Page 1

Driver Version:

1.05

Document Revision:

6

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after November 2011

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-80 McQuay MicroTech® Open Protocol™

A Sierra Monitor Company

Page 2

McQuay Micro Tech Open Protocol Driver Manual Table of Contents

TABLE OF CONTENTS

1 McQuay Micro Tech Open Protocol Description ............................................................................................. 4

1.1 MicroTech Unit and System Controllers ........................................................................................................ 4

1.1.1 McQuay Equipment Types recognized by the driver. ............................................................................. 4

1.1.2 McQuay equipment not currently recongnized by the driver: ............................................................... 4

1.1.3 McQuay MicroTech network products used in conjunction with the driver: ......................................... 5

1.1.4 About MicroTech Network Architecture ................................................................................................ 6

1.2 Applying a FieldServer gateway to different MicroTech situations ............................................................... 6

1.2.1 Single standalone MicroTech 200 Series unit controller ........................................................................ 6

1.2.2 Multiple standalone MicroTech 200 Series unit controllers ................................................................... 7

1.2.3 Multiple standalone MicroTech “non-200 Series” unit controllers ........................................................ 7

1.2.4 Existing MicroTech network (Custom MicroTech Monitor software, NMP Panel, etc) .......................... 7

1.2.5 Existing MicroTech Open Protocol network ........................................................................................... 9

1.2.6 Replacing a BACdrop Gateway panel .................................................................................................... 9

1.3 MicroTech Communication Port Configuration ........................................................................................... 11

1.4 Reference Documents ................................................................................................................................. 12

2 Driver Features ............................................................................................................................................ 13

3 Driver Scope of Supply ................................................................................................................................. 13

3.1 Supplied by FieldServer Technologies for this driver ................................................................................... 13

3.2 Provided by Supplier of 3rd Party Equipment............................................................................................... 13

4 Hardware Connections ................................................................................................................................. 14

5 Data Array Parameters ................................................................................................................................. 15

6 Configuring the FieldServer as a McQuay Micro Tech Open Protocol Client ................................................. 16

6.1 Client Side Connection Parameters ............................................................................................................. 16

6.2 Client Side Node Parameters ....................................................................................................................... 17

6.3 Client Side Map Descriptors......................................................................................................................... 18

6.3.1 FieldServer Related Map Descriptor Parameters ................................................................................. 18

6.3.2 Driver Related Map Descriptor Parameters ......................................................................................... 18

6.3.3 Timing Parameters ............................................................................................................................... 18

6.3.4 Map Descriptor Example 1 – Read Everything. .................................................................................... 19

6.3.5 Map Descriptor Example 2 – Read a particular Data Field. ................................................................. 19

6.3.6 Map Descriptor Example 3 – Write. ..................................................................................................... 20

7 Configuring the FieldServer as a McQuay Micro Tech Open Protocol Server ................................................ 21

7.1 Server Side Connection Paramaters ............................................................................................................ 21

7.2 Server Side Node Parameters ...................................................................................................................... 22

7.3 Server Side Map Descriptors........................................................................................................................ 22

7.3.1 FieldServer Specific Map Descriptor Parameters ................................................................................. 22

7.3.2 Driver Specific Map Descriptor Parameters ......................................................................................... 23

7.3.3 Timing Parameters ............................................................................................................................... 23

7.3.4 Map Descriptor Example – Strategy 1. ................................................................................................ 24

7.3.5 Map Descriptor Example – Strategy 2. ................................................................................................ 24

Appendix A. Useful Features ................................................................................................................................ 25

Appendix A.1. Scaling .............................................................................................................................................. 25

Appendix A.1.1. User Scaling: ........................................................................................................................... 25

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 3

McQuay Micro Tech Open Protocol Driver Manual Table of Contents

Appendix A.1.2. Device Scaling: ....................................................................................................................... 25

Appendix A.2. Direct Addressing ............................................................................................................................. 26

Appendix A.3. Direct Addressing Example 1– Reading direct address. ................................................................... 27

Appendix A.4. Direct Addressing Example 2 – Controlling Bytes per Field – Reading ............................................. 27

Appendix A.5. Advanced Map Descriptor Example 3 – Controlling Bytes per Field – Writing ................................ 28

Appendix B. Troubleshooting ............................................................................................................................... 29

Appendix B.1. Connection Problems ....................................................................................................................... 29

Appendix B.2. Negative Acknowledgement - NAK .................................................................................................. 29

Appendix B.3. Node ID problems............................................................................................................................. 29

Appendix B.4. Server Side Configuration – Consecutive Addresses ........................................................................ 30

Appendix B.5. Configuring the OPM to enable communication between the FieldServer and McQuay devices ... 30

Appendix B.5.1. Configuring multiple McQuay devices to communicate to a FieldServer without an OPM:... 30

Appendix C. Reference ......................................................................................................................................... 32

Appendix C.1. Error Messages ................................................................................................................................. 32

Appendix C.2. Statistics ........................................................................................................................................... 34

Appendix C.3. McQuay Equipment Types recognized by the driver. ...................................................................... 35

Appendix C.4. Device Scaling Method ..................................................................................................................... 35

Appendix C.5. Data Field Name Tables .................................................................................................................... 35

Appendix C.5.1. Equipment Type: 200CFC 200 Series Centrifugal Chiller ......................................................... 35

Appendix C.5.2. Equipment Type: 050RPC Reciprocating Chiller ..................................................................... 37

Appendix C.5.3. Equipment Type: 100CFC 100 Series Centrifugal Chiller ......................................................... 38

Appendix C.5.4. Equipment Type : 001ASC Air Cooled Screw Chiller ................................................................ 40

Appendix C.5.5. Equipment Type : Self-Contained Units (SCUs) ....................................................................... 41

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 4

McQuay Micro Tech Open Protocol Driver Manual Page 4 of 43

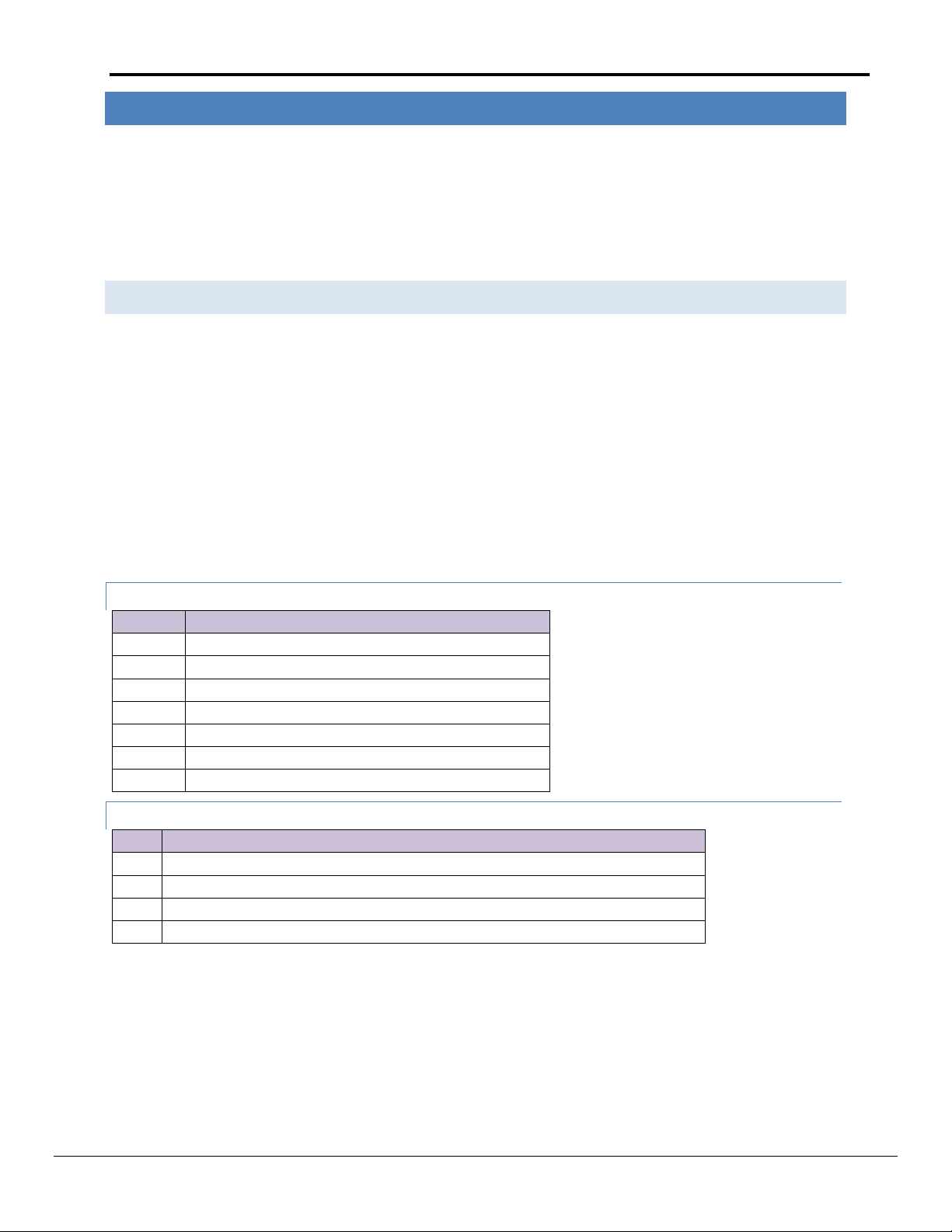

Code

Description

200CFC

200 Series Centrifugal Chiller

100CFC

100 Series Centrifugal Chiller

001ASC

Air Cooled Screw Chiller – V2.2 Single Compressor Only

000SCU

Self Contained Unit

0050RPC

Reciprocating Chiller

Rooftop Unit

Water Cooled Screw Chiller

Code

Description

Global Scroll chiller

Unit Ventilator

Water Source Heat Pump (WSHP)

MicroTech 2000 WSHP (through MCG (MicroTech Communications Gateway panel)

1 MCQUAY MICRO TECH OPEN PROTOCOL DESCRIPTION

This document describes the FieldServer driver used to transfer data between a FieldServer and MicroTech® unit

and/or network of controllers manufactured by McQuay International. Transfers are done using the controller's

Data Terminal Communications Protocol. In this document the protocol is referred to as the McQuay MicroTech®

Open Protocol. MicroTech controls are legacy products that may require the use of a FieldServer device in order to

support existing applications in need of unit or network controller replacements and/or integration into a Building

Automation System (BAS).

1.1 MicroTech Unit and Syst em Controllers

McQuay International has provided BAS manufacturers licensed access to stand-alone MicroTech unit controllers.

The network access, which is called Open Protocol™, allows a BAS to monitor status and change limited control

parameters in McQuay International HVAC equipment. Monitoring and controlling MicroTech unit controllers may

have required the use of a MicroTech system panel, depending on the unit type, number of units and other

network requirements. There are multiple combinations of MicroTech unit controllers and/or system panels (i.e.

Open Protocol networks) that could use a FieldServer device. FieldServer-supported devices, McQuay Open

Protocol controller descriptions, and network architecture diagrams are all described in the following section.

The McQuay MicroTech® Open Protocol driver allows the FieldServer to transfer data to and from devices over

either RS-232 or RS-485 using McQuay MicroTech® Open Protocol. The FieldServer can emulate either a Server or

Client.

