Page 1

FieldServer Technologies

A Sierra Monitor Corporation Company

1991 Tarob Court, Milpitas, California 95035 USA

Phone: (408) 262-2299

Toll Free: (888) 509-1970

Fax: (408) 262-9042

Email: support@fieldserver.com

Web Site: www.fieldserver.com

SlotServer LonWorks Open Interface

APPLICABILITY & EFFECTIVITY

This manual provides instructions for the following FieldServer products:

Description

FS-RA-CLX-LON-000

The instructions are effective for the above as of January 2006

Instruction Manual Part Number: T17010

Applicability and Effectivity

Rev. A2.

Page 2

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Table of Contents

TABLE OF CONTENTS

1.

INTRODUCTION............................................................................................................. 3

1.1.

About this product ...................................................................................................... 3

1.2.

About LonWorks and Profiling.................................................................................... 3

1.3.

Connection Capability ................................................................................................ 3

2.

PRE-STARTUP CHECKLIST.......................................................................................... 4

2.1.

Accessories supplied with the SlotServer................................................................... 4

2.2.

Third party components (not supplied by FieldServer Technologies) ......................... 4

2.3.

Required configuration for the SlotServer................................................................... 4

3.

SLOTSERVER TOPOLOGY........................................................................................... 5

3.1.

Hardware Connection Tips / Hints.............................................................................. 5

4.

SLOTSERVER INSTALLATION ..................................................................................... 6

4.1.

SlotServer Ports and Displays.................................................................................... 6

4.2.

Inside Cover Door Label ............................................................................................ 7

4.3.

Technical Specifications............................................................................................. 8

5.

SLOTSERVER COMMUNICATIONS QUICK START EXAMPLE PROJECT ................. 9

5.1.

Step 1: Create or use an existing RSLogix project ..................................................... 9

5.2.

Step 2: Add and configure the SlotServer as an IO Module ......................................10

5.3.

Step 3: Write Ladder Program to Get LonWorks Input Data......................................11

5.4.

Step 4: Write Ladder Program to Send LonWorks Output Data.................................14

5.5.

Step 5: Download the RSLogix Program and Run.....................................................14

5.6.

Step 6: Bind LonWorks Variables..............................................................................14

5.7.

Step 7: Interpret the Network Variable Data..............................................................14

6.

ACCESSING ALL LONWORKS FUNCTION BLOCK DATA.........................................18

6.1.

Input Data from Function Blocks In[1] to In[24]..........................................................18

6.2.

Output Data from Function Blocks Out[1] to Out[24] .................................................18

6.3.

Optimizing performance for smaller applications.......................................................19

APPENDIX A. ADVANCED TOPICS.....................................................................................21

Appendix A.1. Using the FieldServer RUI for Troubleshooting. ...........................................21

Appendix A.2. Installing SlotServer on a Remote Rack using CNB cards ...........................21

Appendix A.2.1. Hardware and Software requirements....................................................21

Appendix A.2.2. Setup .....................................................................................................21

Appendix A.2.3. RSLogix configuration............................................................................22

Appendix A.2.4. RSNetWorx configuration ......................................................................22

Appendix A.2.5. Testing...................................................................................................23

APPENDIX B. TROUBLESHOOTING TIPS ..........................................................................24

Appendix B.1. Things to check when communications has failed........................................24

APPENDIX C. USING LONMAKER TO COMMISSION A SLOTSERVER ............................25

APPENDIX D. NETWORK VARIABLES LIST – LONWORKS OPEN INTERFACE PROFILE

26

Appendix D.1. LonWorks Network Variables Summary.......................................................26

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 3

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 3 of 28

1. Introduction

1.1. About this product

The SlotServer Instruction Manual provides the information necessary to configure the

SlotServer, allowing an Allen Bradley ControlLogix platform to pass data between a

ControlLogix CPU and other third party communications protocols supported by the

SlotServer. The SlotServer uses implicit communications between the CPU and the

SlotServer and is consequently treated as an I/O Server in RSLogix.

The SlotServer Instruction Manual covers information for installing the SlotServer, and

configuring the module to transfer data with the CPU on the ControlLogix Rack. Depending

on the SlotServer Module ordered, supplementary driver manuals are provided for

information on how to configure the third party protocols residing in the SlotServer.

1.2. About LonWorks and Profiling

Inherent to the design of LonWorks is the intention that all nodes residing on a LonWorks

network possess a profile which accurately describes the network variables available to the

LonWorks network. This profile is declared to the LonWorks network by means of an

External Interface File (XIF). This XIF remains unchanged for any particular profile. In other

words, a change in the XIF is by definition a new profile.

The Open Interface profile for SlotServer provides a generic list of SNVT’s that can be used

to bind the most common LonWorks data types to the SlotServer for data transfer. This

document describes the fixed Open Interface profile for the SlotServer. However, as a

LonMark compatible product, the SlotServer platform is also capable of supporting other

profiles. For further information, please contact FieldServer Technologies and enquire

about available Specific Profiles and other SlotServer Profiling Services.

1.3. Connection Capability

SLOTSERVER MODE

CLIENT (SCANNER) 15

SERVER (ADAPTER) N/A

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

LONWORKS

NODES

COMMENTS

As an implicitly bound object in LonWorks, the

LonWorks protocol only supports the binding of this

device to no more than 15 other nodes.

