Programming Manual

10-064, CyberCat® 1016

®

10-066, CyberCat

Addressable Fire Alarm Control System

254

P/N 06-539, Rev. 3

August 2013

DEVELOPED BY

COPYRIGHT NOTICE

TRADEMARKS

QUALITY

Fike

704 SW 10

th

Street

P.O. Box 610

Blue Springs, Missouri 64013 U.S.A.

Phone: (888) 628-FIKE (3453)

(816) 229-3405

Fax: (866) 211-9239

Copyright © 2011. All rights reserved.

Fike copyrights this manual and pro ducts it describes. You may not reproduce ,

transmit, transcribe, or any part of this manual without express, written

permission from Fike.

This manual contains proprietary information intended for distribution to

authorized persons or companies for the sole purpose of conducting business

with Fike. If you distribute any information contained in this manual to

unauthorized persons, you have violated all distributor agreements and we may

take legal action.

Fike© is a registered trademark of Fike.

CyberCat

®

is a registered trademark of Fike.

Fike has maintained ISO 9001 certification since 1996. Prior to shipment, we

thoroughly test our products and review our documentation to assure the highest

quality in all respects.

WARRANTY

LIMITATIONS OF LIABILITY

Fike provides a one-year limited manufacturer’s warranty on this product. All

warranty returns must be retur ned from an authorized Fike Distribu tor. Contact

Fike’s Marketing department for further warranty information.

Fike maintains a repair department that is available to repair and return existing

electronic components or exchange/purchase previously repaired inventory

component (advance replacement). All returns must be approved prior to return.

A Material Return Authorization (MRA) number must be indicated on the box of

the item being returned. Contact the appropriate Regional Sales Manager for

further information regarding product return procedures.

Installation in accordance with this manual, applicable codes, and the

instructions of the Authority Having Jurisdiction is mandatory. Fike can not be

held liable for any incidental or consequential damages arising from the loss of

property or other damages or losses resulting from the use or misuse of Fike

products beyond the cost of repair or replacement of any defective components.

Fike reserves the right to make product improvements and change product

specifications at any time.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its content, Fike assumes no responsibility for errors or

omissions.

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1.0 About This Manual ................................................................................................................ 1-1

1.1 About This Manual .................................................................................................................. 1-1

1.2 Product Support ...................................................................................................................... 1-1

1.3 Safety Information ................................................................................................................... 1-1

1.4 Related Information ................................................................................................................. 1-2

1.5 Revision History ...................................................................................................................... 1-2

2.0 C-Linx Programming Options .............................................................................................. 2-1

2.1 Understanding CyberCat ......................................................................................................... 2-1

2.2 Software Programming Features ............................................................................................ 2-2

3.0 Getting Started ...................................................................................................................... 3-1

3.1 User Interface .......................................................................................................................... 3-1

3.2 Password Protection ............................................................................................................... 3-2

3.2.1 How to Log onto the System ................................................................................................... 3-3

3.2.2 Changing the System Administrator Password ....................................................................... 3-3

3.3 Configuring the System ........................................................................................................... 3-4

3.3.1 Auto-Program .......................................................................................................................... 3-4

3.3.2 Engineered Configure ............................................................................................................. 3-4

3.4 How to Address a Device ........................................................................................................ 3-5

3.4.1 How to Auto Address Field Devices ........................................................................................ 3-5

3.4.2 How to Use the Panel’s Device Address Function .................................................................. 3-6

3.4.3 How to Address Devices with the IR Tool ............................................................................... 3-8

3.4.4 How to Address Devices with the Hand-Held Programmer .................................................. 3-10

3.4.5 How to Address Devices Using C-Linx Device Address Wizard ........................................... 3-12

3.4.6 How to Address Devices Using C-Linx Device Address Function ........................................ 3-13

4.0 Configuration Menu .............................................................................................................. 4-1

4.1 Configuration Menu ................................................................................................................. 4-1

4.2 Configuration Menu 1 .............................................................................................................. 4-1

4.2.1 How to Configure a Field Device ............................................................................................. 4-1

4.2.1.1 How to Change a Devices Alarm Features ............................................................................. 4-2

A. How to Modify a Sensor .............................................................................................. 4-3

B. How to Modify a Control or Relay Module .................................................................. 4-3

C. How to Modify a Monitor Module ................................................................................ 4-7

D. How to Modify a Pull Station ....................................................................................... 4-8

E. How to Delete a Device from the System Configuration ............................................. 4-8

F. How to Read, Write, Enable or Disable a Device ........................................................ 4-9

G. How to Set the AHU Relay Re-start Delay ............................................................... 4-10

4.2.1.2 How to Perform a Configuration Check ................................................................................. 4-11

4.2.2 How to Modify the Panel’s NAC Circuits ............................................................................... 4-11

4.2.2.1 How to Modify NAC Functions .............................................................................................. 4-12

4.2.2.2 How to Set NAC Zone Assignments ..................................................................................... 4-13

4.2.2.3 How to Set NAC Sync Protocol ............................................................................................. 4-14

4.2.3 How to Change SLC Supervision .......................................................................................... 4-14

4.2.3.1 How to Set SLC Command Mode Functions ........................................................................ 4-15

4.2.4 How to Execute the Learn Function ...................................................................................... 4-16

4.2.4.1 Learn New Devices Only ....................................................................................................... 4-17

4.2.4.2 Learn All Devices .................................................................................................................. 4-17

4.2.5 How To Enable Panel Voice Operations ............................................................................... 4-18

4.2.5.1 How To Set Mass Notification Reset Timeout ....................................................................... 4-19

4.2.5.2 How To Set Voice State Priority Levels ................................................................................ 4-19

4.3 Configuration Menu 2 ............................................................................................................ 4-20

4.3.1 How to Set System Time and Date ....................................................................................... 4-20

4.3.2 How to Set System Silencing Options ................................................................................... 4-21

CyberCat 254/1016 Programming Manual i

P/N: 06-539 Rev 3, 08/2013

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

4.3.3 How to Set System Power Options ....................................................................................... 4-22

4.3.4 How to Modify Daytime Sensitivity Settings .......................................................................... 4-24

4.3.4.1 How to Set Daytime Sensitivity Range ................................................................................. 4-24

4.3.4.2 How to Set Holiday Settings for Daytime Sensitivity ............................................................. 4-25

4.3.5 How to Enable/Disable and Assign Custom Messages to Zones ......................................... 4-25

4.3.5.1 How to Assign a Chime Code to a Zone ............................................................................... 4-26

4.3.5.2 How to Assign Evacuation Sets to a Zone ............................................................................ 4-27

4.4 Configuration Menu 3 ............................................................................................................ 4-28

4.4.1 How to Set Peripheral Device Parameters ........................................................................... 4-28

4.4.1.1 How to Configure Peripheral Devices ................................................................................... 4-29

4.4.1.1.1 Peripheral Device Testing ..................................................................................................... 4-30

4.4.1.1.2 How to Program a 256 LED Graphic .................................................................................... 4-30

4.4.1.1.3 How to Program an Amplifier ................................................................................................ 4-31

4.4.1.1.4 How to Program a Fire-Phone Module ................................................................................. 4-34

4.4.1.2 How to Set the Peripheral Bus Command Source ................................................................ 4-35

4.4.1.3 How to Set the Peripheral Bus Speed .................................................................................. 4-35

4.4.1.4 How to Set the Peripheral Bus Command Set ...................................................................... 4-36

4.4.2 How to Enable/Disable System Walktest .............................................................................. 4-37

4.4.3 How to Enable/Disable System Ground Fault Detection ...................................................... 4-37

4.4.4 How to Enable/Disable Day/Night Sensitivity Feature .......................................................... 4-38

4.5 Configuration Menu 4 ............................................................................................................ 4-38

4.5.1 How to Set AC Trouble Delay ............................................................................................... 4-39

4.5.2 How to Configure VESDA Detectors ..................................................................................... 4-39

4.5.2.1 How to Set VESDA Alarm Features ...................................................................................... 4-40

4.5.2.2 How to Set VESDA Sector/Zone Correlation ........................................................................ 4-41

4.5.2.3 How to Set VESDA Zone Number and Loop/Addr ................................................................ 4-41

4.5.2.4 How to Select VESDA Communication Command Set ......................................................... 4-42

4.5.3 How to Configure Auxiliary Power Circuits as AUX/NACs .................................................... 4-42

4.5.3.1 How to Set an Auxiliary Power Circuit as an AUX/NAC ........................................................ 4-43

4.5.3.2 How to Assign Zones to the AUX/NAC Circuit ...................................................................... 4-44

4.5.4 How to Assign Power Cut-Off Relay Address ....................................................................... 4-45

4.5.5 How to Configure Panel Relays and Optional Modules ........................................................ 4-45

4.5.5.1 How to Set Optional Module Mounting Location ................................................................... 4-46

4.5.5.2 How to Set the Function of the Panel’s On-Board Relays .................................................... 4-47

4.5.5.3 How to Assign Relays to a Zone ........................................................................................... 4-48

4.5.5.4 How to Set Fan Restart Mode ............................................................................................... 4-49

4.6 Configuration Menu 5 ............................................................................................................ 4-49

4.6.1 How to Change System Logo ............................................................................................... 4-50

4.6.2 How to Auto Address Devices .............................................................................................. 4-50

4.6.3 How to Configure Dialer Test ................................................................................................ 4-51

4.6.4 How to Configure Panel Network .......................................................................................... 4-51

4.6.4.1 How to Set Panel’s Network ID ............................................................................................. 4-52

4.6.4.2 How to Configure Network Module ....................................................................................... 4-53

4.6.4.3 How to Assign Panel to Network Zones ................................................................................ 4-54

4.6.4.4 How to Set the Number of History Repeats ............................................................................ 4-5

4.6.4.5 How to Configure Network Switch Functions ........................................................................ 4-55

4.7 Configuration Menu 6 .............................................................................................................. 4-6

4.7.1 How to Set Panel’s IP Addresses ......................................................................................... 4-56

4.7.1.1 How to Clear Monitoring Panel’s IP Addresses .................................................................... 4-56

4.7.2 How to Configure Panel for Network Supervision ................................................................. 4-57

4.7.3 How to Set IP Time Parameters ........................................................................................... 4-58

4.7.4 How to Disable Panel’s Switch Operation ............................................................................. 4-59

4.7.5 How to Set Panel’s LED Operation ....................................................................................... 4-59

4.8 Configuration Menu 7 ............................................................................................................ 4-60

4.8.1 How to Enable AHU Key Requirement Feature .................................................................... 4-60

APPENDIX A CyberCat Menu Structure (V6.XX)

ii CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

TABLE OF CONTENTS

LIST OF EXHIBITS

EXHIBIT DESCRIPTION PAGE

1-1 Related Documentation .................................................................................................................. 1-2

2-1 thru 2-40 C-Linx (V6.XX) Programming Features .......................................................................... 2-2 thru 2-42

3-1 Control Panel Keypad and Display ................................................................................................. 3-1

3-2 Password Access Levels ................................................................................................................ 3-2

3-3 Password Entry Screen .................................................................................................................. 3-3

3-4 Password Entry Screen (Password Change) ................................................................................. 3-3

3-5 Auto Address Screen ..................................................................................................................... 3-5

3-6 Device Address Screen .................................................................................................................. 3-6

3-7 Connect Device Screen .................................................................................................................. 3-6

3-8 New Device Detected Screen ......................................................................................................... 3-7

3-9 Connect Device Screen .................................................................................................................. 3-7

3-10 Address Change Completed Screen .............................................................................................. 3-7

3-11 Address Change Failed Screen ...................................................................................................... 3-7

3-12 IR Communication Screen .............................................................................................................. 3-8

3-13 IR Communication Tool .................................................................................................................. 3-9

3-14 Loop Start Screen ........................................................................................................................ 3-10

3-15 Device Address Screen ................................................................................................................ 3-10

3-16 Connect Device Screen ................................................................................................................ 3-10

3-17 New Device Detected Screen ....................................................................................................... 3-11

3-18 Connect Device Screen ................................................................................................................ 3-11

3-19 Address Change Completed Screen ............................................................................................ 3-11

3-20 Address Change Failed Screen .................................................................................................... 3-11

4-1 Configuration Menu 1 ..................................................................................................................... 4-1

4-2 Device Configuration Menu ............................................................................................................ 4-1

4-3 Alarm Features Screen................................................................................................................... 4-2

4-4 Alarm Features Screen (Sensors and Detectors) ........................................................................... 4-3

4-5 Alarm Features Screen (Control Module) ....................................................................................... 4-3

4-6 Any of 3 Zones Function Screen .................................................................................................... 4-4

4-7 All of 3 Zones Function Screen ...................................................................................................... 4-5

4-8 Select Device Function Screen .............................................................................................

4-9 Row Anding Function Screen ......................................................................................................... 4-6

4-10 Alarm Features Screen (Monitor Module)....................................................................................... 4-7

4-11 Alarm Features Screen (Pull Station Module) ................................................................................ 4-8

4-12 Delete Device Screen ..................................................................................................................... 4-8

4-13 Read/Write/Enable/Disable Screen ................................................................................................ 4-9

4-14 AHU Re-start Delay Screen .......................................................................................................... 4-10

4-15 Configuration Check Screen ......................................................................................................... 4-11

4-16 NAC Configuration Menu.............................................................................................................. 4-11

4-17 NAC Functions Screen ................................................................................................................. 4-12

4-18 NAC Zone Assignment Screen ..................................................................................................... 4-13

4-19 NAC Sync Protocol Screen .......................................................................................................... 4-14

4-20 SLC Configuration Screen ............................................................................................................ 4-14

4-21 SLC Command Mode Screen ....................................................................................................... 4-15

4-22 LEARN Screen ............................................................................................................................. 4-16

4-23 LEARN New Devices Screen ....................................................................................................... 4-16

4-24 LEARN Mode Active Screen ........................................................................................................ 4-16

4-25 LEARN All Devices Screen .......................................................................................................... 4-17

4-26 LEARN Mode Active Screen ........................................................................................................ 4-17

4-27 Voice Operations Screen .............................................................................................................. 4-18

4-28 MNS Reset Screen ....................................................................................................................... 4-19

4-29 Voice States Priority Screen ......................................................................................................... 4-19

4-30 Configuration Menu 2 ................................................................................................................... 4-20

4-31 Time Control Screen .................................................................................................................... 4-20

4-32 Silence Screen ............................................................................................................................. 4-21

4-33 Power Screen (CyberCat 254) ..................................................................................................... 4-22

4-34 Power Screen (CyberCat 1016) ................................................................................................... 4-23

4-35 Daytime Sensitivity Menu ............................................................................................................. 4-24

4-36 Daytime Sensitivity Range Screen ............................................................................................... 4-24

......... 4-6

CyberCat 254/1016 Programming Manual iii

P/N: 06-539 Rev 3, 08/2013

TABLE OF CONTENTS

EXHIBIT DESCRIPTION PAGE

4-37 Holidays Screen ........................................................................................................................... 4-25

4-38 Zone Configuration Screen ........................................................................................................... 4-25

4-39 Chime Code Screen ..................................................................................................................... 4-26

4-40 NAC Functions Screen ................................................................................................................. 4-26

4-41 Evacuation Sets Screen ............................................................................................................... 4-27

4-42 Configuration Menu 3 ................................................................................................................... 4-28

4-43 Peripheral Menu ........................................................................................................................... 4-28

4-44 Peripheral Configuration Screen ................................................................................................... 4-29

4-45 LED Test Screen .......................................................................................................................... 4-30

4-46 Checksum Calc Screen ................................................................................................................ 4-30