1.1.1 McQuay Equipm ent Types recogn ized by the driv er.

1.1.2 McQuay equipm ent not currently reco ngnized by the driver:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 5

McQuay Micro Tech Open Protocol Driver Manual Page 5 of 43

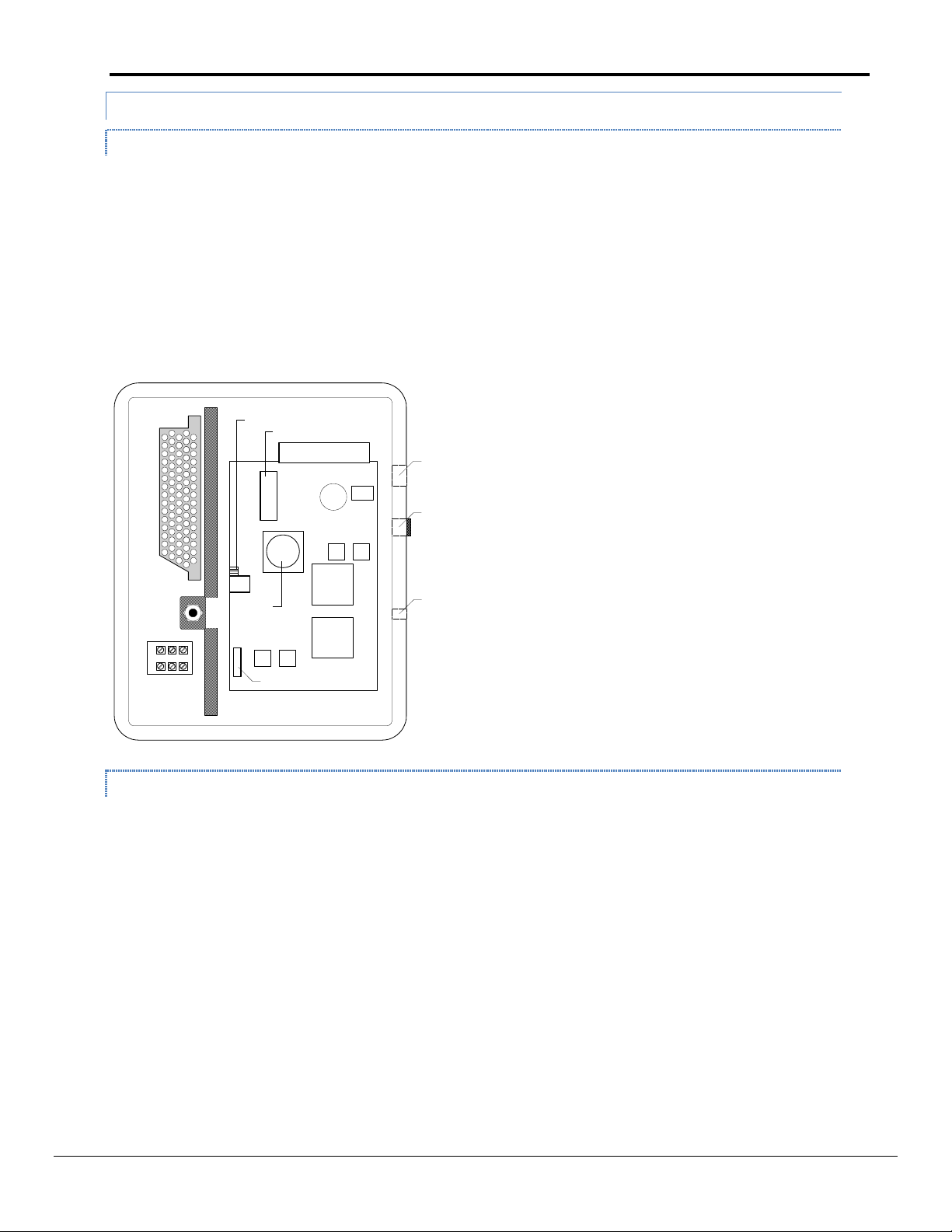

CB

PS

SBC

J1 connector

RJ-45

J22

L2

L1

GRD

“Etherne t” po rt

“Netwo rk” port

“PC” por t

Flash memory chip

Ethernet status LEDs

Speaker

5 Vdc power in

1.1.3 McQuay MicroTech network products us ed in conjunction wit h the driver:

1.1.3.1 MicroTech BACdrop™ panel

The MicroTech BACdrop gateway integrates a MicroTech network into a BACnet™ building automation system

(BAS) facilitating monitoring and control of McQuay International equipment from the BAS. The gateway

translates between BACnet objects on an Ethernet® network and McQuay memory locations on a proprietary

MicroTech network.

The BACdrop gateway is a passive device. It receives, translates, and re-transmits messages including both data

and control signals from one network to the other network in either direction but does not perform any

supervisory control for the various MicroTech controllers connected to it. Figure 1 shows the important features

of the BACdrop panel.

Figure 1. BACdrop Panel

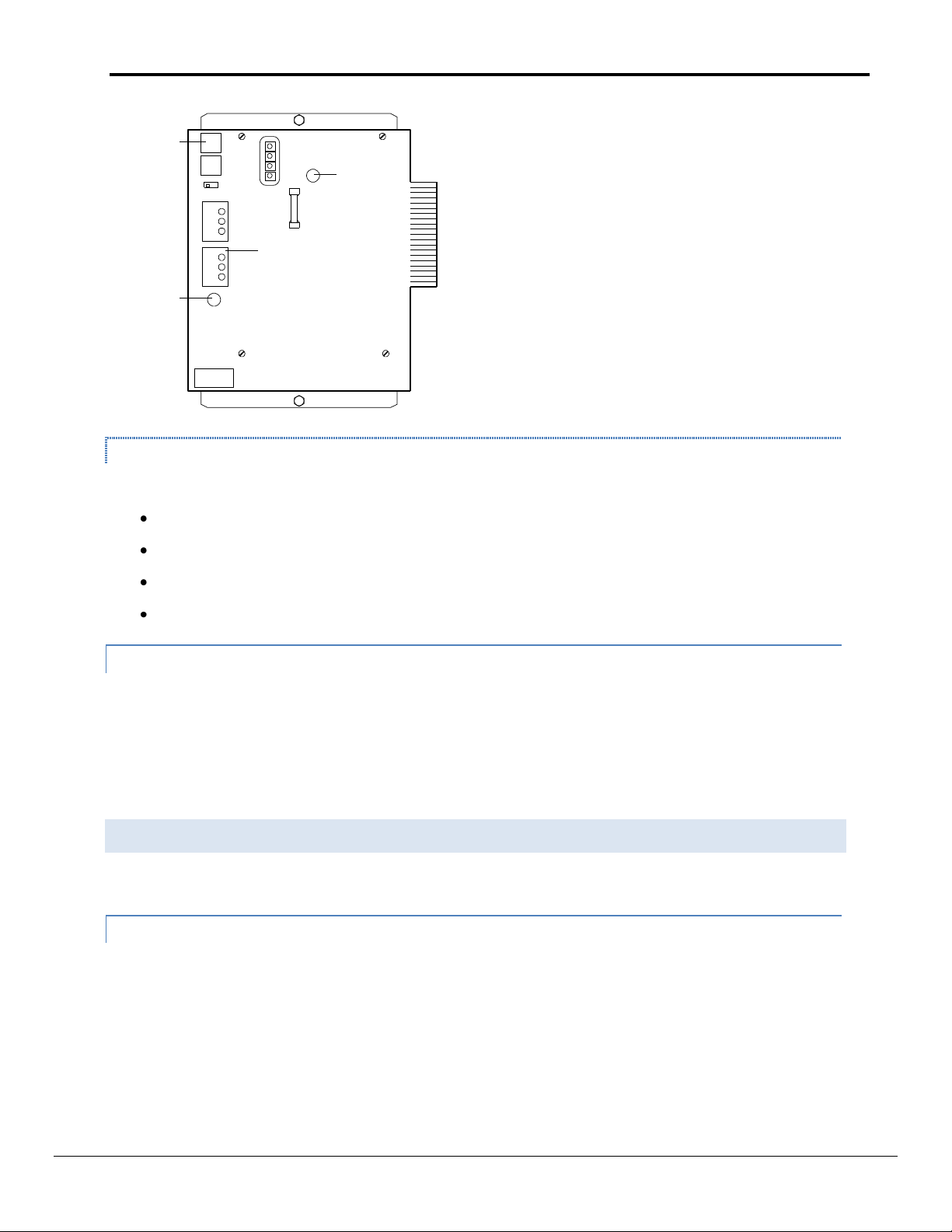

1.1.3.2 OPM – Open Protocol Master Panel

The OPM Panel is used when two or more MicroTech controllers need to be interfaced with a BAS by means of a

single-point connection. The OPM acts as a passive communications link between MicroTech controllers and the

BAS and does not perform any supervisory control for the various MicroTech controllers connected to it. When an

OPM is used, all supervisory control (scheduling, overrides, chiller sequencing) is handled by the BAS. The

maximum number of unit controllers per OPM depends on the BAS. For example, the OPM Panel could combine a

McQuay centrifugal chiller, a McQuay applied rooftop unit, and several unit ventilators into a network that a BAS

could connect to with a single cable. Figure 2 shows the important features of the OPM panel.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 6

McQuay Micro Tech Open Protocol Driver Manual Page 6 of 43

Port A

Port B

HI

LO

F1

L1

Port A Select

1 2 3

3

21

Hex

switches

Communication

ports

Red status

LED

Green

status LED

Figure 2. OPM Panel

1.1.3.3 Alternatives to the OPM Panel

The following MicroTech network controllers, which perform specific supervisory control tasks, can be used as

substitutes for the OPM Panel:

RMC (Remote Monitoring and Control panel – Applied Air product)

CSC (Chiller System Controller panel – chiller product)

RMS (Remote Monitoring and Sequencing panel – chiller product)

LWC (Loop Water Controller – WSHP product)

