Page 1

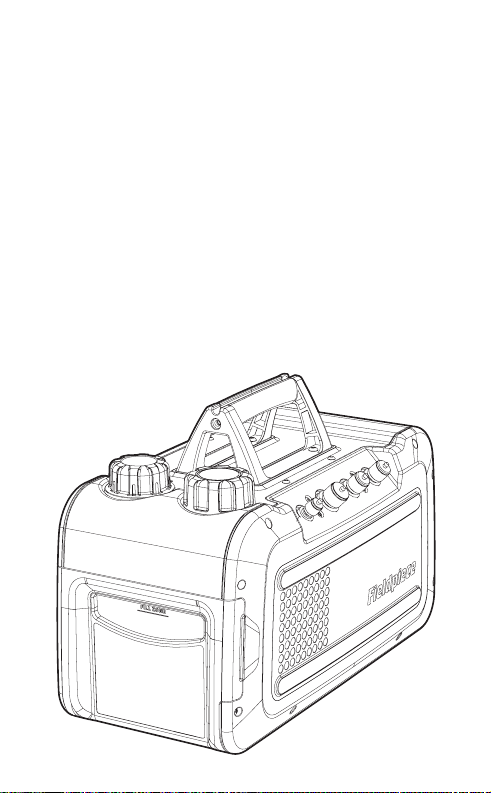

Fieldpiece®

Vacuum Pump with

RunQuick™ Oil

Change System

OPERATOR'S MANUAL

Models VP55 and VP85

Page 2

Contents

Important Notice . . . . . . 4

What’s Included. . . . . . . 5

Warnings . . . . . . . . . 5

Description . . . . . . . . 6

Features

Specifications . . . . . . . 8

Certifications . . . . . . . 9

Safety Information. . . . . . 10

General

Environmental

Personal Protection

VP55/VP85 Protection

Setup

Tech Tips . . . . . . . . .12

General

Cold Weather Starts

Setup

Operation. . . . . . . . . 14

RunQuick™ Oil Change System

Evacuation with a 4 Port Manifold

Evacuation with a 3 Port Manifold

Direct Evacuation

Oil Change Procedure

Dynamic Vacuum Measurement

Remote Exhaust

Gas Ballast Switch

Maintenance. . . . . . . . 28

General

Storage

Vacuum Isolation Test

Contaminated Oil Reservoir

Troubleshooting . . . . . . 30

Limited Warranty . . . . . . 32

Obtaining Service

32

Page 3

Important Notice

!

This is not a consumer machine. Only qualified

personnel trained in service and installation of

A/C and/or refrigeration equipment shall use this

vacuum pump.

This vacuum pump is used for evacuating

(drying) refrigerant lines. Fieldpiece model MR45

is available for recovering refrigerant.

Read and understand this operator’s manual

in its entirety before using VP55/VP85 to prevent

injury or damage to you or equipment.

What’s Included

• VP55/VP85 Vacuum Pump

• (2) 8 Ounce Vacuum Pump Oil

• Operator’s Manual

• 1 Year Warranty

WARNINGS

Ensure proper equipment grounding, electrical shock risk.

Do not use to pump liquid refrigerant, explosion risk.

Do not use to pump flammable media, explosion risk.

Inhalation of high concentrations of refrigerant vapor can block

oxygen to the brain causing injury or death.

Exposure to refrigerant can cause frostbite.

Oil from the vacuum pump can be hot. Handle with caution.

54

Page 4

Description

Performing a proper system evacuation prior

to charging directly increases the expected life

and efficiency of the system. Fieldpiece vacuum

pumps provide a new view at system evacuation.

Good oil is the lifeblood of every evacuation.

You need to know the condition of the oil. You

need to change the oil easily with no mess.

Clearly view the oil condition through the huge

oil tank window. The oil backlight helps to see the

condition of the oil and if the fill level is correct.

With the RunQuick™ oil change system, you can

replace the oil in under 20 seconds, even while

the pump is running. The extra wide base helps

prevent tipping and spilling oil. Four inline ports

in three different sizes give you tidy hose routing

and hose options. Place the power cord on the

handle for tangle free storage. Carry the machine

to and from the job site easily and well protected.

