Filmtech P3550 User Manual

Film-Tech

The information contained in this Adobe Acrobat pdf

file is provided at your own risk and good judgment.

These manuals are designed to facilitate the

exchange of information related to cinema

projection and film handling, with no warranties nor

obligations from the authors, for qualified field

service engineers.

If you are not a qualified technician, please make no

adjuatments to anything you may read about in these

Adobe manual downloads

www.film-tech.com

P-SERIES FILM TRANSPORT

User s Manual

2

The P3550 Platter Film Transport System

Thank you for selecting the BIG SKY P-SERIES Film winding system. This manual will

provide the user and installer with technical information needed to install and operate

the platter and related equipment in this system. For all other equipment (cleaners,

static, tension, etc.), please refer to the proper manuals furnished by the manufacturer.

For Information about: Turn to page:

General Information:

Platter Specifications 4

Platter Layout 5

Unpacking & Set-up 6

Operation:

General Operation, Pay-out, Take-up 7-8

Tension Sensor 9

Switches and Controls 10

Running the Show 11

3

Make-Up Table:

Information and procedure 12

Switches and Control Panel 13

Spare Parts List / Ordering Information 14

Equipment List 15

Warranty 16

Technical Assistance:

Troubleshooting Guide 17

Factory assistance & information 18

Drawings & Schematics 19+

BIG SKY P-SERIES Platter Specifications:

-3-Deck System

-Low profile design allows easier top deck access, only 49" high

-52" Aluminum decks, holds up to 25,000' of film (approx. 4 hrs)

-Simple threading pattern; no awkward reaching, looping, or pulling

-Electronic demand-only system; no switches, arms, etc.

-Mechanical Pay-out head, no electrical connections or plugs

-Each deck operates as an independent unit; no switches or moveable assemblies

-Modular design contains a minimum of spare parts

-Built-in failsafe protection from Brain wrap

-Audio and flashing light alarm when tension sensor activated

4

-Tension sensor easily connects with most automations for full system shut-down

-Built-in sensors for protection from excessive tension and pulling

-Ready to run, no adjustments needed

-Platter dimensions: 66" H x 62" L x 52" Dia. decks

-Platter weight: approx. 350 lbs.