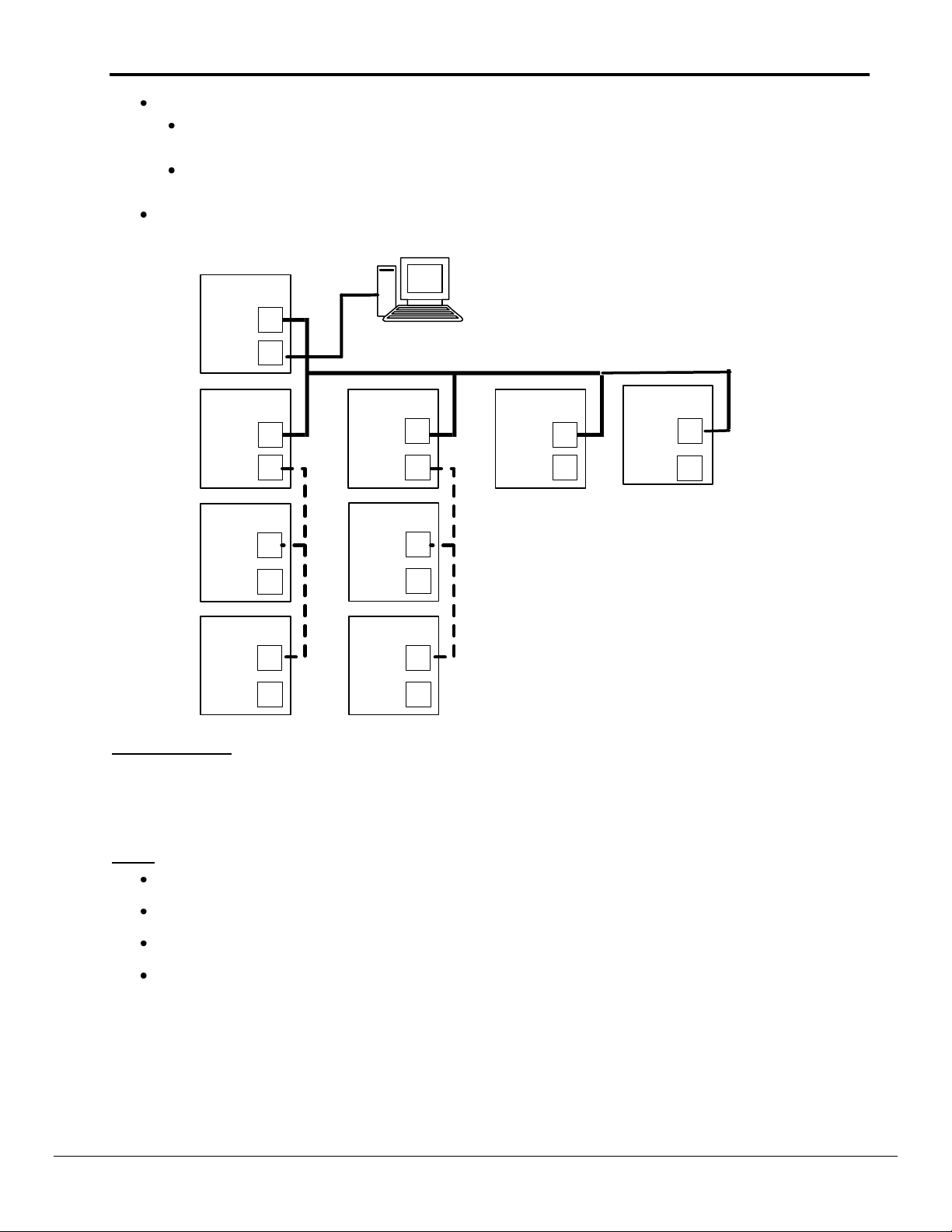

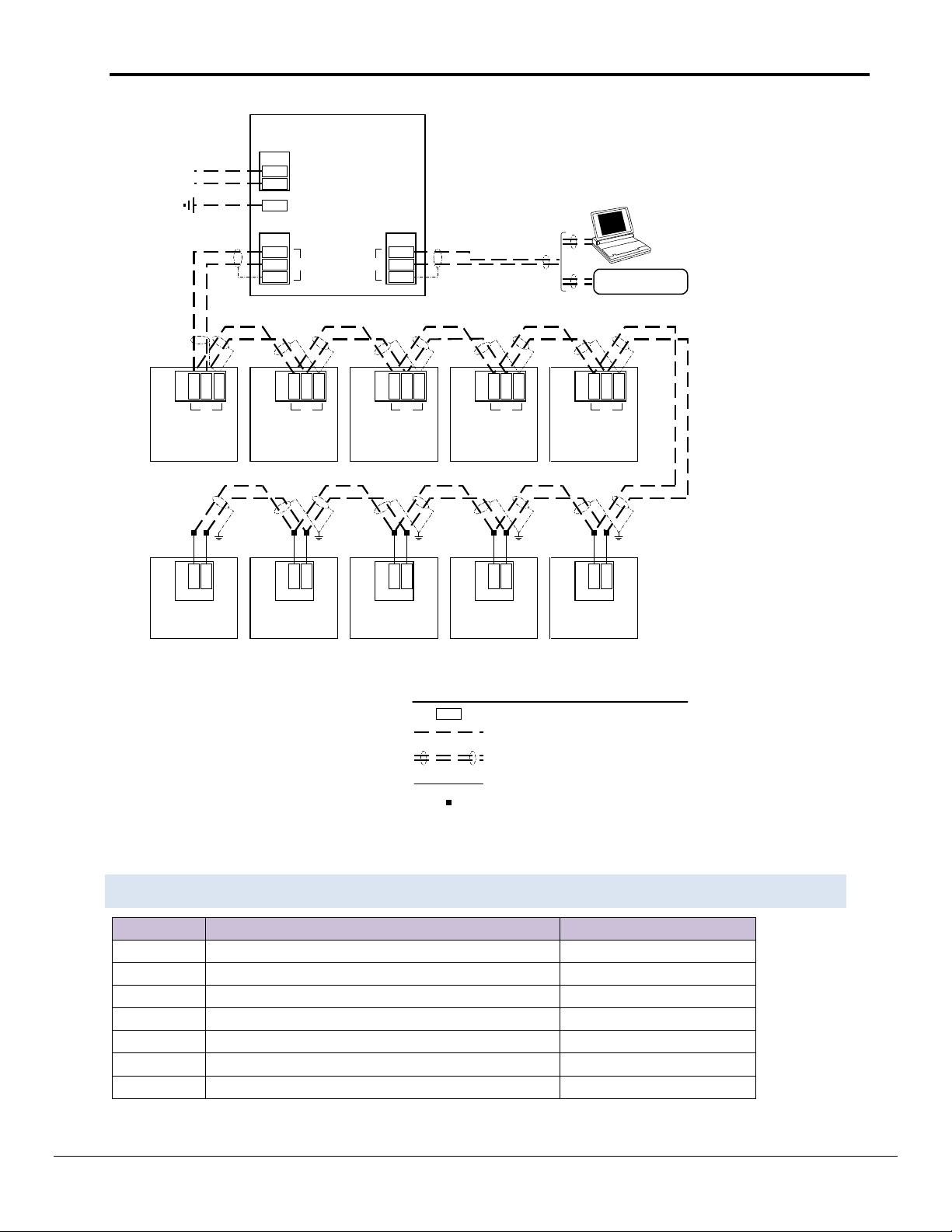

1.1.4 About M ic roTech Network Architecture

All controllers in a MicroTech network are assigned a level: level 1, level 2, or level 3. All networks must have one

level 1 controller to coordinate communications. Multiple level 2 controllers connect to the level 1 controller with

a communications trunk. A trunk is defined as an isolated section of the daisy-chained network wiring. The

network wiring between all controllers is a trunk. Multiple level 3 controllers can be connected to a level 2

controller with a separate trunk; however, this is typically not done in BACdrop applications. The maximum

allowable length of a communications trunk is 5000 ft (1524 m). See Figures 6 and 7 for examples of field wiring.

1.2 Apply ing a FieldServer gateway to diffe re nt MicroTech situation s

There are multiple scenarios where a FieldServer gateway device may be applied to one or more MicroTech

controllers. The most common are listed below, followed by a brief description of each one.

1.2.1 Single st andalone MicroTech 200 Series unit controller

When a FieldServer device is connected to a single MicroTech unit controller, the FieldServer connects to the “A”

port of the MicroTech controller. The unit controller is typically a level 2 device with a Comm Port Configuration of

“L2 TTY/Slave”. MicroTech Level 2 devices must have an address with a non-zero value to the left of the decimal

point and "00" to the right of the decimal point (for example, 01.00, 02.00, 03.00, etc). For a level 2 device, the left

side (the non-zero portion) of the address is set with the controller's rotary hex switches.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 7

McQuay Micro Tech Open Protocol Driver Manual Page 7 of 43

1.2.2 Multiple st andalone MicroTech 20 0 Series unit controllers

1.2.2.1 MicroTech Addressing and Network Archit ecture

When a FieldServer device is connected to two or more MicroTech controllers, a level 1 MicroTech controller is

required to coordinate communications. Typically the level 1 device in this situation is an Open Protocol Master

Panel (an "OPM"). However, the OPM Panel is no longer available from McQuay, so another MicroTech device

may function as the Level 1 device. A 200 Series MicroTech unit controller (for example, a Self-Contained Unit

(SCU) controller) can be re-configured as a level 1 device. Thus if a site has several SCUs, one of them can be reconfigured as level 1 and the FieldServer connects to the "A" port of that unit controller. A Level 2 daisy chain is

then connected from the “B” port of the level 1 SCU to the “B” port of the remaining Level 2 SCU's.

It is also possible to use a supervisory MicroTech network controller as the level 1 device which coordinates

communications between the FieldServer device and multiple level 2 MicroTech controllers. Examples of

supervisory controllers are the RMC, CSC, and RMS panels.

Another alternative is to use an NMP (Network Master Panel) controller. An NMP is the level 1 device used in a

MicroTech network (see Figure 3). The NMP coordinates communications of all level 2 and level 3 MicroTech

controllers in this type of network. The NMP also coordinates unit time scheduling, processes alarms, and does

other functions. If an NMP is used in this way, it is necessary to “corrupt” its checksums so that the NMP

application code no longer runs. The process of corrupting checksums can be performed with MicroTech Monitor®

software using the read/write screen. Please contact the McQuay Controls Customer Support group at 866-4627829 for more information about using Monitor software.

1.2.3 Multiple st andalone MicroTech “ no n-200 Se ries” unit controllers

If a FieldServer gateway device is applied to a site that has several “standalone” unit controllers that have never

been networked together, there are certain guidelines that must be followed. First, a level 1 device is required to

coordinate the communications between the FieldServer device and the MicroTech unit controllers. Typically an

OPM Panel is used for this purpose. However, the OPM is no longer available from McQuay. If the multiple unit

controllers are “non-200 Series” MicroTech controllers such as Unit Ventilators (UVs) or Water Source Heat Pumps

(WSHPs), a Level 1 MicroTech controller must be added to the network to coordinate communications of the Level

2 UVs or WSHPs.

In addition, network wiring would be required to be installed. The FieldServer would be wired to the “A” port of

the Level 1 device. A “level 2 daisy-chain” would be required from the “B” port of the level 1 device to the “B” port

of each level 2 device. See Figures 6 and 7 for network wiring details.

1.2.4 Existing MicroTech netwo rk (Custom M icroTech Monitor soft ware, NMP Panel, etc)

1.2.4.1 With level 3 devices (Unit Vents or WSHPs)

If a FieldServer gateway device is applied to a site that has an existing “MicroTech network” (meaning that it has

custom MicroTech Monitor software for that site and an NMP Panel) and Unit Vents or WSHPs, changes are

required as follows:

The checksums in the NMP’s application code must be corrupted so that the NMP no longer functions as a

Network Master Panel. The FieldServer device connects to the A port of the NMP.

Level 2 LMPs (Local Master Panel) must be removed from the network.

The RS-485 daisy chain connecting all of the Unit Vents or WSHPs must be connected directly to the “B”

port of the Level 1 NMP.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 8

McQuay Micro Tech Open Protocol Driver Manual Page 8 of 43

T

M

M

S

T

S

T

S

Level 1

Laptop PC

RS 232

RS 485

T

S

Port B

Port A

NMP

LMP

MCG RTU

LWC

Port B

Port A

Port B

Port B

Port B

Port A Port A

Port A

Level 2 Trunk

Level 2

Level 3

T

S

WSHP

Port B

Port A

T

S

WSHP

Port B

Port A

T

S

MT 2000

WSHP

Port B

Port A

T

S

Port B

Port A

MT 2000

WSHP

Different application code must be downloaded into all Unit Vents and WSHPs.

