Page 1

FieldServer Technologies

A Sierra Monitor Corporation Company

1991 Tarob Court, Milpitas, California 95035 USA

Phone: (408) 262-2299

Toll Free: (888) 509-1970

Fax: (408) 262-2296

Email: support@fieldserver.com

Web Site: www.fieldserver.com

SlotServer Instruction Manual

APPLICABILITY & EFFECTIVITY

This manual provides instructions for the following FieldServer products:

Description

FS-RA-CLX-BAS

FS-RA-CLX-FIR

FS-RA-CLX-PRO

The instructions are effective for the above as of January 2006

Instruction Manual Part Number: T17011

Rev. A3.

Applicability and Effectivity

Page 2

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Table of Contents

TABLE OF CONTENTS

1.

INTRODUCTION............................................................................................................. 4

1.1.

About this product ...................................................................................................... 4

2.

PRE-STARTUP CHECKLIST.......................................................................................... 5

2.1.

Accessories supplied with the SlotServer................................................................... 5

2.2.

Third party components (not supplied by FieldServer Technologies) ......................... 5

2.3.

Required configuration for the SlotServer................................................................... 5

3.

STEPS FOR IMPLEMENTATION OF A SLOTSERVER PROJECT ............................... 6

3.1.

Read the SlotServer Instruction Manual..................................................................... 6

3.2.

Install the SlotServer in a ControlLogix Rack. ............................................................ 6

3.3.

Write the SlotServer configuration.............................................................................. 6

3.4.

Install the FieldServer Utilities.................................................................................... 6

3.5.

Load the SlotServer Configuration into the SlotServer ............................................... 6

3.6.

Program the ControlLogix CPU to communicate with the SlotServer. ........................ 6

3.7.

Commission the third party network. .......................................................................... 6

4.

SLOTSERVER INSTALLATION ..................................................................................... 7

4.1.

SlotServer Ports and Displays.................................................................................... 7

4.2.

Inside Cover Door Label ............................................................................................ 9

4.3.

Technical Specifications............................................................................................. 9

5.

SLOTSERVER TOPOLOGY..........................................................................................10

6.

CONFIGURING THE CPU INTERFACE TO THE SLOTSERVER .................................11

6.1.

CPU interface Description.........................................................................................11

6.2.

Configuring the SlotServer as a Logix I/O Server......................................................11

6.3.

Data Arrays/Descriptors............................................................................................11

6.4.

Server Side Connection Descriptors .........................................................................12

6.5.

Server Side Node Descriptors...................................................................................12

6.6.

Server Side Map Descriptors ....................................................................................13

6.6.1. SlotServer Specific Map Descriptor Parameters ....................................................13

6.6.2. Driver Specific Map Descriptor Parameters ...........................................................13

6.6.3. Map Descriptors Example......................................................................................14

7.

PROGRAMMING THE CONTROLLOGIX CPU FOR A SMALL SLOTSERVER

INTERFACE .............................................................................................................................15

7.1.

Step 1: Establish an RSLogix project ........................................................................15

7.2.

Step 2: Add and configure the SlotServer as an IO Module ......................................16

7.3.

Step 3: Write Ladder Program to get Input Data from Data Arrays............................17

7.4.

Step 4: Write Ladder Program to Send Output Data to Data Arrays..........................20

7.5.

Step 5: Download the RSLogix Program and Run.....................................................20

7.6.

Step 6: Set up the third party connection ..................................................................20

8.

PROGRAMMING THE CONTROLLOGIX CPU FOR LARGER SLOTSERVER

INTERFACES...........................................................................................................................21

8.1.

Multiple Input Data Arrays.........................................................................................21

8.2.

Accessing Multiple Output Data Arrays .....................................................................21

APPENDIX A. ADVANCED TOPICS.....................................................................................23

Appendix A.1. Description of Data Transfer Process...........................................................23

Appendix A.2. The IO image header ...................................................................................25

Appendix A.3. How to obtain Node Status from the SlotServer ...........................................25

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 3

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Table of Contents

Appendix A.4. Dealing with ControlLogix RPI Settings........................................................26

Appendix A.5. Installing SlotServer on a Remote Rack using CNB Cards...........................27

Appendix A.5.1. Hardware and Software requirements....................................................27

Appendix A.5.2. Setup .....................................................................................................27

Appendix A.5.3. RSLogix configuration............................................................................27

Appendix A.5.4. RSNetWorx configuration ......................................................................28

Appendix A.5.5. Testing...................................................................................................29

Appendix A.5.6. Connection limitations -Controlling the SlotServer using ControlNet ......30

Appendix A.6. Rules for Naming Logix driver Data Arrays ..................................................31

APPENDIX B. TROUBLESHOOTING TIPS ..........................................................................33

Appendix B.1. Things to check when communications fail. .................................................33

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 4

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 4 of 34

1. Introduction

1.1. About this product

The SlotServer Instruction Manual provides the information necessary to configure the

SlotServer, allowing an Allen Bradley ControlLogix platform to pass data between a

ControlLogix CPU and other third party communications protocols supported by the

SlotServer. The SlotServer uses implicit communications between the CPU and the

SlotServer and is consequently treated as an I/O Server in RSLogix.