-110/220V 50/60Hz operation

-Tested and approved to U.L. standards

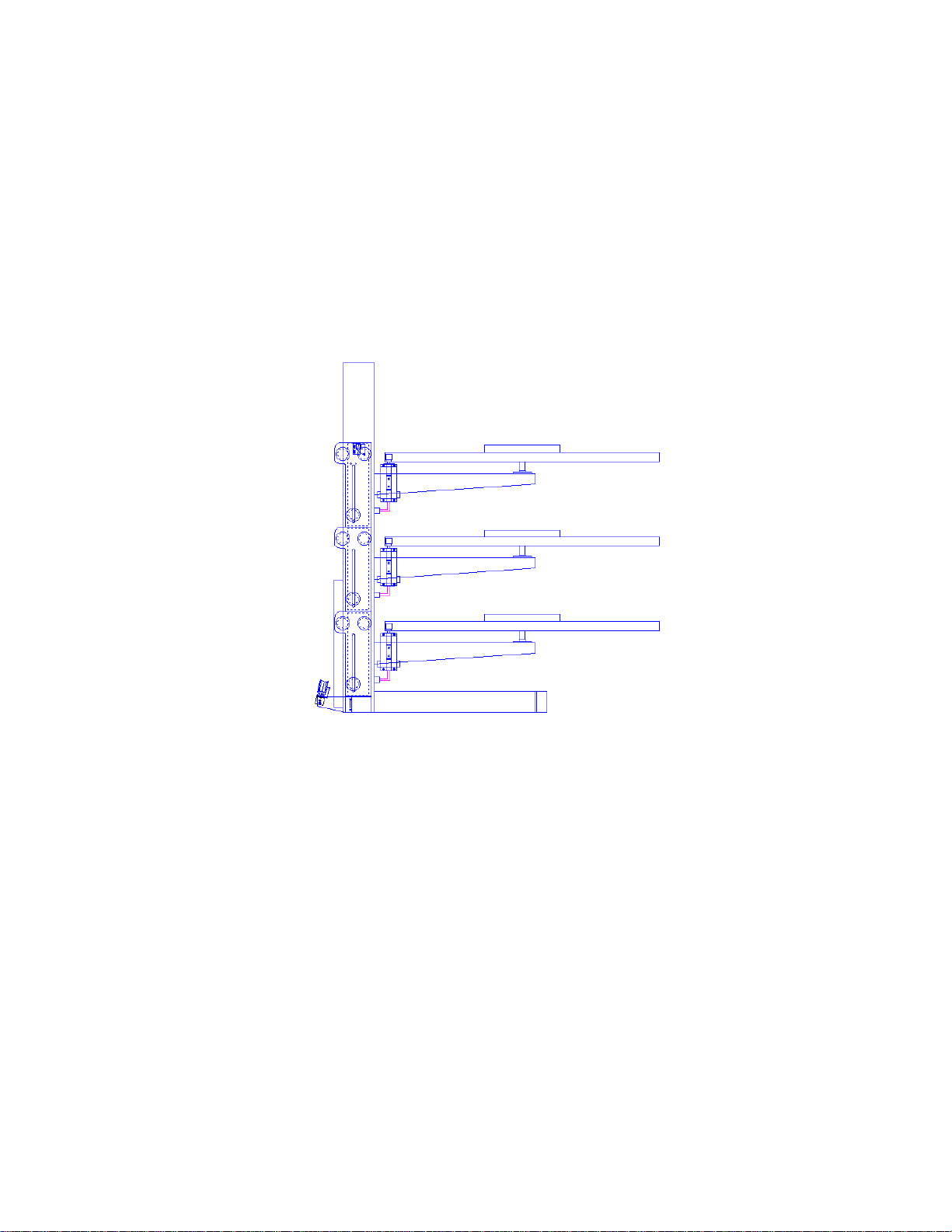

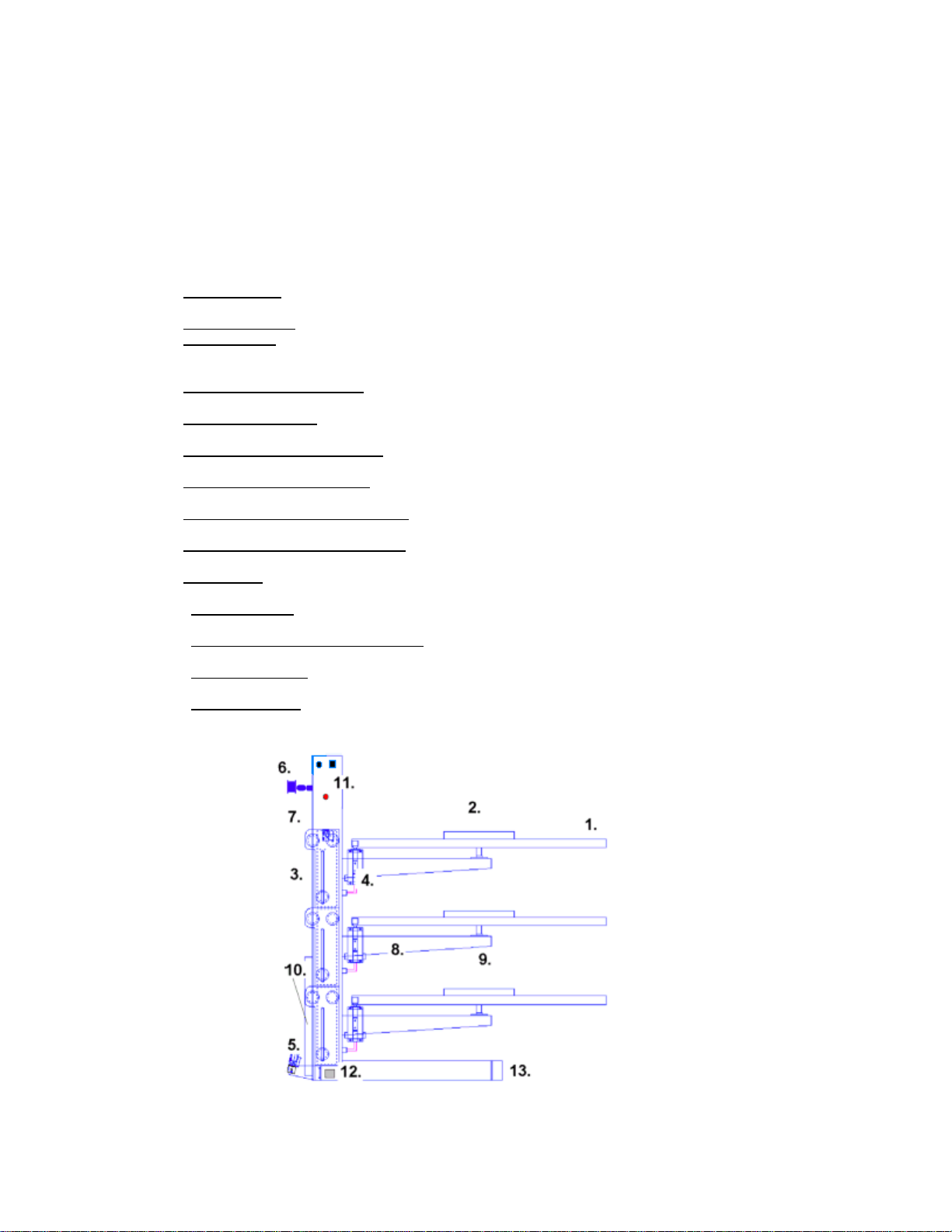

Standard Platter Layout:

Shown below is a diagram of the P3350 Platter, indicating most major

components and controls. Further technical explanations of these components

and systems are elsewhere in this manual.

5

1. Platter Deck (3)

2. Take-Up Ring (2): Ring around which film is wound during take-up

Pay-Out Head: Assembly that locates in the center of the film, controls deck speed during pay-out, and

aligns film to the rollers on the main mast

3. Speed Control Assembly (3): Part of main mast, controls individual deck speed and function

4. Deck Drive Motor (3): DC motor, located under the decks

5. Take-Up Entry Roller Assembly: Guides film from projector to proper deck control assembly

6. Pay-Out Exit Roller assembly: Guides film from tension sensor to projector

7. Pay-Out film Rollers (opposite side):

8. Motor Engage Lever (3) (opp. side): Engages and disengages drive motors from decks

9. Work Lights: For bottom two decks, illuminates deck area

10. Tension Sensor: Detects fatal Brain wraps, and shuts down platter and console

11. Power Plate Switches and Indicators: Main On/Off Switch and Fuse, Tension Alarm light and Beeper.

12. A.C. Input Module:

13. Leveling Feet (4): for leveling platter on uneven surfaces.

: 52" aluminum deck

guides film to tension sensor and detects film speed

AC input cord location

Loading...

Loading...