In the case of Unit Vents, the “Level 3 network code” for use in a MicroTech network must be

replaced with “Level 2 standalone” Unit Vent code.

In the case of WSHPs, the “Level 3” code for use in a MicroTech network must be replaced with

“Level 2 standalone” WSHP code.

See Figure 3 for details.

Figure 3. MicroTech Network Configurations with Level 1 NMP Supervisory Controller

Port Configuration

M=Master

S=Slave

T=TTY (for PC connection)

Notes:

A PC running MicroTechMonitor connects to an NMP through it’s a Port configured as “TTY”

The A Port of a Level 2 MCG is configured as “USER” to communicate with the MCG’s SLTA.

MicroTech WSHP’s on a MicroTech network require a LMP (Level 2 Local Master Panel) above them.

MicroTech 2000 WSHP’s with LonWorks code (vs LonMark code) are installed below an MCG.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 9

McQuay Micro Tech Open Protocol Driver Manual Page 9 of 43

1.2.4.2 With no level 3 devices

If a FieldServer gateway device is applied to a site that has an existing “MicroTech network” (meaning that it has

custom MicroTech Monitor software for that site and an NMP Panel) with only level 2 controllers and no level 3

devices (such as Unit Vents or WSHPs), changes are required as follows:

The checksums in the NMP’s application code must be corrupted so that the NMP no longer functions as a

Network master Panel. The FieldServer device connects to the “A” port of the NMP.

No network wiring changes are necessary

1.2.5 Existing MicroTech Open P ro tocol net work

If a FieldServer gateway device is applied to a site that has an existing “Open Protocol network”, the following

assumptions are made:

The site has either an OPM Panel or some other level 1 MicroTech controller that is functioning as an

OPM.

Any Unit Vents or WSHPs in the network are already running the proper “Level 2” application code

required for an “Open Protocol” network.

No network wiring changes are necessary.

See Figure 7 for details

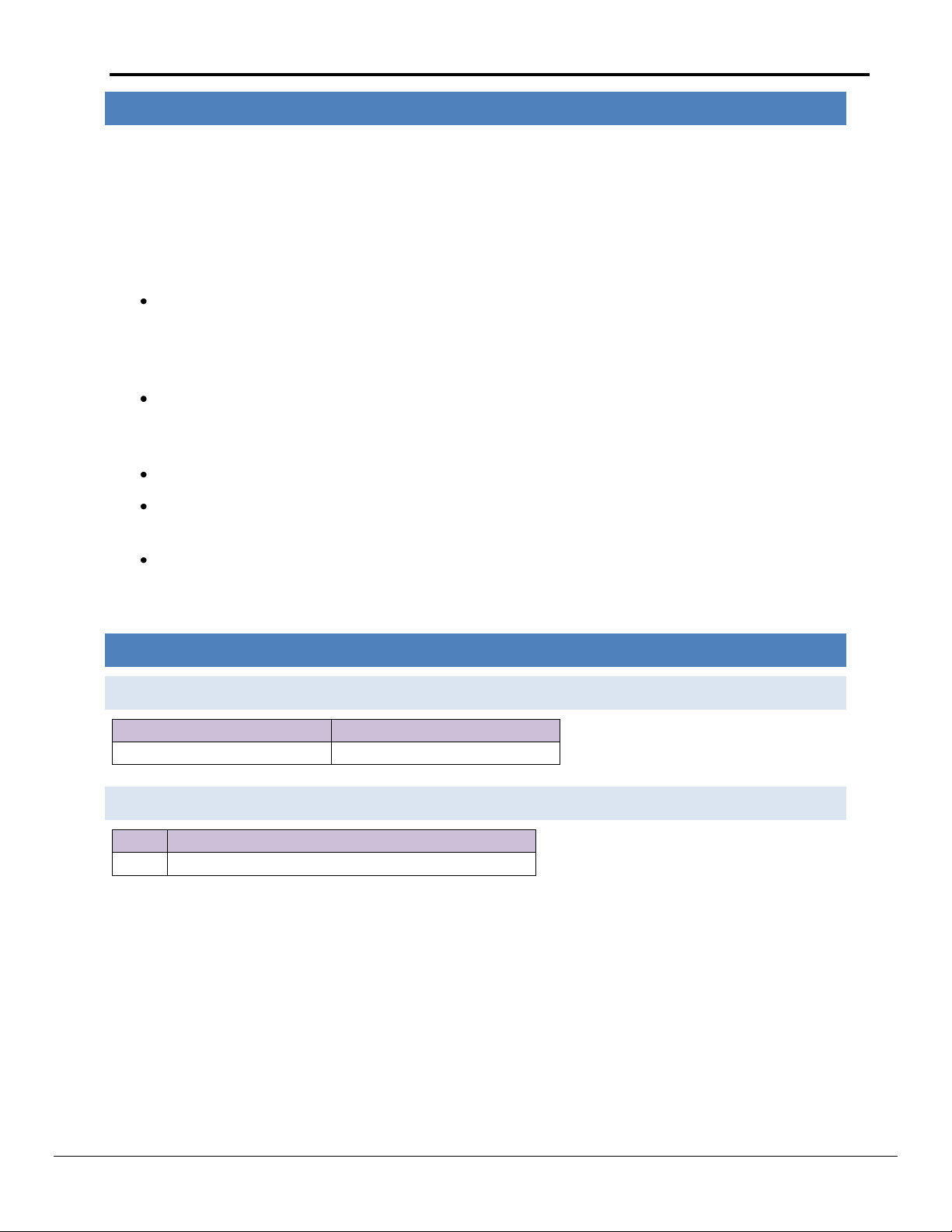

1.2.6 Replacin g a BACdrop Gat eway panel

1.2.6.1 Connected a Single Micro Tech unit controlle r

When a FieldServer device is used to replace a BACdrop panel that has been connected to one MicroTech unit

controller, some re-wiring is necessary. The RS-485 network terminals of the BACdrop panel are connected to the

“B” Port of the MicroTech controller, but the FieldServer connects to the “A” port of the MicroTech controller. The

unit controller will be a level 2 device with a Comm Port Configuration of “L2 TTY/Slave”. MicroTech Level 2

devices must have an address with a non-zero value to the left of the decimal point and "00" to the right of the

decimal point (for example, 01.00). For a level 2 device, the left side (the non-zero portion) of the address is set

with the controller's rotary hex switches.

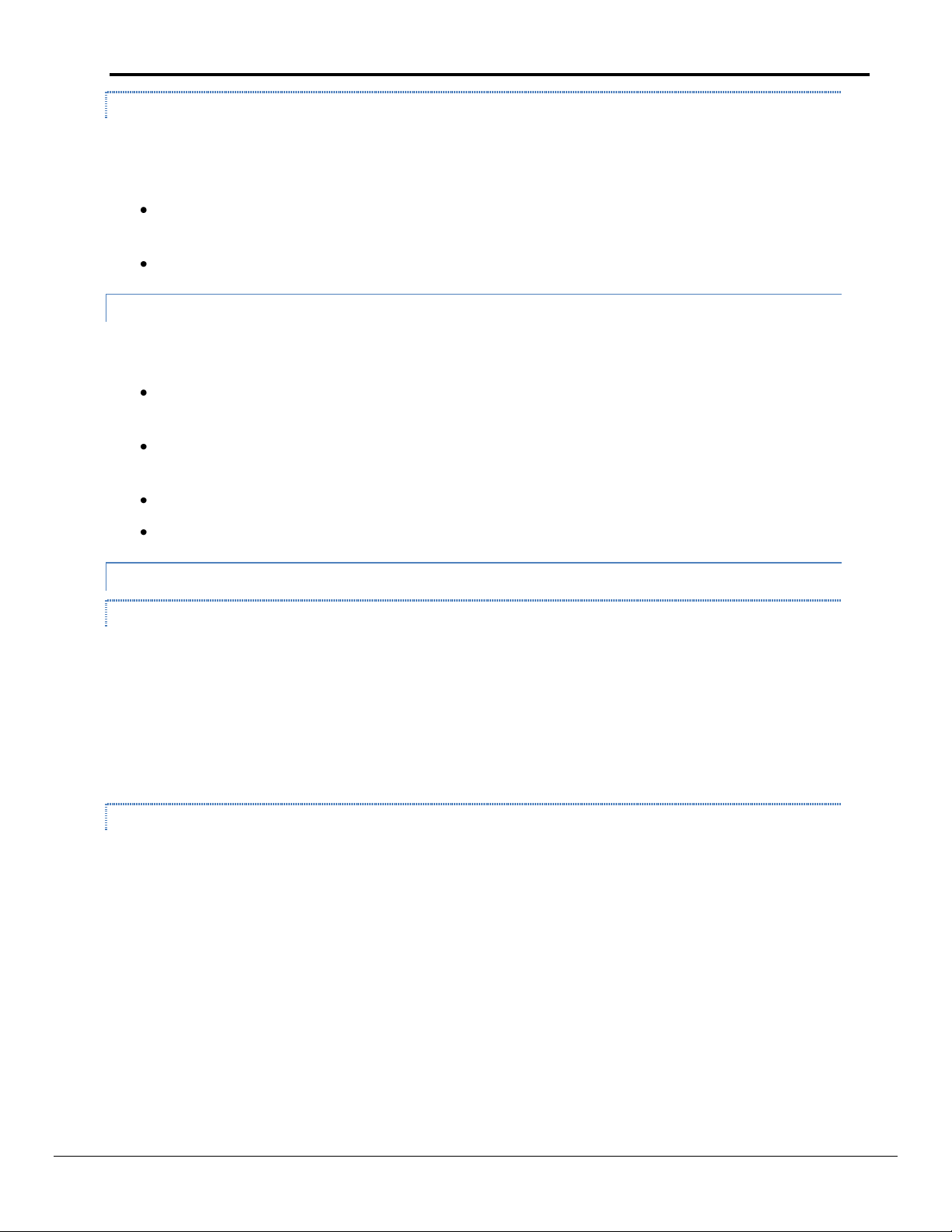

1.2.6.2 Connected to Multiple MicroTech unit control lers

When a FieldServer device is used to replace a BACdrop panel that has been connected to multiple MicroTech unit

controllers with no Level 1 supervisory panel such as an RMC, CSC, or RMS, a Level 1 device must be added. If the

unit controllers are 200 Series MicroTech, this can be accomplished by re-configuring one of the unit controllers to

be Level 1. The alternative to re-configuring one of the existing unit controllers to be a Level 1 device is to add a

level 1 device such as an OPM, RMC, CSC, or RMS, but this may be difficult because all of these control panels are

obsolete and no longer available. For a typical BACdrop network, the BACdrop panel is the level 1 controller and

the unit controllers are level 2 controllers. See Figures 4 and 6 for details.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 10

McQuay Micro Tech Open Protocol Driver Manual Page 10 of 43

RTU UV

Up to 63 MicroTech

controllers per BACdrop

BACnet on ISO 8802-3 (Ethernet), 10BaseT

MicroTech

BACdrop

(level 1)

Chiller UV UV UVSCU

Level 2

MicroTech

Level 1

BACnet BAS

by others

Main "front end"

PC for BAS

MicroTech network (RS-485)

