Page 1

Model 703 True RMS Multimeter

Model 701 Multimeter

USER’S

MANUAL

FINE INSTRUMENTS CORPORATION

FINE INSTRUMENTS CORPORATION

341-5, SONGNAE-DONG, SOSA-GU, BUCHON-SHI, KYUNGGI-DO KOREA

-TEL: (82-32) 656-8771~4 -FAX: (82-32) 656-5844

-E-mail: fine@finest.co.kr

© Copyright 2001 Fine Instruments Corp. All right reserved.

Specifications subject to change without notice.

Litho in Korea.

a world leader in test & measurement

Page 2

SOURCES LIKE S MALL HAND-HELD RADIO

TR ANS CE IVERS, FI XED STA TION RADIO

AND TELEVISION TRANSMITTERS, VEHICLE

RA DI O TRANSM ITTERS AND CE L LUL AR

PHONES GENERATE ELECT ROMAGNETIC

RADIATION THAT MAY INDUCE VOLTAGES

IN THE TEST LEADS OF THE MULTIMETER.

IN SU CH CASES THE ACCURA CY OF T HE

MULT IMETER C ANNOT BE GUARAN TEED

DUE TO PHYSICAL REASONS.

W A R N I N G !

Basic Specifications

DC Voltage : 0 to 1000 V

AC Voltage

703 (True RMS) : 15 mV to 1000 V (@ 40 Hz to 20 kHz)

701 : 0 to 1000 V (@ 40 Hz to 400 Hz)

Basic Accuracy : DC voltage – 0.5%

AC voltage – 0.75%

DC Current : 0 to 10 A (20 A for 30 seconds)

AC Current

703 (True RMS) : 20 µA to 10 A (20 A for 30 seconds)

701 : 0 to 10 A (20 A for 30 seconds)

Resistance : 0 to 40 M

Capacitance : 0.01 nF to 100 µF

Frequency : 0.5 Hz to 10 MHz

Duty Cycle : 0.1 % to 99.9 % for 0.5 Hz to 500 kHz

(pulse width > 2 µsec.)

Diode Test : 2.5 V

Continuity Check : Beep at Approx. < 10 (response time < 1 ms)

Temperature (703 only): –40 C to 1300 C (–40 F to 2372 F)

1. Safety Information 2

2. Electromagnetic Compatibility (EMC) 3

3. Controls and Indicators 4

4. Rotary Switch and Pushbutton Overview 7

5. Meter Operation 9

6. Maintenance 19

7. Specifications 20

Limited Warranty & Limitation of Liability

Warning

Read

Safety Information” before using this Meter.

1

CONTENTS

Page 3

INTERNATIONAL ELECTRICAL SYMBOLS

AC (Alternating Current)

DC (Direct Current)

Either AC or DC

Caution! Refer to the explanation in this manual.

Caution! Dangerous voltage (Risk of electric shock)

Earth (Ground)

Double insulation or Reinforced insulation

Fuse

Not Applicable to Identified Model

Battery

The meters meet EN61326 : 1997+A1: 1998. See the backside of this manual’s

cover page.

This manual contains information and warnings that must be followed for operating

the meter safely and maintaining the meter in a safe operating condition.

If the meter is not used in a man ner specified in this manual, the prote ctio n

provided by the meter may be impaired.

The Model 703 an d Model 701 co mply with IEC 1010-1 (1995), UL 3111-1 (6. 1994),

EN 61010-1 (1995), CSA C 22.2 No, 1010.1 - 92 ; Overvoltage 1000V Category III.

TERMS IN THIS MANUAL

A Warning identifies conditions and actions that could pose serious hazards to the

user. A Caution identifies conditions and actions that co uld cause damage the

meter or the equipment under test.

Warning

Do not expose the meter to rain or moisture in order to reduce the risk of fire or

ele ctric shock. To avoid any e lectrical shock hazard, observe the proper safety

precautions when workin g with voltages above 60 V dc o r 30V ac rms, t hese

voltage lev els p ose a potential sh ock hazard to the user. Inspect test leads,

connectors and probes for damaged insulation or exposed metal before using the

meter. If any defects are found, replace them immediately. Do not touch test lead

tips or the circuit being tested while power is applied to the circuit under test.

Always keep your fingers b ehind the f inger guards of the test leads during

mea surement. Do not m easure any circuit that draws more than the protection

fuse’s current rating. Do not attempt the protection fuse’s voltage rating. Never

attempt a voltage measurement with the test lead inserted into the mA µA or

A

input terminal. When servicing the meter, use only specified replace ment parts.

Remove test leads from the meter before you open the battery door. Do not operate

the meter with the battery door removed or loose ned. To avoid false readings,

which could result in possible electric shock or personal injury, replace the battery

as soon as the low battery indicator appears. Avoid working alone.

Caution

Disconnect the t est l eads from the test points befo re cha nging functions.

Disconnect circuit power and discharge all hig h voltage capacitors before testin g

resistance, continuity, capacitance or diodes. Always set the meter to the highest

range and work downward for an unknown value in the manual ra nging mode.

Before measuring current, check the meter’s fuses and turn power OFF to th e

circuit before connecting the meter to the circuit.