The SlotServer Instruction Manual covers information for installing the SlotServer, and

configuring the module to transfer data with the CPU on the ControlLogix Rack. Depending

on the SlotServer Module ordered, supplementary driver manuals are provided for

information on how to configure the third party protocols residing in the SlotServer.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 5

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 5 of 34

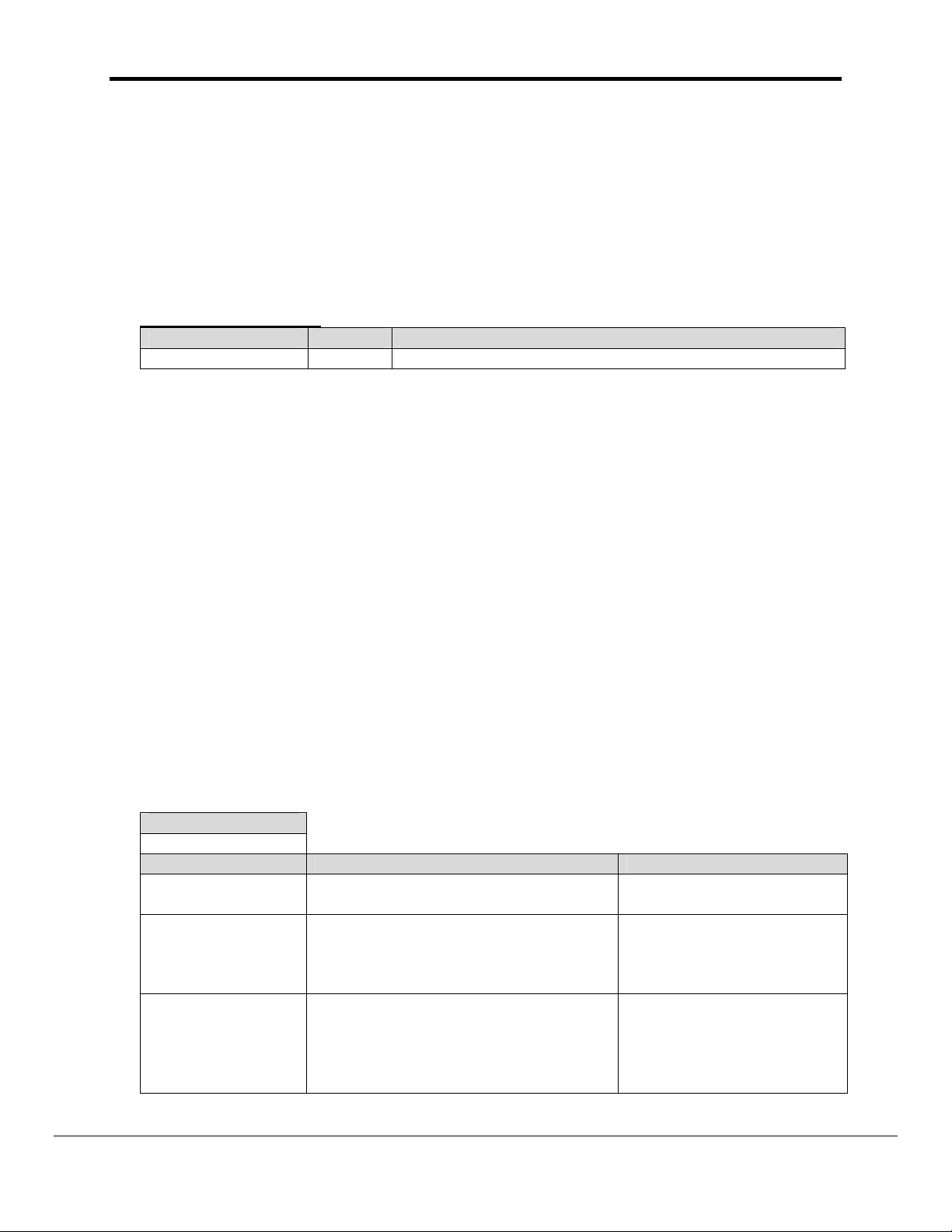

2. Pre-Startup checklist

2.1. Accessories supplied with the SlotServer

Please verify that the following components were supplied with the SlotServer module:

FieldServer Technologies

PART #

2-way combi-comb connector for LonWorks port

Software CD

CAT-5 Direct Ethernet Cable

Documentation Binder

Description

2.2. Third party components (not supplied by FieldServer Technologies)

The following components will need to be procured as a minimum for achieving ControlLogix

integration. Ensure that these are available before commencing with commissioning

Part # Description

AB1756-Ax ControlLogix Rack

AB1756-L55/L61 ControlLogix CPU

AB1756-PA7x ControlLogix PSU

9324-RLD300ENE RSLOGIX 5000

2.3. Required configuration for the SlotServer

To achieve data transfer between CPU tags and the SlotServer third party protocols, it will

be necessary to write and load a configuration into the SlotServer that tells the SlotServer

how to map the ControlLogix Tags to the required protocol addresses. This configuration is

written in a Comma Separated Variable (csv) file, and any text editor or spreadsheet

program that supports csv format can be used for this purpose. FieldServer Technologies

provides an example configuration file so that the configuration does not need to be written

from scratch. Configuration parameters needed to exchange data between the CPU and

the SlotServer data images (Data Arrays) are presented in Section 6. The appropriate

driver manual supplement will describe how to map the data in and out of the Data Arrays

for the relevant protocol.

The FieldServer configuration manual details basic and advanced techniques for the

configuration of the SlotServer Manual, and it is strongly advised that this manual is read

before attempting to write the SlotServer Configuration.

Note: FieldServer Technologies provides SlotServer configuration services if the user does

not wish to perform the configuration themselves.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 6

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 6 of 34

3. Steps for implementation of a SlotServer Project

3.1. Read the SlotServer Instruction Manual

This provides guidelines for getting started with the SlotServer, and is very useful for first

time implementation of a SlotServer application.

3.2. Install the SlotServer in a ControlLogix Rack.

Refer to Section 4 for information on installation.

3.3. Write the SlotServer configuration.

• Refer to the FieldServer configuration manual for instruction on writing a FieldServer

configuration.

• Refer to Section 6 for assistance on managing the Logix driver Parameters

• Refer to the desired protocol driver supplement for assistance on managing the protocol

parameters.

3.4. Install the FieldServer Utilities

Insert the supplied Utilities CD into the CD drive of the PC to be used for configuration and

follow the install instructions.