4-47 256 LED Graphic Configuration Screen ....................................................................................... 4-30

4-48 Amplifier Menu .............................................................................................................................. 4-31

4-49 Amplifier Zone Configuration Screen ............................................................................................ 4-31

4-50 Amplifier Message Configuration Screen ..................................................................................... 4-32

4-51 Dual-Channel Speaker Circuit Configuration Screen .................................................................... 4-33

4-52 Fire-Phone Module Configuration Screen .................................................................................... 4-34

4-53 Peripheral Source Screen ............................................................................................................ 4-35

4-54 Peripheral Bus Speed Screen ...................................................................................................... 4-35

4-55 Peripheral Command Set Screen ................................................................................................. 4-36

4-56 Walktest Screen ........................................................................................................................... 4-37

4-57 Ground Fault Screen .................................................................................................................... 4-37

4-58 Sensitivity Change Screen ........................................................................................................... 4-38

4-59 Configuration Menu 4 ................................................................................................................... 4-38

4-60 AC Delay Screen .......................................................................................................................... 4-39

4-61 VESDA Configuration Menu ......................................................................................................... 4-39

4-62 VESDA Alarm Features Screen .................................................................................................... 4-40

4-63 VESDA Sector Screen .................................................................................................................. 4-41

4-64 VESDA Loop/Addr Screen ........................................................................................................... 4-41

4-65 VESDA Command Set Screen ..................................................................................................... 4-42

4-66 AUX/NAC Menu ............................................................................................................................ 4-42

4-67 AUX/NAC Functions Screen ......................................................................................................... 4-43

4-68 AUX/NAC Functions Screen ......................................................................................................... 4-43

4-69 AUX/NAC Zone Assignment Screen ............................................................................................ 4-44

4-70 Power Cut Relay Assignment Screen ........................................................................................... 4-45

4-71 Relay Configuration Screen .......................................................................................................... 4-45

4-72 Select Module Screen .................................................................................................................. 4-46

4-73 Relay Functions Screen ............................................................................................................... 4-47

4-74 Relay Zone Assign Screen ........................................................................................................... 4-48

4-75 Fan Restart Configuration Screen ................................................................................................ 4-49

4-76 Configuration Menu 5 ................................................................................................................... 4-49

4-77 Panel Logo Screen ....................................................................................................................... 4-50

4-78 Auto Address Screen .................................................................................................................... 4-50

4-79 Dialer Configuration Screen.......................................................................................................... 4-51

4-80 Network Configuration Screen ...................................................................................................... 4-51

4-81 Network Panel ID Screen ............................................................................................................. 4-52

4-82 Network Panel Custom Message Screen ..................................................................................... 4-52

4-83 Network Module Config Screen .................................................................................................... 4-53

4-84 Network Zone Screen ................................................................................................................... 4-54

4-85 History Trouble Screen ................................................................................................................. 4-55

4-86 Network Switch Screen ................................................................................................................ 4-55

4-87 Configuration Menu 6 ................................................................................................................... 4-56

4-88 IP Address Screen ........................................................................................................................ 4-56

4-89 Clear IP Address Screen .............................................................................................................. 4-57

4-0 Network Supervision Screen ........................................................................................................ 4-57

4-91 Network Panel Custom Message Screen ..................................................................................... 4-57

4-92 IP Time Screen ............................................................................................................................. 4-58

4-93 Panel Switch Operation Screen ............................................................................................

4-94 Panel LED Operation Screen ....................................................................................................... 4-59

4-95 Configuration Menu 7 ................................................................................................................... 4-60

4-96 AHU Key Screen .......................................................................................................................... 4-60

........ 4-59

iv CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

1.0 ABOUT THIS MANUAL

1.1 ABOUT THIS MANUAL

This manual is intended for those individuals who are responsible for the programming of the Fike CyberCat

Addressable Control System. It provides a detailed description of how use the control panels configuration

menus to field-program the systems operating parameters. Changes to the system configuration shall only be

made by a factory trained and certified technician.

1.2 PRODUCT SUPPORT

If you have a question or encounter a problem not covered in this manual, you should first try to contact the

distributor that installed the protection system. Fike has a worldwide distribution network. Each distributor

sells, installs, and services Fike equipment. Look on the inside of the door, left side, there should be a sticker

with an indication of the distributor who sold the system. If you can not locate the distributor, please call Fike

Customer Service for locating your nearest distributor, or go to our web-site at www.fike.com. If you are

unable to contact your installing distributor or you simply do not know who installed the system you can

contact Fike Fire Alarm Product Support at (888) 628-FIKE (3453) Option 2, Monday through Friday, 8:00 AM

to 4:30 PM CST.

1.3 SAFETY INFORMATION

Important safety admonishments are used throughout this manual to warn of possible hazards to persons or

equipment.

a WARNING

Warnings are used to indicate the presence of a hazard

which will or may cause personal injury or death, or loss

of service if safety instructions are not followed or if the

hazard is not avoided.

I Caution

Cautions are used to indicate the presence of a hazard

which will or may case damage to the equipment if

safety instructions are not followed or if the hazard is not

avoided.

LNotes: Notes indicate the message is important, but is

not of a Warning or Caution category. These notes can

be of great benefit to the user and should be read.

CyberCat 254/1016 Programming Manual 1-1

P/N: 06-539 Rev 3, 08/2013

1.0 ABOUT THIS MANUAL

1.4 RELATED DOCUMENTATION

To obtain a complete understanding of the specific features of the CyberCat or to become familiar with related

functions in general, refer to the documentation listed below. Please reference the most current version or

the version noted on the label located on the product.

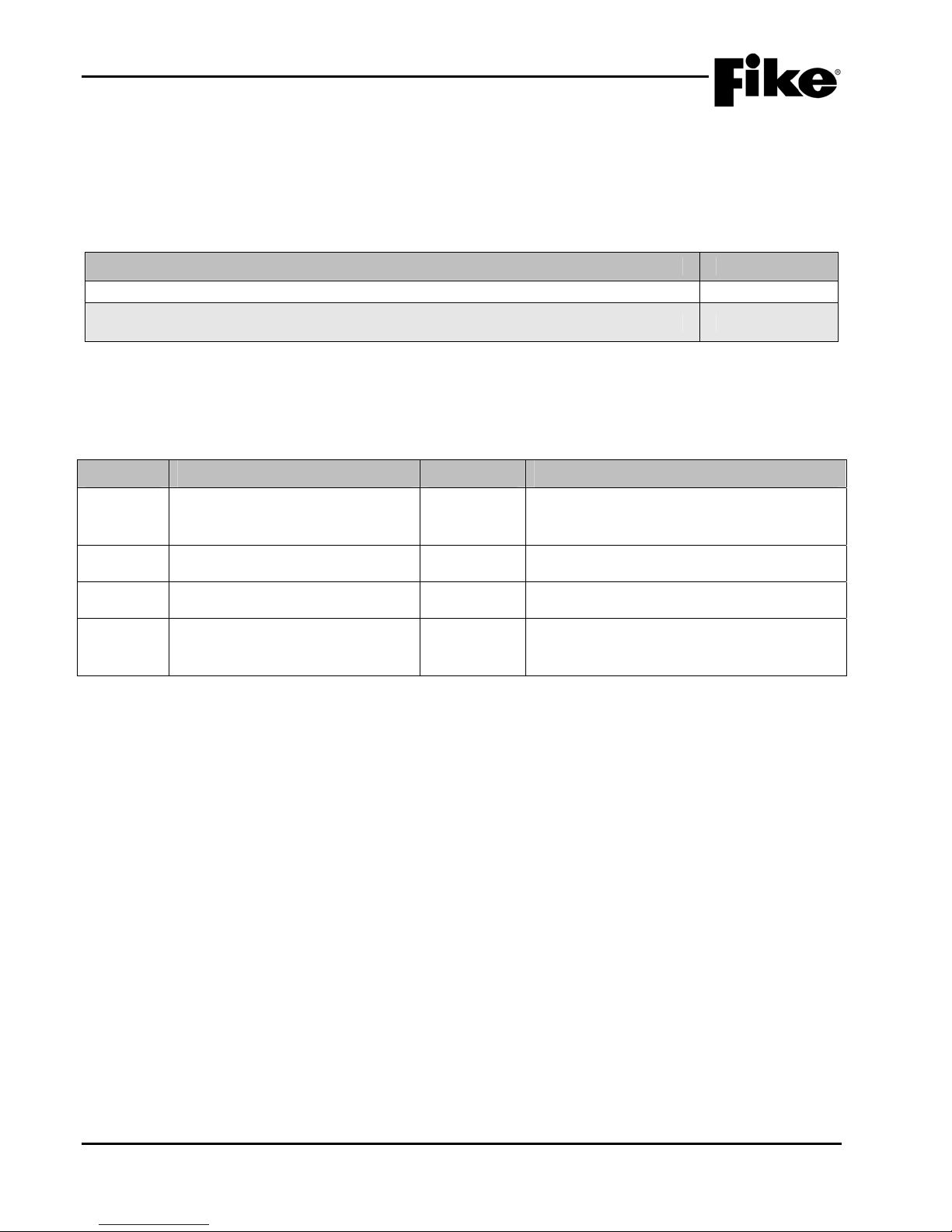

Exhibit 1-1: Related Documentation

Document Title Part Number

CyberCat Addressable Fire Alarm Control System Installation Manual 06-326

CyberCat Addressable Fire Alarm Control System Operation & Maintenance Manual 06-326-2

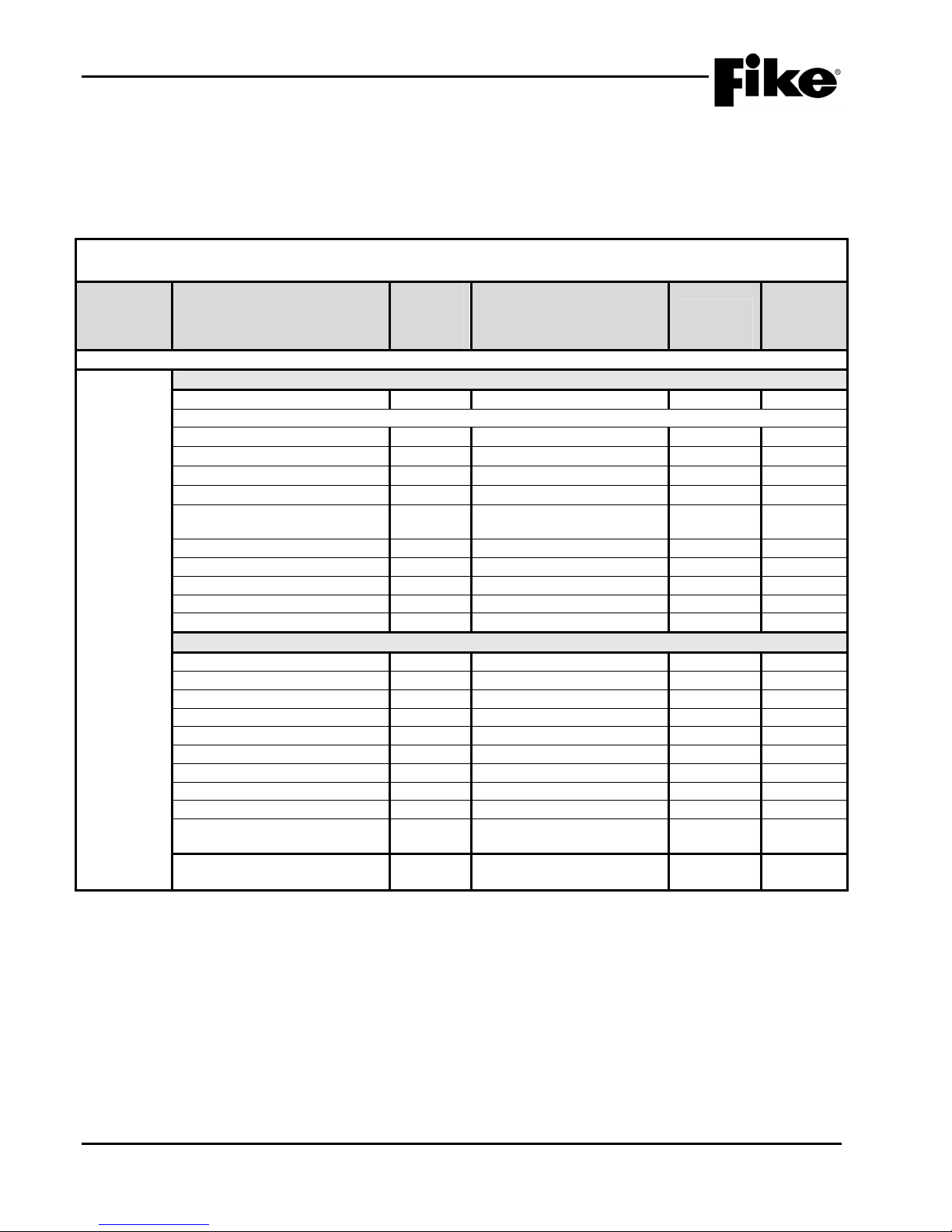

1.5 REVISION HISTORY

Document Title: CyberCat Addressable Fire Alarm System Programming Manual

Document Reorder Number: 06-539

Revision Section Date Reason for Change

Separated manual into separate

0 All Sections 05/2011

Installation, Operation and Programming

Manuals

1 All Sections 12/2011 Added Mass Notification Functions

2 All Sections 06/2012 Added FAAST Detector Functions

Added programming features for AHU

3 Sections 1, 2, 4, and Appendix A 08/2013

restart, audio sync, and MNS activation via

SLC input modules.

1-2 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

2.1 UNDERSTANDING CYBERCAT

The CyberCat system is equipped with an extensive list of configuration parameters. Changes to these

parameters can be made either directly at the panel using its integral configuration menus, or by using the

system’s PC configuration software C-Linx. Not all of the system operating parameters can be set using the

panel’s configuration menus. Section 4.0 of this manual provides a complete description of the configuration

parameters that can changed at the panel.

To set all operating parameters for the system, you must use the panel’s PC programming software C-Linx.

Section 2.2 provides a complete listing of the programming features that are available through C-Linx for your

reference. Refer to Fike document 06-448, “C-Linx Configuration Software” for software details.

It is important to keep in mind that any changes made to the system configuration directly through the panel’s

configuration menus will only be stored within the panel’s on-board memory. To retain a back-up copy of the

system programming, you should download the latest configuration settings from the panel each time you

service the system.