1. SAFETY INFORMATION

2. ELECTROMAGNETIC COMPATIBILITY (EMC)

32

Page 4

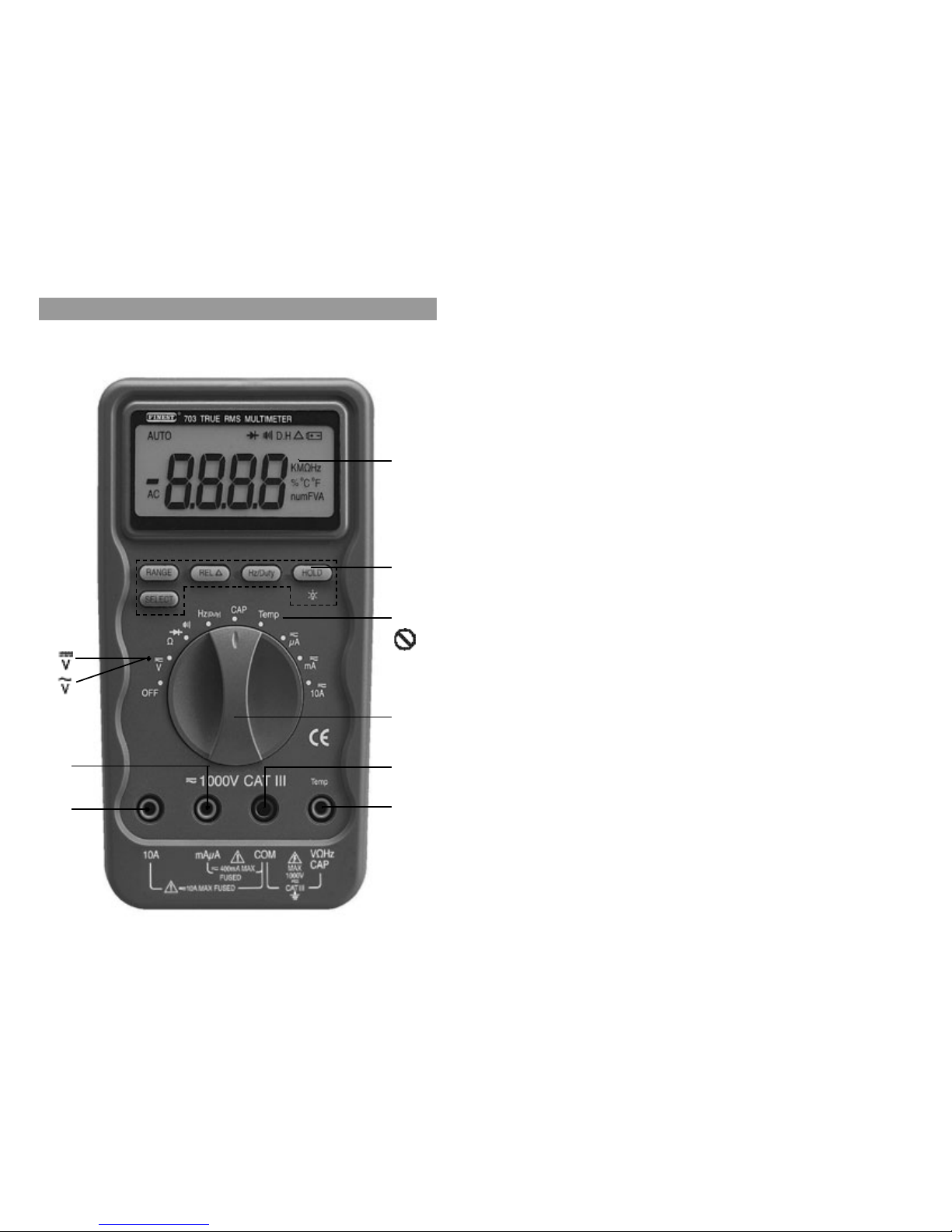

Although this manual describes the operation of both Model 701 and Model 703, all

illustrations and examples assume use of Model 703.

(1) 3-3/4 digit, 4000 count LCD display

(2) Push-buttons for special functions & features

(3) Selector to turn the power ON or OFF and select a function

(4) Input terminal for 10A (20A for 30 sec.) current measurement function

(5) Input terminal for milli-amps and micro-amps current measurement function

(6) Common (Ground reference) input terminal for all measurement functions

(7) Input term inal f or all functions EXCEPT current (A, mA, µA) me asurement

functions

Glossary of Terms for Digital Multimeters

Average sensing RMS calibrated

RMS (Root-Mean-Square) is the term used to describe the effective or equivalent

DC value of an AC signal. Most digit al multimeters use a verage sensing RM

S

ca librated technique to measure RMS values of AC signals. This technique is to

obtain the average value by rectifying and filtering the AC signal. The average

value is then scaled upward (that is, calibrated) to read the RMS value of a sine

wave. In measuring pure sinusoidal waveform, this technique is fast, accurate, and

cost effective. However, in measuring non-sinusoidal waveforms, significant errors

ca n be introduced because of different scaling factors relating average to RMS

values.

True RMS

Tru e RMS is a term wh ich identifies a DMM th at accurately responds to the

effective RMS value regardless of the waveform shapes such as square, sawtooth,

triangle, pulse trains, spikes, and transient glitches as well as distorted waveforms

with the presence of harmonics.

( 1 )

( 3 )

( 6 )

( 7 )

( 4 )

( 7 0 1 )

( 5 )

( 2 )

( 7 0 1 )

3. CONTROLS AND INDICATORS

54

Page 5

Non-sinusoidal waveforms may cause :

– Overheated transformers, generator and motors to burn out faster than normal

– Circuit breakers to trip prematurely

– Fuses to blow

– Neutrals to be overheated due to the triplen harmonics present on the neutral

– Bus bars and electrical panels to vibrate

Crest Factor

Crest Factor is the ratio of the Crest (instantaneous peak) value to the True RMS

value, which is commonly used to define the dynamic range of a True RMS DMM.

