Fincor SERIES 2600, SERIES 2610 Catalog Page

2601/2602

SINGLE-PHASE DC SERIES

2601/2602-1

FIGURE 1.

1/6–5 HP Ratings

115 or 230V, Single Phase

Isolated Regulator

Speed or Torque Control

Overload Protection

DC Tach Feedback

AC Line Starting

External Signal Follower

Run Contact

Configurations

– Open Chassis

– “Bookcase” Style

– NEMA 4/12

NEC enclosed and NEMA Compliance

UL and cUL Listed

1/6 through 5 HP Adjustable Speed

DC Motor Controllers

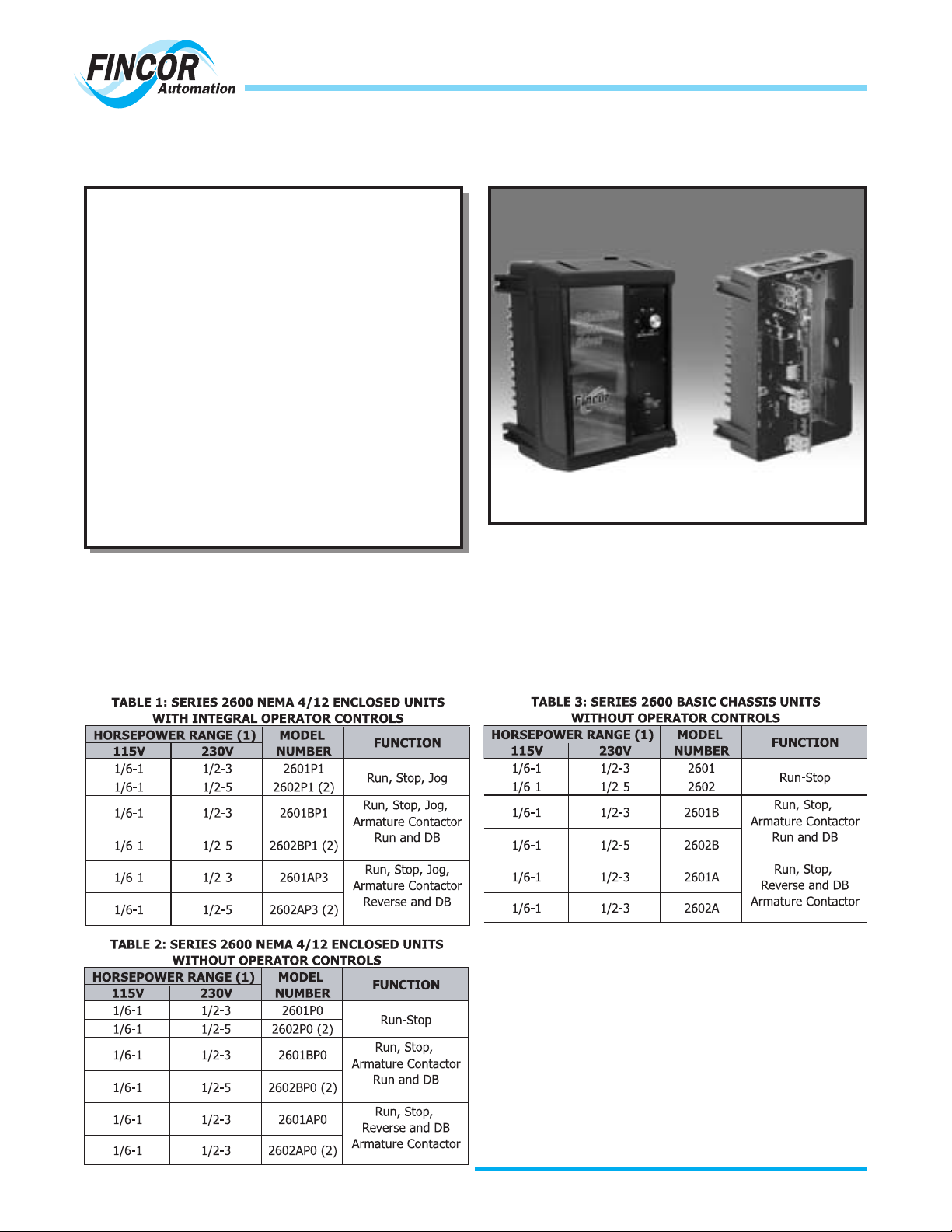

Series 2601, 2602 units are offered in a variety of standard models based on the three functional groups as

shown in Tables 1-3. These units differ from the 2330

series in that they expand horsepower range with

capacities up to 5 HP while offering the on-board customization features of the 2610MKII series.

Model numbers that include a “P” suffix identify

enclosed units assembled by adding a top cover

assembly to a basic chassis unit. Top cover assemblies

P1, P2 and P3 include integral operator controls. Top

cover control P0 does not and is therefore intended for

remote control operation. The top cover assemblies

may be factory installed or, if desired, easily added to

the basic chassis models as field-installed kits. All

models are reconnectable for either a 115V or 230V A C

power source.

NOTES: (1) Units are shipped calibrated for the maximum horsepower rating.

Units may be calibrated for other standard ratings by changing

the position of a jumper in accordance with instructions provided.

Units are shipped connected for 230V.

Units may be easily reconnected for 115V.