3.5. Load the SlotServer Configuration into the SlotServer

Refer to the FieldServer Utilities manual for information on the FieldServer Remote User

Interface.

3.6. Program the ControlLogix CPU to communicate with the SlotServer.

The sections that follow highlight a few examples on how this is done.

3.7. Commission the third party network.

Refer to standard commissioning guidelines for the protocol in question.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 7

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 7 of 34

status

configuration.

4. SlotServer Installation

The SlotServer plugs directly into the AB1756 ControlLogix rack. Take note of the slot number

used for the SlotServer as this will be needed when configuring the I/O in the RSLogix software.

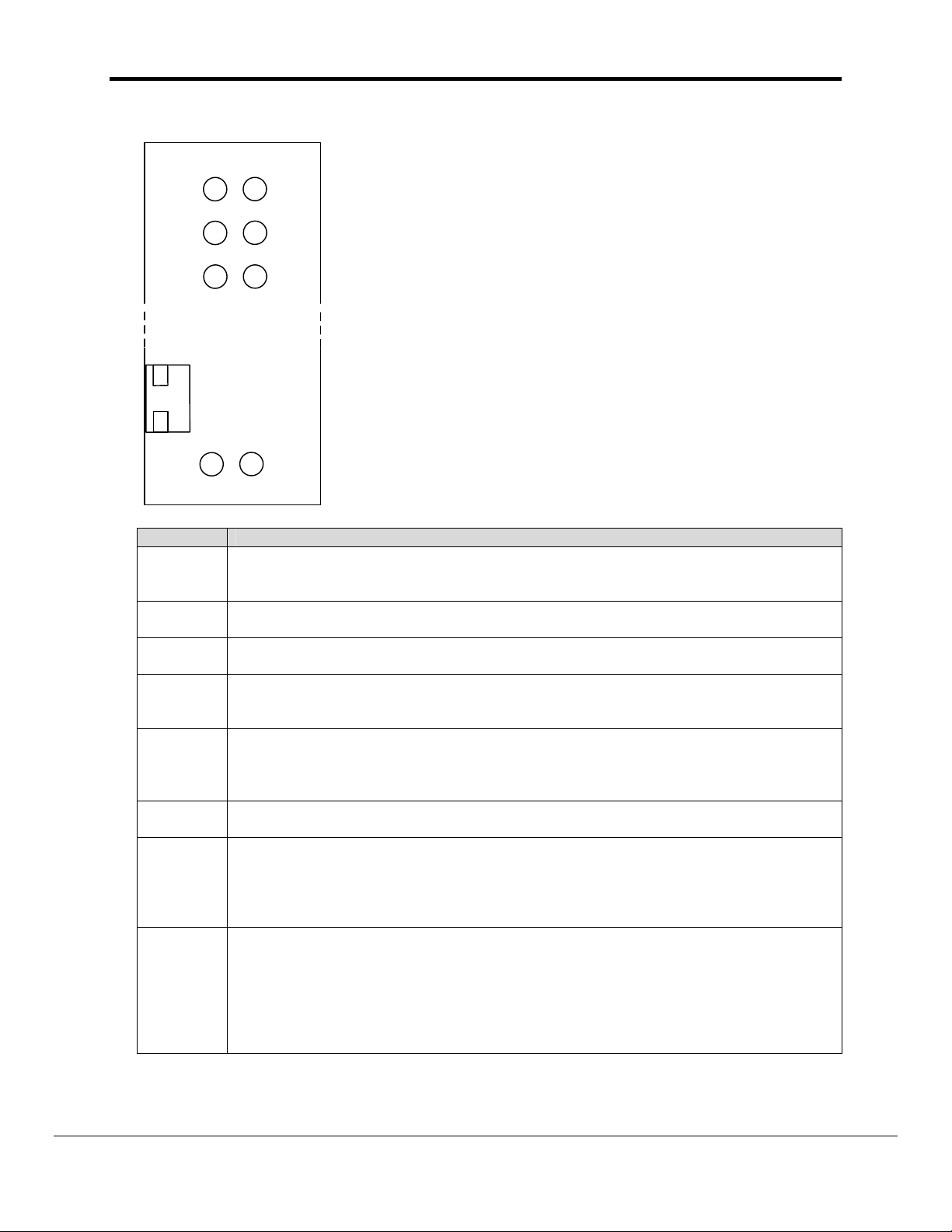

4.1. SlotServer Ports and Displays

Note that there are several hardware ports available on the SlotServer card, but that this

SlotServer model only makes use of a select few. The ports and displays of interest are as

shown in the diagram below:

Scrolling display shows card messages

Card Status Indicators show general card

Service Pin for LonWorks Commissioning

Communications Status LED’s show status of

communications and card software.

TP/FT10 LonWorks Connection

Ethernet Port. Used for configuration and

Ethernet Protocols.

RS-485 Port. Specify as R1 in the

Scrolling Display

This will Display an OK status when the SlotServer has powered up successfully.

Card Status Indicators:

The Comm and OK lights will indicate green when the SlotServer has powered up

successfully. The Sys indicator will indicate green if the external nodes are all

communicating properly; and red otherwise.

Service Pin

To be used for commissioning the SlotServer into a LonWorks network

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 8

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 8 of 34

These lights are related to the two Ethernet network ports provided on the FieldServer.

Communications Status LED’s

Run

Node Off

Sys Err

10/100

Act

Rx

LonSvc

Conf Err

Com Err

Tx

LED Description

When the SlotServer is powered up, this light will start flashing after approximately 2

Run

LonSvc

NodeOff

Conf Err

Sys Err

Com Err

RS-485

(R1)

minutes. If this light does not flash, it is an indication that the firmware is not running,

and that the SlotServer will not be operating.

This light will flash when the card’s Neuron chip is unconfigured, and will extinguish

when the SlotServer has been commissioned into a Network.