Features

• RunQuick™ Oil Change System

- Easy View Window and Oil Backlight

- Change Oil Quickly, Even with the Pump Running

- Extra Oil Bottle Storage (VP85)

- Elevated Oil Drain Ball Valve

- Wide Mouth Fill Port

- Oil Bottle Cap Storage

- Precision Oil Circulator

• 4 Inline Ports

(1) 1/4”

(2) 3/8”

(1) 1/2”

• Two Stage Pump

• 8CFM (VP85)

• 5CFM (VP55)

• Gas Ballast Switch with LED

• Remote Exhaust Port

• Quiet Fan-Cooled Operation

• DC Motor (VP85)

• Heavy Duty Rubberized Construction

• Power Cord Storage

• Stable Base

• Operation in the Rain (IP24)

• Wide Operating Voltage 95 to 130 VAC (VP85)

76

Page 5

Specifications

Flow Rate: 8CFM (VP85), 5CFM (VP55)

Oil Capacity: 8oz (237mL)

Oil Compatibility: Fieldpiece Vacuum Pump Oil

(Highly refined and optimized for proper sealing and lubrication)

Fieldpiece part numbers: OIL8X3, OIL32

Oil Backlight: Blue LED

Oil Drain: Ball valve

Port Sizes: (1) 1/4”, (2) 3/8”, (1) 1/2”

Compressor: Rotary vane, two stage

Motor: 3/4 HP Brushless DC (VP85), 1/3 HP AC (VP55)

RPM: 2500 (VP85), 3440 (VP55)

Power Source: 95 to 130 VAC @ 60 Hz (VP85),

108 to 130 VAC @ 60 Hz (VP55)

Nominal Current Draw: 9.0 AAC (VP85), 8.0 AAC (VP55)

Ultimate Vacuum at Input Ports: 15 microns

Dimensions: 9.25” x 12.4” x 17.7” (235 mm x 315 mm x 450 mm)

Weight: 28 lbs without oil (VP85), 30 lbs without oil (VP55)

Operating Environment: 30°F to 122°F (-1.1°C to 50°C)

Patent: Patents Pending

Certifications

WEEE

Do not dispose through

typical waste streams.

98

Page 6

Safety Information

General

1. This machine is only intended for use by qualified personnel

trained in servicing and installation of A/C/Refrigeration

equipment.

2. Read and understand this operator’s manual in its entirety

before using VP55/VP85 to prevent injury or damage to you or

equipment.

3. Always dispose of oil according to local jurisdiction.

Environmental

1. Use only within operating conditions (42-122°F).

2. Ensure fan opening is clear of debris.

3. Explosion and fire risks:

Do not use near sewer lines.

Do not use in poorly ventilated enclosed areas.

Do not use near gasoline, acetylene, or other flammable gases.

Do not use to pump hydrocarbons.

Do not use near flames or sparks.

Assume all components are pressurized.

Personal Protection

1. Frostbite danger. Be careful using hoses.

2. Use personal protective equipment:

Wear safety goggles.

Wear earplugs if using for long durations.

Wear protective gloves.

3. Oil from the vacuum pump can be hot. Use caution while

handling.

4. Do not use in poorly ventilated enclosed areas.

VP55/VP85 Protection

1. Only use VP55/VP85 with clean Fieldpiece Vacuum Pump Oil

added to a level within the FILL ZONE before every job.

2. Do not use to remove refrigerant from a system. Use a recovery

machine and filter to remove refrigerant and particles from the

system before using VP55/VP85 to evacuate the system.

3. Do not use on pressurized systems. Doing so may damage or

contaminate your vacuum pump.

4. Do not use on ammonia or salt water systems. Doing so may

damage or contaminate your vacuum pump.

5. Store with ports capped to prevent dust from entering.

6. Drain oil after every job and store VP55/VP85 empty to prevent

spillage and reduced oil life.

Setup

1. Inspect the machine and repair any damaged parts before using.

2. Ensure motor power switch is turned OFF (down) before

connecting or disconnecting power.

