Page 1

-

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8704-16 Omron FINS

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2004

Page 2

FS-8704-16 Omron FINS Manual Table of Contents

TABLE OF CONTENTS

1. Omron FINS Description...................................................................................... 1

2. Driver Scope of Supply........................................................................................ 2

1.01 Supplied by FieldServer Technologies for this driver ....................................... 2

1.02 Provided by the Supplier of 3rd Party Equipment.............................................. 2

2.1.1. Required 3rd Party Hardware.........................................................................2

2.1.2. Required 3rd Party Software..........................................................................2

2.1.3. Required 3rd Party Configuration...................................................................2

3. Hardware Connections ........................................................................................3

1.03 Hardware Connection Tips / Hints.................................................................... 3

1.04 Example of Omron PLC Configuration using Omron ETN11 Module. .............. 4

4. Configuring the FieldServer as a FINS Client.................................................... 6

1.05 Data Arrays/Descriptors ................................................................................... 6

1.06 Driver Specific FieldServer Parameters ........................................................... 7

1.07 Client Side Connection Descriptors.................................................................. 7

1.08 Client Side Node Descriptors ...........................................................................8

1.09 Client Side Map Descriptors............................................................................. 9

4.1.1. FieldServer Related Map Descriptor Parameters..........................................9

4.1.2. Driver Related Map Descriptor Parameters................................................... 9

4.1.3. Timing Parameters......................................................................................10

4.1.4. Map Descriptor Example 1 – IO Read.........................................................11

4.1.5. Map Descriptor Example 2 – IO Write.........................................................12

4.1.6. Map Descriptor Example 3: Clock Read:.....................................................13

4.1.7. Map Descriptor Example 4: Clock Write:..................................................... 13

4.1.8. Map Descriptor Example 5: Read CPU Cycle Times: ................................. 13

4.1.9. Map Descriptor Example 6: Run-Stop PLC:................................................ 14

4.1.10. Map Descriptor Example 7: Read CPU Status:........................................14

5. Configuring the FieldServer as a FINS Server.................................................15

1.010 Server Side Connection Descriptors .............................................................. 15

1.011 Server Side Node Descriptors ........................................................................ 16

1.012 Server Side Map Descriptors.......................................................................... 17

5.1.1. FieldServer Specific Map Descriptor Parameters........................................17

5.1.2. Driver Specific Map Descriptor Parameters.................................................17

5.1.3. Map Descriptor Example 1: IO Read...........................................................18

5.1.4. Map Descriptor Example 2: IO Write...........................................................19

5.1.5. Map Descriptor Example 3: Clock Read:.....................................................19

5.1.6. Map Descriptor Example 4: Clock Write:..................................................... 19

5.1.7. Map Descriptor Example 5: CPU Cycle Times:...........................................19

5.1.8. Map Descriptor Example 6: Run-Stop PLC:................................................ 20

5.1.9. Map Descriptor Example 7: CPU Status:.....................................................20

Appendix A. Advanced Topics................................................................................ 21

Appendix A.1. Driver Map Descriptor Parameter’s Bounds ..................................... 21

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 3

FS-8704-16 Omron FINS Manual Table of Contents

Appendix A.2. PLC status to execute commands.................................................... 22

Appendix A.3. End Codes........................................................................................ 23

Appendix B. Driver Notes ........................................................................................ 30

Appendix B.1. Data Storage .................................................................................... 30

Appendix B.2. Driver stats ....................................................................................... 32

Appendix B.3. Driver Error Messages...................................................................... 33

Appendix C. Troubleshooting tips.......................................................................... 35

Appendix C.1. Connection Tips & Hints................................................................... 35

Appendix D. Revision History .................................................................................37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 4

FS-8704-16 Omron FINS Manual Page 1 of 37

1. Omron FINS Description

The Ethernet Omron FINS driver allows the FieldServer to transfer data to and from

devices over Ethernet using Omron FINS protocol. The FieldServer can emulate either

a Server or Client.

FINS is an Omron protocol which can be used by a PLC program to transfer data and

perform other services with a remote PLC connected on an Ethernet Network. It can

also be used by remote devices such as PC’s and FieldServer’s to transfer data and

perform other services.

The protocol uses the Ethernet protocol called UDP to carry the FINS messages back

and forth. The UDP protocol is not connection based and reliability is achieved by using

confirmation messages.

This Ethernet Driver can be used to transfer data to and from the Nodes supporting

FINS communications.