This light indicates that a device bound to the SlotServer on the LonWorks network is

not communicating. Use the LonWorks Network Manager to troubleshoot the problem.

This light indicates an error in the configuration of the card. Since this model is shipped

pre-configured, this light should never come on unless the card configuration is

tampered with

This light indicates that an unexpected operation state occurred. The light can be reset

by cycling power to the card. If the error re-occurs persistently, then contact

FieldServer Technical support for assistance with troubleshooting after setting up the

trade port as shown in Appendix A.

This light indicates that a communication error occurred. Use the LonWorks Network

Manager to troubleshoot the problem, or refer to Appendix B.1.

These lights are related to the RS-485 serial ports provided on the FieldServer. The

Rx (Receive) light will flash red if the FieldServer is receiving data. The Tx (Transmit)

light will flash red if the FieldServer is sending data. (Note that due to the nature of 2wire RS-485 the Rx light will flash every time the Tx light flashes too). The frequency of

the flashing is directly related to the frequency of data transfer.

The 10/100 light will be green if the physical connection to the network hub is running

Ethernet

Lights

(N1,N2)

at 100 MBits/s. If the light is off, the connection is running at 10 MBits/s. The Act

(Activity) light will indicate activity on the network. The frequency of flashing is directly

related to the network activity. It does not necessarily mean data is being received by

the FieldServer. Note that Ethernet Port N2 supports 10 or 100 MBits/s, whereas N1

only supports 10 MBits/s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 9

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 9 of 34

TP/FT10 LonWorks connection

This two wire connection is polarity insensitive and can be multi-dropped into a LonWorks

Network.

Ethernet Port

The Ethernet port can be used for configuration and troubleshooting, as well as for Protocols

that require an Ethernet connection. Use standard Ethernet cables for this connection.

RS-485 Port

This is a standard 2-wire RS-485 port. Specify as R1 in the configuration.

4.2. Inside Cover Door Label

A label has been provided on the inside of the cover door for the User to document

important or useful configuration parameters used. In particular, special provision has been

made to document the Ethernet port IP parameters, as well as the LonWorks DSN

(Domain/Subnet/Node) allocated by the Network Manager. These fields are there to be

utilized at the User’s discretion.

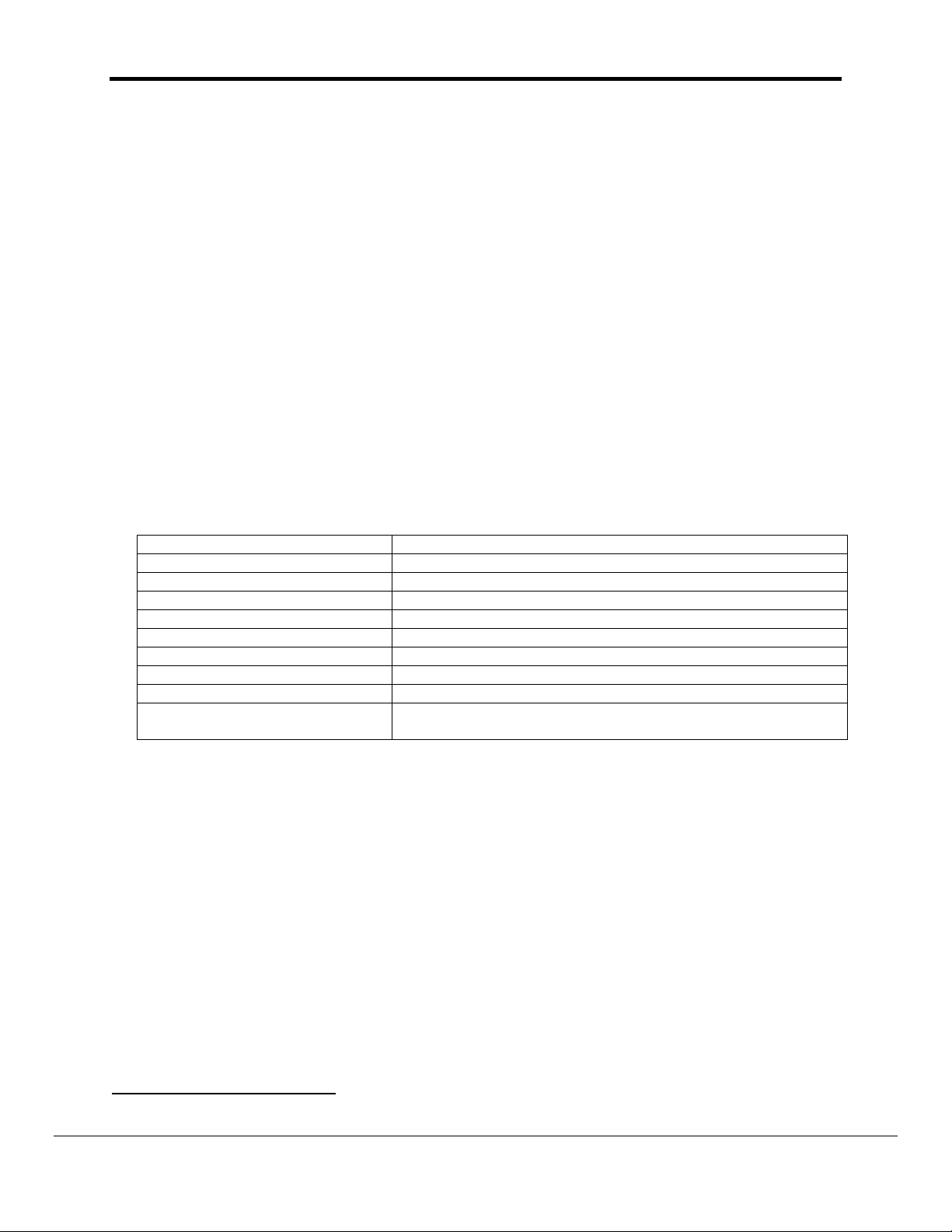

4.3. Technical Specifications

Slot width 1

BackPlane Current Load 0.6A

Operating Temperature 0-60 Deg C (32-140 Deg F)

Storage Temperature -40 – 85 Deg C (-40 – 185 Deg F)

Humidity 5-95% (Non-Condensing)

Allen Bradley Platform: ControlLogix 1756 Rack

LonWorks Connection type: TP/FT-10

Ethernet port 10/100 MB/sec.

