Fincor Series 2230 MKII, Series 2240 Catalog Page

Fincor Series 2230 MKII/2240

Fincor Series 2200 regenerative drives are ideal for your

more demanding applications. They feature flexibility

with ratings up to 5 horsepower. The Series 2230

MKII offers new and improved board design with more

standard features to 3 hp while the larger Series 2240

offers ratings to 5 hp and additional space for internally

mounted options.

FINCOR SERIES 2230 MKII / 2240

•

•

•

•

•

•

•

•

•

•

Speed or Torque Control

0-10 VDC or +/- 10 VDC input signal

Current Stability Adjust

PID / Speed Trim Control

Fused Input

Line Start / Auto Restart Enable / Disable

Dual Field Supply

Tachometer Input standard

Monitoring Output (0-10 VDC or 4-20 mA)

Diagnostic LED

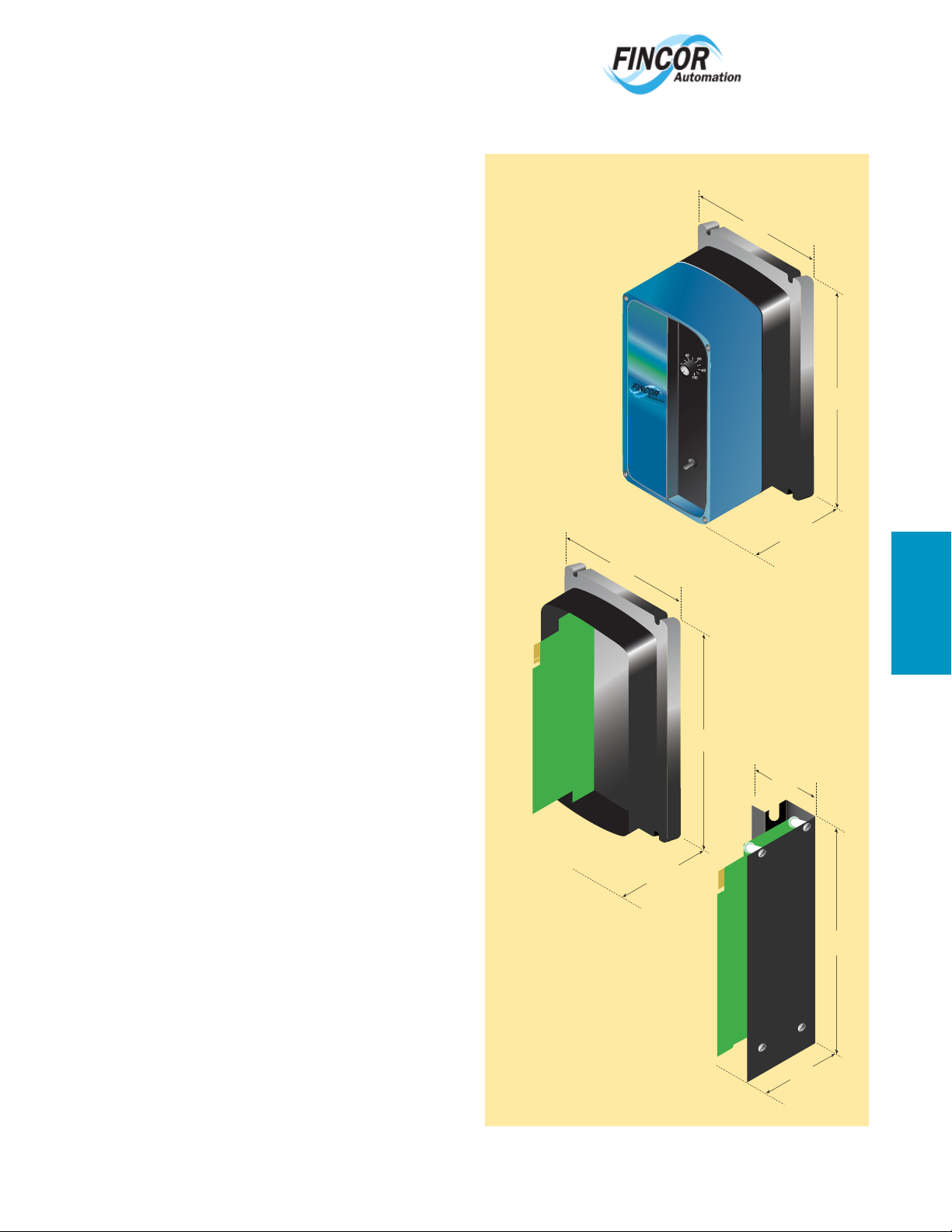

2230 MKII Enclosed

www.emersonct.com

800-334-3040

2240 Enclosed

FINCOR SERIES 2230 MKII SPECIFIC

Fincor 2200

• 1/6 to 3 hp (115-230V)

