INSTALLATION INSTRUCTIONS

Screw Type Rupture Disc Assemblies

Includes models: P , PV , CPV, CPV-C, CPC, HO, HOV, PLHO, PLHOV

Scored: SCRD, SCRD-V

WARNING

• Read these instructions carefully and completely

before attempting to unpack, install or service the

rupture disc and holder.

• Do not vent a rupture disc assembly to an area

where it would endanger personnel.

• Install the rupture disc assembly in such a way

that equipment in the area will not prevent rupture

disc from opening or be damaged by system discharge.

INSPECTION/PREP ARATION

A. NEW RUPTURE DISCS

WARNING: Always handle the rupture disc by its edges

only. Damage to the dome or seat area of the rupture

disc may adversely affect the performance of the rupture disc. Read the rupture disc tag completely before

installing to confirm that the size, burst information,

and type are correct for your system.

06-246-1

• A baffle plate on the outlet end of vent piping does

NOT necessarily prevent potentially dangerous discharge.

• Piping should be braced to absorb shock when

the rupture disc ruptures.

• Install the enclosed DANGER sign in a conspicuous location near the zone of potential danger.

1. Carefully remove the rupture disc from its packaging container.

2. Remove and discard the shipping support (if provided).

Shipping supports have ORANGE STICKERS on them - they

are NOT a part of the rupture disc. (See Figure1)

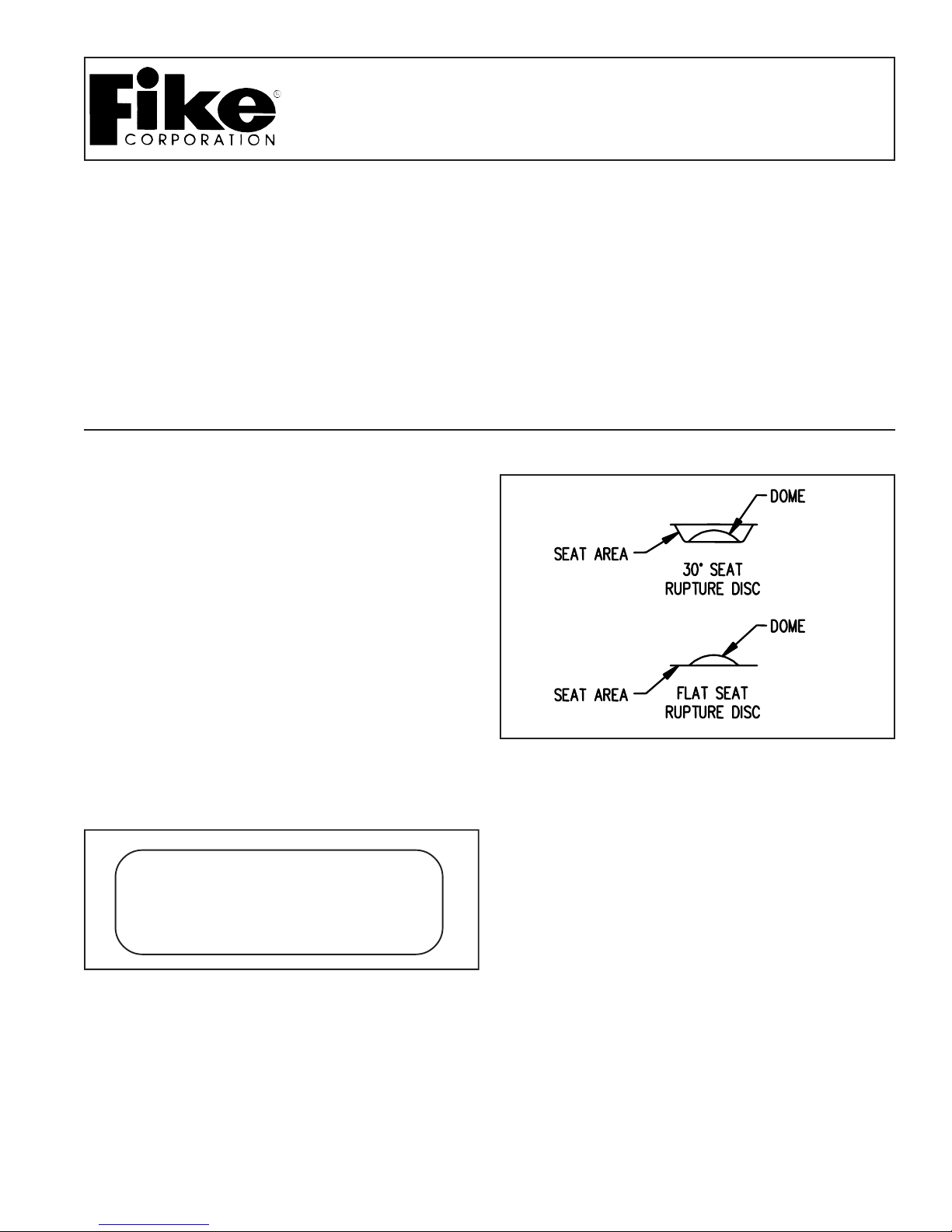

Figure 2

4. If foreign material is present, carefully clean the rupture

disc with a solvent that is compatible with your media.

