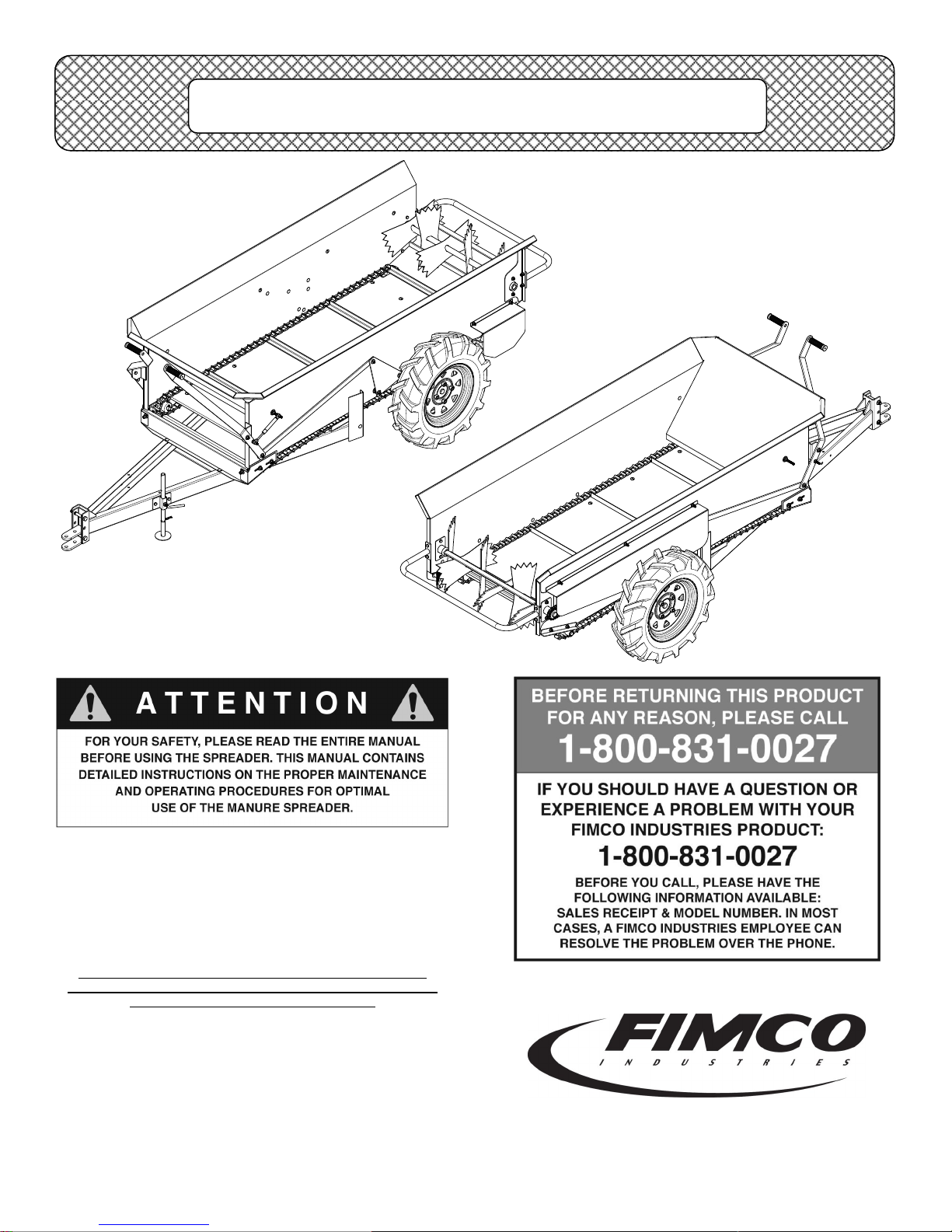

Fimco MS-25BU Owner's Manual

OWNER’S MANUAL

Model: MS-25BU

(5301194)

(25 Bushel Pull-Behind

Manure Spreader)

General Information

Thank you for purchasing this product. The purpose of this

manual is to assist you in operating and maintaining your

manure spreader. Please read it carefully, as it furnishes

information which will help you achieve years of trouble-free

operation.

