Figaro TGS2611 Application Notes

APPLICATION NOTES FOR TGS2611

Application Notes for Methane Gas Detectors using TGS2611

The TGS2611 methane gas sensor

has been presorted into

groupings which will allow users

to simplify the manufacturing

process for methane gas

detectors. This brochure offers

example application circuits and

important technical advice for

designing and manufacturing gas

detectors which use classified

TGS2611 sensors.

Page

an ISO9001 company

Introduction......................................................................................................2

Detector Circuit Design

Basic Circuit with T emperature Compensation............................................2

Selecting a Load Resistor .................................................................................2

Compensation for Internally Generated Heat..............................................3

Heater Breakage Detection Circuit.........................................................3

Sensor Malfunction Detection Circuit.........................................................3

Prevention of Intermittent Alarming..............................................................4

Alarm Prevention during W armup................................................................4

Alarm Delay Circuit..........................................................................5

Application Circuit...................................................................................5

Manufacturing Process

Handling and Storage of Sensors..........................................................5

L Selection...............................................................................................5

R

PCB Assembly....................................................................................5

Sensor Assembly..................................................................................5

Final Assembly.................................................................................................6

Preheating of Final Assembly.....................................................................6

Gas Test..............................................................................................6

Storage of Finished Products..........................................................................6

Anticipated Performance at 10%LEL of Methane...........................................................6

Pre-calibrated Sensor Module...........................................................................................7

Appendix...............................................................................................................8

See also Technical Brochure ‘Technical Information on Usage of TGS

Sensors for Toxic and Explosive Gas Leak Detectors’.

Revised 08/03

IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED

WILL VARY WITH EACH CUSTOMER’S SPECIFIC APPLICATIONS. FIGARO STRONGLY

RECOMMENDS CONSULTING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO

SENSORS IN YOUR APPLICATION AND, IN PARTICULAR, WHEN CUSTOMER’S TARGET

GASES ARE NOT LISTED HEREIN. FIGARO CANNOT ASSUME ANY RESPONSIBILITY

FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR WHICH SENSOR

HAS NOT BEEN SPECIFICALLY TESTED BY FIGARO.

TGS2611-J00 is a UL recognized component in accordance with the

requirements of UL2075. Please note that component recognition testing

has confirmed long term stability in 60ppm of methane; other characteristics

shown in this brochure have not been confirmed by UL as part of component

recognition.

