Fimco LG-3025-TSC Owner's Manual

Owner's Manual

(25 Gallon Lawn & Garden/ATV Boomless Sprayer)

25 Gal. Corrosion-Resistant Polyethylene Tank

•

12 Volt Diaphragm Pump, 3.8 g.p.m. - 45 p.s.i.

•

Deluxe Pistol-Grip Handgun w/15 Ft. Handgun Hose

•

26 Ft. max. vertical throw, 43 Ft. max. horizontal throw

•

Pressure Gauge

•

Adjustable Pressure

•

30 Foot Spray Coverage w/Boom

•

Corrosion-Resistant Nozzles

•

Caution: Always check the vehicle load rating before

using this sprayer. The loaded weight of the sprayer

and boom assembly is about 290 lbs. when the tank is

full. Care must be taken not to tip the vehicle over

backwards, especially when starting or accelerating.

Technical Specifications

General Information

Thank you for purchasing this FIMCO product. The purpose of

this manual is to assist you in operating and maintaining your

lawn & garden/ATV sprayer. Please read it carefully, as it

furnishes information which will help you achieve years of

trouble-free operation.

Warranty/Parts/Service

Products are warranted for one year from date of purchase

against manufacturer or workmanship defects.

Commercial users have a 90 day warranty.

Your authorized dealer is the best source of replacement parts

and service. To obtain prompt, efficient service, always

remember to give the following information...

Assembly

1. Install the tank mounting plates to the tank as shown in

the exploded view drawing.

2. Place the tank with the brackets attached to your ATV

carrier rack. Attach the mounting brackets to the cross

members of the rack, using the hardware supplied. (See

exploded view drawing)

3. Join the boom mounting brackets to the tank mounting

brackets with the hardware shown.

4. Attach the boom to the boom mounting brackets with the

(2) u-bolts and (4) whiz locknuts. Make sure the u-bolts are

positioned within the grooves of the grommets on the boom

tube.

NOTE: The purpose of these grommets is to prevent

metal-to-metal contact between the u-bolts, boom tube,

and boom mounting brackets.

The grommets will 'compress' as you tighten the whiz

locknuts onto the u-bolts. Tighten just so that the boom tube

will NOT rotate within the grommets. Alternate the tightening

of the locknuts to provide even pressure on the grommet.

** DO NOT OVER-TIGHTEN the whiz locknuts, as this

may cause the boom tube to flatten slightly!

5. Thread the pressure gauge into the reducing bushing at

the far end of the manifold assembly. Use a good grade of

thread sealant here, to insure no leaks.

6. Connect the wiring harness to the rear of the pump. Clip

the alligator clip ends to a fully charged 12 Volt battery. Red

wire to the 'Hot' connection, and black wire to the 'Ground'.

- Correct Part Description and/or part number.

- Model number/Serial number of your sprayer.

Part descriptions and part numbers can be obtained from the

illustrated parts list section(s) of this manual.

Whenever you need parts or repair service, contact your

distributor/dealer first. For warranty work, always take your

original sales slip, or other evidence of purchase date, to your

distributor/dealer.

www.fimcoindustries.com

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049

Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440

Form No. 1323 [5004817 (2/09)] Printed in the U.S.A.

