Page 1

SERIES 2600/2610

SINGLE-PHASE

ADJUSTABLE-SPEED

DC MOTOR CONTROLLERS

(1/6 - 5 HP)

BOOK0795-F

Rev. 11/01

Page 2

TABLE OF CONTENTS

SECTION TITLE PAGE

I GENERAL INFORMATION 1

Introduction 1

General Description 1

Model Types 1

Motor Selection 2

II INSTALLATION 3

Installation Guidelines 3

Installing The Controller 5

Initial Startup 15

III OPERATION 17

BOOK0795-F

Power On/Off 17

Run 17

Stop 17

Speed Control 18

Jog 18

Reverse 18

Inoperative Motor 18

IV MAINTENANCE AND REPAIR 21

General 21

Adjustment Instructions 21

Troubleshooting 24

V OPTIONS 29

VI PARTS LIST 31

VII RATINGS AND SPECIFICATIONS 33

Ratings 33

Operating Conditions 34

Performance Characteristics 35

Adjustments 35

Specifications 36

VIII DRAWINGS 39

INDEX 45

iii

Page 3

BOOK0795-F

LIST OF TABLES

TABLE TITLE PAGE

1 Series 2600 Model Matrix 1

2 Series 2610 Model Matrix 2

3 Jumper J4 Positions 5

4 Initial Potentiometer Settings 15

5 Dynamic Braking Characteristics 17

6 Troubleshooting 24-27

7 Allowable Option Combinations 30

8 Parts List, Series 2600/2610 Controllers 31

9 Typical Application Data 33

10 Operating Voltages And Signals 34

11 Controller Weights 34

12 Speed Regulation Characteristics 35

13 Dip Switch S3 Settings 36

14 Shunt Field Data 37

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

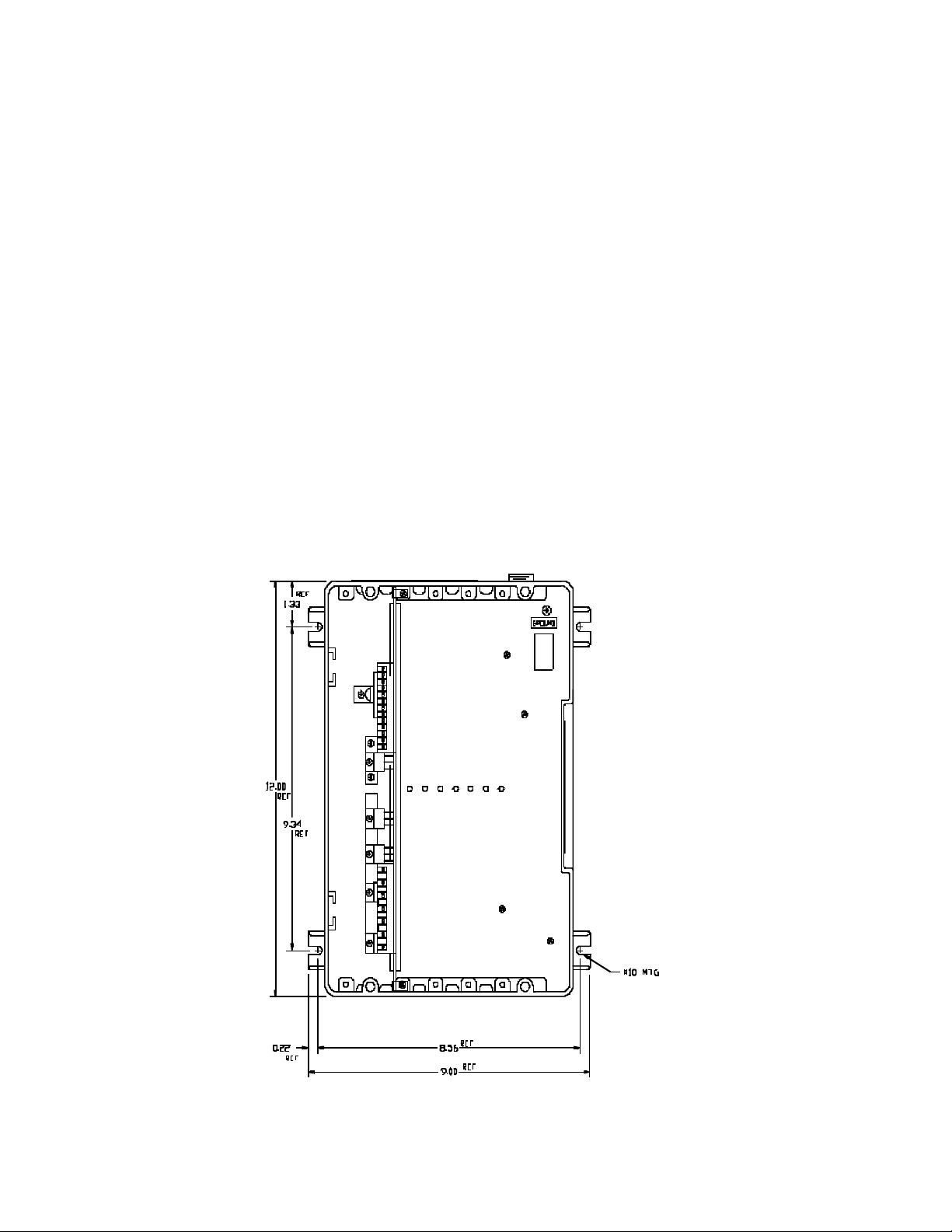

1 Controller Mounting Dimensions, 6

Models 2601 and 2602

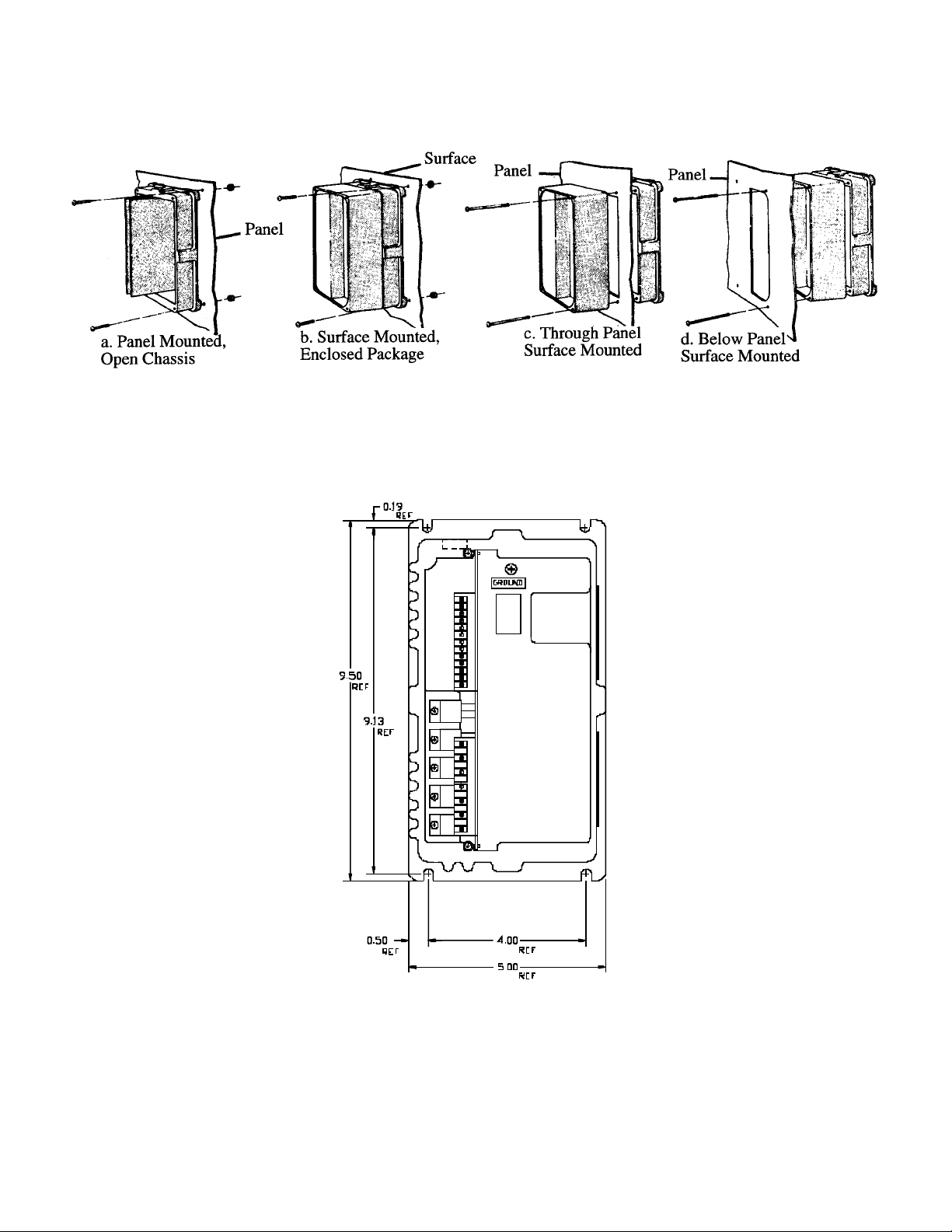

2 Controller Mounting Configurations, 8

Models 2611 and 2612

3 Controller Mounting Dimensions, 8

Models 2611 and 2612

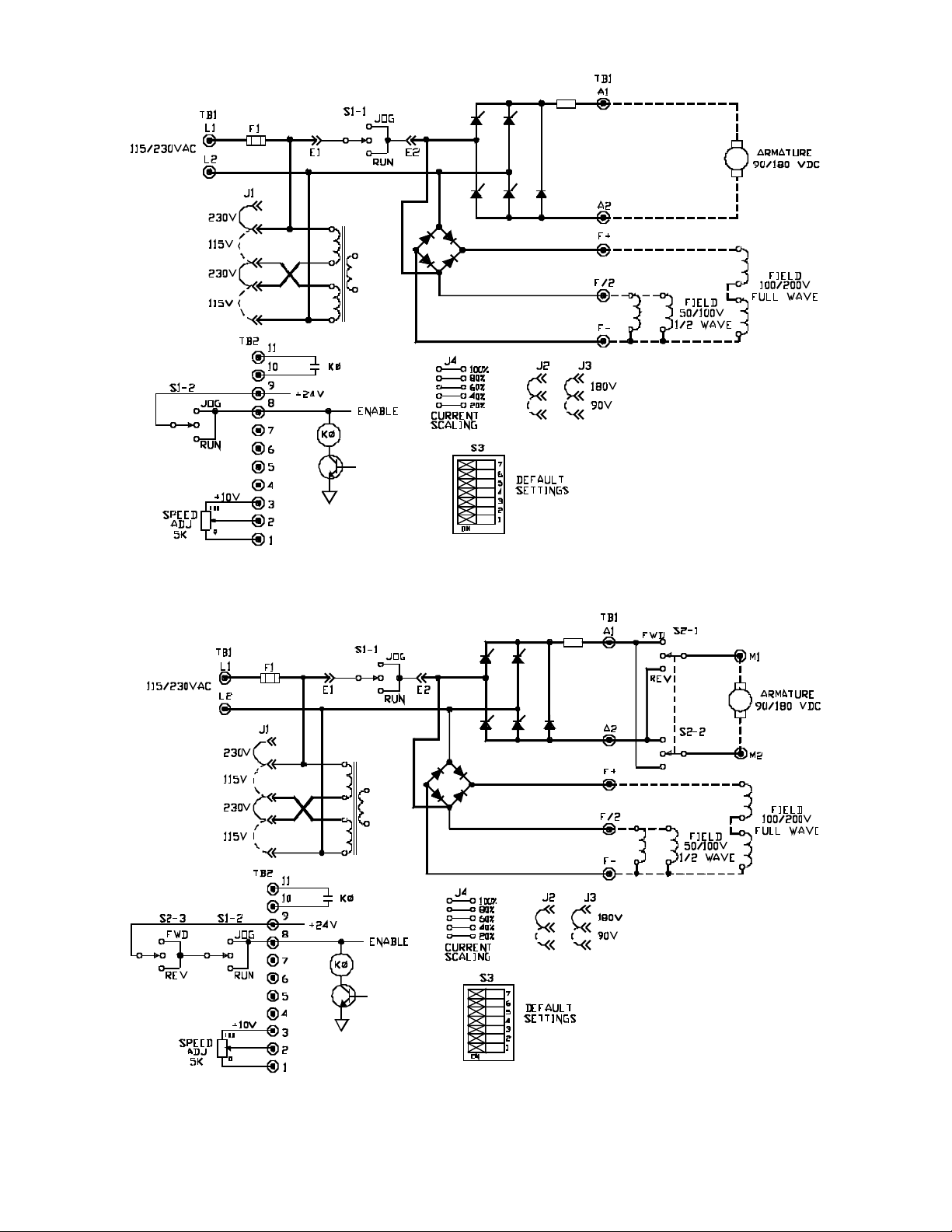

4 Logic Connection Diagram, Run-Stop-Jog 9

Switch, 1/6 - 2 HP

5 Logic Connection Diagram, Forward-Reverse 9

Switch And Run-Stop-Jog Switch, 1/6 - 2 HP

6 Logic Connection Diagram, Run-Stop Pushbuttons 10

And Run-Jog Switch, 1/6 - 5 HP

7 Logic Connection Diagram, Optional Armature 10

Contactor Reversing Using Switches, 1/6 - 5 HP

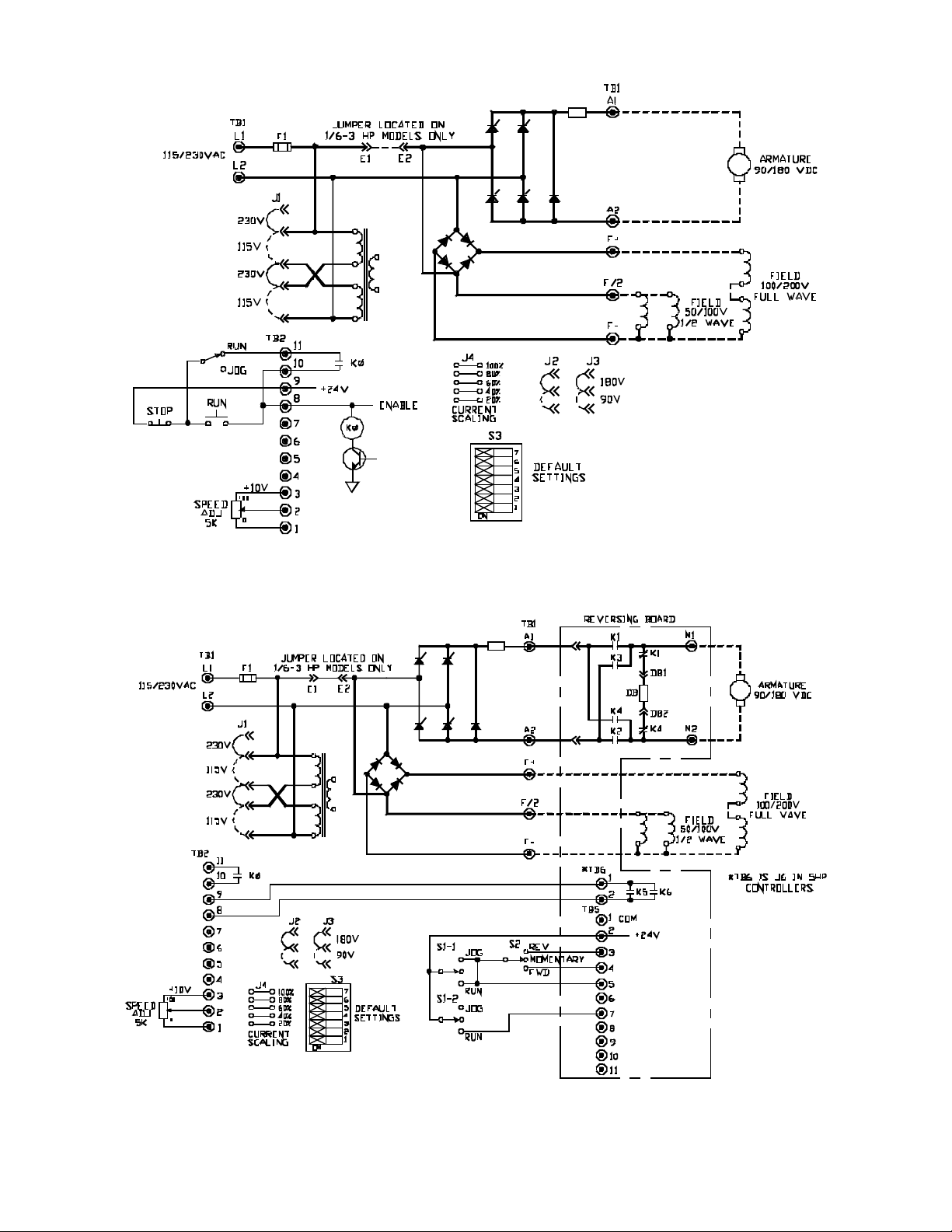

8 Logic Connection Diagram, Optional Armature 11

Contactor Reversing Using Pushbuttons And

Run-Jog Switch, 1/6 - 5 HP

9 Logic Connection Diagram, Line Starting With 11

Motor Speed Potentiometer, 1/6 - 5 HP

10 Signal Connection Diagram, Motor Speed 12

Potentiometer

11 Signal Connection Diagram, Tachometer Feedback 12

12 Signal Connection Diagram, Current (Torque) 12

Reference Potentiometer

13 Signal Connection Diagram, Line Starting Without 13

A Motor Speed Potentiometer

iv

Page 4

LIST OF ILLUSTRATIONS

FIGURE TITLE PAGE

14 Signal Connection Diagram, 4 - 20 mA Interface 13

15 Signal Connection Diagram, 2-Wire Transducer 13

16 Signal Connection Diagram, 4 - 20 mA Transducer 14

With Manual/Auto Switch

17 Signal Connection Diagram, Transducer With External 14

Burden Resistor

18 Signal Connection Diagram, 0 - 10 VDC External 14

Speed Reference Signal

19 Functional Schematic, Series 2600/2610 40

20 Schematic, Series 2600/2610, 1/6 - 3 HP 41

21 Schematic, Series 2600, 5 HP 42

22 Series 2600/2610 Control Board, 1/6 - 3 HP 43

23 Series 2600 Control Board, 5 HP 44