•

•

(0-10 VDC or 4-20 mA)

•

FINCOR SERIES 2240 SPECIFIC

•

•

RATINGS: 1/6 TO 5 hp (115-230 VAC)

Series 2200 Regenerative DC Drives

Chassis w/o Integral

Operator Controls

Integral Operator

Operator Controls

NEMA 4/12 with

Integral Operator

Units shipped calibrated for desired hp rating but jumpers can be adjusted for others. Units shipped ready for 230VAC but may be reconnected for 115VAC.

Fully Isolated Regulator

Speed or Current Monitoring

Surface mount technology circuit board

1/6 to 5 hp (115-230V)

Motor contactor option mounts inside enclosure

Model Motor

Book Case w/o

Controls

NEMA 4/12 w/o

Controls

HP

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 2.0 240 15.8 180 100/200 11.6 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 3.0 240 22 180 100/200 11.6 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 5.0 240 32 180 100/200 25 2.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 2.0 240 15.8 180 100/200 11.6 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 3.0 240 22 180 100/200 15.1 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 2.0 240 15.8 180 100/200 11.6 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 5.0 240 32 180 100/200 25 2.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 2.0 240 15.8 180 100/200 11.6 1.0

1/6 - 1.0 120 15.8 90 50/100 10.5 1.0

1/2 - 5.0 240 32 180 100/200 25 2.0

Input Output Run-Stop,

AC Volts Amps DC Volts Amps Order Code Order Code

Arm

Open Chassis

Field Arm Field

Book Case

Static *

2231 2231B

2232 2232B

2242 2242B

2235 2235B

2236 2236B

2231P0 2231BP0

2242P0 2242BP0

2231P1 2231BP1

2242P1 2242BP1

Run-Stop,

DB **

256

* RUN-STOP, Static, Contactorless Control

** RUN-STOP / DB, Armature Contactor Control & Dynamic Braking

www.emersonct.com

)

Adjustable

Speed

Drives

800-334-3040

Fincor Series 2230 MKII

DIMENSIONS

SPECIFICATIONS:

Operating Conditions

Horsepower 1/6 thru 3 hp, Jumper Selectable

Line Voltage 115-230VAC ±10%, Jumper Selectable

Enclosure Chassis, Bookcase, NEMA 4/12

Rated Frequency 50/60Hz ±2% Selectable

Ambient Temperature 0 – 40°C (32°F - 104°F) (Enclosed)

0 – 55°C (32°F - 131°F) (Chassis)

Altitude 1000m (3,300 ft)

Relative Humidity 95% Non condensing

Overload Capacity 150% for 1 minute

(UL Listed Motor Overload Protection

– File # E184521)

(120% Timing Threshold)

