Page 1

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-64 ATMI ACM

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2001

Page 2

FS-8700-64 ATMI ACM Table of Contents

Table of Contents

1. ATMI ACM DESCRIPTION................................................................................................................... 2

2. DRIVER SCOPE OF SUPPLY..............................................................................................................2

2.1 SUPPLIED BY FIELDSERVER FOR THIS DRIVER ................................................................................... 2

2.2 PROVIDED BY USER ......................................................................................................................... 2

3. HARDWARE CONNECTIONS ............................................................................................................. 3

4. CONFIGURING THE FIELDSERVER AS A ATMI ACM CLIENT ....................................................... 4

4.1 DATA ARRAYS ................................................................................................................................. 4

4.2 CLIENT SIDE CONNECTIONS ............................................................................................................. 5

4.3 CLIENT SIDE NODES ........................................................................................................................ 6

4.4 CLIENT SIDE MAP DESCRIPTORS...................................................................................................... 6

4.4.1 FieldServer Specific Map Descriptor Parameters ..................................................................... 6

4.4.2 Driver Specific Map Descriptor Parameters..............................................................................7

4.4.3 Timing Parameters....................................................................................................................7

4.4.4 Map Descriptor Example 1- Gas Values, Alarms & Warnings for all slots/ports. ..................... 8

4.4.5 Map Descriptor Example2 – Gas values for the current (most recent) port sample.................9

4.4.6 Map Descriptor Example3 – Storing Malfunction Data ........................................................... 10

4.4.7 Map Descriptor Example4 – Gas values for the current (most recent) slot sample. ..............11

5. CONFIGURING THE FIELDSERVER AS A ATMI ACM SERVER ...................................................12

6. DRIVER NOTES .................................................................................................................................12

6.1 DATA POSITION IN THE DATA ARRAYS .............................................................................................12

6.2 DRIVER STATS .............................................................................................................................. 13

6.3 EXPOSING DRIVER STATS ..............................................................................................................13

6.4 DRIVER ERROR MESSAGES............................................................................................................ 15

6.5 TIMEOUTS .....................................................................................................................................17

6.6 DEMAND & LOCK SCAN.................................................................................................................. 17

6.7 MALFUNCTIONS ............................................................................................................................. 17

6.8 GAS VALUES & SCALING................................................................................................................ 18

6.9 ALARMS AND/OR WARNINGS .......................................................................................................... 18

6.10 CURRENT SLOT .............................................................................................................................19

6.11 COMPOSITE VALIDATION SCAN VS NORMAL SLOT SCAN ..................................................................19

7. REVISION CONTROL ........................................................................................................................ 20

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 3

FS-8700-64 ATMI ACM Page 2 of 22

1. ATMI ACM Description

The ATMI ACM driver allows the FieldServer to transfer data to and from devices over

either RS-232 or RS-485 using ATMI ACM protocol. There are eight RS-232 and two

RS-485 ports standard on the FieldServer. The FieldServer can emulate a passive

client. ( A passive client is one that that consumes messages produced by an remote

device.)