BOOK0795-F

v

Page 5

BOOK0795-F

WARNING

The following must be strictly adhered to at all times.

• YOU AS THE OWNER OR OPERATOR OF FINCOR DRIVE EQUIPMENT HAVE THE

RESPONSIBILITY TO HAVE THE USERS OF THIS EQUIPMENT TRAINED IN ITS

OPERATIONS AND WARNED OF ANY POTENTIAL HAZARDS OF SERIOUS INJURY.

• THE DRIVE EQUIPMENT SHOULD BE INSTALLED, OPERATED, ADJUSTED, AND

SERVICED ONLY BY QUALIFIED PERSONNEL FAMILIAR WITH THE CONSTRUCTION

AND OPERATION OF THE EQUIPMENT AND THE HAZARDS INVOLVED INCLUDING

THOSE DESCRIBED BELOW. FAILURE TO OBSERVE THIS WARNING CAN RESULT IN

PERSONAL INJURY, LOSS OF LIFE, AND PROPERTY DAMAGE.

• THE NATIONAL ELECTRICAL CODE REQUIRES THAT AN AC LINE FUSED DISCONNECT

OR CIRCUIT BREAKER BE PROVIDED IN THE AC INPUT POWER LINES TO THE

CONTROLLER. THIS DISCONNECT MUST BE LOCATED WITHIN SIGHT OF THE

CONTROLLER. DO NOT OPERATE THE CONTROLLER UNTIL THIS CODE REQUIREMENT

HAS BEEN MET.

• THE DRIVE EQUIPMENT IS AT AC LINE VOLTAGE WHENEVER AC POWER IS

CONNECTED TO THE DRIVE EQUIPMENT. CONTACT WITH AN ELECTRICAL

CONDUCTOR INSIDE THE DRIVE EQUIPMENT OR AC LINE DISCONNECT CAN CAUSE

ELECTRIC SHOCK RESULTING IN PERSONAL INJURY OR LOSS OF LIFE.

• BE SURE ALL AC POWER IS DISCONNECTED FROM THE DRIVE EQUIPMENT BEFORE

TOUCHING ANY COMPONENT, WIRING, TERMINAL, OR ELECTRICAL CONNECTION IN

THE DRIVE EQUIPMENT.

• ALWAYS WEAR SAFETY GLASSES WHEN WORKING ON THE DRIVE EQUIPMENT.

• DO NOT REMOVE OR INSERT CIRCUIT BOARDS, WIRES, OR CABLES WHILE AC POWER

IS APPLIED TO THE DRIVE EQUIPMENT. FAILURE TO OBSERVE THIS WARNING CAN

CAUSE DRIVE DAMAGE AND PERSONAL INJURY.

• ALL DRIVE EQUIPMENT ENCLOSURES, MOTOR FRAMES, AND REMOTE OPERATOR

STATIONS MUST BE CONNECTED TO AN UNBROKEN COMMON GROUND CONDUCTOR.

AN UNBROKEN GROUNDING CONDUCTOR MUST BE RUN FROM THE COMMON

GROUND CONDUCTOR TO A GROUNDING ELECTRODE BURIED IN THE EARTH OR

ATTACHED TO A PLANT GROUND. REFER TO THE NATIONAL ELECTRICAL CODE AND

LOCAL CODES FOR GROUNDING REQUIREMENTS.

• THE ATMOSPHERE SURROUNDING THE DRIVE EQUIPMENT MUST BE FREE OF

COMBUSTIVE VAPORS, CHEMICAL FUMES, OIL VAPOR, AND ELECTRICALLY

CONDUCTIVE OR CORROSIVE MATERIALS.

• SOLID-STATE DEVICES IN THE CONTROLLER CAN BE DESTROYED OR DAMAGED BY

STATIC ELECTRICITY. THEREFORE, PERSONNEL WORKING NEAR THESE STATICSENSITIVE DEVICES MUST BE APPROPRIATELY GROUNDED.

vi

Page 6

BOOK0795-F

SECTION I

GENERAL INFORMATION

INTRODUCTION

This manual contains installation, operation, and maintenance and repair instructions for Fincor Series 2600/

2610 Single-Phase Adjustable-Speed DC Motor Controllers. A parts list, list of options, ratings and specifications,

and drawings are also included.

GENERAL DESCRIPTION

Series 2600/2610 Controllers statically convert AC line power to regulated DC for adjustable-speed armature control of shunt-wound and permanent-magnet motors.

Series 2600/2610 Controllers comply with applicable standards established by the National Electrical Code

and NEMA for motor and industrial control equipment. The controllers are Underwriters Laboratories Listed (File

No. E60207) and CSA approved (File No. LR19781).