1

APPLICATION NOTES FOR TGS2611

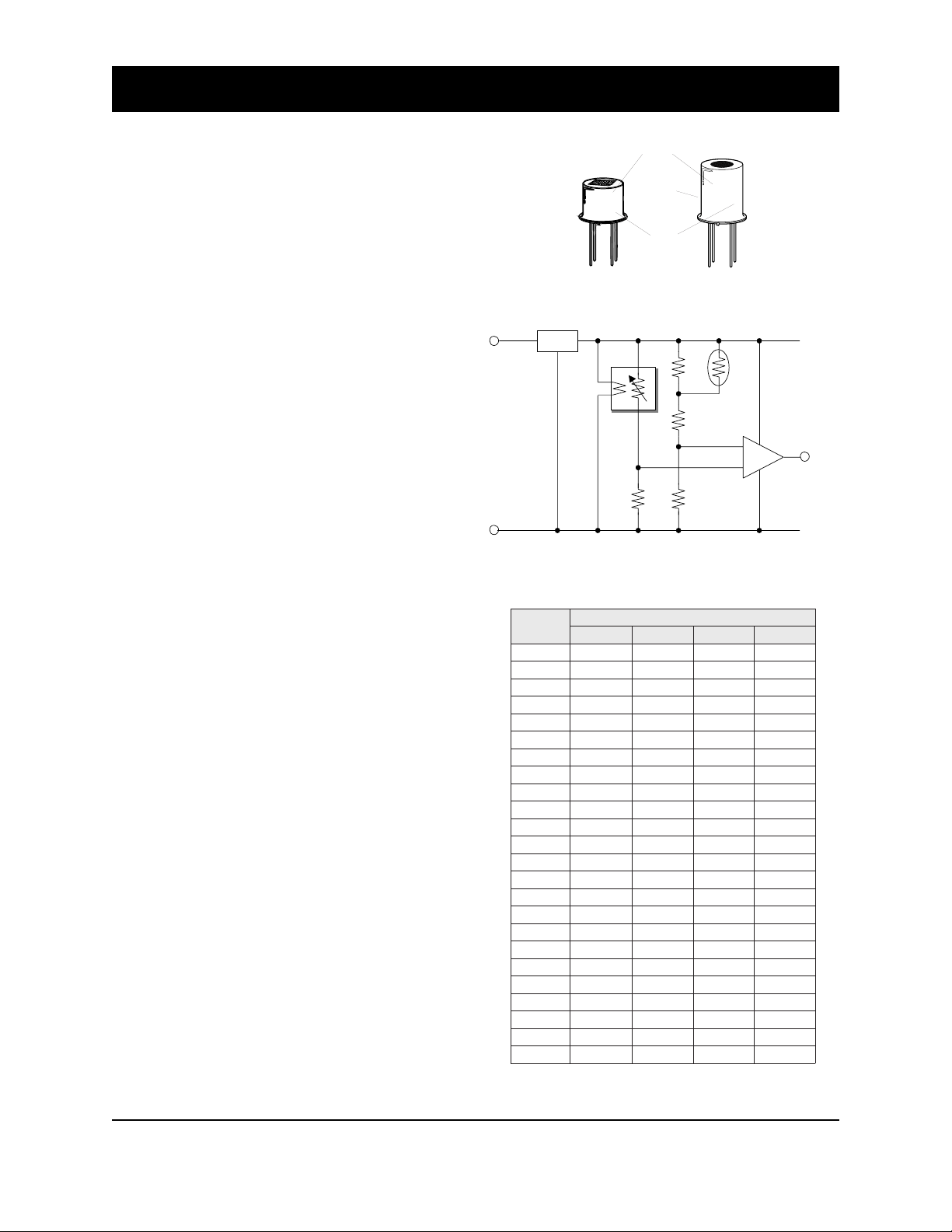

To facilitate ease in manufacturing gas detectors,

both Figaro TGS2611-J00 and TGS2611-B00

methane gas sensors are individually marked with

an ID number (see Figure 1) indicating a factory

presorted classification which corresponds to

narrow ranges of sensor resistance in methane.

When the sensor’s ID number is properly used,

the calibration process can be greatly simplified,

eliminating long preconditioning time and the

complicated handling of calibration gas.

1. Detector Circuit Design

1-1 Basic circuit with temperature compensation

Figure 2 shows an example of a basic circuit for

gas detection, including temperature compensation for variations caused by ambient

temperature fluctuations. Typical values for the

circuit components are as follows:

RL : refer to Table 1

R

TH : 4.7k

Ω (±

3%), B=3977 (±5%)

RA : 11.5kΩ (±1%)

RB : 4.32kΩ (±1%)

RC : 8.25kΩ (±1%)

The values for components related to

temperature compensation should be chosen so

that Vref is one-half of the Vc value at standard

temperature (20˚C). The Vref curve should

approximate the temperature dependency curve

of the VRL when compensation is properly done.

1-2 Selecting a load resistor (R

L)

To optimize resolution of the output signal at

the desired alarming concentration, it is necessary to adjust the resistance of the load resistor

(RL). It is recommended that RL be selected at a

value which is equal to the sensor’s resistance

(Rs) at the alarming concentration (i.e. Rs/RL =

1.0). Please refer to the brochure “General

Information for TGS Sensors” for more details.