CyberCat 254/1016 Programming Manual 2-1

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

2.2 SOFTWARE PROGRAMMING FEATURES

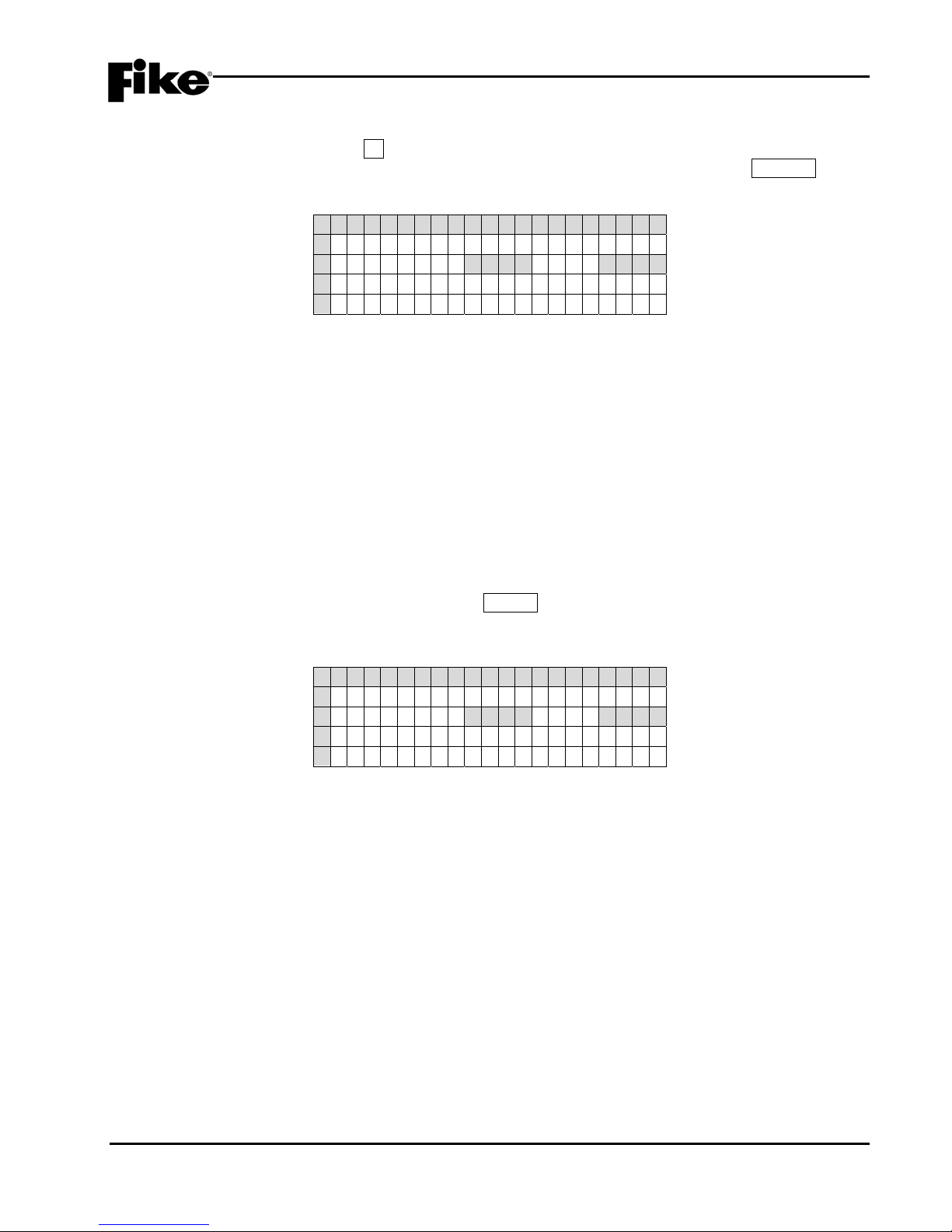

The following tables identify the configurable features that can be changed by using the panel’s programming

software C-Linx. The table also identifies features that are available, but not permitted to be used per the

CyberCat system’s UL listing.

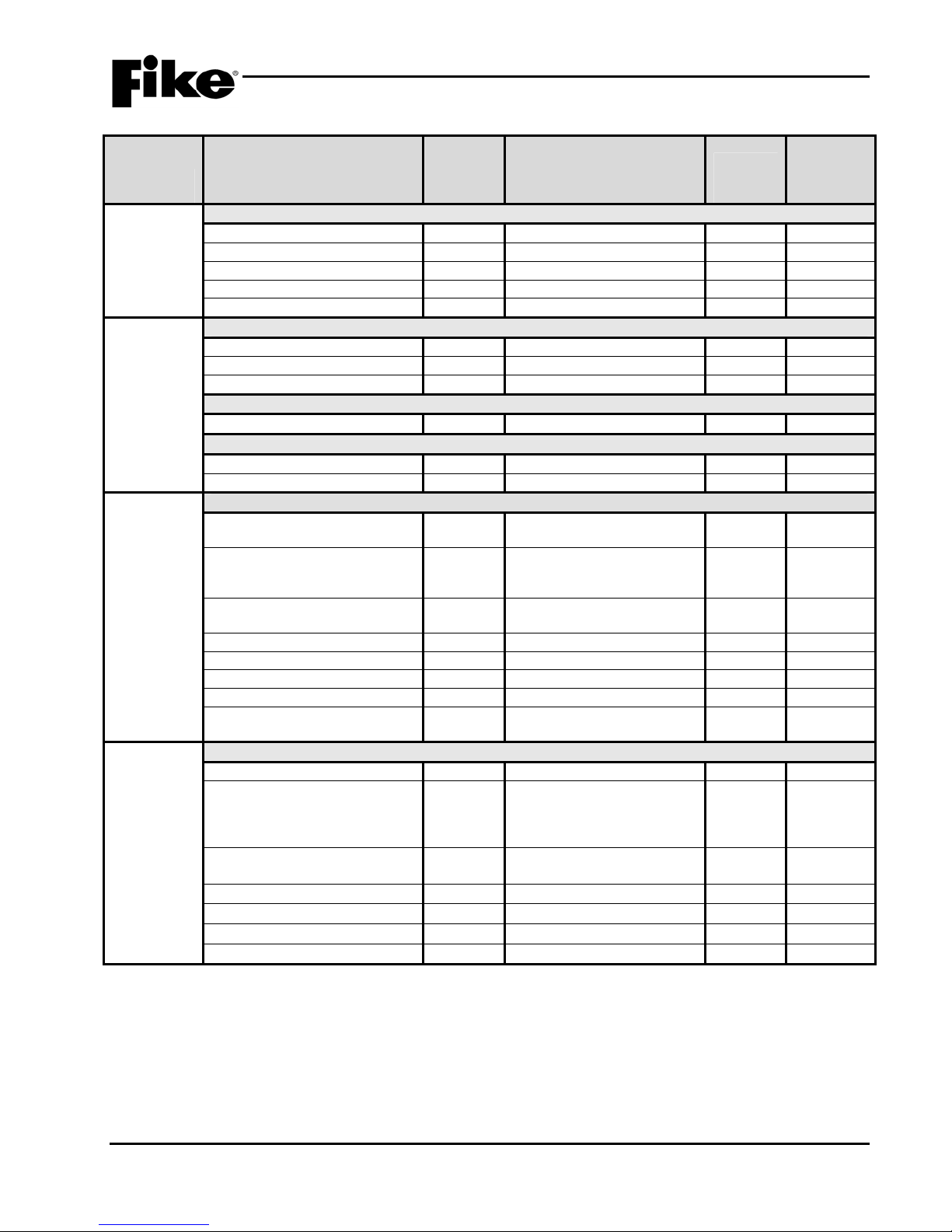

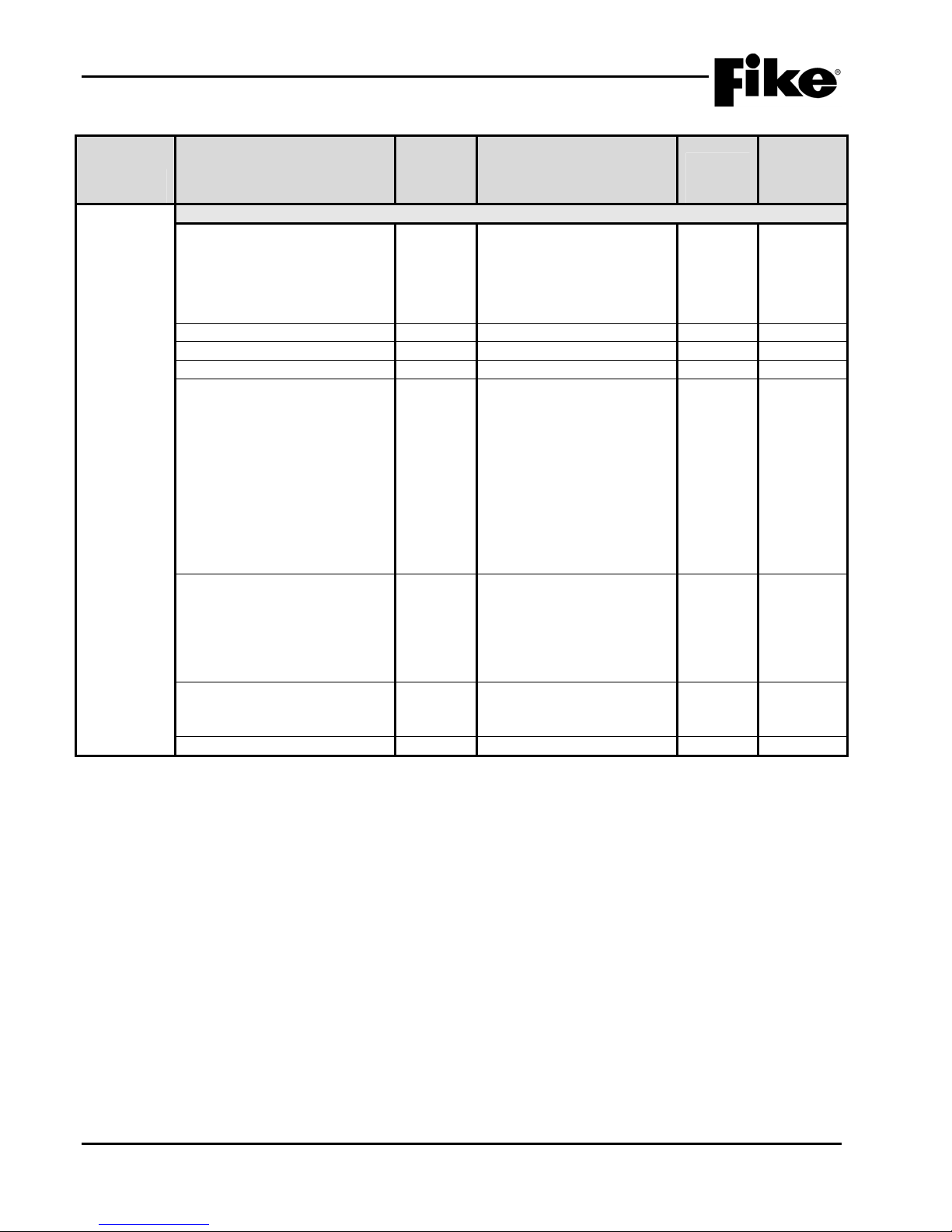

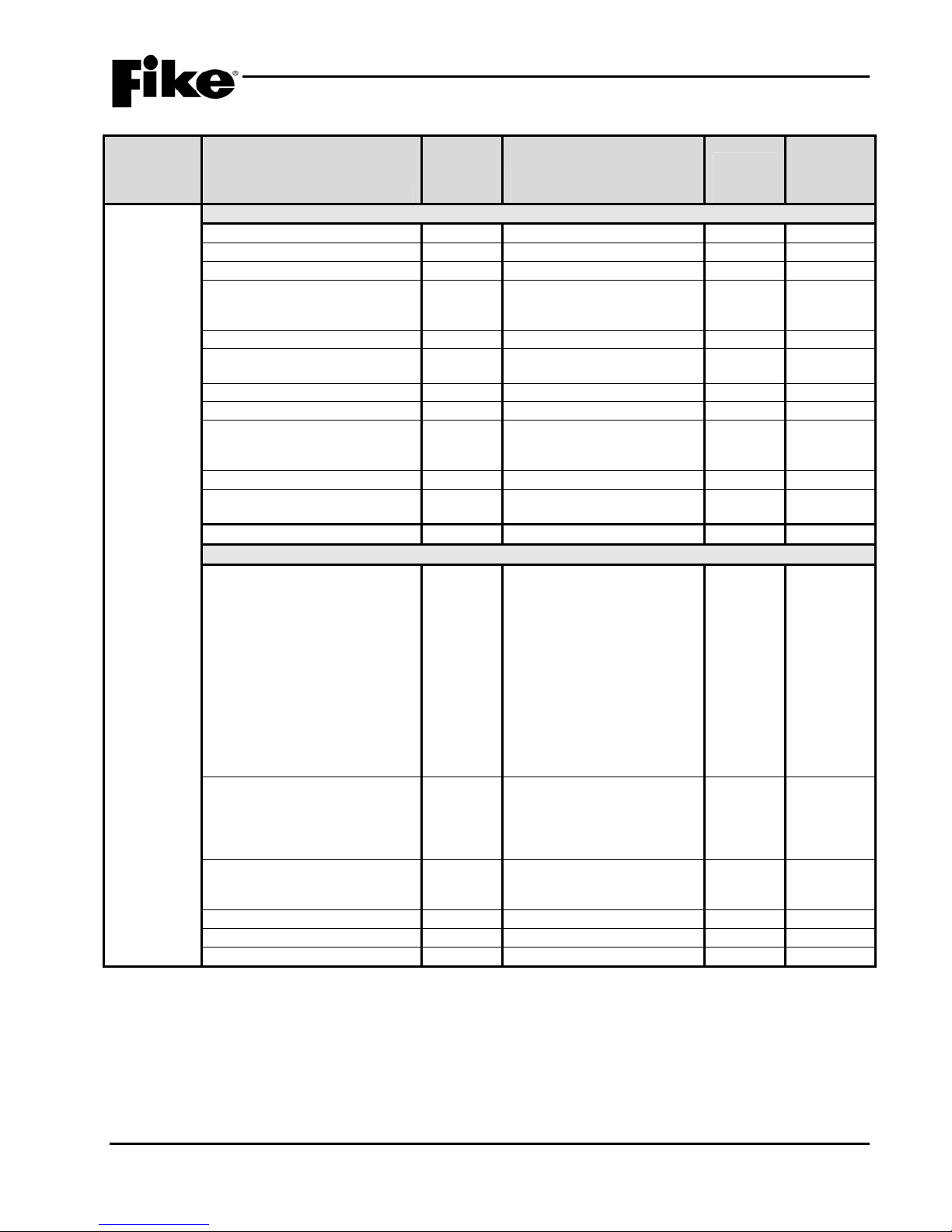

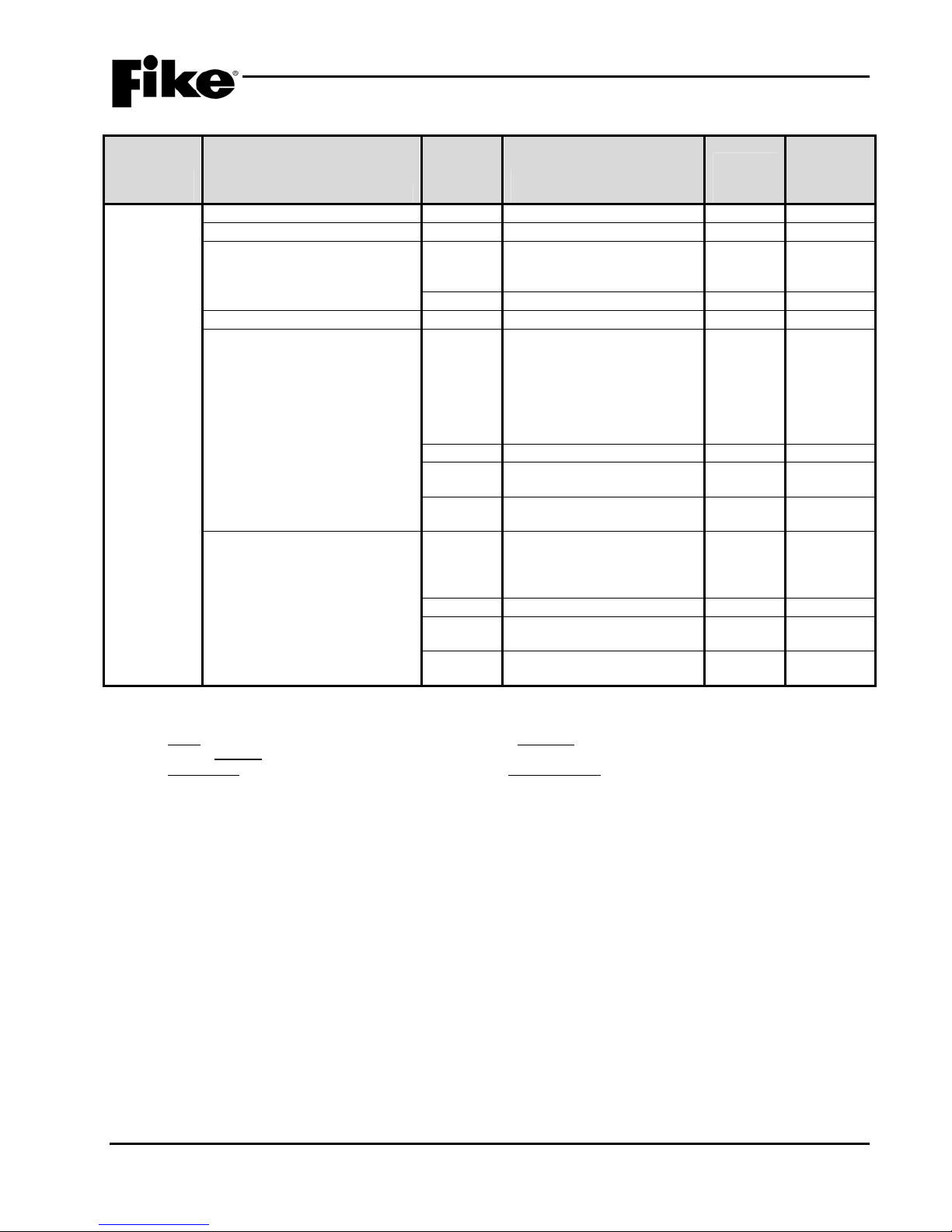

Exhibit 2-1: Programming Features

NOTICE TO USERS, INSTALLERS, AUTHORITIES HAVING JURISDICTION, AND OTHER INVOLVED PARTIES

This product incorporates field-programmable software. In order for the product to comply with the requirements in the Standard for Control Units and Accessories for

Circuit or

Component Program Feature or Option

Main Board Configuration Options

MISC.