3. Ensure power cord is not damaged.

4. Ensure all equipment is grounded.

5. Extension cord options:

14 AWG or thicker, up to 50 feet (15 m)

12 AWG or thicker, up to 100 feet (30 m)

6. Ensure extension cord is grounded, 3 conductor.

1110

Page 7

Tech T ips

General

1. Vacuum pumps are not recovery machines and should not be

used for recovering refrigerant.

2. Purge the A/C system with a few psi of dry nitrogen before

evacuation to pre-dry the system. This extra step actually saves

time overall because it quickly removes a great amount of

moisture, oil, and other contaminants before you even connect

your pump.

3. Performing a triple evacuation is a great way to ensure a system

is dry. The nitrogen flow can help carry moisture with it out of the

system. A triple evacuation is as follows:

1. Purge with nitrogen

2. Evacuate down to 2000 microns

3. Purge with nitrogen

4. Evacuate down to 1000 microns

5. Purge with nitrogen

6. Evacuate down to below 500 microns

Cold Weather Starts

1. Open an unused input port to ambient for a few seconds until the

pump is running.

2. Warm the pump in your truck/home by letting it sit in a warm

environment. You can warm the oil in your truck/home before

adding it to the pump.

Setup

1. Always use fresh Fieldpiece vacuum pump oil. If oil is left in the

pump for more than a week, the oil may have absorbed enough

moisture from ambient air to affect performance.

2. Refrigerant manifolds can be convenient to charge the system

after evacuation, but their hoses and valves can limit or slow

evacuation. It’s best to use vacuum rated hoses, directly

connected to core removal tools at the service ports.

3. If you want to use a manifold, it’s best to use a 4 port manifold. 4

port manifolds typically have a larger bore to increase flow. They

also isolate the pump from the system and micron gauge without

the need of a shut-off valve on the hose.

4. Hoses:

Short as possible.

Widest diameter as possible.

Vacuum rated.

Core depressors removed.

Ball valve shut-offs instead of low loss fittings.

Good seals.

Replace if worn.

5. Use a vacuum rated Schrader valve core removal tool to

temporarily remove valve cores from service valves.

6. Connect multiple hoses to the inline ports on VP55/VP85 to

further decrease hose restriction and increase air flow.

1312

Page 8

Motor Power Switch (OFF)

Extra Oil Bottle

Storage (VP85)

Gas Ballast Switch (Closed)

Operation

Remote Exhaust Cap

Power Cord Storage

Oil Fill Cap

4 Input Ports

Oil Bottle Access Door

Clear Oil Reservoir

Oil Drain Valve (OPEN)

1514

Page 9

RunQuick™ Oil Change System

FILL ZONE

The only way to create a deep vacuum is to

evacuate with fresh oil, especially at the end of

the job. The RunQuick oil change system makes

this old chore a breeze.

Easy View Window and Oil Backlight

There are a few signs that remind you to change your oil. The visual

condition is one of them. If it looks old, change it. You will see tiny air

bubbles with fresh oil. Saturated oil will look more opaque.

Elevated Oil Drain Ball Valve

By elevating the oil reservoir and utilizing a fast opening ball valve,

we made it easy to drain old oil into the empty bottle without a drop

spilled. The spring loaded platform securely holds the bottle in place.

Oil Bottle Cap Storage

When you open a fresh bottle of oil, put the cap on the side of the

bottle so you can cap the bottle after you drain old oil into it.

Wide Mouth Fill Port

It is easy to hit your target with

the wide mouth fill port.

Change Oil Quickly with

the Pump Running

Towards the end of the

evacuation is when you need fresh

oil the most. The RunQuick system

maintains a vacuum for about 30

seconds after you drain the oil so you

can drain and pump without any loss

of vacuum.

Precision Oil Circulator and Fan

Instead of submerging the pump in excess oil, a small oil pump

constantly lubricates targeted sealing zones. The quiet high speed fan

cools the heat sinks of the motor and pump.

Spare Oil Bottle Storage (VP85)

Take an extra bottle to and from the job site so you always have that

fresh oil performance bump at the end of the job.