SHIPPING SUPPORT ONLY.

DO NOT USE

FOR RUPTURE DISC.

Figure 1

PLHO and PLHOV users: DO NOT discard the clear plastic

that is attached to the tag. It is a component of the disc.

3. Inspect the rupture disc for damage. Look for dents,

scratches or dings in the seat area or dents in the dome of

the rupture disc. (See Figure 2)

B. NEW HOLDER

Handle rupture disc holders with care. Damage to the

rupture disc holder could affect the performance of the

rupture disc.

1. After removing the rupture disc holder from it s packaging,

unscrew the holddown nut and disassemble.

2. Discard the white shipping protector which is between

the base and holddown.

3. Inspect the seat area for scratches, dents, nicks or dirt.

Flaws may adversely affect sealing and disc burst pressure.

C. EXISTING HOLDER

1. For ease of installation, carefully remove the rupture

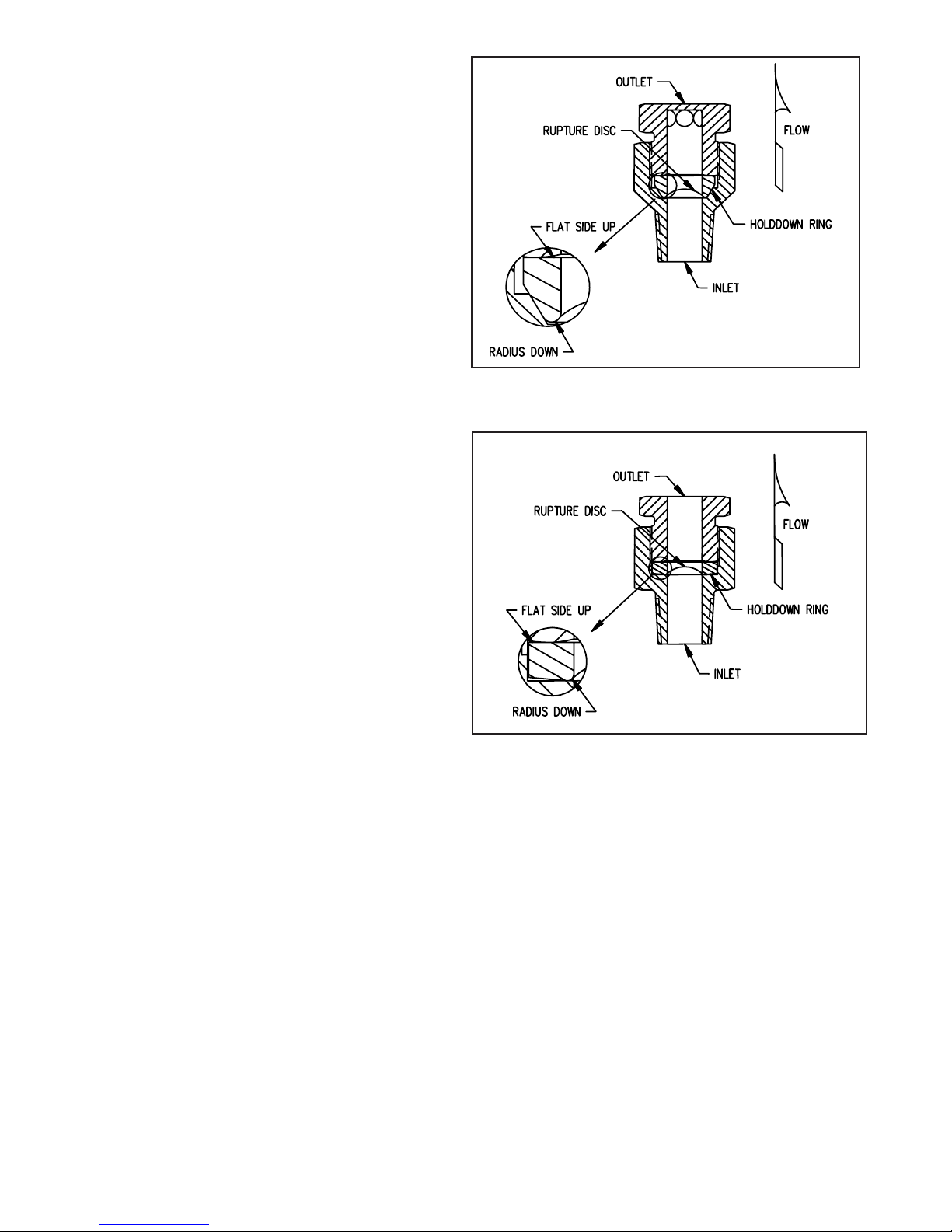

disc assembly from piping. (See Figures 3 and 4)

2. Separate rupture disc holder components.

3. Remove the rupture disc from its holder .

4. Inspect the seat area of the rupture disc holder. Look for

scratches, nicks, corrosion or deposits left from the media.