The ControlLogix CPU is always configured as a

scanner to communicate with the SlotServer adapter.

Page 4

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 4 of 28

2. Pre-Startup checklist

2.1. Accessories supplied with the SlotServer

Please verify that the following components were supplied with the SlotServer module:

FieldServer Technologies

PART #

Description

2-way combi-comb connector for LonWorks port

Software CD

CAT-5 Direct Ethernet Cable

Documentation Binder

2.2. Third party components (not supplied by FieldServer Technologies)

The following components will need to be procured as a minimum for achieving a

LonWorks/ControlLogix integration. Ensure that these are available before commencing

with commissioning

Part # Description

AB1756-Ax ControlLogix Rack

AB1756-L55/L61 ControlLogix CPU

AB1756-PA7x ControlLogix PSU

9324-RLD300ENE RSLOGIX 5000

LonWorks NetWork Manager (e.g: LonMaker)

LonWorks Network components.

2.3. Required configuration for the SlotServer

In order to achieve data transfer between CPU tags and LonWorks network variables, the

SlotServer will need to be commissioned into a LonWorks network using a LonWorks

Network Manager. Once commissioned and bound, data from the LonWorks network is

accessed by I/O image transfer in the ControlLogix CPU.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 5

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 5 of 28

3. SlotServer Topology

The diagram below shows a typical implementation of the SlotServer LonWorks Open Interface

Module

3.1. Hardware Connection Tips / Hints

• Note that the LonWorks TP/FT-10 medium is polarity insensitive and therefore does not

require attention to connection orientation on the pins.

• Follow the Rockwell documentation for guidelines on inserting the SlotServer module

into the ControlLogix backplane / rack.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 6

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 6 of 28

status

4. SlotServer Installation

The SlotServer plugs directly into the AB1756 ControlLogix rack. Take note of the slot number

used for the SlotServer as this will be needed when configuring the I/O in the RSLogix software.

4.1. SlotServer Ports and Displays

Note that there are several hardware ports available on the SlotServer card, but that this

SlotServer model only makes use of a select few. The ports and displays of interest are as

shown in the diagram below:

Scrolling display shows card messages

Card Status Indicators show general card

Service Pin For LonWorks Commissioning

Communications Status LED’s show status of

communications and card software.

TP/FT10 LonWorks Connection

Trade Port. Used for advanced troubleshooting

only. See Appendix A.

Not Used. Do not connect anything here.

Scrolling Display

This will Display an OK status when the SlotServer has powered up successfully.

Card Status Indicators:

The Comm and OK lights will indicate green when the SlotServer has powered up

successfully. The Sys indicator will indicate green if the Lon Nodes are all communicating,

and red otherwise.

Service Pin

To be used for commissioning the SlotServer into a LonWorks network

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 7

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 7 of 28

Communications Status LED’s

LED Description

When the SlotServer is powered up, this light will start flashing after approximately 2

Run

LonSvc

NodeOff

Conf

Err

Sys Err

Com Err

minutes. If this light does not flash, it is an indication that the firmware is not running,

and that the SlotServer will not be operating.

This light will flash when the card’s Neuron chip is unconfigured, and will extinguish

when the SlotServer has been commissioned into a Network.

This light indicates that a device bound to the SlotServer on the LonWorks network is

not communicating. Use the LonWorks Network Manager to troubleshoot the problem.

This light indicates an error in the card configuration. Since this model is shipped preconfigured, this light should not come on unless the card configuration is tampered with

This light indicates that an unexpected operation state occurred. The light can be reset

by cycling power to the card. If the error re-occurs persistently, then contact FieldServer

Technical support for assistance with troubleshooting after setting up the trade port as

shown in Appendix A.

This light indicates that a communication error occurred. Use the LonWorks NetWork

Manager to troubleshoot the problem, or refer to Appendix A.

TP/FT10 LonWorks connection

This two wire connection is polarity insensitive and can be multi-dropped into a LonWorks

Network.

Trade Port

The Trade port is an Ethernet port that can be used for advanced troubleshooting (See

Appendix A). Use standard Ethernet cables for this connection.

4.2. Inside Cover Door Label

A label has been provided on the inside of the cover door for the User to document

important or useful configuration parameters used. In particular, special provision has been

made to document the Trade port IP parameters, as well as the LonWorks DSN

(Domain/Subnet/Node) allocated by the Network Manager. These fields are there to be

utilized at the User’s discretion.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 8

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 8 of 28

4.3. Technical Specifications

Slot width 1

BackPlane Current Load 0.6A

Operating Temperature 0-60 Deg C (32-140 Deg F)

Storage Temperature -40 – 85 Deg C (-40 – 185 Deg F)

Humidity 5-95% (Non-Condensing)

Allen Bradley Platform: ControlLogix 1756 Rack

LonWorks Connection type: TP/FT-10

As an implicitly bound object in LonWorks, the LonWorks

LonWorks Connection Capability1

LonWorks Point Capability See Appendix D.

Approvals2

protocol supports the binding of this device to no more than 15

other nodes.

UL 60950-1:2003

CAN/CSA-C22.2 No.60950-1-03

1

A LonWorks Network Management Tool (e.g. LonMaker,Rover,LonWatcher etc) is required to

commission a LonWorks network. This tool is used for creating the variable bindings on the network.