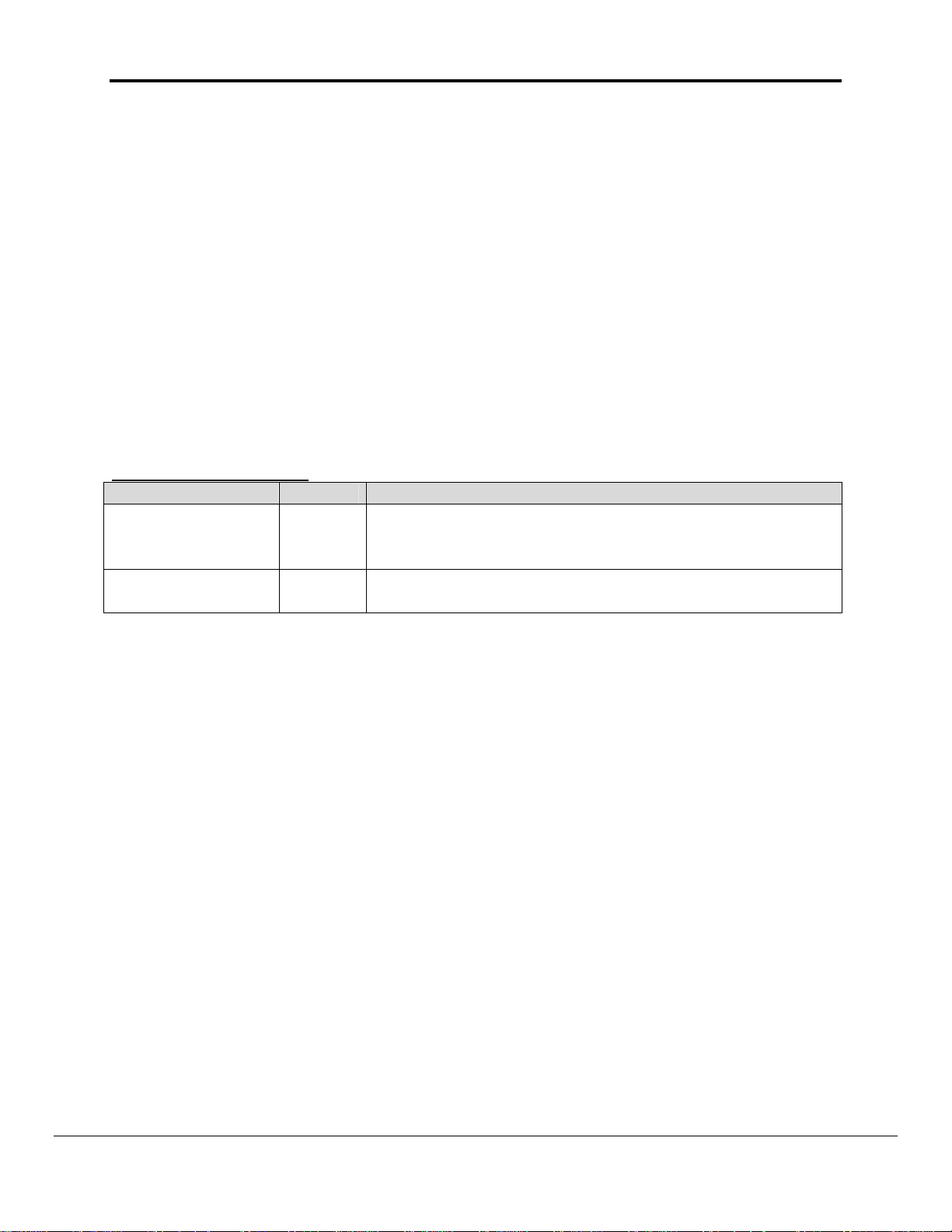

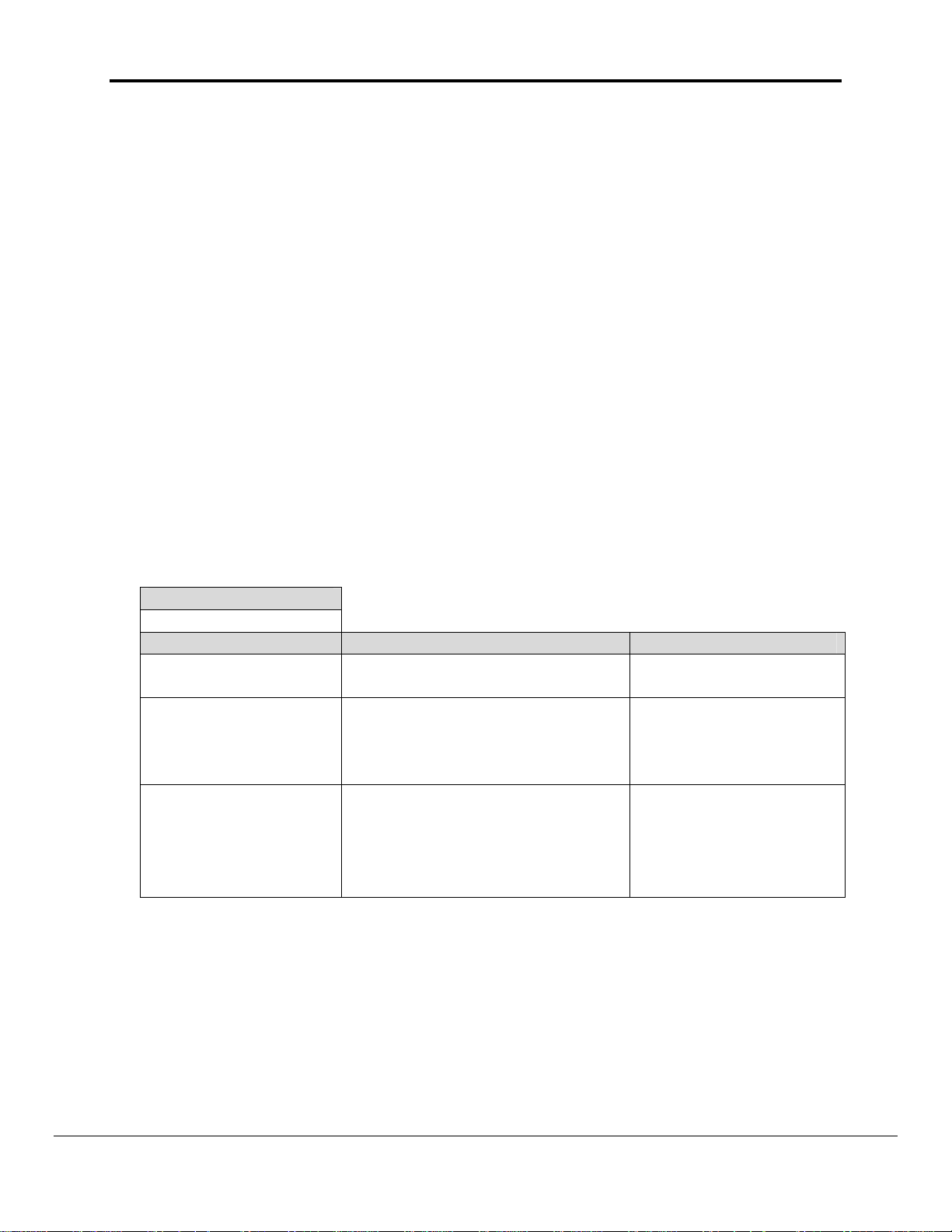

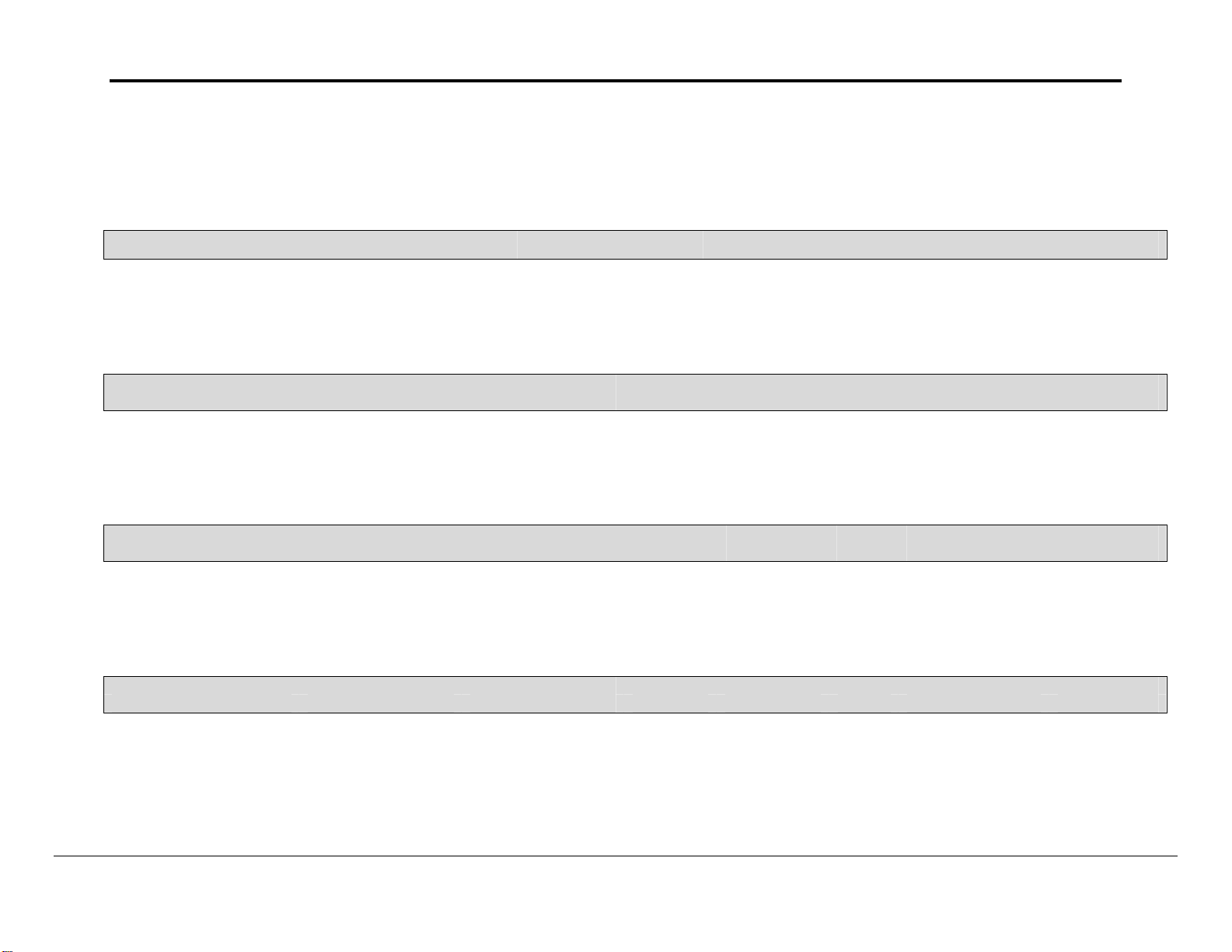

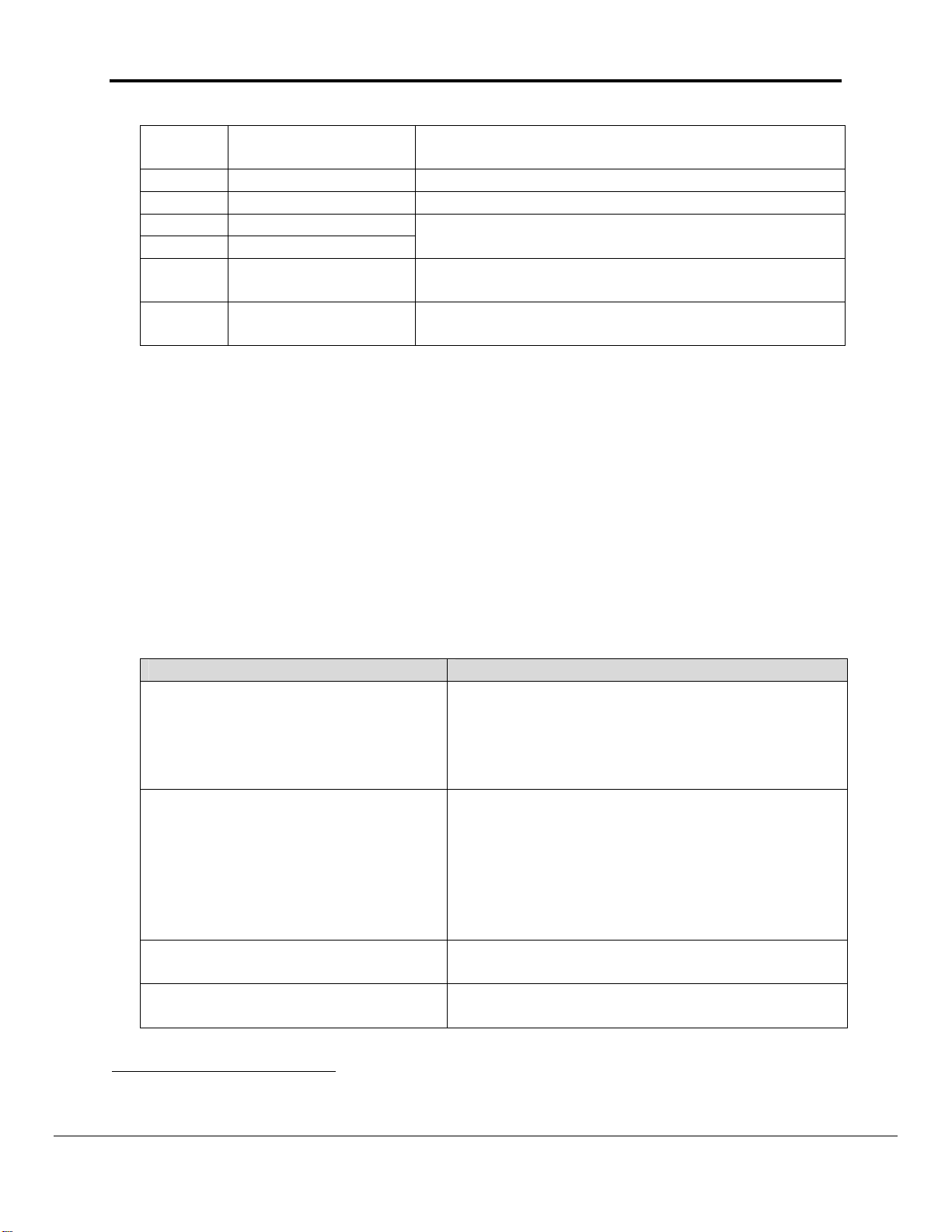

Max Nodes Supported

FieldServer Mode Nodes Comments

Omron limit the set of permitted nodes to 126. They are

Client 126

numbered 1 to 126 corresponding to the last byte of the

remote node IP address.

Server 20

The FieldServer can emulate a maximum of 20 Omron

FINS servers.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 5

FS-8704-16 Omron FINS Manual Page 2 of 37

2. Driver Scope of Supply

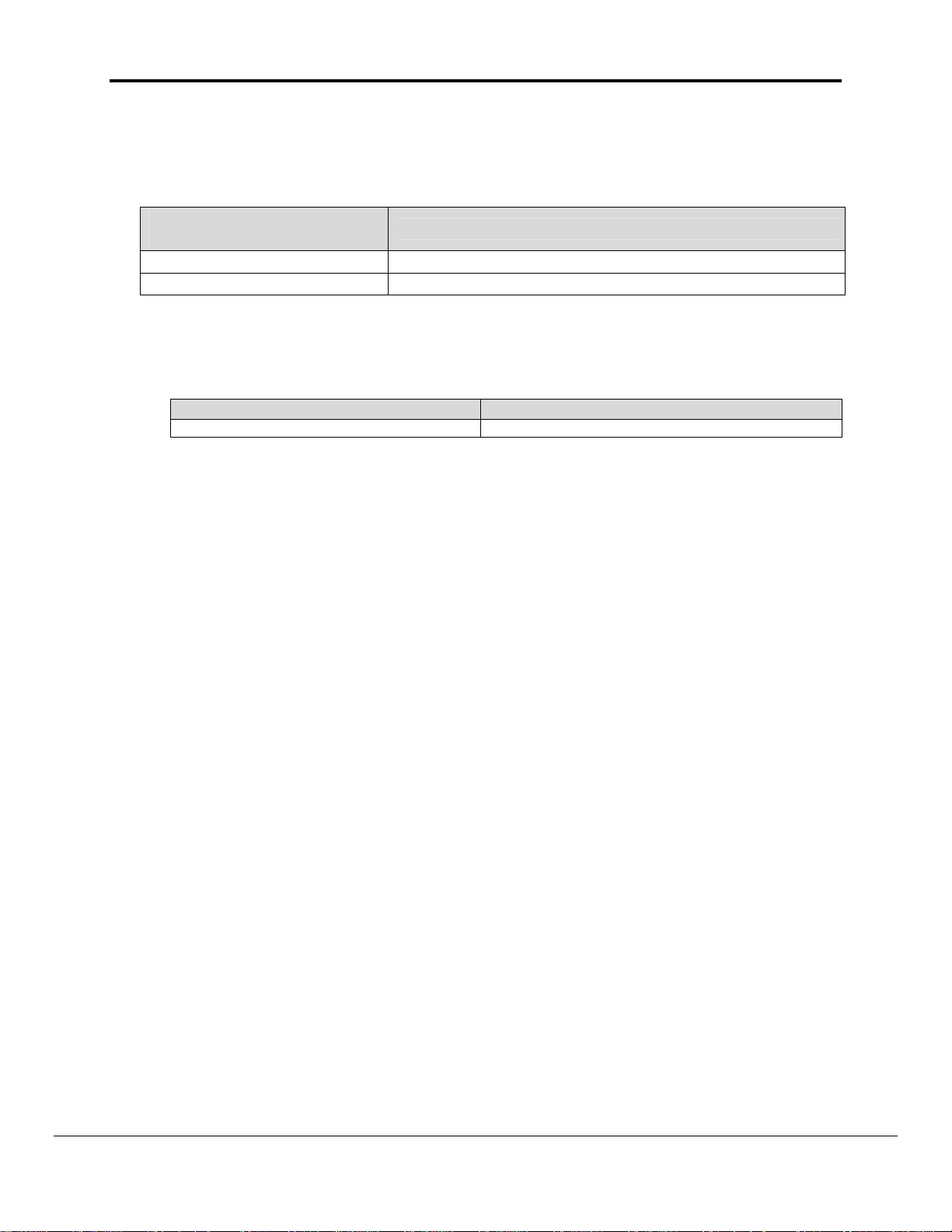

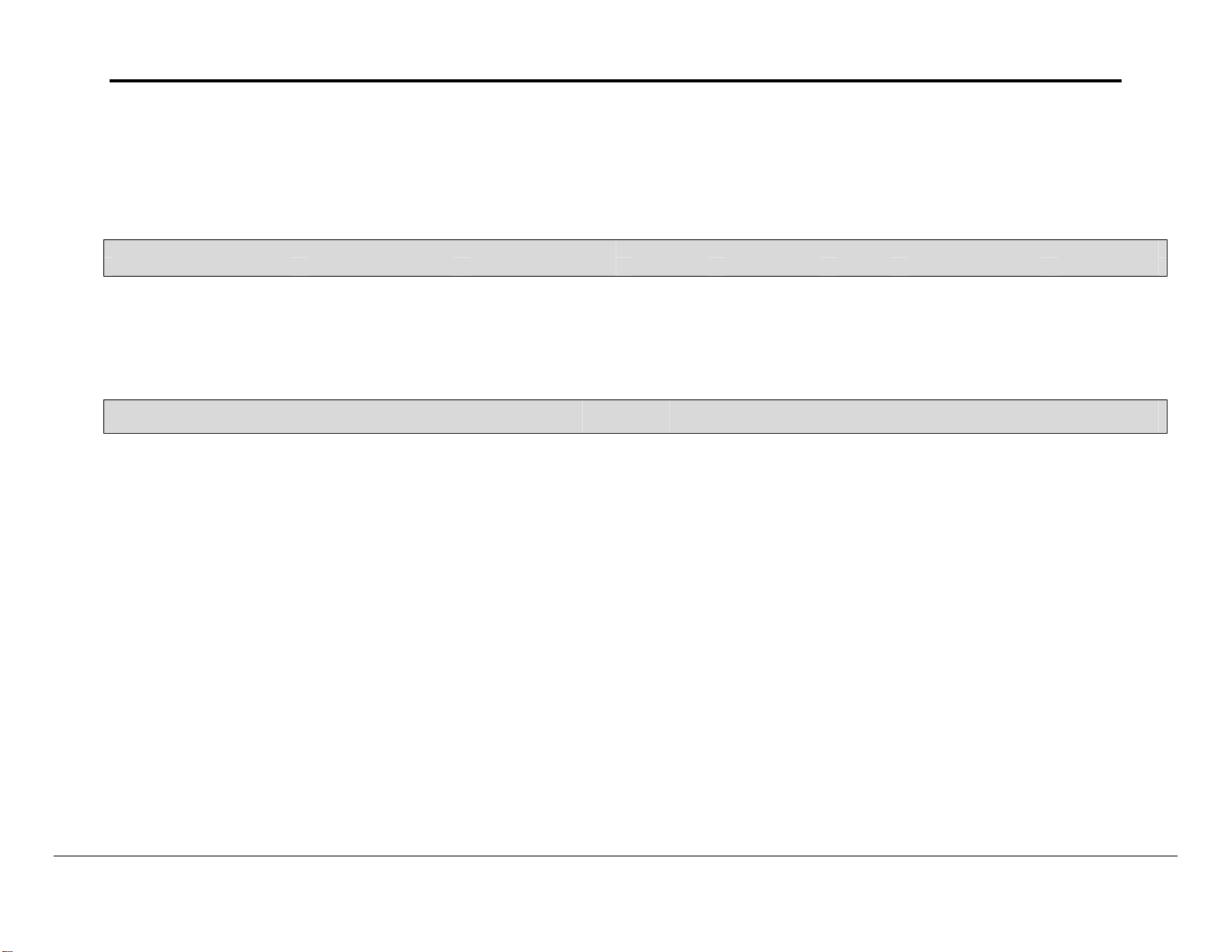

1.01 Supplied by FieldServer Technologies for this driver

FieldServer Technologies

PART #

Description

FS-8915-10 UTP cable (7 foot) for Ethernet connection

FS-8704-16 Driver Manual.

1.02 Provided by the Supplier of 3rd Party Equipment

2.1.1. Required 3rd Party Hardware

Part # Description

2.1.2. Required 3rd Party Software

CX-Programmer Software or any other compatible Software by Omron to setup

the PLC

2.1.3. Required 3rd Party Configuration

The Omron PLC device needs to be set into the Automatic Address Generation

mode using the CX-Programmer or any other compatible Software.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 6

FS-8704-16 Omron FINS Manual Page 3 of 37

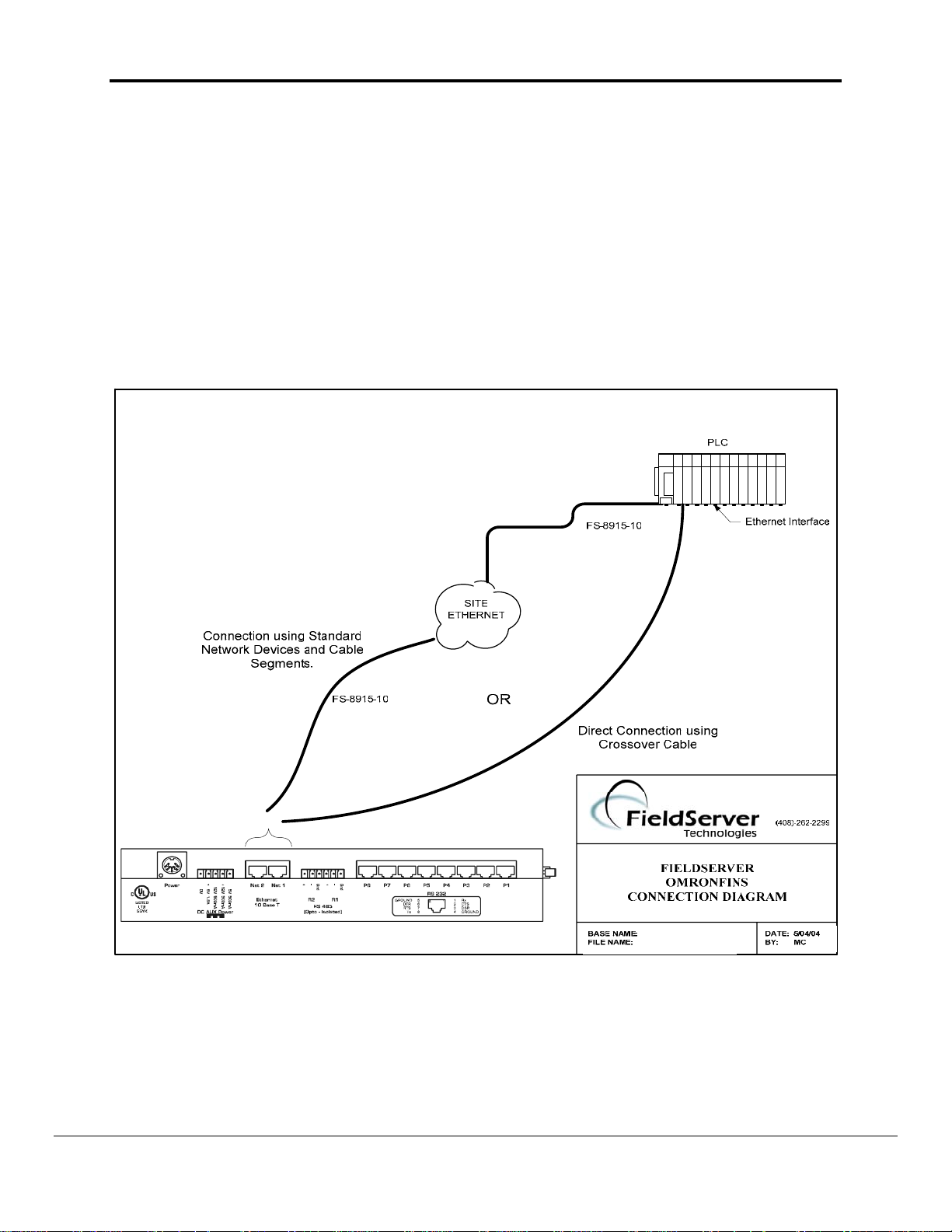

3. Hardware Connections

The FieldServer is connected to the PLC as shown in connection drawing.

Configure the PLC according to manufacturer’s instructions to work with other FINS

supported device.

1.03 Hardware Connection Tips / Hints

If communication doesn’t start check the following.