Warranty

Products are warranted for one year from date of purchase

against manufacturer or workmanship defects for home owner

usage and 90 days for commercial usage.

For technical assistance, visit our website @

www.fimcoindustries.com or call: TOLL FREE @ 1-800-831-0027

Our Technical Support Representatives will be happy to help you.

To obtain prompt, efficient service, always remember to give the

following information…

Correct Part Description and/or part number

Model #/Serial # of your sprayer

Part descriptions and numbers can be obtained from the illustrated

parts list section(s) of this manual.

www.fimcoindustries.com

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049

Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440

[5004582 (02/17)]

Page 1

Assembly Instructions

1. Remove all parts of the manure spreader from the crate.

A. Note that the tongue is fastened to the crate. Free the

tongue parts from the crate and then remove the top

cross boards.

B. The wheels and tires may be lifted from the unit frame.

C. Note the small parts bag with the wheels, open it and

remove the contents.

2. Attach the tongue to the main frame using (4) 5/16-18nc x 1”

carriage bolts and (4) 5/16” lock nuts. You may want to refer to

the exploded view drawings.

3. The control levers must be attached to the bolt on each side,

near the front of the frame. The lock nuts are already attached

to the appropriate parts. Remove them, affix the parts in place

and secure the parts with the lock nuts. Use a 5/16” lock nut to

hold the control levers in place. Tighten the lock nut so that the

levers may pivot easily, but with a minimum of play. You can

now join the gas shock (Item 23) to the lever on the left front

end using a 5/16” lock nut.

4. Place the manure spreader onto a platform at 12” from the

ground. Use a front end loader or a jack to raise the spreader

safely.

A. Note there are right and left wheels. The tread should

point to the rear as viewed from top of the tire.

B. Each wheel is to be attached using (4) bolts (Item 39)

and (4) wheel nuts (Item 38).

Parts Included in Crate

1. Main Frame Assembly

2. Tongue & Hitch Assembly

3. (2) Wheels & Tires

4. Small Parts Bag

A. (8) 1/2”-20 Hex Cone Wheel Nuts

B. (4) 5/16” Whiz Nuts

C. (4) 5/16”-18-1” Carriage Bolts

D. (8) 1/2”-20 x 1-1/8” Serrated (Knurled) Shoulder Bolts

E. (1) Hitch Pin Clip

F. (1) Parking Stand Weldment

G. (1) Gas Cylinder 40 psi Shock

Operating Instructions

1. The towing vehicle should be at least of a 10 H.P. variety.

2. The spreader has an adjustable hitch. Set the hitch so the

adjustable hitch range is from 7” - 16”.

3. Be sire the towing vehicle can not move when attempting to

hitch up to the spreader.

4. Use a quality hitch pin equipped to prevent accidental

unhitching.

5. Be sure the safety guards are in place.

6. The control levers should be in the “off” position (rotated down-

wards) until you are ready to spread manure. Be sure to stop

before engaging the controls.

7. Begin loading to the front end of the spreader and gradually

work to the rear end.

8. Do not load above the side or front panels.

9. Always allow clearance for the rotary blad mechanism to turn

freely before engaging the chain mechanism.

10. It is important to free up any manure that may be frozen or ad-

hered to the floor. This will prolong the life of the drive chain. It

is also a good idea to know that the detachable chain mechanism (slide bar) is not adhered to the floor board. This can happin cold weather when moisture freezes to the chain and floor.

11. Stop moving before engaging or disengaging the controls to the

chain drive mechanisms.

12. The proper speed for the desired spreading is from 3-1/2—5

MPH. Do not exceed 5 MPH or excessive wear and tear will

occur.

13. Always disengage both controls before backing up. Reversing

the chain drive mechanism will cause damage to the drive

mechanism.

14. It is a good idea to use a slow moving vehicle sign for road

travel.