(2) Includes option 1170A cooling fan as standard.

2601/2602

SINGLE-PHASE DC SERIES

2601/2602-2

1. Construction — The die-cast aluminum alloy base assembly

forms the basic Series 2600 open chassis which includes regulator electronics, AC line fuse, power conversion and protective circuitry as a totally functional, self contained unit.

Enclosed models are TENV, NEMA 4 and 12.

Model 2602, when rated five horsepower as an enclosed unit,

requires the addition of Option 1170A cooling fan assembly, as

shown in Figure 3.

Series 2600 unit covers are molded of high strength Noryl® engineering plastic.An aperture in the cover permits mounting a blank

panel for remote control models or various standard or optional

local operator control panels. (See Table 4.)

Where a hinged

cover is desired, Option 1638 provides a kit permitting easy field

installation.

2. Full-Wave Power Conversion — Full-wave converter configuration consisting of four SCR’ s and a free wheeling diode provide

benefits for optimum motor performance and long service.Power

bridge is composed of 600PIV, discrete, encapsulated and electrically isolated devices.The alloy base forms an integral heatsink

with the power control devices electrically isolated from the base.

3. Volta ge T ransient Protection — Metal oxide suppressor across

the AC line is combined with RC snubbers across the power

bridge to limit potentially damaging high voltage spikes from the

AC power source.

4. AC Line Protection — A high (100K amp) interrupting capacity

AC line fuse provides instantaneous protection from peak loads

and fault currents. Optionally offered for Model 2601 is (Option

1010), a two-pole, molded case, magnetic trip circuit breaker

which provides a means of manually disconnecting the AC power

to the controller and motor and automatic, instantaneous trip protection from a peak load.

5. Isolated Regulator – Internal DC circuits are isolated from the

AC power source for operator and equipment safety and for simplified application. The control reference input common may be

grounded or connected without additional isolation to other drive

units or grounded external signal sources.Isolation eliminates the

common condition of line voltage to ground potentials being present on the speed control potentiometer.

6. Feedback Isolation –

(a) Current Feedback – Isolation by optical coupler.

(b) Voltage Feedback – High impedance circuit (two megaohms).

7. Feedback – Two selectable modes of analog feedback are provided. See Table 7 for speed regulation characteristics.

(a) Armature Feedback – Counter EMF voltage feedback with IR

compensation.IR compensation is adjustable to suit individual

motor characteristics and optimize speed regulation in this

mode.

(b) DC Tachometer Feedback – Provides impedance matching,

voltage scaling and terminals for accepting a signal from a DC

tachometer generator mechanically coupled to the drive motor

armature.This results in expanded speed range, improved speed

regulation with load changes and reduced sensitivity to operating conditions such as line voltage variations, ambient temperature changes, motor field heating and other operating variables.

The controller will automatically transfer to counter EMF voltage

feedback to prevent run away if the tachometer circuit is open.

Tachometers producing 7 VDC to 150 VDC at maximum motor

speed may be used.

This feature is suitable for use with unidirectional units using DC

tachometers. See Options 1061C or 1061F for other conditions.

8. Control Voltage – A transformer coupled 24 VDC power supply

isolates all magnetic pushbutton control and logic from the AC

power source for operator protection.

9. Field Supply – Transient protected, half-wave or full-wave. See

Table 6 for output voltages.

10. Contactorless Design – Unit is designed for reliable solid state,

run-stop operation without an armature contactor. Logic includes

a provision to prevent an involuntary restar t after a power failure.

This feature may be defeated when an external customer furnished AC line contactor is used to control the unit.

11. Motor Contactor –

(a) Bidirectional Models — Model numbers which have an “A”suf-

fix such as 2601A, includes DC magnetic armature reversing

contactors.This provides a positive, two-pole disconnection of

the motor armature from the rectified power source. Action of

the contactor is sequenced with the SCR regulator to ensure

that the DC power circuit is “phased-off” before the contactor

is opened.This results in “dry switching”for improved contactor longevity.The standard contactor circuit board permits both

unidirectional and selectable bidirectional operation when

desired. To facilitate this, anti-plug protection is also provided

to prevent armature reversal until a safe minimum speed is

reached.

(b) Unidirectional Models — Model numbers which include a “B”

suffix such as 2602BP1, includes a DC magnetic armature

contactor.This provides a positive, two-pole disconnection of

the motor armature from the rectified power source. Action of

the contactor is sequenced with the SCR regulator to ensure

that the DC power circuit is “phased-off” before the contactor

is opened.This results in “dry-switching”for improved contactor longevity. The contactor circuit board permits unidirectional operation only.

12. Dynamic Braking — Standard feature of model numbers with an

“A” or “B” suffix. Dynamic braking provides exponential rate braking of the DC motor armature. Included is a DB resistor with an

anti-plug circuit to prevent restarting the controller until the braking cycle is complete, thereby preventing a potentially damaging

electrical surge and mechanical stress. The DB resistor is rated

for stopping a typical load, when the external machine inertia

does not exceed that of the motor armature, as shown in Table 9.

13. Motor Overload — A nonadjustable electronic circuit continuously monitors motor armature current and shuts down the drive

whenever the load exceeds 120% for 80 seconds.

(continued)

DESIGN FEATURES AND FUNCTIONS

Loading...

Loading...