Fiengle Tech SY 5D User Manual

he copyright of this instruction is owned by Shenzhen Sucvary Tech Co., Ltd

( Sucvary Co., Ltd), thus without written consent, any company or individual cannot

it by any means, such as electron, machinery, photocopy, record and

he instruction is designed exclusively for the products of Sucvary Co.,Ltd,

s resulting from misusing it to

over, Sucvary Co., Ltd is not responsible for the following

irstly, we will not pay expense for the damage or loss of equipment caused

econdly, if users alter

requirement of Sucvary

Co., Ltd or any damage or consequences resulted from using other fittings or

consumer items instead of that of Sucvary Co., Ltd, we have no responsibility too.

make it clear that how to use the

equipment, we refer to the name of other products, but the ownership of registered

specification and appearance of products may

it if you can understand us!

Preface

T

copy or backup

so on. T

thus, we have no responsibility for any consequence

other equipment. More

cases. F

by user’s unintentionally accidents, abuse or misuse of it. S

repair,operate and maintain them without considering the

There is a formal statement that in order to

trademark belongs to Sucvary Co., Ltd.

For the need of improvement, the

be changed without previous notification. We appreciate

The instruction is only for professionals and repairmen!

,

Notice:

People who are responsible for the operation of the equipment should accept

training of relative technologies and be qualified.

Operators must acquire basic knowledge of the computer and know5D wheel

alignment well.

The reliability and safety of power cable should be checked regularly. Please

allocate ac voltage stabilizer if the voltage of power supply is unstable.

Before installing, lifting machine should be installed according to the

requirement. For the correctness of tests and safety of staff, fastness of the check and

levelness of lifting machine should be paid much attention, cleaning barriers around

the lifting machine for the operation. For the sake of safety, all the loose bolts and

other components should be fixed as requirement.

It should not be installed on vibrating objects or inclined plane.Besides, it

should avoid direct sunlight and moist.

Four-wheel alignment is equipment for precision test. There are sensitive

elements inside, thus it should be handledgently otherwise it will not work well with

its cover deformed, even worse the breakdown of its elements inside.

The surface of the equipment should be away from liquid, or the system will be

damaged forever.

When everything is done, please cut off all power.

The test method of four-wheel alignment is by the use of images, so sensors

cannot be interfere by strong light and any objects that block the light.