Notes:

1. City of Chicago does not allow use of Drill, Silence and Acknowledge switches.

2. Can only be changed with Factory Level password.

3. Not used on the CyberCat 254 panel.

4. Voice Panel Priorities allows the user to program a priority scheme for Fire events and MNS events. 0 is used for systems

5. Locality setting is configured for operation of local jurisdiction requirements for Boston, Chicago and New York only. Outside of

6. Alert, Evac, Page and MNS Active manual activation events are broadcast to the SLC’s to activate or de-activate outputs

7. If device on SLC has an internal error the panel produces a trouble state (Yes) and does not just log the event into its history

8. Level 2 ground fault detection required for use with solenoids.

Fire Alarm Systems, UL 864, certain programming features or options must be limited to specific values or not used at all as indicated below.

Permitted

in UL

864?

(Y/N)

Possible Settings

(Defaults shown bold)

Miscellaneous Options

AC Trouble Delay Y

0-30 hours, Default 2 hours

1–3

Voice Panel Priorities

• Alarm

• Test Alarm

• Supervisory

• Process

Y

Y

Y

Y

Voice City Y

0-254, Default 4

0-254, Default 5

0-254, Default 6

0-254, Default 7

Standard / Boston / Chicago

4

4

4

4

Standard 5

/ New York

Voice States on Loop Y

Fan Restart Y

Drill/Silence/Acknowledge N

Auto Message Y

Walktest Y

Enabled / Disabled

Automatic/Manual

Enabled / Disabled

Enabled / Disabled

Enabled / Disabled

6

Enabled 1,2

Supervision Options

Transformer Y

Loop Style (SLC) Y

Ground Fault Level 1 N

Ground Fault Level 2 N

Main Battery Y

Auxiliary Battery Y

Auxiliary Loop Module Present Y

Auxiliary Power Module Present Y

Eclipse Device Error Trouble Y

AHU Fire Dept Key Required for

Y

120VAC / 240VAC

4, 6, or 7 (Class B, A or X)

Enabled / Disabled

Enabled / Disabled

Supervised / Unsupervised

Supervised / Unsupervised

Enabled / Disabled

Enabled / Disabled

Enabled / Disabled

Enabled / Disabled

Enabled 2

Enabled 2,8

3

3

3

Enabled 7

AHU Restart

Battery Cutoff Y Loop # and Address #

(L: 1-4 Address: 0-254)

where priority is not required (0 = None; 1 = Highest and 254 = Lowest).

these jurisdictions, the setting should be set to Standard.

connected to the SLC.

buffer (No). (i.e. Checksum Error)