MODEL TYPES

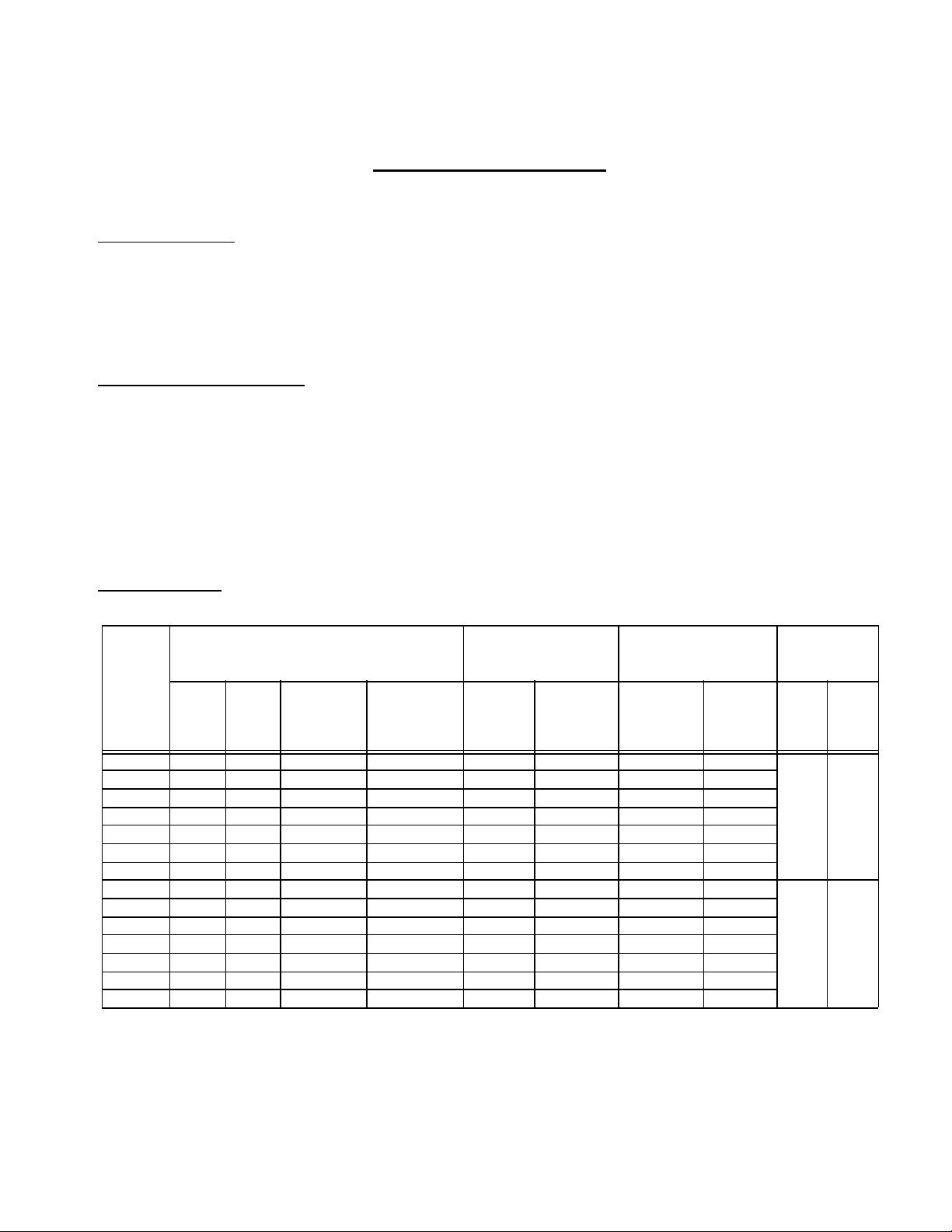

TABLE 1. SERIES 2600 MODEL MATRIX

FUNCTION CONFIGURATION

MODEL

RUN-

STOP

2601 X X X

2601A X X X X

2601P0 X X X

2601P1 X X X

2601AP0 X X X X

2601AP1 X X X

2601AP3 X X X

2602 X X X

2602A X X X X

2602P0 X X X

2602P1 X X X

2602AP0 X X X X

2602AP1 X X X

2602AP3 X X X

a. Units are reconnectable

b. No armature contactor

c. Includes armature contactor

b

RUN-

STOP-

c

DB

ARMATURE

SWITCH

REVERSE

ARMATURE

CONTACTOR

REVERSE

b

AND DB

c

OPEN

CHASSIS

ENCLOSED

OPERATOR

CONTROLS

LOCAL

INTEGRAL

POWER

SOURCEa &

HP RANGE

REMOTE 115V 230V

1/6 - 1 1/3 - 3

1/6 - 2 1/3 - 5

1

Page 7

BOOK0795-F

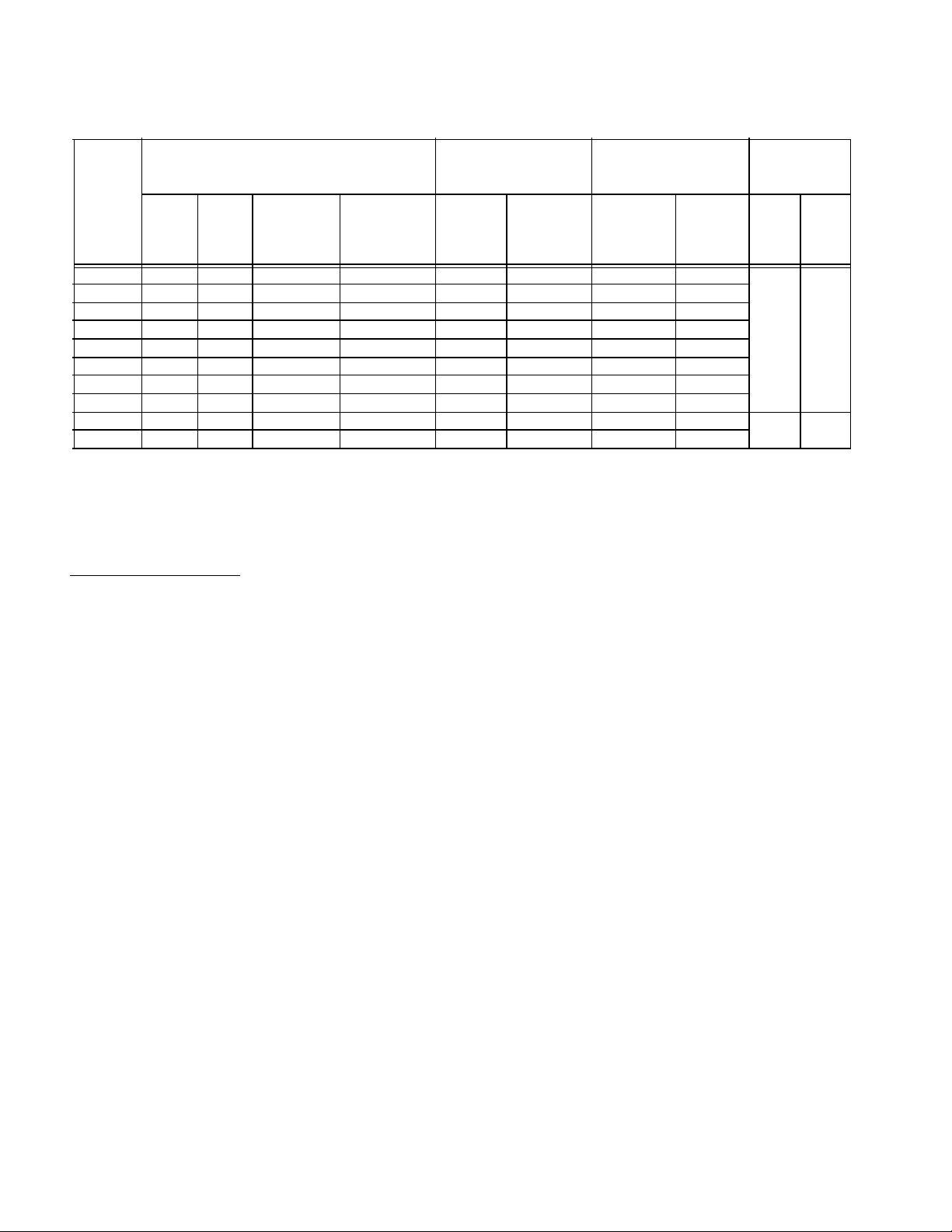

TABLE 2. SERIES 2610 MODEL MATRIX

FUNCTION CONFIGURATION

MODEL

RUN-

STOP

2611 X X X

2611P0 X X X

2611P1 X X X

2611P2 X X X

2611A X X X X

2611AP0 X X X X

2611AP1 X X X

2611AP3 X X X

2612 X X X

2612A X X X X

a. Units are reconnectable

b. No armature contactor

c. Includes armature contactor

b

RUN-

STOP-

c

DB

ARMATURE

SWITCH

REVERSE

ARMATURE

CONTACTOR

REVERSE

b

AND DB

c

OPEN

CHASSIS

ENCLOSED

OPERATOR

CONTROLS

LOCAL

INTEGRAL

MOTOR SELECTION

POWER

SOURCEa &

HP RANGE

REMOTE 115V 230V

1/6 - 1 1/3 - 2

1/6 - 1 1/3 - 3

Series 2600/2610 Controllers control the operation of general purpose DC motors designed for use with

solid-state rectified power supplies. The motor may be shunt-wound, stabilized shunt-wound, or permanent magnet. For maximum efficiency, the motor should be rated for operation from a NEMA Code K power supply.

2

Page 8

BOOK0795-F

SECTION II

INSTALLATION

Before starting the installation, read this section thoroughly. In addition, a through review of the Ratings And

Specifications (Section VII) is recommended. The following installation guidelines should be kept in mind when

installing the controller.

INSTALLATION GUIDELINES

1. CONTROLLER MOUNTING - Controllers rated 1/6 - 3 HP may be mounted either vertically or hori-

zontally. Controllers rated at 5 HP may only be mounted vertically. Never mount the controller upside

down, immediately beside or above heat generating equipment, or directly below water or steam pipes.

The controller must be mounted in a location free of vibration.

Multiple controllers may be mounted side by side, as close to each other as the mounting feet will allow.

However, if a Model 2601 or 2602 Controller enclosure has Cover Hinges (Option 1638), 4 inches (102

mm) clearance must be provided on the hinged side of the enclosure to accommodate the swing of the

cover.

The minimum clearance at the top and bottom of the controller may be as narrow as the conduit fittings

allow.

2. ATMOSPHERE - The atmosphere surrounding the controller must be free of combustible vapors, chemical fumes, oil vapor, and electrically conductive or corrosive materials.

The air surrounding an enclosed controller must not exceed 40 degrees C (104 degrees F), and the air surrounding an open-chassis controller must not exceed 55 degrees C (131 degrees F). Minimum air temperature is 0 degree C (32 degrees F) for enclosed and open-chassis controllers.

Model 2601 and 2602 Controllers (except 5 HP enclosed models) require a natural convection flow of air

over the pins on the back of the controller to dissipate the heat generated by the controller. Allow 4 inches

(102 mm) clearance on all sides from solid objects which block the flow of air to the pins.

3. CONTROLLER CONSTRUCTION - Series 2600/2610 controller bases are made of die-cast aluminum

with a powdered epoxy finish.

Series 2600/2610 Controller enclosures are totally enclosed, nonventilated, and comply with NEMA Type

4 and 12 standards. There is an oil resistant synthetic rubber gasket between the cover and base. Those

models with integral operator controls include flexible boots to seal the switches, and a seal for the

MOTOR SPEED potentiometer.

Series 2600 enclosure covers are molded of Noryl, which is not affected by most water-based solutions,

detergents, acids, and bases. However, the cover may be softened by heptane, acetone, and other halogenated and aromatic hydrocarbons, so install Series 2600 Controllers in a location free of these substances.

Series 2610 enclosure covers are made of a die-cast aluminum alloy.

3

Page 9

BOOK0795-F

4. BRANCH CIRCUIT PROTECTION - The National Electrical Code requires that a two-pole fused disconnect switch be installed in the AC line supply to the controller. Although an optional two-pole circuit

breaker (Option 1010) is available for Model 2601 Controllers, this circuit breaker should not be considered as branch circuit protection. However, the existing branch circuit may already provide the required

protection. Refer to the National Electrical Code and local codes.

5. LINE SUPPLY - The controller should not be connected to a line supply capable of supplying more than

100,000 amperes short-circuit current. Short-circuit current can be limited by using an input supply transformer of 50 KVA or less, or by using correctly sized current limiting fuses in the supply line ahead of the

controller. Do not use a transformer with less than the minimum transformer KVA listed in Table 9, page

33.

