Fife Corporation

PO Box 26508, Oklahoma City, OK 73126, U.S.A.

Phone: 405.755.1600 / Fax: 405.755.8425

www.fife.com / E-mail: fife@fife.com

SBPC-21-PB

FifeNet to Profibus™ Gateway

Customer Instruction Manual

PROFIBUS DP

© 2002 Fife Corporation. All rights reserved.

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

COPYRIGHT

• • • • • •

All rights reserved. Any reproduction of this Instruction Manual, in any form, in whole or in part,

requires the prior written consent of Fife Corporation.

The information given in this Instruction Manual is subject to change without notice.

We have compiled this Instruction Manual with the greatest possible care and attention. However, the

possibility of error cannot be completely excluded. Fife Corporation accepts no legal liability for

incorrect information given and the consequences arising therefrom.

AnyBus is a registered trademark of HMS Industrial Networks AB.

All other trademarks are the property of their respective holders.

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

TABLE OF CONTENTS

• • • • • •

GENERAL INFORMATION ............................................................................................................................1

Introduction ..............................................................................................................................................1

Profibus DP Overview..............................................................................................................................1

Producer/Consumer Model......................................................................................................................3

FifeNet .....................................................................................................................................................3

SBPC-21-PB Switch/Jumper Configuration.............................................................................................4

SBPC-21-PB External Connections/Switches/Indicators.........................................................................5

Profibus DP Baud Rate............................................................................................................................5

SBPC-21-PB Network Status ..................................................................................................................6

SBPC-21-PB Error Codes .......................................................................................................................7

F

IFENET THEORY ......................................................................................................................................9

FifeNet Time Slices..................................................................................................................................9

Multiplexed Time Slices ...........................................................................................................................9

FifeNet Master .......................................................................................................................................10

SBPC-21-PB Data Flow.........................................................................................................................10

C

ONFIGURATIONS....................................................................................................................................13

Hardware Configuration - Single CDP-01..............................................................................................13

Hardware Configuration - Multiple CDP-01’s.........................................................................................14

Software Configuration ..........................................................................................................................14

GSD File ................................................................................................................................................14

C

OMMUNICATION MAPPING......................................................................................................................15

Profibus to FifeNet Data ........................................................................................................................15

FifeNet to Profibus Data ........................................................................................................................16

C

ONTROL INFORMATION ..........................................................................................................................19

CDP-01 Control Matrix...........................................................................................................................19

External Lock .........................................................................................................................................19

Status Data Block ..................................................................................................................................22

PECIAL CONTROL OF FIFENET DEVICES.................................................................................................29

S

CDP-01 Key Code Data Path ................................................................................................................29

CDP-01 Key Codes ...............................................................................................................................30

Simulating Dual-Key Presses ................................................................................................................30

CDP-01 LED Panel Data .......................................................................................................................31

I

NDEX......................................................................................................................................................33

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

1

GENERAL INFORMATION

• • • • • •

Introduction

The Fife SBPC-21-PB (Serial Bus Protocol Converter) provides a gateway between Fife’s proprietary

FifeNet network and Profibus™. Using the SBPC-21-PB, data originating from FifeNet can be sent on

Profibus and data from Profibus can be sent to FifeNet.

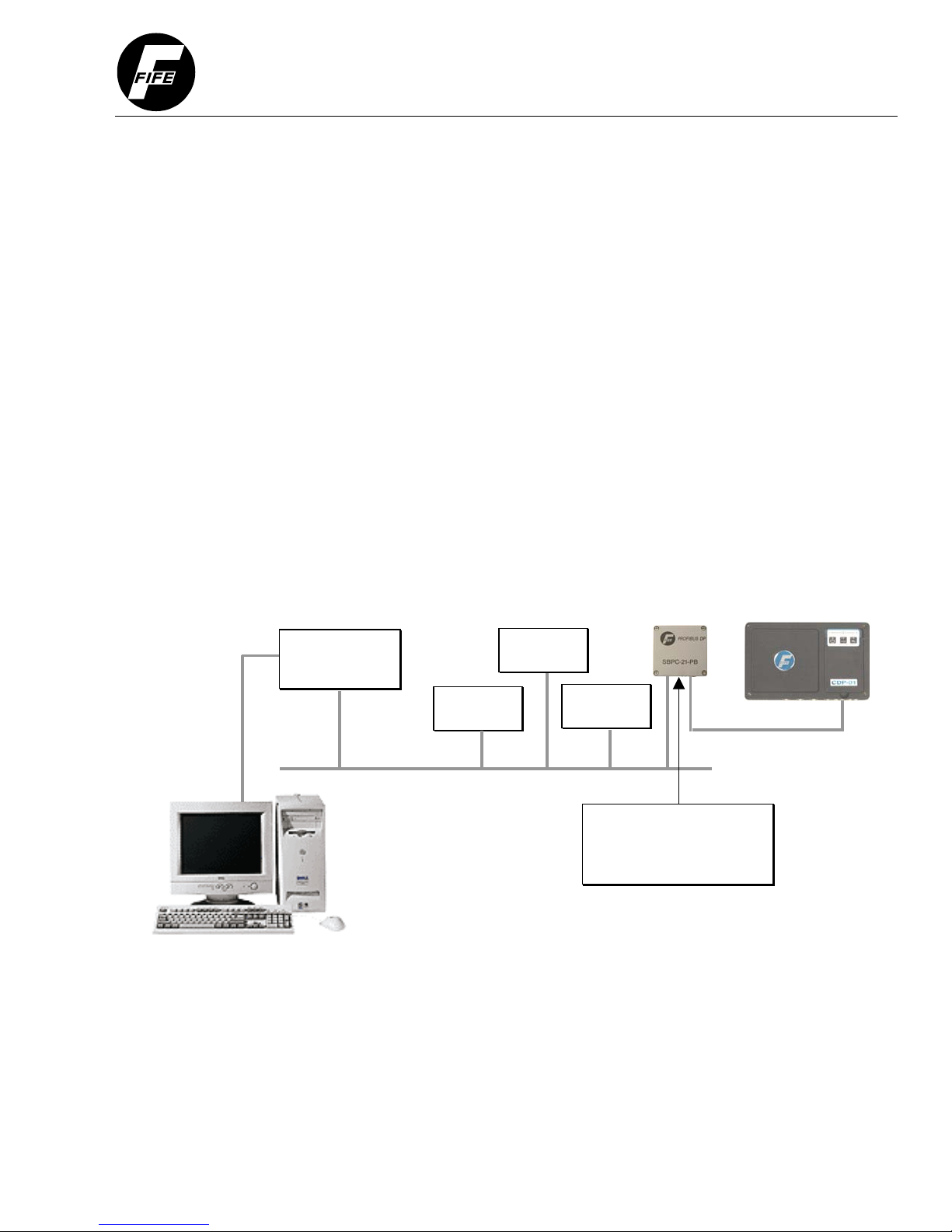

Profibus DP Overview

The supported media for the SBPC-21-PB Profibus is a shielded copper cable consisting of a twisted

pair. The baud rate for the bus is between 9.6K baud to a maximum 12M baud. The Profibus DP

network is able to carry 126 nodes and the total amount of data for Profibus DP is 244 bytes out per

module and 244 bytes in per module. Node 126 is only used for commissioning purposes and should

not be used to exchange user data. An example of a Profibus network with an SBPC-21-PB is shown

in the diagram below.