2

Refer to Error! Reference source not found. to view Certificates.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 9

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 9 of 28

5. SlotServer Communications Quick Start Example Project

The discussion that follows describes the basic steps to set up and test the system for

transferring data between CPU tags and the SlotServer using the I/O image method. 104

Network Variables of the full 2,600 points are available using this easy to get going method.

Refer to the Advanced Project if you wish to access more than 104 Network Variables.

5.1. Step 1: Create or use an existing RSLogix project3

• Use File/New to create a new project or File/Open to open an existing project.

• Make sure to choose the correct Slot number in the rack where your Controller resides.

3

Your Controller may be of a different type to the one shown in the example.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 10

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 10 of 28

your SlotServer reside

will be transferred

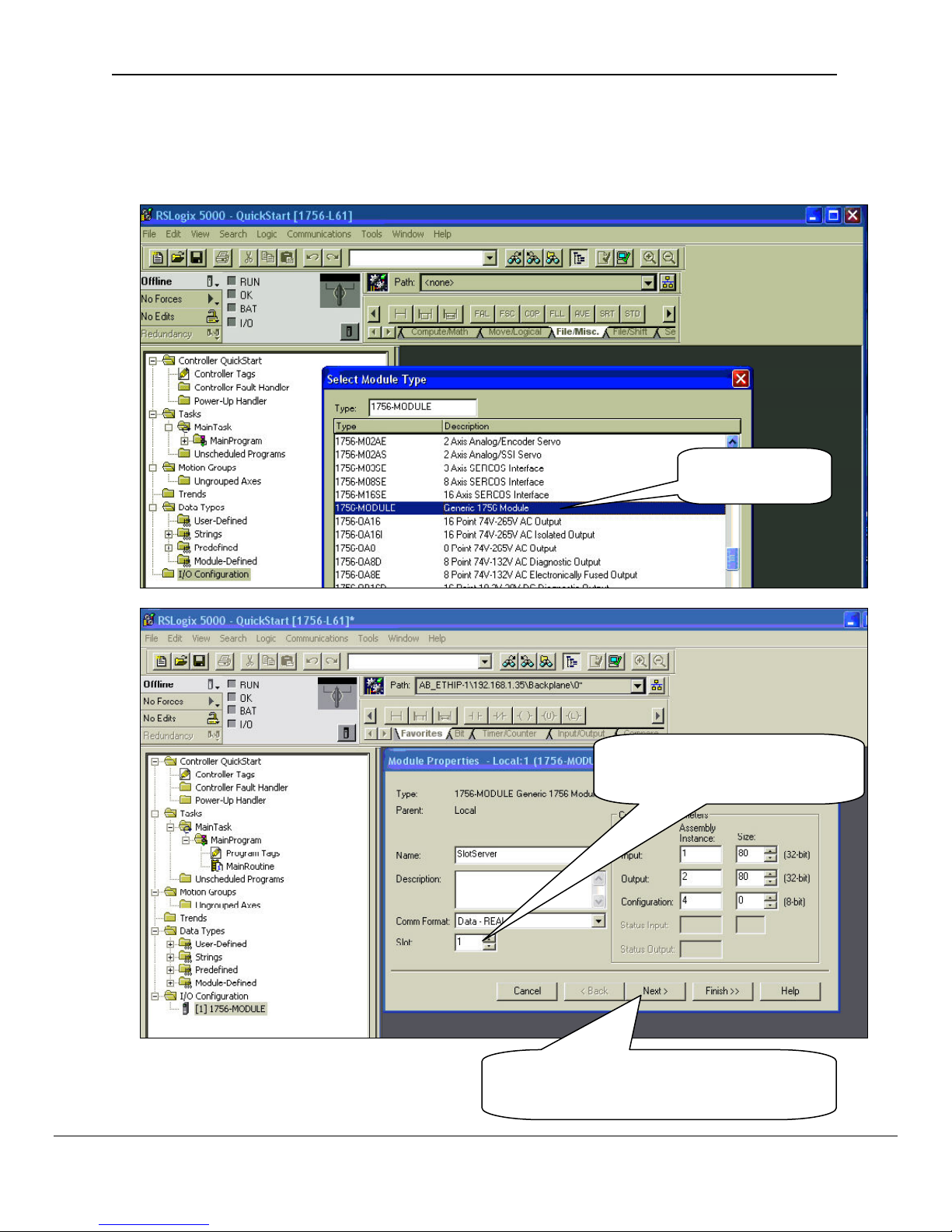

5.2. Step 2: Add and configure the SlotServer as an IO Module

• Right-click on I/O Configuration and select “New Module”.