If rated line voltage is not available, a line transformer will be required. If the line supply comes directly

from a transformer, place a circuit breaker or disconnect between the transformer secondary and the controller. If power is switched in the transformer primary, transients may be generated which can damage the

controller. See Table 9 (page 33) for minimum transformer KVA.

Do not use power factor correction capacitors on the supply line to the controller.

A 12-joule metal oxide varistor (MOV) is connected across the controller terminals. If higher energy transients are present on the line supply, additional transient suppression will be required to limit transients to

150% of peak line voltage.

When a 115 VAC line supply is used, connect the white (common) wire to Terminal L2 and connect the

remaining (hot) wire to Terminal L1.

6. ISOLATION TRANSFORMER - While not required, an isolation transformer can provide the following

advantages:

a. Reduce the risk of personal injury if high voltage drive circuits are accidently touched.

b. Provide a barrier to externally generated AC supply transients. This can prevent controller damage from

abnormal line occurrences.

c. Reduce the potential for damaging current if the motor armature, motor field, or motor wiring become

grounded.

7. GROUNDING - Connect the green or bare (ground) wire of the line supply to the ground screw located

near the top conduit entry hole in the controller base. Then ground the controller base by connecting the

ground screw to earth ground.

The motor frame and operator control stations must also be grounded.

Personal injury may occur if the controller, motor, and operator stations are not properly grounded.

8. WIRING PRACTICES - The power wiring must be sized to comply with theNational Electrical Code,

CSA, or local codes. Refer to the controller data label for line and motor current ratings.

Do not use solid wire

4

Page 10

BOOK0795-F

Signal wiring refers to wiring for potentiometers, tachometer generators, and transducers. Control wiring

refers to wiring for operator controls. Signal and control wiring may be run in a common conduit, but not

in the same conduit with the power wiring. In an enclosure, nonshielded signal and control wiring must be

kept separated from power wiring and only cross at 90 degree angles.

If shielded wire (such as Alpha 2422 - two conductor, 2423 - three conductor, 2424 - four conductor) is

used for the signal and control wiring, connect the shields to chassis ground (ground screw on the controller base) and tape the opposite ends of the shields.

Two 3/4-14 NPT threaded holes are provided for conduit entry, one each in the top and bottom of the controller base.

9. OPTIONS - This equipment manual is for use with the basic controller. If options are installed in the con-

troller, they will be identified on the controller data label. The instruction sheets supplied with the options

should be reviewed before the controller is installed.

INSTALLING THE CONTROLLER

1. Remove the controller front cover (if used) by removing the four cover screws.

2. Check components in the controller for shipping damage. Report shipping damage to the carrier.

3. Check the controller and motor data labels to be sure the units are electrically compatible.

4. Be sure the controller has been calibrated correctly for the motor being used. Calibration is performed by

changing the position of a Jumper (J4) on the controller control board to comply with Table 3. To change

the position of Jumper J4, pull the jumper from the control board and then push it onto the appropriate two

pins on the board. For the location of J4, see Figure 22 (page 43) or Figure 23 (page 44) as applicable.

TABLE 3. JUMPER J4 POSITIONS

JUMPER

POSITION

MOTOR ARMATURE CURRENT RATING (AMPERES)

2 HP Maximum 3 HP Maximum 5 HP Maximum

a

100% 10 15 25

80% 8 12 20

60% 6 9 15

40% 4 6 10

20% 2 3 5

a. Select the position closest to the motor nameplate armature current rating.

5. Check the positions of Jumpers J1, J2, and J3 on the control board. For the locations of J1, J2, and J3, see

Figure 22 (page 43) or Figure 23 (page 44) as applicable. For a 230 VAC line supply and a 180V armature

motor, Jumper J1 must be in the 230V position, and Jumpers J2 and J3 must both be in the 180V position.

For a 115 VAC line supply, J1 must be in the 115V position, and J2 and J3 must be in the 90V position.

NOTE: If Option 1001 (Armature Contactor, Unidirectional), 1004 (Armature Contactor, Reversing), or

1775 (Signal Interface) is to be installed in the controller, do not offset the five-position plug

(supplied with the option) at Connector J1 on the control board. Do not confuse Connector J1

with Jumper J1. Refer to the Instruction Sheet (ISP0703, ISP0666, ISP0653, respectively) supplied with the option for connection instructions.

5

Page 11

BOOK0795-F

MODEL 2601 and 2602 CONTROLLERS

1. Mount the controller. Mounting dimensions are shown in Figure 1, below.

2. Install conduit and connect the power wiring to Terminals L1, L2, A1 (+), A2 (-), F+ and F-. Be sure to

observe Installation Guidelines 5 and 8 on pages 4 and 5. If half-wave shunt field voltage is desired, connect one of the motor shunt field leads to Terminal F/2 (see Table 14 on Page 37).

NOTE: Low inductance motors require a full-wave field to prevent current instability.

3. If the controller contains any options that require external wiring, follow the wiring instructions in the

instruction sheet supplied with the option.

4. If remote operator control wiring and/or signal wiring is required, connect the controller as shown in the

appropriate connection diagram (Figures 4 through 18). Figures 4 through 9 show operator control connections, and Figures 10 through 18 show signal connections.

5. Set the DIP Switch (S3) as shown in the appropriate connection diagram. See Figure 22 (page 43) or Figure 23 (page 44), as applicable, for the location of DIP Switch S3. Also refer to Table 13, “DIP Switch Settings,” page 36.

6. Install the controller cover, if used.

FIGURE 1. CONTROLLER MOUNTING DIMENSIONS, MODELS 2601 AND 2602

6

Page 12

BOOK0795-F

MODELS 2611 AND 2612

1. The controller may be surfaced mounted or panel mounted as shown in Figure 2, page 8. Mount the con-

troller. Mounting dimensions are shown in Figure 3, page 8.

2. Conduit entry is made by punching out the knockout at the top or bottom of the controller base. To prevent

component damage from knockout fragments, apply masking tape to the inside of the knockout before

punching.

3. Connect the power wiring to Terminals L1, L2, A1 (+), A2 (-), F+ and F-. Be sure to observe Installation

Guidelines 5 and 8 on pages 4 and 5. If half-wave shunt field voltage is desired, connect one of the motor

shunt field leads to Terminal F/2 (see Table 14 on Page 37).

NOTE: Low inductance motors require a full-wave field to prevent current instability.

4. If the controller contains any options that require external wiring, follow the wiring instructions in the

instruction sheet supplied with the option.

5. If remote operator control wiring and/or signal wiring is required, connect the controller as shown in the

appropriate connection diagram (Figures 4 through 18). Figures 4 through 9 show operator control connections, and Figures 10 through 18 show signal connections.

6. Set the DIP Switch (S3) as shown in the appropriate connection diagram. See Figure 22 (page 43) or Fig-

ure 23 (page 44), as applicable, for the location of DIP Switch S3. Also refer to Table 13, “DIP Switch Settings,” page 36.

7. Install the controller cover, if used.

7

Page 13

BOOK0795-F

FIGURE 2. CONTROLLER MOUNTING CONFIGURATIONS, MODELS 2611 AND 2612

FIGURE 3. CONTROLLER MOUNTING DIMENSIONS, MODELS 2611 AND 2612

8

Page 14

BOOK0795-F

FIGURE 4. LOGIC CONNECTION DIAGRAM, RUN-STOP-JOG SWITCH, 1/6 - 2 HP

FIGURE 5. LOGIC CONNECTION DIAGRAM, FORWARD-REVERSE SWITCH AND RUN-STOP-JOG

SWITCH, 1/6 - 2 HP

9

Page 15

BOOK0795-F

FIGURE 6. LOGIC CONNECTION DIAGRAM, RUN-STOP PUSHBUTTONS AND RUN-JOG SWITCH,

1/6 - 5 HP

FIGURE 7. LOGIC CONNECTION DIAGRAM, OPTIONAL ARMATURE CONTACTOR REVERSING

USING SWITCHES, 1/6 - 5 HP

10

Page 16

BOOK0795-F

FIGURE 8. LOGIC CONNECTION DIAGRAM, OPTIONAL ARMATURE CONTACTOR REVERSING

USING PUSHBUTTONS AND RUN-JOG SWITCH, 1/6 - 5 HP

FIGURE 9. LOGIC CONNECTION DIAGRAM, LINE STARTING WITH MOTOR SPEED POTENTIOME-

TER, 1/6 - 5 HP

11

Page 17

BOOK0795-F

FIGURE 10. SIGNAL CONNECTION DIAGRAM, MOTOR SPEED POTENTIOMETER

FIGURE 11. SIGNAL CONNECTION DIAGRAM, TACHOMETER FEEDBACK

FIGURE 12. SIGNAL CONNECTION DIAGRAM, CURRENT (TORQUE) REFERENCE POTENTIOMETER

12

Page 18

BOOK0795-F

FIGURE 13. SIGNAL CONNECTION DIAGRAM, LINE STARTING WITHOUT A MOTOR SPEED

POTENTIOMETER

FIGURE 14. SIGNAL CONNECTION DIAGRAM, 4 - 20 mA INTERFACE

FIGURE 15. SIGNAL CONNECTION DIAGRAM, 2-WIRE TRANSDUCER

13

Page 19

BOOK0795-F

FIGURE 16. SIGNAL CONNECTION DIAGRAM, 4 - 20 mA TRANSDUCER WITH MANUAL/AUTO

SWITCH

*

TRANSDUCER CURRENT

RANGE

1 - 5 mA 1,000 Ohms, 0.25W, ± 1%

2 - 10 mA 499 Ohms, 0.25W, ±1%

4 - 20 mA 249 Ohms, 0.25W, ±1%

10 - 50 mA 100 Ohms, 0.50W, ±1%

FIGURE 17. SIGNAL CONNECTION DIAGRAM, TRANSDUCER WITH EXTERNAL BURDEN RESISTOR

EXTERNAL BURDEN

*

RESISTOR

FIGURE 18. SIGNAL CONNECTION DIAGRAM, 0 - 10 VDC EXTERNAL SPEED REFERENCE SIGNAL

14

Page 20

BOOK0795-F

INITIAL STARTUP

1. Open the controller cover (if used) by removing the four cover screws.

2. Be familiar with all options installed in the controller by reviewing the instruction sheets supplied with the

options.

3. Be sure all wiring is correct and all wiring terminations are tightened securely.

4. Be sure the controller is calibrated correctly. See steps 4 and 5 under “Installing The Controller” on page 5.

5. Be sure the AC supply voltage to the controller agrees with the controller data label.

6. The potentiometers in the controller are factory adjusted as shown in Table 4. These settings will provide

satisfactory operation for most applications. If different settings are required, refer to “Adjustment Instructions” starting on page 21.

TABLE 4. INITIAL POTENTIOMETER SETTINGS

POTENTIOMETER SETTING DESCRIPTION

ACCEL 2/3 Turn Clockwise 8 Seconds

CUR LMT Fully Clockwise (100%) 150% Load

DECEL 2/3 Turn Clockwise 8 Seconds

IR/TACH Fully Counterclockwise (0%) 0% Boost

MAX SPD 3/4 Turn Clockwise 100% Speed

MIN SPD (Offset) Fully Counterclockwise (0%) 0% Speed

7. If the controller has a cover, place it on the controller and secure it with the four cover screws.

8. Turn-on the AC supply to the controller.

9. Check motor rotation, as follows:

a. If a MOTOR SPEED potentiometer is used, turn it fully counterclockwise. If an external signal is used

for the speed reference, set it at minimum.

b. If a RUN-STOP-JOG switch is used, place it in RUN position. Otherwise, initiate a Run command.

c. Turn the MOTOR SPEED potentiometer clockwise or increase the speed reference signal, as applica-

ble. To stop the motor, place the switch in STOP position or initiate a Stop command, as applicable.