Figure 1-2: Example of an SBPC-21-PB Network Connection

Profibus DP

Master

Profibus DP

Slave #1

Profibus DP

Slave #2

Profibus DP

Slave #3

FifeNet

RS-232

Profibus

The SBPC-21-PB connects

to both FifeNet and Profibus

providing translation between

two networks.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 1

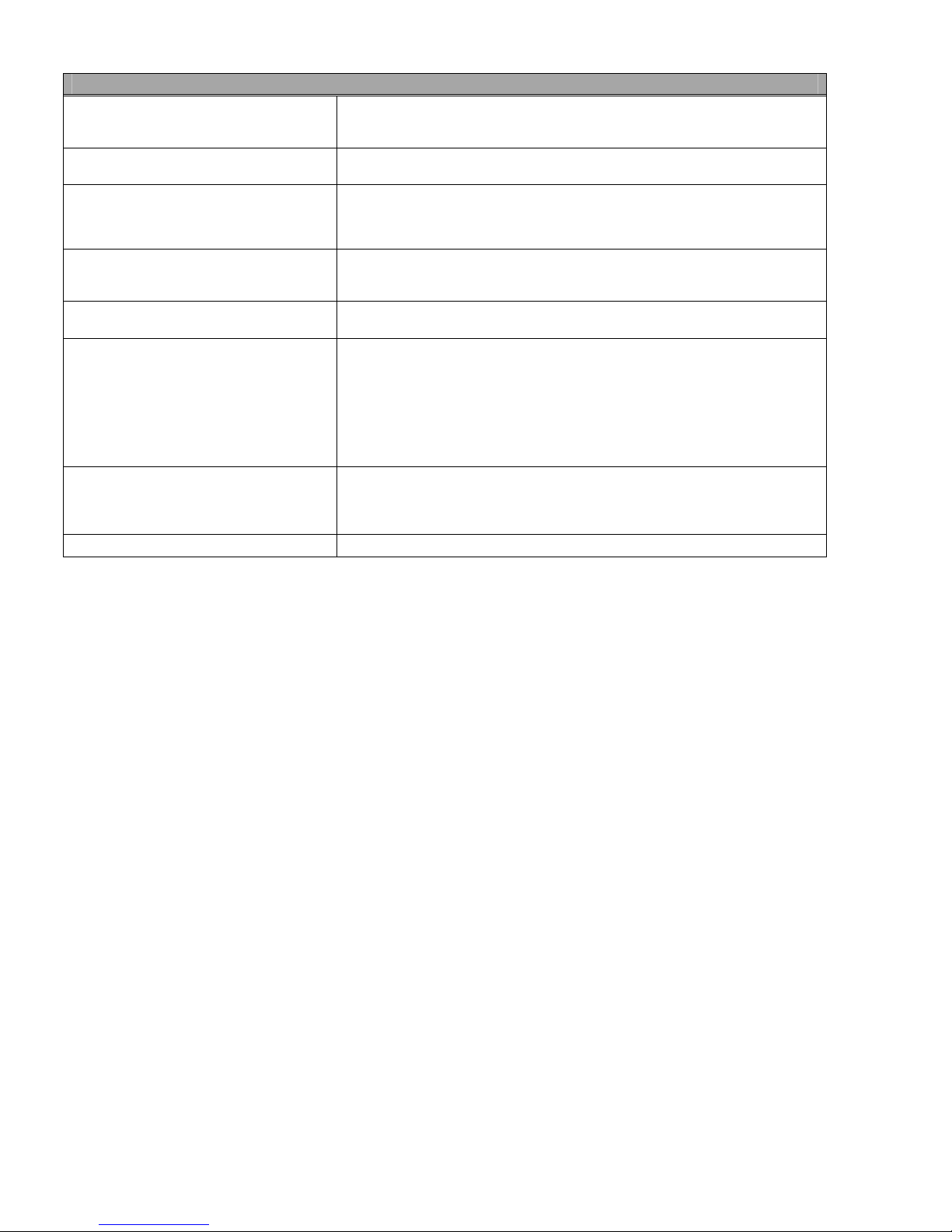

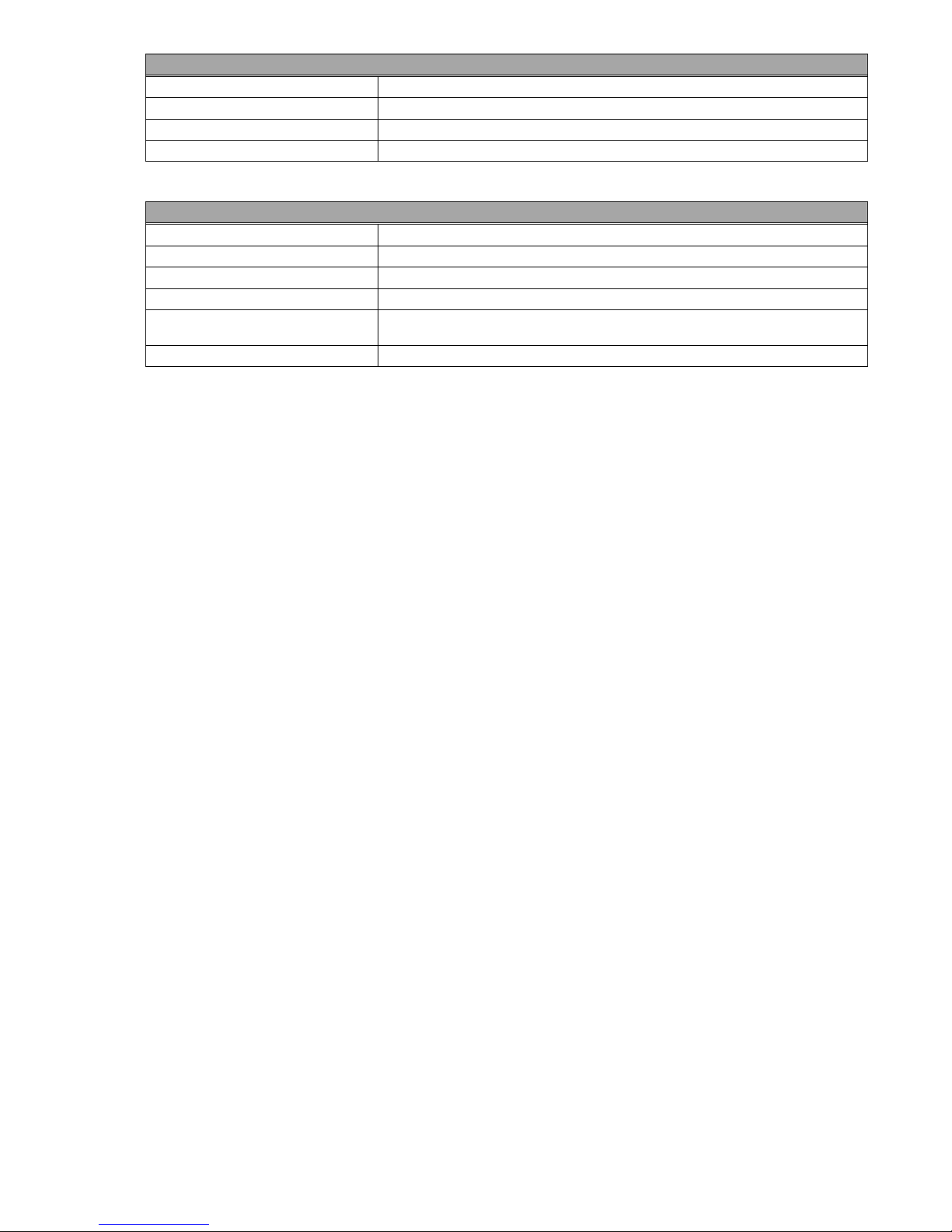

Table 1-1: Technical Features for Profibus DP

Transmission Technique:

Profibus DIN 19245, Part 1

Medium Access: Hybrid medium access

protocol according to DIN 19245, Part 1

Communications: Peer-to-Peer (User Data

Transfer)

or Multicast (Synchronization)

Operation Modes

Synchronization: Enables synchronization of

the inputs and/or outputs of all DP slaves.

Functionality

Security and Protection Mechanisms

Cabling and Installation

SUMMARY OF PROFIBUS DP TECHNICAL FEATURES

• EIA RS 485 twisted pair cable or fiber optic.

• 9.6 kbit/s up to 12 Mbit/s, maximum distance 200m at 1.5 Mbit/s extendible with

repeaters.

• Monomaster or multimaster systems supported.

• Master and slave devices, maximum 126 stations possible.

• Cyclic master slave transfer and acyclic master-master data transfer.

• Operate: cyclic transfer of input and output data.

• Clear: inputs are read and outputs are cleared.

• Stop: only master-master functions are possible.

• Sync-Mode: Outputs are synchronized.

• Freeze-Mode: Inputs are synchronized.

• Cyclic user data transfer between DP-Master(s) and DP Slave(s).

• Activation or deactivation of individual DP Slaves.

• Checking of the configuration of the DP Slaves.

• Powerful diagnosis mechanisms, 3 hierarchical levels of the diagnosis messages.

• Synchronization of inputs and/or outputs.

• Address assignments for the DP-Slaves over the bus with Master Class 2.

• Configuration of the DP-Master (DPM1) over the bus.

• Maximum 244 bytes input and output data per DP Slave, typical 32 bytes.

• All messages are transmitted with Hamming Distance HD=4

• Watchdog timer at the DP slaves.

• Access protection for the inputs/outputs at the DP slaves.

• Data transfer monitoring with configurable timer DP Master (DPM1).

• Connecting or disconnecting of stations without affecting of other stations.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 2

PROTOCOL AND SUPPORTED FEATURES

Fieldbus Type PROFIBUS-DP EN 50 170 (DIN 19245)

Protocol Version Version 1.10

Protocol Stack Supplier Siemens

Auto Baud Rate Detection Supported Baud Rate Range: 9.6 kbit to 12Mbit

PHYSICAL INTERFACE

Transmission Media Profibus Bus Line, Type A or B Specified in EN 50170

Topology Master-Slave Communication

Fieldbus Connector 9-Pin Female DSUB

Cable Shielded Copper Cable, Twisted Pair

Isolation

Profibus DP Ccommunication IC SPC3 Chip from Siemens

The bus is galvanically separated from the other electronics with an on-board DC/DC

converter. Bus signals (A-line and B-line) are isolated via optocouplers.