Settings

permitted

in UL 864 Notes

2-2 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

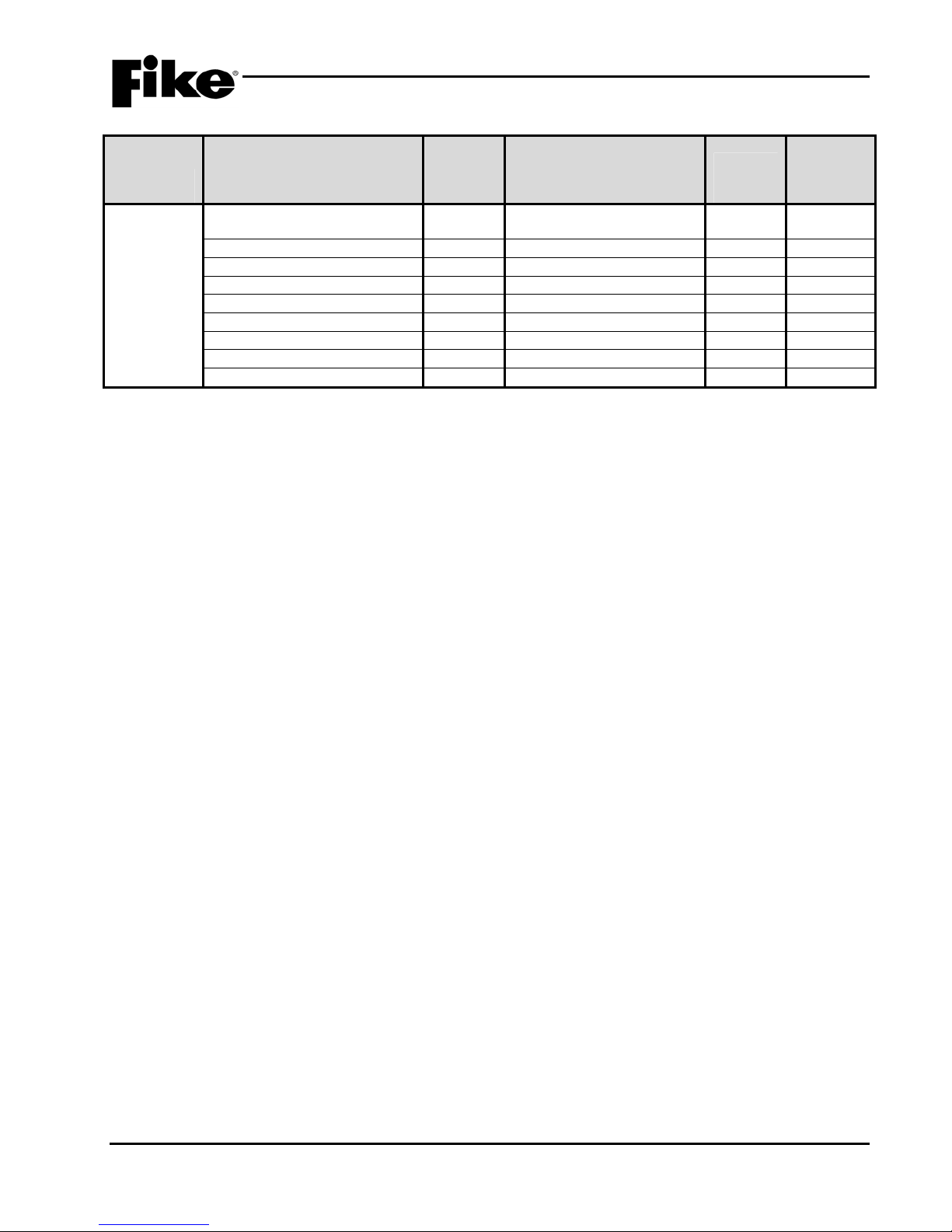

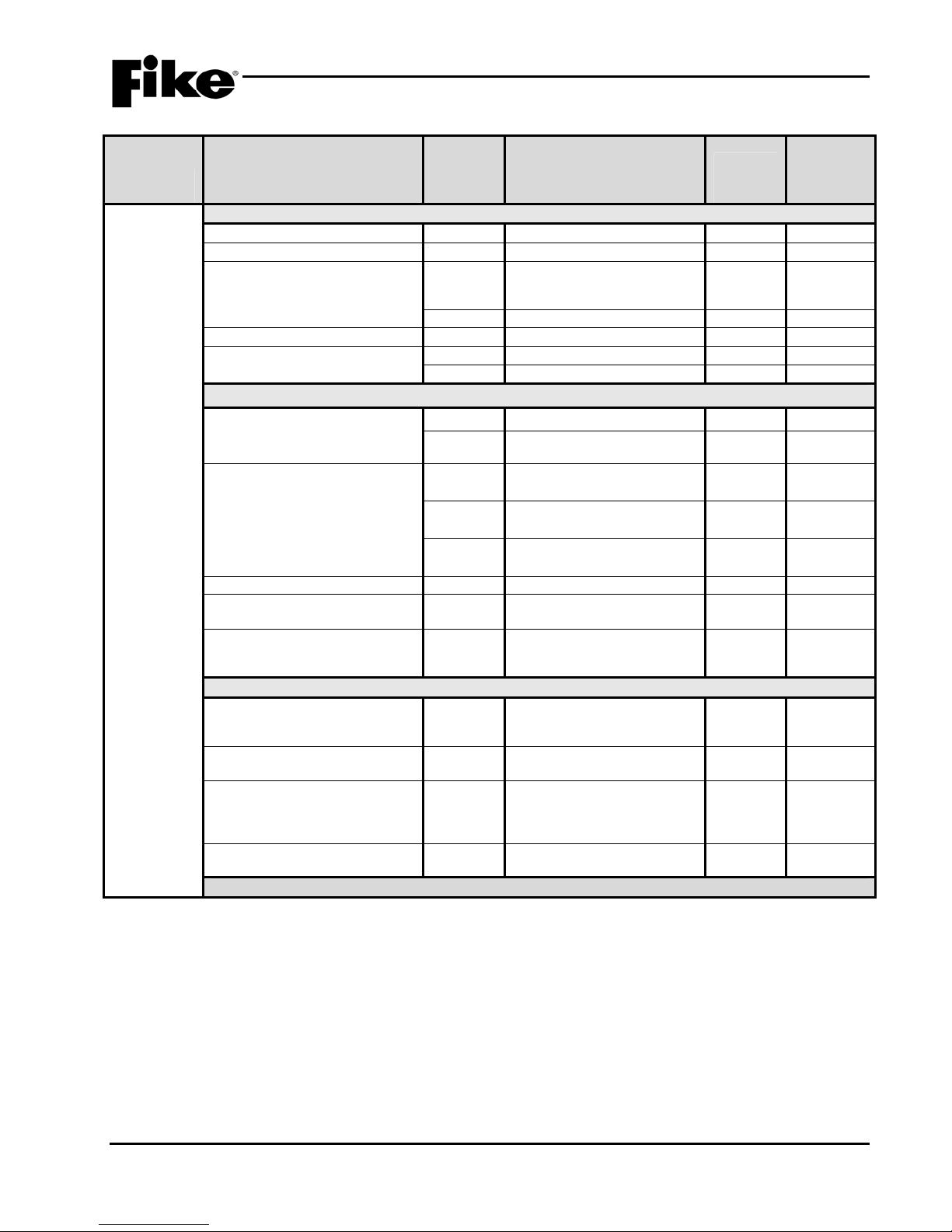

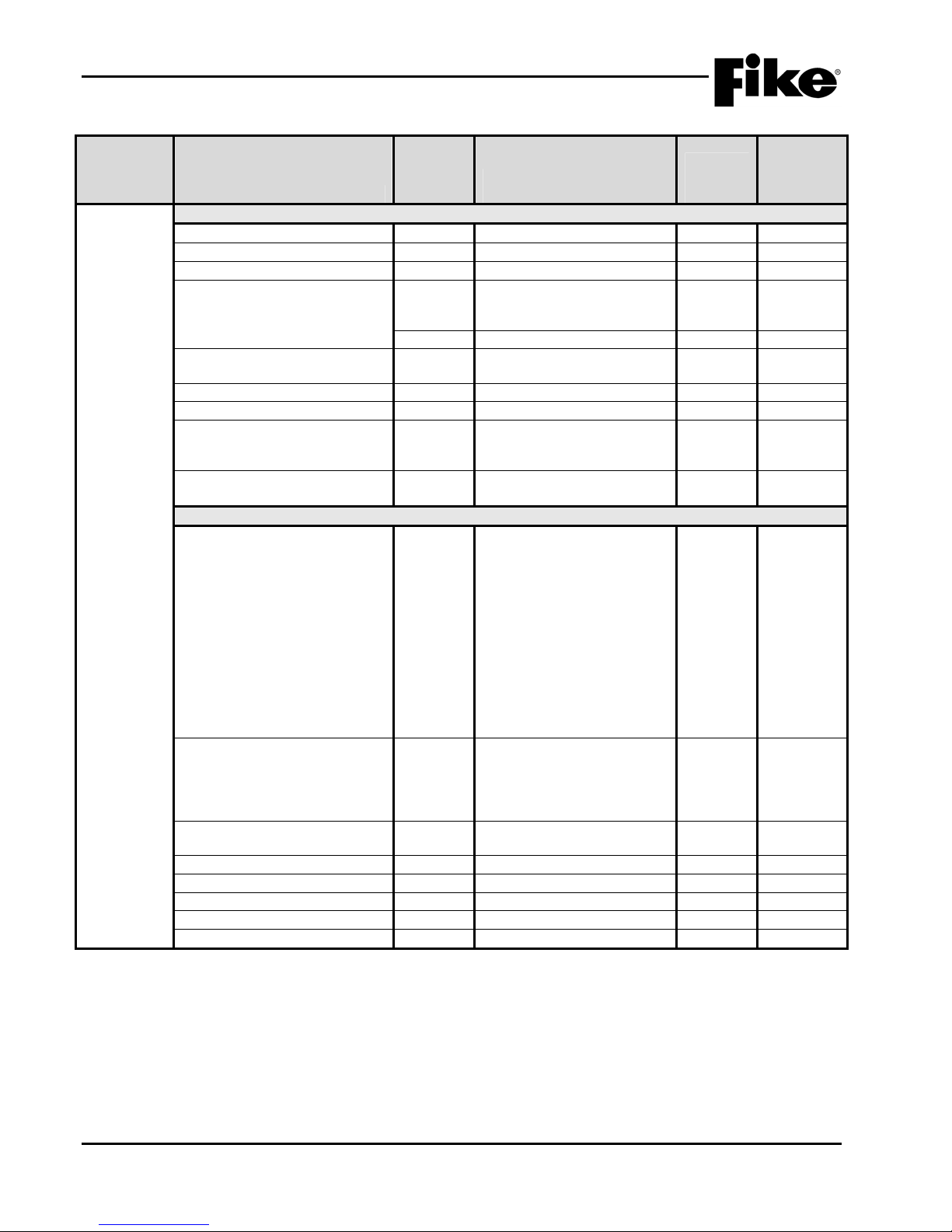

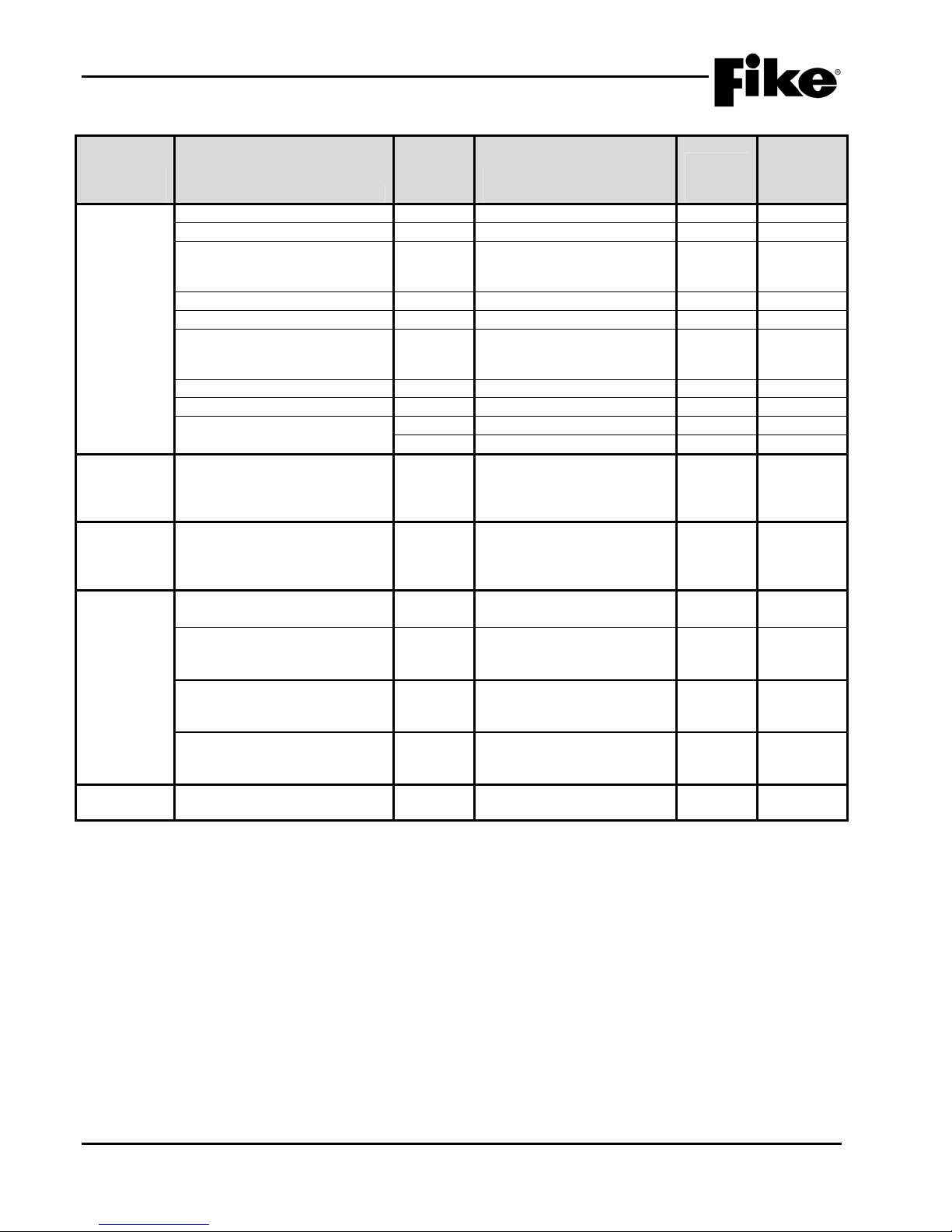

Exhibit 2-2: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

MISC.

Silence Options

Unsilence Time Y

Silence Reminder Y

Silence Inhibit Y

Positive Alarm Sequence Y

Silence Mode Y

Time

Functions

Alarm Sensitivity Changes

Daytime Sensitivities start/stop Y 12:00 AM – 12:00 AM

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1-24 hours

Enabled / Disabled

Enabled / Disabled

Enabled / Disabled

UL

Days that use daytime sensitivity Y Sunday – Saturday

Use Daylight Savings Time Y

Enabled / Disabled

Holiday Schedule

Night time sensitivity Y 20 days total (mm/dd/yyyy) 4

DACT Auto Test

DACT Auto test start hour Y

DACT Auto test period (hrs.) Y

0 – 23 (2 default)

0 - 24

NAC P10 and P11 (NAC 1 & NAC 2)

Sync Protocol Y

NO / Gentex / System

Sensor / Wheelock

State (Activation) Y

Alarm / Pre-Alarm 1 / PreAlarm 2 / Supervisory /

Trouble / Process

Silenceable Y

Silenceable / Non

silenceable

Zone Assignment Y

Circuit Y

Drill Y

Walktest Y

Panel Sync Protocol Y

1 – 254

Enabled / Disabled

Enabled / Disabled

Enabled / Disabled

Gentex / System Sensor /

Wheelock

Relays

P2 Main Board Relay

Relay Selection Y

State (Activation) Y

R1 / R2

Alarm / Pre-Al arm 1 / Pre-

Alarm 2 / Supervisory /

Trouble / Process / Zone

Disable

Silenceable Y

Non-Silenceable /

Silenceable

Relay Y

Zone Assignment Y

Circuit Y

Drill Y

Notes:

1. An audible signal that has been silenced at the protected premises shall automatically resound and remain energized until

silenced and retransmitted the signal to any supervising station to which the original signal was transmitted, as applicable, at

least once every 24 hours until the condition is corrected and the product is restored to the normal supervisory condition.

2. If synchronization is selected, both NAC circuits will use the same sync protocol.

3. Refer to Fike document 06-186 for compatible sync protocol.

4. Only allows the installer to assign the night time sensitivity to a different obscuration level than during normal working hours.

No other functions are affected or disabled.

5. Allows on board relays to be configured from the default setting of Alarm for R1 and Supervisory for R2 to the states listed in

State (Activation).