If the motor rotates in the wrong direction, turn-off the AC supply to the controller, and then interchange

the motor armature leads at the motor connection box or at the controller terminal board.

10. Refer to Section III, “Operation” for operating instructions.

15

Page 21

BOOK0795-F

Blank Page

16

Page 22

BOOK0795-F

SECTION III

OPERATION

POWER ON/OFF

To energize the drive, turn-on the AC supply voltage to the controller. When this occurs, the motor shunt

field energizes with rated field voltage, and potentially hazardous voltage is present at the motor armature terminals. These voltages can cause electric shock resulting in personal injury or loss of life.

If the AC supply is interrupted, and the controller is not set up for line starting, the motor will not restart

when the AC supply is restored until the controller is reset by initiating a Stop command and then a Start command.

If the controller is set up for line starting, and the AC supply is interrupted, the motor will restart when the AC supply is restored, provided the external AC line contactor is pulled in.

RUN

If a RUN-STOP-JOG switch is used, place the switch in RUN position. Otherwise, initiate a Run command.

A Run command will accelerate the motor to the setting of the MOTOR SPEED potentiometer or external speed

reference signal, as applicable. The rate of acceleration is preset by the ACCEL potentiometer on the controller

control board.

STOP

If a RUN-STOP-JOG switch is used, place the switch in STOP position. Otherwise, initiate a Stop command.

A Stop command will stop the motor at a rate proportional to the stopping rate of the motor load.

If the controller has dynamic braking, the motor stopping time will be reduced. Dynamic braking provides

exponential rate braking of the motor armature, which occurs when the circuit is opened between the controller and

the motor armature, and one or more resistors connect across the motor armature.

The dynamic braking resistors provide initial braking torque as shown in Table 5.

TABLE 5. DYNAMIC BRAKING CHARACTERISTICS

COMPONENT MODEL

2601

2602

BRAKING TORQUE (%)

STOPS PER MINUTE

a. HIGH INERTIA LOADS MAY EXTEND BRAKING TIME AND CAUSE THE WATTAGE RATING OF THE DYNAMIC

BRAKING RESISTORS TO BE EXCEEDED.

2612

2611

2601

2602

2612

2611

RATED

VOLTAGE

115V 300 215 170 110 75 60 NA NA NA NA

230V NA NA NA 400 320 220 145 105 85 96

115V 180 129 103 66 44 34 NA NA NA NA

230V NA NA 400 278 190 130 88 62 NA NA

115V 9 6 5 5 4 4 NA NA NA NA

230V NA NA NA 5 4 4 3 3 2 2

115V 15 12 11 8 6 2 NA NA NA NA

230V NA NA 12 8 6 1 1 1 NA NA

1/6 1/4 1/3 1/2 3/4 1 1-1/2 2 3 5

RATED HORSEPOWER

a

17

Page 23

BOOK0795-F

An antiplug feature is included with optional Armature Contactor Reversing With Dynamic Braking (Option

1004). This feature prevents restarting the motor before the motor has braked to a stop.

SPEED CONTROL

Motor speed is directly proportional to the setting of the MOTOR SPEED potentiometer or the magnitude of

an external speed reference signal, as applicable. This potentiometer or the speed reference signal may be adjusted

while the motor is running or may be preset before the motor is started.

The rates of acceleration and deceleration are preset by the ACCEL and DECEL potentiometers, respectively, located on the controller control board.

Maximum speed and minimum speed (or offset) are preset by the MAX SPD and MIN SPD potentiometers,

respectively, located on the control board.

JOG

If a RUN-STOP-JOG switch is used, place the switch in JOG position. Otherwise initiate a Jog command.

Jog is momentary, causing motor rotation only while the switch is held in JOG position or while a Jog command is

active. Release the switch to stop the motor.

Normally, jog speed is directly proportional to the setting of the MOTOR SPEED potentiometer. If a separate JOG SPEED potentiometer is used, jog speed will be directly proportional to the setting of the JOG SPEED

potentiometer.

REVERSE

To reverse motor rotation on controllers with reversing capabilities, initiate a Stop function and then initiate

a reversing command. The motor will then accelerate to the setting of the MOTOR SPEED potentiometer or external speed reference signal, as applicable. Forward and reverse speed ranges are identical.

If a FWD-REV switch is used, it must have a center position interlock, which requires a momentary relaxation of pressure before the opposite position can be engaged. The center position causes a Stop command and

allows time for the motor to stop before a Reverse command is initiated. If a Reverse command is initiated while

the motor is rotating, motor and controller damage may occur.

If Option 1004 (Armature Contactor Reversing With Dynamic Braking) is installed, an antiplug feature prevents reversing the motor before the motor has stopped.

INOPERATIVE MOTOR

If the motor stops and/or won’t start, turn-off the AC supply to the controller, remove the controller cover (if

used), and check the AC line fuse on the controller control board. For the location of the fuse, see Figure 22 (page

43) or Figure 23 (page 44), as applicable. If the fuse is blown, refer to the Troubleshooting Table (Table 6).

18

Page 24

BOOK0795-F

If the fuse is not blown, the internal overload monitor may have shut down the controller. The overload monitor will shut down the controller if the motor armature current exceeds 120% of rated for a length of time of continuous operation. The length of time is determined by the amount of the overload. If the overload monitor trips,

reset the controller by initiating a Stop command, removing the overload, and then initiating a Run command to

restart. Repeated shutdown indicates an overload condition (mechanical or electrical) which must be removed.

Refer to the Troubleshooting Table (Table 6).

19

Page 25

BOOK0795-F

Blank Page

20

Page 26

BOOK0795-F

SECTION IV

MAINTENANCE AND REPAIR

GENERAL

1. Keep the controller dry and free of dust, dirt, and debris. No parts require periodic replacement.

2. Periodically turn-off the AC line supply to the controller and check all wire terminations to be sure they are

tight.

3. Visually check components for damage due to overheating or breakage. All damaged and/or faulty components must be replaced for satisfactory operation.

4. Maintain the motor according to maintenance instructions supplied by the motor manufacturer.

ADJUSTMENT INSTRUCTIONS

ACCELERATION

1. Set the MOTOR SPEED potentiometer at 100% or the external speed reference signal at maximum, as

applicable.

2. Initiate a Run command and observe the time required for the motor to reach maximum speed.

3. Adjust the ACCEL potentiometer for the desired rate. Full clockwise rotation is the fastest acceleration

(0.2 second), and full counterclockwise rotation is the slowest acceleration (30 seconds).

DECELERATION

1. With the motor running at maximum speed, quickly reset the MOTOR SPEED potentiometer to zero, or

quickly decrease the speed reference signal to minimum, as applicable, and observe the time required for

the motor to reach minimum speed.

2. Adjust the DECEL potentiometer for the desired rate. Full clockwise rotation is the fastest deceleration

(0.2 second), and full counterclockwise rotation is the slowest deceleration (30 seconds).

IR COMPENSATION

IR compensation is used only when the controller is programmed for armature feedback. The IR/TACH

potentiometer is factory set at zero (full counterclockwise rotation) for satisfactory operation with most motors. If

improved speed regulation is desired, readjust IR compensation as follows:

21

Page 27

BOOK0795-F

1. Be sure Segments 2 and 3 of DIP Switch S3 are in ON (Closed) position.

2. If the motor is shunt-wound, run it at rated base speed. If the motor is a permanent-magnet type, run it

about 1/3 speed.

3. Turn the IR/TACH potentiometer clockwise slowly until motor speed becomes unstable. Then turn the

potentiometer counterclockwise until motor speed stabilizes.

MAXIMUM SPEED (ARMATURE FEEDBACK)

The MAX SPD potentiometer adjusts maximum speed by setting maximum armature voltage. The voltage

range is from 50% to 100% of rated armature voltage. If the controller is programmed for tachometer feedback, the

MAX SPD potentiometer sets the armature backup voltage.

1. Be sure Segments 2 and 3 of DIP Switch S3 are in ON (Closed) position.

2. Turn the MAX SPD potentiometer fully clockwise (100%). This setting provides 90 VDC armature voltage with a 115 VAC line, or 180 VDC armature voltage with a 230 VAC line.

3. Run the motor at maximum speed, and turn the MAX SPD potentiometer counterclockwise for the desired

maximum speed.

NOTE: If the MAX SPD potentiometer is turned too far counterclockwise, speed instability may occur.

MAXIMUM SPEED (TACHOMETER FEEDBACK)

Tachometer feedback provides speed regulation characteristics as shown in Table 12, page 35. However, these

characteristics are based on the use of Fincor Electronics cataloged motors and generators. Regulation characteristics and drive performance cannot be guaranteed with motors and/or tachometer generators that have not been evaluated. For example, some tachometer generators with low voltage/RPM ratios may not provide adequate feedback

signal levels at low speed.

1. Be sure Segments 2 and 3 of DIP Switch S3 are in OFF (Open) position.

2. Set Segment 1 of DIP Switch S3 for the expected tachometer generator speed at maximum speed, as follows:

SEGMENT 1 POSITION TACH VOLTAGE

ON (Closed) 8V - 30V

OFF (Open) 31V - 175V

3. Turn the IR/TACH potentiometer fully counterclockwise (0%). This setting provides maximum motor

speed.

4. Be sure the MAX SPD potentiometer has been adjusted correctly.

22

Page 28

BOOK0795-F

5. Run the motor at maximum speed, and start turning the IR/TACH potentiometer clockwise until motor

speed increases above desired speed. Continue turning the potentiometer clockwise until motor speed

decreases to desired speed.

MINIMUM SPEED

1. Be sure Segment 6 of DIP Switch S3 is in ON (Closed) position.

2. Turn the MIN SPD potentiometer fully counterclockwise (0%) for zero speed.

3. Set the MOTOR SPEED potentiometer at 0% or the external speed reference signal at minimum, as appli-

cable.

4. Initiate a Run command and adjust the MIN SPD potentiometer for the desired minimum speed (adjustable

from 0 to 40% of motor base speed).

OFFSET

An offset adjustment is desirable when a 4 mA to 20 mA speed reference signal is used. The MIN SPD

potentiometer compensates for the 4 mA offset.

1. Be sure Segment 6 of DIP Switch S3 is in OFF (Open) position, and a wire jumper connects between TB2-

1 and TB2-3.

2. Set the speed reference signal at 4 mA and initiate a Run command.

3. Adjust the MIN SPD potentiometer as desired.

NOTE: The MIN SPD potentiometer may be ineffective between 50% and 100%.

CURRENT LIMIT

1. Turn the CUR LMT potentiometer fully clockwise (100%) to limit motor armature current at 150% of

rated.

2. Turn the CUR LMT potentiometer counterclockwise to reduce maximum motor armature current.

NOTES: a. An LED glows red on the controller control board when motor armature current is being lim-

ited.

b. An external 5K ohm Current (Torque) Limit potentiometer can be used as shown in Figure 12

on page 12. Segment 5 of DIP Switch S3 must be in OFF (Open) position if an external Current (Torque) Limit potentiometer is desired.

23

Page 29

BOOK0795-F

TROUBLESHOOTING

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

1. Motor won’t start

(See “Inoperative

Motor,” page 18.)

AC line open

Operator controls inoperative or connected incorrectly

Open circuit between Connectors E1

and E2 in 1/6 - 3 HP controllers

Controller not reset

Line Voltage Selection Jumper J1 in

wrong position

Controller not enabled

Loss of speed reference signal

Controller not adjusted correctly

Be sure rated AC line voltage is applied to the

controller.

Repair accordingly.

A wire jumper or switch must connect E1 to

E2.

Initiate a Stop command and then a Start command.

See Step 5 on page 5 under, “Installing The

Controller.”

Be sure +24 VDC is applied to Terminal TB2-

8.

Check for 0 - 10 VDC, 4 - 20 mA, or 0 - 5

VDC speed reference signal, as applicable.

Turn the ACCEL and CUR LIM potentiometers fully clockwise (100%).