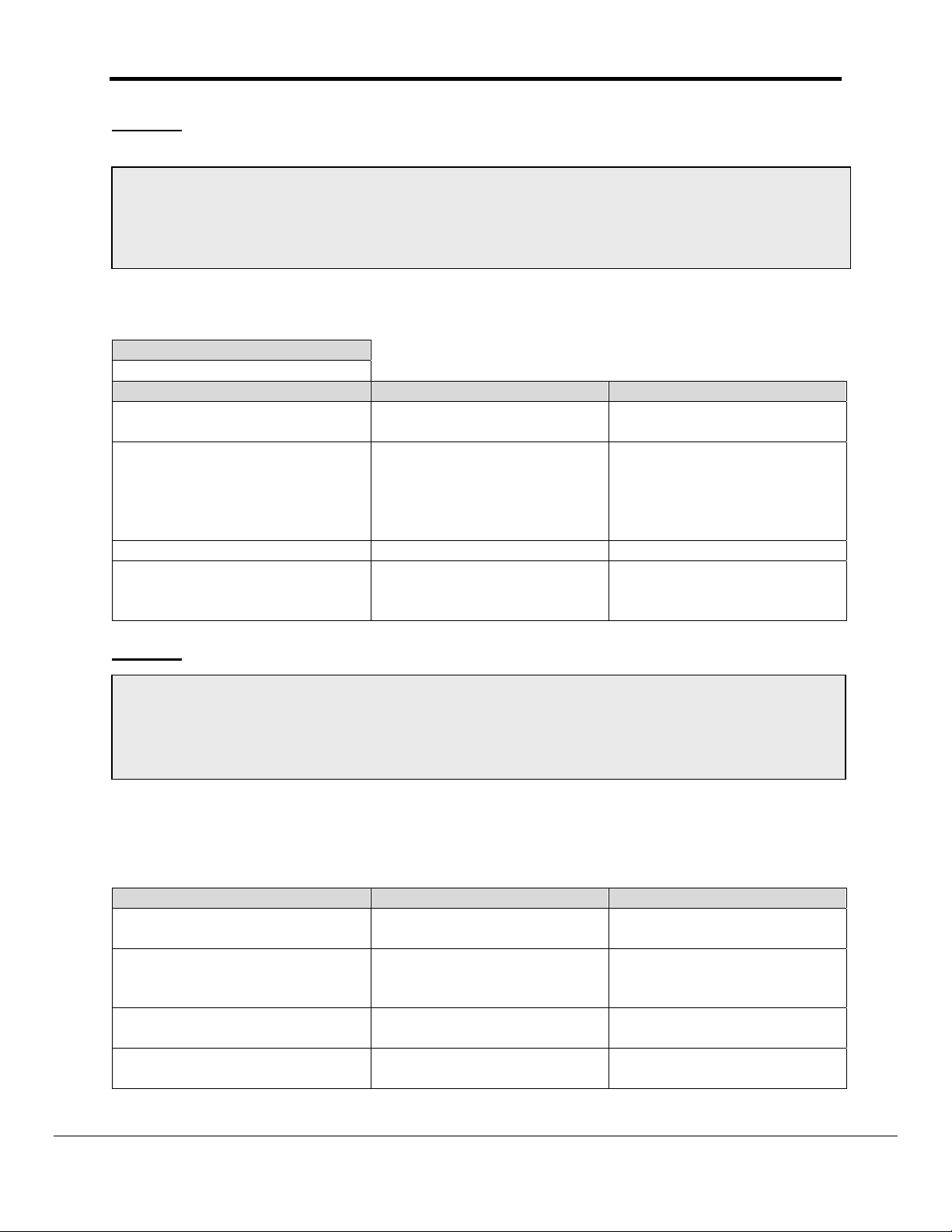

2. Driver Scope of Supply

2.1 Supplied by FieldServer for this driver

FieldServer

Technologies

PART #

FS-8915-10 UTP cable (7 foot) for RS-232 use

FS-8915-10 UTP cable (7 foot) for Ethernet connection

FS-8917-02 RJ45 to DB9F Connector adapter

FS-8917-01 RJ45 to DB25M connection adapter

SPA59132 RS-485 connection adapter

Driver Manual.

DESCRIPTION

2.2 Provided by user

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 4

FS-8700-64 ATMI ACM Page 3 of 22

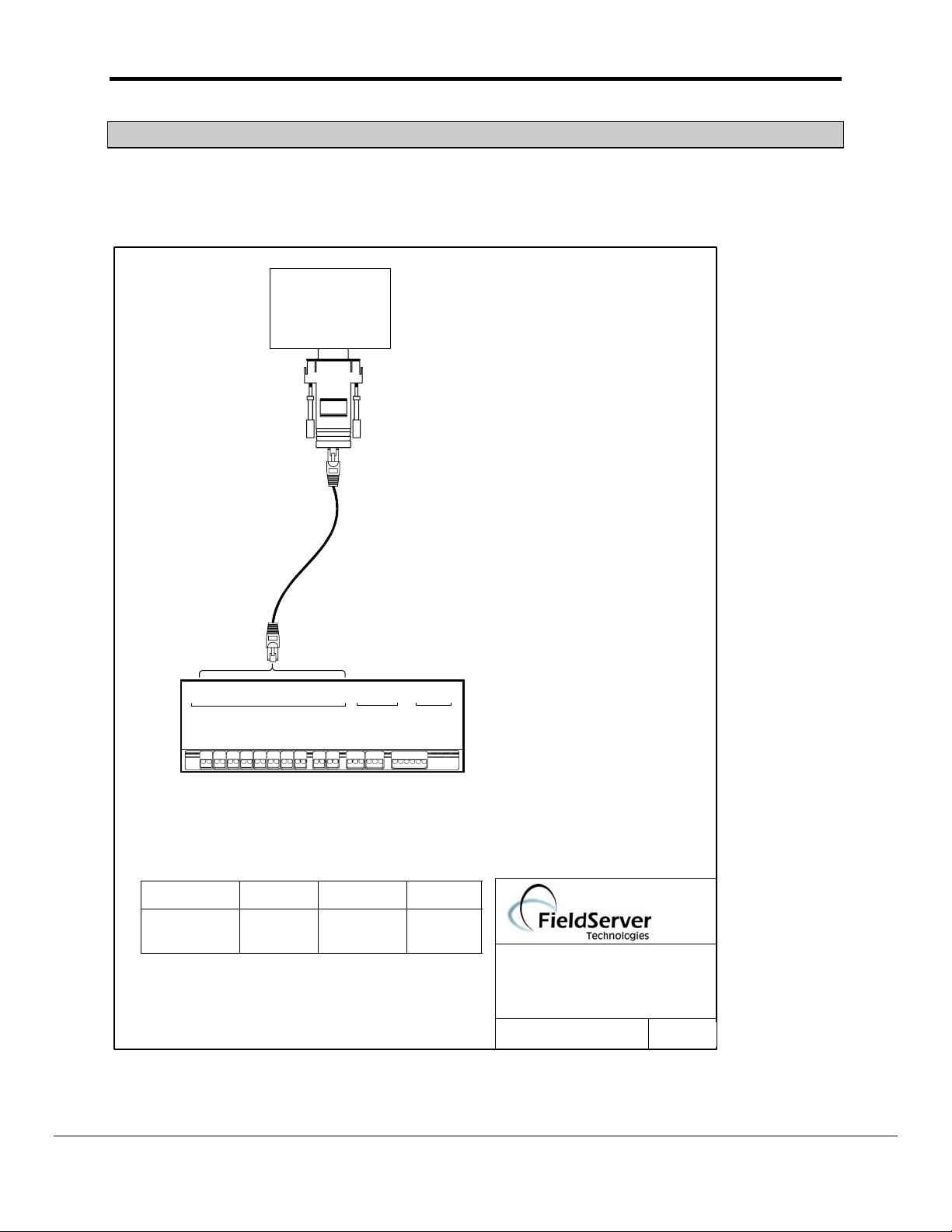

3. Hardware Connections

The FieldServer is connected to the ATMI ACM Panel as shown below.

Configure the ATMI ACM Panel according to manufacturer’s instructions

ATMI ACM PAN EL

COM 2

8917-02

RJ45 CAT 5 Cable

Connect to

RS232 port P1-P8

P1 P7 R1P2 R2

P3 P4 P5 P6 P8 N1 N2

Tx Rx Tx

P4P1RxP2 P3

TxRx Rx

RS232

Tx Rx Tx TxRx R x

P7P5 P6

P8 R1

Tx Rx Tx Rx Tx

R2 Net 1

TxRx RxTx Con

RS485

Net 2

Tx Rx Con

FieldServer

8917-02 WIRE LIST

FIELDSERVER

FUNCTION FROM TO COLOR

RX RJ45-01 DB9F -03 WHITE

GND RJ45-04 DB9F-05 GREEN

TX RJ45-08 DB9F-02 BLUE

Sys

Com

10 Base T

ETHERNET

Act

Run

Pwr

ATMI - ACM

CONNECTION DIAGRAM

BASE NAME:

FILE NAME: FS-T28700-64 .VSD

DATE: 1/21/02

BY: MN

(408)-262-2299

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 5

FS-8700-64 ATMI ACM Page 4 of 22

4. Configuring the FieldServer as a ATMI ACM Client

The ATMI ACM driver is a passive client driver. This means that it processes unsolicited

incoming data. It cannot poll for data.

