Fimco LG-14-SM, LG-14-PM Assembly And Operation Instructions Manual

5301144

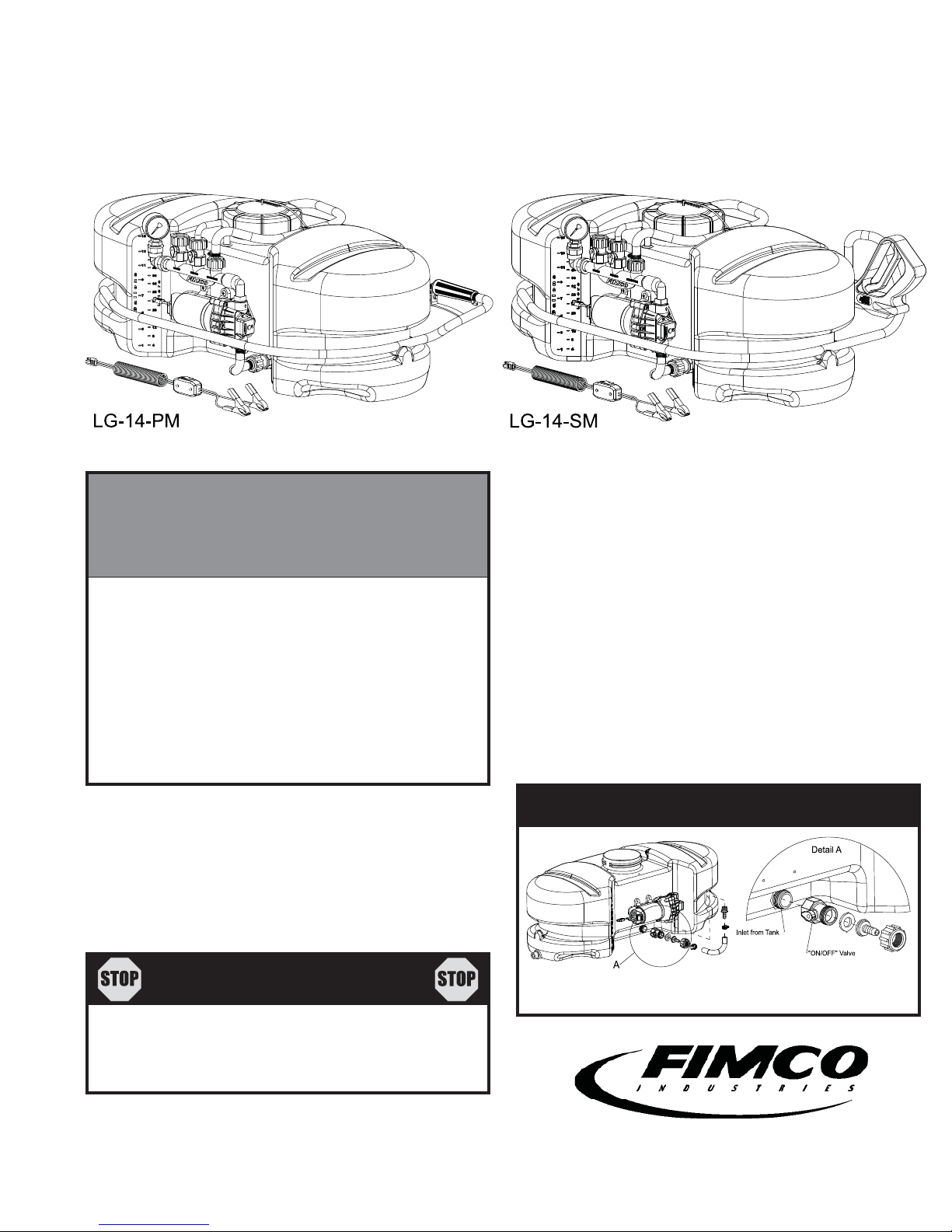

MODEL NO. LG-14-PM

15 Gallon Lawn & Garden Spot Sprayers

Assembly / Operation Instructions / Parts

BEFORE RETURNING THIS PRODUCT

FOR ANY REASON, PLEASE CALL

5301145

MODEL NO. LG-14-SM

Your authorized dealer is the best source of replacement

parts and service. To obtain prompt, efficient service, always

remember to give the following information:

1-800-831-0027

IF YOU SHOULD HAVE A QUESTION OR

EXPERIENCE A PROBLEM WITH YOUR

FIMCO INDUSTRIES PRODUCT:

1-800-831-0027

BEFORE YOU CALL, PLEASE HAVE THE

FOLLOWING INFORMATION AVAILABLE:

SALES RECEIPT & MODEL NUMBER. IN MOST

CASES, A FIMCO INDUSTRIES EMPLOYEE CAN

RESOLVE THE PROBLEM OVER THE PHONE.