Producer/Consumer Model

The Producer/Consumer Model allows the exchange of information between a sending device

(“producer”) and many receiving devices (“consumer”) without requiring the same data to be sent

multiple times to different destinations. The producer sends the data once and each consumer on the

network receives the data at the same time. The data can be used (“consumed”) or ignored by each

receiving device independently. FifeNet uses the Producer/Consumer Model.

FifeNet

FifeNet’s deployment of the Producer/Consumer Model allows data sent by a single device to be

received simultaneously by multiple devices on the same network. Each receiving device can choose

to use (“consume”) the information or ignore it as its needs dictate. FifeNet is based on a fixed time

slicing architecture where transmitting devices send data in fixed, predetermined time intervals.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 3

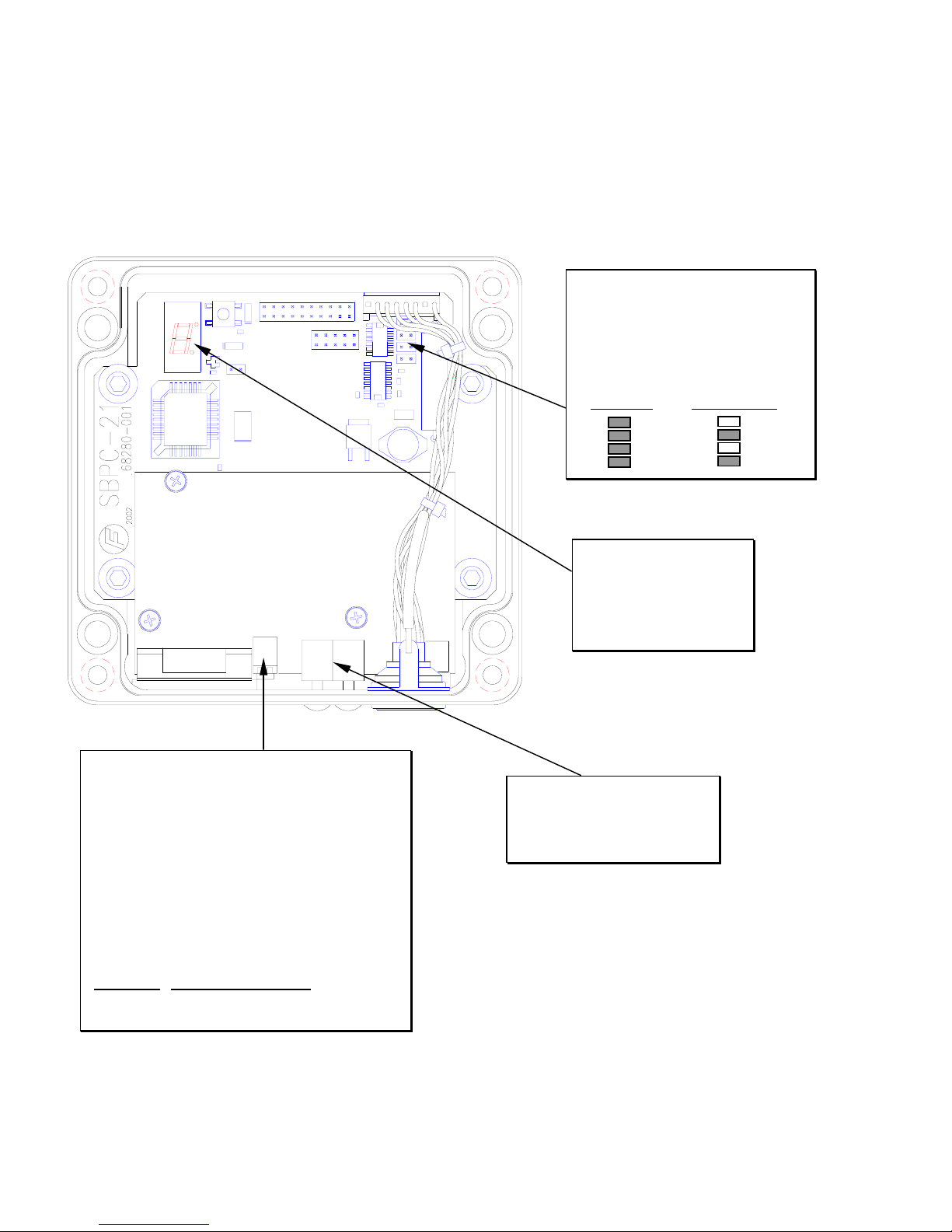

SBPC-21-PB Switch/Jumper Configuration

Since the SBPC-21-PB participates in two networks at the same time, it must have two network

addresses (a FifeNet address and a Profibus node address). The FifeNet address is set via the

FifeNet serial port, which is common with many FifeNet peripherals. The Profibus master sets the

baud rate for the Profibus network. If the SBPC-21-PB is installed as the end point in a FifeNet

network, the jumpers shown below should be installed to provide network termination.

Figure 2-2: SBPC-21-PB Top View

These jumpers should be installed if the

SBPC-21-PB is at the end of a FifeNet

network. They provide network

termination. The other two jumpers

should always be installed as they

select half-duplex FifeNet

communication.

Terminated Not Terminated

Profibus Termination

The end nodes in a Profibus DP network must be

terminated to avoid reflections on the bus line. To

accomplish this, the Profibus DP module is equipped

with a termination switch. If the module is used as the

first or last module in a network, the termination switch

must be in the ON position. Otherwise, the switch

must be in the OFF position. If an external termination

connector is used, the switch must be in the OFF

position.

The termination dip switch can only be accessed with

the SBPC-21-PB top cover removed. To enable

termination, the switch must be in the OFF position.

Termination Switch Position

OFF Up toward top cover.

ON Down toward circuit board.

The 7-segment LED is

used to display errors or

exceptions. During normal

operation, the display will

continuously “cycle” the

outer segments.

Profibus node address switches.

See the following page for

description of these switches.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 4

SBPC-21-PB External Connections/Switches/Indicators

SBPC-21-PB mounting considerations are simplified as all connections to the SBPC-21-PB are on the

same side of the box. The node address and rotary switches are accessible after removal of the plastic

hole plugs which should be reinstalled after configuration is completed.

Figure 1-3: SBPC-21-PB Side View

Connection to FifeNet is

accomplished using the

standard FifeNet

connector. Configuration

is also downloaded using

this connection.

LED indicators provide

feedback for network

troubleshooting.

Pin Name Signal

Housing Shield Connected to PE.

1 Not connected

2 Not connected

3 B-Line Positive RXD/TXD

4 RTS Request to Send1

5 GND BUS Isolated GND from RS-485 side1.

6

7 Not connected

8 A-Line Positive RXD/TXD

9 Not connected

1

+5V Bus and GND Bus are used for bus termination. Some

devices, like optical transceivers (RS485 to fiber optics), might

require external power from these pins. RTS is used in some

equipment to determine the direction of transmission. In normal

applications only A-Line, B-Line, and Shield are used.

+5V BUS Isolated +5VDC from RS-485

D-SUB Connector

1

.

side3

The Profibus Node address is set using these

rotary switches. This enables address settings

from 1-99 in decimal format. The left switch

sets the most significant digit and the right

switch sets the least significant digit. The node

address cannot be changed during operation.

Profibus DP Baud Rate

The baud rate on a Profibus DP network is set during configuration of the master. Only one baud rate

is possible in a Profibus DP installation. The SBPC-21-PB uses auto baud rate detection so the user

does not have to configure the baud rate. Baud rates supported are:

• 9.6 kbit/s • 187.5 kbit/s • 3 Mbit/s

• 19.2 kbit/s • 500 kbit/s • 6 Mbit/s

• 93.75 kbit/s • 1.5 Mbit/s • 12 Mbit/s

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 5

SBPC-21-PB Network Status

The SBPC-21-PB network status is determined by interpretation of the external LED status indicators

as described below.

Figure 1-4: SBPC-21-PB LED Indicators

Table 1-1

ONLINE

LED State Meaning

Green

Off Module is not ONLINE

LED State Meaning

Red

Off Module is ONLINE.

LED State Meaning

Off No faults present.

Flashing Red (1 Hz)

Flashing Red (2 Hz)

Flashing Red (4 Hz)

Indicates that the module is

ONLINE and data exchange is

possible.

OFFLINE

Indicates that the module is

OFFLINE and no data exchange is

possible.

FAULTS

Error in configuration: IN and/or

OUT length set during initialization

of the module is not equal to the

length set during configuration of the

network.

Error in user parameter data: The

length/contents of the user

parameter data set during

initialization of the module is not

equal to the length/contents set

during configuration of the network.