A pure sinusoidal waveform has a Crest Factor of 1.414.

A badly distorted sinusoidal waveform normally has a much higher Crest Factor.

NMRR (Normal Mode Rejection Ratio)

NMRR is the DMM’s ability to reje ct unwanted AC noise effect which can cause

inaccurate DC measurements. NMRR is typically specified in terms of dB (decibel).

The Meter has a NMRR specification of > 60dB at 50Hz/60Hz, which means a good

ability to reject the effect of AC noise in DC measurements.

CMRR (Common Mode Rejection Ratio)

Common mode voltage is voltage existing o n both the COM and Voltage i n p u t

term inals of a DMM, with respect to ground. CMRR is a DMM’s ability to rejec

t

common mode voltage effect which can cause dig it rattle or offset in voltage

measurements. The Meter has a CMRR specification of > 60dB at DC to 60 Hz in

AC volts measurement function and > 120 dB at DC, 50Hz and 60Hz in DC volts

measurement function.

Burden Voltage

Burden voltage is a voltage drop across the input terminals of a current-measuring

device, caused by internal shunt resistance.

Burden voltage contributes measurement error, and should be as low as practical.

Temperature Coefficient

Temperature Coefficient is a factor use d to calculate t he change in indicatio n or

output of an instrument with changes in temperature.

Un compensated changes in temperature contribute uncertainty by an a mount

determined by the temperature coefficient to instrument.

Turning the Meter On

To turn the meter on, turn the rotary switch from OFF to any switch setting.

Rotary Switch

Turn the meter on by selecting any measurement function. The meter presents a

standard displa y for that function (range, measurement units, etc.). Use the

SELECT button to select any rotary switch alternate function.

When you turn the rotary switch from one function to another, a display for the new

function appears. Button choices made in one fu nction do not carry over int o

another function.

OFF. Turns the meter off.

. (Model 703). Volts ac rms and Volts dc.

. (Model 701). Volts ac.

. (Model 701). Volts dc.

. Access to resistance measurement, continuity test and diode test.

Hz (Duty).

Frequency measurement. Duty cycle is also displayed if it is toggled by

the Hz / Duty button.

CAP. Capacitance measurement.

Temp (Model 703 only). Temperature measurement in degrees Ce ntigrade or

Fahrenheit. Changing the reading mode should be preset at the factory.

. Micro-amps ac rms and micro-amps dc measurements (Model 703).

Micro-amps ac and micro-amps dc measurements (Model 701).

.

Milli-amps ac rms and milli-amps dc measurements (Model 703).

Milli-amps ac and milli-amps dc measurements (Model 701).

4. ROTARY SWITCH AND PUSHBUTTON OVERVIEW

76

Page 6

. Amperes ac rms and amperes dc measurements (Model 703)

Amperes ac and amperes dc measurements (Model 701)

Pushbuttons

The buttons activate features that augment the function selected with the rotary

switch.

RANGE. Use the RANGE button to manually sele ct a range. Press and hold

RANGE button for two seconds to return the meter to auto range mode. The meter

is in auto range mode wh en the A UTO in dica tor is on. The RANGE sele ction

function is not available in Hz (Duty), CAP

, and

Temp modes.

The range and units are displayed on the LCD.

REL¡â. Use this button to set the meter to relative ( ) mode and make relative

mea sure ments. Relative zero allows t he user to offset the meter consecutive

measurements with the displaying reading as the re ference va lue. Pract ically all

displaying readings can be set as relative reference value. Press the REL button

momentarily to activate and to exit relative zero mode.

Hz/Duty. Press this button to toggle between the Hz measurement mode and the

Duty measurement mode when the selector switch is set to Hz (Duty), and

.

HOLD. Press this button to turn hold

mode ON

and OFF. When the

hold mode is

activated, the meter beeps, freezes the display, and displays the D.H indicator on

the LCD. HOLDmode freezes the display for later view.

(Backlight). Press the HOLD ( ) button for two seconds to turn the

backlight ON or OFF, when the HOLD function is simultaneously activated with the

D.H symbol on the display. Press the HOLD button momentarily again to activate

the Backlight function only.

SELECT. Press this button to toggle between the dc measurement mode and the

ac measurement mode when the rotary selector switch is se t to (Model 703

only), , and . And also press this button to cycle through or or

measurement mode when the rotary selector switch is set to .

9

8

5. METER OPERATION

Voltage ( or , ) Measurements

Voltage is the difference in electrical potential between two points.

The polarity of ac (alternating current) voltage varies over time, while the polarity of

dc (direct current) voltage is constant over time.

function defaults at dc. Press SELECT button momentarily to select ac.

Range available in volts functions are :

400 mV, 4 V, 40 V, 400 V, and 1000V

When mea suring voltage, th e meter acts like a 10M (10 x 106) impedance in

parallel with the circuit. This loading effect can cause measurement errors in highimpedance circuits. In most cases, the error is negligible (0.1 % or less) if the circuit

impedance is 10 k or less.

Tips for measuring voltage

In 4 00 mV range, displayed value may fluctuate when disconnecting inpu

t

terminals. This is normal.

AC voltage measuring circuit in Model 703 is of root-mean-square (True RMS)

value system so the meter can accurately measure ac voltage of non-sinusoidal

waveforms including harmonics caused by various non-linear loads.

Page 7

Tips for measuring resistance

Because the meter’s test curren t flows through all possible paths betwe en the

test probe tips, the measured value of a resistor in a circuit is often different from

the resistor’s rated value.

The test leads can add 0.1 to 0.2

of error to resistance measurements.