For a detailed discussion on FieldServer configuration, please refer to the instruction manual for

the FieldServer. The information that follows describes how to expand upon the factory defaults

provided in the configuration files included with the FieldServer (See “.csv” files on the driver

diskette).

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a ATMI ACM Server.

The configuration file tells the FieldServer about its interfaces, and the routing of data required.

In order to enable the FieldServer for ATMI ACM communications, the driver independent

FieldServer buffers need to be declared in the “Data Arrays” section, the destination device

addresses need to be declared in the “Client Side Nodes” section, and the data required from

the servers needs to be mapped in the “Client Side Map Descriptors” section. Details on how to

do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

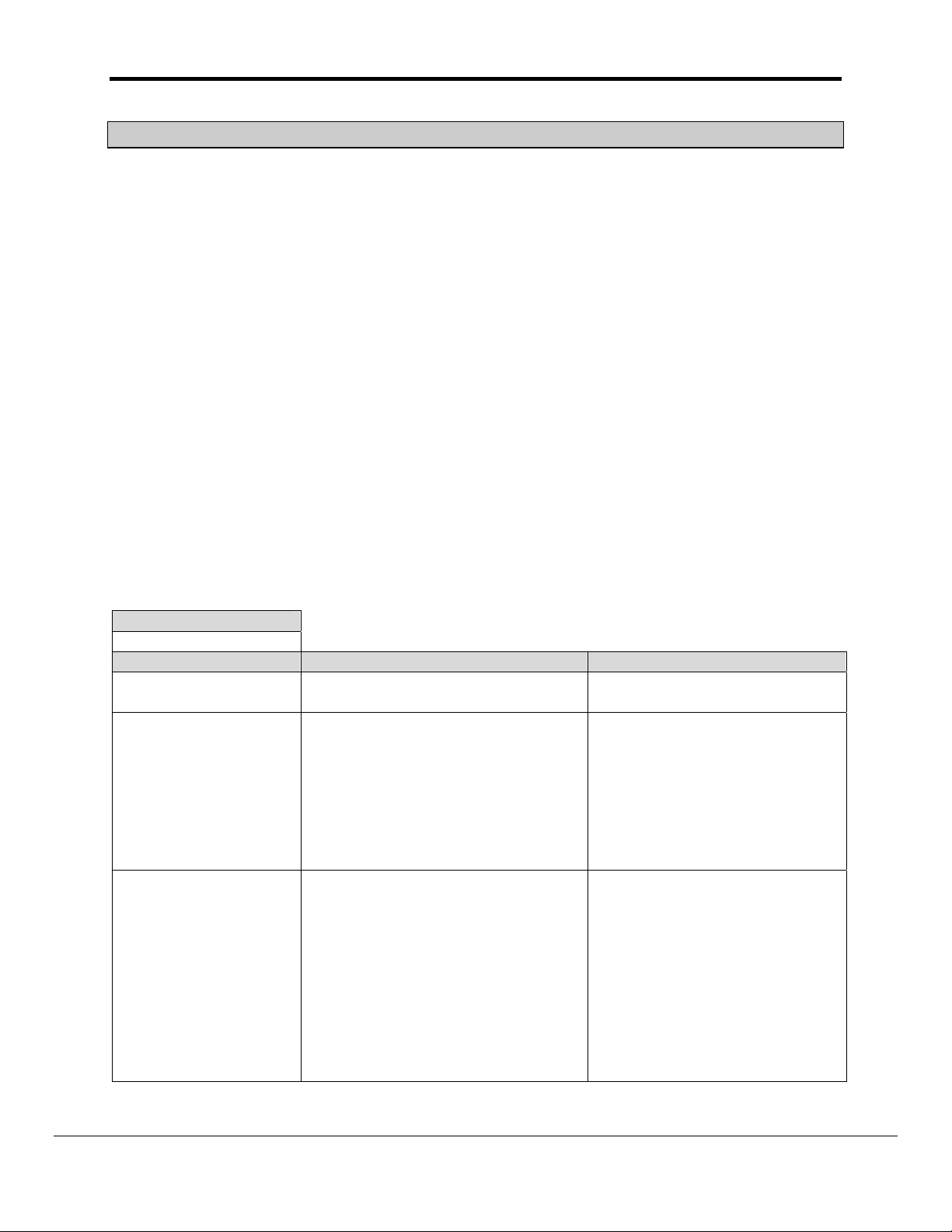

4.1 Data Arrays

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array Up to 15 alphanumeric

characters

Data_Format Provide data format. Each data

array can only take on one format.

Data_Array_Length Number of Data Objects. Must be

larger than the data storage area

required for the data being placed

in this array.

Data from one ACM can be stored

in multiple data arrays. Position in

the array is dependent on gas

number area number. Further

details are provided in section 6.1

FLOAT, BIT, UInt16, SInt16,

Packed_Bit, Byte, INT32

Packed_Byte, Swapped_Byte

Gas values should only be

stored in INT32 or FLOAT

arrays.