Error in initialization of the Profibus

communication ASIC.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 6

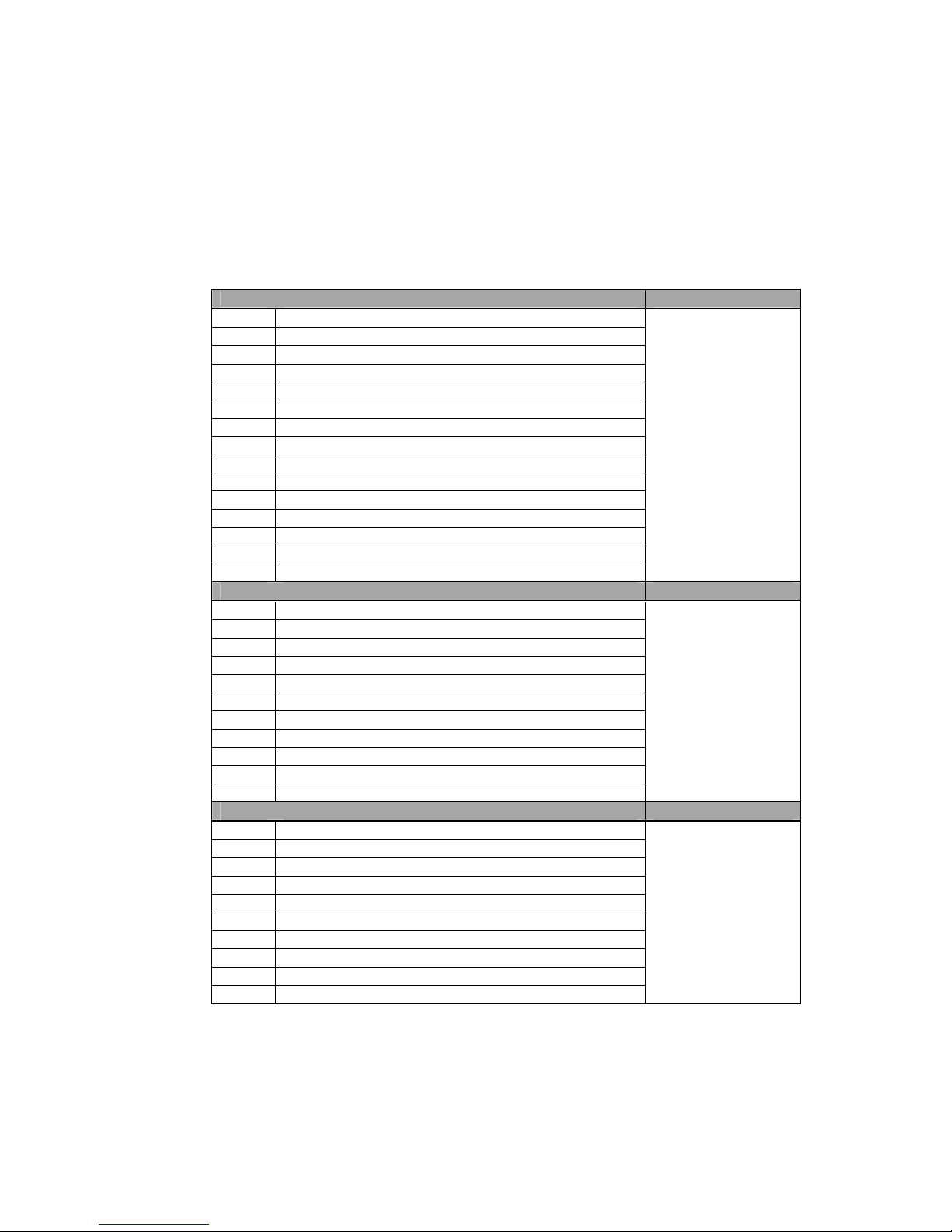

SBPC-21-PB Error Codes

The 7-segment LED digit on the SBPC-21-PB main board is used to indicate errors or other potential

problems. See page 2 of this manual for the location of this LED. The error codes are divided into the

categories listed below. Since there is only a single-digit display and the error codes are 3 digits in

length, the error codes are displayed in three parts. The most significant digit will appear first followed

by the second and third digits. The display will go blank for a moment and the cycle repeats unless the

SBPC-21-PB has been configured to attempt to restart after an error. If this is the case, the error will

only cycle once. All state machine errors 5XX are considered nonfatal and only cycle once. Below are

the error codes and their meanings:

Table 1-2

SBPC PROCESSOR ERRORS

F01 Processor attempted to execute and undefined instruction.

F02 Software interrupt vector occurred.

F03 Attempt to fetch instruction from invalid memory.

F04 Attempt to read data from invalid memory.

F05 Reserved exception vector.

F06 FLASH memory checksum fault.

F07 Pool memory allocation error.

F08 Byte memory allocation error.

F09 Unable to create thread.

F0A Unable to create event.

F0B Unable to create semaphore.

F0C Unable to create mutex.

F0D Unable to create queue.

F0E Unable to write to queue.

F0F Console I/O error.

COMMUNICATION MODULE ERRORS

E01 The configuration matrix is corrupted.

E02 No HMS Anybus module detected.

E03 Anybus module failed to initialize (no interrupt received).

E04 Anybus module failed to initialize (interrupt stuck).

E05 Anybus module failed to initialize (mailbox not ready).

E06 Anybus mailbox timeout.

E07 Anybus mailbox response indicated error.

E08 Anybus mailbox response timeout.

E09 Anybus dual-port RAM fault.

E0A Anybus output area release timeout.

E0B Anybus initialization timeout.

STATE MACHINE ERRORS

501 State machine file is corrupted.

502 State machine is disabled.

503 State machine started in shutdown mode.

504 Bad state machine instruction encountered.

505 State machine instruction fetch from address is out of range.

506 State machine stack error (too many nested calls).

507 State machine stack error (too many returns).

508 State machine attempted divide by zero.

509 State machine tried to access more than four timers.

50A State machine variable address is out of range.

Errors that begin with ‘F’

are unrecoverable faults.

The SBPC cannot

participate in FifeNet or

Profibus operations. In

the default configuration

the SBPC will attempt to

restart.

Errors that begin with ‘E’

are associated with the

Profibus interface. In the

default configuration, the

SBPC will attempt to

restart. With the

exception of error ‘E01,’

FifeNet is functional;

however, the default

configuration will attempt

to restart which will

interrupt FifeNet.

Errors that begin with ‘5’

are related to the state

machine capability of the

SBPC. These errors are

cycled only once and do

not cause the SBPC to

restart.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 7

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 8

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

2

FIFENET THEORY

• • • • • •

FifeNet Time Slices

Data on FifeNet is divided into time intervals called time slices. The FifeNet protocol runs in fixed

repeating cycles. Each time slice can transmit a single 16-bit value. All time slice values are updated

every cycle.

Multiplexed Time Slices

FifeNet devices can send a single 16-bit value in one or more time slices. This is acceptable for

values that require high performance such as guiding. The penalty for this performance is the usage

of one time slice per value sent. With limited time slices available, network bandwidth can be

consumed quickly. If some variables are not needed at a high rate, FifeNet offers a way to “multiplex”

a single time slice to carry multiple data words. There are two multiplex options available in the

CDP-01 permitting a single time slice to carry 16 words or 64 words. Multiplexing works by inserting

the specified data words in a sequential repeating cycle. The receiving SBPC-21-PB synchronizes

with the multiplexed data to extract it. This method trades data update speed for higher data quantities

(up to 64 words per time slice). Any combination of real-time or multiplexed data can exist on FifeNet.

Figure 2-1: Multiplexed Data Time Slices

D1 ACTIVITY

D1 is real-time. This data

is updated every cycle.

T0 T1 T2 T3

− −−−−−−−−−−−−−−−−− − −−−−−−−−−−−−−−−−− − −−−−−−−−−−−−−−−−− − −−−−−−−−−−−−−−−−−

D1 D5 D1 D5 D1 D5 D1 D5

MULTIPLEXING

D5 is multiplexed or switched to a

different variable every cycle.

After the last variable is sent, the

process repeats continuously.

Tn TS Contents

T0 - Edge Right Sensor

T1 - Line Edge Sensor

T2 - CDP Key Pressed

T3 - Status Register Common

T4 - Drive 1 Mode

T5 - Drive 1 Sensor Mode

T6 - Drive 1 Encoder

T7 - Drive 1 Status Reg 0

T8 - Drive 2 Mode

T9 - Drive 2 Sensor Mode

T10 - Drive 2 Encoder

T11 - Drive 2 Status Reg 0

T12 - Drive 3 Mode

T13 - Drive 3 Sensor Mode

T14 - Drive 3 Encoder

T15 - Drive 3 Status Reg 0

D5 ACTIVITY

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 9

In the example diagram (Figure 2-1), there is real-time data on D1 and 16 multiplexed data words on

D5. D1 contains the Edge Left Sensor value from a CDP-01. D5 is used to send 16 different values

from the CDP-01. For the real-time value, the CDP-01 sends the Edge Left Sensor value in D1 every

cycle. For the multiplexed time slice, the CDP-01 sends the Edge Right Sensor value in D5 during

time T0. During time T1, D5 contains the Line Edge Sensor value.