RS-485 port 2-wire, half duplex.

Approvals1

UL 60950-1:2003

CAN/CSA-C22.2 No.60950-1-03

1

Refer to Error! Reference source not found. to view Certificates.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 10

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 10 of 34

5. SlotServer Topology

The SlotServer connection varies based on the protocol being used. Refer to the appropriate

driver supplement for more details. The diagram in section 4.1 shows the ports available on the

SlotServer for each of the protocols.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 11

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 11 of 34

6. Configuring the CPU interface to the SlotServer

6.1. CPU interface Description

The SlotServer Data Images (Data Arrays) share data with the ControlLogix CPU tags using

the backplane for communication and the FieldServer Logix driver. To map the Logix Driver,

the Driver needs to be configured in the SlotServer Configuration. The information that

follows details the configuration parameters that can be used for this driver. The driver can

only act as an I/O Server (Adapter) to a Control-Logix CPU.

Max Nodes Supported

SlotServer Mode Nodes Comments

Server 1 Only one IO image connection supported

6.2. Configuring the SlotServer as a Logix I/O Server

For a detailed discussion on SlotServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the

factory defaults provided in the configuration files included with the SlotServer (See “.csv”

sample files provided with the SlotServer).

The configuration file tells the SlotServer about its interfaces, and the routing of data

required. In order to enable the SlotServer for Logix communications, the driver

independent SlotServer buffers need to be declared in the “Data Arrays” section, the

SlotServer virtual node(s) needs to be declared in the “Server Side Nodes” section, and the

data to be provided to the Clients needs to be mapped in the “Server Side Map Descriptors”

section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

6.3. Data Arrays/Descriptors

The configuration file tells the SlotServer about its interfaces, and the routing of data

required. In order to enable the SlotServer for Logix communications, the driver

independent SlotServer buffers need to be declared in the “Data Arrays” section.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Data_Array_Format

Data_Array_Length

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Provide data format. Each Data Array

can only take on one format.

Number of Data Objects. Must be

larger than the data storage area

required by the Map Descriptors for

the data being placed in this array.

Up to 15 alphanumeric

characters

Float, Bit, UInt16, SInt16,

Packed_Bit, Byte,

Packed_Byte,

Swapped_Byte

For IO_Data_Type:

REAL 1-120

INT 1-244

SINT 1-492

DINT 1-120

Page 12

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 12 of 34

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Array_Format, Data_Array_Length

In_1, Float, 76

In_2, Float, 76

Out_1, Float, 76

Out_2, Float, 76

6.4. Server Side Connection Descriptors

Section Title

Connections

Column Title Function Legal Values

Adapter Adapter Name ControlNet

Example

// Server Side Connections

Connections

Adapter

ControlNet

6.5. Server Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID Virtual Node ID 0-15

Protocol Specify protocol used Logix_SS

Timeout IO image connection timeout 0.5s

Retry_Interval Time to retry node online status 0.1s

Recovery_Interval

Interval to recover node to

online status

Example

// Server Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Timeout, Retry_Interval, Recovery_Interval

SlotServer_CPU, 11, Logix_SS, 0.5s, 0.1s, 0.5s

Up to 32 alphanumeric

characters

0.5s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 13

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 13 of 34

IO image to indicate

6.6. Server Side Map Descriptors

6.6.1. SlotServer Specific Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name

Scan_Interval

Name of this Map

Descriptor

Rate at which IO image

data is updated

Up to 32 alphanumeric

characters

Use twice the rate used in

RSLogix e.g. 0.2s

WRBC - to write into Input

Image Data buffer

RDBC - to read from Output

Function

Function of Server Map

Descriptor

Image Data buffer

6.6.2. Driver Specific Map Descriptor Parameters

Column Title Function Legal Values

Node_Name

Name of Node to fetch data

from

IO_Data_Type Data type of IO image

DA_Name_Start2

DA_Count

Name of Data Array to

include in IO image data

Number of Data Arrays to

include in IO image data

Custom Value transferred in

Protocol_Type_ID

protocol of IO image data

One of the node names

specified in “Client Node

Descriptor” above

Use same as used in

RSLogix to add the module

INT (16-bit integer)

SINT (8-bit signed)

DINT (32-bit double)

REAL (32-bit float)

One of the Data Array

names from “Data Array”

section above. Data Arrays

must be named as follows:

DaName_x where x is a

value e.g. DaName_1

1-200

0 - value permitted by

IO_Data_Type3

e.g. 0 - 65535 for INT

2

Refer to Appendix A.6 for information specific to naming Logics driver Data Arrays.

3

T

he update rate decreases as the number of blocks go up. For 25 blocks we have an update rate of

25*RPI = 25*0.1 = 2.5 seconds.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 14

Protocol_Type_ID

DA_Count,

,

4

See the Data Arrays section for the

maximum Data Array lengths allowed per

IO_Data_Type chosen on the Map

REAL, In_1, 2, 0

REAL, Out_1, 2, 0

Node_Name, IO_Data_Type, DA_Name_Start

Function,

Scan_Interval,

The data format should be chosen to

allow no loss of resolution with the

Descriptor.

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

chosen IO_Data_Type of the Map

Descriptor, e.g. don’t use integer here

if you intend transferring float data.