To measure the resistance of the leads, touch the probe tips together and read

the resistance. If necessary, you can press the REL button to automatically

subtract this value.

The resistance function can produce enough voltage to forward-bias silicon diode

or transistor junctions, causing them to conduct.

Do not use the 40 M range for measuring the in-circuit resistance to avoid this.

Whe n meas uring large resi stance, rea d in g may b e uns tabl e due to

environmentally induced electrical noise. In this case , direct ly connect the

resistor to input terminals of the meter or shield the resistor at potential of the

COM input terminal to obtain stable reading.

For resistance above 1 M , the display may take a few seconds to stabilize. This

is normal for high resistance readings..

The met er h as a circuit to p rotect the resistance range from over-voltage.

However, to prevent accidentally exceeding the protection circuit’s rating and to

ensure a correct measurement, NEVER CONNECT THE LEADS TO A SOURCE

OF VOLTAGE when the rotary switch is set to or or functions.

11

10

To improve the accuracy of dc voltage measurements taken in the presence of

ac voltages (such as, measuring the dc voltage of an amplifier in the presence of

an ac signal), measure the ac voltage first. Note the just measured ac voltage

range a nd select a d c voltage range that is the same or h igher than t he ac

voltage range. This method improves the dc voltage accuracy by preventing the

input protection circuits from being activated.

Resistance ( , , ) Measurements

(Ohms, Diode, and Continuity)

Resistance is an opposition to current flow. The unit of resistance is the ohm ( ).

The meter measures resistance by sending a small current through the circuit.

Ranges available in resistance functions are :

400.0 , 4.000 k , 40.00 k , 400.0 k , 4 M , and 40 M

Warning

To avoid the risk of electrical shock and instrument damage,

input voltages must not exceed 1000 V dc or ac (rms). Do not

attempt to take any unknown voltage measurement that may

be in excess of 1000 V dc or ac (rms).

Caution

To avoid d amaging the meter or the e quipment under test,

re move a ll power f rom the circu it a nd disch arg e all hig hvoltage capacitors before measuring resistance.

Page 8

Frequency (Hz) Measurements

Frequency is the number of cycles a signal completes each second. The m eter

measures the frequency of a voltage or current signal by counting the number of

tim es the signal crosses a threshold level each second.

To measure the frequency of a voltage or current signal, press the Hz/Duty button

momentarily while measuring volts or currents.

The available frequency ranges are 5 Hz, 50 Hz, 500 Hz, 5 kHz, 50 kHz, 500 kHz,

5 MHz and 10 MHz.

Diode ( ) Test

Use the diode test to check dio des, tra nsistors, silicon controlled rectifiers (SCRs),

and othe r sem ic on ductor dev ices. T h e test sends a curr en t thr ough a

semiconductor junction, then me asures the junction’s vo ltage drop.

Normal forward voltage drop (forward biased) for a good silicon diode is between

0.4 V to 0.9 V. A reading higher than that indicates a leaky (defective ) diode. A

zero reading indica tes a shorted (defective) diode.

An indicates an open diode (d efect ive).

Reverse the test leads connectio ns ( reverse biased ) across the dio de.

The display shows if the diode is good. Any other readin gs indicate the diode

is shorted or resistive ( defective )

.

Continuity ( ) Te st

The co ntinuity function detects intermittent opens and shorts lasting as little as 1

millisecond. Th ese brief contacts cause the meter to emit a short beep. This

f

unction is convenient for checking wiring co nnectio ns and operation of switches

.

A continuous beep tone indicates a complete wire.

1312

Caution

Discharge all high-voltage capacitors before testing diodes.

Large value capacitors sh ould be dis charged through an

appropriate resistance load.

Caution

Using resistance and continuity function in a live circuit will

produce false results and may damage the instrument.

In many cases the s uspic iou s c o mpone nts mu s t be

disconnected fro m the circuit under test to obtain accurate

results.

Page 9

Tips for me asuring capacitanc e

Temperature (Temp) Measure ments [Model 703 only]

Tips for measuring freque ncy

In frequency, the meter is always autoranging.

When disconnecting the input term inals, the overload sign may be displayed or

the display may unsteadily fluctuate. This is typical.

Duty Cycle Measurements

Duty Cycle (or Duty Factor) is the percentage of time a signal is above or below a

trigger level during one cycle.

The duty cycle mode is optimized for measuring the ON or OFF time of logic and

switching signals. Systems such as electronic fuel injection systems and switching

power supplies are controlled by pulses of varying width, which can be checked by

measuring duty cycle.

Press the Hz/Duty button to toggle between the Hz mode and the Duty Cycle mode

when the rotary selector knob is set to Hz (Duty), , , , or .

Capacitance Measurements

Capacitance is the ability of a component to store an electrical charge.

The unit of capacitance is the farad (F). Most capacitors are in the nanofarad (nF)

to microfarad (µF) range.

The available capacitance ranges are 40nF, 400 nF, 4 µF, 40 µF, and 100 µF.

1514

Caution

To avoid damaging the meter or the equipment under test,

remove a ll power fro m the circuit and discharge a ll highvoltage capacitors before measuring capacitance.

Large value ca pacitors should be discharged through an

appropriate resistance load. Use the dc voltage function to

confirm that the capacitor is discharged.

In capacit ance, the Meter is always

a u t o r a n g i n g .

In 40 nF r ange, the readings ar e

probably unstable du e to en vir o nmen tally induced ele ctrical noise and

floating capa city of the t es t le ads.

Therefore, directly connect the object

to be measured to the input terminals.