1716

Page 10

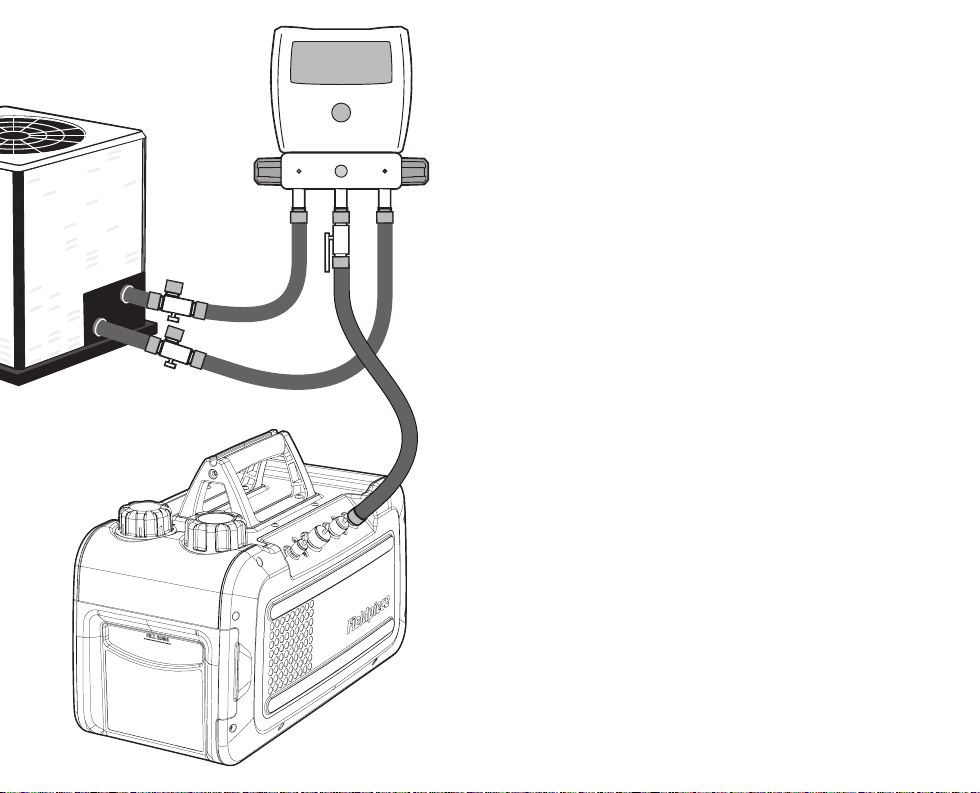

Evacuation with a 4 Port Manifold

This is the most common evacuation method.

Read the tech tips (page12) for optimum gauge

placement and variations to reduce recovery

times.

Vapor

Liquid

Schrader Valve Core

Removal Tools (optional)

4 Port

Manifold

with

Micron

Gauge

1. Always fill with fresh Fieldpiece Vacuum Pump Oil. (page 24)

Running the pump without oil will damage the pump and void the

warranty. Oil can be drained while the pump is running if refilled

within 3 minutes (within 30 seconds to maintain your vacuum).

2. Ensure the VP55/VP85 motor power switch is turned OFF (down).

3. Plug VP55/VP85 into an outlet (oil backlight should illuminate).

4. Ensure the gas ballast is closed (vertical). (page 26)

5. Connect VP55/VP85 to the empty, depressurized A/C system.

6. Turn the motor power switch to ON (up).

7. Open line set (hoses, manifolds, removal tools, etc.) to expose the

pump to the system.

To reduce oil contamination early in the job, open the gas ballast until

the sound of the pump quiets down (about 3000 microns). The LED

shines if the ballast is open.

8. After the appropriate vacuum is reached, isolate the system from

the pump. You can check the system for potential leaks at this time

by monitoring your micron gauge.

VP55/VP85 has a unique oil suck back prevention feature to keep your

hoses clean. Still, it’s good practice to release the vacuum at the input

port before turning off the pump.

9. Turn the motor power switch to OFF (down), remove your hoses,

and cap the ports to keep components free of contaminants.

10. Disconnect VP55/VP85 from the system and unplug from power.

11. Drain the contaminated oil while the oil is still warm to keep the

pump as clean as possible when stored.