5. If necessary , clean the seat area with a solvent that is

compatible with your media. If this does not remove dirt,

hand polish the seat area with ScotchBrite, fine emery cloth

or #0000 steel wool. DO NOT MACHINE THE RUPTURE

DISC HOLDER! If scratches, nicks, corrosion or deposits

from the media cannot be removed by hand, contact the

factory.

WARNING: Inversion of the holddown ring (inst alling

the ring upside down) may result in unexpected

performance characteristics, such as premature

opening or increased burst pressures.

Figure 3: Screw T ype - 30o Seat

D. ASSEMBL Y

WARNING: Before attempting to assemble the rupture

disc and rupture disc holder, confirm that the seat area

of the rupture disc is designed to fit the rupture disc

holder.

1. Place rupture disc in the inlet of the rupture disc holder

with the dome pointing in the direction of flow.

2. Place the holddown ring on the rupture disc. Refer to

Figure 3 for proper orientation of 30

proper orientation of flat seat.

3. Screw the outlet into place, hand tight.

4. Check holder rating and type located on the side of the

holder. Refer to Table 1 for torque values. Locate the table

with the corresponding type and rating. Locate burst pressure. The column to the right contains the required torque in

ft-lbs.

5. T orque holddown nut to required torque.

o

seat and Figure 4 for

Figure 4: Screw T ype - Flat Seat

E. INST ALLA TION

1. If necessary , clean NPT threads on the holder. Wire brushing is usually sufficient. Seal threads with T eflon® tape or

pipe thread sealant.

2. Thread screw type assembly into the installation. Onehalf turn past hand tight is recommended. Always apply torque

using the flats nearest to the end being installed.

3. Experience has shown that, in some installation conditions, it may be necessary to re-torque the assembly after

the system has operated through normal pressure and temperature cycles.

Under normal operating conditions, the rupture disc should

be replaced yearly. Severe operating conditions may require

that the rupture disc be replaced more frequently .

4. The metal tag shall be attached to the ST assembly in a

manner that will prevent changing the rupture disc without

breaking the seal. Reference figures 5 showing the tag attached using a lead shunt and 0.02” SST wire as recommended practice.

Figure 5 - Screw T ype

Table 1

)ISP0003(epyTwercS03"2/1 )ISP00001(epyTwercS001"2/1

erusserPtsruB

o

27@gisp

F

005otniM5111 005otniM0303

0001ot005>0291 0001ot005>8383

0051ot0001>520002ot0051>03- 0003ot0002>660052ot0002>53- 0004ot0003>180003ot0052>04- 0005ot0004>69-

005ot00303 0008ot0007>031-

0001ot005>8383 0009ot0008>041-

0002ot0001>25- 00001ot0009>0510003ot0002>660004ot0003>18- )ISP0003(epyTwercS03"4/3

0005ot0004>69- 005ot08643

scsiDdiloS

bl-tf

)ISP00051(epyTwercS051"2/1 0007ot0006>021-

csiDtfoS

bl-tf

erusserPtsruB

o

F

27@gisp

0002ot0001>25-

0006ot0005>011-

scsiDdiloS

bl-tf

csiDtfoS

bl-tf

0006ot0005>0110007ot0006>021- 0051ot0001>380008ot0007>031- 0002ot0051>090009ot0008>041- 0052ot0002>89-

00001ot0009>051- 0003ot0052>501-

00521ot00001>57100051ot00521>002-

0001ot005>5783

T able 1 (continued)

)ISP00051(epyTwercS051"4/3 )ISP0005(epyTwercS05"1

005ot05454

0001ot005>8585

0002ot0001>870003ot0002>0010004ot0003>2210005ot0004>5410006ot0005>7610007ot0006>1810008ot0007>6910009ot0008>212-

00001ot0009>722-

Solid Disc T ypes

Seals: Hastelloy (C-276), Titanium (T i) Tantalum

Liners: Lead (Pb)

Coatings: Gold (Au), T eflon (FEP), Urethane

005ot05454

0001ot005>9595

0051ot0001>170002ot0051>380052ot0002>690003ot0052>7010053ot0003>1210004ot0053>4310054ot0004>7410005ot0054>061-

00521ot00001>46200051ot00521>103-

NOTE: In the event of a conflict between solid and

soft discs, the soft disc torque shall be used.

(T a), 316 SST, Inconel, Monel, Nickel (Ni)

NOTE: Rupture disc specifications and year of

manufacture can be found on the rupture disc tag.

Acrylic, Urethane

Soft Disc T ypes

Seals: Silver (Ag), Gold (Au), Aluminum (Al), T eflon

Liners: T eflon (FEP and PF A)

Coatings: T eflon (FEP), Urethane Acrylic, Urethane

(FEP and PF A)

704 South 10th Street • Blue Springs, Missouri 64015 U.S.A.

Phone 816 229-3405 • Fax (816) 228-9277 • e-mail fmpsales@fike.com • www.fike.com

P/N 06-246-1-4 Copyright © 2005 by Fike Corporation All rights reserved

Loading...

Loading...