DIP Switch S3 not set correctly See Table 13, page 36.

2. Controller fuse blows

when AC line power is

applied to the controller

Contd on next page

Open shunt field winding or wiring to

the motor shunt field, causing loss of

a

torque

Check the motor shunt field and associated

circuitry for a loose connection or a broken

wire. Repair accordingly.

Motor failure Repair or replace the motor.

Control board failure Replace the control board.

Wiring faulty or incorrect

Circuit, component, or wiring

grounded

Check all external wiring terminating in the

controller. Correct accordingly.

Remove ground fault.

Two or more SCR’s shorted Replace shorted SCR’s or the control board.

Varistor RV1 shorted Replace RV1 or the control board.

Shunt Field Bridge BR1 shorted

a

Replace BR1 or the control board.

Motor shunt field shorted or groundedaRepair or replace the motor.

Control board failure Replace the control board.

24

Page 30

BOOK0795-F

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

3. Controller fuse blows

when a Start command is

initiated

4. Controller fuse blows

while the motor is running

One or more SCR‘s or Diode D1

shorted

Replace shorted devices or the control board.

Motor shorted or grounded Repair or replace the motor.

Control board failure causing SCR’s to

turn-on fully

Replace the control board.

Check shunt field current.a Low shunt field

current causes excessive armature current. If

field current is adequate, check for a mechani-

Motor overloaded

cal overload. If the unloaded motor shaft does

not rotate freely, check motor bearings. Also

check for a shorted motor armature. Motor

overload can also be caused by incorrect gear

ratio. Correct accordingly.

Loose or corroded connection. Wiring

faulty, incorrect, or grounded

Check all terminals, connections, and wiring

between the line, controller, and motor.

Motor shorted or grounded Repair or replace the motor.

One or more SCR‘s or Diode D1

breaking down (shorting intermit-

Replace shorted devices or the control board.

tently)

5. Minimum speed excessive

6. Maximum speed

excessive

Contd on next page

Control board failure causing SCR

false firing or misfiring

Minimum speed not adjusted correctly

Replace the control board.

Turn the MIN SPD potentiometer counterclockwise.

Control board failure Replace the control board.

Maximum speed set too high

Turn the MAX SPD potentiometer counterclockwise.

Controller not calibrated correctly Refer to Steps 4 and 5 on page 5.

Open shunt field winding or wiring to

the motor shunt field

Motor field demagnetized

a

b

Check the motor shunt field and associated

circuitry for a loose connection or a broken

wire. Repair accordingly.

Replace the motor.

25

Page 31

BOOK0795-F

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

7. Motor won’t reach top

speed

Low line voltage

Check for rated line voltage, ±10%, on the

controller line terminals.

Check shunt field current.a Low shunt field

current causes excessive armature current. If

field current is adequate, check for a mechani-

Motor overloaded

cal overload. If the unloaded motor shaft does

not rotate freely, check motor bearings. Also

check for a shorted motor armature. Motor

overload can also be caused by incorrect gear

ratio. Correct accordingly.

Maximum speed set too low Turn the MAX SPD potentiometer clockwise.

Current limit set too low Turn the CUR LMT potentiometer clockwise.

Current Scaling Jumper J4 in wrong

position

Motor field demagnetized

b

See Step 4 and Table 3, page 5.

Replace the motor.

Control board failure Replace the control board.

Observe line voltage with a voltmeter or oscil-

AC line voltage fluctuating

loscope. If fluctuations occur, correct condition accordingly.

8. Unstable speed

Contd on next page

Loose or corroded connection. Wiring

faulty, incorrect, or grounded

Oscillating load connected to the

motor

Voltage Selection Jumpers J1, J2, J3 in

wrong position

IR compensation not adjusted correctly

Maximum speed not adjusted correctly

Motor faulty

Tachometer generator or coupling

faulty (if used)

Check all terminals, connections, and wiring

between the line, operator controls, controller,

and motor.

Stabilize the load. Turning the IR/TACH

potentiometer counterclockwise may minimize oscillations.

See Step 5 on page 5 under, “Installing The

Controller.”

See the IR Compensation adjustment instructions on page 21.

See the Maximum Speed (Armature Feedback) adjustment instructions on page 22.

Check motor brushes. Replace if needed.

Repair or replace the motor.

Repair accordingly.

26

Page 32

TABLE 6. TROUBLESHOOTING

INDICATION POSSIBLE CAUSE CORRECTIVE ACTION

Check shunt field current.a Low shunt field

current causes excessive armature current. If

field current is adequate, check for a mechani-

9. Line and motor armature current excessive

Motor overloaded

cal overload. If the unloaded motor shaft does

not rotate freely, check motor bearings. Also

check for a shorted motor armature. Motor

overload can also be caused by incorrect gear

ratio. Correct accordingly.

BOOK0795-F

10. Shunt field current a

too low

11. Shunt field current a

too high

12. Motor thermal guard

tripped (if used)

Open shunt field winding or wiring to

the motor shunt field

Shunt field connected for incorrect

voltage

Check the motor shunt field and associated

circuitry for a loose connection or a broken

wire. Repair accordingly.

Check motor rating and refer to Table 14,

page 37.

Shunt Field Bridge BR1 failure Replace BR1 or the control board.

Shunt field connected for incorrect

voltage

Check motor rating and refer to Table 14,

page 37.

Measure the shunt field resistance and com-

Shunt field windings shorted

pare with the motor rating. Repair or replace

the motor.

Ventilation insufficient

Remove dirt, dust, and debris from the motor

intake and exhaust screens.

Excessive motor load at low speed Reduce the load or increase the speed.

Line and motor armature current

excessive

See Indication 9.

Motor overheating from friction Check for misalignment. Realign the motor.

Shorted motor windings or faulty bearings

Contd on next page

a. Does not apply to permanent-magnet motors.

b. Does not apply to shunt-wound motors.

Repair or replace the motor.

27

Page 33

BOOK0795-F

Blank Page

28

Page 34

SECTION V

OPTIONS

Options are available for Series 2600/2610 Controllers which increase the functional use of the basic control-

ler. Table 7 (page 22) lists all available options and allowable option combinations.

Options can be added to the basic controller at any time. Each option consists of all required components,

mounting hardware, and instruction sheet.

BOOK0795-F

29

Page 35

BOOK0795-F

TABLE 7. ALLOWABLE OPTION COMBINATIONS

OPTION TYPE

Enclosure Options - Choice of any or all

within this group. May be combined with

options from any other groups.

Options Used To Convert Open Chassis

Units Into Enclosed Package Controllers - Choice of one within this group. May

be combined with options from any other

groups.

Power Options

Input Signal Options - Choice of one

within this group unless Option 1037 is

selected. May be combined with options

from any other groups except Group F.

Option 1775 is required for all options in

this group.

Feedback Options - Choice of one within

this group unless Option 1037 is selected.

May be combined with options from any

other groups except Group F. Option 1775

is required for all options in this group.

Input And Feedback Options - May be

combined with options from any other

groups except Groups D and E.

External Options - Choice of any or all

within this group

Miscellaneous Options - Choice of any or

all within this group when mounted externally. Choice of one when mounted in a

Model 2601 or 2602. May be combined

with options from any other groups.

a. XK = Factory Installed Or Field Kit

K = Field Kit

P = Plug-In Option

OPTION

GROUP

A 1638 XK Hinge, Enclosure Cover (Models 2601 And 2602 Only)

A 1170A XK

B 1639 XK Cover Assembly, Blank Type P0

B 1639C XK Cover Assembly, Type P1

B 1639E XK Cover Assembly, Type P2

B 1639G XK Cover Assembly, Type P3

C 1010 XK Circuit Breaker - Two Pole (Model 2601 Only)

C 1014 XK AC Line Switch (Model 2602 Only)

C 1004 XK

D 1775 XK Interface, Signal Options

D 1037 XK, P Input, External Interface

D 1049 XK, P Follower, External DC Signal

D 1050 XK, P Follower, External AC Signal

D 1050A XK, P Follower, AC Current Transducer

D 1051 XK, P Follower, MIRC

D 1055 XK, P Follower, AC Or DC Tachometer Generator

D 1057A XK, P Follower, Digital Pulse Generator

D 1059 XK, P Precision Reference

E 1775 XK Interface, Signal Options

E 1037 XK, P Feedback, External Interface

E 1061C XK, P Feedback, AC Or DC Tachometer Generator

E 1061F XK, P Feedback, AC Or DC Tachometer Generator With Tach Loss

E 1062A XK, P Feedback, Digital Pulse Generator

E 1064 XK, P Torque (Current) Limit Control

E 1190 XK, P Torque Taper

F 1064A XK Follower, Current Regulator

F 1191 XK Centerwind Torque Control

F 1220 XK Constant Velocity Winder

G 1120 K Operator Control Station - Remote

G 1120A K Motor Speed Potentiometer, Ten-Turn With Analog Dial

G 1120B K Motor Speed Potentiometer, One-Turn

G 1120C K Motor Speed Potentiometer, Ten-Turn With Digital Dial

G 1022 K Jog, Toggle Switch Selection

G 1058A K Follower/Manual Mode Select Switch

G 1037A K Input-Feedback Adapter, External - One Position

G 1166 K Equipment Manual

H 1047 XK Controlled (Ramp) Stop

H 1081B XK Current (Torque) Monitor

H 1015 XK Magnetic Control Interface (115V)

OPTION

NUMBER

OPTION

CODE

a

Fan Assembly (5 HP Units Only) (Required When Enclosed

Model 2602 Is Operated At 5 HP Rating)

Armature Contactor Reversing With Dynamic Braking (May Be

Combined With All Options In This Group)

OPTION

30

Page 36

SECTION VI

PARTS LIST

TABLE 8. PARTS LIST, SERIES 2600/2610 CONTROLLERS

FINCOR PART NUMBER

BOOK0795-F

PART RATING

Control Board NA 106105702 106109601 106105701 106105702

30A, 600V (ATM-30) 3002396 NA 3002396 3002396

Fuse, Line

60A, 300V (SC-60) NA 3002526 NA NA

55A, 800V 3302231 NA NA 3302231

SCR

Silicon Rectifier

(Freewheeling Diode)

65A, 600V NA 3302223 NA NA

15A, 600V NA NA 3302201 NA

15A, 600V NA NA 3303207 NA

24A, 600V 3303292 3303292 NA 3303292

MODEL

2601

MODEL

2602

MODEL

2611

MODEL

2612

31

Page 37

BOOK0795-F

Blank Page

32

Page 38

BOOK0795-F

SECTION VII

RATINGS AND SPECIFICATIONS

RATINGS

1. Current/Torque Reference Potentiometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5K Ohms, 1/2W

2. Duty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Continuous

3. Horsepower Range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/6 - 5 HP (See Table 1, Page 1)

4. Line Fuse Interrupting Capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100,000 Amperes

5. Line Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115V Or 230V, Single-Phase, 50 Or 60 Hz

6. Motor Speed Potentiometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5K Ohms, 1/2W

7. Overload Capacity, Armature Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150% For 1 Minute

8. Service Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0

TABLE 9. TYPICAL APPLICATION DATA

COMPONENT RATINGS

RATED HORSEPOWER (HP) 1/6 1/4 1/3 1/2 3/4 1 1-1/2 2 3 5

RATED KILOWATTS (kW) 0.124 0.187 0.249 0.373 0.560 0.746 1.120 1.492 2.238 3.730

115V

1-PHASE

AC INPUT

(FULL-LOAD)

DC OUTPUT

(FULL-LOAD)

FULL-LOAD TORQUE (lb-ft) with

1750 RPM Base Speed Motors

MINIMUM TRANSFORMER KVA FOR

VOLTAGE MATCHING OR ISOLATION

Line

Amps

KVA 0.48 0.58 0.71 1.00 1.40 2.00 3.00 4.00 5.00 8.00

Motor

Armature

Amps

Motor

Field

Amps

(Maximum)

Unit

230V

Unit

90V 2.0 2.8 3.5 5.4 8.1 10.5 NA NA NA NA

180V NA NA NA 2.6 3.8 5.5 8.2 11.6 15.1 25.0

Series

2600

Series

2611

Series

2612

3.9 5.0 6.0 8.7 12.4 15.8 NA NA NA NA

NA NA NA 4.2 5.9 8.8 12.6 15.8 22.0 32.0

2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0

1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 NA NA

1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 NA

0.5 0.75 1.0 1.5 2.2 3.0 4.5 6.0 9.0 15.0

0.5 0.75 0.75 1.0 1.5 2.0 3.0 5.0 7.5 10.0

33

Page 39

BOOK0795-F

TABLE 10. OPERATING VOLTAGES AND SIGNALS

POWER SOURCE

(Single-Phase)

115V, 50 or 60 Hz 0 - 90 50/100 0 - 5 VDC,

230V, 50 or 60 Hz 0 - 180 100/200

a. Grounded or ungrounded. Choice of one.