1918

Page 11

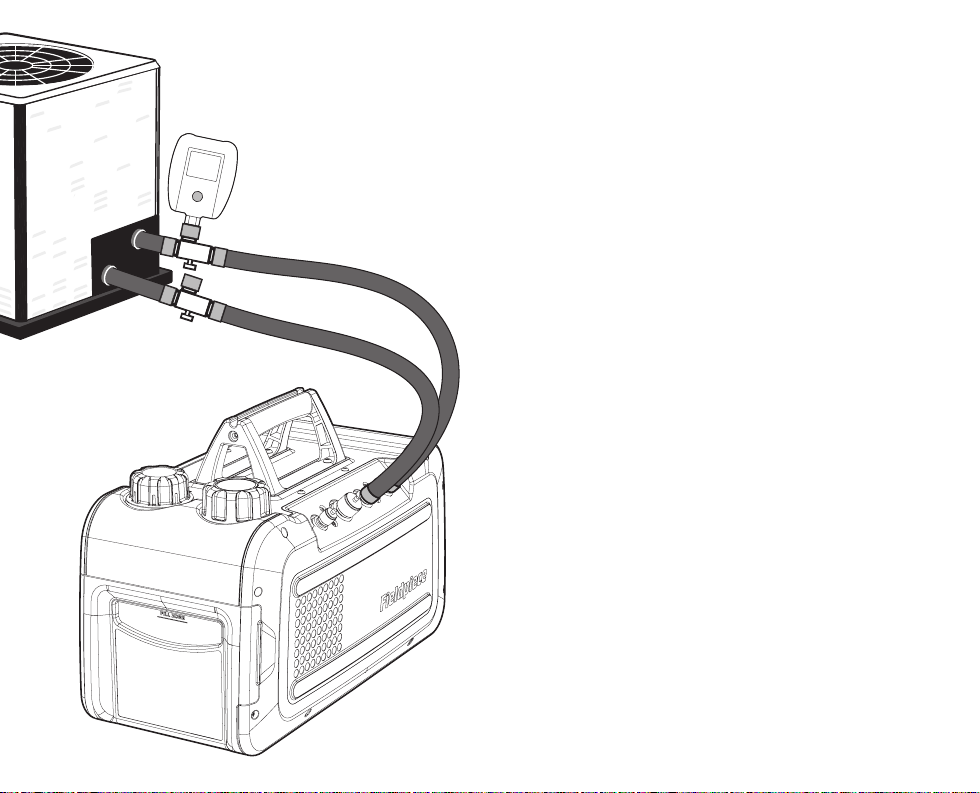

Evacuation with a 3 Port Manifold

This is a common, but less than ideal evacuation

method. Read the tech tips (page 12) for optimum

gauge placement and variations to reduce

recovery times.

Vapor

Liquid

Schrader Valve Core

Removal Tools (optional)

Hose with

Shut-off Valve

3 Port

Manifold

with

Micron

Gauge

1. Always fill with fresh Fieldpiece Vacuum Pump Oil. (page 24)

Running the pump without oil will damage the pump and void the

warranty. Oil can be drained while the pump is running if refilled

within 3 minutes (within 30 seconds to maintain your vacuum).

2. Ensure the VP55/VP85 motor power switch is turned OFF (down).

3. Plug VP55/VP85 into an outlet (oil backlight should illuminate).

4. Ensure the gas ballast is closed (vertical). (page 26)

5. Connect VP55/VP85 to the empty, depressurized A/C system.

6. Turn the motor power switch to ON (up).

7. Open line set (hoses, manifolds, removal tools, etc.) to expose the

pump to the system.

To reduce oil contamination early in the job, open the gas ballast until

the sound of the pump quiets down (about 3000 microns). The LED

shines if the ballast is open.

8. After the appropriate vacuum is reached, isolate the system from

the pump. You can check the system for potential leaks at this time

by monitoring your micron gauge.

VP55/VP85 has a unique oil suck back prevention feature to keep your

hoses clean. Still, it’s good practice to release the vacuum at the input

port before turning off the pump.