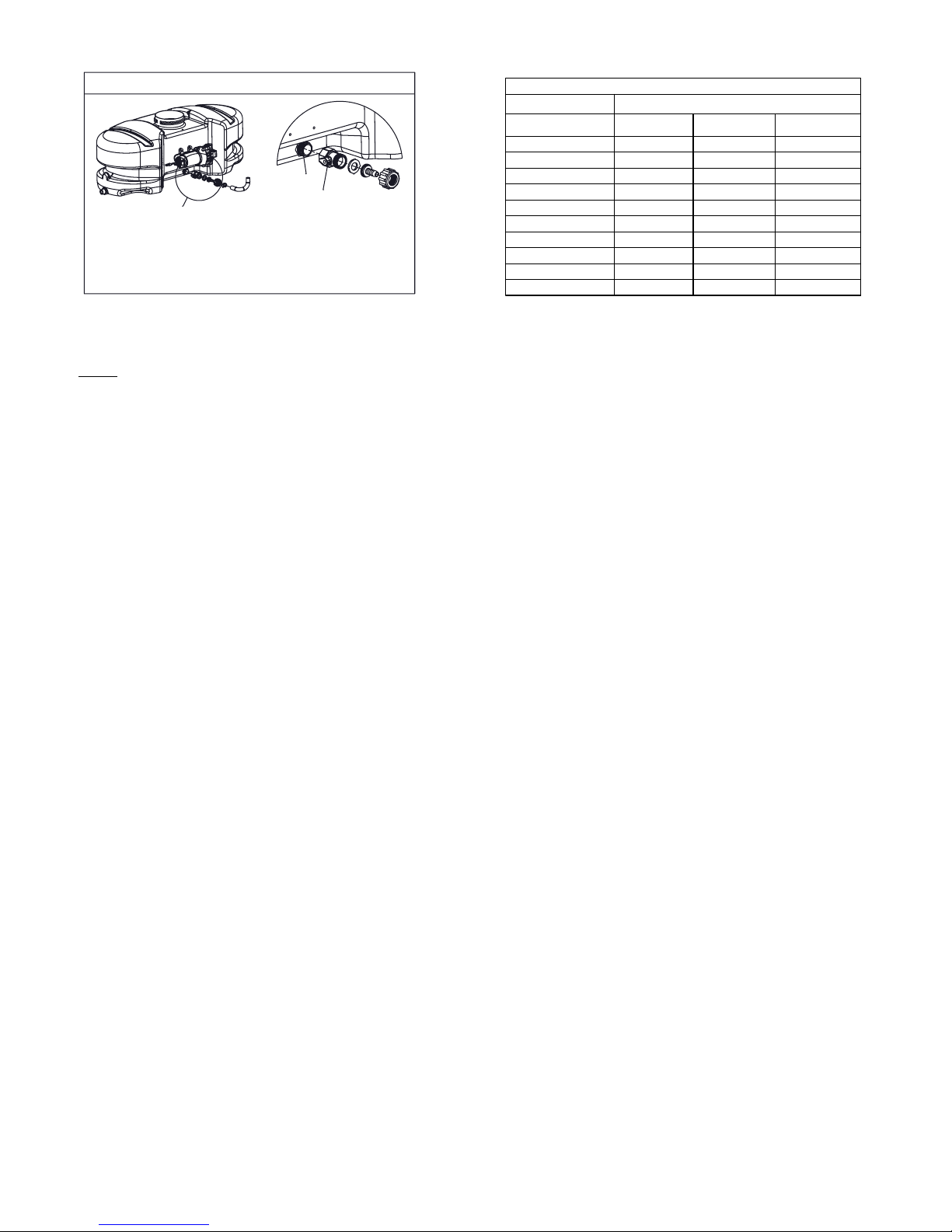

*** IMPORTANT REMINDER ***

Inlet from Tank

"ON/OFF" Valve

A

This unit comes with an On/Off valve, located near

the inlet of the tank, towards the underside. (See Detail A)

You must make sure the valve is in the

"open" position before using your unit.

Detail A

Testing the Sprayer

NOTE:

It is VERY important for you to test your sprayer with plain water

before actual spraying is attempted. This will enable you to

check the sprayer for leaks, without the possibility of losing any

expensive chemicals.

Add water to the tank & drive to the starting place for spraying. When

you are ready to spray, turn the boom valve to the "on" position. This

will start solution spraying from the tips of the boom. The pressure

will decrease slightly when the boom is spraying. Adjust the pressure

by turning the "ON/OFF" valve lever on the bypass line valve.