1-10,000

Ensure that the arrays are 16 *

81 elements big.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 6

FS-8700-64 ATMI ACM Page 5 of 22

Example

// Data Arrays

//

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

DA_AI_01, UInt16, 200

DA_AO_01, UInt16, 200

DA_DI_01, Bit, 200

DA_DO_01, Bit, 200

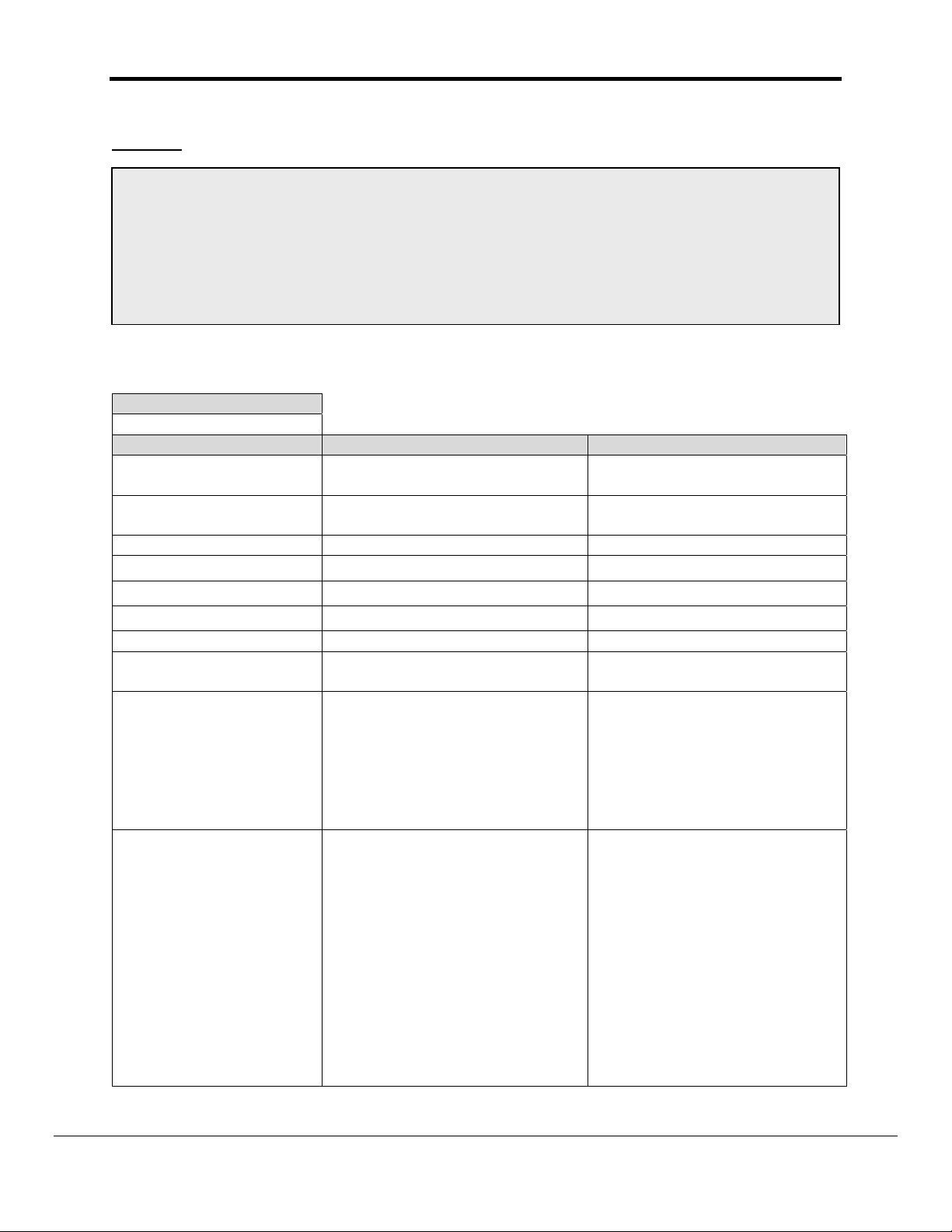

4.2 Client Side Connections

Section Title

Connections

Column Title Function Legal Values

Port Specify which port the device is

connected to the FieldServer

Baud* Specify baud rate 110 – 115200, standard baud

Parity* Specify parity Even, Odd, None, Mark, Space

Data_Bits* Specify data bits 7, 8

Stop_Bits* Specify stop bits

Protocol Specify protocol used ATMI

Handshaking* Specify hardware handshaking RTS, RTS/CTS, None

Poll Delay* Time between internal polls 0-32000 seconds

Timeout Specifies the amount of time that

may pass between complete

data screens. If this time expires

a timeout error is produced but

the processing of data is not

affected. The port is not cleared

and gas data is not reset.

IC_Timeout This parameter is used in a way

that is different to most

FieldServer driver applications.

In this case of this driver it

specifies the maximum amount

of time that may pass between

the driver receiving an incoming

character. If the time is

exceeded then an error is

produced but note that the error

has no other effect on the driver.

The port is not cleared and gas

data is not reset.

P1-P8, R1-R2

rates only

1

default 1 second

This value should provide a

margin over the time configured

between samples in the

CONFIG.DAT profile of the

ACM unit.

This value (specified in

seconds) should be set allow a

margin between time stamp

messages from the ACM unit.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 7

FS-8700-64 ATMI ACM Page 6 of 22

Example

The following FieldServer settings are suitable for default ACM settings.

// Client Side Connections

Connections

Port, Baud, Parity, Protocol, Handshaking, Poll_Delay

P8, 9600, None, ATMI , None, 0.100s

4.3 Client Side Nodes

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node Up to 32 alphanumeric

characters

Node_ID ACM units do not have a

node ID contained in the

serial data. This field s not

used in the ATMI ACM

driver.

Protocol Specify protocol used ATMI

Port Specify which port the

device is connected to the

FieldServer

Example

// Client Side Nodes

Nodes

Node_Name, Protocol, Port

ACM-1 , ATMI , P8

P1-P8, R1-R2

4.4 Client Side Map Descriptors

4.4.1 FieldServer Specific Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name Name of this Map Descriptor Up to 32 alphanumeric

characters

Data_Array_Name Name of Data Array where

data is to be stored in the

FieldServer

Data_Array_Location Starting location in Data

Array

Function Function of Client Map

Descriptor

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

One of the Data Array

names from “Data Array”

section above

0 to maximum specified in

“Data Array” section above

PASSIVE

Page 8

FS-8700-64 ATMI ACM Page 7 of 22

4.4.2 Driver Specific Map Descriptor Parameters

Column Title Function Legal Values

Node_Name Name of Node to fetch data

from

One of the node names

specified in “Client Node

Descriptor” above

Data_Array_Offset Position in the data array to

0, 1 , 2 , 3

which data should start being

written.