1. Are the FieldServer and PLC on the same network?

2. Are all intended Nodes configured to communicate on FINS?

3. Are all FINS Nodes configured to use the same Port Number?

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 7

FS-8704-16 Omron FINS Manual Page 4 of 37

4. Is the Network healthy?

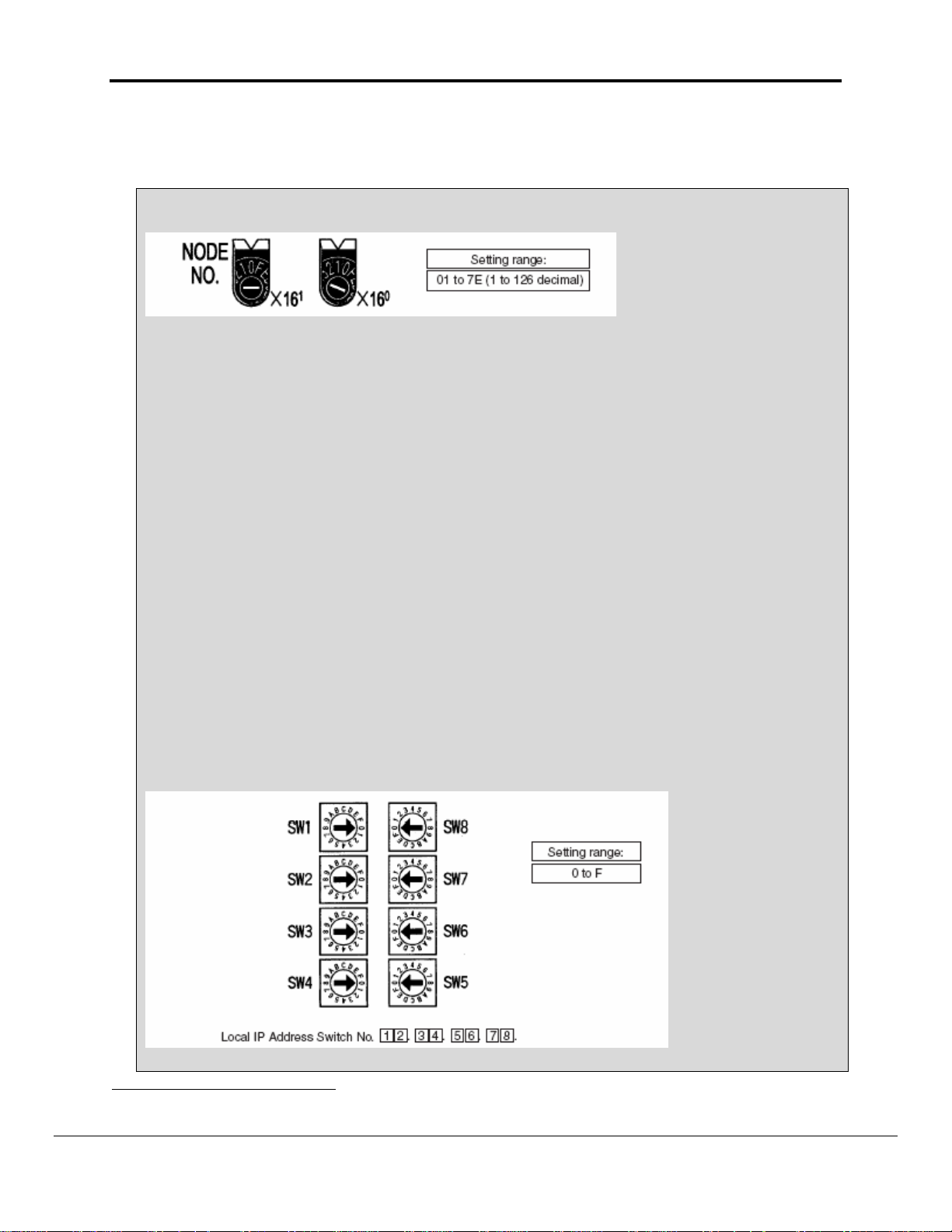

1.04 Example of Omron PLC Configuration using Omron ETN11 Module.1

Setting the Node Number

With the FINS communications service, when there are multiple Ethernet Units connected to the

Ethernet network, the Ethernet Units are identified by node numbers. Use the node number switches

to set the node number between 01 and 7E hexadecimal (1 to 126 decimal). Do not set a number

that has already been set for another node on the same network.

The left switch sets the sixteens digit (most significant digit) and the right switch sets the ones digit

(least significant digit). The node number is factory set to 01. When using the automatic generation

method for address conversion, set the node number to the same value as that of the local IP

address switches. If this is not possible, then either the IP address table method or the combined

method must be used for address conversion. For details, refer to 4-2 CPU

Bus Unit System Setup. If the FINS communications service is not being used over the Ethernet

network, then there is no problem if the node number duplicates that of another Ethernet Unit. The

node number must still be set from 01 to 7E, however, or the ERC indicator will light.

Note Turn OFF the power supply before setting the node number.

Setting the Local IP Address

The nodes on an Ethernet network are identified by IP addresses. Each IP address is set with 32 bits

of binary data. These 32 bits are divided into four 8- bit fields called octets, and each octet is

expressed as four decimal numbers. At CS-series Ethernet Units, four bits are expressed as a

hexadecimal digit, and the eight hexadecimal rotary switches (the local IP address switches) on the

back of the Unit are used to set the local IP address. Set the eight switches in hexadecimal as shown

below, combining SW1 and SW2, SW3 and SW4, SW5 and SW6, and SW7 and SW8. Each switch

can be set from 0 to F.

1

The following notes are extracted from the Omron Manual “W343-E1-05 9/03”

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 8

FS-8704-16 Omron FINS Manual Page 5 of 37

The switches are all factory-set to 0 (00.00.00.00). The Ethernet Unit cannot be used with this

setting; a proper IP address must be set.

The following settings cannot be made for the IP address, or the ERC indicator will flash.

All bits in the network number field set to 0 or 1.

All bits in the host number field set to 0 or 1.

All bits in the subnet number field set to 1.

The beginning of the IP address set to 127 (7F Hex) Example: 127.35.21.16

Note 1. When using the automatic generation method for address conversion, set switches 7 and 8

to the same values as the node number setting, and set the rest of the host number to zeroes. For

details regarding the host number, refer to 1-7 IP Addresses. The value for the host number field in

the IP address must match the value for the node number or the ERC indicator will flash.

2. If a subnet mask is to be set, use the CX-Programmer to set it in the CPU Bus Unit System Setup.

For details, refer to 4-2 CPU Bus Unit System Setup.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 9

FS-8704-16 Omron FINS Manual Page 6 of 37

4. Configuring the FieldServer as a FINS Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the

factory defaults provided in the configuration files included with the FieldServer (See

“.csv” sample files provided with the FieldServer).

This section documents and describes the parameters necessary for configuring the

FieldServer to communicate with a FINS Server. As a Client this driver reads and writes

data to Server Nodes. Server nodes should be FINS capable and be configured to

communicate over FINS

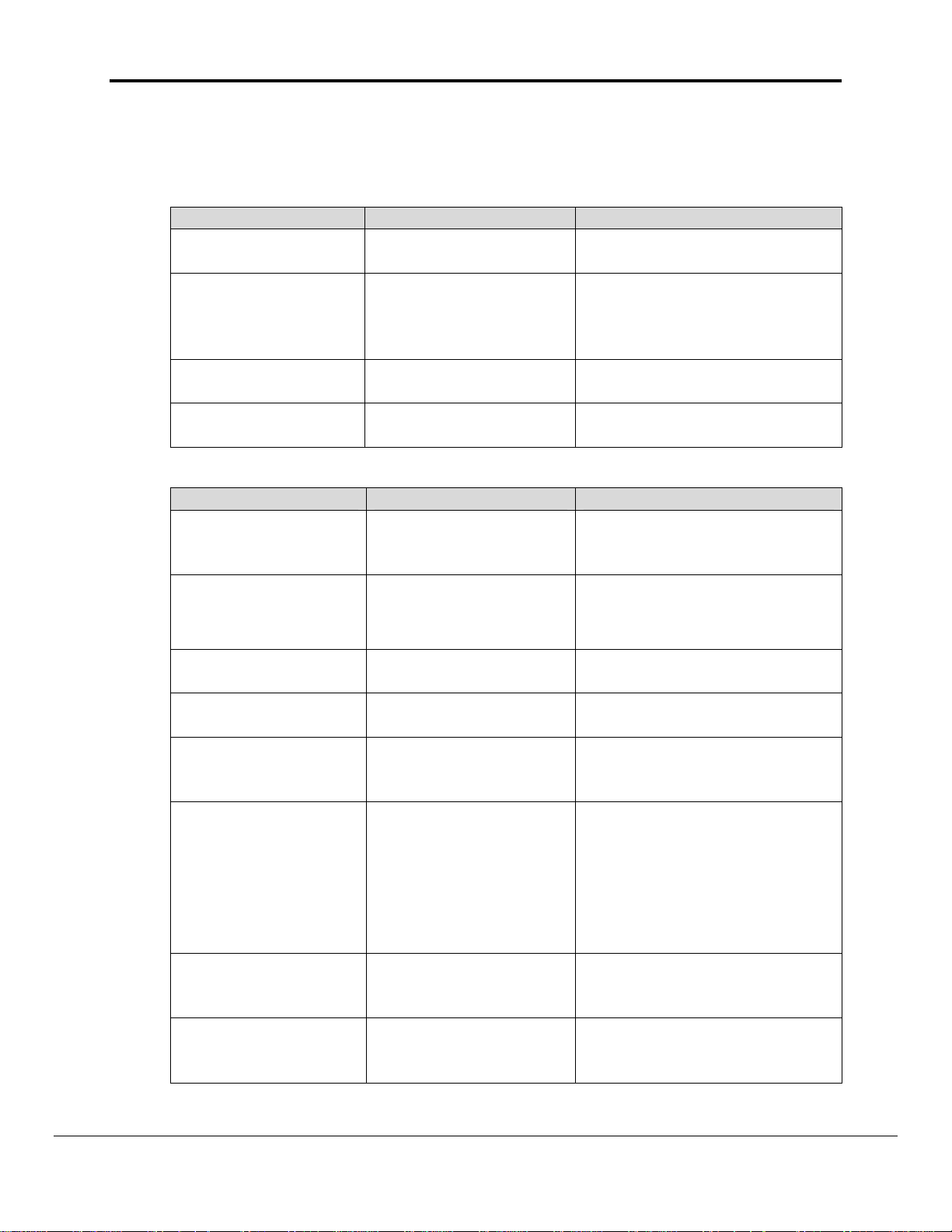

1.05 Data Arrays/Descriptors

The configuration file tells the FieldServer about its interfaces, and the routing of

data required. In order to enable the FieldServer for FINS communications, the

driver independent FieldServer buffers need to be declared in the “Data Arrays”

section, the destination device addresses need to be declared in the “Client Side

Nodes” section, and the data required from the servers needs to be mapped in the

“Client Side Map Descriptors” section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value

being the default.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Provide data format. Each Data

Data_Array_Format

Array can only take on one

format.

Up to 15 alphanumeric

characters

Float, Bit, UInt16,

SInt16, Packed_Bit,

Byte, Packed_Byte,

Swapped_Byte

Number of Data Objects. Must

be larger than the data storage

Data_Array_Length

area required by the Map

1-32767

Descriptors for the data being

placed in this array.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 10

FS-8704-16 Omron FINS Manual Page 7 of 37

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length,

DA_CIO, UInt16, 5143

DA_WR, UInt16, 511

DA_HR, Uint16, 511

DA_DM, Uint16, 32767

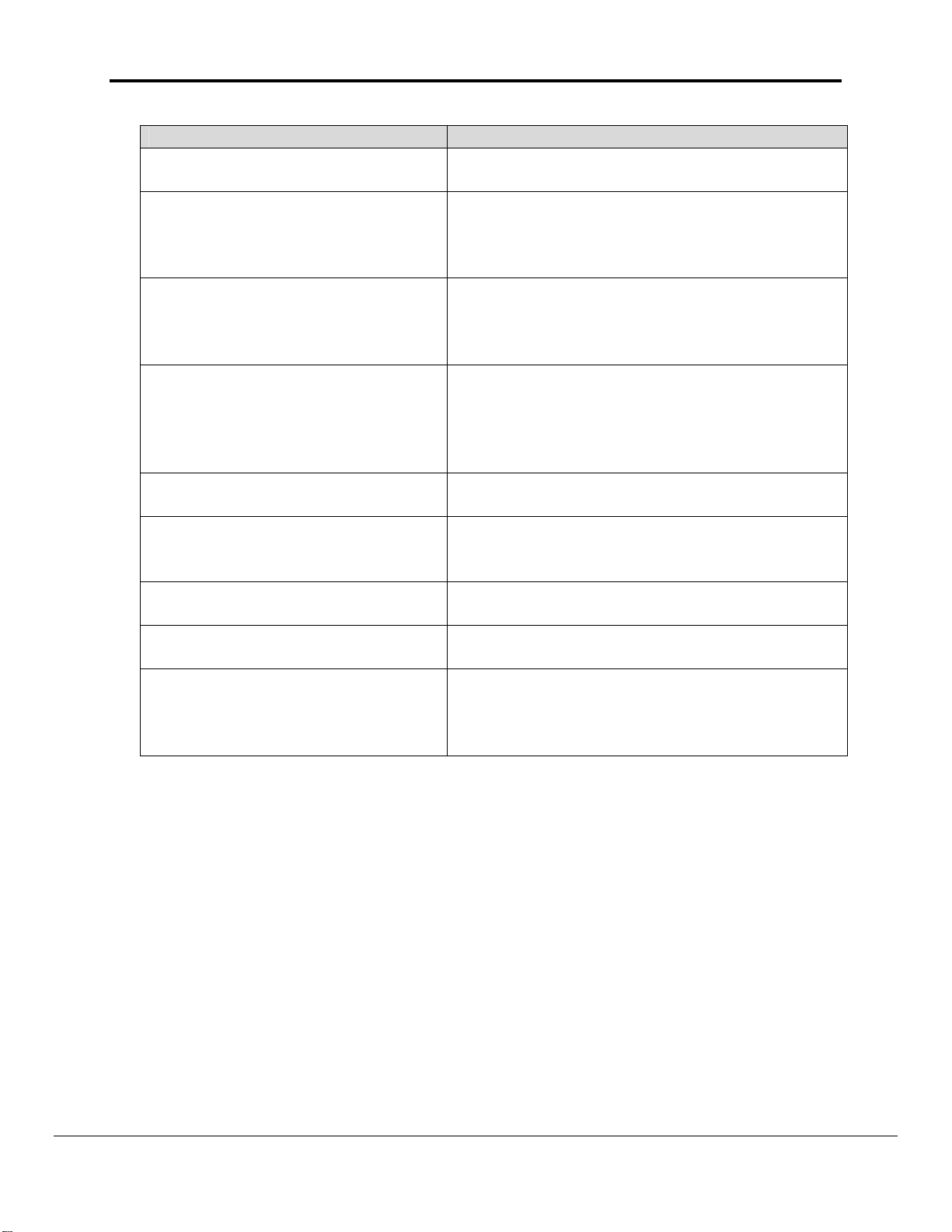

1.06 Driver Specific FieldServer Parameters

Section Title

FieldServer

Column Title Function Legal Values

Title Name for FieldServer Text

Specify physical node Id on

network.