• Choose the 1756-MODULE

Choose the

1756-MODULE

Be sure to choose the correct

Slot number in the rack where

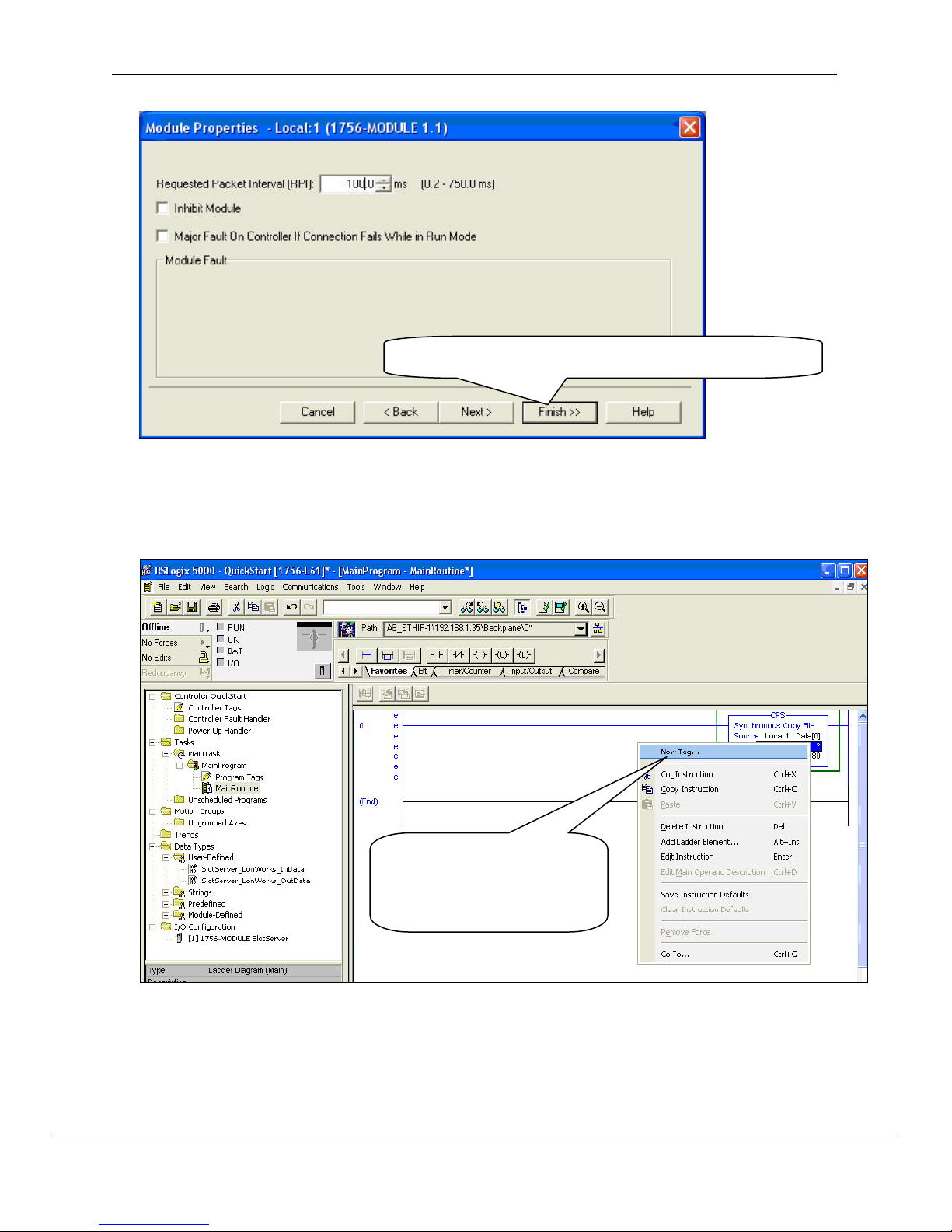

Click Next and choose a RPI of 100 ms.

This is the rate at which the I/O image data

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 11

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 11 of 28

Click Finish to complete the Module Properties setup

5.3. Step 3: Write Ladder Program to Get LonWorks Input Data

• Add a CPS (Synchronous Copy File) Ladder element to synchronize the incoming Data

from the LonWorks network. Use the Input Image Data as Source.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

You can create the

Destination Tag by right

clicking on Destination and

choosing New Tag.

Page 12

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 12 of 28

for the Destination

Create a Controller Tag of

Type REAL, dimension of 80

• Add an EQU (Compare if equal) ladder element to check when the first LonWorks data

block has been received. The block number is at offset 2 of the input image.

• Finally, add another CPS ladder element to copy the Lonworks Data from the InData_Copy

Tag to a new Controller Tag, called Lon_In_01. Also create the Tag by right clicking on

Destination and choosing New Tag. The New Tag must be of type REAL and a dimension of

76.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 13

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 13 of 28

Below is the final ladder program to access data from Lonworks Function Block In[0]

Very Important Note!

It is very important to first make a synchronous copy of the input image data before using it. If

this is not done, the input data cannot be guaranteed to be from a specific LonWorks