15. Use safe practices when operating the spreader. Better to be

safe than sorry.

16. Cleaning the spreader after each use will prolong the life of the

spreader and make maintenance easier.

17. Be sure to oil the roller chain, as well as the detachable chain,

and grease the axle and the pivoting shaft bushings for the

rotary blades. A regular practice of maintenance will prolong the

life of the spreader.

18. Raise the control levers to engage the ground drive mecha-

nisms.

General Maintenance

Do not attempt, under any circumstance, to work with the chain

drive mechanisms while the spreader is moving. To clean, ser-

vice, adjust, unclog or any other function, the spreader must be stationary. (Even though it would appear to be safe). If the mechanism

starts to move, your safety could be at risk. Follow these steps before

attempting to maintain or repair any part of the spreader.

1. Unhitch the spreader from the towing vehicle.

2. Block both wheels front and back or raise the entire spreader.

Support the spreader so the wheels may turn if necessary. Use

care to provide adequate stationary support.

3. Engage the control levers only to move the drive chain mecha-

nism.

4. Always be sure the safety guards are in place after maintenance

and before moving the spreader.

5. Oil the roller chain and detachable chain once a week or as use

and weather conditions demand. Do not let the chains go dry.

6. Grease the bushings for the axle shafts, the shafts for the rota-

ry, blades and the shaft for the detachable chain drive.

7. Cleaning the spreader after each use will prolong its life and

make the maintenance easier.