GENERAL INFORMATION

The purpose of this manual is to assist you in operating and

maintaining your lawn and garden sprayer. Please read it

carefully as it furnishes information which will help you achieve

years of dependable trouble free operation.

WARNING

DO NOT USE PUMP IN AN EXPLOSIVE

ENVIRONMENT. DO NOT USE TO PUMP

FLAMMABLE FLUIDS, GASOLINE,

KEROSENE FUEL, OIL, ETC.

1. Correct part description and part number.

2. Model Number of your sprayer.

3. Serial Number of your sprayer.

Part description and part numbers can be obtained from the

illustrated parts list section of this manual.

Whenever you need parts or repair service, contact your

distributor / dealer first. For warranty work always take your

original sales slip, or other evidence of purchase date, to your

distributor / dealer.

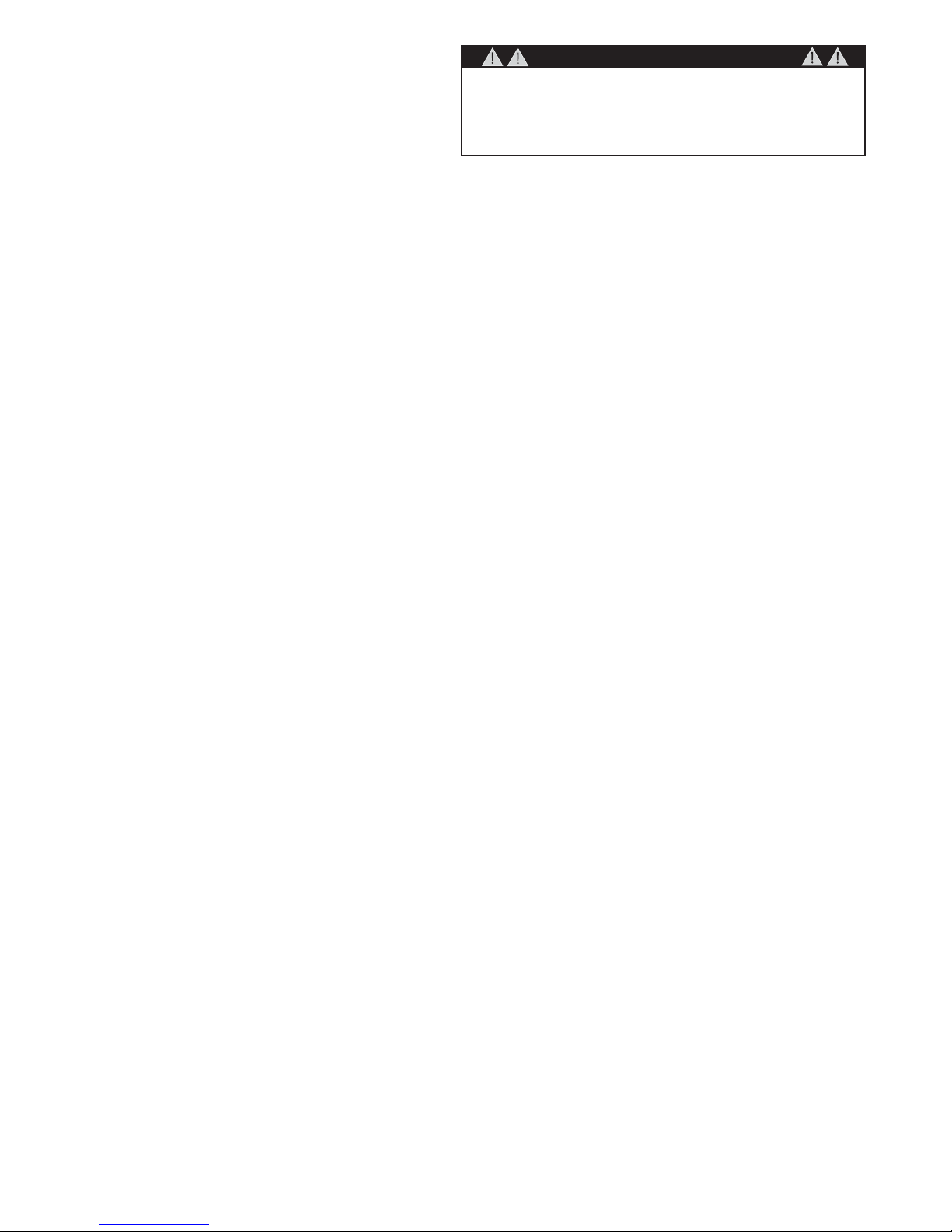

IMPORTANT REMINDER

This unit comes with an On/Off valve located near the inlet of the tank, towards the underside.

(See Detail A). You must make sure the valve is in the "open" position before using your unit.

WARRANTY / PARTS / SERVICE

Products are warranted for one year from date of purchase

against manufacturer or workmanship defects.

WWW.FIMCOINDUSTRIES.COM

1000 FIMCO LANE • P.O. BOX 1700 • NO. SIOUX CITY, SD 57049

TOLL FREE: 800-831-0027 • TOLL FREE FAX: 800-494-0440

Form No. 1310 (5004804 4/07) Printed In U.S.A.

Page 1

TECHNICAL SPECIFICATIONS

• Corrosion Resistant Polyethylene Tank.

• 12 Volt Diaphragm Pump.

• Pressure Gauge-Adjustable Pressure Range.

• 15 Foot Handgun Hose.

CAUTION

PRESSURE SWITCH OPERATION

Pressure switch is pre-set at the factory. Improper

adjustment of the pressure switch, may cause severe overload or

premature failure. If the pump is subjected to rapid cycling during

normal operation, or infrequent periods, damage may occur.

CAUTION: Always check the vehicle load rating before

using this sprayer. The loaded weight of the sprayer and

boom assembly is about 170 lbs. when the tank is full for a

15 gallon unit and 250 lbs. for a 25 gallon unit.

It is important to test the sprayer with plain water before

actual spraying is attempted. This will enable you to check

the sprayer for leaks in the plumbing system.

ASSEMBLY

1. Thread the gauge into the reducing bushing at the end of

the manifold assembly. Use a good grade of thread sealant