Function Block.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 14

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 14 of 28

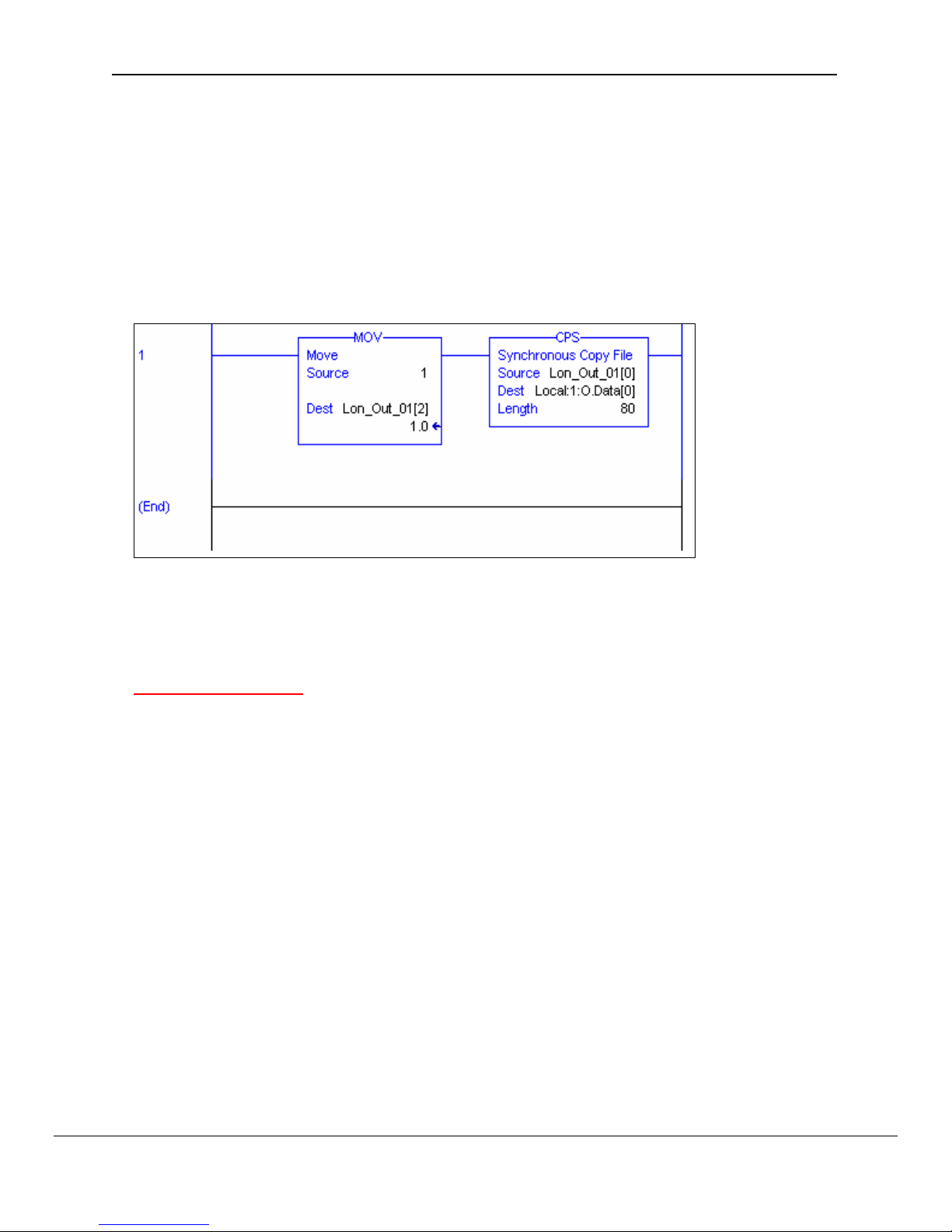

5.4. Step 4: Write Ladder Program to Send LonWorks Output Data

This step is only necessary if you need to write data to the LonWorks Network on Function

Block Out[0]

• Create a Controller Tag called Lon_Out_01 of type REAL[80].

• Add a new rung to the Ladder program and add a MOV element to move a block number

value of 1 into Lon_Out_01[2].

• Finally add a CPS ( Synchronous Copy File ) element to copy the full Lon_Out_01 tag

into the Output Image Tag.

The LonWorks Data are present from Lon_Out_01[4] to Lon_Out_01[79]

You can create a User Defined Data Type to replace the type of Lon_Out_01 mapping the

points to LonWorks point names.

Very Important Note!

It is very important to only update all the data of the Output Image Tag once using a

Synchronous File Copy element. It is not permissible to update the block number into the

Output Image Tag and then the data as this will cause an asynchronous transfer of data.

5.5. Step 5: Download the RSLogix Program and Run

Use the Who Active or Communications Path directly to Download and Run the Program on

the Controller / CPU.

5.6. Step 6: Bind LonWorks Variables

The SlotServer’s LonWorks Network Variables must be bound to other devices using a

Network Management Tool such as LonMaker. See Appendix C for more details on how to

use a Network Management Tool to make the bindings.

5.7. Step 7: Interpret the Network Variable Data

LonWorks Input Variable Values can be found in the Lon_In_01 Tag.