Length Length of Map Descriptor. The

1 – 1280

length is required to help the

driver validate the CSV file.

Set the length to a multiple of

16. The multiple should be the

maximum area number.

Address Starting address of read block 0

Driver specific keywords

The following parameters apply only to the AMI ACM driver.

ATMI_Data* Used to specify which

component of the gas data

structure to store.

You will need one map

descriptor for each

component that you are

interested in storing.

See section 6.9 for more

info.

Slot-alarm,

Slot-warning,

Slot-combo

Slot-values

Port-alarm,

Port-warning,

Port-combo

Gas-value, (== Port-values)

Current-Port

Current-Slot

Malfunctions

4.4.3 Timing Parameters

Column Title Function Legal Values

Scan_Interval Rate at which data is polled >0.1s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 9

FS-8700-64 ATMI ACM Page 8 of 22

f

p

H

A

4.4.4 Map Descriptor Example 1- Gas Values, Alarms & Warnings for all slots/ports.

This example illustrates the map descriptors required to complete store ACM data for 80 areas. Each map descriptor tells the ATMI ACM driver

where to store each component of ACM data. The gas number & area number determine the position in the array. Read section 6.1 for more

information

Map_blocks

Map_block_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, Address, Length, protocol, atmi_data

MAP1 , DATA1_1 , 0 , passive , ACM1 , 0, 1280 , ATMI , port-values

MAP2 , DATA1_2 , 0 , passive , ACM1 , 0, 1280 , ATMI , port-alarm

MAP3 , DATA1_3 , 0 , passive , ACM1 , 0, 1280 , ATMI , port-warning

MAP4 , DATA1_4 , 0 , passive , ACM1 , 0, 1280 , ATMI , slot-alarm

MAP5 , DATA1_5 , 0 , passive , ACM1 , 0, 1280 , ATMI , slot-warning

MAP6 , DATA1_6 , 0 , passive , ACM1 , 0, 1280 , ATMI , slot-combo

MAP7 , DATA1_7 , 0 , passive , ACM1 , 0, 1280 , ATMI , port-combo

MAP8 , DATA1_8 , 0 , passive , ACM1 , 0, 1280 , ATMI , slot-values

These keywords tell the driver which component of the

A different array is

used for each

atmi_data

component being

stored.

The gas value array

would typically be

an array of FLOATs

and the alarms and

This is a passive

client driver so the

unction must be

assive.

This node name will

connect this map

descriptor to a node

which in turn is

connected to a port.

ence the map

descriptor is

connected to a port.

CM data should be

Stored using each map descriptor.

If you were only interested in the current value then

you would only use one map descriptor and set the

atmi_data parameter equal to gas-value

The “…-combo” types store a 1 for an alarm OR

warning and a zero when neither conditionis present.

warnings could be

any data type

including bit arrays

.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 10

FS-8700-64 ATMI ACM Page 9 of 22

N

4.4.5 Map Descriptor Example2 – Gas values for the current (most recent) port sample.

This example illustrates a map descriptors used to store the data from the most recent port sample. The map descriptor stores the following

information :-

1. Port Number

2. Up to 16 gas values (The gas name is not provided) The position in the array is based on the Gas Number.

For example. A port may sample two gasses. The first is Gas #4 and the second may be Gas #2, The driver stores the value of Gas#4 in

array location 4 and stores the value of Gas#2 at array location 2.

The following additional information may also be stored if the DA_Bit_Name & DA_Byte_Name parameters are specified.

3. A bit indicating the number of the port

4. The Alarm/Warning States for each gas

Map_blocks

Map_block_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, protocol, timeout, atmi_data , da_bit_name, da_byte_name

Current_Port_MD, DA_CURR_PORT, 0 , passive , ACM1 , ATMI ,120.0s , current-port, DA_PORT , DA_PORT_ALA

The current port

number and up to 16

gas values are stored

in this data array.

st

The 1

element

stored is the port

number. The next

16 values stored are

the gas values

(multiplied by 100).

The location is

based on the Gas

umber and not the

row number.

This keyword tells

the driver to use this

map descriptor to

store the current

port’s sample data..

If x is the number of the current

port (port most recently

sampled) then the data array

position corresponding to x is

set to 1 and all other elements

are set to zero.

E.g. If Port 1 is the current port

then the 2

nd

element of the

array (index=1) is set non-zero.

The array can be any data

format.

If the DA_Bit_Name parameter

is omitted then this data is not

Alarm / Warning Status for each gas is

indicated in this array.

If gas x is in alarm then x is used as the

index into the array. E.g. If Gas #1 is in

alarm then the 2

(index=1) is set non-zero.

The value of each element indicates

alarm/warning. If the Value is 1 then the

gas in alarm. If the value is two then the

gas is at a warning level.

The array format should be capable of

storing a value. If a Bit/Packed_Bit format

is used then you will not be able to

distinguish between an alarm/warning.

If the DA_Byte_Name parameter is

omitted then this data is not stored.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

nd

element of the array

Page 11

FS-8700-64 ATMI ACM Page 10 of 22

4.4.6 Map Descriptor Example3 – Storing Malfunction Data

This example illustrates a map descriptor used to store malfunction data reported by the ACM unit. When a malfunction is cleared then 100

elements of the array are set to zero. When a Malfunction is present the 1

contains the minor type and element x (x=major*10+minor) is set to a value of 1. Additional information is provided in section 6.7

Map_blocks

Map_block_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, timeout, atmi_data , length

Malfucntion_MD , DA_MALFNS , 0 , passive , ACM1 , 120.0s , malfunctions, 100

st

element contains the malfunction’s major type, the 2nd element

This keyword tells

One hundred

elements of this

data array are used

to store

malfunction data.

the driver to use

this map

descriptor to

malfunction data.

One map

descriptor is

required per node.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 12

FS-8700-64 ATMI ACM Page 11 of 22

N

4.4.7 Map Descriptor Example4 – Gas values for the current (most recent) slot sample.

This example illustrates a map descriptors used to store the data from the most recent slot sample. The map descriptor stores the following

information :-

5. Slot Number

6. Up to 16 gas values (The gas name is not provided) The position in the array is based on the Gas Number.

For example. A slot may sample two gasses. The first is Gas #4 and the second may be Gas #2, The driver stores the value of Gas#4 in

array location 4 and stores the value of Gas#2 at array location 2.

