Fike Twinflex 302-0023 Installation And Maintenance Instructions Manual

INSTALLATION AND MAINTENANCE INSTRUCTIONS

302-0023 Twinflex

Flashpoint Weatherproof

General Description

The Twinflex Weatherproof Flashpoint device provides visual indication when

the system enters an alarm condition. This device is compatible with the

Twinflex 2-wire range of Fire Alarm equipment and comprises a 2-wire zonepowered visual indication beacon. This device may be installed on the same

zone as the Multipoint detector/sounder and associated Twinflex devices.

Before Installation

The Flashpoint must be installed in compliance with the control panel

installation manual. The installation must also meet the requirements of any

local authority. For maximum performance the Flashpoint should be installed

in compliance with BS5839 Pt1 : 2002 + A2 : 2008.

Spacing

Fike recommends spacing of sounders and strobes in accordance with BS5839 Pt1. For more specific information

regarding spacing, placement and special applications please refer to BS5839 Pt1 : 2002 + A2 : 2008.

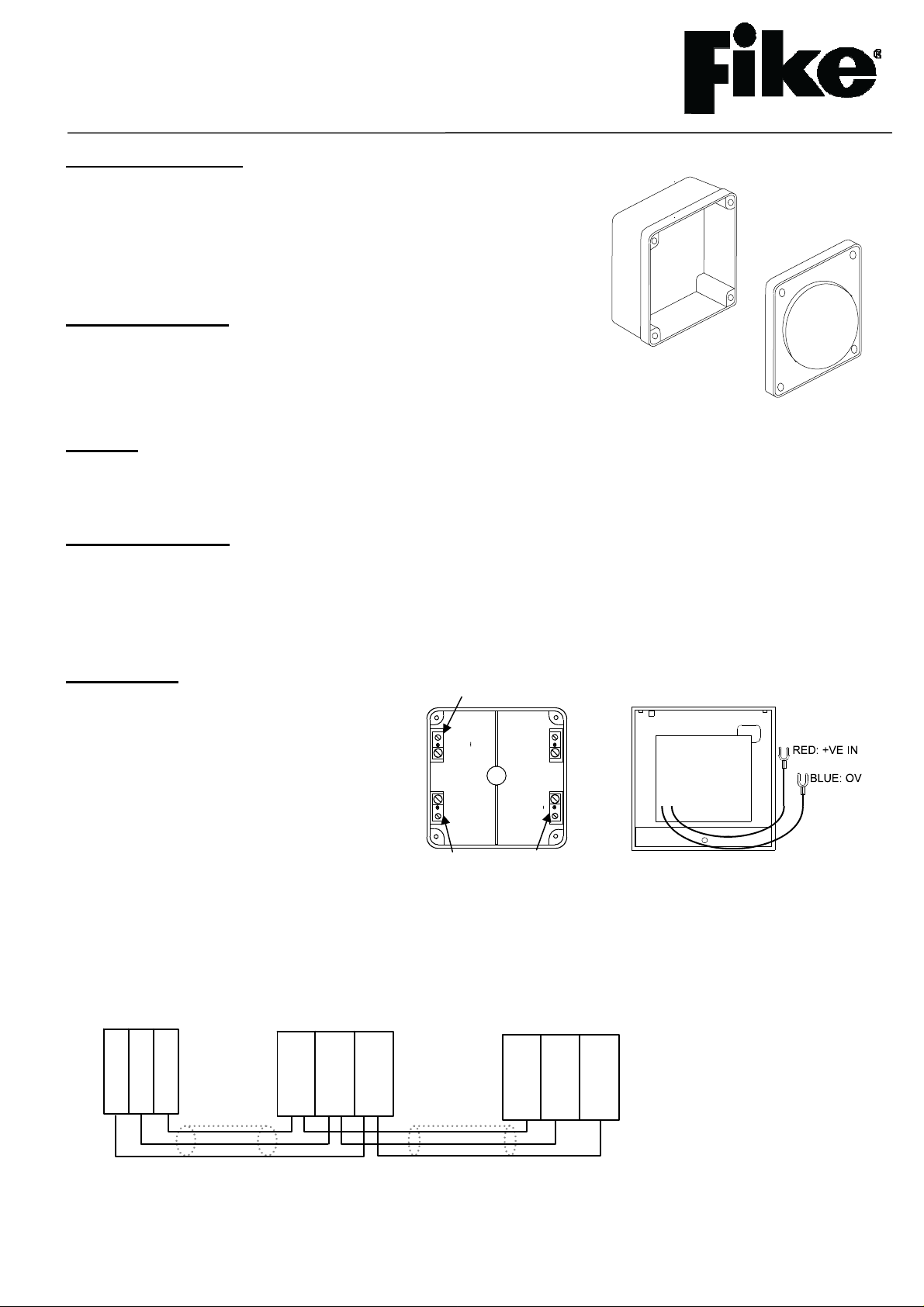

Device Installation

Pre-drill a minimum of 2 fixing holes in the back box as required. Fix the back box in a suitable position,

remembering to allow enough space for the correct termination of the appropriate fire resistant cable. All wiring

must be installed in compliance with the recommendations laid out by BS5839 Pt1 : 2002 as well as any special

recommendations documented in the control panel installation manual.

Connections

The cabling used should be 2-core 1.5mm

screened/earthed and fire resistant, of an

MICC or FP200 equivalent type and is to be in

the form of a 2-core radial circuit terminating at

the End of Line device. Cables may be

terminated into the connectors mounted in the

back box, as shown below. Also please ensure

that you use suitable cable glands for cable

entry in order to maintain the IP rating.