Chiller

Level 2

MicroTech

Up to 63 MicroTech

controllers per BACdrop

BACnet BAS

by others

BACnet on ISO 8802-3 (Ethernet), 10BaseT

MicroTech

BACdrop

(level 2)

Level 1

ChillerChiller

Main "front end"

PC for BAS

CSC

Chiller

MicroTech network (RS-485)

All data requests from BACnet BAS to

MicroTech level-2 controllers are routed

through level-1 MicroTech controller

Figure 4. MicroTech Architecture

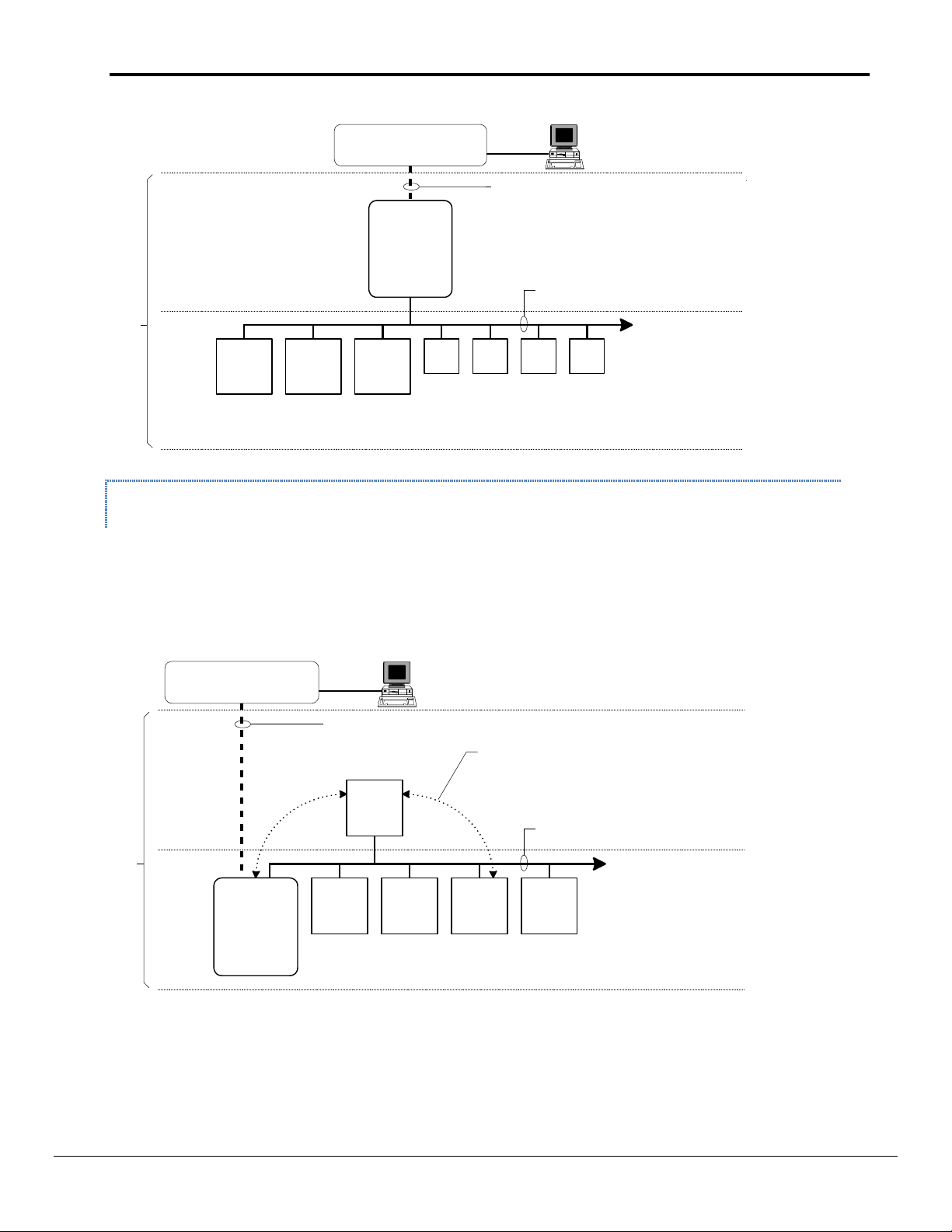

1.2.6.3 Connected to multiple MicroTech unit controllers and a supervisory panel su ch as an RMC,

CSC, or RMS panel

When a FieldServer device will be replacing a BACdrop Gateway panel that was connected to multiple MicroTech

unit controllers with a Level 1 supervisory panel such as an RMC, CSC, or RMS, some re-wiring may be necessary.

The FieldServer device must be wired to the A Port of the Level 1 device. The B Port of the Level 1 device is then

wired to the B Port of all Level 2 devices with a daisy chain. See Figure 5 for details.

Figure 5. Level 2 BACdrop Panel with Level 1 Supervisory Panel

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 11

McQuay Micro Tech Open Protocol Driver Manual Page 11 of 43

TS2

BACdrop

Hot

Neutral

100 – 240 Vac

Power

L2

L1

GRD

Notes:

1. Twisted, shielded pair cable must meet the following

minimum requirements: 300 V, 60°C, 20 AWG, polyethylene

insulated, with a PVC outer jacket and drain wire (Belden

8762 or equivalent). Some local codes may require the use

of plenum rated cable.

2. 10BaseT Ethernet cable. To directly connect a PC to the

Ethernet port, a hub or a special crossover cable must be

used.

3. Cable length must not exceed 5000 ft (1524 m).

4. Standard serial cable. A null modem is not required.

See notes 1 & 3

Self-contained AC

Port B

GND

TB7

Reciprocating

chiller

Port B

139

TB4

Screw chiller

Port B

55

BLK

WHT

B+

B–

138

137

54

53

Comm B

UVC (325)

1

2

PNK

GRY

Comm B

UVC (125)

4

5

PNK

GRY

RJ-45

3rd-party BAS

See note 2

TB1

Centrifugal chiller

(series 200)

Port B

858684

TB2

Applied rooftop

Port B

130

128

129

Legend

Field wiring terminal

Field wiring: discrete

Factory wiring

Field wiring: twisted, shielded pair cable

with drain wire (see note 1)

B+

Crimp or solder splice

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

BLK

WHT

Comm B

UVC (325)

1

2

PNK

GRY

Comm B

UVC (325)

1

2

PNK

GRY

Comm B

UVC (325)

1

2

PNK

GRY

Ethernet

DB9

PC

PC

+

–

GRD

Network

See note 4

Field wiring: 10BaseT Ethernet

Standard serial cable

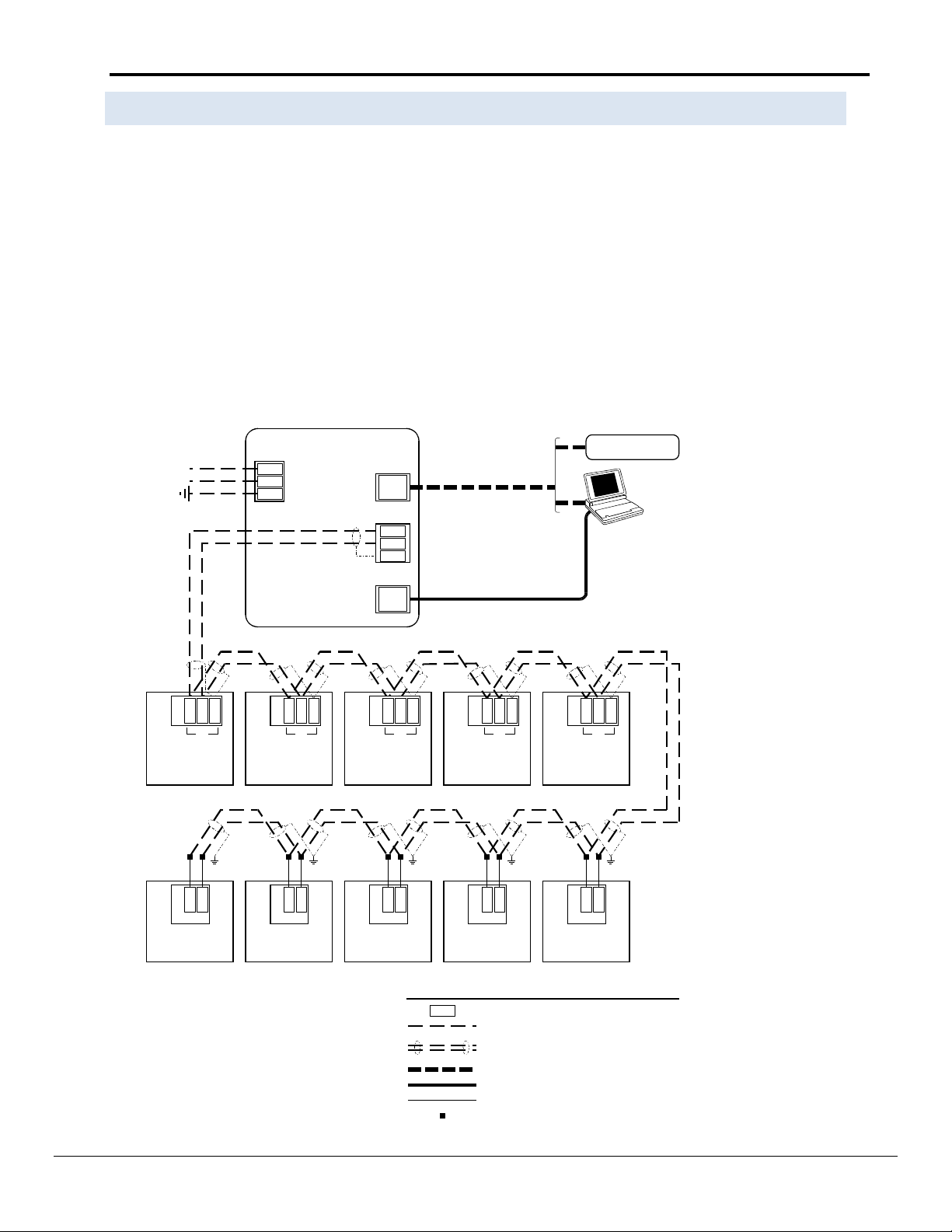

1.3 MicroTech Comm unicat ion Port Configuration

In addition to the rules about MicroTech architecture and addressing, there is also a critical parameter called the

Comm Port Configuration. The Comm Port Configuration must also be set correctly for a unit controller to be able

to communicate. This comm port configuration for level 1 devices is different to level 2 devices. While it is

necessary to know this for proper unit controller setup and for troubleshooting communication problems, it is not

critical from the FieldServer side for programming or routing.

A level 1 device must have its communication port configuration set up as “Level 1 TTY/Slave”. To change this

configuration, connect to the unit controller with MicroTech Monitor software through the “A” port, proceed to

the “Read/Write” screen, read memory address “0A11”, and change the value to “C1” (Level 1 TTY/Slave). After

doing this, the controller must also have its rotary hex switches set to the Level 1 address of “00” to make the unit

controller’s network address 00.00. Please note that power must be cycled to the controller for this new hex

switch setting to take effect.