Enabled / Disabled

1 – 254

Enabled / Disabled

Enabled / Disabled

Settings

permitted

in UL 864 Notes

UL 1

2,3

5

CyberCat 254/1016 Programming Manual 2-3

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

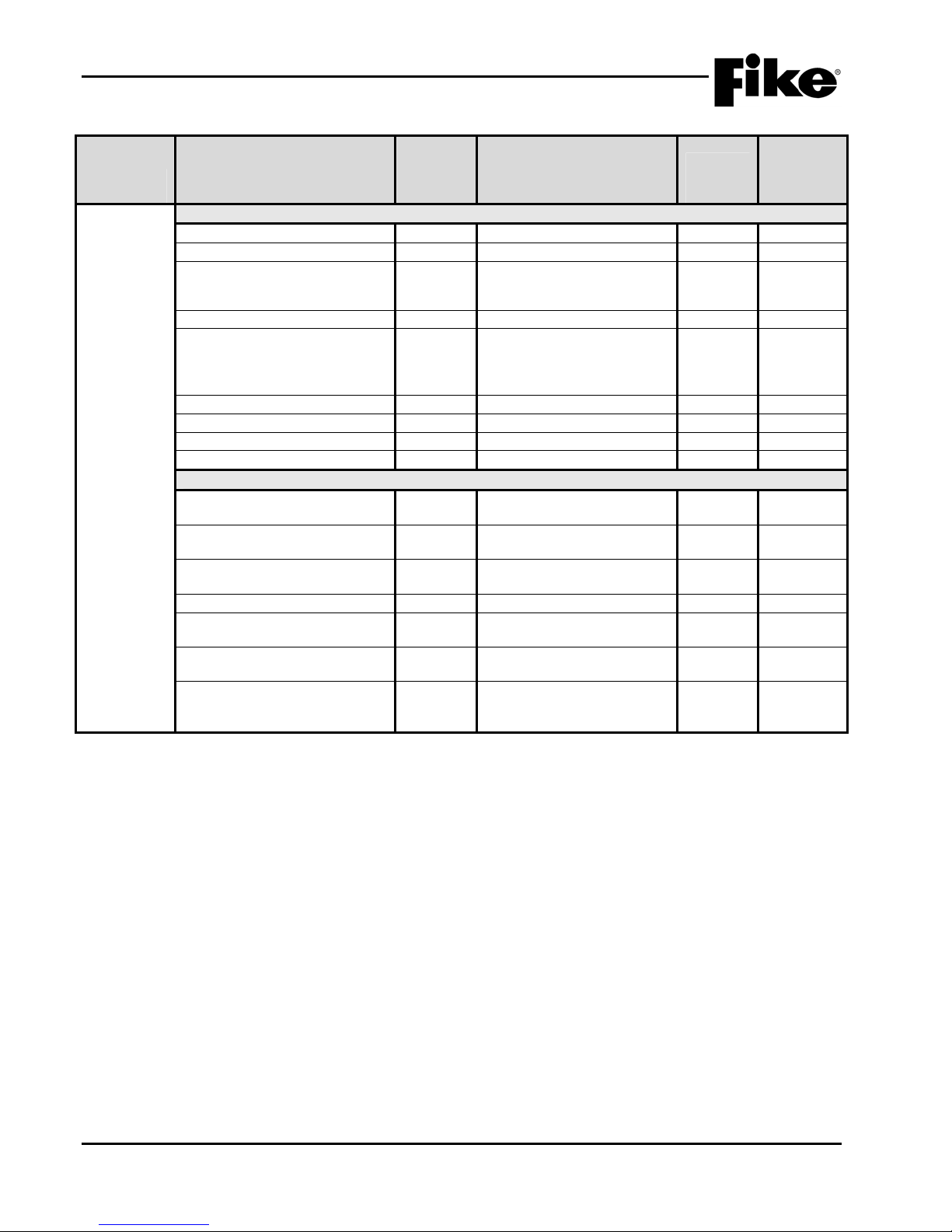

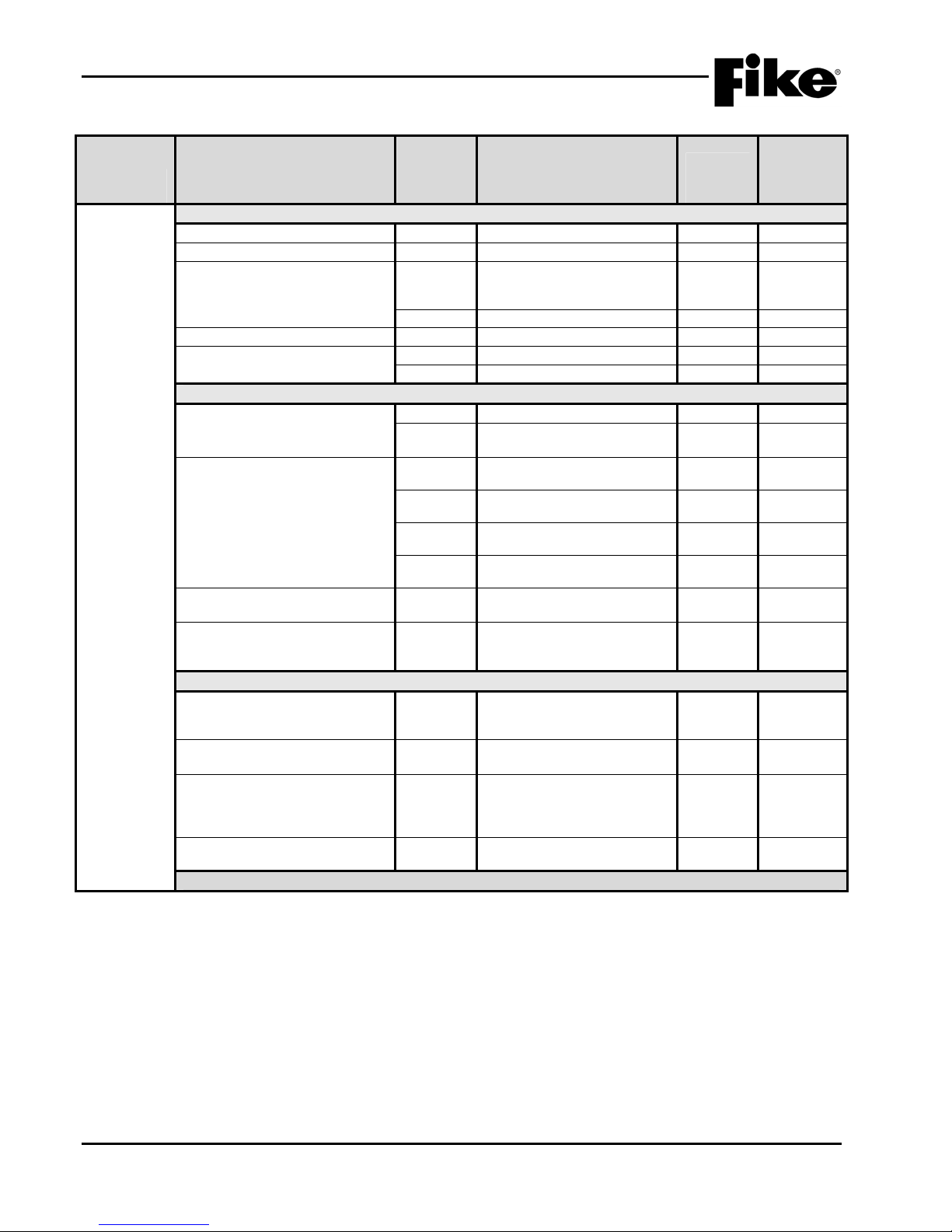

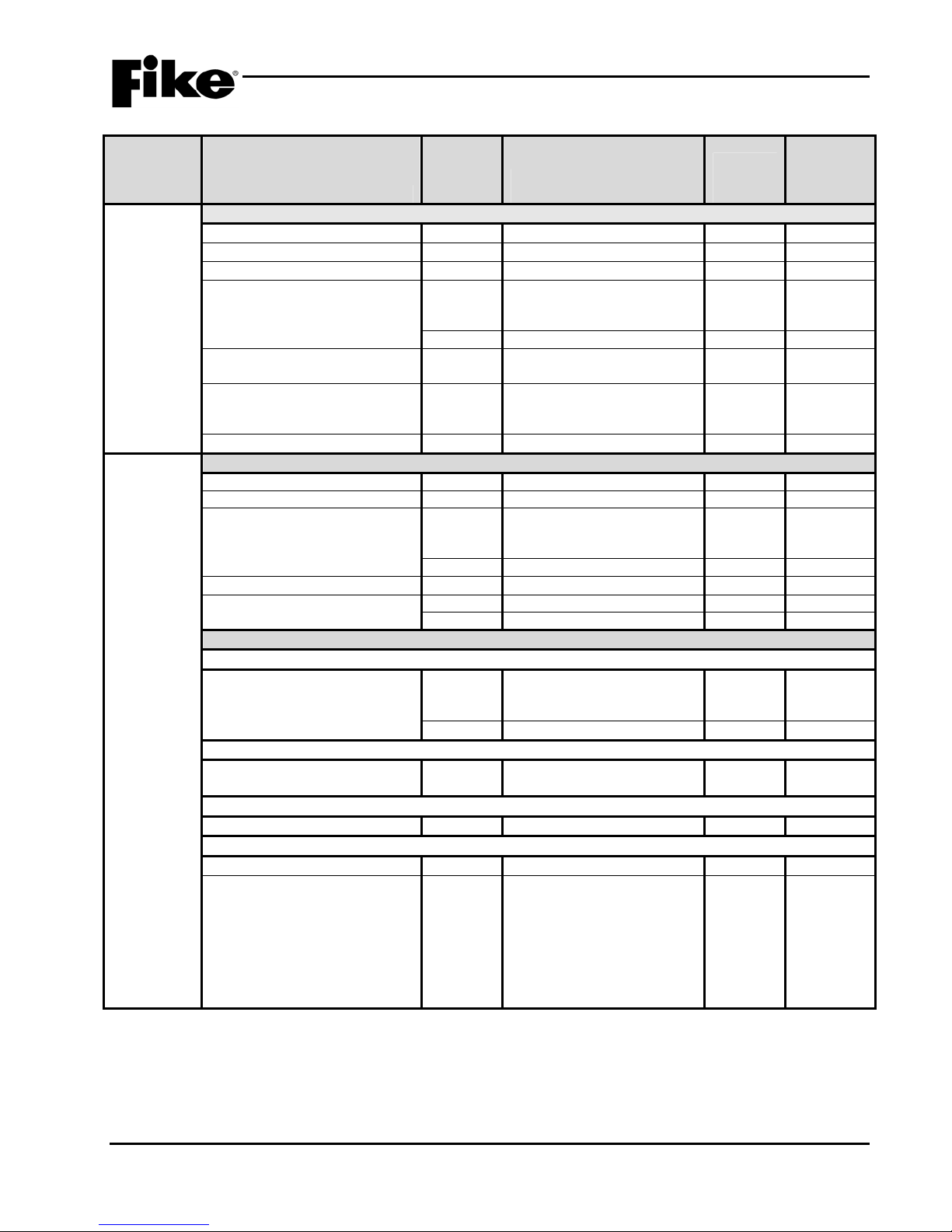

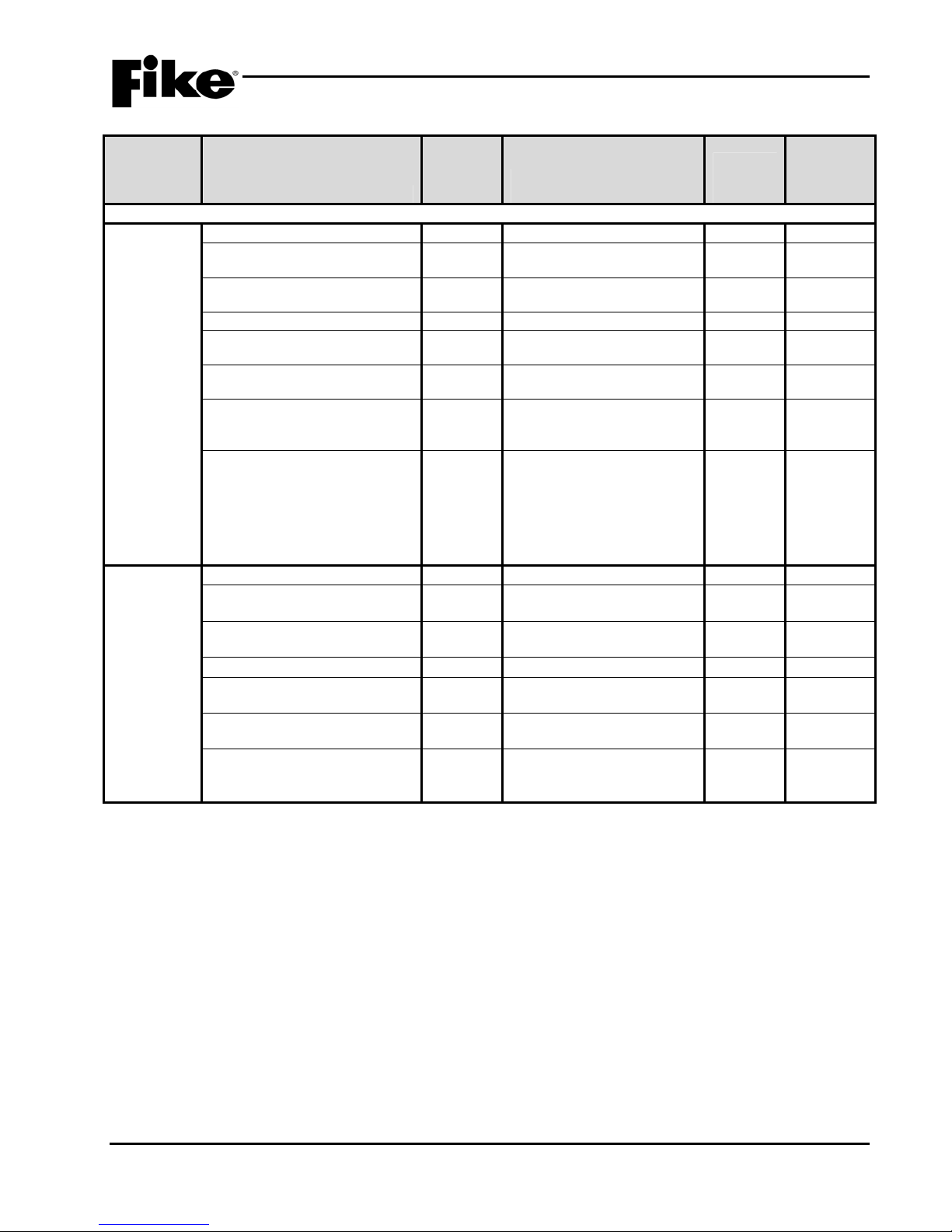

Exhibit 2-3: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Relays

Zones Zones Y

P12

Relay Selection Y A / B / C / D

Module Y

State Y Alarm / Pre-Alarm 1 / Pre-

Restart Delay Y

Silenceable Y

Zone Assignment Y

Relay Y

Drill Y

P13

Relay Selection Y A / B / C / D

Module Y

State Y Alarm / Pre-Alarm 1 / Pre-

Restart Delay Y

Silenceable Y

Zone Assignment Y

Relay Y

Drill Y

Type Y

Custom Message Y 20 character user defined

Voice EVAC Mapping Y Zones 1 - 254

Voice Alert Mapping Y Zones 1 - 254

Zone Enabled Y

Zone Chimes Y Assign chime code to zones

864?

(Y/N)

No Module Installed / CRM4 /

CRPM (Opt 1) / CRPM (Opt

2) / Fire Communicator

Alarm 2 / Supervisory /

Trouble / Process / Zone

Disable

0 – 250 (sec)

Non-Silenceable /

Silenceable

1 – 254

Enabled / Disabled

Enabled / Disabled

No Module Installed / CRM4 /

CRPM (Opt 1) / CRPM (Opt

2) / Network Interface Card

Alarm 2 / Supervisory /

Trouble / Process / Zone

Disable

0 – 250 (sec)

Non-Silenceable /

Silenceable

1 – 254

Enabled / Disabled

Enabled / Disabled

1 – 254

Alarm Zone

Enabled / Disabled

Possible Settings

(Defaults shown bold)