OUTPUT VDC SPEED

Armature Field

REFERENCE

SIGNAL

0 - 10 VDC,

4 - 20 mA

MAGNETIC

CONTROL

a

VOLTAGE

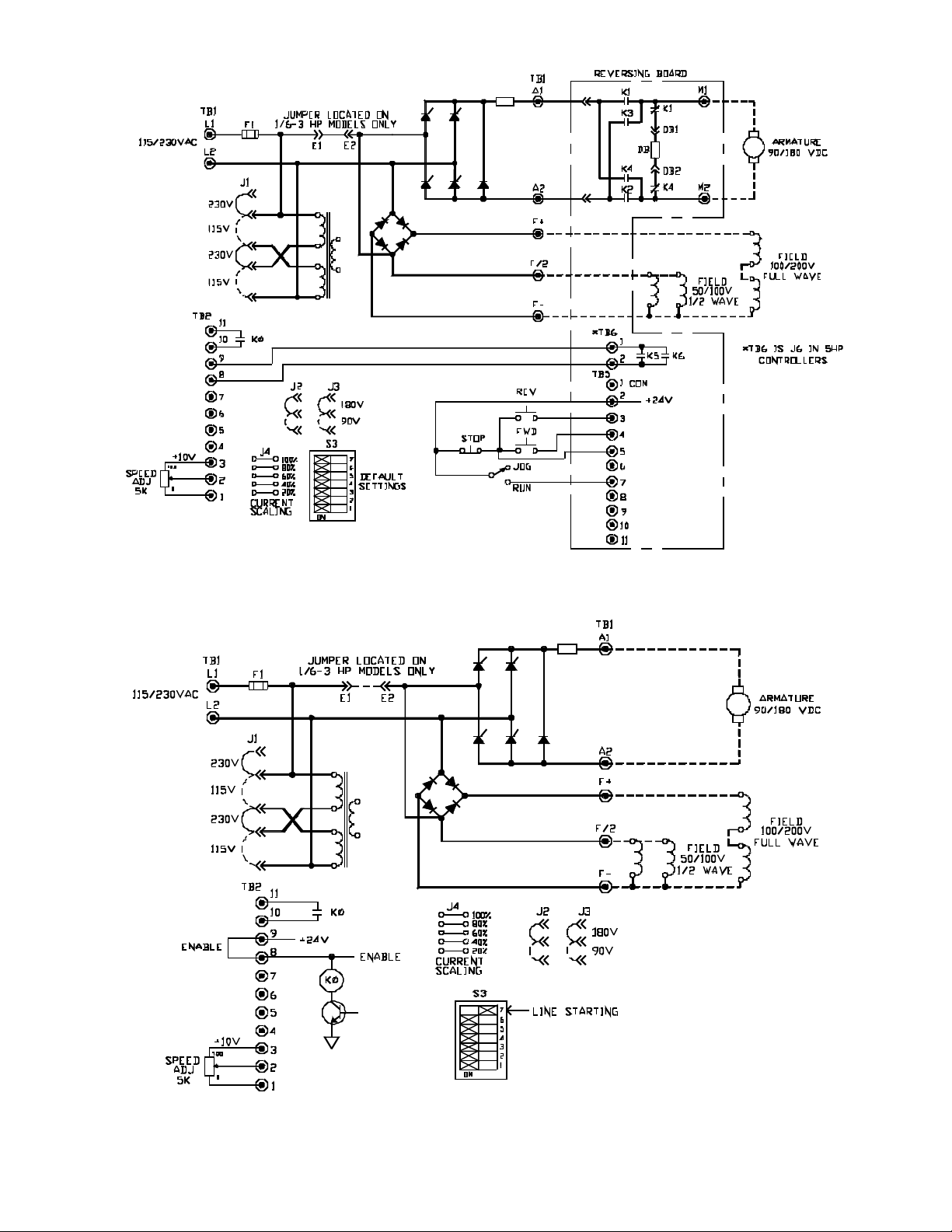

24 VDC

TABLE 11. CONTROLLER WEIGHTS

CONTROLLER MODEL WEIGHT - LBS (KG)

Rated Horsepower (HP) 1/6 - 2 3 5

2601 7.70 (3.50) NA

2602 8.20 (3.72) 8.60 (3.90)

2601A 8.50 (3.86) NA

2602A 8.90 (4.04) 9.30 (4.22)

2601P0, P1, P3 11.60 (5.26) NA

2602P0, P1, P3 12.10 (5.49) 12.50 (5.67)

2601AP0, P1, P3 12.40 (5.62) NA

2602AP0, P1, P3 12.80 (5.81) 13.20 (6.00)

2611, 2612 3.25 (1.47) NA

2611A, 2612A 3.80 (1.72) NA

2611P0, P1, P2 5.50 (2.50) NA

2611AP0, P3 6.05 (2.74) NA

OPERATING CONDITIONS

1. Altitude, Standard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1000 Meters (3300 Feet) Maximum.1

2. Ambient Temperature2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 40°C (32°F - 104°F)

3. Line Frequency Variation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 2 Hz Of Rated

4. Line Voltage Variation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±10% Of Rated

5. Relative Humidity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95% Noncondensing

1. Controller can be derated by 1% per 100 meters to operate at higher altitudes.

2. 55°C (131°F) maximum in enclosed areas where open-chassis controllers are mounted.

34

Page 40

BOOK0795-F

PERFORMANCE CHARACTERISTICS

1. Controlled Speed Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 To Motor Base Speed

2. Displacement Power Factor (Rated Speed/Rated Load). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87%

3. Efficiency (Rated Speed/Rated Load)

a. Controller Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98%

b. Controller With Motor, Typical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85%

4. Speed Regulation. . . . . . . . . Regulation percentages are of motor base speed under steady-state conditions

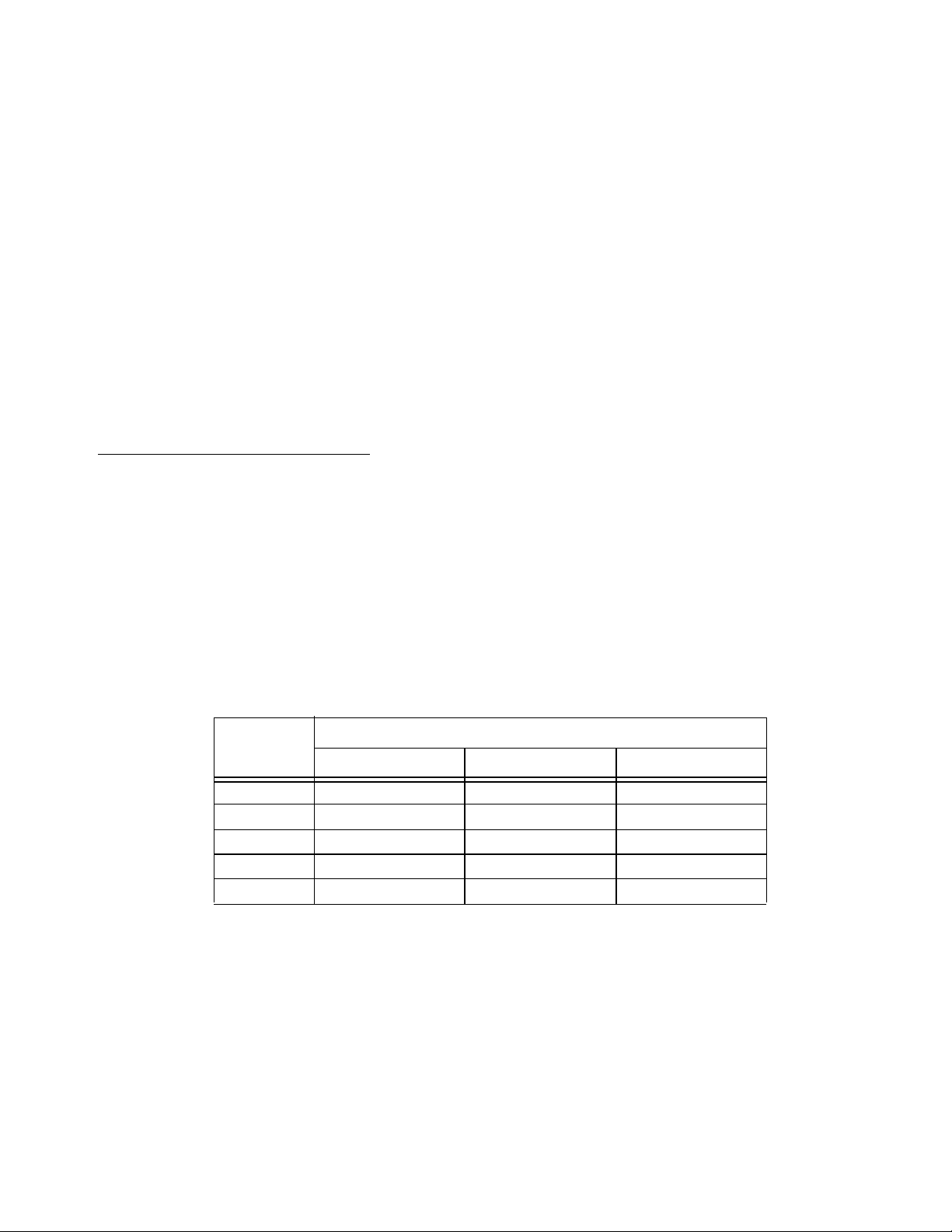

TABLE 12. SPEED REGULATION CHARACTERISTICS

VARIABLE

REGULATION

METHOD

Load

Change

(95%)

Line

Voltage

(±10%)

Field

Heating

a

(Cold/Normal)

Temperature

(±10°C)

Speed

Range

Standard Voltage

Feedback with IR

Compensation

Optional Speed

(Tach) Feedback

(Option 1061C)

with Sigmation or

5PY DC Tach

a. With Precision Reference (Option 1059), regulation due to ±10% line voltage

change is ±0.1%.

b. Speed regulation characteristics are based on the use of Fincor Electronics cataloged motors and tachometer generators. Regulation characteristics cannot be guaranteed with motors and/or tachometer generators that have not been evaluated.

b

2% ±1% 5 - 12% ±2% 50:1

0.5% ±1% 0.2% ±2% 200:1

ADJUSTMENTS

1. Acceleration, Linear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 - 30 Seconds

2. Deceleration, Linear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.2 - 30 Seconds

3. IR (Load) Compensation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 10% Boost

4. Jog Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 100% Of Motor Base Speed

5. Maximum Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50% - 100% Of Motor Bas e Speed

6. Minimum Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 40% Of Motor Base Speed

7. Torque (Current) Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0 - 150% Of Full-Load Torque

35

Page 41

BOOK0795-F

SPECIFICATIONS

1. AC LINE PROTECTION - A 100,000 ampere interrupting capacity AC line fuse provides instantaneous

protection from peak loads and fault currents. This line fuse is located inside the controller. A moldedcase, magnetic-trip circuit breaker (Option 1010) is available for Model 2601 Controllers, which provides

a manual disconnection to the controller, and also provides automatic instantaneous trip protection from a

peak load.