Figure 6. MicroTech Network with BACdrop Panel as Level 1 Device

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 12

McQuay Micro Tech Open Protocol Driver Manual Page 12 of 43

Document

Description

Location

IM 474

Open Protocol Master (OPM) Panel

www.mcquay.com

IM 689

BACdrop Gateway for MicroTech

www.mcquay.com

IM 658

Network Master Panel (NMP)

Contact McQuay

CD 573875Y

Microtech Open Protocol Wiring Diagrams

Contact McQuay

IM 444

Remote Monitoring and Control (RMC) Panel

Contact McQuay

IM 498

Remote Monitoring and Sequencing (RMS) Panel

Contact McQuay

IM 618

MicroTech Chiller System Controller (CSC) Panel

Contact McQuay

*Or other Level 1 Device (CSC, etc.)

Figure 7. MicroTech Network with OPM Panel as Level 1 Device

1.4 Reference Documents

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 13

McQuay Micro Tech Open Protocol Driver Manual Page 13 of 43

FieldServer Technologies Part #

Description

FS-8917-16

RJ45 to terminal connector cable.

Part #

Description

McQuay Motor Mount Connector for Port A connection

2 DRIVER FEATURES

When emulating a Client, the driver enables the FieldServer to request ‘Everything’ from the McQuay, allow

specific fields to be read or written and apply device scaling to be applied.

When emulating a Server, the driver provides an emulation of the byte memory of a device and responds to read

and write requests.

The following important points and limitations should be noted.

Arising from a feature of the McQuay MicroTech® Open Protocol is the peculiarity that when a multi-byte

value is written to a McQuay device, the write is done one byte at a time (one byte of data can be

transferred per poll/response message pair) allowing for the possibility that the multi byte value is only

partially correct until all the messages have been completed.

The vendor equipment is limited to a maximum of 9600 baud. Given that each message packet can only

transfer one byte of data and that some data of interest is multi-byte, users of this protocol should expect

low data transfer rates.

Port expansion is not supported for this driver.

Each MicroTech® controller is shipped from the factory with a unique job site password. The passwords

are provided by the McQuay International representative at the time of startup.

The driver does not validate passwords when configured as a Server. This means that requests to read or

write data will succeed even if the password supplied with the request is incorrect.

3 DRIVER SCOPE OF SUPPLY

3.1 Sup plied by FieldServ er Technologies for this driver

3.2 Provided by Supplier of 3

rd

Party Equipment

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 14

McQuay Micro Tech Open Protocol Driver Manual Page 14 of 43

FS-8917-16

RJ45-04

BLUE/WHITE

RJ45-08

ORANGE/WHITE

SERIES 200 CONTROLLER

FS-COM

RJ45-01

BROWN

FS-Tx/+

FS-Rx/-

FieldServer

Connect to one of the RS-232

Ports on the FieldServer

P1

18

4 HARDWARE CONNECTIONS

The FieldServer is connected to the McQuay device as shown below.

Configure the McQuay device according to manufacturer’s instructions.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 15

McQuay Micro Tech Open Protocol Driver Manual Page 15 of 43

Section Title

Data_Arrays

Column Title

Function

Legal Values

Data_Array_Name

Provide name for Data Array

Up to 15 alphanumeric characters

Data_Array_Format

Provide data format. Each Data Array can only take

on one format.

FLOAT, BIT, UInt16, SInt16,

Packed_Bit, Byte, Packed_Byte,

Swapped_Byte

Data_Array_Length

Number of Data Objects. Must be larger than the

data storage area required by the Map Descriptors

for the data being placed in this array.

1-10, 000

// Data Arrays

Data_Arrays

Data_Array_Name

, Data_Array_Format

, Data_Array_Length

DA_AI_01

, UInt16,

, 200

DA_AO_01

, UInt16

, 200

DA_DI_01

, Bit

, 200

DA_DO_01

, Bit

, 200

5 DATA ARRAY PARAMETERS

Data Arrays are “protocol neutral” data buffers for storage of data to be passed between protocols. It is necessary

to declare the data format of each of the Data Arrays to facilitate correct storage of the relevant data.

Example

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 16

McQuay Micro Tech Open Protocol Driver Manual Page 16 of 43

Section Title

Connections

Column Title

Function

Legal Values

Port

Specify which port the device is connected to

the FieldServer

P1-P8, R1-R21

Baud*

Specify baud rate

300, 1200, 2400, 4800, 9600 (Vendor

limitation).

Parity*

Specify parity

Even (Vendor limitation)

Data_Bits*

Specify data bits

7 (Vendor limitation)

Stop_Bits*

Specify stop bits

1

Protocol

Specify protocol used

MCQ, McQuay

Poll Delay*

Time between internal polls

0-32000 s, 1s

// Client Side Connections

Connections

Port

, Baud

, Parity

, Data_Bits

, Protocol

, Poll_Delay

P1

, 9600

, Even

, 7

, McQuay

, 0.100s

6 CONFIGURING THE FIELDSERVER AS A MCQUAY MICRO TECH OPEN PROTOCOL CLIENT

For a detailed discussion on FieldServer configuration, please refer to the FieldServer Configuration Manual. The

information that follows describes how to expand upon the factory defaults provided in the configuration files

included with the FieldServer. (See “.csv” sample files provided with the FieldServer).

This section documents and describes the parameters necessary for configuring the FieldServer to communicate

with a McQuay Micro Tech Open Protocol Server.

The configuration file tells the FieldServer about its interfaces, and the routing of data required. In order to enable

the FieldServer for McQuay Micro Tech Open Protocol communications, the driver independent FieldServer buffers

need to be declared in the “Data Arrays” section, the destination device addresses need to be declared in the

“Client Side Nodes” section, and the data required from the Servers needs to be mapped in the “Client Side Map

Descriptors” section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the default.

6.1 Client Side Connectio n Parameters

Example

1

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for details of the ports available

on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 17

McQuay Micro Tech Open Protocol Driver Manual Page 17 of 43

Section Title

Nodes

Column Title

Function

Legal Values

Node_Name

Provide name for Node

Up to 32 alphanumeric

characters

Protocol

Specify protocol used

MCQ, McQuay

Port

Specify which port the device is connected to the FieldServer

P1-P8, R1-R22

PLC_Type

The name of the McQuay Equipment type being polled. The

equipment type must be known for the driver to operate

correctly.

200CFC, 100CFC, 050RPC,

001ASC, 000SCU, TypeUnknown

Password

Maximum of 8 characters.

Ascii characters only.

Node_Hi

Specify the rotary Hi address switch setting of the Mcquay

controller

0 to F

Node_Lo

Specify the rotary Lo address switch setting of the Mcquay

controller

0 to F

// Client Side Nodes

Nodes

Node_Name

, Node_Hi

, Node_Lo

, Protocol

, Port

, Password

, PLC_Type

Node_200CFC

, 3

, B

, McQuay

, P1

, 85760430

, 200CFC

6.2 Client Side Node Param eters

2

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for details of the ports available

on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 18

McQuay Micro Tech Open Protocol Driver Manual Page 18 of 43

Column Title

Function

Legal Values

Map_Descriptor_Name

Name of this Map Descriptor

Up to 32 alphanumeric characters

Data_Array_Name

Name of Data Array where data is to be

stored in the FieldServer

One of the Data Array Names

specified in Section 5.

Data_Array_Offset

Starting location in Data Array

0 to maximum specified in Section 5.

Function

Function of Client Map Descriptor

Rdbc, Wrbc, Wrbx

Column Title

Function

Legal Values

Node_Name

Name of Node to fetch data from

One of the Node

Names specified

in Section 6.2.

Length*

This parameter normally refers to the length of Map Descriptor. Since

one data field can be read or written per poll/response sequence, the

driver assumes a length of 1. When Bytes_Per_Field is specified, must be

set to 1. When used to read addresses (Appendix A.3), this parameter is

used to specify the number of data elements to be read.

Any positive

integer, 1.

Field_Name*

The name of the data field of interest. Each address with meaningful

data in the McQuay device has a name. The field names are defined in a

specification for each device type. If the field name is unknown, the

Address can be defined. Refer to Appendix A.2 for further information.

A field name

from Appendix

C.3, Everything,

Device_Scaling*

If set to No then the driver stores the raw values, if set to Yes, the data is

scaled before storing. Refer to Appendix A.1.2 for information on the

device scaling applied. Note that ‘Device_Scaling’ has no meaning when

writing to a McQuay device. The Device_Scaling keyword needs to be

used in conjunction with Field_Name

Yes, No

Address*

The address in the McQuay device that contains the data of interest. .

Used with direct addressing – refer to Appendix A.2.

Any positive

integer, -

Bytes_Per_Field*

This parameter is used with direct addressing. When reading, up to 4

consecutive address locations in the McQuay device can be combined

and stored in a single Data Array element. When writing, one value from

the Data Array may be sent to up to 4 consecutive address locations in

the McQuay device. Refer to Appendix A.2 for more information. If this

parameter is specified, length must be set to 1.

1, 2, 3, 4

Column Title

Function

Legal Values

Scan_Interval

Rate at which data is polled

>0.1s

6.3 Client Side Map Descri ptors

6.3.1 Field Server Related Ma p Descriptor Parame ters

6.3.2 Drive r Related Map Descripto r Parameters

6.3.3 Timing P arameters

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 19

McQuay Micro Tech Open Protocol Driver Manual Page 19 of 43

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Node_Name

, Length

, Scan_Interval

, Field_Name

, Device_Scaling

Read Chiller 1

, DA_CHILLER1

, 0

, Rdbc

, Chiller1

, 1

, 1.0s

, Everything

, Yes

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Scan_Interval

, Node_Name

, Length

, Field_Name

Chiller10_Op_Mode

, DA_OPERATIONAL_MODES

, 10

, Rdbc

, 0s

, Chiller10

, 1

, Chiller Operation Mode

Many validation or

error messages report

the name of the Map

Descriptor in the

message and, thus it is

strongly recommended

that unique names be

used.

Each field read has its

value stored in this

Data Array. The

location is dependent

on the field name. The

length of the Data

Array should be at least

200, so that all

parameters can be

stored.

The driver will read

every data field

known for the

device.

The values will be scaled

before storage.

Example: The ‘Evaporator

Refrigerant Pressure’ will be

stored by dividing the raw

value read by 10.

This parameter

connects the Map

Descriptor to a

Node which in turn

connects the Map

Descriptor to a port.

Ensure that the field name is spaced and spelled exactly as it is

printed in Appendix C.3

6.3.4 Map D escriptor Example 1 – Read Everything.

In this example the Map Descriptor tells the driver to read all data fields known for the Node. The data fields are read sequentially and the values placed in the

Data Array at a location determined by the driver. Appendix C.3 outlines the data read and the Data Array location of each field. There is no way of telling this

command to read some fields more often than others. Each field is read in turn and when the end of the list is reached the driver starts at the beginning again.

6.3.5 Map D escriptor Example 2 – Read a particular Data Field.

This example illustrates how to read data for one particular field of interest. The data is read every 2.0 seconds and the value obtained is stored in the Data

Array named DA_OPERATIONAL_MODES at location 10.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 20

McQuay Micro Tech Open Protocol Driver Manual Page 20 of 43

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Node_Name

, Length

, Field_Name

Chiller1_Op_Mode

, DA_MODES

, 0

, Wrbx

, Chiller1

, 1

, Chiller Operation Mode

The data is only written

when the contents of

element zero of the array

named DA_MODES

changes.

The name of the

data field to be

written to.