Lon_In_01 Tag Layout:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 15

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 15 of 28

Offset Network Variable Name SNVT_Type

0 nviAmp1 SNVT_amp

1 nviAmp2 SNVT_amp

2 - 4 nviChlr1 SNVT_chlr_status

5 nviCount1 SNVT_count_f

6 nviCount2 SNVT_count_f

7 nviCtInc1 SNVT_count_inc_f

8 nviCtInc2 SNVT_count_inc_f

9 nviFlow1 SNVT_flow_f

10 nviFreq1 SNVT_freq_hz

11 nviHVMod1 SNVT_hvac_mode

12 - 18 nviHVSts1 SNVT_hvac_status

19 nviLev1 SNVT_lev_cont

20 - 21 nviObj1 SNVT_obj_status

22 nviOcc1 SNVT_occupancy

23 nviOcc2 SNVT_occupancy

24 nviPerc1 SNVT_lev_percent

25 nviPerc2 SNVT_lev_percent

26 nviPerc3 SNVT_lev_percent

27 nviPerc4 SNVT_lev_percent

28 nviPerc5 SNVT_lev_percent

29 nviPerc6 SNVT_lev_percent

30 nviPerc7 SNVT_lev_percent

31 nviPerc8 SNVT_lev_percent

32 nviPPM1 SNVT_ppm

33 nviPress1 SNVT_press

34 nviPress2 SNVT_press

35 - 40 nviSetpt1 SNVT_temp_setpt

41 nviState1 SNVT_state

42 nviState2 SNVT_state

43 nviState3 SNVT_state

44 nviState4 SNVT_state

45 - 46 nviSw1 SNVT_switch

47 - 48 nviSw2 SNVT_switch

49 - 50 nviSw3 SNVT_switch

51 - 52 nviSw4 SNVT_switch

53 - 54 nviSw5 SNVT_switch

55 - 56 nviSw6 SNVT_switch

57 - 58 nviSw7 SNVT_switch

59 - 60 nviSw8 SNVT_switch

61 nviTemp1 SNVT_temp_p

62 nviTemp2 SNVT_temp_p

63 nviTemp3 SNVT_temp_p

64 nviTemp4 SNVT_temp_p

65 nviTemp5 SNVT_temp_p

66 nviTemp6 SNVT_temp_p

67 nviTemp7 SNVT_temp_p

68 nviTemp8 SNVT_temp_p

69 - 71 nviTodEv1 SNVT_tod_event

72 nviVltAC1 SNVT_volt_ac

73 nviVltAC2 SNVT_volt_ac

74 nviVolt1 SNVT_volt

75 nviVolt2 SNVT_volt

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 16

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 16 of 28

LonWorks Output Variable Values can be found in the Lon_Out_01 Tag from Offset 4

Lon_Out_01 Tag Layout:

Offset Network Variable Name SNVT_Type

0 Protocol Type Not applicable

1 Node Status Not applicable

2 Lon Block Number [1-25] Not applicable

3 Reserved Not applicable

4 nviAmp1 SNVT_amp

5 nviAmp2 SNVT_amp

6 - 8 nviChlr1 SNVT_chlr_status

9 nviCount1 SNVT_count_f

10 nviCount2 SNVT_count_f

11 nviCtInc1 SNVT_count_inc_f

12 nviCtInc2 SNVT_count_inc_f

13 nviFlow1 SNVT_flow_f

14 nviFreq1 SNVT_freq_hz

15 nviHVMod1 SNVT_hvac_mode

16 - 22 nviHVSts1 SNVT_hvac_status

23 nviLev1 SNVT_lev_cont

24 - 25 nviObj1 SNVT_obj_status

26 nviOcc1 SNVT_occupancy

27 nviOcc2 SNVT_occupancy

28 nviPerc1 SNVT_lev_percent

29 nviPerc2 SNVT_lev_percent

30 nviPerc3 SNVT_lev_percent

31 nviPerc4 SNVT_lev_percent

32 nviPerc5 SNVT_lev_percent

33 nviPerc6 SNVT_lev_percent

34 nviPerc7 SNVT_lev_percent

35 nviPerc8 SNVT_lev_percent

36 nviPPM1 SNVT_ppm

37 nviPress1 SNVT_press

38 nviPress2 SNVT_press

39 - 44 nviSetpt1 SNVT_temp_setpt

45 nviState1 SNVT_state

46 nviState2 SNVT_state

47 nviState3 SNVT_state

48 nviState4 SNVT_state

49 - 50 nviSw1 SNVT_switch

51 - 52 nviSw2 SNVT_switch

53 - 54 nviSw3 SNVT_switch

55 - 56 nviSw4 SNVT_switch

57 - 58 nviSw5 SNVT_switch

59 - 60 nviSw6 SNVT_switch

61 - 62 nviSw7 SNVT_switch

63 - 64 nviSw8 SNVT_switch

65 nviTemp1 SNVT_temp_p

66 nviTemp2 SNVT_temp_p

67 nviTemp3 SNVT_temp_p

68 nviTemp4 SNVT_temp_p

69 nviTemp5 SNVT_temp_p

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 17

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 17 of 28

Offset Network Variable Name SNVT_Type

70 nviTemp6 SNVT_temp_p

71 nviTemp7 SNVT_temp_p

72 nviTemp8 SNVT_temp_p

73 - 75 nviTodEv1 SNVT_tod_event

76 nviVltAC1 SNVT_volt_ac

77 nviVltAC2 SNVT_volt_ac

78 nviVolt1 SNVT_volt

79 nviVolt2 SNVT_volt

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 18

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 18 of 28

6. Accessing All LonWorks Function Block Data

The Quickstart example is for accessing only LonWorks Data in Functional blocks:

In[0] and Out[0]

6.1. Input Data from Function Blocks In[1] to In[24]

To access Input Data Blocks In[1] up to In[24] simply add to the existing ladder program as

shown in the Quickstart example. Add a branch after the CPS element that copies the input

image Tag and copy and paste EQU and CPS elements from the first rung. Create a new

Input Tag for Lon_In_02 of type REAL and dimension 76. Finally, remember to set the

EQU Source B value to 2 to compare for incoming data from the 2nd LonWorks functional

block which is In[1].

See the ladder program below how to add In[1].

Very Important Note!

It is very important to first make a synchronous copy of the input image data before using it.