This is the last byte of the

IP Address of the

System_Node_Id

FieldServer. eg. If

1-126

FieldServer’s IP Address is

192.168.1.81 then this

parameter should be set to

81

Example

// FieldServer Driver specific parameters

FieldServer

Title, System_Node_Id

Fins Client, 81

1.07 Client Side Connection Descriptors

Section Title

Adapter

Column Title Function Legal Values

Adapter Adapter Name N1, N22

Protocol Specify protocol used Fins, omn_fins or fins_udp

Udp_port_number Specify UDP port number 0, 9600 etc

2

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for

details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 11

FS-8704-16 Omron FINS Manual Page 8 of 37

Example

// Client Side

Connections

Adapters

Adapter, Protocol, Udp_port_number

N1, Fins, 9600

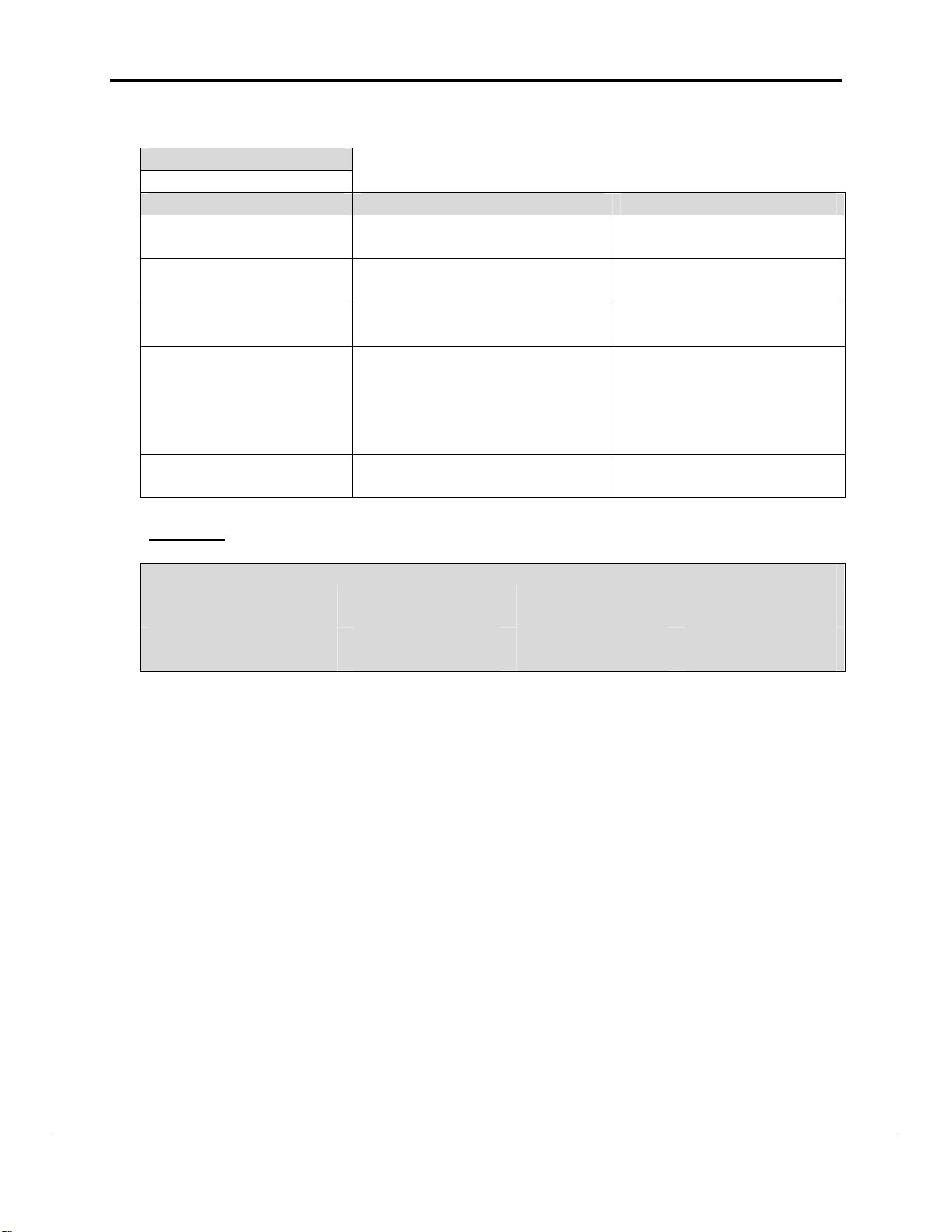

1.08 Client Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Up to 32 alphanumeric

characters

IP_Address Provide IP Address of PLC Eg. 192.168.1.105

Node number set at PLC

The node number should

Node_ID

correspond to the last byte of

1-126

the IP address. Eg. 105

corresponds to the example IP

address above.

Protocol Specify protocol used Fins, omn_fins or fins_udp

Adapter

*Net_Number

Specify which port the device is

connected to the FieldServer

Provide the network number of

PLC

N1, N23

1-255

Example

// Client Side Nodes

Nodes

Node_Name, IP_Address, Node_ID, Protocol, Adapter, Net_Number

PLC 1, 192.168.1.5, 1, Fins, N1, 1

3

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for

details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 12

FS-8704-16 Omron FINS Manual Page 9 of 37

1.09 Client Side Map Descriptors

4.1.1. FieldServer Related Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Na

me

Data_Array_Name

Data_Array_Offset

Function

Name of this Map

Descriptor

Name of Data Array

where data is to be

stored in the

FieldServer

Starting location in

Data Array

Function of Client Map

Descriptor

Up to 32 alphanumeric

characters

One of the Data Array names

from “Data Array” section

above

0 to maximum specified in

“Data Array” section above

RDBC, WRBC, WRBX

4.1.2. Driver Related Map Descriptor Parameters

Column Title Function Legal Values

One of the node names

specified in “Client Node

Descriptor” above

CIO-WORD, WR-WORD, HRWORD, AR-WORD, EMWORD

Node_Name

*Data_Type

(see Note 1

Appendix A.1)

Name of Node to fetch

data from

Data type

Length

Address

*Memory_Code

(see Note 1

Appendix A.1)

Command_Name

(see Note 2 section

6.1)

*MRC

(see Note 2

Appendix A.1)

*SRC

(see Note 2

Appendix A.1)

Length of Map

Descriptor

Starting address of

read block

Memory code for PLC

memory type

1- 729

0, 1,…100, etc

see Appendix A.1 for details

B0, B1, B2, B3, 82, 98 and

A0 ---- AC

MEMORY AREA READ

MEMORY AREA WRITE

RUN-STOP

Name of the command

CLOCK READ

CLOCK WRITE

CYCLE TIME READ

CPU UNIT STATUS READ

Main Request Code 1,4,6,7

Sub Request Code 1,2,20

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 13

FS-8704-16 Omron FINS Manual Page 10 of 37

*Unit_Number

Unit number of CPU at

PLC

0,1,2 etc

4.1.3. Timing Parameters

Column Title Function Legal Values

Scan_Interval Rate at which data is polled ≥0.001s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 14

FS-8704-16 Omron FINS Manual Page 11 of 37

4.1.4. Map Descriptor Example 1 – IO Read

This example provides all the required information to read and write to the IO memory area of the PLC. The following Map

Descriptor creates a task for the driver to read the first 20 Words from the CIO memory area and store them in the Data

Array DA_CIO. The first word from the PLC will be stored as the first element in the Data Array. Whenever an upstream

device writes any element in the Data Array, the Driver will write the same value to the PLC at the corresponding address.

This scheme is known as Write-thru. In this example the Driver can write only one value at a time.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Address, Length, Data_Type, Command_Name, Unit_number

CMD_CIO, DA_CIO, 0, RDBC, PLC1, 0, 20, CIO-WORD, MEMORY AREA READ, 0

One of the Data

Arrays declared in

the Data_Array

section

The Data for CIO

memory area from

the Node (PLC1)

will be stored in this

Data Array.

Forcing the Driver to issue a

read request for each

Scan_Interval .

In particular case Driver

will read this portion of CIO

memory area for each

second if Scan_Interval is set

1s.

Starting Address

of the memory

area to read.

Specifies the type of target

memory at PLC.

Also this parameter can be

replaced with

Memory_Code parameter.

See chapter 6 to for memory

codes read CIO Word area.

Unit number at PLC

Offset within the Data

Array at which Driver will

the store the data for initial

Address defined under

“Address” parameter.

In particular this case data

for Address 0 will be

stored at offset 0, for

Address 1 offset 1 and so

on.

Specify the number of

elements (number of Words

in this case) to read from

This is the logical name

of the target device

having the parameters

defined in section

“Client Node

Descriptors”.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

PLC.

Command Name specifies the Main and

Sub request codes to make a request to

read this memory from PLC.

Assigning Direct MRC and SRC

parameters can replace this parameter.

See chapter 6 to know valid MRC –SRC

values to read this CIO memory area.

Page 15

FS-8704-16 Omron FINS Manual Page 12 of 37

4.1.5. Map Descriptor Example 2 – IO Write

This example is used to write a value(s) to the PLC. The write is done when the contents of the Data Array are updated

(written to by a remote device.). In the previous example, it was shown how a ‘read’ Map Descriptor can also be used to

write by using FIeldServer’s Write-Through technology.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name Address, Length, Data_type, Command_Name, Unit_Number

CMD_CIOw, DA_CIOw, 0, WRBX, PLC1, 0, 20, CIO-WORD, MEMORY AREA WRITE, 0

One of the Data

Arrays declared in

the Data_Array

section (See section

1.05)

The Data in this

Data Array will be

written to the PLC1.

Driver will

fetch

consecutive 20

(Length)

elements

starting from

this offset to be

written at Node

PLC1

Forcing the Driver to issue a

write request upon updating

this dedicated portion of Data

Array. In this case first 20

elements comes under

dedicated portion for this map

descriptor.

Note : If WRBC , It will Force

the Driver to issue a write

request for each Scan_Interval

In this particular case Driver

will write this portion of CIO

memory area for each second.

Specify the

number of

elements

(number of

Words in this

case) to read

from PLC.

Specifies the type

of target memor y

at PLC.

Also this

parameter can be

replaced with

Memory_Code

parameter.

See Appendix A

to for memory

codes read CIO

Word area.

Command Name

specifies the

Main and Sub

request codes to

make a request to

write this

memory from

PLC.

Assigning Direct

MRC and SRC

parameters can

replace this

parameter.

See Appendix A

to know valid

MRC –SRC

values to read

this CIO memory

area.

Unit

number at

PLC

(Keep

mostly

zero, or

undefined

keep it

zero)

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 16

FS-8704-16 Omron FINS Manual Page 13 of 37

4.1.6. Map Descriptor Example 3: Clock Read:

This Map Descriptor reads the PLC clock and stores the information in a Data Array DA_CLK. For detail on how the

Driver stores clock information see Appendix B.1.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Command_Name, Unit_Number

CMD_CLKr, DA_CLKr, 0, RDBC, PLC1, 7, CLOCK READ, 0

4.1.7. Map Descriptor Example 4: Clock Write:

Write-thru is not possible for Clock write. A dedicated Map Descriptor is required to overwrite the PLC clock. This

Map Descriptor overwrites the clock whenever an upstream device updates the DA_CLKw Data Array. See Appendix

B.1 for details.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Command_Name, Unit_Number

CMD_CLKw, DA_CLKw, 0, WRBX, PLC1, 7, CLOCK WRITE, 0

Note: All elements must be updated in DA_CLKw to set the clock as expected. Whenever any element updates, the

Driver will write all seven values to the PLC along with the one updated value. If all elements are updated by the

upstream device in a single operation then the Driver will also set the all elements at the PLC in a single operation.

4.1.8. Map Descriptor Example 5: Read CPU Cycle Times:

This Map Descriptor reads the CPU cycle time at the PLC and stores the data in a Data Array DA_CYCT. Average,

maximum and minimum cycle times will be stored in three consecutive locations starting with the location indicated by

the Data_Array_Offset parameter. See Appendix B.1

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Command_Name, Unit_Number

CMD_CYCT, DA_CYCT, 0, RDBC, PLC1, 3, CLOCK READ, 0s

The Driver stores these values as it gets them from the PLC. Scaling can provided to determine the unit in which the

value is stored. Default is 10 times milliseconds.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 17

FS-8704-16 Omron FINS Manual Page 14 of 37

4.1.9. Map Descriptor Example 6: Run-Stop PLC:

Defining this Map Descriptor Driver can change the PLC mode to STOP (Program), MONITOR or RUN mode. The

Driver issues a change mode command to the PLC whenever the value at the declared offset is updated.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name Length Command_Name Unit_Number

CMD_RUN_ST, DA_RUN_ST, 0, WRBX, PLC1, 1, RUN-STOP 0s

The Driver will change PLC modes depending upon the value poked by the upstream device at offset (0 in this case).

See section Appendix B.1 for values corresponding to PLC modes.

4.1.10. Map Descriptor Example 7: Read CPU Status:

Defining this Map Descriptor Driver reads the CPU status and stores it in the Data Array DA_STATUS.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name Length Command_Name Unit_Number

CMD_STATUS, DA_STATUS, 0, REBC, PLC1, 67, CPU UNIT STATUS READ 0s

The Driver stores the status information in the named Data Array at consecutive locations starting with

Data_Array_Offset.

See Appendix B.1 for further information.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 18

FS-8704-16 Omron FINS Manual Page 15 of 37

5. Configuring the FieldServer as a FINS Server

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the

factory defaults provided in the configuration files included with the FieldServer (See

“.csv” files on the driver CD).

This section documents and describes the parameters necessary for configuring the

FieldServer to communicate with a FINS Client.

As a Server, the Driver responses to read requests and updates the FieldServer Data

Arrays with write requests from the Client.

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for FINS communications, the driver

independent FieldServer buffers need to be declared in the “Data Arrays” section, the

FieldServer virtual node(s) needs to be declared in the “Server Side Nodes” section,

and the data to be provided to the clients needs to be mapped in the “Server Side Map

Descriptors” section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being

the default.