9. Turn the motor power switch to OFF (down), remove your hoses,

and cap the ports to keep components free of contaminants.

10. Disconnect VP55/VP85 from the system and unplug from power.

11. Drain the contaminated oil while the oil is still warm to keep the

pump as clean as possible when stored.

2120

Page 12

Liquid

Schrader Valve Core

Removal Tools

Vapor

Micron

Gauge

Direct Evacuation

This is usually the fastest evacuation method.

Read the tech tips (page 12) for optimum gauge

placement and variations to reduce recovery

times.

1. Always fill with fresh Fieldpiece Vacuum Pump Oil. (page 24)

Running the pump without oil will damage the pump and void the

warranty. Oil can be drained while the pump is running if refilled

within 3 minutes (within 30 seconds to maintain your vacuum).

2. Ensure the VP55/VP85 motor power switch is turned OFF (down).

3. Plug VP55/VP85 into an outlet (oil backlight should illuminate).

4. Ensure the gas ballast is closed (vertical). (page 26)

5. Connect VP55/VP85 to the empty, depressurized A/C system.

6. Turn the motor power switch to ON (up).

7. Open line set (hoses, manifolds, removal tools, etc.) to expose the

pump to the system.

To reduce oil contamination early in the job, open the gas ballast until

the sound of the pump quiets down (about 3000 microns). The LED

shines if the ballast is open.

8. After the appropriate vacuum is reached, isolate the system from

the pump. You can check the system for potential leaks at this time

by monitoring your micron gauge.

VP55/VP85 has a unique oil suck back prevention feature to keep your

hoses clean. Still, it’s good practice to release the vacuum at the input

port before turning off the pump.

9. Turn the motor power switch to OFF (down), remove your hoses,

and cap the ports to keep components free of contaminants.

10. Disconnect VP55/VP85 from the system and unplug from power.

11. Drain the contaminated oil while the oil is still warm to keep the

pump as clean as possible when stored.

2322

Page 13

Oil Change Procedure

Changing oil is easy and visible. Start each job

with fresh oil. Change as needed during the job.

DRAINING OLD OIL

1. For extended pump life, drain the oil immediatly after the job

instead of waiting until the beginning of the next job.

2. Ensure the pump oil inside is warm enough (>75°F) for proper

drainage. Run the pump for 10 minutes if ambient temp is low.

3. Ensure the VP55/VP85 motor power switch is turned OFF (down).

Running the pump for longer than 3 minutes without oil will damage

the pump and void the warranty.

4. Plug in VP55/VP85 to activate the oil backlight.

5. Pull open the oil bottle access door.

6. Ensure your old empty oil bottle is located under the oil reservoir.

7. Open the oil drain valve clockwise (vertical) to empty the oil

reservoir of old oil.

8. Close the valve counter clockwise (horizontal).

9. Remove and cap the old oil for disposal.

ADDING FRESH OIL

10. Ensure the drain valve is closed (horizontal).

11. Unscrew the pump’s OIL FILL cap 1/4 turn counter clockwise.

12. Open a new 8 ounce bottle of Fieldpiece Vacuum Pump Oil (OIL8X3).

Put the bottle cap on the side of the bottle (CAP STORAGE).

13. Pour the entire 8 ounce bottle of fresh oil into the OIL port. The oil

level should land within the FILL ZONE. Replace OIL FILL cap.

14. Place the empty bottle under the drain valve so it’s ready to gather

oil at the next oil change.

Push down on the spring loaded platform to locate the bottle

underneath the drain.

15. Close the oil access door.

16. Your vacuum pump is now ready to operate.

Dynamic Vacuum Measurement

During the pull down, the system’s vacuum

level drops faster at the front of the system, near

the vacuum pump.

To ensure that your full system achieves the

target micron level, place the vacuum gauge

as far to the back of the system, away from the

pump, as possible.