2. AUXILIARY CONTACT - A normally-open Form A relay contact, rated 5 ampere @115 VAC and 30

VDC, is available for external use. The relay energizes when a Run command is initiated, and de-energizes

when a Normal Stop command is initiated, the overload monitor trips, or the anti-restart circuit is activated.

3. CONTROL VOLTAGE - A transformer coupled 24 VDC power supply isolates all magnetic control

logic and operator controls from the AC power source for operator protection.

4. DIP SWITCH SETTINGS - A 7-position DIP Switch (S3) is used to program the controller for various

applications as shown in Table 13.

TABLE 13. DIP SWITCH S3 SETTINGS

SEGMENT

1

2

3

4

5

6

SEGMENT POSITION

ON

(Closed)

OFF

(Open)

DESCRIPTION

X Low voltage tachometer generator signal (8 VDC - 30 VDC)

X High voltage tachometer generator signal (31 VDC - 175 VDC)

X Armature feedback

X Tachometer feedback with armature feedback backup

X Armature feedback

X Tachometer feedback with armature feedback backup

X 4 mA - 20 mA input speed reference signal

X 0 - 5 VDC input speed reference signal

X

X

Enables the internal current limit circuit, adjustable with the CUR LMT

potentiometer.

Enables the use of an external current (torque) limit potentiometer (5K

ohm, 1/2W)

X Selects the MIN SPD potentiometer as a minimum speed adjustment

X

Selects the MIN SPD potentiometer as an offset adjustment for a 4 mA 20 mA input speed reference signal

7

X

Enables anti-restart. Prevents the controller from restarting automatically after an AC power interruption.

X Line starting. Disables anti-restart.

36

Page 42

BOOK0795-F

5. FEEDBACK - Two selectable modes of analog feedback are provided, as follows. See Table 12 (page 35)

for speed regulation characteristics.

a. Armature Feedback - Counter EMF voltage feedback with IR compensation, adjustable for individ-

ual motor characteristics.

b. DC Tachometer Feedback - The controller provides voltage scaling, and terminals for accepting the

output of a DC tachometer generator, mechanically coupled to the drive motor armature. The controller will automatically transfer to armature feedback if the tachometer signal is lost. Tachometer generators with an output of 8 VDC to 175 VDC at maximum speed may be used.

6. FIELD SUPPLY - A half-wave or full-wave shunt field supply is available as shown in Table 14.

TABLE 14. SHUNT FIELD DATA

CONTROLLER RATING

(VAC)

SHUNT FIELD VOLTAGE

(VDC)

Half-Wave Full-Wave

MOTOR SHUNT FIELD

LEAD CONNECTIONS

a

F1 F2

50 F/2 F-

115

100 F+ F-

100 F/2 F-

230

200 F+ F-

a. Low inductance motors require a full-wave field to prevent current instability.

7. ISOLATED REGULATOR - The internal DC circuits are isolated from the AC power source for opera-

tor and equipment safety, and for simplified application. The common of the input speed reference signal

may be grounded or connected without additional isolation to other drive controllers or grounded external

signal sources. This isolation eliminates line voltage to ground potentials on the motor speed potentiometer.

8. MOTOR CONTACTOR - Controller model numbers with an ‘A’ suffix, e.g., 2601A, 2611AP3, have a

DC magnetic armature contactor, which disconnects both motor armature leads from the controller. An

antiplug circuit ensures that the contactor does not make or break DC.

9. MOTOR OVERLOAD - A nonadjustable inverse time overload circuit continuously monitors motor

armature current and shuts down the controller whenever the current exceeds 120% of rated for a length of

time of continuous operation. The length of time is determined by the amount of overload.

10. POWER CONVERSION - The DC power bridge consists of four SCR’s and a freewheeling diode. Each

device is rated at least 600 PIV. The controller base forms an integral heat sink, with the power devices

electrically isolated from the base.

11. SELECTABLE CAPABILITIES - The DIP Switch (S3) allows the user to select various modes of oper-

ation, as follows:

37

Page 43

BOOK0795-F

a. External DC Signal Follower - The controller will operate with an external 0 - 5 VDC, 0 - 10 VDC,

b. Line Starting - By placing S3-7 in OFF (Open) position, the ‘anti-restart’ feature will be disabled, and

c. Tachometer Feedback - To select tachometer feedback with armature feedback backup, place S3-2

or 4 - 20 mA speed reference signal. The signal may be grounded or not grounded, isolated or not isolated. Motor speed will be proportional to the signal.

0 - 5 VDC - Place S3-4 in OFF (Open) position, and connect the signal to TB2-6.

0 - 10 VDC - Place S3-4 and S3-6 in ON (Closed) position, and connect the signal to TB2-2.

4 - 20 mA - Place S3-4 in ON (Closed) position, and connect the signal to TB2-6 (+) and TB2-5 (-). To

use the MIN SPD potentiometer as a 4 mA offset adjustment, place S3-6 in OFF (Open) position, and

jumper TB2-1 to TB2-3.

the controller may be started and stopped with an external AC line contactor. In addition, a wire

jumper must be connected between TB2-8 and TB2-9. If full speed operation is desired, connect

another wire jumper between TB2-2 and TB2-3.

and S3-3 in OFF (Open) position, and connect the tachometer generator signal to TB2-7 (-) and TB2-5

(+). Select the tachometer generator voltage range with S3-1, as follows:

8 VDC - 30 VDC at maximum speed, place S3-1 in ON (Closed) position.

31 VDC - 175 VDC at maximum speed, place S3-1 in OFF (Open) position.

d. Torque Regulator - The controller will function as a torque regulator when S3-5 is set to OFF (Open)

position. This allows an external potentiometer to set maximum motor torque (0 - 150% of rated).

12. STATUS INDICATOR - A bicolor LED glows red when motor armature current is being limited by the

controller current limit, and glows green when armature current is not being limited.

13. VOLTAGE TRANSIENT PROTECTION - A metal oxide suppressor (varistor) across the AC line is

combined with RC snubbers across the power bridge to limit potentially damaging high voltage spikes

from the AC power source.

38

Page 44

SECTION VIII

DRAWINGS

BOOK0795-F

39

Page 45

BOOK0795-F

C1061676

Rev. B

249

40

FIGURE 19. FUN C TION AL SCHEMATIC, SERIES 2600/2610

Page 46

BOOK0795-F

C1061059

Rev. D

41

FIGURE 20. S CH E MATIC, SERIES 2600/2610, 1/6 - 3 HP

Page 47

BOOK0795-F

C1061098

Rev. E

42

FIGURE 21. S C HE MATIC, SERIES 2600, 5 HP

Page 48

90V/180VDC

JUMPER J3

(Shown in

180VDC Position)

90V/180VDC

JUMPER J2

(Shown in

180VDC Position)

MOTOR CURRENT

JUMPER J4

BOOK0795-F

CONNECTOR J5

ACCELERATION POT

DECELERATION POT

MAXIMUM SPEED POT

CURRENT LIMIT POT

MINIMUM SPEED POT

115V/230VAC

JUMPER J1

(Shown in

230VAC Position)

AC LINE FUSE F1

CONNECTOR E1

CONNECTOR E2

IR/TACH POT

CURRENT LIMIT

INDICATOR

DIP SWITCH S3

LOGIC & SIGNAL

CONNECTION

TERMINALS

AC LINE

CONNECTION

TERMINALS

MOTOR SHUNT FIELD

CONNECTION

TERMINALS

FIGURE 22. SERIES 2600/2610 CONTROL BOARD, 1/6 - 3 HP

43

MOTOR ARMATURE

CONNECTION

TERMINALS

Page 49

BOOK0795-F

90V/180VDC

JUMPER J3

(Shown in

180VDC Position)

90V/180VDC

JUMPER J2

(Shown in

180VDC Position)

MOTOR CURRENT

JUMPER J4

CONNECTOR J6

CONNECTOR J7

ACCELERATION POT

CONNECTOR J5

DECELERATION POT

MAXIMUM SPEED POT

CURRENT LIMIT POT

CURRENT LIMIT

INDICATOR

IR/TACH POT

MINIMUM SPEED POT

DIP SWITCH S3

LOGIC & SIGNAL

CONNECTION

TERMINALS

115V/230VAC

JUMPER J1

(Shown in

230VAC Position)

AC LINE FUSE F1

AC LINE

CONNECTION

TERMINALS

MOTOR SHUNT FIELD

CONNECTION

TERMINALS

MOTOR ARMATURE

CONNECTION

TERMINALS

FIGURE 23. SERIES 2600 CONTROL BOARD, 5 HP

44

Page 50

INDEX BOOK0795-F

A

AC Line Protection 36

AC Supply Transients 4

ACCEL Potentiometer 21

Acceleration 21, 35

Altitude 34

Ambient Temperature 34

Antiplug Circuit 37

Antiplug Feature 18

Anti-restart Feature 38

Armature Feedback 37

Atmosphere 3

Auxiliary Contact 36

B

Branch Circuit Protection 4

C

Calibration 5

Circuit Breaker (Option 1010) 4

Conduit Entry 5

Connector J1 5

Control Voltage 36

Control Wiring 4

Controlled Speed Range 35

Controller Construction 3

Controller Mounting 3

Cover Hinges (Option 1638) 3

CSA 1,4

CUR LMT Potentiometer 23

Current (Torque) Limit Potentiometer 23

Current Limit 23

Current Limiting Fuses 4

Current/Torque Reference Potentiometer 33

D

DC Tachometer Feedback 37

DECEL Potentiometer 21

Deceleration 21, 35

DIP Switch (S3) 37

DIP Switch Settings 36

Displacement Power Factor 35

Duty 33

Dynamic Braking 17

Dynamic Braking Resistors 17

E

Efficiency 35

External DC Signal Follower 38

F

Feedback 37

Field Supply 37

Full-wave Field 6, 7

Fused Disconnect Switch 4

G

Ground Screw 4

Grounding 4

H

Half-wave Shunt Field Voltage 6, 7

Horsepower Range 33

I

IR (Load) Compensation 21, 35

IR/TACH Potentiometer 21, 23

Isolated Regulator 37

Isolation Transformer 4

J

Jog Speed 35

JOG SPEED Potentiometer 18

Jumper J4 5

Jumpers J1, J2, and J3 5

L

Line Frequency Variation 34

Line Fuse 18, 36

Line Fuse Interrupting Capacity 33

Line Power 33

Line Starting 17, 38

Line Supply 4

Line Voltage Variation 34

Low Inductance Motors 6, 7

M

MAX SPD Potentiometer 22

Maximum Speed 35

Maximum Speed (Armature Feedback) 22

Maximum Speed (Tachometer Feedback) 22

MIN SPD Potentiometer 23

45

Page 51

BOOK0795-F INDEX

Minimum Speed 23, 35

Minimum Transformer KVA 4, 33

Motor Contactor 37

Motor Overload 37

Motor Rotation 15

Motor Speed Potentiometer 33

N

National Electrical Code 1, 4

NEMA 1

NEMA Type 4 and 12, 3

O

Offset 23

Options 5

Oscillating Load 26

Overload Capacity, Armature Circuit 33

Overload Circuit 37

Overload Monitor 19

P

Power Bridge 37

Power Conversion 37

Power Factor Correction Capacitors 4

Power Wiring 6, 7

U

Underwriters Laboratories Listed 1

V

Varistor 4, 38

Vibration 3

Voltage Transient Protection 38

W

Wiring Practices 4

R

Relative Humidity 34

S

Selectable Capabilities 37

Service Factor 33

Shielded Wire 5

Shipping Damage 5

Short-circuit Current 4

Signal Wiring 4

Speed Regulation 35

STATUS INDICATOR 38

T

Tachometer Feedback 38

Tachometer Generators 37

Torque (Current) Limit 35

Torque Regulator 38

Transformer 4

Transients 4

46

Loading...

Loading...