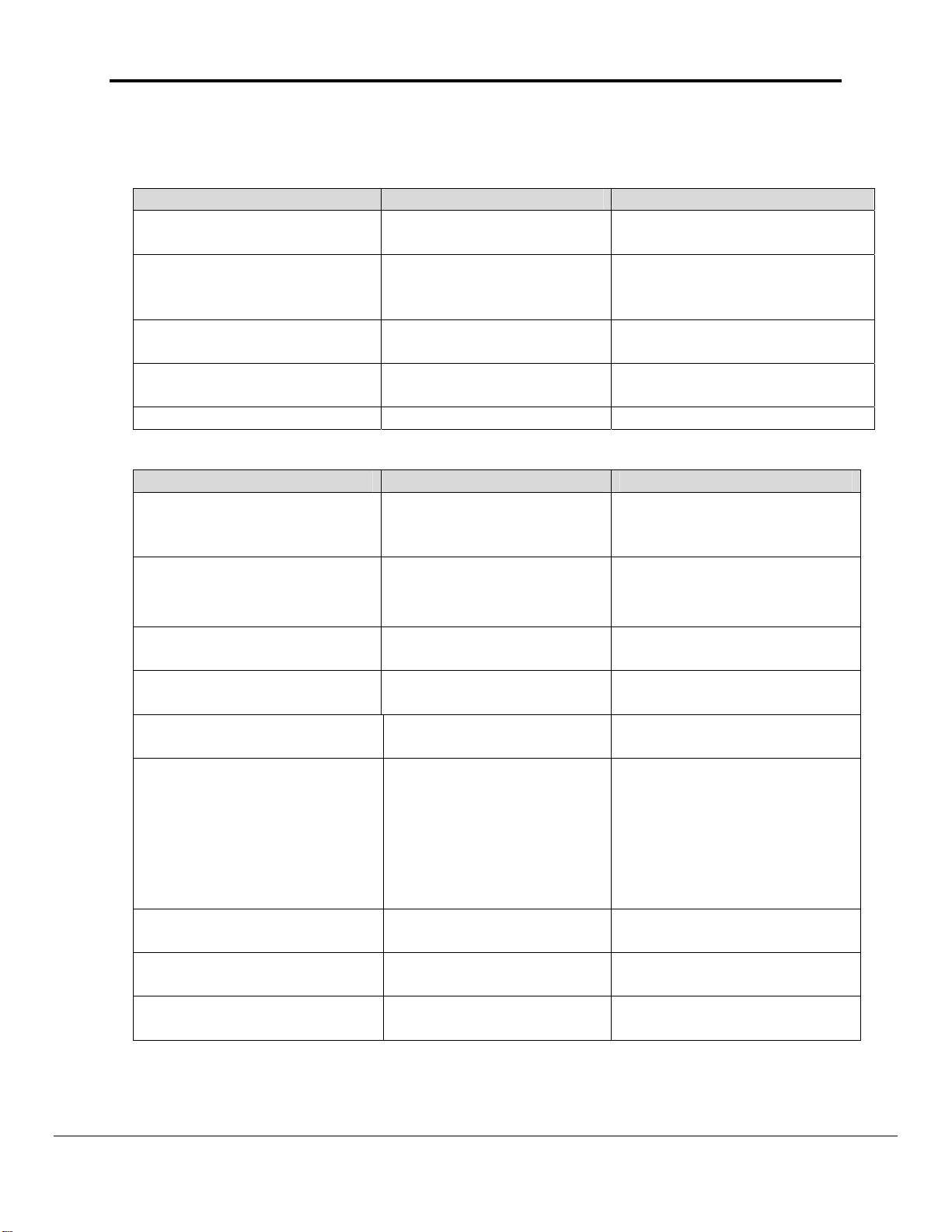

1.010 Server Side Connection Descriptors

Section Title

Adapter

Column Title Function Legal Values

Adapter Adapter Name N1, N24

Protocol Specify protocol used Fins, omn_fins or fins_udp

Udp_port_number Specify UDP port number 0,9600 etc

Example

// Server Side

Connections

Adapters

Adapter, Protocol, Udp_port_number

N1, Fins, 9600

4

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for

details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 19

FS-8704-16 Omron FINS Manual Page 16 of 37

1.011 Server Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID

Virtual Node number of FINS

server.

Protocol Specify protocol used

Up to 32 alphanumeric

characters

1-126

Fins, omn_fins or

fins_udp

Specifies time FieldServer

will reserve server side

Server_Hold_Timeout*

connection while waiting for

>1.0s

the Client side to update data

in Data_Array (if necessary)

Net_Number

Provide the network number

of FINS Server network

1-255

Example

// Server Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Net_Numer

PLC 1, 1, Modbus_RTU, 1

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 20

FS-8704-16 Omron FINS Manual Page 17 of 37

1.012 Server Side Map Descriptors

5.1.1. FieldServer Specific Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name

Data_Array_Name

Data_Array_Offset

Function

Name of this Map

Descriptor

Name of Data Array

where data is to be

stored in the FieldServer

Starting location in Data

Array

Function of Server Map

Descriptor

Up to 32 alphanumeric

characters

One of the Data Array names

from “Data Array” section

above

0 to maximum specified in

“Data Array” section above

Server

5.1.2. Driver Specific Map Descriptor Parameters

Column Title Function Legal Values

One of the node names

specified in “Server Node

Descriptor” above

CIO-WORD, WR-WORD,

HR-WORD, AR-WORD,

EM-WORD

Node_Name

*Data_Type

(see Note1 Appendix A.1)

Name of Node to fetch

data from

Data type

Length Length of Map Descriptor

*Address

*Memory_Code

(see Note1 Appendix A.1)

*Command_Name

(see Note2 Appendix A.1)

*MRC

(see Note2 Appendix A.1)

*SRC

(see Note2 Appendix A.1)

*Unit_Number

Starting address of read

block

Memory code for PLC

memory type

Name of the command

Main Request Code 1,4,6,7

Sub Request Code 1,2,20

Unit number of CPU at

PLC

1 to maximum specified in

Data Array section above

0,100, 32767 etc

see section 6.1 for detail

B0, B1, B2, B3, 82, 98 and

A0 ---- AC

MEMORY AREA READ

MEMORY AREA WRITE

RUN-STOP

CLOCK READ

CLOCK WRITE

CYCLE TIME READ

CPU UNIT STATUS READ

0,1,2 etc

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 21

FS-8704-16 Omron FINS Manual Page 18 of 37

y

5.1.3. Map Descriptor Example 1: IO Read

The following Map Descriptor enables the Driver to serve the clients for CIO memory operations. The Command_Name

“MEMORY AREA READ” makes this memory readable.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Address Length Data_Type Command_Name Unit_Number

SRV_CIOr, DA_CIO, 0, SERVER, PLC1, 0, 6143, CIO-WORD MEMORY AREA READ 0

One of the Data

Arrays declared in

the Data_Array

section.

Driver will serve

client for CIO

operations using this

Data Array.

Starting

location for data

within Data

Array

Specify the

Driver to Serve

Clients.

This is the

logical name of

the server device

having the

parameters

defined in section

“Server Node

Descriptors”.

Starting Address

of the memory

area to serve.

Specify the

number of

elements

(number of

Words in this

case) that this

Map

Descriptor

can serve.

Specifies the type

of memor y to

serve.

Also this

parameter can be

replaced with

Memory_Code

parameter.

See chapter 6 to

for memory

codes

Command Name

specifies the

Main and Sub

request codes to

make a request to

read this

memory.

Assigning Direct

MRC and SRC

parameters can

replace this

parameter.

See chapter 6 to

for MRC –SRC

values to enable

to read this CIO

memor

area.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 22

FS-8704-16 Omron FINS Manual Page 19 of 37

5.1.4. Map Descriptor Example 2: IO Write

This Map Descriptor makes the memory area writable which was made readable by the previous Map Descriptor.

Thus memory area can be made read only, write only or read and write enabled.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Address Length Data_Type Command_Name Unit_number

SRV_CIOw, DA_CIO, 0, SERVER, PLC1, 0, 6143, CIO-WORD MEMORY AREA WRITE 0

5.1.5. Map Descriptor Example 3: Clock Read:

This Map Descriptor enables the Driver to serve the client with a Clock read request. See Appendix B.1for further

information

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Length Command_Name Unit_Number

SRV_CLKr, DA_CLKr, 0, SERVER, PLC1, 7, CLOCK READ 0s

5.1.6. Map Descriptor Example 4: Clock Write:

This Map Descriptor enables the Driver to update Clock information when the Client makes a Clock Write request. See

section Appendix B.1 for further information.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name Length Command_Name Unit_Number

SRV_CLKr, DA_CLKr, 0, SERVER, PLC1, 7, CLOCK WRITE 0

5.1.7. Map Descriptor Example 5: CPU Cycle Times:

This Map Descriptor enables the Driver to serve Clients with CPU cycle time information upon request. See Appendix

B.1 for further information.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Length Command_Name Unit_Number

SRV_CYCT, DA_CYCT, 0, SERVER, PLC1, 7, CLOCK READ 0

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 23

FS-8704-16 Omron FINS Manual Page 20 of 37

5.1.8. Map Descriptor Example 6: Run-Stop PLC:

This Map Descriptor enables the Driver to give access to the Client to change the Server’s Operating Mode. See

Appendix B.1 for stored values corresponding to PLC modes.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Length Command_Name Unit_Number

SRV_RUN_ST, DA_RUN_ST, 0, SERVER, PLC1, 1, RUN-STOP 0

5.1.9. Map Descriptor Example 7: CPU Status:

This Map Descriptor enables the Driver to respond to clients requesting CPU status. See Appendix B.1for further

information.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Length Command_Name Unit_Number