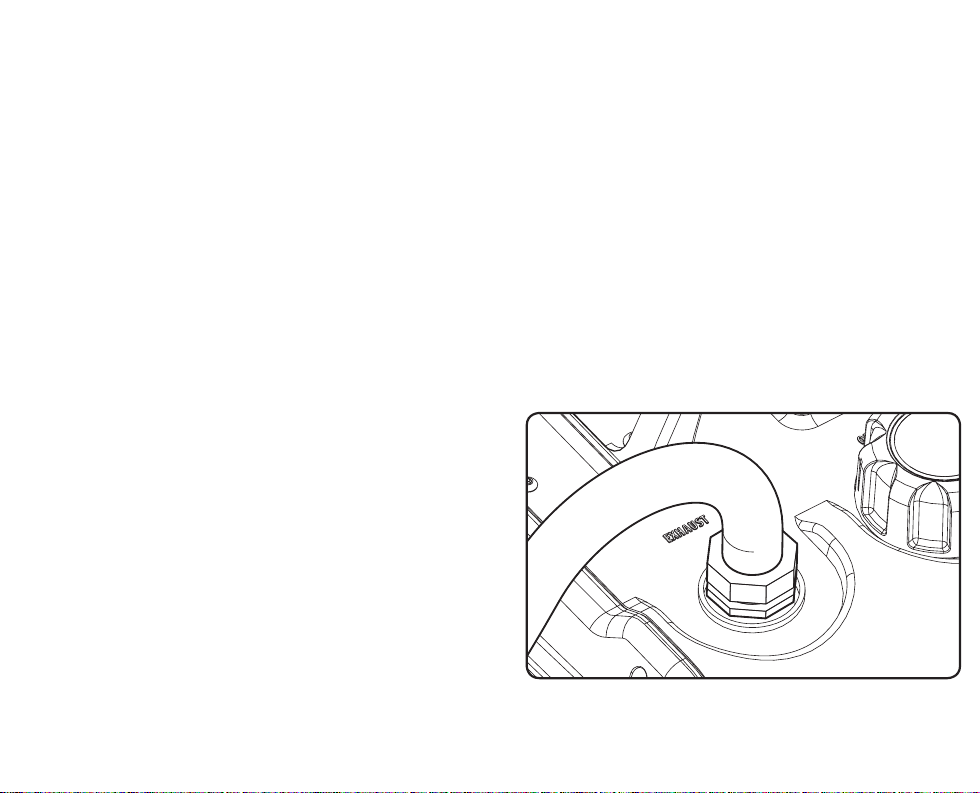

Remote Exhaust

Unscrew the EXHAUST cap and connect an

obstruction-free garden hose if you need to

exhaust oil mist and vapor remotely to the

outside of a building structure.

2524

Page 14

Gas Ballast Switch

Much of the air and moisture in a system are

removed before reaching 3000 microns. For wet

systems, you should open the gas ballast during

this initial pull down. Doing so helps the pump

run smoothly and keeps the oil in good condition

for when you need it most -- towards the end of

the evacuation.

At about 3000 microns, when the sound of the

pump quiets down, the gas ballast should be

closed so that a deep vacuum can be generated.

Closed

• Normal operating position.

• LED off.

• Discharge stroke isolated from

ambient.

Fully Open

• Set here for initial pumping down

(above 3000 microns) of wet

systems.

• LED on.

• Discharge stroke exposed to

ambient.

2726

Page 15

Maintenance

General

Wipe with damp cloth to clean the exterior.

Do not use solvents.

Storage

Empty or replace oil at the end of every job.

Don’t leave old oil in the machine. Store the pump

and oil in dry clean areas for longest life.

Oil can lose its sealing properties if left

uncovered. Keep oil sealed until it’s ready for use.

Vacuum Isolation Test

Perform this test to ensure VP55/VP85 and your

micron gauge are working properly.

1. Connect your vacuum gauge directly to a port on VP55/VP85.

2. Seal the 3 other ports.

3. Turn on VP55/VP85 to create a vacuum at your gauge.

If your gauge measures below 200 microns within 1 minute, you

know VP55/VP85 and your micron gauge are working correctly

Contaminated Oil Reservoir

After some jobs, solids, sludge, and other

waste may gather in the oil reservoir. The large

oil drain ball valve will typically drain these when

changing the oil.