The following additional information may also be stored if the DA_Bit_Name & DA_Byte_Name parameters are specified.

7. A bit indicating the number of the slot

8. The Alarm/Warning States for each gas

Map_blocks

Map_block_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, protocol, timeout, atmi_data , da_bit_name, da_byte_name

Current_Port_MD, DA_CURR_SLOT, 0 , passive , ACM1 , ATMI ,120.0s , current-slot, DA_SLOT , DA_SLOT_ALA

The current slot

number and up to 16

gas values are stored

in this data array.

st

The 1

element

stored is the slot

number. The next

16 values stored are

the gas values

(multiplied by 100).

The location is

based on the Gas

umber and not the

row number.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

This keyword tells

the driver to use this

map descriptor to

store the current

slot’s sample data..

If x is the number of the current

slot (slot most recently

sampled) then the data array

position corresponding to x is

set to 1 and all other elements

are set to zero.

E.g. If Slot 1 is the current slot

then the 2

nd

element of the

array (index=1) is set non-zero.

The array can be any data

format.

If the DA_Bit_Name parameter

is omitted then this data is not

Alarm / Warning Status for each gas is

indicated in this array.

If gas x is in alarm then x is used as the

index into the array. E.g. If Gas #1 is in

alarm then the 2

nd

element of the array

(index=1) is set non-zero.

The value of each element indicates

alarm/warning. If the Value is 1 then the

gas in alarm. If the value is two then the

gas is at a warning level.

The array format should be capable of

storing a value. If a Bit/Packed_Bit format

is used then you will not be able to

distinguish between an alarm/warning.

If the DA_Byte_Name parameter is

omitted then this data is not stored.

Page 13

FS-8700-64 ATMI ACM Page 12 of 22

5. Configuring the FieldServer as a ATMI ACM Server

The ATMI ACM driver cannot be used as a server.

6. Driver Notes

6.1 Data position in the Data Arrays

To understand how the driver stores data for the current port, read the notes provided with mapdescriptor example 2 as the following notes do not apply.

To understand how the driver stores data for malfunctions, read the notes provided with mapdescriptor example 3 as the following notes do not apply.

For each component stored the values are stored as a one-dimensional array. Data storage is

zero referenced. This means that the first area or first gas is stored in the first location, which

has an index of zero. To find the element of interest use the following formula.

Port Alarm / Warnings / Gas Values Data Array locations

Port_Index = (Gas_number-1) + 16 * ( Area_Number – 1 )

‘Area’ and ‘Port’ are synonyms.

Example. If you wish to know the Data Array index for gas #7 of area 11

Index = (7-1) + 16 * ( 10 – 1 ) = 166

Example. If you wish to know the Data Array index for the 7

11

Index = 7 + 16 * ( 10 – 1 ) = 167.

Slot Alarm / Warnings / Values Data Array locations

Slot_Index = (Gas_number-1) + 16 * ( Slot_Number – 1 )

Example. The Data Array location for gas #12 of Slot 4

Index = (12-1) + ( 4 – 1 ) * 16 = 59

th

gas of area

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 14

FS-8700-64 ATMI ACM Page 13 of 22

6.2 Driver Stats

The ATMI ACM Driver counts all incoming bytes as the ‘PLC Byte Received’ statistic. This can

be viewed on the connection detail and overview screen. Typically this count will increase by

approx 2500 bytes per full screen of area data.

IN addition the driver reports one count of ‘PLC READ MSG RECD’ statistic for each map

descriptor used to store information from a complete message. Typically this count will increase

by 5 if you are storing l slot & port alarms & warnings and the gas value.

If a complete message is received but no map descriptor is found to store any of the data the

data then the MSG IGNORED statistic will be incremented by one.

6.3 Exposing Driver Stats

IN addition to the normal FieldServer statistics this driver can expose some statistics and

diagnotic information in a data rray so that it may be read or reset by a remote device.

A special map descriptor is required. The driver recognizes the map descriptor by its name

which must be "ATMI-stats" .

The following example shows how this special map descriptor can be configured.

Nodes

Node_name, Protocol

null_node, ATMI

Data_Arrays

Data_Array_Name , Data_Format, Data_Array_Length

STAT-DATA , UINT32 , 400

Map_blocks

Map_block_Name, Data_Array_Name, Node_name

ATMI-stats , STAT_DATA , null_node

When the driver sees this map descriptor it uses the data array STAT_DATA (in this example)

to store driver specific statistics. Only one of these map descriptors may be specified per

FieldServer.

The array position is dependent on the port number. The offset is calculated by multiply the port

number by 30. Thus port 2 data will start at element 60.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 15

FS-8700-64 ATMI ACM Page 14 of 22

The driver stores the following data.

Array

Element

(offset

dependent

on port

number)

Contents

0 Not Used

1 ATMI_STAT_SCAN1 FieldServer Tech Support diagnostic.

2

FieldServer Tech Support diagnostic.

Screen decoding abandoned because

the area number was unintelligible (>

ATMI_STAT_DECODE1

3

ATMI_STAT_FINIS

4

80)

Driver has found an end-of-screen

identifier.

FieldServer Tech Support diagnostic.

The line number was unintelligible ( >

ATMI_STAT_COLLECT1

5

25 ).

FieldServer Tech Support diagnostic.

The collection function returned an

ATMI_STAT_COLLECT2

6

error. Row or Column were inconsistent.

FieldServer Tech Support diagnostic. A

start-of-screen identifier was found

ATMI_STAT_COLLECT3

7

ATMI_STAT_ERRORLIGHT

8

ATMI_STAT_START

9

ATMI_STAT_LF

10

before whilst processing screen data.

Equivalent to the error light on the ATMI

ZD80 processor.

A start of screen identifier has been

found.

A new line of screen data has been

identified.

FieldServer Tech Support diagnostic.