As you can see in the example on the previous page, 17 values are being sent over FifeNet, but only

two time slices of network bandwidth are used. The 16 values in time slice 5 are updated at a slower

rate than the value in time slice 1. The application dictates which method should be implemented.

FifeNet Master

The FifeNet protocol uses the time slice architecture described previously for configurable network

traffic. Without some synchronization, however, neither the SBPC-21-PB, nor the CDP-01, would

know where the time slice boundaries were located. This would create problems when they are trying

to send and receive data. This is one of the primary functions of the FifeNet Master, in this case, that

would be the SBPC-21-PB.

SBPC-21-PB Data Flow

In order to effectively connect two dissimilar networks, some means must be provided to collect the

data from each network and exchange it in a controlled manner so that no partial or incomplete data is

sent on either network. This is accomplished by using a block of memory in the SBPC-21-PB to

reassemble FifeNet time slice data and then, when it is complete, transfer it to the Profibus buffers for

transmission on Profibus. Keep in mind that the gateway has to be bidirectional so this process works

the same way for data traveling from Profibus to FifeNet. The diagram below shows the process:

Figure 2-2: SBPC-21-PB Data Flow Block Diagram

FifeNet

D1

D2

D3

•

•

•

•

•

•

•

•

The time slice

buffers hold

the raw time

slice data.

M

A

T

R

I

X

M

A

T

R

I

X

Profibus

Data

This matrix is used

to connect any time

slice to any memory

buffer location.

The memory array

is used to assemble

and hold data

passing through the

gateway.

This matrix is used to

connect Profibus

data to any memory

buffer location.

Profibus data is

placed here for

transmission. FifeNet

transmit data is read

from here and sent to

FifeNet.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 10

As you can see in Figure 2-2, each time slice has enough memory to store 64 16-bit data words. This

is the maximum amount of data that appears on a FifeNet multiplexed time slice. These data words

are referenced by their order of reception in the multiplexed sequence with DW0 being first and DW63

being last. When the time slice is used in the real-time mode, only the first location DW0 in the

memory array is used. Multiplexed modes 4, 8, and 16 each use 4, 8, and 16 words of memory,

respectively.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 11

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 12

A

A

A

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

3

CONFIGURATIONS

• • • • • •

Hardware Configuration - Single CDP-01

The SBPC-21-PB connection diagram is shown below. As you can see, this allows a single CDP-01 at

FifeNet address 1 and an SBPC-21-PB at FifeNet address 10. The SBPC-21-PB default Profibus

node address is 2, but can be easily changed using the rotary switches in the SBPC-21-PB.

Figure 3-1: SBPC-21-PB Network Connection With Single CDP-01

Profibus Node

ddress 2

FifeNet Master

ddress 10

FifeNet

FifeNet

ddress 1

Profibus Network

SBPC-21-PB to

CDP-01 Cable:

Fife P/N 68554-001

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 13

A

A

A

A

A

Hardware Configuration - Multiple CDP-01’s

In the network below, the default SBPC-21-PB configuration is used multiple times to provide control to

multiple CDP-01’s. Each SBPC-21-PB is connected to a single CDP-01 creating a separate FifeNet

network for each CDP-01. Each SBPC-21-PB appears as both a FifeNet node and a Profibus node.

Notice the SBPC-21-PB Profibus address must be different for each SBPC-21-PB. The Profibus

address is set by rotary switches accessible via holes in the connector side of the SBPC-21-PB.

Figure 3-2: SBPC-21-PB Network Connection With Multiple CDP-01’s

FifeNet Master

ddress 10

FifeNet

ddress 1

FifeNet Master

ddress 10

FifeNet

ddress 1

Profibus

ddress 3

FifeNet

SBPC-21-PB to

CDP-01 Cable:

Fife P/N 68554-001

Profibus Network

Software Configuration

Configurations have been created to match the single CDP-01 network shown in Figure 3-1. Since the

CDP-01 can have one, two, or three drives, a configuration has been created to match the parameters

present in each drive configuration. This prevents inefficient use of Profibus bandwidth for data that is

inapplicable. The three configurations are:

Table 3-1

CONFIGURATION

SBPC-21-PB Default Matrix for use with Single-Drive CDP-01 100410-02X 100246-02X

SBPC-21-PB Default Matrix for use with Dual-Drive CDP-01 100411-02X 100247-02X

SBPC-21-PB Default Matrix for use with Triple-Drive CDP-01 100412-02X 100248-02X

GSD File

A GSD file is provided with the SBPC-21-PB. Use this file when adding a new Profibus node to the network and

it will automatically set up the configuration for that network node. The table below indicates the quantity of data

transferred for single-, dual-, and triple-drive configurations.

Field Size Size Size Bit

Input 20 26 32 (16-bit)

Output 7 7 7 (16-bit)

SINGLE-

DRIVE

DUALDRIVE

SBPC-21-PB

MATRIX

TRIPLE-

DRIVE

CDP-01

MATRIX

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 14

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

4

COMMUNICATION MAPPING

• • • • • •

Profibus to FifeNet Data

In each of the three configurations (single-, dual-, or triple-drive CDP-01), the Profibus to FifeNet data

is the same. The table below shows the configuration mapping for data traveling from Profibus to

FifeNet. The control matrix data on data word 1 is present so that if it is mapped to the parallel input

for the CDP-01, a great deal of control can be exercised without a special state machine. If this control

is insufficient, the data capabilities on Data Words 2 through 6 provide for custom applications using

state machine interpretation.

SBPC-21-PB Matrix

100410-02X Single

100411-02X Dual

100412-02X Triple

Description

Network commands sent to the CDP-01.

Simulated key presses, etc.

Used to control the CDP-01 in accordance with

the control matrix.

These values are reserved for state machine

communication.

CDP-01 Matrix

100246-02X Single

100247-02X Dual

100248-02X Triple

Profibus Scheduled

Data Word Source

0 WORD Device 1 Command3

1 WORD Control Matrix

2 WORD [0] Reserved

3 WORD [1] Reserved

4 WORD [2] Reserved

5 INT [3] Reserved

6 INT [4] Reserved

Table 4-1

PROFIBUS TO FIFENET DATA — SINGLE-, DUAL-, AND TRIPLE-DRIVE

Variable

1

Data Type

2

2 = Data Types:

* INT 16-bit signed value in the range of –32,768 to +32,767.

* WORD 16-bit unsigned value in the range of 0 to 65,535.

3 = Commands to the CDP-01.

1 = All data words are 16-bit.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 15

FifeNet to Profibus Data

The following single-, dual-, and triple-drive tables show the default configuration mapping for data

traveling from FifeNet to Profibus.

Single-Drive CDP-01

Table 4-2

FIFENET TO PROFIBUS DATA — SINGLE-DRIVE

CDP-01 Matrix: 100246-02X SBPC-21-PB Matrix: 100410-02X

Profibus

Scheduled

Data Word

Destination

1 = All data words are 16-bit.

2 = Data Types:

* INT 16-bit signed value in the range of –32,768 to +32,767.

* WORD 16-bit unsigned value in the range of 0 to 65,535.

* DWORD 32-bit unsigned value in the range of 0 to 4,294,967,295.

3 = This is the device response from the CDP-01.

1

0 WORD Reserved Reserved.

1

2

3

4

5 WORD Device 1 Response3 CDP-01 Fife network responses.

6 INT Edge Left Sensor Value Sensor signal.

7 INT Edge Right Sensor Value Sensor signal.

8 INT Line Center Sensor Value Sensor signal.

9 INT Line Edge Sensor Value Sensor signal.

10 WORD SM Command Feedback Reserved for state machine control.

11 WORD SM Status Feedback Reserved for state machine control.

12 WORD Common Status Register CDP-01 status.

13 WORD Key Pressed Current key pressed on CDP-01 panel.

14 WORD Drive 1 Operation Mode Drive 1 status.

15 WORD Drive 1 Sensor Mode Drive 1 status.

16 WORD Drive 1 Fault Register Drive 1 fault status.

17 WORD Drive 1 Encoder Register Drive 1 encoder status.

18 WORD Drive 1 Alarm Register Drive 1 alarm status.

19 INT Drive 1 Encoder Value Drive 1 encoder value.

Data Type

DWORD Reserved Reserved.

DWORD

2

Panel Data 0

Panel Data 1

Variable

CDP-01 LED panel data.

Description

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 16

Dual-Drive CDP-01

Table 4-3

FIFENET TO PROFIBUS DATA — DUAL-DRIVE

CDP-01 Matrix: 100247-02X SBPC-21-PB Matrix: 100411-02X

Profibus

Scheduled

Data Word

Destination

1 = All data words are 16-bit.