Care should be taken when terminating devices to ensure all cables are correctly sleeved and connections are

secure. Improper connections will prevent a system from responding properly in the event of a fire. Please

remember that all high voltage testing must be carried out before the installation of the Flashpoint front unit as this

may cause damage. It is important to maintain the screen continuity in order to protect against data corruption from

interference.

2

CONTROL PANEL

ZONE +VE

ZONE -VE

SCRN

TWINFLEX

FLASHPOINT

ZONE +VE

ZONE -VE

(BLUE)

(RED)

SCREEN

(SCRN)

SCRN

BLUE

RED

TWINFLEX

FLASHPOINT

ZONE +VE

ZONE -VE

(BLUE)

(RED)

(SCRN)

SCREEN

26-0693 Issue 3

Twinflex Flashpoints can be mixed on the same zone as other types of Twinflex device (eg. Twinflex Multipoint

Detectors). The above diagram shows how to make the zone positive, zone negative and screen connections

between the control panel and Twinflex Flashpoints. Refer to the instruction leaflets supplied with other Twinflex

devices for their equivalent wiring/terminal labelling details.

Please note that the SCRN terminal in the Flashpoint back boxes should only be connected to the zone cable

screen and NOT to the building earth. The cable screen is connected to earth at the panel end only, via the zone

“SCRN” terminal (or EARTH terminal on the Twinflex V3 2/4/8 Zone panels).

Once all testing has been carried out on the cabling and ‘continuity & integrity’ has been proven, the Flashpoint unit

may be assembled. The Flashpoint is installed by pushing the front unit gently home. The four fixing screws may

then be tightened as required.

Remember that the device at the end of the line must have its EOL signal activated using the

relevant DIL switch. Do not use a resistor or capacitor (or another manufacturer’s End of Line

device) as the end of line, as this may prevent correct operation of the zone.