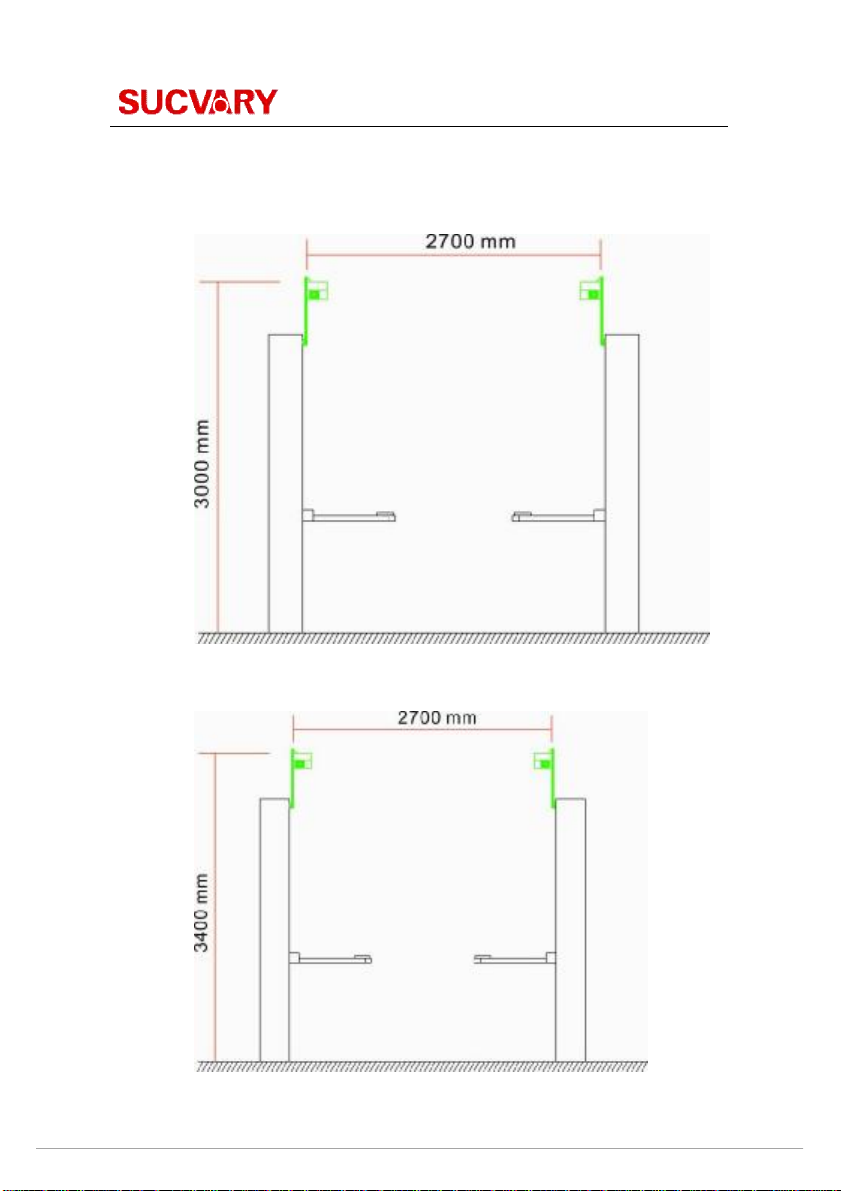

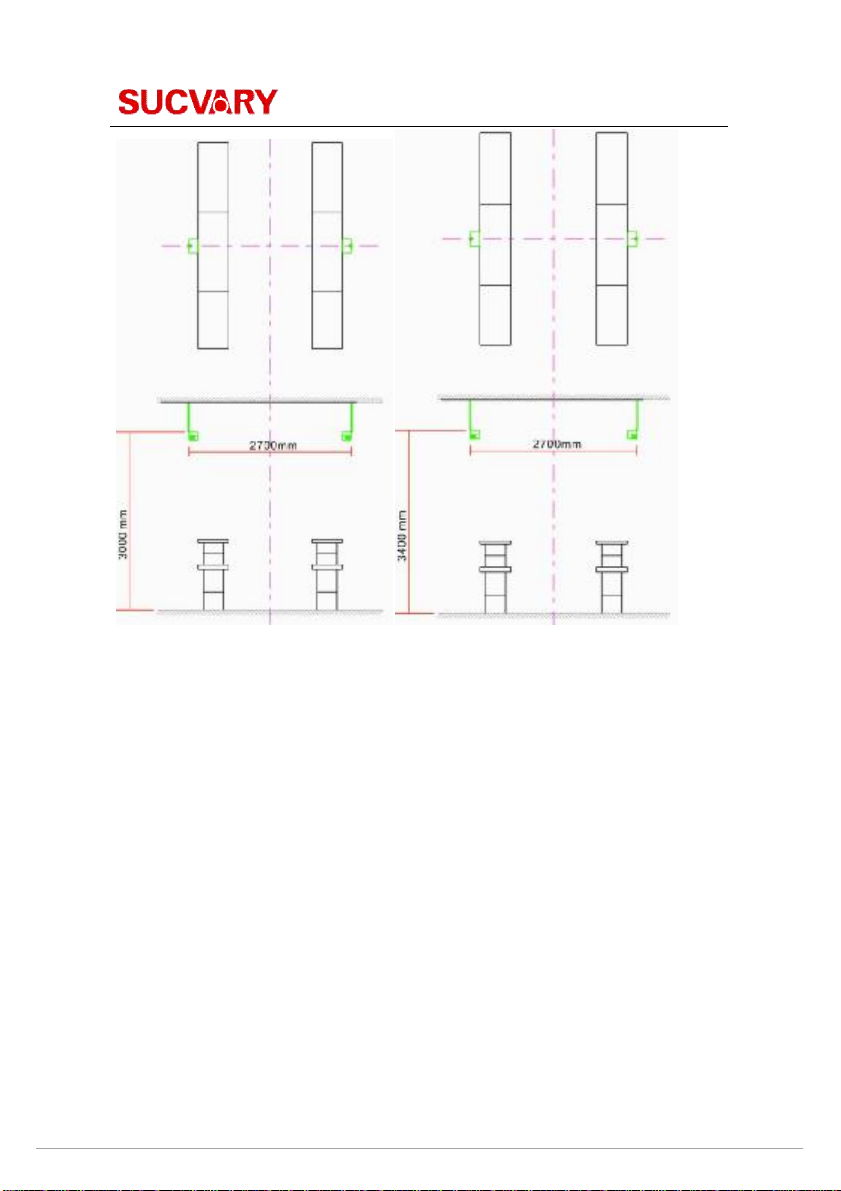

post lift: the distance between the sensor and the ground is 3m to

1.For two-

3.4m, and the distance between two sensors are 2.7m.