Read the operating instructions and Initially begin spraying by closing

the 'bypass' valve (this is the center ON/OFF valve located at the

center port of your manifold assembly) and opening the boom line

valve (this is the 'other' valve on the manifold). This will enable the air

in the line to be eliminated (purged) through all the tips, while building

pressure. When everything tests all right (no leaks, & good pressure),

add the desired chemicals to the mixture and water combination and

start your spraying operation. Adjust the pressure and spray as you

did in the testing procedure.

Conditions of weather and terrain must be considered when setting

the sprayer. Do not spray on windy days. Protective clothing must be

worn in some cases.

Be sure to read the chemical label(s) correctly!

Calibration

Chemical labels may show application rates in gallons per

acre, gallons per 1000 square feet, or gallons per 100

square feet. You will note that the tip chart shows all 3 of

these rating systems.

Once you know how much you are going to spray, then

determine (from the tip chart) the spraying pressure (PSI),

and the spraying speed (MPH).

Determining the proper speed of the pulling vehicle can be

done by marking off 100, 200, & 300 feet. The speed chart

indicates the number of seconds it takes to travel the

distances. Set the throttle and with a running start, travel the

distances. Adjust the throttle until you travel the distances in

the number of seconds indicated by the speed chart. Once

you have reached the throttle setting needed, mark the

throttle location so you can stop and go again, returning to

the same speed.

Add water and proper amount of chemical to the tank and

drive to the starting place for spraying.

Adjusting Pressure

- When the bypass valve is closed, pressure is at the highest

point.

- Opening the valve will decrease pressure.

Speed Chart

Time Required in seconds to travel a distance of:

Speed in M.P.H.

(Miles per Hour)

1.0

2.0 34 68 102

3.0 23 45 68

4.0 17 34 51

5.0 14 27 41

6.0 11 23 34

7.0 9.7 19 29

8.0 8.5 17 26

9.0 7.6 15 23

10.0 6.8 14 20

100 Ft. 200 Ft. 300 Ft.

68 sec.

136 sec. 205 sec.

Operation

Your sprayer is equipped with (2) ON/OFF switches. One is

on the wire assembly that you hook up to your battery, the

other is on the pump itself, on the opposite end of the

pressure switch. The "-" is the "ON" position and the "o" is

the "OFF" position for the switches. Make sure both

switches are depressed in the "-" position for operation.

In addition to the ON/OFF switch, the pump is equipped with

an electronic pressure switch that is factory pre-set for it to

shut off at 45 p.s.i.. This switch assembly is the 'square box'

on the head portion of the pump.

Always fill the tank with a desired amount of water first, and

then add the chemical slowly, mixing as you pour the

chemical into the tank. You may use the handgun to spray

into the solution in order to mix the chemical and water.

Initially begin spraying by opening the handgun. This will

enable the air in the line to be purged through the handgun

tip, while building pressure.

The pumping system draws solution from the tank, through

the strainer/filter, and to the pump. The pump forces the

solution under pressure to the handgun and/or boom

nozzles.

Open the handgun by squeezing the handle lever.

•

Rotating the adjustable nozzle tip on the handgun will

•

change the tip pattern from a straight stream to a cone

pattern (finer mist).

The pump's electronic pressure switch shuts the motor

•

off when all lines are closed. The system will remain

pressurized, and the pump motor will restart

automatically when either the handgun, or boom line is

opened. If the bypass line valve is in the open position,

the pump will not shut off automatically.

The (3) nozzles are fixed at 17 1/2" spacing.

•

All (3) nozzles spraying at the same time will allow a

•

maximum coverage of 30 feet.

The center nozzle will spray an 80" swath.

•

Each of the (3) nozzles has a shutoff valve, so you can

•

shut off each nozzle individually. This may help in

achieving the actual coverage needed for your

application.

When it becomes necessary to clean the screen, you will

need to shut off the ON/OFF valve down by the tank, on the

inlet side of the pump. Next, unscrew the knurled nut on the

outside of that valve. Remove the screen/washer which is

located in the knurled nut at that location. Rinse and tap out

the dirty screen and put back in it's original position when

clean. Do this on a regular basis to maintain a clean screen.

Page 2

Loading...

Loading...