The collection function returned an

ATMI_STAT_ERRORLIGHT1

11

error. Row was inconsistent.

FieldServer Tech Support diagnostic.

The collection function returned an

ATMI_STAT_ERRORLIGHT2

12

error. Column was inconsistent.

A time greater than the port timeout has

elapsed since the last complete screen

ATMI_STAT_TIMEOUT

13

full of data.

A time greater than the port’s inter

character timeout (ic_timeout) has

passed since the driver last received a

ATMI_STAT_ICTIMEOUT

14

ATMI_STAT_BYTECOUNT

15

ATMI_STAT_STREAMING

16

new character from the ACM unit.

The number of ACM data byte

processed

The number of streaming (buffer

overflow) errors.

When processing the most recent

message, at least one map descriptor

ATMI_STAT_STORE_LASTMAPDESCP

was found with which to store data.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 16

FS-8700-64 ATMI ACM Page 15 of 22

17

ATMI_STAT_STORE_NO_MAP

18

ATMI_STAT_STORE

19

ATMI_STAT_STORE_NONZERO

20

ATMI_STAT_MALFN_BAD_MAJOR

21

ATMI_STAT_MALFN_BAD_MINOR

22

ATMI_STAT_MALFN_STREAMING

6.4 Driver Error Messages

When processing the most recent

message, no map descriptors were

found to tell the driver how to store the

incoming data.

Increment’s once for each time data is

stored. Ie will increase by 5 for one

screen full of data stored using 5 map

descriptors.

Will increase by one for each screen full

of data processed in which at least one

gas value was non-zero.

Count of the number of times that a

malfunction’s major type could not be

recognized.

Count of the number of times that a

malfunction’s minor type could not be

recognized.

Count of the number of times that the

buffer overflowed when analyzing

malfunction data. Each time this

happens the malfunction is not stored.

The following error messages should be reported to FieldServer Technologies.

ATMI:#4 Error. atmi_chan_init() Init with null chan.

The following errors indicate a driver, connection or remote device problem if they occur

frequently.

ATMI:#8 Error. Discard because area=%d max=%d

Incoming data has been discarded because the driver could not resolve a valid area number.

The following error messages or warning arise from problems that can normally be

resolved by users without support from FieldServer Technologies.

ATMI:#7 Error. No read/writes permitted. Mapdesc=<%s>

Edit the CSV file. Change the map descriptor function to passive. Reset the FieldServer.

ATMI:#1 FYI. Some data is being abandoned. Mapdesc too short. <%s>

Edit the CSV file. Increase the map descriptor’s length to allow the driver to process the

maximum data area. Not each data area requires 16 storage elements. Reset the FieldServer.

This message is only printed once even if the error occurs more than once.

ATMI:#2 FYI. Some data is being abandoned. Array too short. <%s>

Edit the CSV file. Increase the Map Descriptor’s data array length. Reset the FieldServer. This

message is only printed once even if the error occurs more than once.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 17

FS-8700-64 ATMI ACM Page 16 of 22

ATMI:#3 Error. Incoming data on port=%d is being abandoned. MapDesc rqd.

No map descriptors were found on the indicated port with which the driver could store the

incoming data. Change the CSV file and reset the FieldServer. This message is only printed

once even if the error occurs more than once.

ATMI:#6 FYI. The mapDesc called <%s> is too short.

Edit the CSV file. Increase the length of the map desc and reset the FieldServer.

ATMI:#5 FYI. You could have used a mapDesc called <%s> to expose diagnostic info.

No action I s required. Read section 6.3 for more information..

*ATMI:#9 Err. Mapdesc=<%s> data array=<%s> too short

The data array associated with the map descriptor being used to store ‘current port‘ data is too

short. Increase the length of the data array (not the length of the map descriptor) to at least 17.

For malfunction map descriptors set the length to at least 100. Edit the CSV file, make the

change and then reset the bridge.

*ATMI:#10 Err. Mapdesc=<%s> data array=<%s> too short

The data array defined by the DA_Bit_Name parameter associated with the map descriptor

being used to store ‘current port‘ data is too short. Increase the length of the data array (not the

length of the map descriptor) to at least 90. Edit the CSV file, make the change and then reset

the bridge.

*ATMI:#11 Err. Mapdesc=<%s> data array=<%s> too short

The data array defined by the DA_Byte_Name parameter associated with the map descriptor

being used to store ‘current port‘ data is too short. Increase the length of the data array (not the

length of the map descriptor) to at least 90. Edit the CSV file, make the change and then reset

the bridge.

2Mapdesc=<%s> Gas#=%d. Too big.The driver is trying to store the the current port’s gas data.

A Gas number larger than 16 has been found. It cannot be stored and has been discarded.

Your ACM may need re-configuring. Changing the driver configuration will not correct this

problem. Report this error to ATMI.*These messages are produce once only and then

suppressed so that they do not fill the error log every by being re-printed every time a new

message is processed. A consequence of this, is that, if the error occurs more than once in a

configuration, the second and subsequent occurrences will not be revealed until the first has

been corrected.

*ATMI:#13 Error. Illegal Map Descriptor length - defaulting to 1

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 18

FS-8700-64 ATMI ACM Page 17 of 22

6.5 Timeouts

See section 4.2 for information on how timeouts should be specified.

Occasional timeouts may be expected when there are noisy messages or if the ACM device has

been locked. Timeouts do not stop the driver processing the next valid screen of data.

6.6 Demand & Lock Scan

The driver can process data from demand and locked scans. Incoming data is processed in the

same way as normal scans and stored using the same map descriptors.

6.7 Malfunctions

The driver can process malfunctions reported by the ACM unit.

When a malfunction is cleared then the driver sets all (1

elements to zero A malfunction is considered cleared when a normal scan is processed.

When a malfunction is recognized the driver stores data in the following locations.

1

2

st

Element : Major type of the malfunction ( as a number )

nd

Element : Minor type of the malfunction. (as a number )

And

Element x : Value set to 1.

X = major * 10 + minor

This additional data element is provided so that relays / indicating lamps in a downstream

device can be set without additional logic.