SRV_STATUS, DA_STATUS, 0, SERVER, PLC1, 67, CPU UNIT STATUS READ 0

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 24

FS-8704-16 Omron FINS Manual Page 21 of 37

Appendix A. Advanced Topics

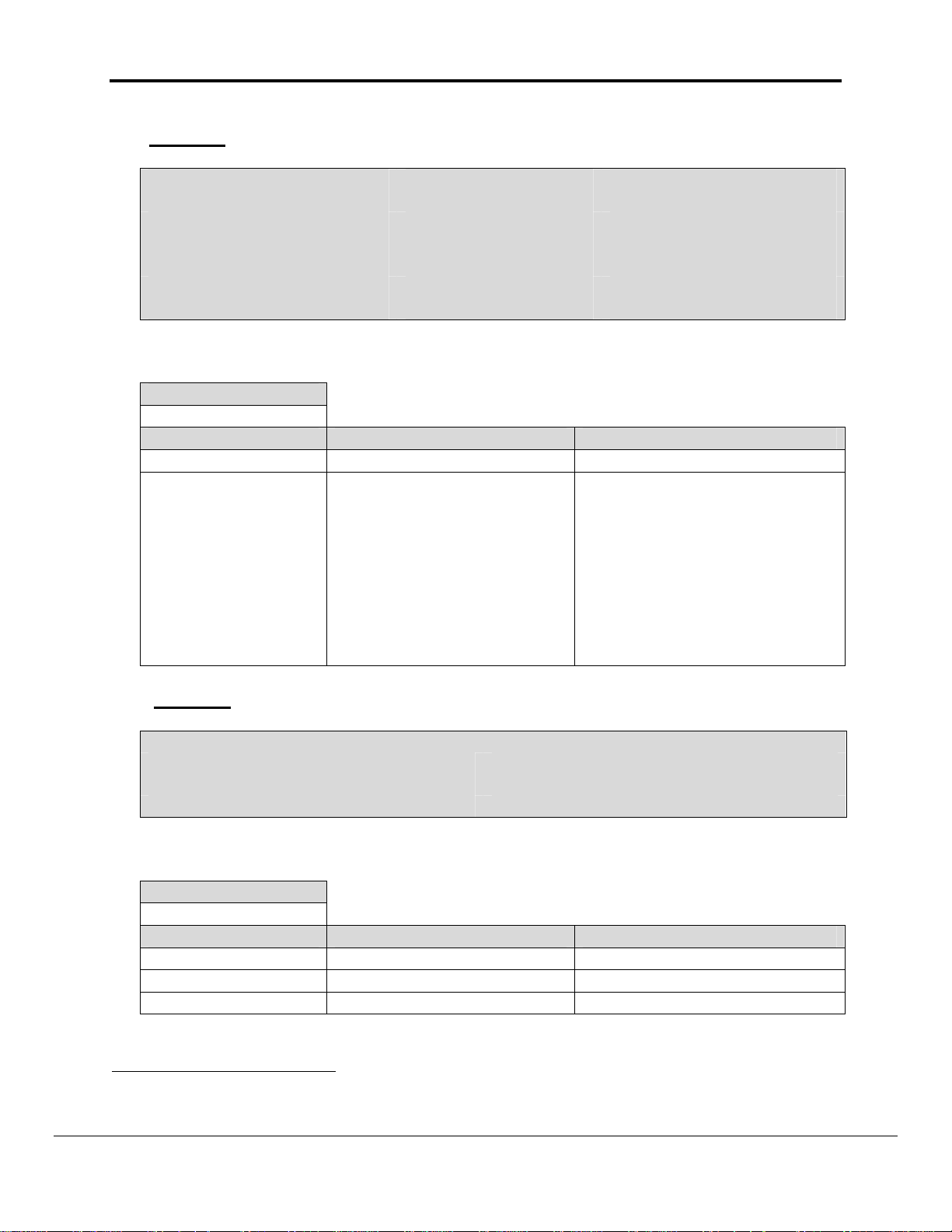

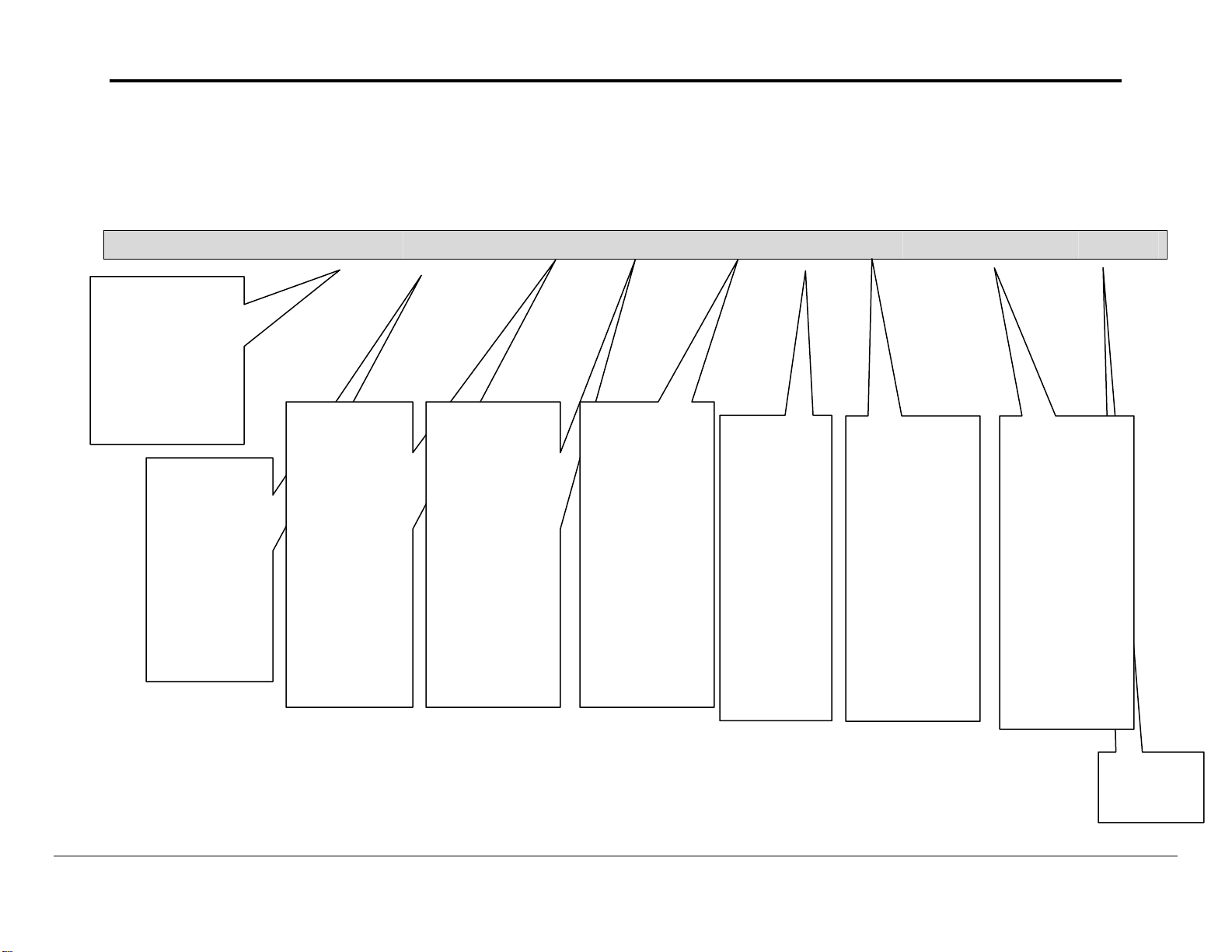

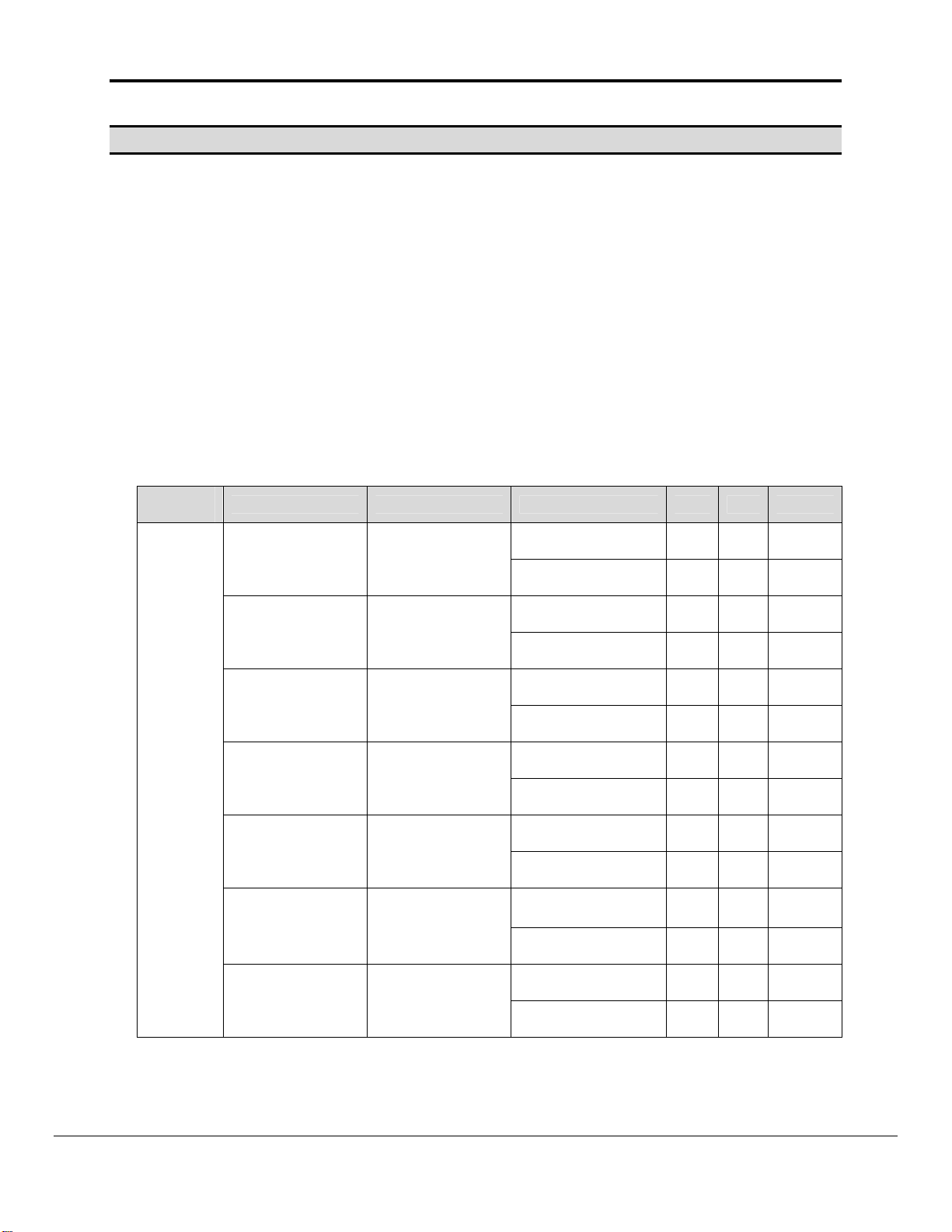

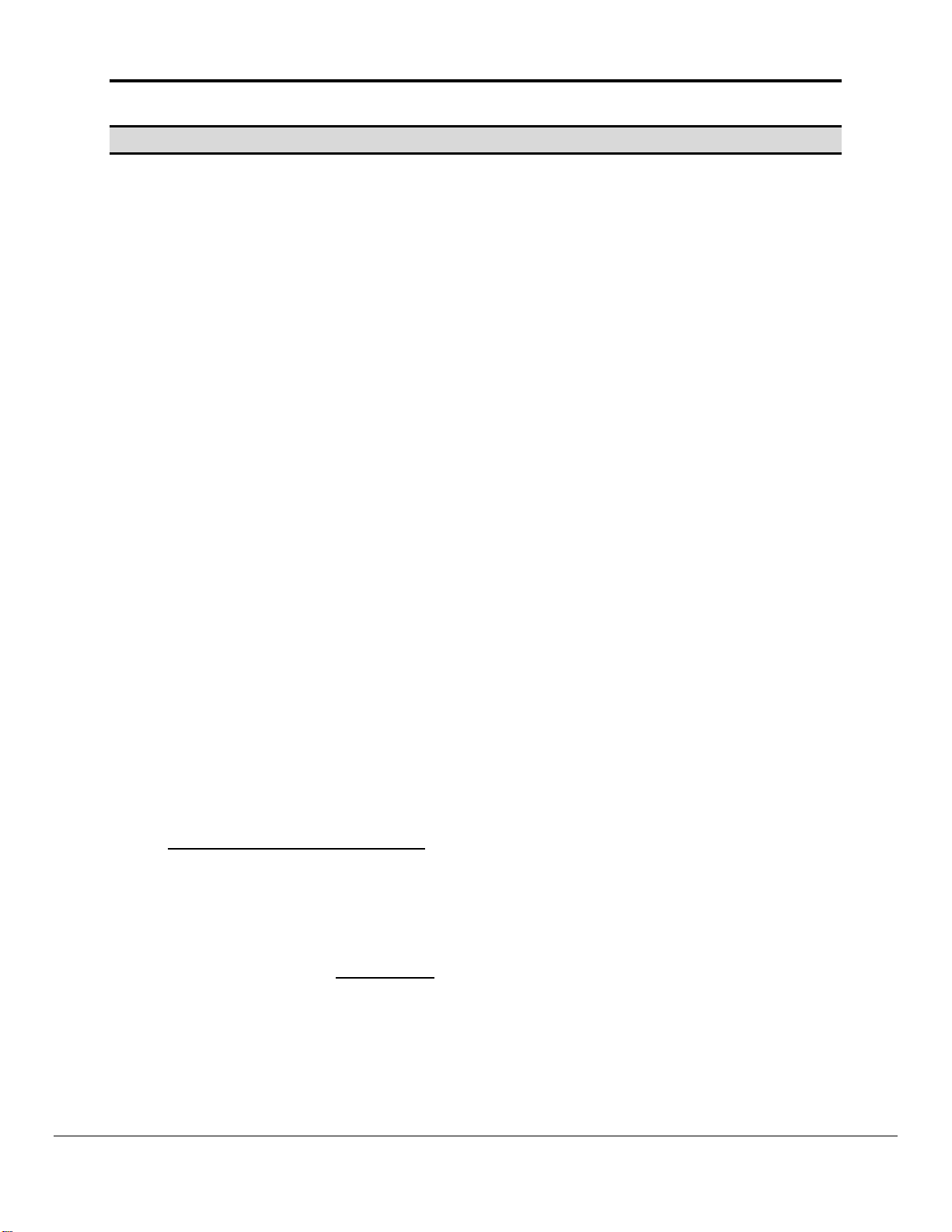

Appendix A.1. Driver Map Descriptor Parameter’s Bounds

Most Map Descriptors need to know the following

The Data Type to

be read or written:

Specify Either

a) Data Type or

b) Memory Code.

This is how the driver determines which memory area of the

PLC must be processed. (For EM Banks you can only specify

the Memory_Code.)

The Command to

be executed

Specify either

a) The command name or

b) The MRC/SRC Pair.

Memory

Type

I/O

Memory

Data_Type Memory_Code Command_Name MRC SRC Address

CIO-WORD B0

WR-WORD B1

HR-WORD B2

AR-WORD B3

DM-WORD 82

98

EM-WORD

Not Available

(Use only

memory_code)

Present Current

EM Bank

A0-AC

(Any other EM

Bank)