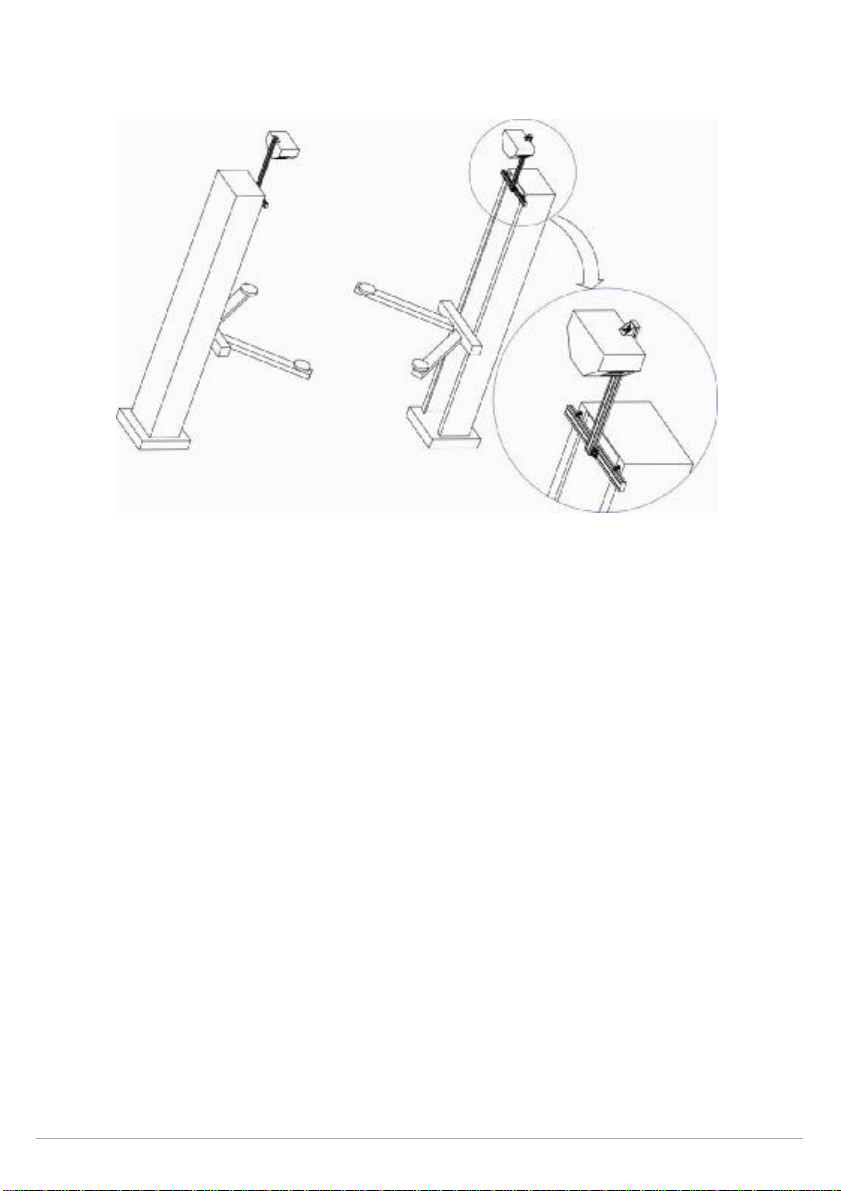

figure:1-1

figure:1-2

2. For double gantry lift: the distance between the sensor and the ground is 3.4m,

and the distance between two sensors are 2.7m.