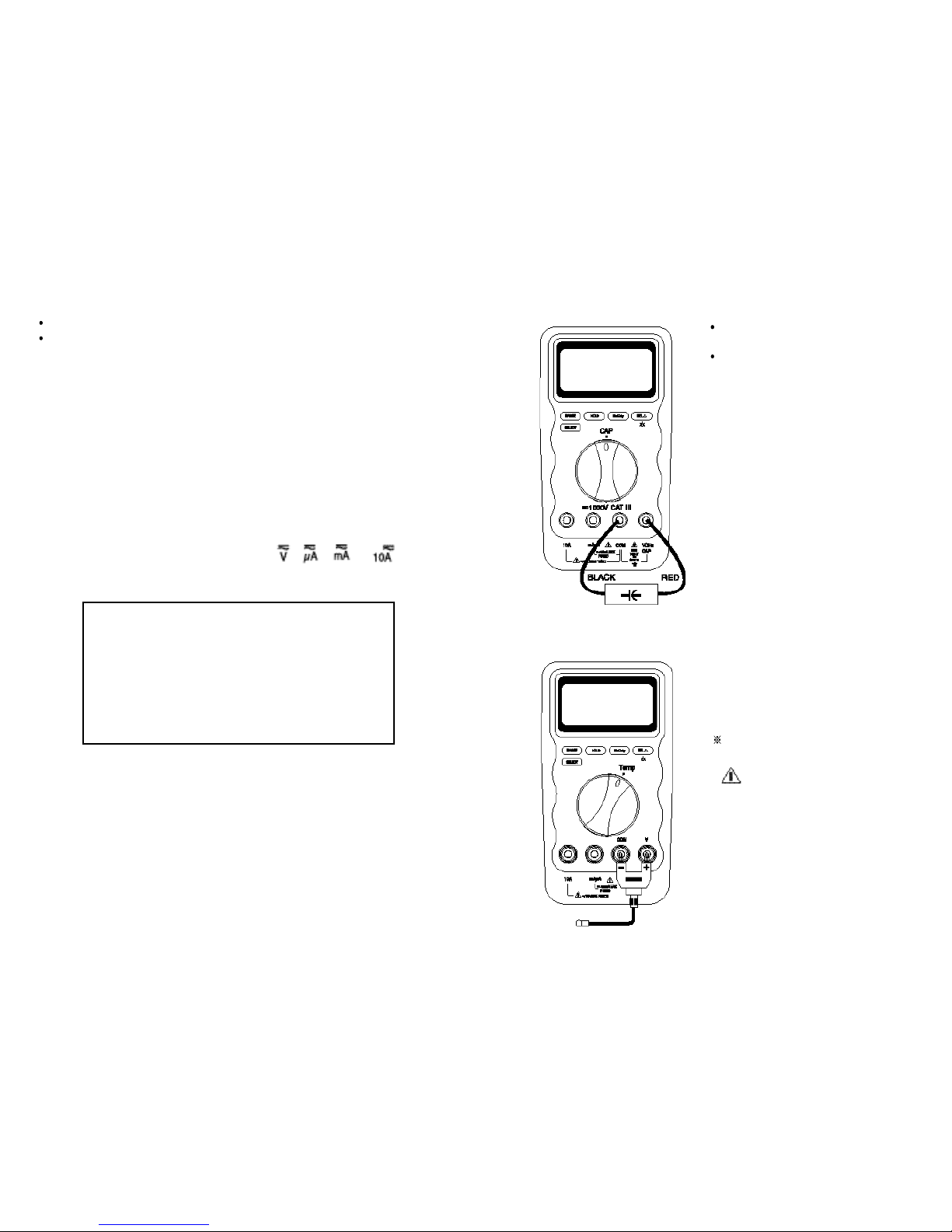

The me ter c omes wi th temp era t ur e

re ading in either Centigra d e or

Fahrenheit preset at the f actory. The

re ading mode can be c hanged at the

f

act ory only.

The SELECT function is not available

in Temperature mode.

WARNING - Do not a pply

the rmoco u pl e to circuits exceeding

30V rms , 42. 4 V peak or 60V dc.

Be sure to insert the banana p lug K-type

temperature bead probe TP7 with correct

+ – po larities. You ca n als o us e a

thermocou p l e pro be ad a pter T P1 A

(O ptio nal purc hase) to ada p t other

standard K-type temperature probes.

Page 10

1716

4 . Turn on power to the circuit and read the display.

5 . After measuring current, t urn off power to th e circuit and discharge all high-

voltage capacitors. Dis connect the meter and restore the circu it t o normal

o p e r a t i o n .

Tips for measur ing current

When measuring a 3-phase syste m, special attention should be taken to the

phase to phase voltage which is significantly higher than t he phase to earth

volt age. To a vo id e xceedin g the voltage rat in g of t he protecti on fuse(s)

accidentally, always consider the phase to phase voltage as the working voltage

for the protection fuse(s).

When measuring current, the meter’s internal shunt resistors develop a voltage

across the meter’s terminals called “burden voltage”.

This voltage drop may affect precision circuits or measurements.