6.6.3. Map Descriptors Example

Refer to Appendix A.6 for information specific to naming Logics driver Data Arrays.

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 14 of 34

Only two Map Descriptors are allowed, one to transfer data to the Logix CPU and one to accept data from the Logix CPU.

// Server Side Map Descriptors

Map_Descriptors

Map_Descriptor_Name,

Input_BP_Image, 0.2s, WRBC, SlotServer_CPU,

Output_BP_Image, 0.2s, RDBC, SlotServer_CPU,

The following Data Arrays section must exist for the above Map Descriptors:

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

In_1, Float, 76

In_2, Float, 76

Out_1, Float, 76

Out_2, Float, 76

4

Page 15

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 15 of 34

7. Programming the ControlLogix CPU for a small SlotServer Interface

The discussion that follows describes the basic steps to set up and test the system for

transferring data between CPU tags and the SlotServer using the I/O image method. The quick

Start example uses LonWorks as the example 3rd Party Protocol. A hardcoded template is filled

with Lon variables is created. Each item uses a different amount of bytes and the total adds up

to 104 Lon Network Variables. This limit of 104 does not apply when using customized data

items – the actual limit is 496 bytes. Refer to the Advanced Project to access more than 104

Network Variables.

7.1. Step 1: Establish an RSLogix project5

• Use File/New to create a new project or File/Open to open an existing project.

Ensure that this is the slot

number in the rack where

your Controller resides.

5

Your Controller may be of a different type to the one shown in the example.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 16

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 16 of 34

your Slot

Server

reside

will be transferred

7.2. Step 2: Add and configure the SlotServer as an IO Module

• Right-click on I/O Configuration and select “New Module”.

• Choose the 1756-MODULE

Choose the

1756-MODULE

Be sure to choose the correct

Slot number in the rack where

Click Next and choose a RPI of 100 ms.

This is the rate at which the I/O image data

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 17

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 17 of 34

Click Finish to complete the Module Properties setup

7.3. Step 3: Write Ladder Program to get Input Data from Data Arrays

• Add a CPS (Synchronous Copy File) Ladder element to synchronize the incoming Data

from the Input Data Arrays. Use the Input Image Data as Source.

You can create the

Destination Tag by right

clicking on Destination and

choosing New Tag.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 18

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 18 of 34

for the Destination

Create a Controller Tag of

Type REAL, dimension of 80

• Add an EQU (Compare if equal) ladder element to check when the first Data Array has been

received. The block number is at offset 2 of the input image.

• Finally, add another CPS ladder element to copy the LonWorks Data from the InData_Copy

Tag to a new Controller Tag, called Lon_In_01. Also create the Tag by right clicking on

Destination and choosing New Tag. The New Tag must be of type REAL and a dimension of

76.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 19

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 19 of 34

Below is the final ladder program to access data from LonWorks Function Block In[0]

Very Important Note!

It is very important to first make a synchronous copy of the input image data before using it. If

this is not done, the input data cannot be guaranteed to be from a specific SlotServer Data

Array.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 20

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 20 of 34

7.4. Step 4: Write Ladder Program to Send Output Data to Data Arrays

This step demonstrates how to write data to the Data Array Out[0]

• Create a Controller Tag called Lon_Out_01 of type REAL[80].

• Add a new rung to the Ladder program and add a MOV element to move a block number

value of 1 into Lon_Out_01[2].

• Finally add a CPS (Synchronous Copy File) element to copy the full Lon_Out_01 tag into

the Output Image Tag.

The LonWorks Data are present from Lon_Out_01[4] to Lon_Out_01[79]

You can create a User Defined Data Type to replace the type of Lon_Out_01 mapping the

points to LonWorks point names.

Very Important Note!

It is very important to only update all the data of the Output Image Tag once using a

Synchronous File Copy element. It is not permissible to update the block number into the

Output Image Tag and then the data as this will cause an asynchronous transfer of data.

7.5. Step 5: Download the RSLogix Program and Run

Use the Who Active or Communications Path directly to Download and Run the Program on

the Controller / CPU.

7.6. Step 6: Set up the third party connection

In this example, this step would involve binding the LonWorks variables using a LonWorks

Network Manager..

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 21

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 21 of 34

8. Programming the ControlLogix CPU for larger SlotServer Interfaces

The previous example is for accessing only one Data Array. The following steps describe how to

access multiple Data Arrays.

8.1. Multiple Input Data Arrays

In this example, we access Input Data Arrays In[1] up to In[24]. We simply add to the

existing ladder program as shown in the Quickstart example. Add a branch after the CPS

element that copies the input image Tag and copy and paste EQU and CPS elements from

the first rung. Create a new Input Tag for Lon_In_02 of type REAL and dimension 76.

Finally, remember to set the EQU Source B value to 2 to compare for incoming data from

the 2nd LonWorks functional block which is In[1].

See the ladder program below how to add In[1].

Very Important Note!

It is very important to first make a synchronous copy of the input image data before using it.

If this is not done, the input data cannot be guaranteed to be from a specific LonWorks

Function Block.

8.2. Accessing Multiple Output Data Arrays

To access more output Data Arrays is slightly more complicated since we need to create a

Multiplexer in Ladder.

The basic steps include:

• Create a Counter which counts up every 100ms.

• Place the counter value into the Lon_Out_xx Tag at offset 2.

• Copy and the whole Tag into the output Data Image Tag for transferring to the LonWorks

network.

The example program below shows an output counter that can count up to 25 which allows

the transfer of data into 25 Output Function Blocks. Only 2 rungs are shown to transfer data

for blocks 1 and 2. Add more rungs with more Lon_Out_xx tags to transfer data to other

output Function Blocks.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 22

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 22 of 34

It is possible to add up to 65535 blocks. The update rate decreases as the number of

blocks goes up. For 25 blocks we have an update rate of 25*RPI = 25*0.1 = 2.5 seconds.