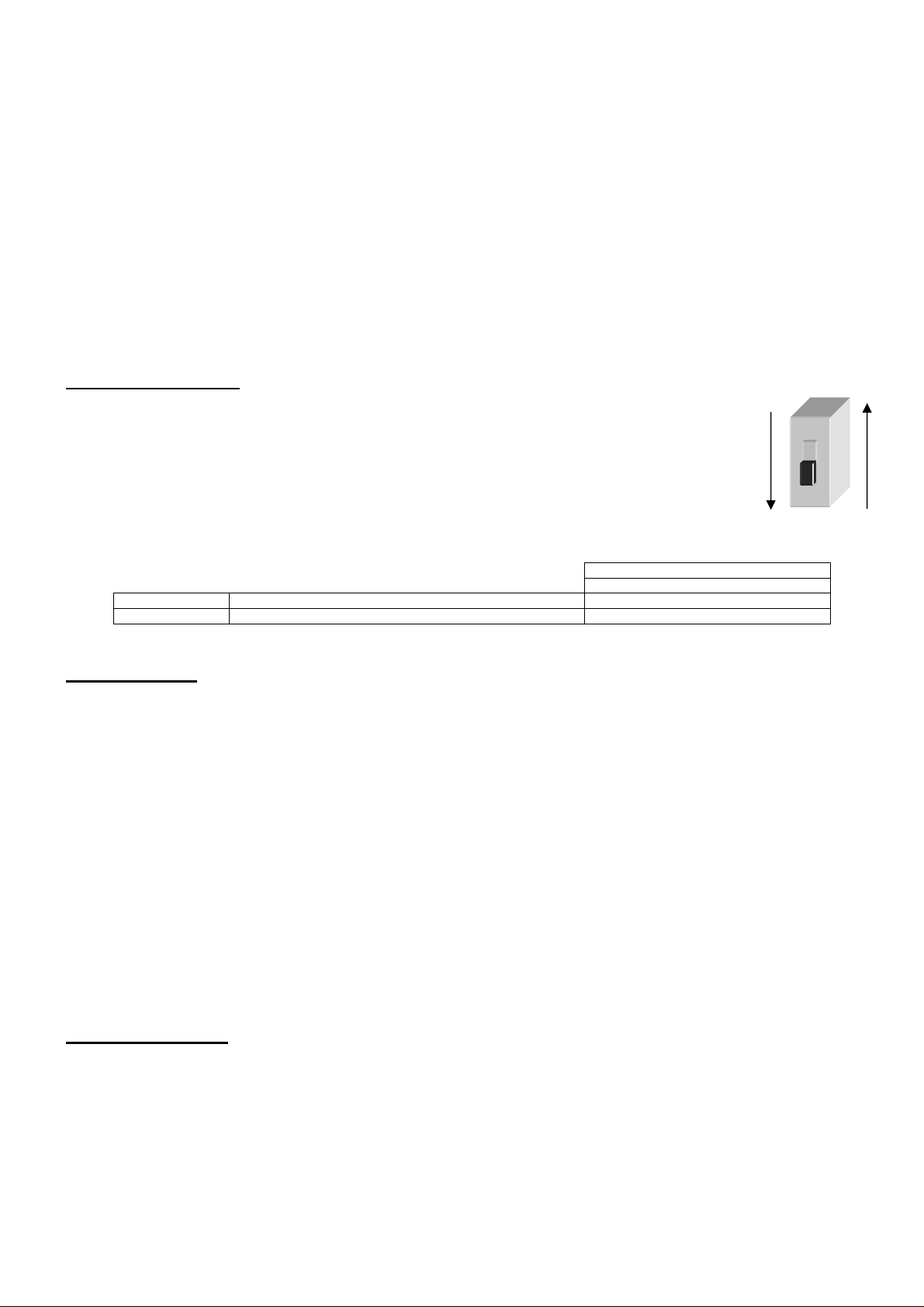

DIL Switch Settings

The device DIL switches may be used to program the operation of the Flashpoint Beacon.

They may be altered whilst the device is still powered or the system may be powered down

completely.

SWITCH ON

The last device on the circuit must have the EOL signal enabled (switch number 1 in the ‘ON’

position).

End of line

Enabled ON

Disabled OFF

DIL SWITCH SETTINGS

1

Technical Data

Dimensions . . . Width . . . 115mm

Height . . . 115mm

Depth . . 70mm

Operating temperature . . . . . . -10

o

C to +50oC.

Voltage Ranges . . . Mains Powered. . . 25.5 to 35V DC

Battery Powered . 20 to 26V DC

Operating Current . . Quiescent . . 428 uA (Typical)

Beacon . . . 5 mA

LED Operation . . . EOL indication . . 5 second interval

Beacon Operation . . Period . . . 1s

Flash Duration . . 15 ms

Loading Units (SLUs) . . Max per zone . . 27 SLU

Beacon . . 1 SLU

Flammability . . . . . . . UL94-V2

IP Rating . . . . . . . IP52

Part Code . . . . . . . 303 0023

Technical Support

Contact your supplier for technical support on this product.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential and

commissioning should only be carried out by competent persons. Fike cannot guarantee the operation of any

equipment unless all documented instructions are complied with, without variation. This unit complies with the EMC

directive.

O N

SWITCH OFF

1

26-0693 Issue 3

Loading...

Loading...