here to insure no leaks.

2. Connect the wiring harness to the wires coming out of the

pump. Connect the wiring from the wiring assembly to the 12

Volt power source of the vehicle. The red wire of the 2-wire

set must be connected to the positive (+) post on the battery

or the “hot” connection on a switch or to the ammeter. The

brown wire may be grounded or connected to the negative

(-) post on the battery.

3. Remove the drain plug assembly from the parts bag and

thread it onto the drain bung located at the lower rear end

of the tank.

AFTER SPRAYING

After use fill the sprayer part way with water, start the sprayer

and allow clear water to be pumped through the plumbing

system and out through the handgun. Use the handgun on

the sprayer to thoroughly wash all internal parts of the tank

and tank cover.

Refill the tank about half full with plain water and use a chemical neutralizer such as Nutra-Sol or equivalent and repeat

cleaning instructions above. Flush the entire sprayer with

the neutralizing agent. Follow the chemical manufacturers

disposal instructions of all wash or rinsing water.

WINTER STORAGE

Drain all water out of sprayer paying special attention to pump,

valves, and handgun. These items are especially prone to

damage from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a

solution of R.V. anti-freeze through the entire plumbing. Proper

care and maintenance will prolong the life of the sprayer.

4. Remove the handgun clips/screws from the parts bag,

if applicable, and attach them to the side of the tank, for

handgun storage.

OPERATION

The pump on the sprayer is equipped with a pressure switch

that is factory set at a maximum of 60 PSI. Pressure may

be decreased by opening the regulating valve. The more it

is opened, the lower the pressure will be.

The handgun has an adjustable nozzle which allows the spray

to be adjusted from a cone shaped fine mist to a straight

stream. It is normal for the pump to cycle when spraying

with a fine mist spray.

WARNING: Some chemicals will damage the pump valves if

allowed to soak untreated for a length of time. Always flush

the pump with water after use. Do not allow chemicals to sit

in pump for extended times of idleness. Follow the chemical manufactures instructions on disposal of all waste water

from the sprayer.

Page 2

Loading...

Loading...