You can restrict the upcount to a certain value, e.g.2 by changing the Preset value of the

CTU element.

Very Important Note!

It is very important to only update all the data of the Output Image Tag once using a

Synchronous File Copy element. It is not permissible to update the block number into the

Output Image Tag and then the data as this will cause an asynchronous transfer of data.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 23

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 23 of 34

Appendix A. Advanced Topics

Appendix A.1. Description of Data Transfer Process

The data connection from the SlotServer to the Logix CPU consists of 496 bytes of input

and 496 bytes of output data. Of the 2 Map Descriptors specified, the one with the WRBC

function writes data to the Logix CPU filling its input data, and the one with the RDBC

function accepts the Logix CPU’s output data.

The Map Descriptor’s IO_Data_Type field organizes the 496 bytes into either Bytes (SINT),

Words (INT) or Double Words (DINT or REAL) reducing the number of elements that can be

transferred. Of the resulting number of elements, the first 4 are reserved for the IO image

header (Refer to Appendix A.2).

The SlotServer acts as a multiplexer when it sends data to the Logix-CPU and as a

demultiplexer when it receives data from the Logix-CPU.

The diagram on the next page describes the SlotServer operation methodology:

For input data, the input data from the external device is placed into the 25 Data Arrays

numbered In_1 to In_25. The SlotServer sends the data from these Data Arrays over the IO

image connection one at a time by placing the block number at offset 2 of the image header

and the data from offset 4. The reverse happens at the Logix-CPU where a demultiplexer is

implemented in Ladder to route the data to each of the 25 CPU Tags.

For output data, the Logix-CPU has to place the data and block number into the Output

Image Tag and send it to the SlotServer. The SlotServer then demultiplexes the data by

placing it into the appropriate Out_x Data Array depending on the block number specified in

the IO image header.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 24

In [24]

Modbus

Metasys

eg. LonWorks

External Device

In [1]

In [0]

Input Data

Input Data

SlotServer

Multiplexer

In_1

In_2

In_3

In_4..In_25

Output Data

In_x

Out [1]

Out [0]

Output Data

DeMultiplexer

Data

Out [24]

Out_1

Out_2

Out_3

Out_4..Out_25

Out_x

Data

Protocol Type

Node Status

Data Block Number

Reserved

Offset Description

0

1

2

3

4

...

79

Logix CPU

Controller Tag

Input Data Image

Local:Slot:I:Data

Controller Tag

Output Data Image

Protocol Type

Node Status

Data Block Number

Reserved

Offset Description

0

1

2

3

4

...

79

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Local:Slot:O:Data

SlotServer Data Transfer over IO Data Image

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 24 of 34

Page 25

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 25 of 34

Appendix A.2. The IO image header

The IO image header appears at the start of every block of image data that is transferred to

or from the SlotServer to the Logix CPU. It consists of 4 items of data:

Offset into image

data block

0

1

2

3 Reserved Not used

Item Description

The value specified under the Map Descriptor’s

Protocol

Type

Node

Status

Block

Number

Protocol_Type_ID field is transferred to the Logix CPU

and can be used to decode the protocol. The same

value has to be transferred back to the SlotServer to

indicate the protocol.

This field is automatically filled in by the SlotServer if a

Node Status Data Array with the name

SlotServerNodes is declared. Its value can be used in

the Logix CPU to check the status of Nodes connected

to the SlotServer.

The number of the Data Array for which the IO image

data is valid for, e.g. a block number of 1 will indicate

the data is to or from DataArray_1

Appendix A.3. How to obtain Node Status from the SlotServer

By declaring the following Data Array, the Node Status field in the IO image header will be

filled in with the Node Statuses of all Nodes declared on the SlotServer:

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length, Data_Array_Function

SlotServerNodes, Bit, 256, Node_Status

Note: The Data Array Name must be as shown for this function to work correctly.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 26

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 26 of 34

Appendix A.4. Dealing with ControlLogix RPI Settings

When setting up the SlotServer for ControlLogix, it is necessary to select the Request

Packet Interval (RPI). The RPI is the rate at which data is transferred to and from the

SlotServer IO buffers. The following factors need to be considered when deciding on an

RPI:

1. Minimum RPI setting for the SlotServer is 100ms.

2. The Scan_Interval parameter of the two Logix Map descriptors must be larger than the

RPI to ensure smooth communications and prevent timeouts.

3. The number of message blocks used does not affect the RPI setting, but will affect the

effective update rate for any one message block. The effective update rate for data

to/from the SlotServer’s Data Arrays to the Logix CPU tags is the scan interval of the

block since data is updated to the block every scan interval. Increasing the number of

blocks will decrease the effective update rate per block. This update rate does not

include the time taken to obtain data from the third party network, which is dependant

entirely on the third party protocol involved.

4. The program scan rate should be set to run faster than the RPI. We recommend twice

as fast. If the ladder program scan is slower than the RPI rate, it would be possible to

miss some blocks altogether. It is further recommended that diagnostics be added to

the ladder program to detect missed blocks

The effective update rate can be calculated using the following formula:

Effective update rate (EUR) = Scan interval * (number of msg block pairs6)

e.g. (EUR) = 0.2s * 1 = 0.2s

when using only one input and output block

e.g. (EUR) = 0.2s * 25 = 5s

when using the full LonWorks Open Interface configuration.

6

a message block pair consists of an output and input block

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 27

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 27 of 34

Appendix A.5. Installing SlotServer on a Remote Rack using CNB Cards

Appendix A.5.1. Hardware and Software requirements

In order to perform this application, the following hardware and software is required as a

minimum:

• At least two 1756 racks, where one rack contains the CPU and the other rack

contains the SlotServer

• Two Controlnet CNB cards (with cable for connection) to connect the racks to each

other

• RSlinx

• RSLogix

• RSNetworx

• SlotServer EDS file (Available on SlotServer CD, or call Technical Support)

Note that it is possible to connect to SlotServer on a remote rack using other 1756

bridging cards. This chapter only deals with CNB, but the principles for using other

bridging cards are similar.