2 = Data Types:

* INT 16-bit signed value in the range of –32,768 to +32,767.

* WORD 16-bit unsigned value in the range of 0 to 65,535.

* DWORD 32-bit unsigned value in the range of 0 to 4,294,967,295.

3 = This is the device response from the CDP-01.

1

0 WORD Reserved Reserved.

1

2

3

4

5 WORD Device 1 Response3 CDP-01 Fife network responses.

6 INT Edge Left Sensor Value Sensor signal.

7 INT Edge Right Sensor Value Sensor signal.

8 INT Line Center Sensor Value Sensor signal.

9 INT Line Edge Sensor Value Sensor signal.

10 WORD SM Command Feedback Reserved for state machine control.

11 WORD SM Status Feedback Reserved for state machine control.

12 WORD Common Status Register CDP-01 status.

13 WORD Key Pressed Current key pressed on CDP-01 panel.

14 WORD Drive 1 Operation Mode Drive 1 status.

15 WORD Drive 1 Sensor Mode Drive 1 status.

16 WORD Drive 1 Fault Register Drive 1 fault status.

17 WORD Drive 1 Encoder Register Drive 1 encoder status.

18 WORD Drive 1 Alarm Register Drive 1 alarm status.

19 INT Drive 1 Encoder Value Drive 1 encoder value.

20 WORD Drive 2 Operation Mode Drive 2 status.

21 WORD Drive 2 Sensor Mode Drive 2 status.

22 WORD Drive 2 Fault Register Drive 2 fault status.

23 WORD Drive 2 Encoder Register Drive 2 encoder status.

24 WORD Drive 2 Alarm Register Drive 2 alarm status.

25 INT Drive 2 Encoder Value Drive 2 encoder value

Data Type

DWORD Reserved Reserved.

DWORD

2

Panel Data 0

Panel Data 1

Variable

Description

CDP-01 LED panel data.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 17

Triple-Drive CDP-01

Table 4-4

FIFENET TO PROFIBUS DATA — TRIPLE-DRIVE

CDP-01 Matrix: 100248-02X SBPC-21-PB Matrix: 100412-02X

Profibus

Scheduled

Data Word

Destination

1 = All data words are 16-bit.

2 = Data Types:

* INT 16-bit signed value in the range of –32,768 to +32,767.

* WORD 16-bit unsigned value in the range of 0 to 65,535.

* DWORD 32-bit unsigned value in the range of 0 to 4,294,967,295.

3 = This is the device response from the CDP-01.

1

0 WORD Reserved Reserved.

1

2

3

4

5 WORD Device 1 Response3 Fife network response.

6 INT Edge Left Sensor Value Sensor signal.

7 INT Edge Right Sensor Value Sensor signal.

8 INT Line Center Sensor Value Sensor signal.

9 INT Line Edge Sensor Value Sensor signal.

10 WORD SM Command Feedback Reserved for state machine control.

11 WORD SM Status Feedback Reserved for state machine control.

12 WORD Common Status Register CDP-01 status.

13 WORD Key Pressed Current key pressed on CDP-01 panel.

14 WORD Drive 1 Operation Mode Drive 1 status.

15 WORD Drive 1 Sensor Mode Drive 1 status.

16 WORD Drive 1 Fault Register Drive 1 fault status.

17 WORD Drive 1 Encoder Register Drive 1 encoder status.

18 WORD Drive 1 Alarm Register Drive 1 alarm status.

19 INT Drive 1 Encoder Value Drive 1 encoder value.

20 WORD Drive 2 Operation Drive 2 status.

21 WORD Drive 2 Sensor Mode Drive 2 status.

22 WORD Drive 2 Fault Register Drive 2 fault status.

23 WORD Drive 2 Encoder Register Drive 2 encoder status.

24 WORD Drive 2 Alarm Register Drive 2 alarm status.

25 INT Drive 2 Encoder Value Drive 2 encoder value.

26 WORD Drive 3 Operation Mode Drive 3 status.

27 WORD Drive 3 Sensor Mode Drive 3 status.

28 WORD Drive 3 Fault Register Drive 3 fault status.

29 WORD Drive 3 Encoder Register Drive 3 encoder status.

30 WORD Drive 3 Alarm Register Drive 3 alarm status.

31 INT Drive 3 Encoder Value Drive 3 encoder value.

Data Type

DWORD Reserved Reserved.

DWORD

2

Panel Data 0

Panel Data 1

Variable

Description

CDP-01 LED panel data.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 18

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

5

CONTROL INFORMATION

• • • • • •

CDP-01 Control Matrix

The CDP-01 parallel input matrix normally applies to the X7 port on the CDP-01. In the default matrix

using the SBPC-21-PB, the CDP-01 parallel input matrix is connected to a time slice. This connection

allows serial commands to be used to control the CDP-01 instead of the hardware parallel input. The

commands described in the control matrix tables on the following pages apply to the commands issued

from Profibus to FifeNet over the network via Data Word 1 in Table 4-1.

External Lock

There is one command, however, that the CDP-01 firmware will not accept over a serial connection for

safety reasons. This command is “EXTERNAL LOCK.” Even though the CDP-01 matrix has the

parallel inputs mapped to a FifeNet time slice, the EXTERNAL LOCK command is still activated by the

matrix shown below when this condition appears on the X7 port of the CDP-01. For multidrive

CDP-01’s, the command is applied to all drives present.

CDP-01 Parallel Input Matrix for Use with SBPC-21-PB

Table 5-1

INPUTS

Command Via X7 Parallel Port 5 4 3 2 1 0

External Lock (All drives applicable.) -- -- -- -- -- 1

Single-Drive CDP-01

CDP-01 Matrix: 100246-02X CDP-01 State Machine: 581000-020 SBPC-21-PB Matrix: 100410-02X

CDP-01 Control Matrix

Table 5-2

COMMAND VIA NETWORK HEX

DRIVE 1, AUTOMATIC 04

DRIVE 1, MANUAL 08

DRIVE 1, SERVO-CENTER 0C

DRIVE 1, JOG LEFT 10

DRIVE 1, JOG RIGHT 20

DRIVE 1, AUTO SETUP 30

DRIVE 1, RGPC SHIFT LEFT 18

DRIVE 1, RGPC SHIFT RIGHT 28

DRIVE 1, RGPC RESET 38

DRIVE 1, SENSOR EDGE LEFT 14

DRIVE 1, SENSOR EDGE RIGHT 24

DRIVE 1, SENSOR EDGE CENTER 34

DRIVE 1, SENSOR LINE CENTER 1C

DRIVE 1, SENSOR LINE EDGE 2C

DRIVE 1, SENSOR LINE E&C 3C

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 19

Dual-Drive CDP-01

CDP-01 Matrix: 100247-02X CDP-01 State Machine: 581000-020 SBPC-21-PB Matrix: 100411-02X

CDP-01 Control Matrix

Table 5-3

COMMAND VIA NETWORK HEX

DRIVE 1, AUTOMATIC 04

DRIVE 1, MANUAL 08

DRIVE 1, SERVO-CENTER 0C

DRIVE 1, JOG LEFT 10

DRIVE 1, JOG RIGHT 20

DRIVE 1, AUTO SETUP 30

DRIVE 1, RGPC SHIFT LEFT 18

DRIVE 1, RGPC SHIFT RIGHT 28

DRIVE 1, RGPC RESET 38

DRIVE 1, SENSOR EDGE LEFT 14

DRIVE 1, SENSOR EDGE RIGHT 24

DRIVE 1, SENSOR EDGE CENTER 34

DRIVE 1, SENSOR LINE CENTER 1C

DRIVE 1, SENSOR LINE EDGE 2C

DRIVE 1, SENSOR LINE E&C 3C

DRIVE 2, AUTOMATIC 05

DRIVE 2, MANUAL 09

DRIVE 2, SERVO-CENTER 0D

DRIVE 2, JOG LEFT 11

DRIVE 2, JOG RIGHT 21

DRIVE 2, AUTO SETUP 31

DRIVE 2, RGPC SHIFT LEFT 19

DRIVE 2, RGPC SHIFT RIGHT 29

DRIVE 2, RGPC RESET 39

DRIVE 2, SENSOR EDGE LEFT 15

DRIVE 2, SENSOR EDGE RIGHT 25

DRIVE 2, SENSOR EDGE CENTER 35

DRIVE 2, SENSOR LINE CENTER 1D

DRIVE 2, SENSOR LINE EDGE 2D

DRIVE 2, SENSOR LINE E&C 3D

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 20

Triple-Drive CDP-01

CDP-01 Matrix: 100248-02X CDP-01 State Machine: 581000-020 SBPC-21-PB Matrix: 100412-02X