Standard Features

Isolated Regulator Circuit Grounded I/O signals possible

Regulator Function Speed or Torque selectable

Power Conversion 8 SCR Full Wave - Four Quadrant

Field Supply Full Wave

Protection MOV Voltage Transient Suppression

High Interrupting Capacity Line Fuse

Speed Regulation Armature or DC Tach Feedback

Line Start Selectable for Auto-Restart

Controlled Stop Provides Ramp to Stop Function

Zero Speed Deadband Selectable 2% or Off

Zero Speed Indication Open Collector – Active Low

Direction Indication Open Collector – Active Low = FWD

Speed Regulator Node External PID Input or Speed Trim

Speed Outputs -10 – 10Vdc and 4 – 20ma

Torque Outputs -10 – 10Vdc and 4 – 20ma

Diagnostic LED Green Normal – Red Current Limit

Option Connector Connects Additional Option Boards

Control

Control Logic Power 24VDC for Maintained Switch or

Pushbutton Operation

Speed Potentiometer 5K Ohms, ½ Watt

Input Reference 0 – 10Vdc or -10 – +10Vdc

Speed Regulation 2% with Armature Feedback

(95% Load Change) 0.5% with Tachometer Feedback

Adjustments

Maximum Speed 50% – 100% of Motor Base Speed

Current Limit FWD 0 – 150% of Full Load

Current Limit REV 0 – 150% of Full Load

IR Comp/Tach Scaling 0 – 10% IR or 0 – 100% Tach

Acceleration/Deceleration 0.1 – 30 Seconds

Voltage (Speed) Stability Speed Gain Fine Tune

Current Stability FWD Current Gain FWD Fine Tune

Current Stability REV Current Gain REV Fine Tune

Efficiency

Controller (only) 98%

With Motor (typical) 85%

Approvals & Listings

UL and cUL

2230 MKII

Enclosure

Weight (Chassis)

3 lbs. 1.36 kg

5”

(127 mm)

2230 MKII

Bookcase

Adjustable

Adjustable

Speed

Speed

Drives

Drives

2230

(108 mm)

4.25”

Weight (Enclosed)

3 lbs. 1.36 kg

M

OTO

R SPE

ED (%)

RUN

STO

JOG

P

9.5”

(241 mm)

5”

(127 mm)

2230

5.25”

(133 mm)

2230 MKII

Chassis

Weight (Bookcase)

1 lb. .45 kg

1.75”

(43 mm)

4.25”

(108 mm)

9.5”

(241 mm

8.85”

(218 mm)