If this is not done, the input data cannot be guaranteed to be from a specific LonWorks

Function Block.

6.2. Output Data from Function Blocks Out[1] to Out[24]

To access more output blocks is slightly more complicated since we need to create a

Multiplexer in Ladder.

The basic steps are:

• Create a Counter which counts up every 100ms.

• Place the counter value into the Lon_Out_xx Tag at offset 2.

• Copy the whole Tag into the output Data Image Tag for transferring to the LonWorks

network.

The example program below shows an output counter that can count up to 25 which allows

the transfer of data into all 25 Output Function Blocks. Only 2 rungs are shown to transfer

data for blocks 1 and 2. Add more rungs with more Lon_Out_xx tags to transfer data to

other output Function Blocks.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 19

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 19 of 28

Very Important Note!

It is very important to only update all the data of the Output Image Tag once using a

Synchronous File Copy element. It is not permissible to update the block number into the

Output Image Tag and then the data as this will cause an asynchronous transfer of data.

6.3. Optimizing performance for smaller applications

If less than the full number of Function Blocks is needed, it is advisable to trim the Preset

value in the CTU element in the full SlotServer RSLogix project to the maximum block value.

The blocks should be used starting from 0 upwards. This will ensure that update rate is kept

as short as possible.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 20

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 20 of 28

For example, if only block 25 is used and all the other points are left unbound and the

project is untrimmed, when the data updates, the LonWorks driver will scan all the Map

Descriptors for all blocks which will be unnecessarily time consuming.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 21

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 21 of 28

Appendix A. Advanced Topics

Appendix A.1. Using the FieldServer RUI for Troubleshooting.

As a FieldServer enabled product, the SlotServer supports the use of the FieldServer

Utilities for diagnostic purposes. It should not be necessary to connect these utilities to the

SlotServer. However, if the need arises, then the following steps are advised:

• Download the utilities software (or just RuiNet) from www.fieldserver.com

• Download the FieldServer Utilities manual

• Get familiar with the utilities by reading the Utilities manual

• Connect to the Ethernet port on the SlotServer as prescribed by the FieldServer Utilities

manual.

• Follow directions on each of the features of the Utilities to achieve the needed result

Note: It is possible to change the profile of the SlotServer by loading a new configuration

with these utilities. However, doing so for this particular product will void the Warranty on

the product and doing so without consulting FieldServer Technologies is strongly

discouraged.

Appendix A.2. Installing SlotServer on a Remote Rack using CNB cards

Appendix A.2.1. Hardware and Software requirements

In order to perform this application, the following hardware and software is required as a

minimum:

• At least two 1756 racks, where one rack contains the CPU and the other rack

contains the SlotServer

• Two Controlnet CNB cards (with cable for connection) to connect the racks to each

other

• RSlinx

• RSLogix

• RSNetworx

• SlotServer EDS file (Available on SlotServer CD, or call Technical Support)

Note that it is possible to connect to SlotServer on a remote rack using other 1756

bridging cards. This chapter only deals with CNB, but the principles for using other

bridging cards are similar.

Appendix A.2.2. Setup

• Install the CPU and the first CNB card in the local rack.

• Install the second CNB card and the SlotServer in the remote rack.

• Connect the ControlNet Network

• Power up the racks

• Install the SlotServer EDS File using the RSLinx Hardware EDS Installation Tool.

• Make sure the SlotServer has a valid configuration loaded. The default configuration

shipped with the SlotServer should suffice.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 22

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 22 of 28

Appendix A.2.3. RSLogix configuration

In order to see the SlotServer from the CPU, the Hardware must be configured in

RSLogix as follows:

• Configure the cards in the local rack in the I/O Configuration section, including the

CPU and the local CNB card.

• Right click on the local CNB card and add the remote CNB card using the “New

Module” function.

• Right Click on the remote CNB card, and add the 1756 Backplane

• Right Click on the 1756 Backplane and add the cards that are present in the remote

rack, including the SlotServer (As a generic I/O module-see earlier section on how to

do this)

• Save the RSLogix configuration, and download it to the PLC.

The finished I/O configuration should look similar to this:

Appendix A.2.4. RSNetWorx configuration

• Open up RSNetWorx and add the two CNB Cards to the Network by dragging them

onto the Network in the Graph tab (Must be done with Edits Enabled). Follow the

prompts on the screen to configure the Chassis being used, and the cards in each

Chassis (Rack).

• Go Online with RSNetWorx, and then press “save”. This will transfer the RSNetWorx

Configuration to the Keeper.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 23

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 23 of 28

The final RSNetworx Configuration should look similar to this:

Appendix A.2.5. Testing

The SlotServer should now be visible to the CPU. Go Online with RSLogix and check

the Input buffer of the SlotServer for data. A good check is to examine offset 2 of the

input tag for a non-Zero value. If the SlotServer is multiplexing (DA_Count >1), then this

value will be cycling through the Buffer numbers, otherwise if DA_Count=1, then offset 2

will be fixed at 1. If offset 2 is zero, then the SlotServer is not being seen by the CPU,

and Diagnostics will need to be performed using RSNetWorx and RSLogix to determine

the cause of the problem.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 24

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 24 of 28

Appendix B. Troubleshooting tips

Appendix B.1. Things to check when communications has failed.