CDP-01 Control Matrix

Table 5-4

COMMAND VIA NETWORK HEX

DRIVE 1, AUTOMATIC 04

DRIVE 1, MANUAL 08

DRIVE 1, SERVO-CENTER 0C

DRIVE 1, JOG LEFT 10

DRIVE 1, JOG RIGHT 20

DRIVE 1, AUTO SETUP 30

DRIVE 1, RGPC SHIFT LEFT 18

DRIVE 1, RGPC SHIFT RIGHT 28

DRIVE 1, RGPC RESET 38

DRIVE 1, SENSOR EDGE LEFT 14

DRIVE 1, SENSOR EDGE RIGHT 24

DRIVE 1, SENSOR EDGE CENTER 34

DRIVE 1, SENSOR LINE CENTER 1C

DRIVE 1, SENSOR LINE EDGE 2C

DRIVE 1, SENSOR LINE E&C 3C

DRIVE 2, AUTOMATIC 05

DRIVE 2, MANUAL 09

DRIVE 2, SERVO-CENTER 0D

DRIVE 2, JOG LEFT 11

DRIVE 2, JOG RIGHT 21

DRIVE 2, AUTO SETUP 31

DRIVE 2, RGPC SHIFT LEFT 19

DRIVE 2, RGPC SHIFT RIGHT 29

DRIVE 2, RGPC RESET 39

DRIVE 2, SENSOR EDGE LEFT 15

DRIVE 2, SENSOR EDGE RIGHT 25

DRIVE 2, SENSOR EDGE CENTER 35

DRIVE 2, SENSOR LINE CENTER 1D

DRIVE 2, SENSOR LINE EDGE 2D

DRIVE 2, SENSOR LINE E&C 3D

DRIVE 3, AUTOMATIC 06

DRIVE 3, MANUAL 0A

DRIVE 3, SERVO-CENTER 0E

DRIVE 3, JOG LEFT 12

DRIVE 3, JOG RIGHT 22

DRIVE 3, AUTO SETUP 32

DRIVE 3, RGPC SHIFT LEFT 1A

DRIVE 3, RGPC SHIFT RIGHT 2A

DRIVE 3, RGPC RESET 3A

DRIVE 3, SENSOR EDGE LEFT 16

DRIVE 3, SENSOR EDGE RIGHT 26

DRIVE 3, SENSOR EDGE CENTER 36

DRIVE 3, SENSOR LINE CENTER 1E

DRIVE 3, SENSOR LINE EDGE 2E

DRIVE 3, SENSOR LINE E&C 3E

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 21

Status Data Block

For reference, the CDP-01 Status Data Blocks are listed in the tables on the following pages:

NOTE: In the “Data Word Bit #” fields on the following tables: _ 0 = Low, 1 = High, Blank = Ignore

DW3, DW4: CDP-01 LED Panel Data

PANEL DATA WORD 0: DW3 PANEL DATA WORD 1: DW4

Bit CDP-01 LED Bit CDP-01 LED

0 LED 12 (Line Edge Sensor Mode 0

1 LED 11 (Line Center Sensor Mode) 1

2 LED 10 (Edge Right Sensor Mode) 2

3 LED 9 (Edge Left Sensor Mode) 3

4 LED 17 (Polarity) 4

5 LED 16 (Gain) 5

6 LED 15 (Guide Point) 6

7 LED 14 (Auto Setup) 7

8 8 LED 3 (Manual Key)

9 9 LED 2 (Servo-Center Key)

10 10 LED 1 (Auto Key)

11 Not Used 11 LED 8 (Sensor Key)

12 Drive 3 LED 12 LED 4 (F1 Key)

13 Drive 2 LED 13 LED 5 (F2 Key)

14 Drive 1 LED 14 LED 6 (F3 Key)

15 LED 13 (Setup Key) 15 LED 7 (ASC Key)

DW5: Device 1 Response

DEVICE 1 RESPONSE: DW5

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

0 0 0 Automatic

0 0 1 Servo-Center

0 1 0 Manual

0 1 1 Jog Plus

1 0 1 Jog Minus

0 0 0 Edge Left

0 0 1 Edge Right

0 1 0 Center

0 1 1 Line Center

1 0 0 Line Edge

1 0 1 Line Edge & Center

0 0 Drive 1

0 1 Drive 2

1 0 Drive 3

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 22

Status Data Block (cont’d)

DW6: EDGE LEFT Sensor Value

DW7: EDGE RIGHT Sensor Value

DW8: LINE CENTER Sensor Value

DW9: LINE EDGE Sensor Value

NOTE: These data words contain the normalized values of the connected sensors.

Data Type: Signed 16-bit number

Range: -32,768 to +32,767

DW12: Common Status Register

COMMON STATUS REGISTER: DW12

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

0 0 Drive 1 Panel Active

0 1 Drive 2 Panel Active

1 0 Drive 3 Panel Active

1

1

1

1 Drive 3 Installed

1

1 Drive 2 Installed

1 Status of Parallel Output A

1 Status of Parallel Output B

1 Status of Parallel Input 0

1 Status of Parallel Input 1

1 Status of Parallel Input 2

1 Status of Parallel Input 3

1 Status of Parallel Input 4

1 Status of Parallel Input 5

External A/D Converter

Installed

Bit = 1 indicates transistor on (output active).

Bit = 0 indicates transistor off (output inactive).

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 23

Status Data Block (cont’d)

DW13: Key Pressed

To ensure proper recognition, a key must be depressed for a minimum of 500 ms.

KEY PRESSED: DW13

Data Word Bit No.

Key 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Hex Value

ASC 0 0x07FF

F3 0 0xBFFF

F2 0 0xDFFF

F1 0 0xEFFF

Sensor 0 0xF7FF

Automatic 0 0xFBFF

Servo-Center 0 0xFDFF

Manual 0 0xFEFF

Drive Select 0 0xFF7F

Setup 0 0xFFBF

Jog Plus 0 0xFFDF

Jog Minus 0 0xFFEF

RGPC Right 0 0xFFF7

RGPC Left 0 0xFFFB

Remote Calibration 0 0xFFFD

Error 0 0 0 0 0x0FFF

Timeout 0 0 0 0 0xF0FF

No Key Pressed 0 0 0 0 0xFF0F

Saving 0 0 0 0 0xFFF0

Undefined Key 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0x0000

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 24

Status Data Block (cont’d)

DW14, DW20, DW26: Drive-Specific Operating Mode

DW14 – Drive 1

DW20 – Drive 2

DW26 – Drive 3

OPERATING MODE: DW14, DW20, DW26

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

0 0 1 Automatic

0 1 0 Servo-Center

1 0 0 Manual

0 0 1 Jog Left

0 1 0 Jog Right

1 0 0 0 Setup (Auto or Man is Also Set)

DW15, DW21, DW27: Drive-Specific Sensor Selection and Temperature Fault

DW15 – Drive 1

DW21 – Drive 2

DW27 – Drive 3

SENSOR SELECTION: DW15, DW21, DW27

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

0 0 0 0 0 1 Edge Left (X2)

0 0 0 0 1 0 Edge Right (X1)

0 0 0 1 0 0 Edge Center (X1 and X2)

0 0 1 0 0 0 Line Center (X3)

0 1 0 0 0 0 Line Edge (X3)

1 0 0 0 0 0 Line Edge and Center (X3 with VTB-20)

1 Fault – Overtemperature

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 25

Status Data Block (cont’d)

DW16, DW22, DW28: Drive-Specific Fault Register

DW16 – Drive 1

DW22 – Drive 2

DW28 – Drive 3

FAULT REGISTER (SR0): DW16, DW22, DW28

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

1 Fault – Motor Drive Power Supply

1 Fault – Motor Overcurrent

1 Fault – +12V Power Supply

1 Fault – -12V Power Supply

1 Fault – Analog Ground

1 Fault – A/D Converter Initialization

1 Fault – Overtemperature

DW17, DW23, DW29: Drive -Specific Encoder Register

DW17 – Drive 1

DW23 – Drive 2

DW29 – Drive 3

ENCODER REGISTER (SR2): DW17, DW23, DW29

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

1 Encoder – Counterclockwise Stroke Limit

1 Encoder – Clockwise Stroke Limit

1 Counterclockwise Web Measurement Limit

1 Clockwise Web Measurement Limit

1 Counterclockwise Limit Switch

1 Clockwise Limit Switch

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 26

Status Data Block (cont’d)

DW18, DW24, DW30: Drive-Specific Alarm Register

DW18 – Drive 1

DW24 – Drive 2

DW30 – Drive 3

ALARM REGISTER (SR3): DW18, DW24, DW30

Data Word Bit No.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Description

1 Encoder – Stroke Alarm

1 Web Measurement Alarm

1 Loss of Null

1 ASC (Automatic Sensor Control) Active

1 Fault – Serial Power

1 Drive Centered

1 Drive in Shutdown

1 Counterclockwise Maximum Motor Speed

1 Clockwise Maximum Motor Speed

1 Motor Blocked; Motor Current

1 SSC (Sensor Signal Comparator) Active

1 Counterclockwise Maximum Motor Current

1 Clockwise Maximum Motor Current

1 Valid Motor Installed

DW19: Drive 1 Encoder Value

DW25: Drive 2 Encoder Value

DW31: Drive 3 Encoder Value

NOTE: These data words contain the normalized values of the connected encoders.