6.3.6 Map D escriptor Example 3 – Write.

In this example data is written to control fields in the McQuay device using the Wrbx (write on change) function. A write message will be generated each time

the data at index 0 in the Data Array changes. When writing multibyte fields, several messages are required to transfer the byte values to the McQuay devices.

Note that ‘Device_Scaling’ has no meaning when writing to a McQuay device. The user must ensure that valid numbers are written to the data fields.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 21

McQuay Micro Tech Open Protocol Driver Manual Page 21 of 43

Section Title

Connections

Column Title

Function

Legal Values

Port

Specify which port the device is connected to

the FieldServer

P1-P8, R1-R23

Baud*

Specify baud rate

300, 1200, 2400, 4800, 9600 (Vendor

limitation)

Parity*

Specify parity

Even (Vendor limitation)

Data_Bits*

Specify data bits

7 (Vendor limitation)

Stop_Bits*

Specify stop bits

1(Vendor limitation)

Protocol

Specify protocol used

MCQ, McQuay

// Server Side Connections

Connections

Port

, Baud

, Parity

, Data_Bits

, Protocol

, Stop_Bits

, Poll_Delay

P1

, 9600

, Even

, 7

, McQuay

, 1

, 0.100s

7 CONFIGURING THE FIELDSERVER AS A MCQUAY MICRO TECH OPEN PROTOCOL

SERVER

7.1 Server Side Connection Paramaters

Example

3

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for details of the ports available

on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 22

McQuay Micro Tech Open Protocol Driver Manual Page 22 of 43

Section Title

Nodes

Column Title

Function

Legal Values

Node_Name

Provide name for node

Up to 32 alphanumeric characters

Protocol

Specify protocol used

MCQ, McQuay

Port*

Specify which port the device is connected

to the FieldServer. This parameter is

optional for Server side nodes. The reason

is that when a poll is received on any port

an attempt will be made to match it

against any Map Descriptor/node

irrespective of the port. If emulating more

than one Node with the same address,

however, the Nodes must be linked to

specific ports.

P1-P8, R1-R24

PLC_Type

This parameter has no meaning for a

Server but it must be specified to allow the

driver to complete its configuration file

validation.

200CFC, 100CFC, 050RPC, 001ASC, 000SCU, TypeUnknown

Password*

This parameter is ignored for a Server.

Although every poll contains a password,

this driver does no password validation

when configured as a Server.

Ascii characters only.

Node_Hi

Specify the rotary Hi address switch

setting of the Mcquay controller

0 to F

Node_Lo

Specify the rotary Lo address switch

setting of the Mcquay controller

0 to F

// Server Side Nodes

Nodes

Node_Name

, Node_Hi

, Node_Lo

, Protocol

, PLC_Type

, Password

Node_A

, 3

, B

, McQuay

, 200CFC

, 85760430

Column Title

Function

Legal Values

Map_Descriptor_Name

Name of this Map Descriptor

Up to 32 alphanumeric characters

7.2 Server Side Node P arameters

Example

7.3 Server Side Map Descri ptors

7.3.1 Field Server Specific M a p Descriptor Param eters

4

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction manual for details of the ports available

on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 23

McQuay Micro Tech Open Protocol Driver Manual Page 23 of 43

Data_Array_Name

Name of Data Array where data is to be

stored in the FieldServer

One of the Data Array names from

Section 5

Data_Array_Offset

Starting location in Data Array

0 to (Data_Array_Length -1) as specified

in Section 5

Function

Function of Client Map Descriptor

Passive

Column Title

Function

Legal Values

Node_Name

Name of Node to fetch data from

One of the Node Names

specified in Section 7.2

Length

Length of Map Descriptor

1-10000

Address

Starting address of read block. Addresses cannot be specified

in hexadecimal format.

Any positive integer

Column Title

Function

Legal Values

Scada_Hold_Timeout

Specifies time Server side waits before responding to Client that

node is offline on FieldServer Client side.

>1.0s

7.3.2 Drive r Specific Map Desc ript or Parameters

7.3.3 Timing P arameters

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 24

McQuay Micro Tech Open Protocol Driver Manual Page 24 of 43

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Node_Name

, Address

, Length

Chiller1_emulation

, DA_CHILLER1

, 0

, Passive

, Chiller1

, 1

, 10000

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Node_Name

, Address

, Length

Chiller1_emulation1

, DA_CHILLER1

, 0

, Passive

, Chiller1

, 1024

, 256

Chiller1_emulation2

, DA_CHILLER1

, 256

, Passive

, Chiller1

, 2048

, 256

Ensure that Data Array’s

length is at least as long as

the Map Descriptor’s.

A data format of BYTE is

appropriate.

Passive means that the Map

Descriptor responds to polls but

does not generate any polls itself.

The Node name connects the

Map Descriptor to a Node

definition and possibly to a port.

10, 000 is the maximum length of a

Data Array so there is no point in

making the Map Descriptor longer.

The same Data

Array is used for

both Map

Descriptors.

By using the same

Data Array and

changing the offset

the data can all be

packed into a

smaller array.

1024 = 0x400; 2048 = 0x800

These two address ranges cover almost all the data fields in a 200 series chiller.

A few more Map Descriptors could be added to serve the remaining data field

addresses.

7.3.4 Map D escriptor Example – Strategy 1.

This example illustrates the configuration of the FieldServer as a McQuay Micro Tech Open Protocol Server where a single Map Descriptor is used to emulate a

McQuay device’s memory as one large single block of bytes. Any requests in the address range 1 -0x270F can be serviced by this one Map Descriptor. Is has

the drawback that a large Data Array which will be mostly empty is used. This does not affect performance but uses the FieldServer’s memory resource.

When a poll is received, the driver looks through the Map Descriptor and finds one with a matching Node and one whose address and length cover the poll’s

address.

7.3.5 Map D escriptor Example – Strategy 2.

In this example the memory being emulated is divided into chunks to avoid having a large sparse array. When a poll is received, the driver looks through the

Map Descriptors and finds one with a matching Node and one whose address and length cover the poll’s address.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 25

McQuay Micro Tech Open Protocol Driver Manual Page 25 of 43

Map_Descriptors

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Function

, Node_Name

, Address

, Length

, Field_Name

, Device_Scaling

, Scan_Interval

Read_field1

, DA_TEMP_SCALED

, 0

, Rdbc

, Node_200CFC

, 1

, 1

, Outdoor Air Temperature - BAS

, Yes

, 9.5s

Appendix A. Useful Features

Appendix A.1. Scaling

Appendix A.1.1. User Scali n g :

The user can specify scaling in the configuration file which allows a value to be scaled before being stored in a Data Array or after being extracted from a data for writing

to McQuay device. This scaling is specified by using the following keywords in Map Descriptor definition.

Data_Array_Low_Scale,

Data_Array_High_Scale,

Device_Low_Scale,

Device_High_Scale…..

Appendix A.1.2. Device Scal i n g:

The raw values read from a McQuay device may be treated as raw values or they may be scaled. Device scaling is the term used to describe the hard-coded scaling

specified by McQuay for each data field. By applying device scaling the user can avoid details or knowledge of the scaling and used the converted value directly.

If this scaling is required then use the Device_Scaling parameter (see 6.3.2). Note that this parameter needs to be used in conjunction with Field_Name.

There are 5 device scaling methods. Refer to Appendix C.4 and Appendix C.5 for information on the application of these parameters.

Note that when device scaling is applied it is applied without consideration of the raw value. Where the raw value has a special meaning (available in the McQuay packet

documents for the equipment type of interest); this driver does not apply any special consideration to these special values.

As a Client: - Device and User scaling may be applied.

As a Server. Device Scaling and User scaling is not applied. The raw value written to any data location is stored as is and the raw value read from a Data Array used in

formatting the response to a read.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 26

McQuay Micro Tech Open Protocol Driver Manual Page 26 of 43

Appendix A.2. Direct Addressing

Direct addressing allows data to be read from the McQuay device when the field name is unknown. McQuay

specifies the addresses in hexadecimal notation but they must be specified in the CSV file in decimal format. For

example, to read McQuay address 0x0400, the address in the CSV file must be entered as 1024.

If reading multiple addressing at once (i.e. if the length is greater than 1) it may be necessary to adjust the timeout

for the Map Descriptor.

It is possible to read multiple addresses using one Map Descriptorbut it is only possible to write to a single address.

Refer to examples on the following pages.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 27

McQuay Micro Tech Open Protocol Driver Manual Page 27 of 43

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Node_Name

, Address

, Length

, Scan_Interval

, Function

Chiller1_emulation

, DA_CHILLER1

, 0

, Chiller1

, 4096

, 10

, 1.0s

, Rdbc

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Node_Name

, Address

, Length

, Bytes_per_Field

, Scan_Interval

, Function

Chiller1_emulation

, DA_CHILLER1

, 0

, Chiller1

, 4096

, 1

, 4

, 1.0s

, Rdbc

Specify the address

in decimal

A data format of

BYTE is appropriate,

Specify the address

in decimal

Length must be set

to 1 when

Bytes_per_Field is

specified.

A value between 1 and 4 - tells

the driver how many consecutive

addresses to read from the

remote device. The data value for

each address is combined into a

single value before it is stored.

Appendix A.3. Direct Addressing Example 1– Reading direct address.

This example reads 10 data elements from a McQuay device starting at address 4096 (= 0x1000). The 10 values obtained are stored in DA_CHILLER1 starting at

offset zero.

Appendix A.4. Direct Addressing Example 2 – Controlling Bytes per Field – Reading

This example reads a McQuay device starting at address 4096 (= 0x1000) to 4099 incl. Before storing the data from the responses, the FieldServer combines

the 4 values into a single value and stores this single value in a single Data Array element.

The driver reads address 4096 and gets a value. Call this value v0.

The driver reads address 4097 and gets a value. Call this value v1.

The driver reads address 4098 and gets a value. Call this value v2.

The driver reads address 4099 and gets a value. Call this value v3.

When the 4th address has been read, the driver calculates Total_Value = v0 + v1 * 0x100 + v2 * 0x10000 + v3 * 0x1000000. The Total_Value is stored in the

Data Array.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 28

McQuay Micro Tech Open Protocol Driver Manual Page 28 of 43

Map_Descriptor_Name

, Data_Array_Name

, Data_Array_Offset

, Node_Name

, Address

, Length

, Bytes_Per_Field

, Scan_Interval

, Function

Chiller1_emulation

, DA_CHILLER1

, 0

, Chiller1

, 4096

, 1

, 2

, 1.0s

, Wrbc

Specify the address

in decimal

Length must be set

to 1 when

Bytes_Per_Field is

specified.

A value from 1 to 4 -tells the

driver how many consecutive

addresses to write to The data

value written to each address is

based on the single value

extracted from offset 0 in the

Data Array DA_CHILLER1

Appendix A.5. Advanced Map Descriptor Example 3 – Controlling Bytes per Field – Writing

This example writes to a McQuay device starting at address 4096 (= 0x1000) to 4097incl. The value written to each address location is based on a single value

extracted from the FieldServer’s Data Arrays.

The value v0 = (value_extracted_from_DA) AND 0xff

The value v1 = (value_extracted_from_DA shift right by 8) AND 0xff

The driver writes value v0 to address 4096.