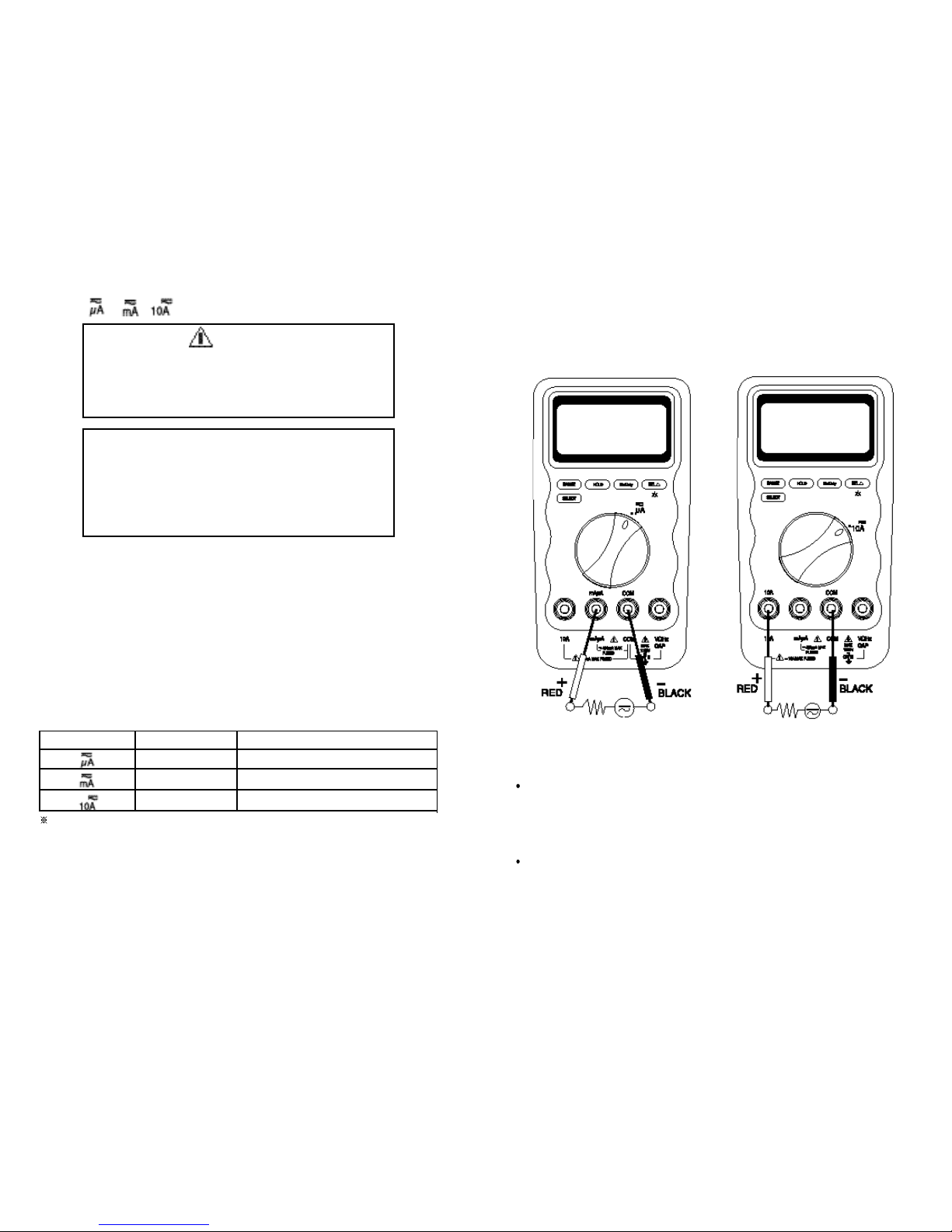

Current ( , , ) Measurements

Current is the flow of electrons through a conductor. To measure current, you must

open the circuit under test, then place the meter in series with the circuit.

The available current ra nges are :

400.0 µA, 4000 µA, 40.00 mA, 400.0 mA, 4.000 A, and 10.00 A

The meter defaults at d c. Press S E L E C T button momentarily to select a c .

To measure dc or

ac current,

1 . Turn off power to the circuit and discharge all high-voltage capacito rs.

2 .Insert the black le ad into the C O M terminal and the red lead into an input

terminal appropriate for the me asurement range as the following table.

To avoid blowing the meter’s 440 mA fuse, use the mAµA terminal only if you are sure the

current is less than 400 mA.

3 . Open the current path to be t ested. Touch the red probe to the more positive

side of the break and touch the black probe to the more negative side of th e

break. (Reversing the leads will produce a negative reading, but will not damag e

the meter.)

Warning

Neve r attempt an in-circuit current measurement where the

open-circuit potential to earth is greater than 1000V. You may

damage the meter or be injured if the fuse blows during such

a measurement.

Caution

Ch eck the meter fuses before measuring current. Use the

proper t erm in als , function, and ra nge for c urrent

measurements. Never place the probes in parallel with any

circuit or component when the test leads are plugged into the

current terminals.

Range RangesInput

mAµA

mAµA

10A

400.0 µA, 4000 µA

40.00 mA, 400.0 mA

4.000 A, 10.00 A

SERIES CONNECTION SERIES CONNECTION

Page 11

1918

Auto / Manual Range Operation

Press the RANGE button momentarily to select manual-ranging in volts, ohms,

and currents measurement function, and the meter will remain in the range it was

in, when the LCD annunciator A U T O turns off.

P

ress the button momentarily again to step through the range s

.

Press and hold the RANGE button for 2 seconds to resume auto- ranging.

Manual-ranging feature is not available in Hz (Duty), CAP, Temp , and

f u n c t i o n s .

Auto - Power - Off

The Auto-Power-Off feature automatically turns the meter off to extend battery life

after approximately 30 minutes of n o activities. To turn on the met er after AutoPower-Off, turn the rotary switch from OFF to any function (ON).

Cleaning and Storage

Perio dica lly wipe the case with a damp cloth and mild detergent; do not use

abrasives or solvents.