Since the ID number corresponding to sensor

resistance in methane gas is indicated on the

sensor cap, the load resistor value can be selected

according to Table 1. For example, for an alarm

setting at 10% LEL, when using a sensor having

an ID number of 7, the R

L value should be set at

1.27kΩ. By using the recommended RL, the VRL

value at the alarming point typically will be 2.5V,

which is equal to half of the circuit voltage (Vc).

Sensor

code

TGS2611

984AA

TGS2611-J00 TGS2611-B00

Fig. 1 - Sensor markings

Voltage

regulator

78M05

D.C. input

#DI

10679.0517.0095.0115.0

2070.1787.0946.0265.0

3081.1668.0517.0916.0

4003.1359.0787.0186.0

5034.150.1668.0057.0

6085.151.1359.0528.0

7047.172.150.1909.0

8019.104.151.100.1

9001.245.172.101.1

0123.296.104.112.1

1155.278.145.133.1

2108.250.296.174.1

3190.362.278.126.1

4104.394.250.287.1

5147.347.262.269.1

6121.410.394.251.2

7135.423.347.273.2

8199.456.310.316.2

9194.520.423.378.2

0240.624.456.361.3

1256.678.420.484.3

2223.763.524.438.3

3260.809.578.422.4

4278.894.663.546.4

Note: Lower explosion limit (LEL) of methane = 50,000ppm

Vc = 5.0 ± 0.2V

4

1

Fig. 2 - Basic circuit with

temperature compensation

rosneS

Table 1 - Recommended RL by sensor ID

Lot #

#07

ID #

3

2

TGS

2611

R

L

RLk( Ω htiw) ± ecnarelot%1

LEL%5 LEL%01 LEL%51 LEL%02

A

R

B

R

C

R

TGS2611

314AE #07

REF

V

RL

V

TH

R

+

-

Alarm signal

(Active = 'L')

Comparator

GND

Revised 08/03

2

APPLICATION NOTES FOR TGS2611

)