• Check for loose cabling on the LonWorks network

• Verify that the bindings in the LonWorks network have not been broken by checking the

variable status’ with the LonWorks Network Manager.

• Verify that the correct program is loaded to the CPU

• Verify that the correct data types for the tags have been used.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 25

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 25 of 28

Appendix C. Using LonMaker to Commission a SlotServer

Ensure that the SlotServer and the LonMaker PC are on the same LonWorks network.

• Open the existing Network in LonMaker, or create a new Network

• Click on “Create New Network” and follow the network wizard, making the following

selections:

Network Interface Network Attached

Management Mode Onnet (unless you are working offline)

Register Plug-ins required None

• Once Visio is open with the Network showing, drag a new device onto the drawing from the

toolbox.

• Follow the Device Network, making the following selections

Enter Device Name Commission device

Specify Device Template Upload from device

Specify Device Channel Auto Detect

Specify Device Properties Leave as is (Ping is optional)

Identify Device Service pin

Device Application Image Leave unchecked

Initial State Online

• Press the service pin on the SlotServer when asked to do so, and the SlotServer will be

commissioned.

• Drag a new function block onto the drawing from the toolbox. Give the function block a

name and ensure that it is allocated to the SlotServer device.

• Once the function block is on the drawing, you can drag input and output variables onto the

function block. When you do this, LonMaker will show you the variables available for

binding. Click on the variables you require (or use the select all option), and they will be

commissioned onto the function block.

• You are now ready to connect these variables to other devices by dragging connections

from the toolbox and connecting the variables.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 26

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 26 of 28

Appendix D. Network Variables List – LonWorks Open Interface Profile

Appendix D.1. LonWorks Network Variables Summary

The SlotServer LonWorks Open Interface Profile contains 50 Functional Blocks containing a

total of 2,600 Network Variables of different SNVT Types.

Input Data Function Blocks:

In[0] - In[24]

Output Data Function Blocks:

Out[0] - Out[24]

Each Function Block contains the following Network Variables:

(nvi for Input Data Function Blocks, and nvo for Output Data Function Blocks)

Network Variable Name SNVT_Type

nv(i)(o)Amp1 SNVT_amp

nv(i)(o)Amp2 SNVT_amp

nv(i)(o)Chlr1 SNVT_chlr_status

nv(i)(o)Count1 SNVT_count_f

nv(i)(o)Count2 SNVT_count_f

nv(i)(o)CtInc1 SNVT_count_inc_f

nv(i)(o)CtInc2 SNVT_count_inc_f

nv(i)(o)Flow1 SNVT_flow_f

nv(i)(o)Freq1 SNVT_freq_hz

nv(i)(o)HVMod1 SNVT_hvac_mode

nv(i)(o)HVSts1 SNVT_hvac_status

nv(i)(o)Lev1 SNVT_lev_cont

nv(i)(o)Obj1 SNVT_obj_status

nv(i)(o)Occ1 SNVT_occupancy

nv(i)(o)Occ2 SNVT_occupancy

nv(i)(o)Perc1 SNVT_lev_percent

nv(i)(o)Perc2 SNVT_lev_percent

nv(i)(o)Perc3 SNVT_lev_percent

nv(i)(o)Perc4 SNVT_lev_percent

nv(i)(o)Perc5 SNVT_lev_percent

nv(i)(o)Perc6 SNVT_lev_percent

nv(i)(o)Perc7 SNVT_lev_percent

nv(i)(o)Perc8 SNVT_lev_percent

nv(i)(o)PPM1 SNVT_ppm

nv(i)(o)Press1 SNVT_press

nv(i)(o)Press2 SNVT_press

nv(i)(o)Setpt1 SNVT_temp_setpt

nv(i)(o)State1 SNVT_state

nv(i)(o)State2 SNVT_state

nv(i)(o)State3 SNVT_state

nv(i)(o)State4 SNVT_state

nv(i)(o)Sw1 SNVT_switch

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 27

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 27 of 28

Network Variable Name SNVT_Type

nv(i)(o)Sw2 SNVT_switch

nv(i)(o)Sw3 SNVT_switch

nv(i)(o)Sw4 SNVT_switch

nv(i)(o)Sw5 SNVT_switch

nv(i)(o)Sw6 SNVT_switch

nv(i)(o)Sw7 SNVT_switch

nv(i)(o)Sw8 SNVT_switch

nv(i)(o)Temp1 SNVT_temp_p

nv(i)(o)Temp2 SNVT_temp_p

nv(i)(o)Temp3 SNVT_temp_p

nv(i)(o)Temp4 SNVT_temp_p

nv(i)(o)Temp5 SNVT_temp_p

nv(i)(o)Temp6 SNVT_temp_p

nv(i)(o)Temp7 SNVT_temp_p

nv(i)(o)Temp8 SNVT_temp_p

nv(i)(o)TodEv1 SNVT_tod_event

nv(i)(o)VltAC1 SNVT_volt_ac

nv(i)(o)VltAC2 SNVT_volt_ac

nv(i)(o)Volt1 SNVT_volt

nv(i)(o)Volt2 SNVT_volt

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 28

FS-RA-CLX-LON-000_SlotServer_LonWorks_Open_Interface_(T17010) Page 28 of 28

THIS PAGE INTENTIONALLY LEFT BLANK

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Loading...

Loading...