The driver uses the keyword ‘MALFUNCTION’ to recognize ACM malfunctions. If the ACM

firmware is changed and this keyword is no longer produced then the driver will no longer

recognize malfunctions.

If the driver recognizes that there is a malfunction but cannot interpret the malfunction type then

the major and/or minor types are set to a value of 99 and element x is not set at all.

The table below shows malfunction’s major and minor types.

st

100) of the malfunction data array

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 19

FS-8700-64 ATMI ACM Page 18 of 22

Malfunction Major Type Mafunction Minor Type

1. INADEQUATE BYPASS FLOW 0.

2. EMERGENCY SWITCH

CLOSURE

1.TEMP_LOW

2. TEMP_HIGH

3. LOSS_OF_NH3_FLOW

3. FAILED LEAK CHECK 0.

4. DSP FAILURE in module 0.

5. FAILURE to get interferogram

1. Bench timeout

2. Bench short scan

3. Zero ZPD value or address

4. Bench reports Bad Scan

5. Bench DREQ stuck TRUE

6. Energy (ZPD) address out of

range

7. energy (ZPD) value too high

8. energy (ZPD) value too low

9. DSP reports bad scan

6.8 Gas Values & Scaling

The driver stores all gas values after multiplying them by 100. This allows the driver to store

values in arrays with formats other than floats without losing the precision provided by the ACM

unit. This is done because some downstream devices’ and protocols cannot handle floating

point numbers. This may not suite you in which case you will need to use scaling.

These parameter keywords should be added to each CSV Map Descriptor definition.

…..Data_Array_Low_Scale, Data_Array_High_Scale, Device_Low_Scale,

Device_High_Scale…….

To store the actual values reported by the ACM unit you should use the following values :

…..Data_Array_Low_Scale, Data_Array_High_Scale, Device_Low_Scale,

Device_High_Scale…….

…..0 , 1 , 0 , 100…..

6.9 Alarms and/or Warnings

The following list are valid entries in specifying the ATMI_Data parameter in the csv file.

Slot-alarm,

Slot-warning,

Slot-combo

Port-alarm,

Port-warning,

Port-combo

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 20

FS-8700-64 ATMI ACM Page 19 of 22

When you use a “…-alarm” keyword then the driver stores a 1 when the gas is in an alarm

condition and a zero when it is not in alarm condition. This means a zero is stored even if the

gas in a warning condition.

When you use a “…-warning” keyword then the driver stores a 1 when the gas is in a warning

condition and a zero when it is not in warning condition. This means a zero is stored even if the

gas in an alarm condition as well as when the gas is in a normal condition.

When you use a “….-combo” keyword then the driver stores a 1 whether the gas is in an alarm

OR warning condition and the driver stores a zero when the gas is in neither an an alarm or

warning state.

6.10 Current Slot

Current slot information is the same as current port information. On a Normal Scan, a single

slot is referenced. The gas values/warnings/alarms will be stored to the current slot data arrays

every time slot information is stored. Note, this only occurs once during any Normal Slot Scan

image.

6.11 Composite Validation Scan vs Normal Slot Scan

On a Normal Slot Scan Image, gas data is stored to the "slot" value/warning/alarm data arrays

and the "port" value/warning/alarm data arrays. If more than one port (area) is referenced in the

image, then the same value/warning/alarm gas data is copied to each section of the area "data

array". For example, if Areas 2 and 39 were referenced, then the gas data values and

warning/alarm status would be copied twice to the data array offset for Area 2 and the offset for

Area 39.

On a Composite Validation Image, only one area (port) should be referenced. The gas

values/warnings/alarms for the particular area referenced will be updated. As well the current

port data values will also be updated. Note, on Composite Validation Images, slot information is

not updated.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 21

FS-8700-64 ATMI ACM Page 20 of 22

7. Revision Control

Date Rev Resp Description

1.01a Rev1 PMC This revision and all previous revisions did not have a

revision control section.

1.01a Rev

2

1.01b Rev

0

101c Rev0 Section 4.4.5 Corrections and additional notes to

102a Rev0 Section 4.4.2 New valid keywords for ATMI_Data

PMC This issue of the manual corresponds to the release of

driver version 1.01a in which functionality was added to

store the current port sample’s data separately.

The following sections of this manual have been

amended.

• Section 1. Driver previously described as

client /server.

• Section 4.4.2 New keyword

• Section 4.4.4 Title Changed

• Section 4.4.5 New example

• Section 6.1 Amended

• Section 6.4 Error messages 9,10,11 added.

• Section 4.4.2 New keyword

• Section 4.4.6 New example

• Section 6.1 Amended

• Section 6.3 New stats 20-22

• Section 6.4 Amended notes for msg #9.

• Section 6.7 New Section

describe storage of gas values

based on sample number.

Section 6.8 New notes on scaling. Prior to revision

1.01c of the driver this feature did not operate and all

values were stored 100 times too large.

parameter. “port-combo” and “slotcombo”

Section 4.4.4 Modified example to illustrate use

of “…-combo” keywords.

Section 6.9 New section on ATMI_Data parameter.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 22

FS-8700-64 ATMI ACM Page 21 of 22

10Feb03 1.03a Rev 0 PMC Section 4.4.2

New keywords. Added slot-values and portvalues (as synonym for gas-values)

Section 6.1

Calculation of Data Array offsets

Section 7

Consolidated the revision information into a

table.

TOC

Updated Table of Contents

9Apr03 1.04aRev 0 DNC Section 4.4.2

Added new key word "Current-Slot"

Section 4.4.7

Added Current-Slot example

Section 6.10

Added section discussing current slot

information

Section 6.11

Added section discussing Composite

Validation Scan handling, and Normal Scan

Driver Enhancement:

1. On normal scan, driver will save

values/warns/alarms for up to 4 ports per screen

2. On a decomposed screens port data will be updated

for port that was referenced, no changed to slot info

3. Current slot info implemented. Data references last

update to slot info.

10Apr03 1.04aRev1 DNC -updated error numbers

21July03 1.04Rev1 JDM Releasing

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Loading...

Loading...