The oil reservoir is permanently attached to

the machine. If contaminants build up in the

reservoir, use a bottle brush (with plastic bristles)

through the oil fill and/or exhaust openings to

reach in and clean the clear reservoir.

Rubbing alcohol can be used in conjuction

with brushing without damaging the reservoir.

Always allow alcohol to fully evaporate before

refilling the reservoir with oil.

If your gauge does not reach 200 microns, there is a problem with

your gauge, VP55/VP85, or both.

2928

Page 16

Troubleshooting

Appropriate vacuum is never reached.

Ensure the gas ballast is closed (vertical position, LED off).

Ensure oil is fresh.

Ensure oil level is within the FILL ZONE.

Ensure all port caps are closed and have working seals.

Limit amount of connections. Check for leaks at connections.

Use vacuum rated hoses.

Check for blockages between the pump and the system.

Check for a system leak.

Verify your vacuum gauge is in the correct location and is accurate.

Use the right pump for the job, 5CFM or 8CFM (over 20 tons).

Perform a triple evacuation to carry moisture out of the system by

purging the system with dry nitrogen.

Vacuum rises when isolating the system.

Ensure your micron gauge is located on the system side of the

shut-off valve. The micron gauge of a 3 port (2 valve) manifold cannot

measure a system’s vacuum if the valves are closed. Use a shut-off valve

at the third port to isolate the pump from the system (page 20).

Check for a system leak.

Oil backlight does not turn on when plugged in.

Ensure power cord and outlet are okay. If backlight does not shine

and the pump turns on, the oil backlight LED module may need to be

replaced.

Pump makes excessive noise.

The pump may be experiencing a high load.

Loose objects may be vibrating in the case.

Motor bearings may be bad. Motor needs to be replaced.

Motor may have come loose. Tighten motor mount bolts.

Oil level or condition may be bad. Change the oil.

Leaks may be present. Tighten or fix all connections.

Oil mist is coming out of the exhaust.

Some slight oil mist is normal due to airflow carrying oil as it passes

through the pump. You can attach a garden hose to the exhaust port to

control oil misting (page 25).

For larger systems with long evacuation times, extended high

pressure conditions can cause excessive misting to occur. Add oil as

needed if excessive oil loss occurs.

Motor does not start when switched ON.

Oil in the pump may have become highly viscous due to

contamination or low temperature. Use only fresh Fieldpiece Vacuum

Pump Oil within the pump’s operating temperature.

The pump may be cold. Warm the pump in your truck/home by

letting it sit in warm environment. You can warm the oil in your truck/

home before adding it to the pump.

The pump may be cold. Open an unused input port to ambient for a

few seconds until the pump is running.

Voltage is incorrect. Ensure proper voltage and cord length.

Motor may be damaged. Motor needs to be replaced.

Motor thermal protection activated. Wait for the machine to cool

down to operating range and determine why it may have overheated.

Loading may be excessive.

Oil is leaking.

Oil likely fell into the housing from around the fill port and is now

dripping through the internal housing. Wipe clean and make sure oil is

not spilled when adding to the wide mouth OIL FILL port.

3130

Page 17

Limited Warranty

This machine is warranted against defects in

material or workmanship for one year from date

of purchase from an authorized Fieldpiece dealer.

Fieldpiece will replace or repair the defective unit,

at its option, subject to verification of the defect.

This warranty does not apply to defects

resulting from abuse, neglect, accident,

unauthorized repair, alteration, or unreasonable

use of the machine.

Any implied warranties arising from the sale of

a Fieldpiece product, including but not limited to

implied warranties of merchantability and fitness

for a particular purpose, are limited to the above.

Fieldpiece shall not be liable for loss of use of the

machine or other incidental or consequential

damages, expenses, or economic loss, or for any

claim of such damage, expenses, or economic

loss.

State laws vary. The above limitations or

exclusions may not apply to you.

Obtaining Service

Visit www.fieldpiece.com/rma for the latest

information on how to obtain service.

Warranty for products purchased outside of the

U.S. should be handled through local distributors.

Visit our website to find your local distributor.

3332

Page 18

VP55

VP85

© Fieldpiece Instruments, Inc 2018; v10

Loading...

Loading...