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

MEMORY AREA

READ

MEMORY AREA

WRITE

1 1 0-6143

1 2 0-6143

1 1 0-511

1 2 0-511

1 1 0-511

1 2 0-511

1 1 0-959

1 2 448-959

1 1 0-32767

1 2 0-32767

1 1 0-32767

1 2 0-32767

1 1 0-32767

1 2 0-32767

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 25

FS-8704-16 Omron FINS Manual Page 22 of 37

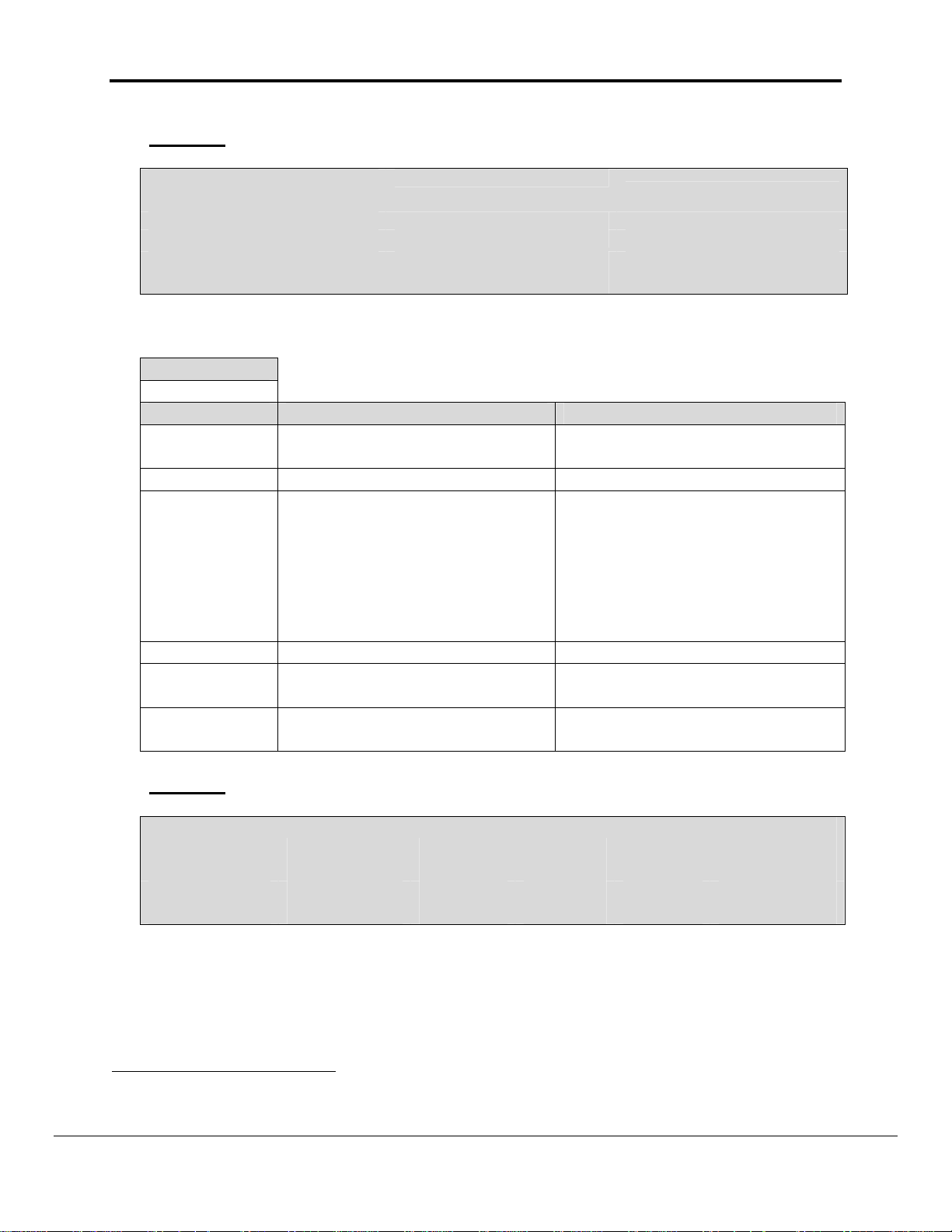

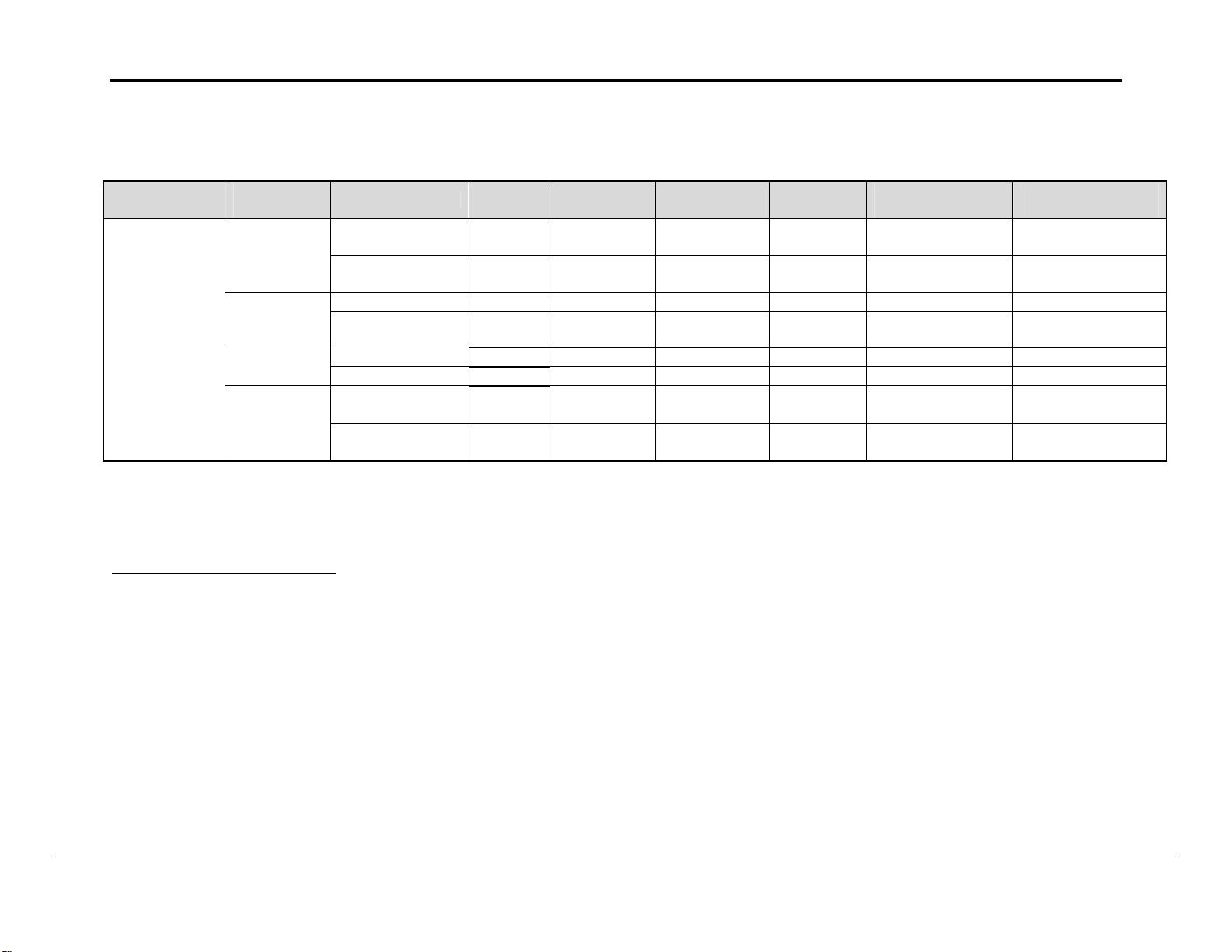

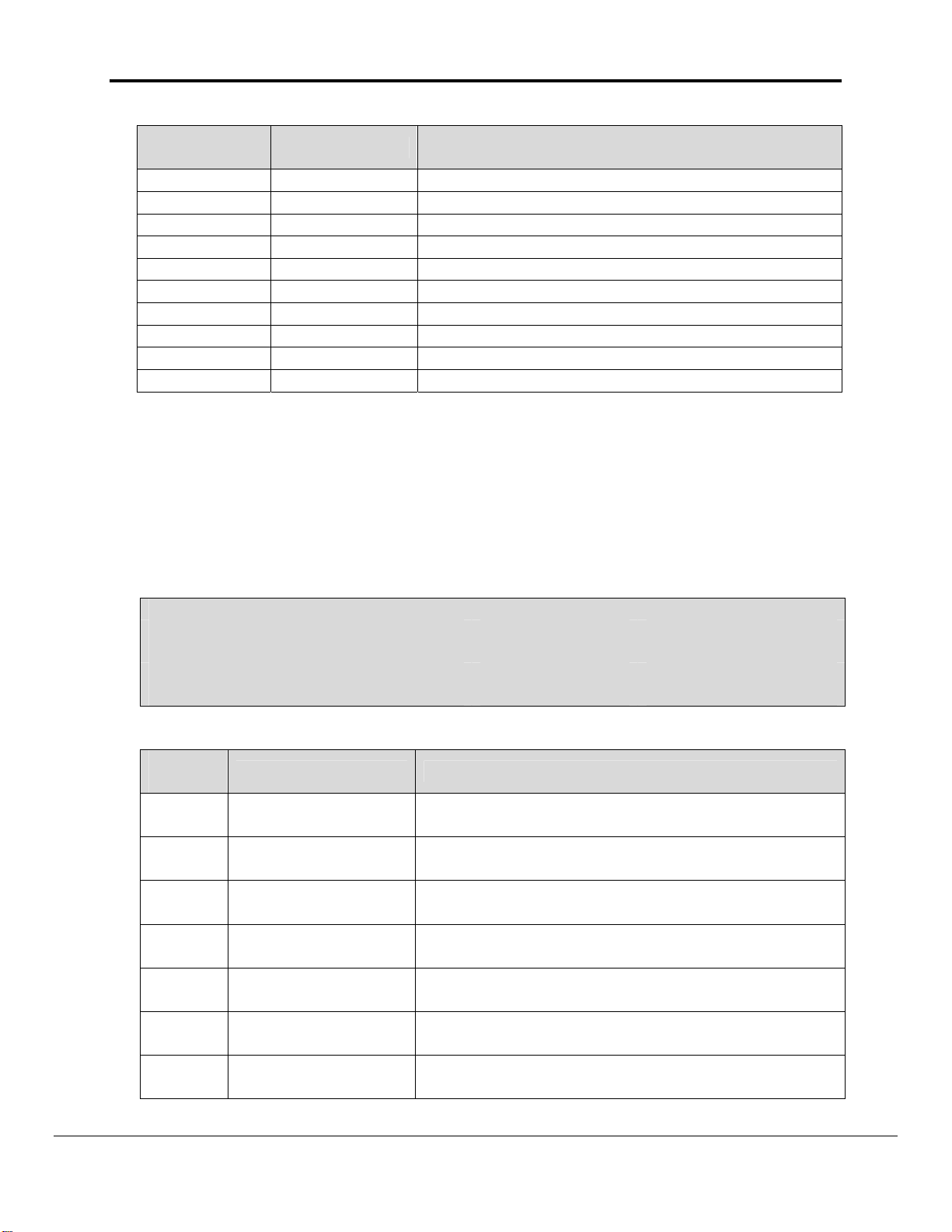

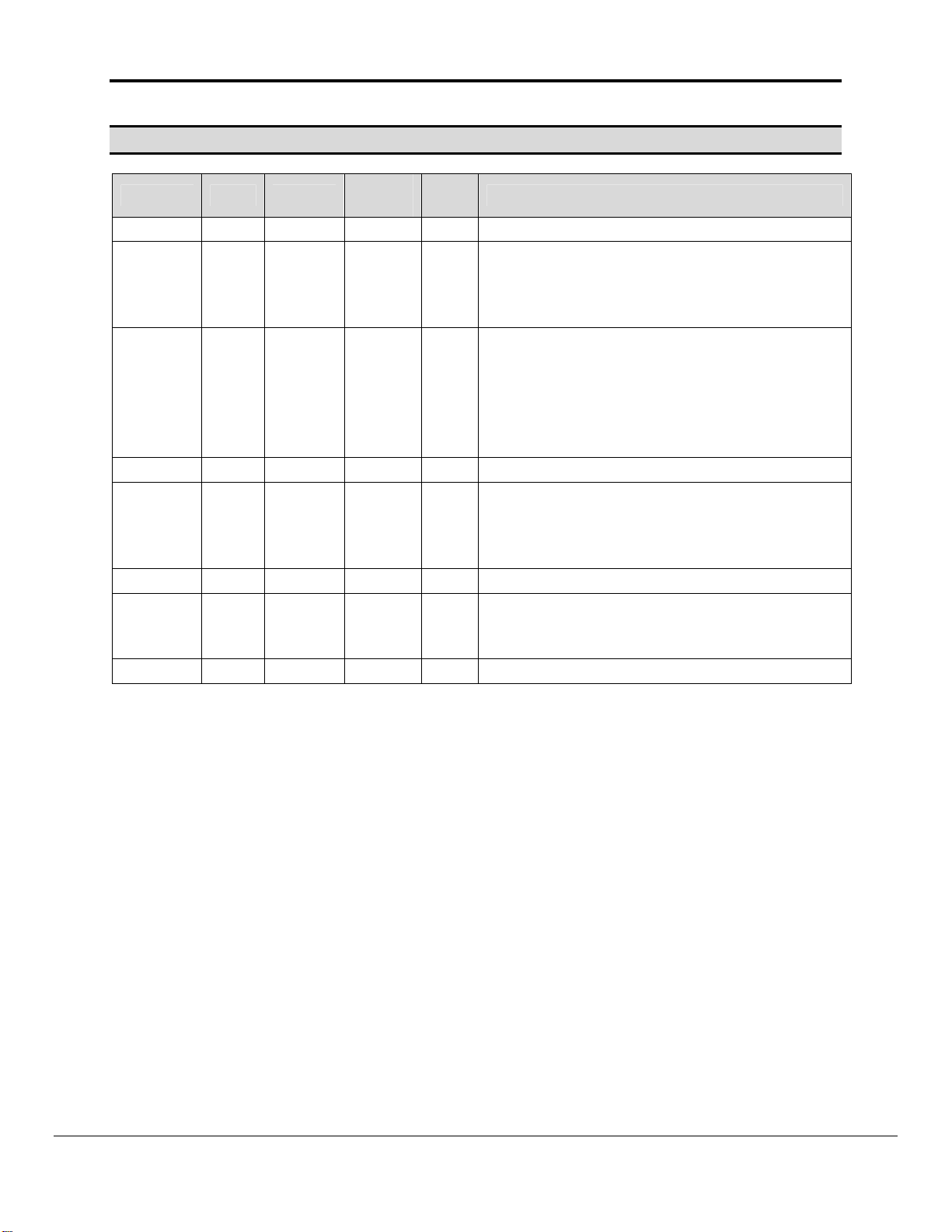

Appendix A.2. PLC status to execute commands

PLC Type

CS1/CJ1

Series

Memory

Type

I/O Memory

Mode

Changes

Access

Status

Reading

Command name

MEMORY AREA

READ

MEMORY AREA

WRITE

RUN OK OK OK Disabled OK OK Operating

STOP OK OK OK Disabled OK OK

CLOCK READ OK OK OK OK OK OK Time Data

CLOCK WRITE OK OK OK Disabled OK OK

CPU UNIT

STATUS READ

CYCLE TIME

READ

Run

Mode

OK OK OK OK OK OK

OK OK OK OK OK OK

OK OK OK OK OK OK

OK OK Disabled OK OK OK

Monitor

Mode

Program

Mode

Access

right 5

UM Read

Protection6

DIP UM

Protection7

5

Access Right at Other Device: The Access right at other device column tells whether the CPU Unit can or cannot receive a command when another device has

the access right to the CPU Unit.

6

UM Read Protection: The UM read protection column tells whether the CPU Unit can or cannot receive the command when UM (user memory) is protected

from a Peripheral Device.

7

DIP Switch UM Protection: The DIP switch UM protection column tells whether the CPU Unit can or cannot receive a command when UM is write-protected

by turning ON pin 1 of the DIP switch on the CPU Unit’s front panel.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 26

FS-8704-16 Omron FINS Manual Page 23 of 37

8

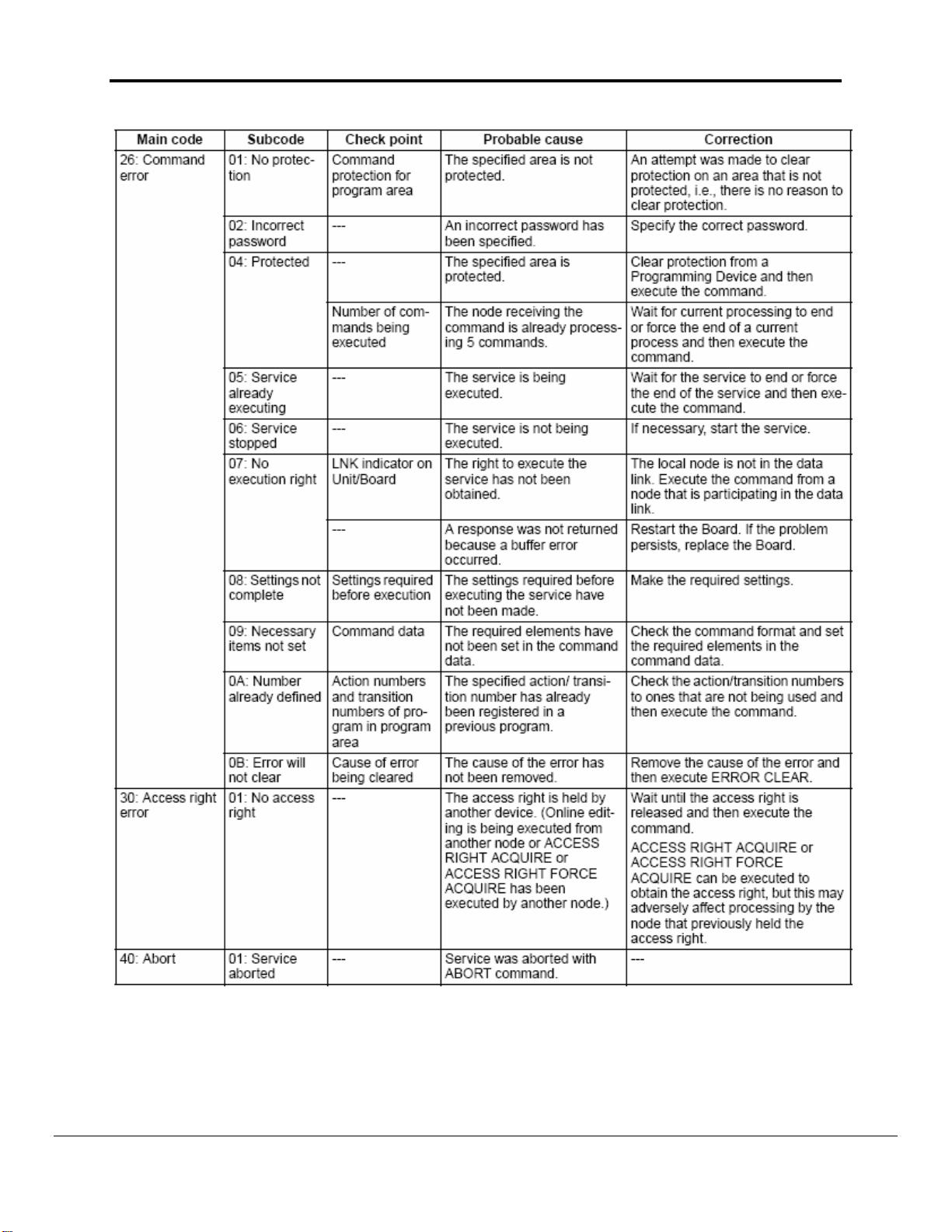

Appendix A.3. End Codes

The following table lists the main codes and the sub-codes, which combine to form

the end code (response code) returned for a FINS command. The probable cause

and corrections for each error code are also given. Depending on the command, the

destination code will sometimes make a request of another node on a network. The

other node is referred to as the third Node.

8

This section is a reproduction of Section 5-1-3 End Codes from Omron Communication Commands Reference

Manual (M11W342e160603.pdf)

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 27

FS-8704-16 Omron FINS Manual Page 24 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 28

FS-8704-16 Omron FINS Manual Page 25 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 29

FS-8704-16 Omron FINS Manual Page 26 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 30

FS-8704-16 Omron FINS Manual Page 27 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 31

FS-8704-16 Omron FINS Manual Page 28 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 32