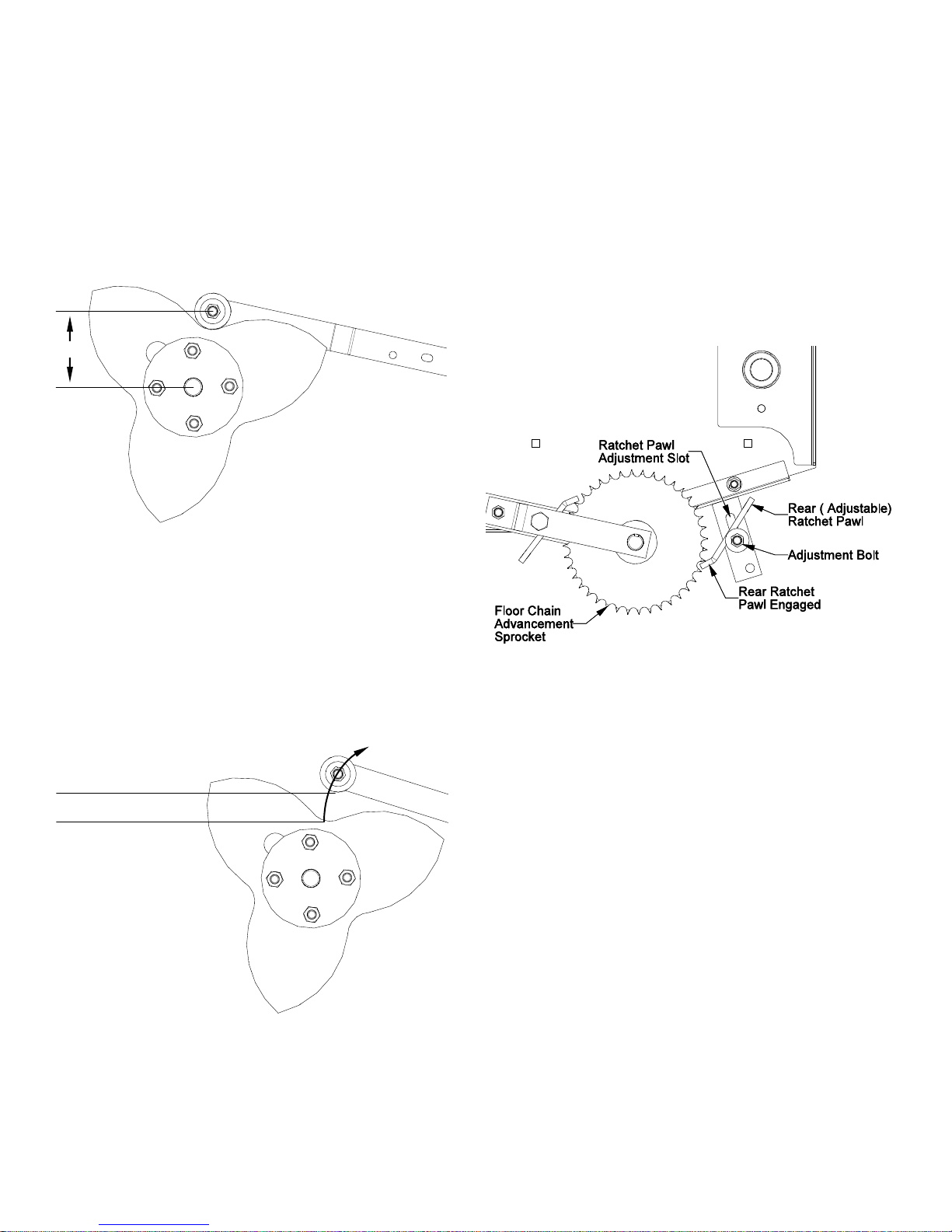

Floor Chain Drive Mechanism Adjustment

Periodically adjustments must be made to your manure spreader in

order to keep it in peak operating condition. One area which may

require periodic adjustment (to compensate for normal usage wear)

is the floor chain drive mechanism.

Page 2

Assembly Instructions

Step 1: On a flat and level surface, unhitch the spreader from its

towing vehicle.

Step 2: Adjust front tip stand so unit is in a reasonably level position.

Step 3: Inspect cam follower roller (Item 32), shown in Detail C, and

replace if worn.

Step 4: Raise handle (Item 16), shown in Detail B, on floor chain

drive mechanism side only, to its full upright (engaged) position.

Step 5: Roll spreader slightly, a few inches should do the trick, either

forward or rearward until the cam follower roller resides at its lowest

point on cam (Item 34), shown in Detail C. See Figure 1.

4.28

Step 6: At this point block both wheels, front and back, to secure the

spreader in place.

Step 7: Using a needle nose pliers, unseat the lower end of the 6”

spring (Item 46), shown in Detail C, from its vertical mounting bracket.

Step 8: Remove left side shield (Item 48), shown in Detail D. Set

shield and hardware off to the side for the time being.

Step 9: Next, slowly lift the cam follower roller (Item 32) upward until

the rear ratchet pawl engages. The instant the rear ratchet pawl becomes engaged, a reasonably loud “click” should be heard. Refer to

Figure 2.

Rear Rachet Pawl should

become engaged at between

3” to 4” of elevation

3½” = Optimal Setting

in most instances

**NOTE** It is crucial that the lifting of the cam follower roller is

stopped the very instant the rear ratchet pawl becomes engaged, in

order to provide an accurate reading for set-up. If you happen to go

too far, simply push the cam follower roller back down into its lowest

position and lift again slowly.

The optimal setting most instances is 3½”, depending upon the

spreader’s age and wear pattern.

Figure 1

Figure 2

Step 10: If the rear ratchet engages too quickly or does not engage

soon enough, it is out of phase and must be repositioned.

Step 11: Repositioning of the rear ratchet pawl is accomplished quite

simply by loosening the rear ratchet pawl adjustment bolt and moving

it either up or down with the ratchet pawl adjustment slot and then

retightening. Refer to Figure 3.

Some trial and error may be involved in this process, as every

spreader will require slightly different settings to achieve proper lift

distance of the cam follower.

Step 12: Re-attach the 6” spring to its vertical mounting bracket, as

well as the left side shield, prior to testing.

Step 13: Test empty spreader at a reduced speed for a period of time

insuring the floor chain drive mechanism is running smoothly.

Step 14: Place back in service.