Clean the input terminals as follows :

1. Turn the meter off and remove all test leads.

2. Shake out any dirt that be in the terminals.

3. Soak a new swab with alcohol and work the swab around in each terminal.

If the meter is not to be used for periods of longer than 60 days, remove the battery

and store it separately.

Battery and Fuse Replacement

The meter uses a single standard 9V battery (NEDA 1604, JIS006P, IEC 6F 22), a

1000 V/440 mA IR 10 kA fast acting F fuse (F

71

) for mAµA current input, and a 1000

V/11 A IR 10KA fast acting F fuse (F72) for A current input. The (F71) 440 mA, (F72) 11

A fuse must be replaced by qualified service personnel only.

Trouble Shooting

If the meter fails to operate e ven with th e battery or fuse replacements, check it

twice over according to operating procedure as described in this manual.

If the meter’s V/ input terminal has subjected to high voltage transient (caused by

lightning or switching su rge to the system) b y accident or abnormal operating

conditions, the series fusible resistors will be blown off like fuses in order to protect

the user and the meter. Most measuring functions through this terminal will then be

open circuit.

In this case, the series fusible resistors and the spark gaps should be replaced by

qual ified p erson nel. Ref er to the LIMITED WA RRANTY & L I MITAT ION O F

LIABILITY section for obtaining warranty or repairing service.

6. MAINTENANCE

Warning

To avoid electrical shock or personal injury, remove the test

leads and any input signals before replacing the battery or

fuses. To prevent damage or injury, install only the same type

of fuses or equivalents.

Page 12

2120

Safety & Compliances

Maximum voltage between any terminal

and earth ground

: 1000 V ac/dc

Compliances : Complies with CSA C22.2 No 1010.1-92,

ANSI/ISA-S82, 01-94 to 1000 V Overvoltage

Category lll.

Certifications : UL & cUL standard UL 3111-1 Listed

CE-marking certificated

Surge Protection : 8 kV peak per IEC 1010.1-92

Fuse Protection for mA or µA inputs : 1000 V / 440 mA lR 10 kA FAST fuse

Fuse Protection for A input : 1000 V / 11 A lR 10 kA FAST fuse

Physical Specifications

Display (LCD) : Digital – 4000 counts display;updates

5 times/sec.

Operating Temperature : 0 C to 40 C

Storage Temperature : –20 C to 60 C

Temperature Coefficient : nominal 0.15 x (specified accuracy) / C

@(0 C to 18 C or 28 C to 40 C),

or otherwise specified

Relative Humidity : 0 % to 80 % @ (0 C to 35 C)

0 % to 70 % @ (35 C to 40 C)

Altitude : Operating – up to 2000m

Storage – 10000m

Battery Type : Single 9V battery –NEDA 1604, JIS 006P or

IEC 6F 22

7. SPECIFICATIONS

Battery Life : 250 hrs. typical (with backlight off) [703]

750 hrs. typical (with backlight off) [701]

Shock Vibration : Per MIL-T-PRF 28800 for Class II instruments

Pollution Degree : 2

Electromagnetic

Compatibility (EMC) : Susceptibility – Commercial Limits for

EN 50082-1

Emissions – Commercial Limits for EN 50081-1

Size (H x W x L) : 40.5 x 92 x 172 mm

Weight : Approx. 386g

Warranty :

3 years

Calibration Interval : 1 year

Feature Summary

Backlight : For clear readings in poorly lighted areas

Fast Autoranging : Meter automatically selects the best range

momentarily

HOLD

:

Holds readings on display

Continuity / Open test : Beeper sounds

Battery/Fuse Access Door : battery or fuse replaceable without voiding

calibration

High-Impact Overmolded Case : Protective holster features

Page 13

2322

Electrical Specifications

Accuracy is given as ± ([% of reading] + [number of digits]) at 18 C to 28 C with

relative humidity up to 80%, for a period of one year after calibration.

True RMS responding a ccuracie s a re specified from 5% to 100% of range or

otherwise specified; Crest Factor < 3:1 at full scale and < 6:1 at half scale.

DC Voltage

NMRR : > 60dB @ 50/60 Hz

CMRR : > 120 dB @ DC, 50/60 Hz, Rs=1k

Input Impedance : 10 M , 30 pF nominal

(50 M , 100 pF nominal for 400 mV range)

AC Voltage

CMRR : > 60dB @ DC to 60 Hz, Rs = 1 K

Input Impedance

:

10 M , 30 pF nominal

(50 M , 100 pF nominal for 400 mV range)