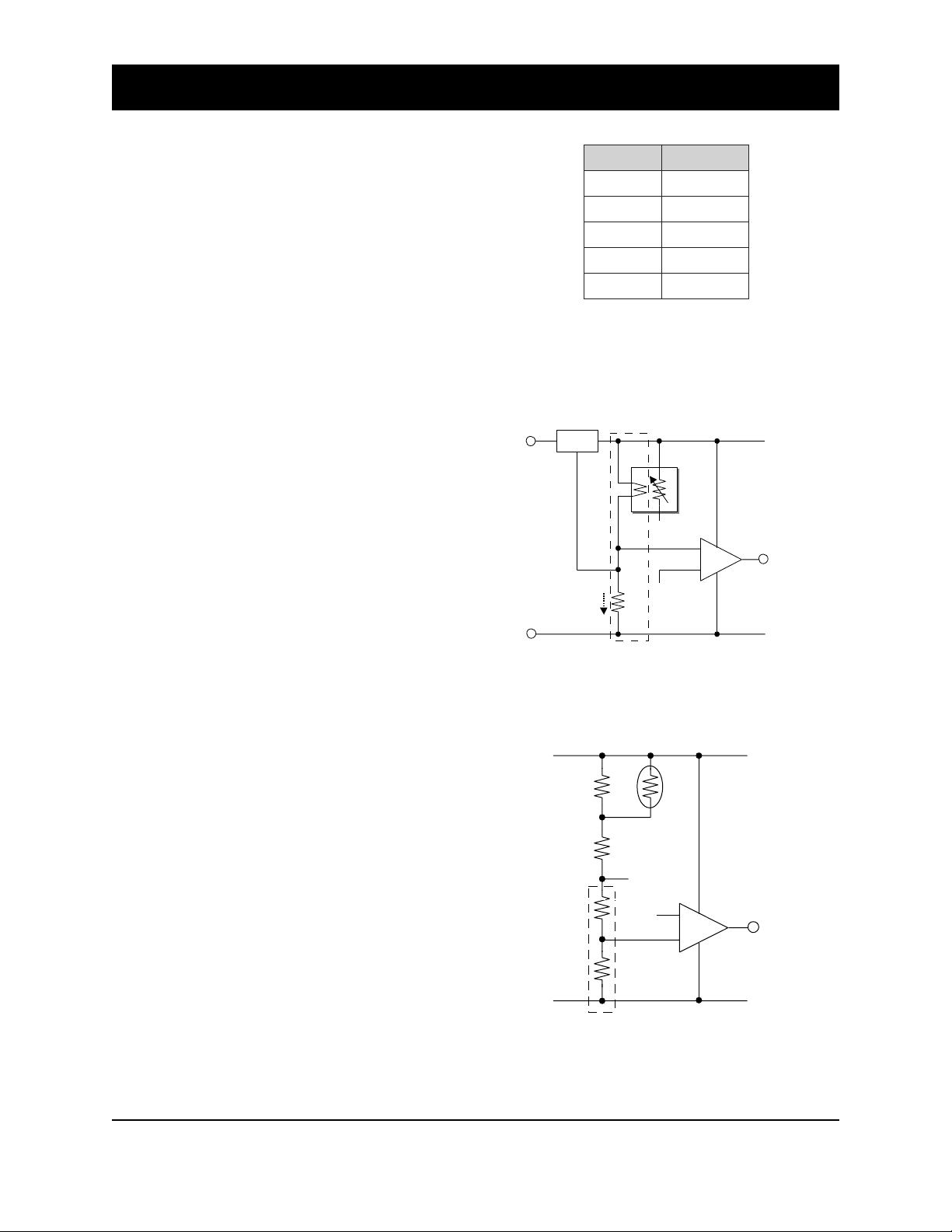

1-3 Compensation for internally generated heat

Depending on the design of the case and the

PCB, there is often a difference between the

temperature near the thermistor’s placement in

the detector and the ambient temperature.

Therefore it is recommended to measure the

actual temperature difference between the inside

and the outside of the detector and select the

value of RC according to Table 2. When RC is

selected in this manner and used in the basic

circuit (Figure 2), the result would be that

Vref=1/2 Vc.

1-4 Heater breakage detection circuit

Figure 3 shows an example of how breakage of

the sensor’s heater wire and/or heater element

can be detected. By adding R

E (3.57Ω±1%) into

the circuit and monitoring VRE, a malfunction

can be considered to have occurred when VRE

(0.2V typ.) drops to near 0V. Please note that a

circuit voltage (Vc) of 5.2V should be applied to

a circuit which incorporates a heater malfunction

detection circuit.

∆∆∆∆∆ )C˚(T

k(cR Ω)

052.8

586.7

0151.7

5156.6

0243.6

∆

T= (temp near themistor)-(temp outside detector)

Table 2 - Effect on selection of Rc by temperature

differential inside and outside of detector

Vc=5.2V

78M05

Heater breakage

signal

(Active = 'L')

GND

56mA (typ.)

R

0.05~0.1V

E

0.2V (typ.

+

-

1-5 Sensor malfunction detection circuit

Breakage of lead wires to the sensor’s electrodes

and/or sensor element can be detected by using

a circuit such as that shown in Figure 4. This

involves replacing R

C with RC1 and RC2, selecting

their values so that RC1/RC2≈35. Since VRL is

normally greater than 70mV in any atmospheric

conditions, by comparing VRL to a reference

voltage of 70mV, breakage of the lead wires and/

or sensor element can be considered to have

occurred if VRL drops below 70mV.

Figure 3 - Heater breakage detection circuit

C

V

C1

R

C2

R

Figure 4 - Sensor malfunction detection circuit

(RE = 3.57Ω±1%)

A

R

B

R

70mV (typ.)

TH

R

REF

V

+

RL

V

(RC1/RC2 ≈ 35)

-

Sensor breakage

signal

(Active = 'L')

GND

Revised 08/03

3

Loading...

Loading...