Figure 3

Page 3

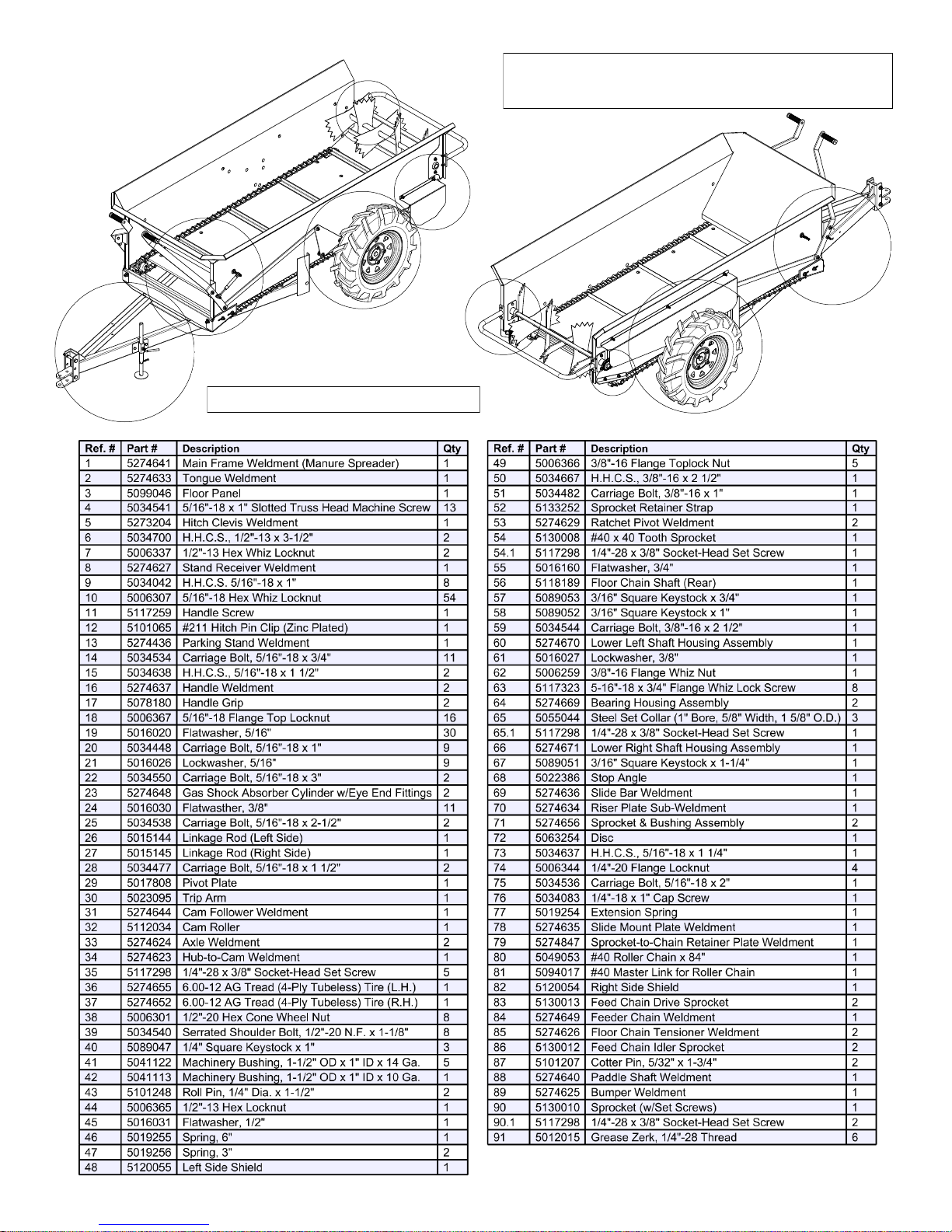

MS-25BU

(5301194)

See Detail A

See Detail I

See Details C

See Detail B

See Detail E

See Details J for Underside of Spreader

**Refer to all detail views for parts call-out

and notes on following pages**

See Detail D

See Detail F

See Detail H

See Details G

Page 4

Loading...

Loading...