (PC).

70-pin Connector

The module interface connector is a 70-pin, printed circuit board edge connection with a 0.5 mm

pitch. The appropriate mating connector for the customer PCB is a 70-pin SMT, dual row, right

angled, edge connector, 0.5 mm pitch (Tyco Electronics part number 1367337-1, Molex part number

74441-0003 or equivalent).

Rail Requirement

The X2 rail system required to mount the X2 module is fully defined by the MSA.

(Tyco Electronics part number 1367608-1: designed for belly to belly applications;

and 1367610-1, designed for single sided board mount to fit into the standard host PCB

footprint; or equivalent). For further details please refer to vendor-supplied information.

Aqueous Wash

Finisar X2 transponders are neither solderable nor aqueous washable and are not

intended for these processes.

VI. Regulatory Compliance

Feature Standard Comments

ESD:

Electrostatic Discharge to the

Electrical Pins (HBM)

Immunity:

Against Electrostatic Discharge

(ESD) to the Module Receptacle

Immunity:

Against Radio Frequency

Electromagnetic Field

Emission:

Electromagnetic Interference

(EMI)

EIA/JESD22-A114-B

(MIL-STD 883D

Method 3015.7)

EN 61000-4-2

IEC 61000-4-2

EN 61000-4-3

IEC 61000-4-3

FCC 47 CFR

Part 15, Class B

EN 55022 Class B

CISPR 22

Class 1a (> 500 V)

Discharges ranging from

front end / faceplate / receptacle cause no damage

to module (under recommended conditions).

With field strength of 10 V/m, noise frequency

ranges from 10 MHz to 2 GHz. No effect on

module performance between the specification

limits.

Noise frequency range:

30 MHz to 40 GHz

Radiated emission does not exceed specified

limits when measured with module inside a

shielding enclosure with a MSA conforming

cutout.

±2 kV to ±25 kV to the

© Finisar Corporation – October 2008 Rev B Page 8

Page 9

FTLX1341E2 Product Specification – October 2008

Eye Safety

Finisar FTLX1341E2 transponders are Class 1 Laser Products. They are certified per the following

standards:

Feature Agency Standard Certificate

Number

Laser Eye

Safety

Laser Eye

Safety TÜV

FDA/CDRH CDRH 21 CFR 1040 and Laser Notice 50 9210176-77

EN 60825-1: 1994+A11:1996+A2:2001

IEC 60825-1: 1993+A1:1997+A2:2001

R 72082131

IEC 60825-2: 2000, Edition 2

Electrical

Safety

Electrical

Safety

TÜV EN 60950 R 72082131

UL/CSA

CLASS 3862.07

CLASS 3862.87

1439230

Copies of the referenced certificates are available from Finisar Corporation upon request.

VII. DOM Parameters

Values

Parameter

Transponder Temperature Monitor Accuracy1) -5 +5 °C

Laser Bias Current Monitor Accuracy2) -10 +10 %

Transmit Power Monitor Accuracy3) -3 +3 dB

Receive Power Monitor Accuracy3) -3 +3 dB

1)

0 to 70°C case temperature.

2)

0 to 12.5 mA.

3)

-8.2 dBm to +0.5 dBm.

min. typ. max.

Unit

VIII. Mechanical Specifications

Values Parameter Symbol

min. typ. max.

Module Retention Force (latch strength) F

Module Insertion Force FIN 40 N

Module Extraction Force (with kick-out) F

Module Extraction Force (without kick-out) F

200 N

RET

16 N

EXT-K

25 N

EXT

Pull Sleeve front face color is orange.

Unit

© Finisar Corporation – October 2008 Rev B Page 9

Page 10

FTLX1341E2 Product Specification – October 2008

Package Outline

Figure 3-X2 Mechanical Dimensions

IX. References

The following references are provided for informational purposes only. The parameters and

operational behavior outlined in this specification describe the complete functionality of the 10G

Transponder. Contact Finisar for any items concerning the operational characteristics of this device.

1. IEEE 802.3ae-2002, August 30, 2002.

2. IEEE Std 802.3aq™-2006

3. X2 MSA Rev 2.0b, January 30, 2003

X. For More Information

Finisar Corporation

1389 Moffett Park Drive

Sunnyvale, CA 94089-1133

Tel. 1-408-548-1000

Fax 1-408-541-6138

sales@finisar.com

www.finisar.com

© Finisar Corporation – October 2008 Rev B Page 10

Loading...

Loading...