figure:2-1

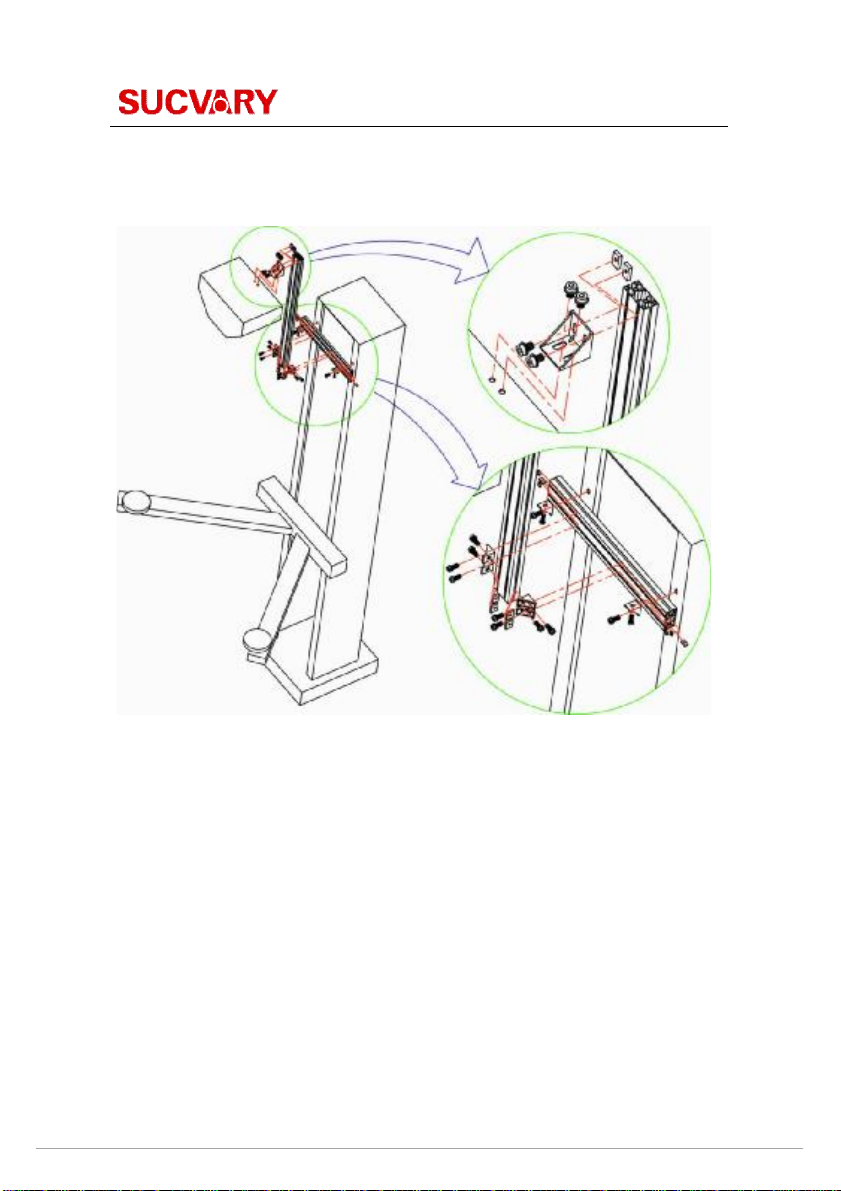

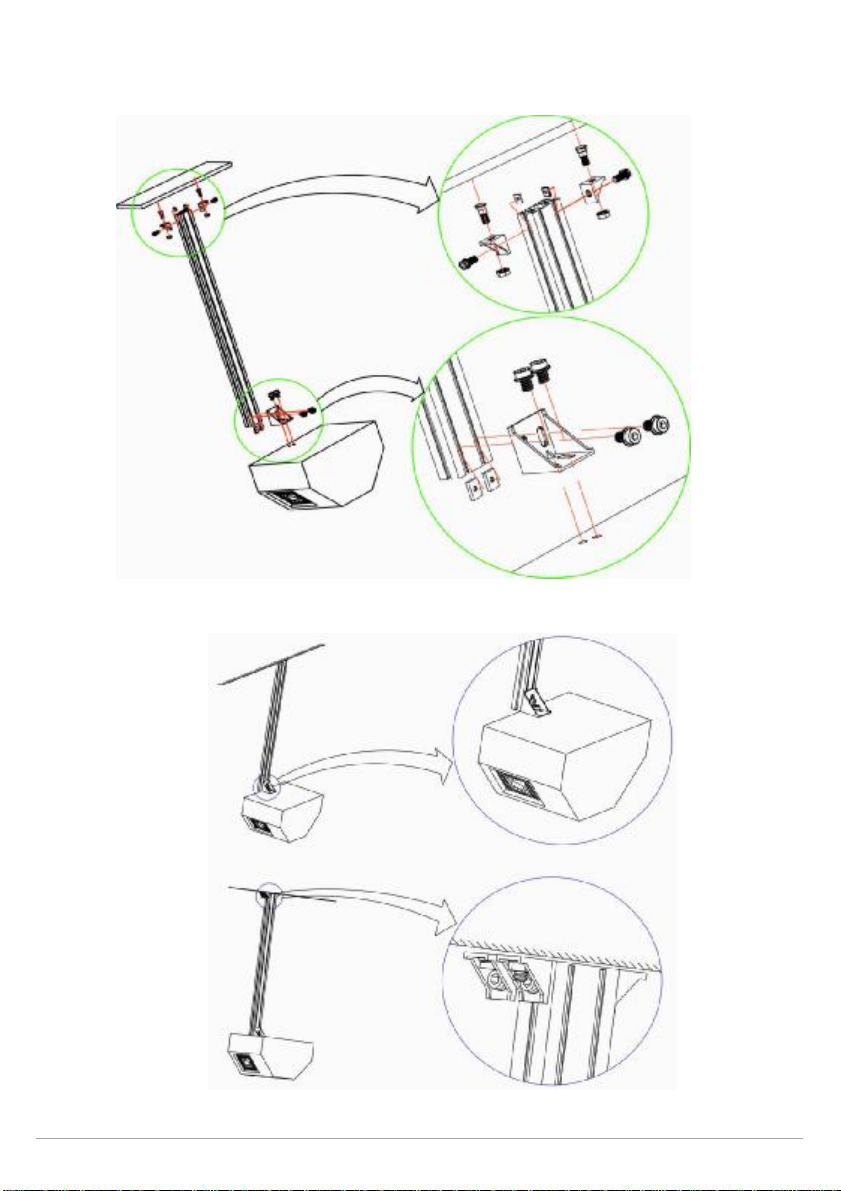

3. The way to install sensors

figure:3-1

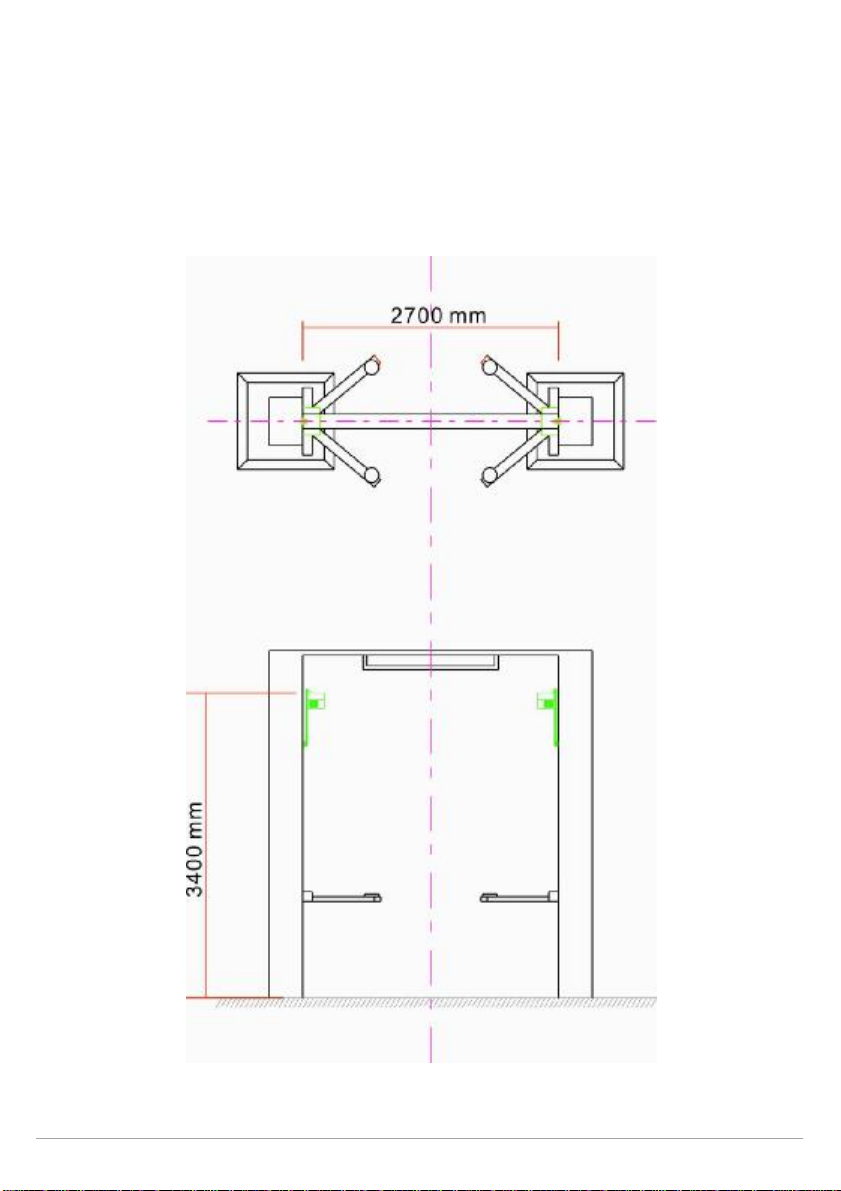

4. For scissors lift and small scissors lift—ceiling -mounted

The distance between the sensor and the ground is 3m to 3.4m, and the

distance between two sensors are 2.7m. Two sensors should be installed over

the middle part of the scissors lift.

figure:3-2

figure:4-1 figure:4-2

figure:4-3

figure:4-4

1. Positioning detection

Click the icon of

positioning detection on the

main interface and enter the

interface as the following

picture. (There are five parts in

positioningdetection: fast

measure, camera monitor,

special measure, user data,

started measure .)

2. To choose the type of cars

In the first step, we should

introduce standard data of the

car. And these data will be used

as reference during the detection.

And then select the right type

and click “yes”.

Loading...

Loading...