The driver writes value v1 to address 4097.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 29

McQuay Micro Tech Open Protocol Driver Manual Page 29 of 43

Appendix B. Troubleshooting

Appendix B.1. Connection Problems

The driver produces a timeout each time a message is sent. If the number of timeouts is the same as the number

of messages sent then the McQuay device has never sent a response. The following reasons may be applicable:

Incorrect connection settings - the messages sent by the FieldServer cannot be interpreted by the

McQuay device.

Incorrect connection wiring – the McQuay device may require a jumper on its serial port to deflect

hardware handshaking. Refer to the vendor manual.

Serial port failure – If the Tx LED is not flashing each time a message is sent, the port is not working

The McQuay device is off.

If the Node_ID and Route are incorrect, the McQuay device will not respond at all.

Appendix B.2. Negative Acknowledgement - NAK

The Server sends a NAK message and increments the NAK stat each time a poll is unsuccessful. An occasional NAK

may indicate a corrupted message. If the number of NAK's is the same as the number of transmitted messages to

a Node, one of the following problems could apply:

Bad Password - the password specified in the "read" command did not match any of the access level

passwords stored in the MicroTech controller to which the terminal is connected. Call FST Tech support

for default passwords or call your Vendor. FST recommends checking the password first as in almost all

reports the problem was resolved by changing the password.

Device has been polled with an invalid command code.

Bad Node_ID / Route parameters for the node.

The MCQ device received the message and thought it was badly formatted. This is unlikely on a repeated

basis unless the connection settings were slightly wrong.

The packet structure was invalid

The packet was received with a parity or framing error

Appendix B.3. Node ID problems

If the Node is incorrectly specified, the FieldServer will not get a response from the McQuay unit. The ID used to

communicate with the McQuay unit needs to be determined. This may not be the same as shown on the Rotary

switches of the unit. Note that McQuay uses Hexadecimal notation for addressing, therefore, if connection to the

Unit is with address 0201, this is in Hex and the Node ID for the FieldServer configuration needs to be 513.

Use Node_Id=256 only if it is required that connected panel should respond regardless of its own internal address.

For Driver Versions 1.05a and later, the Node_ID parameter has been replaced with the Node_Hi/Node_Lo

Parameters. Refer to Sections 6.2and 7.2

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 30

McQuay Micro Tech Open Protocol Driver Manual Page 30 of 43

Map_Descriptors

Map_Descriptor_Name

,

Data_Array_Name

,

Data_Array_Offset

,

Function

,

Node_Name

,

Address

,

Length

Supply Fan Status

, DA_AI_01

, 01

, Passive

, Node_A

, 1118

, 1

Supply Temp

, DA_AI_01

, 02

, Passive

, Node_A

, 1063

, 1

Space Temp

, DA_AI_01

, 03

, Passive

, Node_A

, 1066

, 1

Control Temp Part 1

, DA_AI_01

, 04

, Passive

, Node_A

, 1074

, 1

Connect FieldServer

to port A of the OPM

(RS-232 or RS-485

depending on the Port

A select)

Connect daisy chained

McQuay devices to

port B of the OPM

Set HI and LO rotary

switches on the OPM

to “00”

Appendix B.4. Server Side Configuration – Consecutive Addresses

Some variables have their values stored in two consecutive address locations. When the Client polls for the value it

actually sends two read messages – one for each address. When configuring the Server side, therefore, it is

necessary to define two Map Descriptors for variables which require two consecutive addresses.

Appendix B.5. Configuring the OPM to enable communication between the FieldServer and McQuay

devices

Appendix B.5.1. Con figu ring multip le McQuay d evices to c o mmunicat e to a Fi eldS e r ver

without an OPM:

The FieldServer will be wired to a Level 1 Microtech controller at port A. Port B of the Level 1 MicroTech controller

will be connected to the daisy chained Level 2 Microtech controllers. This has been tested with a SCU.

1. Power down the Microtech controller to be configured as Level 1. Set HI and LO rotary switches to “00”.

Power up the unit.

2. Connect the Microtech controller to a PC through Port A (RS-232).

3. Daisy chain other McQuay devices to Port B (RS-485)

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 31

McQuay Micro Tech Open Protocol Driver Manual Page 31 of 43

4. Start McQuay Open Protocol Monitoring Software

5. Enter the User Name as “McQuay” and the password as ”SGC”

6. Once in the main menu, hit ‘F7’ to enter Advanced Features

7. Hit ‘F1’ to enter Read/Write Memory

8. Enter “b00.00” to change the Box Address (Node_HI and Node_LO) to “00”

9. Enter “w0A11 C1” to write C1 to memory address 0A11. This will set up the comm port configuration

with Port A as TTY and Port B as Master

10. Test if the wiring to the daisy chained devices is correct by doing the following:

o To read from a controller with the rotary hex switches set to “01”, change the box address to

01.00 and enter r0A11

o If you get a response, then it is wired correctly

o It is suggested that you read from each daisy chained controller

11. Shut down the McQuay Open Protocol Monitoring Software

12. Disconnect unit from the PC

13. Connect FieldServer to Port A (RS-232)

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 32

McQuay Micro Tech Open Protocol Driver Manual Page 32 of 43

Error Message

Action

McQuay:#1 FYI. The MapDesc called <%s> is too

short

The length of the Map Descriptor used to expose driver

statistics is too short. Set the length to at least 1000.

You can ignore this message – the driver will abandon

excess statistics.

McQuay:#2 FYI. You could have used a MapDesc

called <%s> to expose diagnostic info.

You can safely ignore this message. It is a prompt. Refer

to Appendix C.2.

McQuay:#3 FYI. Normally passwords are defined for

each node.

This is a reminder that a password is expected when a

node is defined. Refer to sections 6.2 or 7.2. Even though

password checking is not enforced when the driver is

configured as a Server, the driver expects one to be

defined for every node.

McQuay:#4 Err. Node list if full. Max=%d

A maximum of 100 McQuay device nodes can be

configured per FieldServer. If the limit is reached, call

support.

McQuay:#5 Err. Node=%d has more than one

password.

A node has been provided with two passwords. This is

either a configuration error or two nodes with the same

address are connected to different ports. The driver can

only store one password per node address and cannot

use the port number to differentiate them. Re-program

the McQuay devices to have the same passwords if they

have the same addresses.

*McQuay:#9 FYI. Device scaling method unknown.

Device Scaling is being applied and the driver doesn’t

know how to scale a variable. Please submit your

configuration file with your request for support.

McQuay:#10 Err. Node=%s. Equip. type not

recognized.

The driver doesn’t recognize the equipment type

specified using the PLC_Type parameter in the

configuration file. Refer to Appendix C.3 for a list of valid

equipment types.5

McQuay:#11 Err. Node=%s. Equip. Type not

specified.

Refer to Sections 6.2, 7.2. and Appendix C.35

McQuay:#13 Err. MapDesc=%s. Field Name

unknown.

Refer to Appendix C.3 for a list of valid field names. Refer

also to Sections 6.3 or 0.

McQuay:#14 Err. MapDesc=%s. Max Len=1 for

Writes with direct addr.

Corrective action is required. When writing to a McQuay

device using direct addressing the length may only be 15

Appendix C. Reference

Appendix C.1. Error Messages

Those messages marked with an * are only printed once even if they occur repeatedly.

5

Correct the configuration by editing the CSV file and downloading it to the FieldServer, then reset the FieldServer for the changes to take

effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 33

McQuay Micro Tech Open Protocol Driver Manual Page 33 of 43

Error Message

Action

McQuay:#15 Err. MapDesc=%s. Field Name/Address

Required.

Neither a field name nor an address was specified. The

driver does not know what location to read. Specify a

field name from Appendix C.3.5

McQuay:#16 Err. MapDesc=%s. No Node.

Each Map Descriptor must be connected to a node. This is

done by specifying a node name. 5

McQuay:#17 Err. MapDesc=%s. Md too short.

The offset added to the length of the Map Descriptor

extends beyond the Data Array. Increase the Data Array

length. 5

McQuay:#18 Err. MapDesc=%s. Cannot write

'Everything'.

When using ‘everything’ as a field name the Map

Descriptor function must be Rdbc or Rdb as this is a read

only function.5

McQuay:#19 do diagnostic 3

Call FieldServer Technical Support. A developer

diagnostic has been called and should not have been.

McQuay:#20 do diagnostic 1

McQuay:#21 do diagnostic 2

McQuay:#22 Err. Illegal Node_ID [%d] - Set to 1

Check configuration file, a Node_ID is out of range. 6

McQuay:#25 Err. Max Len=1 when Bytes_Per_Field >

1. MD=%s.

The length parameter must be set to 1 when a Map

Descriptor has the Bytes_Per_Field parameter specified5

McQuay:#26 Err. Max Bytes_Per_Field=4. MD=%s.

Legal values for the Bytes_Per_Field parameter are whole

numbers in the range 1 to 4 inclusive. 5

McQuay:#27* Err. Response=NAK. Read Manual.

Maybe password or Node_ID

This message is printed if a NAK response is received in

the first few polls to a node. The driver guesses that the

reason is that the Node_ID/route or password has been

incorrectly specified in the configuration file. Verify these

settings. The message is printed once and suppressed for

subsequent occurrences. Refer to Appendix B.2

McQuay:#28* Err. Device responded with a NAK.

The message is printed and then suppressed for

subsequent occurrences, but the NAK stat is incremented

for each occurrence. The driver is reporting that the

McQuay device responded with a NAK under different

circumstances from msg#27 which is printed if the NAK is

received during the first few polls. The message indicates

that the McQuay device could not respond. If the NAK's

are occasional, assume that noise has corrupted an

occasional message. If they occur frequently assume a

systematic or connection error. Refer to Appendix B.2.

McQuay : #29 FYI. Config requires non-critical

update. Route parameter is not used any more. In

driver version V1.05a and later either use

NODE_HI(0-F) and \NODE_LO(0-F) or NODE_ID(0-

255), use Node_Id(256) only if it is required that

connected Mcquay panel should respond regardless

of its own internal address

For Driver versions 1.05a and later, the route parmeter is

replaced by NODE_HI(0-F) and NODE_LO(0-F). NODE_ID

is still supported for backward compatibility with previous

driver versions. Use NodeID(0-255), use Node_Id(256)

only if it is required that connected Mcquay panel should

respond regardless of its own internal address6

6

Correct the configuration by editing the CSV file and downloading it to the FieldServer, then reset the FieldServer for the changes to take

effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web: www.fieldserver.com

Tel: (408) 262 2299 Fax: (408) 262 2269 Toll Free: (888) 509 1970 email: support@fieldserver.com

Page 34

McQuay Micro Tech Open Protocol Driver Manual Page 34 of 43

Statistic

Description

NAK

Each time a negative acknowledgement message is received.

CHECKSUM

Each time that a message is received that contains a non-ASCII character.

NOISE

An acknowledgement message contains an unrecognized code.

NO START

Each time a message is received that doesn’t begin with a space.

PROTOCOL

All other errors are reported as protocol errors

Location

Statistic

0

MCQ_STAT_PASSWORD

10

MCQ_STAT_NAK

11

MCQ_STAT_NOISE

12

MCQ_STAT_NOISE_CODE

13

MCQ_STAT_NON_ASCII_CHARS

14

MCQ_STAT_BAD_START_BYTE

15

MCQ_STAT_OTHER_CMPLT_ERR

16

MCQ_STAT_CLIENT_BYTES_RCVD

Location

Statistic

17

MCQ_STAT_CLIENT_FRAGS_RCVD

18