Settings

permitted

in UL 864 Notes

2-4 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

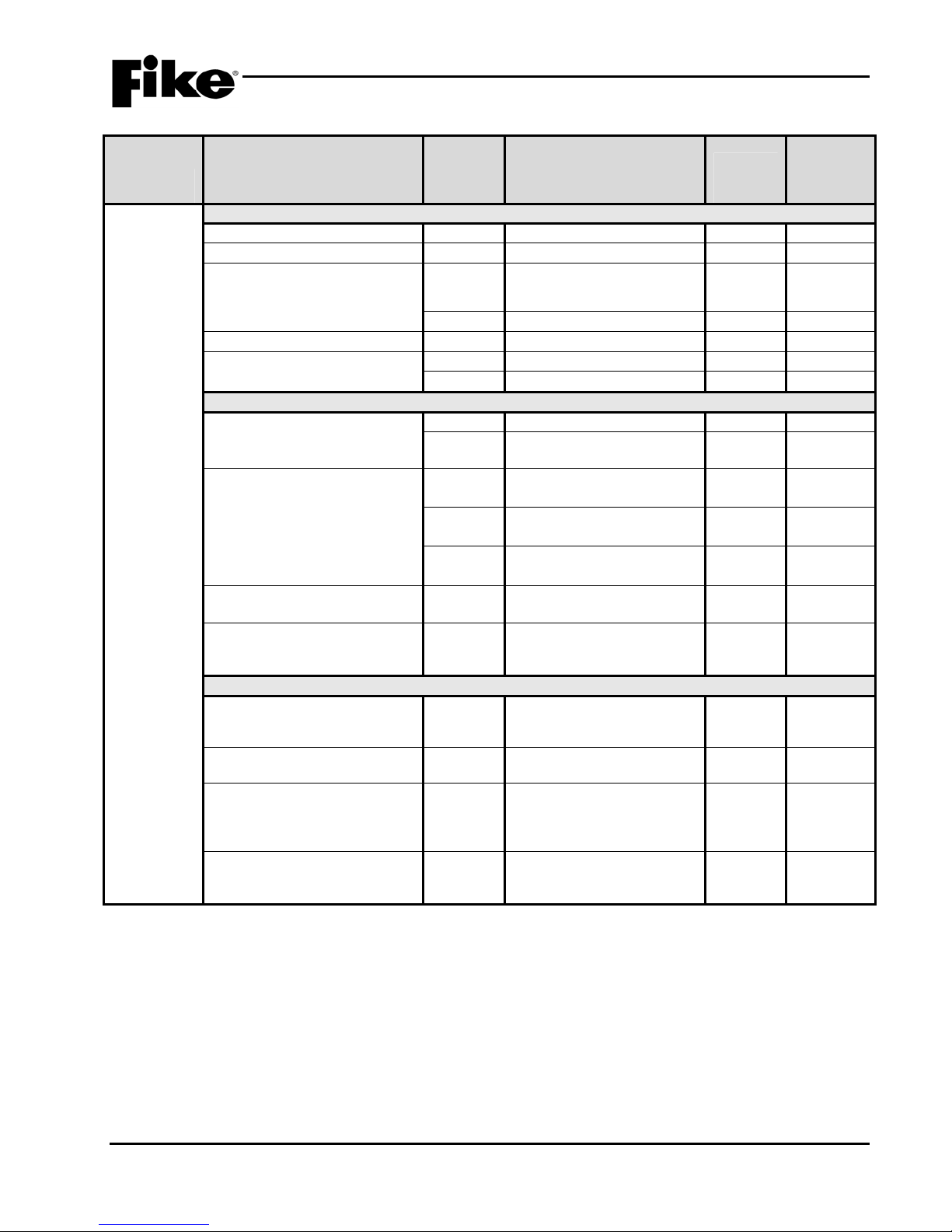

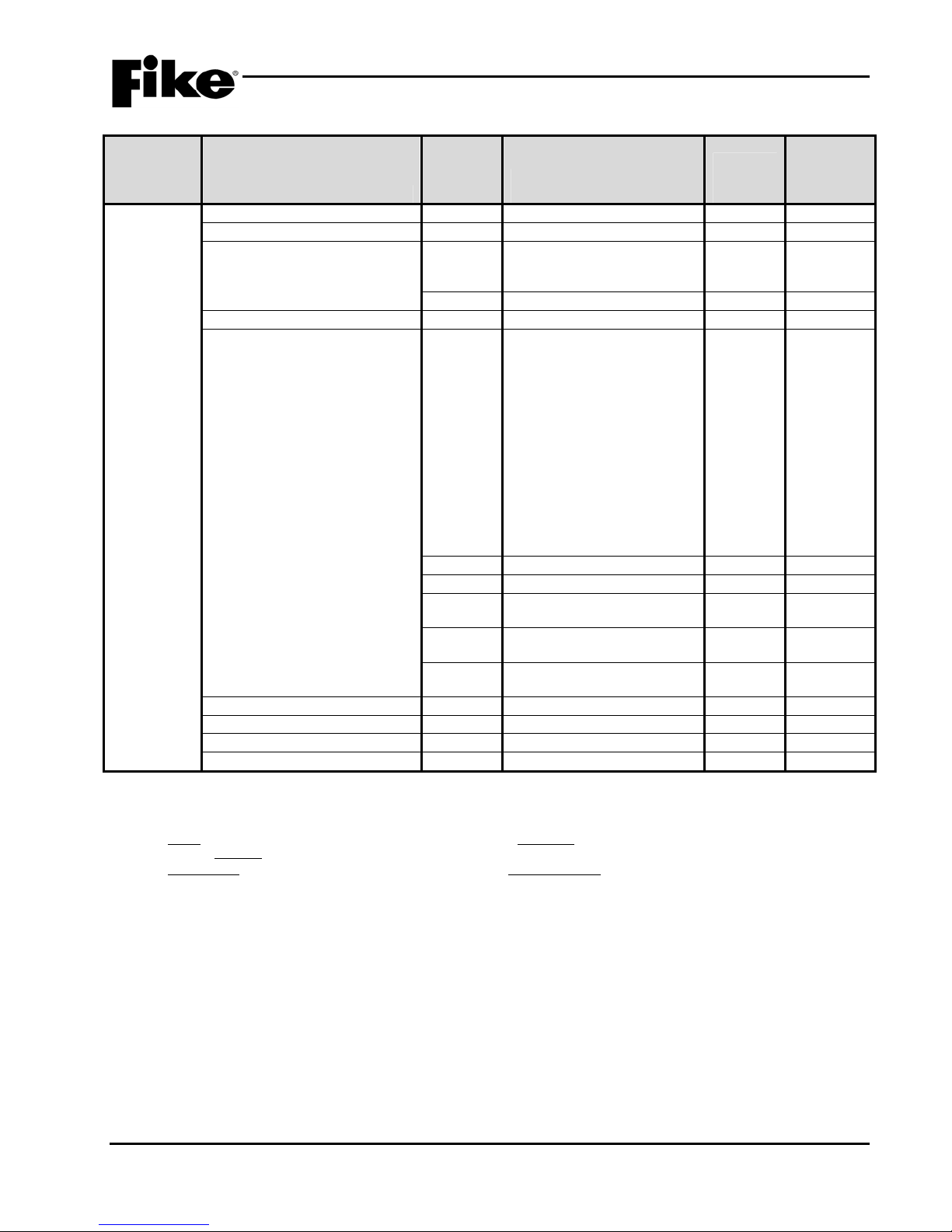

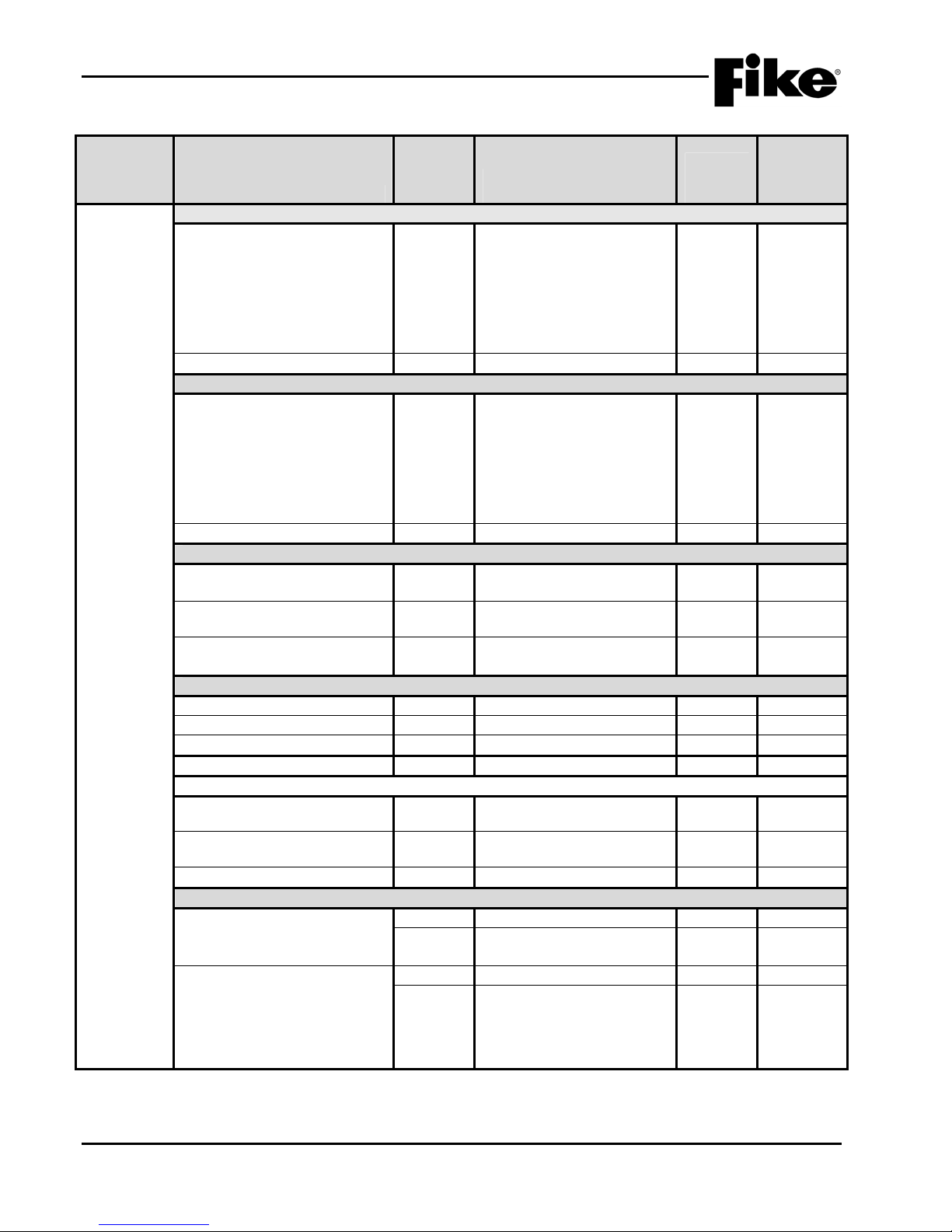

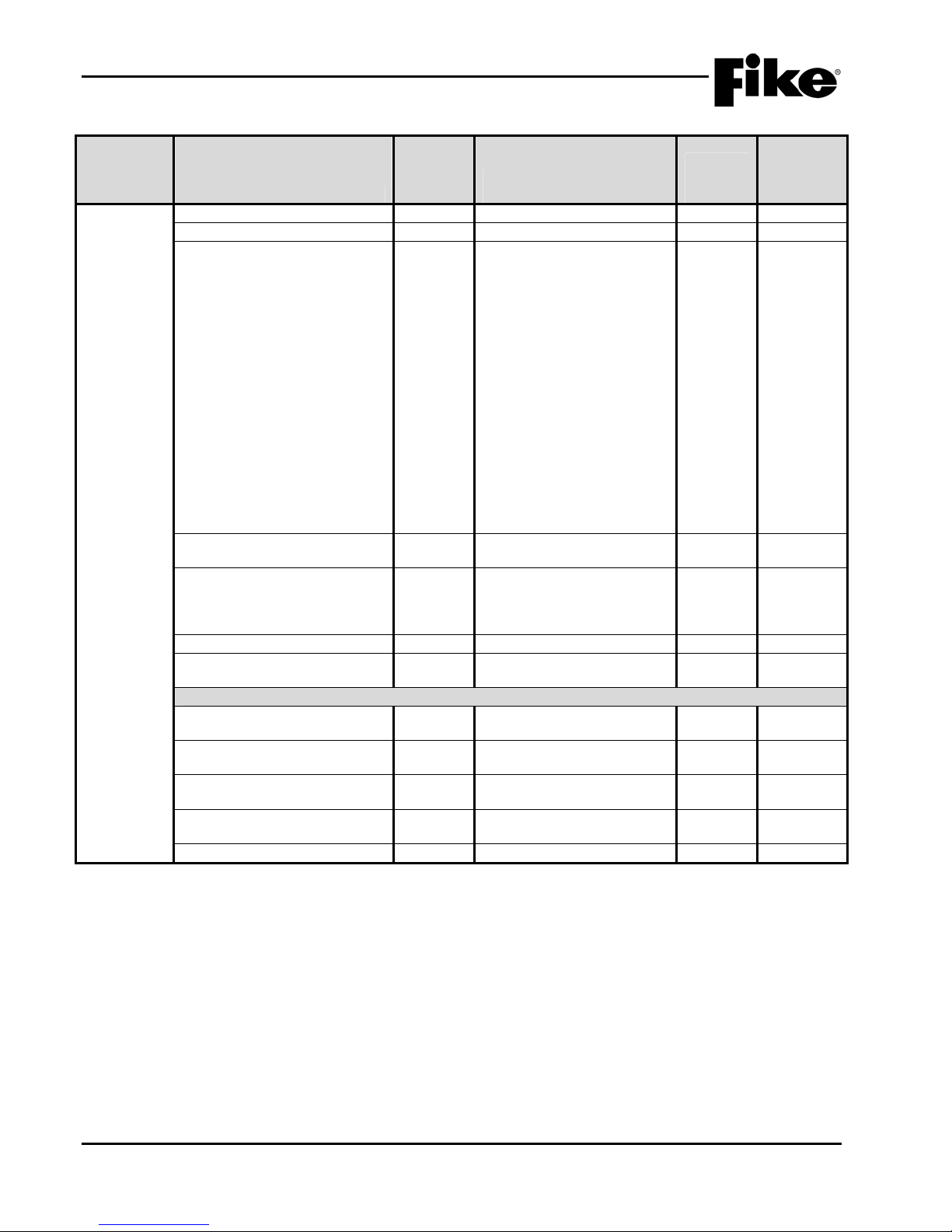

Exhibit 2-4: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

864?

(Y/N)

Possible Settings

(Defaults shown bold)

Peripherals Message Y 20 character user defined

Settings

permitted

in UL 864 Notes

1

(PERIPHERAL ID 02)

Zone Assignment Y

Supervision Y

Voice Y

Status Y

History Transmit Y

History Packing Y

History Message Y

Dual Channel Voice Y

Notes:

1. Peripheral device must be added to the Peripherals list before these configuration options are available.

2. This command contains status for Alarm, Supervisory, Trouble and all other states. Peripheral devices that have firmware

version before 3.00 should set this variable to STD, which is the original CyberCat format. The ESP selection refers to an

“Expanded” format. Peripheral devices with 3.00 firmware or newer will used this command. The EXP setting speeds up

operation of the peripheral bus.

3. If set to COMPACT, a message filter within the panel is used to prevent transmission of certain history record events, including

the NEW DEVICE history messages. This is done so that the peripherals do not display messages that are not required. If set

to VERBOSE, all history messages are transmitted.

4. HISTORY PACKING refers to how many history records are transmitted back-to-back with minimum time in between. If set to

UNPACKED, history records are sent one at a time. If set to PACKED, up to 50 history records are sent back-to-back. This

will speed up transmission of large amounts of history data.

5. HISTORY MESSAGE refers to what kind of data is packed into the history command. If set to STD (standard), data is packed

as with previous versions. If set to EXP (expanded), both lines 1 and 2 of the history data as shown on the LCD of the panel is

packed into the history command.

0 - 254

Unsupervised / Supervised

No Voice / EVAX / Fike

STD / EXP

Compact / Verbose

Unpacked / Packed

STD / EXP

Enabled / Disabled

1

1

2

3

4

5

CyberCat 254/1016 Programming Manual 2-5

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-5: Programming Features Cont.

Permitted

Circuit or

Component Program Feature or Option

Network

Network Settings

Network Address (Panel ID) Y

Network Module Type Y

Network Panel Message Y 20 character user defined

in UL

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 128

None / First / Middle / Last

(CUSTOM MSG PANEL 001)

Settings

permitted

in UL 864 Notes

1

where ZZZ = zone number

Network Switch Operation Y

Network Switch IDs Y

Global / Local

1 – 128

2

Selects which network

devices the panel will receive

switch commands from.

Network Zones Y 1 – 254 3

Panel Supervision Y 1 – 254 4

Wiring Style Y

History Y

Style 4 / Style 7

Single / Multiple

Ethernet Settings

Source IP Address Y

000.000.000.000

5

User Defined

Destination IP Address Y

000.000.000.000

6

User Defined

Supervision IP Address Y

000.000.000.000

7

User Defined

Panel IP Supervision Y

History Transmits Y

000.000.000.000

1 – 10

4

(Fike recommends 2)

Supervision Timeout Y 1 – 59 (Sec., Min., Hour)

4 min. default

IP Time Y

IP Time Disabled

8

Accept IP Time

Send IP Time

Notes:

1. Defines the location of the panel with respect to others on the network.

2. Defines if the respective panel will react to Reset, Silence, Acknowledge, and Drill commands received from other networked

panels.

3. Defines which network zones will participate in the local panel zone(s).

4. Defines which network panel(s) the selected panel should supervise.

5. Defines the unique Internet Protocol (IP) address for the selected panel.

6. Defines the unique Internet Protocol (IP) address for the panel that is to receive history events from the selected panel.

7. Defines the unique Internet Protocol (IP) address for the panel that is to supervision responses from the selected panel.

8. Used to synchronize panel time over the network.

2-6 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-6: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Photo

Sensor)

Common

Loop Number of Device Y

Address of Device Y

Custom Message Y 60 character user defined

Zone Assignments Y

Alarm Verification Y Time: 0 – 60 seconds

Sensitivity

Pre-Alarm 1 & 2 Levels Y

Alarm Levels Y

Drift Compensation

(Warning/Trouble)

Walktest Y

Device Summing

Broadcast Thresholds for

Summing (%OBS)

Summing Activation Level

(%OBS)

Summing Broadcast State No

Summing Addresses No 1 – 8 (Device addresses to

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Pre-Alarm 2 setting must always be set equal or higher than Pre-Alarm 1 setting.

4. High setting must be equal or lower obscuration setting than Low setting.

5. Can be set in 1% increments. Trouble must be higher % than Warning.

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

(1-001 PHOTO DETECT

Loop 1 - Address 001)

Y

Default / User Defined

1 – 254

Y

Enabled / Disabled

Enabled / Disabled

Y

0.5%/ft. – 4.0%/ft.

(0.1%/ft. increments)

Acclimate: 1.3%/ft. – 3.6%/ft.

(High 2.0% - Low 2.5%)

Y

Day/Night: 1.3%/ft. – 3.6%/ft.

(Day 3.6% - Night 3.6%)

Y

Alarm / Supervisory /

Supervisory NL

Y 50 – 100%

Warning 80%/Trouble 100%

Walktest at Alarm Level /

Walktest with IR / Walktest at

1.3%

N

Enabled / Disabled

(8 levels 0.5%/ft. – 4.0%/ft. in

0.1%/ft. increments)

N 1.0 – 10%/ft.

(0.5%/ft. increments)

Disabled / Alarm / Summing

Alarm / Supervisory Latching

/ Supervisory Non-Latching /

Pre-Alarm 1 / Pre-Alarm 2

participate in summing

group)

Settings

permitted

in UL 864 Notes

1

2

3

4

5

CyberCat 254/1016 Programming Manual 2-7

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-7: Programming Features Cont.

Permitted

Circuit or

Component Program Feature or Option

Defaults

(Photo

Sensor)

Remote Annunciator

Annunciator Type Y

Silenceable Y

Positive Alarm Sequence (PAS) Y

Output Settings – Priority Row Y 1 – 8 1

Activation State Y

Action Type Y No Action / Activate on

in UL

864?

(Y/N)

Possible Settings

(Defaults shown bold)

None / Remote LED –

Follows Red / Remote LED –

Follows Green / Remote LED

– Follows Amber / Remote

LED – Independent /

Sounder Base / Relay Base

Silenceable / Non- Silence

Disabled / Enabled

No State / Alarm / Summing

Alarm / Test Alarm / Alarm

Verification ON / Pre-Alarm 1

/ Pre-Alarm 2 / Supervisory /

Trouble / Open Circuit

Trouble / Short Circuit

Trouble / Low Power Trouble

/ Maintenance Trouble /

Process / Zone Disable

Switch / Voice Alert / Voice

Evacuate / Voice Page /

Voice Play Message ID

Settings

permitted

in UL 864 Notes

1,2

2

2

Any of 3 zones / Activate

on All of 3 zones / Activate

on Specific Device /

Activate on multiple

priority rows active

Output Pattern Y OFF / ON Continuous /

Slow / Fast / Temporal /

Walktest / Alert / Action

State Counter Y 1 – 16

Notes:

1. If annunciator type is set to Independent Operation, Sounder Base, or Relay Base an 8-row priority table will be displayed.

Table values are set using the Output Settings fields.

2. If annunciator type is set to Sounder Base, Silence and Positive Alarm Sequence (PAS) options will be displayed.

2-8 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-8: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Photo/Heat

Sensor)

Common

Loop Number of Device Y

Address of Device Y

Custom Message Y

Zone Assignments Y

Alarm Verification Y

Sensitivity

Pre-Alarm 1 & 2 Levels Y

Alarm Levels Y

Flame Enhance N

Drift Compensation

(Warning/Trouble)

Walktest Y

Device Summing

Broadcast Thresholds for

Summing (%OBS)

Summing Activation Level

(%OBS)

Summing Broadcast State N

Summing Addresses N

Remote Annunciator (See Exhibit 2-7 for programming features)

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Pre-Alarm 2 setting must always be set equal or higher than Pre-Alarm 1 setting.

4. High setting must be equal or lower obscuration setting than Low setting.

5. Can be set in 1% increments. Trouble must be higher % than Warning.

864?

(Y/N)

Y

Y

Y

Y

Y

Y

N

N

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

60 character user defined

(1-001 PHO/HT DETECT

Loop 1 - Address 001)

Default / User Defined

1 – 254

Time: 0 – 60 seconds

Enabled / Disabled

Enabled / Disabled

0.5%/ft. – 4.0%/ft.

(0.1%/ft. increments)

Acclimate: 1.3%/ft. – 3.6%/ft.

(High 2.0% - Low 2.5%)

Day/Night: 1.3%/ft. – 3.6%/ft.

(Day 3.6% - Night 3.6%)

Alarm / Supervisory /

Supervisory NL

ON / OFF

50 – 100%

Warning 80%/Trouble 100%

Walktest at Alarm Level /

Walktest with IR / Walktest at

1.3%

Enabled / Disabled

(8 levels 0.5%/ft. – 4.0%/ft. in

0.1%/ft. increments)

1.0 – 10%/ft.