FS-8704-16 Omron FINS Manual Page 29 of 37

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 33

FS-8704-16 Omron FINS Manual Page 30 of 37

Appendix B. Driver Notes

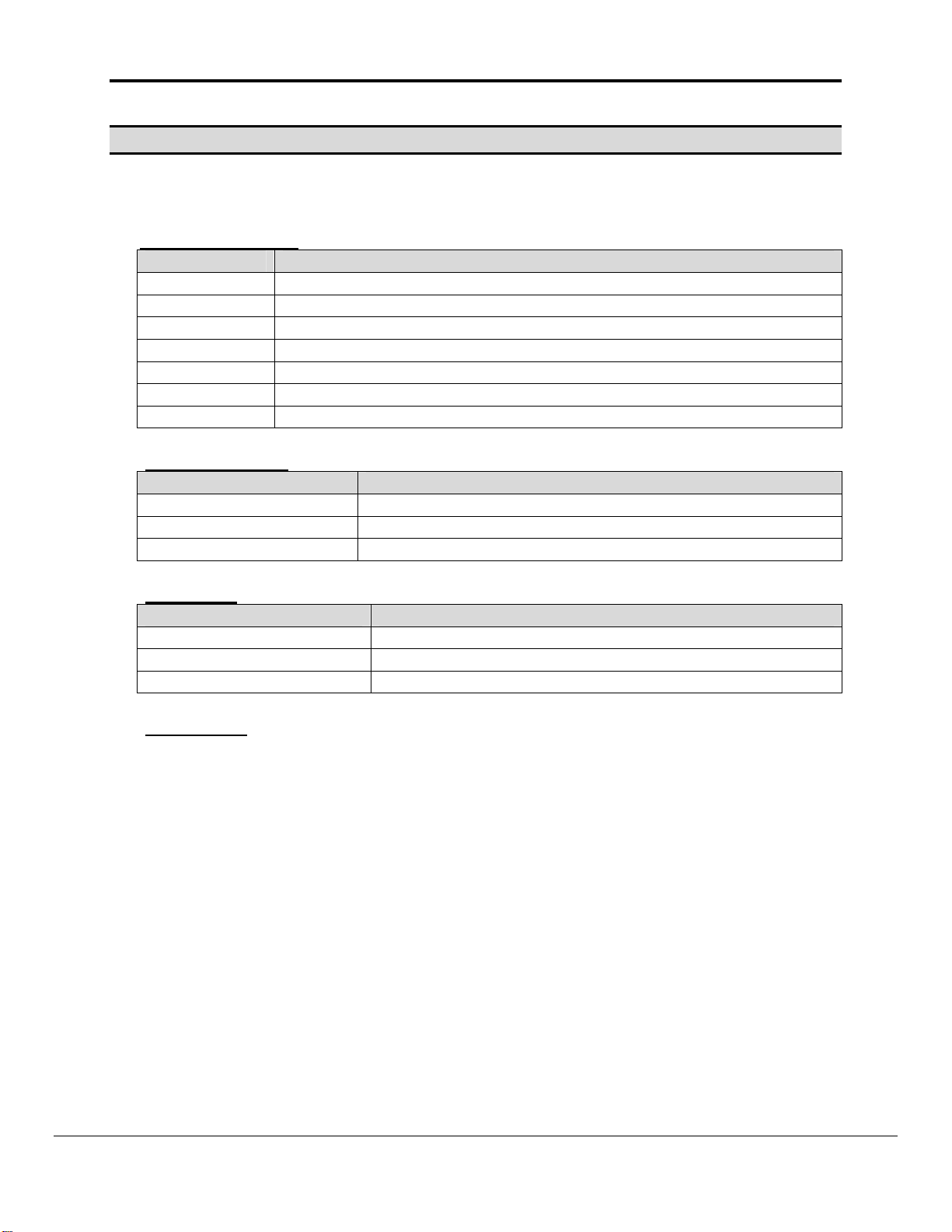

Appendix B.1. Data Storage

Clock Information

Element Contents

1 Year (4 for 2004, 12 for 2012)

2 Month

3 Day of Month

4 Hours

5 Minutes

6 Seconds

7 Day of the week (Sunday = 0, Saturday=6)

CPU Cycle Time

Element Contents

1 Average Cycle Time

2 Maximum Cycle Time

3 Minimum Cycle Time

PLC Mode

Stored Value PLC Mode

1 STOP

2 MONITOR

3 RUN

CPU Status

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 34

FS-8704-16 Omron FINS Manual Page 31 of 37

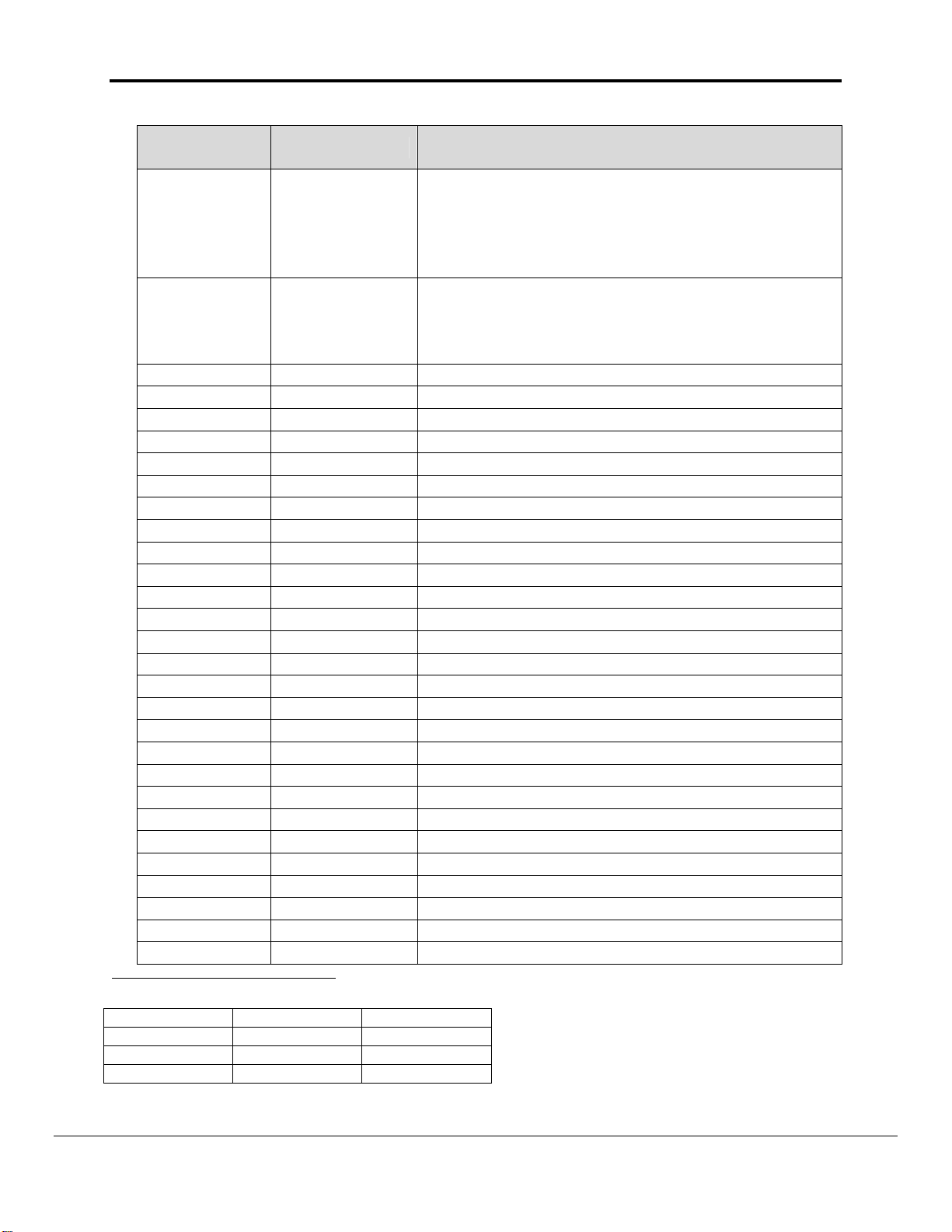

ELEMENT

NUMBER

CONTENTS DESCRIPTION

CPU Status9

1

1

2

3

1= Stop

2= Standby (waiting for signal from another

Device)

3= Run

CPU Mode

1= PROGRAM

2= MONITOR

3= RUN

2

1

2

3

3 1/0 1: Memory Error

4 1/0 1: I/O Bus Error

5 1/0 1:Duplication Error

6 1/0 1:Fatal Inner Board Error

7 1/0 1:I/O Point overflow

8 1/0 1:I/O Setting Error

9 1/0 1:Program Error

10 1/0 1:Cycle Time Over

11 0 12 1/0 1:FALS Error

13-18 0 19 1/0 1:FAL Error

20 Unknown Reserved for System

21 1/0 1:Interrupt Task Error

22 1/0 1:Basic I/O Unit Error

23 Unknown Reserved for System

24 1/0 1:PLC Setup Error

25 1/0 1:I/O Verification Error

26 1/0 1:Inner Board Error

27 1/0 1:CPU Bus Unit Error

28 1/0 1:Special I/O Unit Error

29 1/0 1:Sysmac Bus Error

30 1/0 1:Battery Error

31 1/0 1:CPU Bus Unit Setting Error

32 1/0 1:Special I/O Unit-Setting Error

33-34 Unknown Reserved for System

35-42 0 -

9

PLC Value Driver Value Meaning

0x00 1 Stop

0x80 2 Standby

0x01 3 Run

Note: During testing it has been found that the PLC Value corresponds with this book value. Hence the Driver

stores or sends any other value as it is. User has to do some experiment on it.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 35

FS-8704-16 Omron FINS Manual Page 32 of 37

ELEMENT

NUMBER

CONTENTS DESCRIPTION

43 1/0 1:Message # 7 Present

44 1/0 1:Message # 6 Present

45 1/0 1:Message # 5 Present

46 1/0 1:Message # 4 Present

47 1/0 1:Message # 3 Present

48 1/0 1:Message # 2 Present

49 1/0 1:Message # 1 Present

50 1/0 1:Message # 0 Present

51 0-65535 Error Code

52-67 A-Z 16 Character Text

Appendix B.2. Driver stats

In addition to the standard FieldServer operating statistics the driver exposes certain

key stats in a Data Array if required. An upstream device can then monitor these

stats.

Add the following to your configuration file to activate these stats.

// Expose Driver Operating Stats.

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

fins-stats, UINT32, 200

Stat

Number

0 FINS_BAD_START

1 FINS_NET

2 FINS_STATION

3 FINS_UNIT

4 FINS_MRC

5 FINS_SRC

6 FINS_SID

Stats Description

Number of Messages received with bad start

byte.

Number of Messages received with bad or

unsupported Network Number.

Number of Messages received with bad or

unsupported Node Number.

Number of Messages received with bad or

unsupported Unit Number.

Number of Messages received with bad or

unsupported Main Request Code

Number of Messages received with bad or

unsupported Sub Request Code

Number of Messages received with wrong or

Sequence Id.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 36

FS-8704-16 Omron FINS Manual Page 33 of 37

7 FINS_ECODE

Total number of Messages ignored by PLC due to

error.

8 FINS_EMC Latest Main Error code returned by PLC.

9 FINS_ESC Latest Sub Error code returned by PLC.

10 FINS_EMRC

11 FINS_ESRC

12 FINS_STOR_SP

13 FINS_NO_WR_THU

Main and Sub Request codes for which PLC

returned Error Code.

Number of times Driver ignored messages

because of insufficient storage space.

Number of blocked attempts to write data via

write-thru operation.

Appendix B.3. Driver Error Messag es

Some configuration errors might produce an error every time a poll is generated.

This will fill the error buffer quickly and not add any clarity. For this reason the driver

suppresses subsequent similar messages on the System Error Screen. Thus it is

possible for the same error produced by multiple Map Descriptors to produce only

one error message on the System Error screen. The driver displays subsequent

error messages on the Driver Messages screen.

Note : In the actual message you will see that %d has been replaced by an integer,

%s by text indicating a data array name or map descriptor name and %x by two hex

characters.

Error Message Description and Action Required

FINS_UDP#1: Err. Not Enough

Space for <%d> items.

When offset <%d> DA <%s> MD

Data array length needs to be increased.10

<%s>

MRC <%2X> SRC<%2X>

FINS_UDP#2: Err. MD <%s>.

Error Returned by PLC.

MRC <%2X> SRC<%2X>

Main End Code <%2X> Sub End

Code <%2X>

This message shows a request that produced

this error at the PLC. Check Appendix A.1 to

see the detail for error and action.

See Driver Manual for End Codes

detail...

FINS_UDP#3: FYI. MRC<%2X>

SRC<%2X> Not Supported

FINS_UDP#11: Err. Station

Reqd/Ext <%d/%d>

This command is not supported by the Driver.

Response from PLC is not addressed to this

Client.

10

Some error messages require that the user correct a problem in the configuration. This is done by editing the

configuration CSV file, downloading the modified file and resetting the FieldServer to have the changes take effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 37

FS-8704-16 Omron FINS Manual Page 34 of 37

Error Message Description and Action Required

FINS_UDP#12: Err. Mrc-Src

Reqd/Ext <%2X-%2X/%2X-%2X>

Response from PLC not for current request.

FINS_UDP#21: Err. Message from

PLC is Not a Response>

MRC <%2X> SRC <%2x> MD

Message from PLC for shown request is not a

response.

<%s>

FINS_UDP#22: Err. Unknown

Device with Parameters...

Reqd/Ext dna <%d/%d> node

Response from PLC ignored because

mismatching for any shown parameters.

<%d/%d> unit <%d/%d>

FINS_UDP#23: Err. Message

Sequence Not Matched.Reqd/Ext

<%d/%d>

MRC <%2X> SRC <%2X> MD

Response from PLC ignored because of

mismatching request-response sequence Id.

<%s>

FINS_UDP#24: FYI. Bad

Start<%2X>

FINS_UDP#31 : FYI Net_Number

set to 1 Node <%s>

FINS_UDP#32 : FYI Udp Port is

<%d>

FINS_UDP#41: FYI. Write-thru not

Possible On MD <%s>

The message was ignored because the first

byte was bad.

The Net_Number parameter is 0 or not

specified. The Driver will automatically

change it to the default of 1

Information about UDP Port number in use.

Upstream device tried Write-thru operation on

other than IO memory area.

FINS_UDP:#51 FYI. You could

have used an Array called <%s>

to expose diagnostic info. Read

Define an array to expose stats if required.

See Appendix B.1

Manual.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 38

FS-8704-16 Omron FINS Manual Page 35 of 37

Appendix C. Troubleshooting tips

Appendix C.1. Connection Tips & Hints

1. Each transaction must be completed in one UDP message fragment. The

maximum length of a UDP fragment is 1500 bytes. Thus, if you wanted to read

730 words of PLC memory you will need to configure two MD’s. The one should

have a length of 729 and the other a length of 1. The reason is that when the

length is set to 729, then 729 words (or 1500 bytes including FINS and UDP

header) of data are read and this is the maximum for one message fragment.

Similarly as a Server, the Driver can handle transactions composed of a

maximum 1500 bytes (or 729 Words).

2. Ensure that the IP Address of the PLC provided under IP_Address parameter in

configuration is correct

3. Ensure the Node number of the FieldServer on the network is mentioned under

System_Node_Id parameter in configuration file

4. Ensure that the “Udp_port_number” parameter has the correct value in the

configuration file

5. Omron PLC's respond to remote FINS polls by sending UDP response messages

on the ethernet network. The PLC does not use the IP address of the incoming

poll to determine the IP address it must respond to. The PLC builds the IP

address it will send the response to using

1) Its own IP address and the Node ID of the polling device or

2) A routing table built using Omron software. To find out more information

consult the Omron Manaul W343-E1-3, Chapter 3 provides more information.

When the PLC uses its own IP address to build the IP address it will send the

response to, then special consideration should be taken if the PLC IP address is

Class A or B.

On a Class B network, the PLC uses the 1st two bytes of its own IP address, sets

the 3rd byte to zero and sets the 4th byte equal to the polling station's Node_Id.

Example: - Class B Addressing

A FieldServer with IP address=192.168.1.81 and system_node_id=34 polls for

data from a PLC with IP address =192.168.2.33 and Subnet mask = 255.255.0.0

The PLC responds to 192.168.2.33

255.255.0.0

192.168.x.y

Where x is always set to zero and

y is equal to 34 (The PLC obtains the node ID of 34 by

inspecting the contents of the poll message.)

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 39

FS-8704-16 Omron FINS Manual Page 36 of 37

Therefore the PLC responds to 192.168.0.34 which is clearly the wrong address

and the FieldServer will not see the response.

Example: - Class A Addressing

A FieldServer with IP address=192.168.1.81 and system_node_id=34 polls for

data from a PLC with IP address =192.168.2.33 and Subnet mask = 255.255.0.0

The PLC responds to 192.168.2.33

255.0.0.0

192.x.x.y

Where x is always set to zero and

y is equal to 34 (The PLC obtains the node ID of 34 by

inspecting the contents of the poll message.)

Therefore the PLC responds to 192.0.0.34 which is clearly the wrong address

and the FieldServer will not see the response.

Thus, if the PLC is using Class A/B IP addressing then the 3rd (Class B) or the

2nd and 3rd (Class A) bytes of the address must be zero as must the

FieldServer's if communications are to work.

There are ways around this problem, we believe. The solution requires usage of

the Omron PLC routing table. For more help consult with Omron's Tech Support.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 40

FS-8704-16 Omron FINS Manual Page 37 of 37

Appendix D. Revision History

Date Resp Format

Driver

Ver.

Doc.

Rev.

Comment

4/17/04 SSS 0.00 0 Issued for PMC review.

Reviewed and made some reference

4/20/04 PMC 0.00 1

changes, some type changes, changed

some wording and included Omron manual

excerpts for IP address setting.

Changed section 7.1.4, Value from PLC

does not agree with book value. Updated

4/20/04 SSS 0.00 2

section 8.1 Maximum words are 729 Not

750. This is the limit for one UDP message

fragment because of FINS and UDP

header.

4/20/04 SSS 0.00 2 Issued for Release.

Reformatted document. Changed

5/20/04 Meg Meg 0.00 3

language and grammar. Improved

readability of document. Updated

according to DUR0356

6/14/04 JD 0.00 4 Releasing

Updated according to DUR0372. Changed

8/26/04 Meg Meg 0.00 5

Appendix numbers to letters and updated

cross referencing.

12/29/04 JD 0.00 6 Releasing

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Loading...

Loading...