Fincor 2200

257

www.emersonct.com

800-334-3040

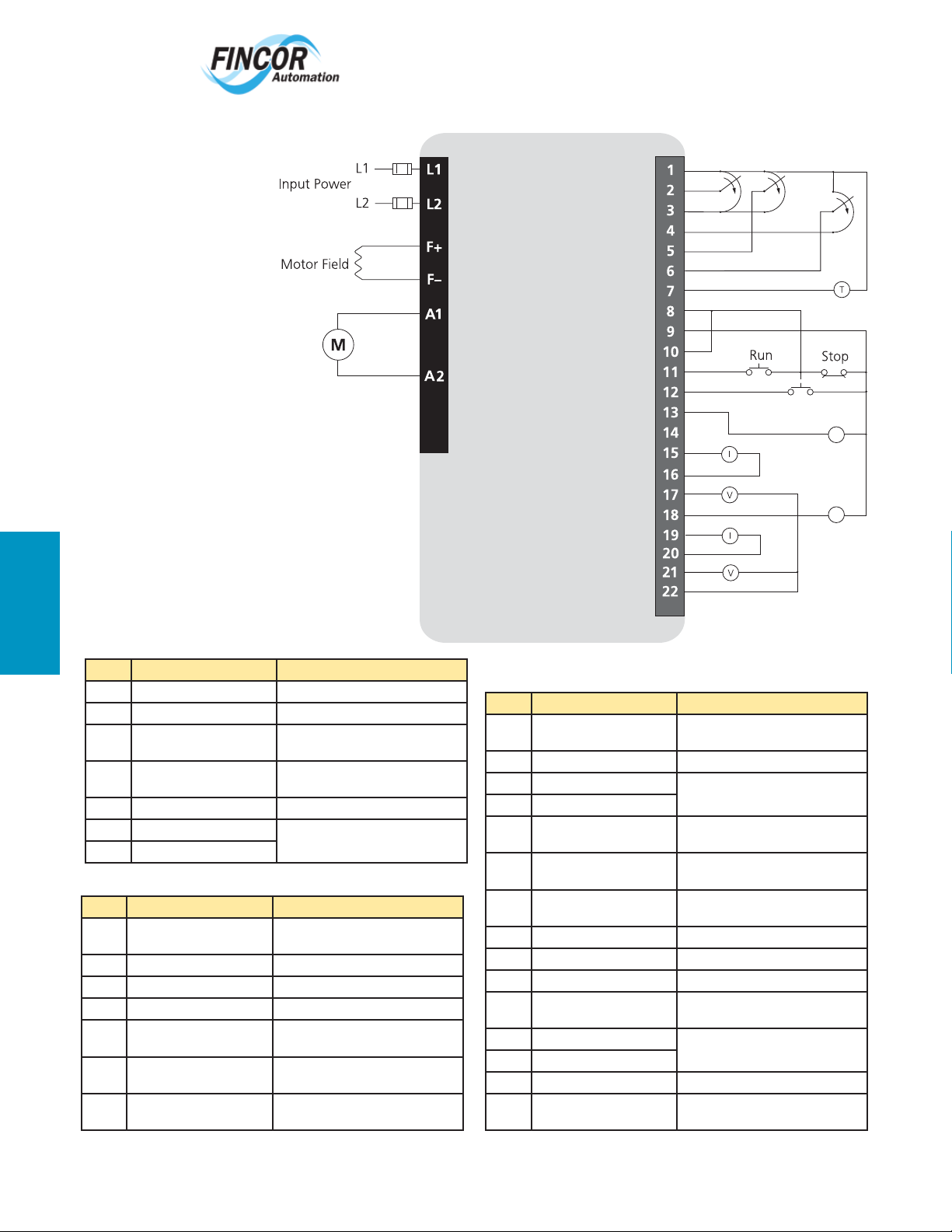

TERMINAL DIAGRAM: 2230 MKII

Fincor 2200

TERMINAL DESCRIPTION

TB1

Circuit Common

Speed Ref Input

Ext Current Ref Input FWD

Ext Current Ref Input REV

Tachometer Fdbk Input

Run Enable Input (+24VDC)

Run Relay N.O. Contacts

Run Relay N.O. Contacts

Controlled Stop Input

Zero Speed Output

Speed Reg Node Input

Cur. (4 to 20mA) Output Speed

Circuit Common

-10 to +10VDC Output Speed

Direction Output

Cur. (4 to 20mA) Output Torque

Circuit Common

-10 to +10VDC Output Torque

Circuit Common

+10V Ref

-10V Ref

+24VDC

TB2

Speed

Ref Pot

Torque

Ref Pot

Torque

Ref Pot

FWD

Controlled Stop

REV

K

K

TB1

Pin# Type Notes

L1 Line Voltage Input 115 or 230VAC J1 Selectable

L2 Line Voltage Input 115 or 230VAC J1 Selectable

F+ Field Voltage Output +100VDC @ 115VAC or +200VDC

F/2 Field Voltage (Half-Wave)

Output

F- Field Voltage Output Field Minus Output

A1 Armature Output -90 to +90VDC @ 115VAC or -180 to

A2 Armature Output

@230VAC Input

+50VDC @ 115VAC or +100VDC

@230VAC Input

+180VDC @ 230VAC Input

TB2

Pin# Type Notes

1 Speed Reference Pot ‘0’ End Speed Pot Common for Uni-Directional

2 Speed Reference Input

3 +10V Reference Output 5ma max

4 -10V Reference Output 5ma max

5 External Current Reference

Input FWD

6 External Current Reference

Input REV

7 Tachometer Input (Speed

Feedback)

Operation

200KΩ Input Resistance

Refer to DIP Switch SW3-2

Refer to DIP Switch SW3-7

3-30VDC, 31-175VDC

TB2 Continued

Pin# Type Notes

8 Enable Input (+24VDC)

– Run Relay

9 +24VDC For drive enable use only

10 Run Relay N.O. Contacts Form A Contact Rated 0.5A @ 115VAC

11 Run Relay N.O. Contacts

12 Controlled Stop Input

(+24VDC)

13 Zero Speed Indication Output Open Collector, Active Low, Rated

14 Speed Regulator Node Input Speed Trim or External PID Input

15 Current Loop Output 4 to 20ma – Speed (Arm Volts)

16 Current Loop Output 4 to 20ma – Speed (Arm Volts)

17 Voltage Output -10 to 10VDC – Speed (Arm Volts)

18 Direction Indicator Output Open Collector, Active Low for FWD;

19 Current Loop Output 4 to 20ma – Torque (Arm

20 Current Loop

21 Voltage Output -10 to 10VDC – Load (Arm Amps)

22 Voltage Output Common Isolated From Line – Can be connected

24VDC @ 6ma Input

or 2A @ 30VDC

Momentary +24VDC Input to Initiate

Controlled (Ramp) to Stop

24VDC @ 50ma

(Bypasses Accel/Decel Ramps)

Rated 24VDC @ 50ma

Amps)

to Earth

258

Loading...

Loading...