(0.5%/ft. increments)

Disabled / Alarm / Summing

Alarm / Supervisory Latching /

Supervisory Non-Latching /

Pre-Alarm 1 / Pre-Alarm 2

1 – 8 (Device addresses to

participate in summing group)

Settings

permitted

in UL 864 Notes

1

2

3

4

5

CyberCat 254/1016 Programming Manual 2-9

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-9: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Photo/Duct

Sensor)

Common

Loop Number of Device Y

Address of Device Y

Custom Message Y 60 character user defined

Zone Assignments Y

Alarm Verification Y Time: 0 – 60 seconds

Sensitivity

Pre-Alarm 1 & 2 Levels Y

Alarm Levels Y

Drift Compensation

(Warning/Trouble)

Walktest Y

Device Summing

Broadcast Thresholds for

Summing (%OBS)

Summing Activation Level

(%OBS)

Summing Broadcast State N

Summing Addresses N 1 – 8 (Device addresses to

Remote Annunciator (See Exhibit 2-7 for programming features)

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Pre-Alarm 2 setting must always be set equal or higher than Pre-Alarm 1 setting.

4. High setting must be equal or lower obscuration setting than Low setting.

5. Can be set in 1% increments. Trouble must be higher % than Warning.

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

(1-001 DUCT DETECT

Loop 1 - Address 001)

Y

Default / User Defined

1 – 254

Y

Enabled / Disabled

Enabled / Disabled

Y

0.6%/ft. – 4.0%/ft.

(0.1%/ft. increments)

Acclimate: 0.8%/ft. – 3.4%/ft.

(High 2.0% - Low 2.5%)

Y

Day/Night: 0.8%/ft. – 3.4%/ft.

(Day 1.5% - Night 3.4%)

Y Alarm / Supervisory /

Supervisory NL

Y 50 – 100%

Warning 80%/Trouble 100%

Walktest at Alarm Level /

Walktest with IR / Walktest at

1.3%

N

Enabled / Disabled

(8 levels 0.5%/ft. – 4.0%/ft. in

0.1%/ft. increments)

N 1.0 – 10%/ft.

(0.5%/ft. increments)

Disabled / Alarm / Summing

Alarm / Supervisory Latching

/ Supervisory Non-Latching /

Pre-Alarm 1 / Pre-Alarm 2

participate in summing group)

Settings

permitted

in UL 864 Notes

1

2

3

4

5

2-10 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-10: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Heat

Sensor)

Common

Loop Number of Device Y

Address of Device Y

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

Custom Message Y 60 character user defined

(1-001 HEAT DETECT

Loop 1 - Address 001)

Y

Zone Assignments Y

Default / User Defined

1 – 254

Alarm Verification Y Time: 0 – 60 seconds

Y

Enabled / Disabled

Sensitivity

Pre-Alarm 1 & 2 Levels Y

Y

Enabled / Disabled

70°F - 190°F

(5°F increments)

Alarm Levels (Day/Night) Y

Fixed Temp: 135°F - 190°F

(5°F increments)

Y

Rate of Rise: 135°F - 174°F

(5°F increments)

Walktest Y

Walktest at 135°F / Walktest

with IR

Remote Annunciator (See Exhibit 2-7 for programming features)

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Pre-Alarm 2 setting must always be set equal or higher than Pre-Alarm 1 setting.

4. Rate of Rise temperature range is 135°F - 174°F. Fixed temperature operation will be used for detection above this ran ge.

Settings

permitted

in UL 864 Notes

1

2

3

4

4

CyberCat 254/1016 Programming Manual 2-11

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-11: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Ion Sensor)

Common

Loop Number of Device Y

Address of Device Y

Custom Message Y

Zone Assignments Y

Alarm Verification Y

Sensitivity

Pre-Alarm 1 & 2 Levels Y

Alarm Levels Y

Drift Compensation Y

Walktest Y

Device Summing

Broadcast Thresholds for

Summing (%OBS)

Summing Activation Level

(%OBS)

Summing Broadcast State N

Summing Addresses N

Remote Annunciator (See Exhibit 2-7 for programming features)

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Pre-Alarm 2 setting must always be set equal or higher than Pre-Alarm 1 setting.

4. High setting must be equal or lower obscuration setting than Low setting.

5. Can be set in 1% increments. Trouble must be higher % than Warning.

864?

(Y/N)

Y

Y

Y

Y

Y

N

N

N

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

60 character user defined

(1-001 ION DETECT

Loop 1 - Address 001)

Default/User Defined

1 – 254

Time: 0 – 60 seconds

Enabled / Disabled

Enabled / Disabled

100 – 40 Microns

(5 Micron increments)

Acclimate: 80 – 50 Microns

(5 Micron increments)

Day/Night: 80 – 50 Microns

(5 Micron increments)

Alarm / Supervisory /

Supervisory NL

Smolder Enhance Off /

Smolder Enhance On

50 – 100%

Warning 80%/Trouble 100%

Walktest at Alarm Level /

Walktest with IR / Walktest at

1.3%

Enabled / Disabled

(8 levels 0.5%/ft. – 4.0%/ft. in

0.1%/ft. increments)

1.0 – 10%/ft.

(0.5%/ft. increments)

Disabled / Alarm/Summing

Alarm / Supervisory Latching /

Supervisory Non-Latching /

Pre-Alarm 1 / Pre-Alarm 2

1 – 8 (Device addresses to

participate in summing group)

Settings

permitted

in UL 864 Notes

1

2

3

4

5

2-12 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-12: Programming Features Cont.

Permitted

Circuit or

Component Program Feature or Option

Defaults

(Monitor

Module)

Loop Number of Device Y

Address of Device Y

Custom Message Y 60 character user defined

in UL

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

Settings

permitted

in UL 864 Notes

1

(1-001 INPUT MANALRM

Loop 1 - Address 001)

Y

Zone Assignments Y

Input Function Type Y

Default / User Defined

1 – 254

No Input Function /

2

ManAlarm / Detection/

Waterflow /Pre-Alarm 1 / PreAlarm 2 / Supervisory /

Trouble / Process / PAS

Inhibit / Reset / Silence /

Acknowledge / Drill / Zone

Disable / Fan Restart /

Smoke Control Confirmation /

Manual Alarm Stage 2 / AHU

Fie Dept Key / Voice Alert /

Voice Evacuation / Voice

Play Message ID / MNS Play

Message ID

Y Verify Time: 0 – 255 seconds 3

Y

Y

Latching / Non-Latching

Normally Open / Normally

4

5

Closed

Y

Class B Contact / Class A

Latching

Y

No Short Detection / Short

Detection

Voice/MNS Priority Y

Msg 1 ID Y

Msg 2 ID Y

MNS Timeout Y

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. If monitor module function type is set to Detection, an alarm verification time can be set.

4. Either = PA1, PA2, Supervisory, Trouble, Process, PAS Inhibit; Non-Latch = Reset, Silence, Acknowledge, Zone Disable, Fan

Restart; Latching = ManAlarm, Detection, Waterflow, Drill.

5. NO Contacts = Detection, Manual Alarm, Reset, Supervisory; NO/NC Contacts = Process, Waterflow, PA1, PA2, Trouble, Drill,

Silence, Acknowledge, Zone Disable, PAS Inhibit, Fan Restart.

6. Priority field becomes available only when Input Function is set to a Voice or MNS function.

7. Priority setting cannot be set the same as the panel priority settings for Alarm, Test Alarm, Supervisory, and Process.

8. Message ID field becomes available only when Input Function is set to Voice or MNS Play Message ID.

9. MNS Timeout field becomes available only when input Function is set to MNS Play Message ID.

1 - 255

0 - 16

0 - 16

0 - 250

6, 7

8

8

9

CyberCat 254/1016 Programming Manual 2-13

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-13: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Mini Monitor

Module)

Loop Number of Device Y

Address of Device Y

Custom Message Y 60 character user defined

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

(1-001 MINI MANALRM

Loop 1 - Address 001)

Custom Message Y

Zone Assignments Y

Input Function Type Y

Default / User Defined

1 – 254

No Input Function /

ManAlarm / Detection/

Waterflow /Pre-Alarm 1 / PreAlarm 2 / Supervisory /

Trouble / Process / PAS

Inhibit / Reset / Silence /

Acknowledge / Drill / Zone

Disable / Fan Restart /

Smoke Control Confirmation /

Manual Alarm Stage 2 / AHU

Fire Dept Key / Voice Alert /

Voice Evacuation / Voice

Play Message ID / MNS Play

Message ID

Y Verify Time: 0 – 255 seconds 3

Y

Y

Latching / Non-Latching

Normally Open / Normally

Closed

Y

No Short Detection / Short

Detection

1 - 255

0 - 16

0 - 16

0 - 250

1 - 4

1 – 254

Defaults

(Pull Station

Module)

Voice/MNS Priority Y

Msg 1 ID Y

Msg 2 ID Y

MNS Timeout Y

Loop Number of Device Y

Address of Device Y

Custom Message Y 60 character user defined

(1-001 PULL STATION

Loop 1 - Address 001)

Custom Message Y

Zone Assignments Y

Input Function Y

Default/User Defined

1 – 254

No Input Function / Manual

Alarm

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. If monitor module function type is set to Detection, an alarm verification time can be set.

4. Either = PA1, PA2, Supervisory, Trouble, Process, PAS Inhibit; Non-Latch = Reset, Silence, Acknowledge, Zone Disable, Fan

Restart; Latching = ManAlarm, Detection, Waterflow, Drill.

5. NO Contacts = Detection, Manual Alarm, Reset, Supervisory; NO/NC Contacts = Process, Waterflow, PA1, PA2, Trouble, Drill,

Silence, Acknowledge, Zone Disable, PAS Inhibit, Fan Restart.

6. Priority field becomes available only when Input Function is set to a Voice or MNS function.

7. Priority setting cannot be set the same as the panel priority settings for Alarm, Test Alarm, Supervisory, and Process.

8. Message ID field becomes available only when Input Function is set to Voice or MNS Play Message ID.

9. MNS Timeout field becomes available only when input Function is set to MNS Play Message ID.

Settings

permitted

in UL 864 Notes

1

2

4

5

6, 7

8

8

9

1

2

2-14 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-14: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Supervised

Control

Module)

Common

Loop Number of Device Y

Address of Device Y

Output Y

Custom Message Y 60 character user defined

Custom Message Y

Zone Assignments

(device troubles)

Defaults for Pre-Action Y

Defaults for 2 Stage Alarm N

Drill Output Pattern Y

Output Silenceable Y

Positive Alarm Sequencing

(PAS)

Power Supply Monitor Y

Output Control

Activation State Y

Action Type Y

Output Pattern Y

Output Pattern Set Y

State Counter Y

Zone Assignments (activation) Y 0 - 255 5

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Can be assigned to 4 discrete zones, 2 zone ranges or 1 range and 2 discrete zones.

3. Modifies control module configuration for use with Pre-Action solenoid.

4. If selected, the control module configuration will be modified for 2-Stage Alarm Operation (City of Chicago).

5. Can be assigned to any 3 zones, 254 any zone, or 255 any zone (non-disable).

864?

(Y/N)

Y

Y

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

Enabled/Disabled

(1-001 OUTPUT MODULE

Loop 1 - Address 001)

Default/User Defined

1 – 254

Yes/No

Yes/No

Drill Disabled / On

Continuous / Slow / Fast /

Temporal

Silenceable/Non-Silenceable

Disabled / Enabled

Enabled/Disabled

Alarm / Summing Alarm /

Test Alarm / Alarm

Verification ON / Pre-Alarm 1

/ Pre-Alarm 2 / Supervisory /

Trouble / Open Circuit

Trouble / Short Circuit

Trouble / Low Power Trouble

/ Maintenance Trouble /

Process / Zone Disable

Switch / Voice Alert / Voice

Evacuate / Voice Page /

Voice Play Message ID /

MNS Message Active

No Action / Activate on Any

of 3 zones / Activate on All of

3 zones / Activate on Specific

Device / Activate on multiple

priority rows active

OFF / ON Continuous / Slow

/ Fast / Temporal / Walktest /

Times / Custom Defined

1 - 3

1 – 16

Settings

permitted

in UL 864 Notes

1

2

3

4

CyberCat 254/1016 Programming Manual 2-15

P/N: 06-539 Rev 3, 08/2013

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-15: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Relay

Module)

Common

Loop Number of Device Y

Address of Device Y

Output Y

Custom Message Y 60 character user defined

Zone Assignments (Device

Troubles)

AHU Shutdown Relay Y Enabled / Disabled

Restart Delay Y

Misc. Options

(feedback relay monitoring)

Positive Alarm Sequencing

(PAS)

Output Control (Note 6)

Activation State Y

Action Type Y

Relay State Y

Timeout Y 0 – 80 minutes 2

State Counter Y

Output Y

Drill Y

Zone Assignments (activation) Y 0 - 255 3

Notes:

1. CyberCat 254 has only one (1) addressable loop. CyberCat 1016 can have up to four (4) addressable loops.

2. Timeout delay becomes active if relay state is set to ‘Time Delay’.

3. Can be assigned to any 3 zones, 254 any zone, or 255 any zone (non-disable).

4. Restart delay becomes active if relay is configured for AHU shutdown operation.

5. These options are not available if relay is configured for AHU shutdown operation.

6. Output control is disabled if relay is set for AHU Shutdown operation.

864?

(Y/N)

Y

Y

Y

Y

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

Enabled/Disabled

(1-001 RELAY MODULE

Loop 1 - Address 001)

Default/User Defined

1 – 253

(4 zones available)

0 – 255 seconds

Not Monitored / Monitored

by dry contact / Independent

dry contact

Enabled / Disabled

Alarm / Summing Alarm /

Test Alarm / Alarm

Verification ON / Pre-Alarm 1

/ Pre-Alarm 2 / Supervisory /

Trouble / Open Circuit

Trouble / Short Circuit

Trouble / Low Power Trouble

/ Maintenance Trouble /

Process / Zone Disable

Switch / Voice Alert / Voice

Evacuate / Voice Page /

Voice Play Message ID /

MNS Message Active

No Action / Activate on Any

of 3 zones / Activate on All of

3 zones / Activate on Specific

Device / Activate on multiple

priority rows active

ON / OFF / Timed / Time

Delay

1 – 16

Silenceable/Non-Silenceable

Enabled / Disabled

Settings

permitted

in UL 864 Notes

1

4

5

5

2-16 CyberCat 254/1016 Programming Manual

Rev 3, 08/2013 P/N: 06-539

2.0 C-Linx PROGRAMMING OPTIONS

Exhibit 2-16: Programming Features Cont.

Permitted

in UL

Circuit or

Component Program Feature or Option

Defaults

(Releasing

Module)

Common

Loop Number of Device Y

Address of Device Y

Output Y

864?

(Y/N)

Possible Settings

(Defaults shown bold)

1 - 4

1 – 254

Enabled/Disabled

Custom Message Y 60 character user defined

(1-001 RELEASING MOD

Loop 1 - Address 001)

Y

Zone Assignments Y

Default/User Defined

1 – 253

(2 zones available)

Output Type Y

No Output / Solenoid /

Expanded Solenoid /

Masterbox

No Output State / Alarm

1 - 4

Defaults

(FAAST

Detector)

Output State Y

Common

Loop Number of Device Y

Address of Device Y 1 – 254

Custom Message Y 60 character user defined

(1-001 FAAST DETECT

Loop 1 - Address 001)

Y

Zone Assignments Y

Walktest Y

Default/User Defined

1 – 253

Enabled / Disabled

Y 0.1% - 0.99645% ft. (slider)

States

State Assignments

Fire 2 / Fire 1 / Action 2 / Action

1 / Alert

Y

Disabled / Alarm / PreAlarm

2 / PreAlarm 1 / Supervisory /

Process

Y

Latching / Non-Latching

Alarm Verification Timers

Fire 2 / Fire 1 / Action 2 / Action

1 / Alert

Y

No Timer / Timer 1 / Timer 2

/ Timer 3

Verification Timer Values