Data Type: Signed 16 bit-number.

Range: -32,768 to +32,767

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 27

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 28

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

6

SPECIAL CONTROL OF FIFENET DEVICES

• • • • • •

NOTE: This section is intended to be used for special commands not available in the control matrix via

keypad emulation or for setup purposes.

CDP-01 Key Code Data Path

When a key is pressed on a FifeNet CDP-01, the key code goes through many steps before any action

is taken. The keys are scanned and the key is detected, but the key is not acted upon yet. Instead,

the key is buffered until the FifeNet Master polls the CDP-01 with a command that asks, “What keys

are pressed on your panel?” The CDP-01 responds with the key code representing which key (or

keys) are currently pressed. Normally, the FifeNet Master then issues a command back to the CDP-01

with the key code and a command that tells the CDP-01 which keys are pressed. Now that the

CDP-01 has received the command from the FifeNet Master telling it that a key has been pressed, it

will act on that key. (This is why a FifeNet CDP-01 keypad does not work when the network is down.)

Figure 6-1: CDP-01 Key Code Data Path

FifeNet Master

1) What keys are pressed?

2) My AUTO key is pressed.

3) Your AUTO key is pressed.

By skipping steps 1 and 2 in the sequence above, and injecting key codes/commands into the

command stream for the CDP-01, the SBPC-21-PB can simulate keys being pressed on the CDP-01’s

local panel. This provides the ability to make a fully functional remote control over the network.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 29

CDP-01 Key Codes

The CDP-01 keypad is shown below, along with the key codes for each key. The key codes can be

used to send a command to the CDP-01 to simulate a key pressed on the CDP-01 keypad.

Commands are sent via a 16 bit command word, Register 0 in Table 4-1. Commands are issued by

placing an 8-bit “command” byte in the lower half of the command word and an 8-bit “action” byte in

the upper half of the command word. The “Key Pressed’ command is byte 0x13. The “Manual” key

code is 0x88. To simulate that the “Manual” key is pressed, send the command word 0x8813 to the

CDP-01. As long as the command is issued, the CDP-01 acts as though the key is being held down.

Even the actual keys on the CDP-01 keypad will be ignored until the command is cleared by writing

zero 0x0000 to the command word. This provides the ability to lock out the CDP-01 keypad. If local

keypad operation was needed concurrently with network control, the command should be maintained

until the correct feedback is obtained. Feedback is obtained by monitoring the CDP-01 status data

block parameters of Section 5. For instance, Register 0x40D could be monitored to verify that the key

pressed command was received and Register 0x405 could be monitored to see what the CDP-01

response was to the key pressed command.

Figure 6-2: CDP-01 Key Codes

Automatic 0xAA

Servo-Center 0x99

Manual 0x88

F1 0xCC

F2 0xDD

F3 0xEE

ASC 0xFF

Sensor 0xBB

Setup 0x66

Jog Minus 0x44

Drive Select 0x77

Jog Plus 0x55

KEY

HEX

CODE

Simulating Dual-Key Presses

It is also possible to simulate dual-key presses. Single-key presses contain values like 0x44 for “Jog

Minus” or 0x55 for “Jog Plus.” To simulate two keys pressed simultaneously, combine the two key

codes like this: “Jog Minus” combined with “Jog Plus” is 0x54. Any two keys can be combined as long

as the key code with the higher value is placed in the upper nibble. This allows simulation of setup

functions. Key combinations of three keys or more cannot be simulated by network commands.

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 30

CDP-01 LED Panel Data

To make remote control complete, we must have a way to duplicate the CDP-01 panel LED’s. The

CDP-01 keypad contains integrated LED’s to indicate operating modes, sensors selected, and many

other parameters. The CDP-01 can be configured to send its panel LED data over FifeNet so that

remote devices can duplicate the CDP-01 panel state. We have to look a little deeper to understand

how to use this capability.

Since there are 31 LED’s on the CDP-01 panel, the information has to use the multiplexed mode to

send all the LED states. The CDP-01 sends the panel data in two parts: Input Registers 0x403 and

0x404 as shown in Section 5, Status Data Block. The first word (Input Register 0x403) contains the

state of 15 panel LED’s, while the second word (Input Register 0x404) contains the remaining 16 LED

states. The logic is negative so a bit that is zero indicates that this LED is on.

By using the panel data, the setup procedures in the CDP-01 reference manual can be monitored to

ensure proper sequence of steps.

Figure 6-3: CDP-01 LED Panel Data

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 31

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 32

SBPC-21-PB CUSTOMER INSTRUCTION MANUAL

7

INDEX

• • • • • •

Address

FifeNet....................................................... 4

Profibus ..................................................... 4

CDP-01

Commands........................................ 29, 30

Key Codes............................................... 30

LED Panel Data ...................................... 31

Parallel Input ........................................... 19

Simulating Dual-Key Press ..................... 30

Codes

CDP-01, Key ..................................... 29, 30

Error Codes............................................... 7

Commands

FifeNet to Profibus, Dual ......................... 17

FifeNet to Profibus, Single ......................16

FifeNet to Profibus, Triple ....................... 18

Profibus to FifeNet, Dual ......................... 20

Profibus to FifeNet, Single ......................19

Profibus to FifeNet, Triple .......................21

Special ....................................................29

Configuration

CDP-01, Multiple ..................................... 14

CDP-01, Single ....................................... 13

Drive, FifeNet to Profibus ........................ 16

Drive, Profibus to FifeNet ........................ 15

Network ................................................... 13

Switch/Jumper........................................... 4

Connections

FifeNet....................................................... 5

Network ..................................................... 1

Consumer .....See Producer/Consumer Model

Control Matrix

Dual-Drive ............................................... 20

Single-Drive............................................. 19

Triple-Drive.............................................. 21

Data Flow.................................................... 10

Data Mapping

Profibus to FifeNet ..................................15

Data Transfer.............................................. 10

Error Codes ..................................................7

FifeNet

Definition....................................................3

Master......................................................10

GSD File......................................................14

Indicators

Channel Status ..........................................6

Network Status ..........................................6

Jumpers ........................................................4

Key Codes

CDP-01..............................................29, 30

LED’s

7-Segment .................................................7

Error.......................................................6, 7

Status ........................................................6

Matrix Files..................................................14

Network

Node Setup ...............................................14

Status ........................................................6

Panel Data

CDP-01....................................................31

Parallel Input

CDP-01....................................................19

Produced Data

Dual-Drive................................................17

Single-Drive .............................................16

Triple-Drive ..............................................18

Producer....... See Producer/Consumer Model

Producer/Consumer Model ...........................3

Profibus

Node.........................................................14

SBPC-21-DN

Definition....................................................1

Software

Matrix Files ..............................................14

Parallel Input Matrix.................................19

State Machine..........................................15

Status Data Block

DW12, Common Status Register ............23

DW13, Key Pressed ................................24

DW14, Drive 1 Operating Mode ..............25

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 33

DW15, Drive 1 Sensor Selection............. 25

DW16, Drive 1 Fault Register ................. 26

DW17, Drive 1 Encoder Register ............ 26

DW18, Drive 1 Alarm Register ................ 27

DW19, Drive 1 Encoder Value ................ 27

DW20, Drive 2 Operating Mode .............. 25

DW21, Drive 2 Sensor Selection............. 25

DW22, Drive 2 Fault Register ................. 26

DW23, Drive 2 Encoder Register ............ 26

DW24, Drive 2 Alarm Register ................ 27

DW25, Drive 2 Encoder Value ................ 27

DW26, Drive 3 Operating Mode .............. 25

DW27, Drive 3 Sensor Selection............. 25

DW28, Drive 3 Fault Register ................. 26

DW3, CDP-01 Panel Data Word 0 ..........22

DW30, Drive 3 Alarm Register ................27

DW31, Drive 3 Encoder Value.................27

DW4, CDP-01 Panel Data Word 1 ..........22

DW5, Device 1 Response .......................22

DW6, EDGE LEFT Sensor Value ............23

DW7, EDGE RIGHT Sensor Value..........23

DW8, LINE CENTER Sensor Value ........23

DW9, LINE EDGE Sensor Value.............23

Switch Settings..............................................5

Time Slices

Multiplexed ................................................9

Real-Time ..................................................9

________________________________________________________________________________________________________________

12-20-2002 Figure Sheet 1-851-A Page 34

Loading...

Loading...