Appendix A.5.2. Setup

• Install the CPU and the first CNB card in the local rack.

• Install the second CNB card and the SlotServer in the remote rack.

• Connect the ControlNet Network

• Power up the racks

• Install the SlotServer EDS File using the RSLinx Hardware EDS Installation Tool.

• Make sure the SlotServer has a valid configuration loaded. The default configuration

shipped with the SlotServer should suffice.

Appendix A.5.3. RSLogix configuration

In order to see the SlotServer from the CPU, the Hardware must be configured in

RSLogix as follows:

• Configure the cards in the local rack in the I/O Configuration section, including the

CPU and the local CNB card.

• Right click on the local CNB card and add the remote CNB card using the “New

Module” function.

• Right Click on the remote CNB card, and add the 1756 Backplane

• Right Click on the 1756 Backplane and add the cards that are present in the remote

rack, including the SlotServer (As a generic I/O module-see earlier section on how to

do this)

• Save the RSLogix configuration, and download it to the PLC.

The finished I/O configuration should look similar to this:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 28

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 28 of 34

Appendix A.5.4. RSNetWorx configuration

• Open up RSNetWorx and add the two CNB Cards to the Network by dragging them

onto the Network in the Graph tab (Must be done with Edits Enabled). Follow the

prompts on the screen to configure the Chassis being used, and the cards in each

Chassis (Rack).

• Go Online with RSNetWorx, and then press “save”. This will transfer the RSNetWorx

Configuration to the Keeper.

The final RSNetworx Configuration should look similar to this:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 29

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 29 of 34

Appendix A.5.5. Testing

The SlotServer should now be visible to the CPU. Go Online with RSLogix and check

the Input buffer of the SlotServer for data. A good check is to examine offset 2 of the

input tag for a non-Zero value. If the SlotServer is multiplexing (DA_Count >1), then this

value will be cycling through the Buffer numbers, otherwise if DA_Count=1, then offset 2

will be fixed at 1. If offset 2 is zero, then the SlotServer is not being seen by the CPU,

and Diagnostics will need to be performed using RSNetWorx and RSLogix to determine

the cause of the problem.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 30

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 30 of 34

Appendix A.5.6. Connection limitations -Controlling the SlotServer using

ControlNet

• Only one remote I/O rack is supported.

• I/O can only be added online using a direct connection.

The following Vendor information provides clarification:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 31

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 31 of 34

Appendix A.6. Rules for Naming Logix driver Data Arrays

Unlike most other FieldServer drivers, the Logix driver attaches significance to the name of

the Data Array used in the Logix Driver Map Descriptor. This is done to allow the user to

easily declare a series of Data Arrays to be multiplexed through the input and output buffers

of the SlotServer. Most users will probably stick to a naming convention where the Data

Arrays are named In_1 to In_x for input buffer arrays, and Out_1 to Out_y for output buffer

arrays (where x and y are numbers reflecting the maximum input and output Array numbers

respectively).

For example, an application that multiplexes 6 Data Arrays worth of data through the Input

buffer will probably use data arrays named In_1 though In_6. In this example,

DA_Name_Start is declared as In_1, and DA_Count is declared as 6.

It is not absolutely necessary to use the naming convention described above, however, and

while the user has some latitude for declaring names, the following restrictions must be

understood before attempting a different naming convention:

• The Data Array name must end in _x, where x is a positive integer number.

• The total length of the Data Array name (including _x) must not exceed 15 characters.

• No leading zeros should be used in the _x number (For example, use _5, not _05)

• The “x” part of the _x in the data array name will be the number shown in offset 2 of the

input buffer for the purposes of de-multiplexing in the CPU.

• There can only be one Map Descriptor for linking Data Arrays to the input buffer, and

one Map Descriptor for linking Data Arrays to the output buffer (Using wrbc in the

function parameter links the Map description to the input buffer, and using rdbc links the

map description to the output buffer). This means that trying to map Data Array number

sequences that are not continuous will not be possible (For example, you can map

numbers 5 through 25, but you cannot map numbers 1 through 3, and then 5 through 8

at the same time).

• The Data Arrays must be declared individually in the Data Arrays Section. Declare all

data arrays, not just the start Data Array.

The following examples describe legal and illegal naming conventions respectively:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 32

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 32 of 34

Example 1: Legal Map Descriptors:

Map_Descriptors

Map_Descriptor_Name, Scan_Interval, Function , Node_Name, IO_Data_Type, DA_Name_Start, DA_Count

Input_BP_Image, 0s, WRBC, CPU1, INT, Test_5, 2

Output_BP_Image, 0s, RDBC, CPU1, INT, Test_3, 2

Example 2: Illegal Map Descriptors:

Map_Descriptors

Map_Descriptor_Name, Scan_Interval, Function, Node_Name, IO_Data_Type, DA_Name_Start, DA_Count

Input_BP_Image, 0s, WRBC, CPU1, INT, Test_05, 2

Output_BP_Image, 0s, RDBC, CPU1, INT, Test, 2

Output_BP_Image2, 0s, RDBC, CPU1, INT, Test_-3, -5

Output_BP_Image3, 0s, RDBC, CPU1, INT, Test6, 2

Page 33

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 33 of 34

Appendix B. Troubleshooting tips

Appendix B.1. Things to check when communications fail.

• Check for loose cabling on the third party network

• Verify that the correct program is loaded to the CPU

• Verify that the correct data types for the tags have been used.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 34

FS-RA-CLX_SlotServer_Instruction_Manual_(T17011) Page 34 of 34

THIS PAGE INTENTIONALLY LEFT BLANK

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldServer.com

Loading...

Loading...