*1: Accuracy for 400 Hz to 1 kHz

Range

701 703

Accuracy

400 mV 100 µV

0.5 % + 2

0.5 % + 2

4 V 1 mV

0.75 % + 3

40 V 10 mV

400 V 100 mV

1000 V 1 V 0.75 % + 3

Resolution

DC Current

AC Current

Resistance

Open Circuit Voltage : < 1.3 V dc

Range

40 Hz – 400 Hz 400 Hz – 10 kHz

Accuracy

701

703 703

400 µA 0.1 µA

4000 µA 1 µA

1.0 % + 5

40 mA 10 µA

400 mA 100 µA

4 A

1 mA

1.0 % + 5

1.5 % + 10

1.5 % + 10

2.0 % + 10

10 A 10 mA

1.5 % + 5

Resolution

Range

701 703

Accuracy

400 µA

4000 µA

1.0% + 2

40 mA

400 mA

4 A

10 A

0.1 µA

1 µA

10 µA

100 µA

1 mA

10 mA

1.0% + 2

1.5 % + 5 1.5 % + 5

Resolution

Range

40 Hz – 400 Hz 400 Hz – 1 kHz 1 kHz – 20 kHz

Accuracy

701 703 703

400 mV 100 µV

4 V 1 mV

0.75 % + 3

40 V 10 mV

400 V 100 mV

1000 V 1 V 1.0% + 5 1.0 % + 5 2.0% + 5 *1–

0.75 % + 3

2.0 % + 3

Resolution

Range

701 703

Accuracy

400 0.1 1.0 % + 5 1.0 % + 5

1.5 % + 10 1.5 % + 10

1.0 % + 5

1.0 % + 5

4 k 1

0.5 % + 340 k 10

400 k 100

4 M 1 k

40 M 10 k

0.5 % + 3

Resolution

2.0 % + 10 2.0 % + 10

Page 14

Continuity

Diode Test

Capacitance

*1. Accuracy with film capacitor or better

Using

Mode

Frequency and Duty Cycle

25

Temperature (Model 703 only)

* This specification is effective at the ambient temperature of 23 C (73.4 F) only.

Frequency Counter Sensitivity

Burden Voltage ( A, mA, µA)

24

Remark

Accuracy

701 703

Minimum frequency :

0.5 Hz

Sensitivity :

5 Hz–1 MHz, > 250 mV

1 MHz–10 MHz, > 350 mV

0.001 Hz

0.01 Hz

0.05 % + 3

0.05 % + 3

0.1 Hz

1 Hz

10 Hz

Range

5 Hz

50 Hz

500 Hz

5 kHz

50 kHz

500 kHz

100 Hz

5 MHz

1 kHz

10 MHz

10 kHz

0.1%

0.5 Hz to 500 kHz (pulse width > 2 µsec.)

(0.1% + 0.05% per kHz + 1 count) for 5 V input (Logic signals only)

0.1% to

99.9%

Resolution

Function

Burden Voltage (typical)

mA / µA

Range

400 µA

4000 µA

40 mA

400 mA

4 A

10 A

150 µV / µA

150 µV / µA

3.3 mV / mA

3.3 mV / mA

0.03 V / A

0.03 V / A

10 A

Range Accuracy Open Circuit Voltage

4V 2%

Test Current

(Typical)

0.25 mA < 1.5 V dc

Audible threshold : the beeper sounds if the measured resistance is lower than

10 , and turns off when greater than about 60 .

Response time : < 1 msec.

Range

701 703

Accuracy

*

1

2.5 % + 10 2.5 % + 10

40 nF 10 pF

400 nF 100 pF

4 µF 1 nF

40 µF 10 nF

100 µF 100 nF

Resolution

Range Accuracy

- 40 C to -10 C

(-40 F to 14 F)

Resolution

1 C

1 F

3% ± 5 C

(3% ± 5 F)

- 10 C to 400 C

(14 F to 752 F)

1 C

1 F

1% ± 3 C

(1% ± 3 F)

400 C to 1300 C

(752 F to 2372 F)

1 C

1 F

3% of reading

(3% of reading)

Range

Minimum Sensitivity ( RMS Sine Wave )

V

(4 V to 1000 V)

500 mV

40 Hz to 10 kHz 40 Hz to 20 kHz

500 mV

µA

(400 µA to 4 mA)

> 15 % F.S. of AC range Not Specified

mA

(40 mA to 400 mA)

> 15 % F.S. of AC range

Not Specified

A

(4.0 A to 10 A)

> 45 % F.S. of AC range Not Specified

*

1

Page 15

LIMITED WARRANTY & LIMITATION OF LIABILITY

Fine Instruments Corporation (Finest) warrants this product to be free from defects

in material and workmanship under normal use and service for 3 years. This

warranty extends only to the original buyer or end-user customer of a Finest

authorized reseller, and is not applied to fuses, battery or to any product which, in

Finest’s option, has been misused, altered, neglected or damaged by accident or

abnormal conditions of operation or handling.

Finest warrants that software will operate on appropriate Finest instruments

substantially in accordance with its functional specifications for 90 days and that it

has been properly recorded on non-defective media. Finest does not warrant that

software will be error free or operate without interruption.

Finest authorized resellers shall extend this warranty on new and unused products

to end-user customers only but have no authority to extend a greater or different

warranty on behalf of Finest.

Finest’s warranty obligation is limited, at Finest’s option, to refund of the purchase

price, or free of charge repair or replacement of a defective product which is

returned to the Finest’s factory within the warranty period.

To obtain warranty service, contact your nearest Finest authorized reseller or send

the product, with a description of the difficulty, postage and insurance prepaid (FCA

Destination), to the nearest Finest authorized reseller. Finest assumes no risk for

damage in transit. Finishing warranty repair, the product will be returned to Buyer,

transportation prepaid (FCA Destination). If Finest determines that the failure was

caused by misuse, accident, abnormal condition of operation / handing, or

alteration, Finest will provide an estimate of repair costs and obtain authorization

before commencing the repair work. Finishing repair, the product will be returned to

the Buyer transportation prepaid and the Buyer will be billed for the repair and

return transportation charges (FCA shipping Point).

Warranty service is available outside the Republic of Korea only if product was

purchased through a Finest Authorized Sales Outlet in the country of use. Finest

reserves the right to invoice Buyer for importation costs of repair/replacement parts

when product purchased in one country is submitted for repair to the Finest factory

in the Republic of Korea.

DISCLAIMER

THIS WARRANTY IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED O

R

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. FINEST SHALL NOT BE LIABLE FOR ANY SPECIAL

,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES,

INCLUDING LOSS OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY

OR BASED ON CONTRACT, TORT, RELIANCE OR ANY OTHER THEORY.

Loading...

Loading...