Page 1

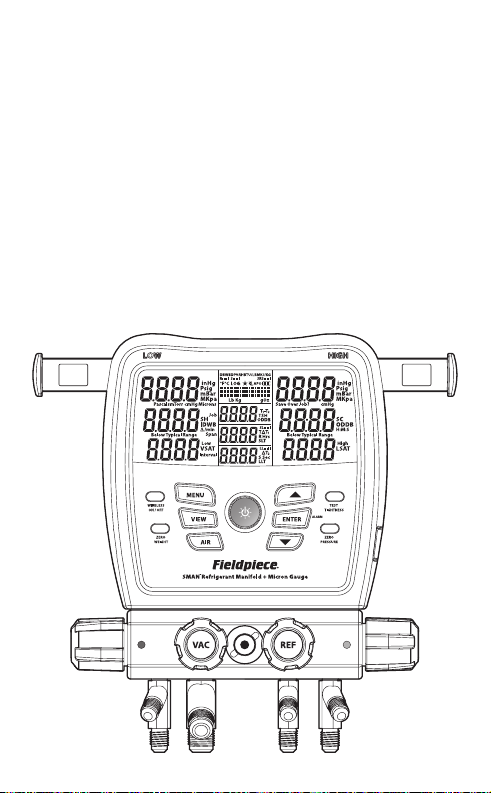

Fieldpiece®

SMAN™ Refrigerant

Manifold + Micron

Gauge (4 Port)

OPERATOR'S MANUAL Model SM480V

Page 2

Contents

Important Notice . . . . . . 4

Class A2L/A2/A3 Refrigerant Safety Notice

Warnings

Quick Start . . . . . . . . 5

What’s Included

Description . . . . . . . . 6

Features

Display

Front View

Rear View

Operation. . . . . . . . . 14

Buttons

Recent Refrigerants

VIEW Select

AIR Select

Superheat (SH) and Subcooling (SC)

Target Superheat (TSH)

Deep Vacuum

Test Tightness (Pressure Test)

Test for Noncondensables

Menu . . . . . . . . . . 22

Data Logging

Auto Power Off (APO)

Temperature Calibration

Wireless Measurement Sources

Target Superheat (TSH) Sources

Units

Vacuum Alarms

Backlight Timer

Advanced Pressure Calibration

Firmware View and Update

Restore User Settings

Delete Log File

Format Internal Flash Drive

Maintenance. . . . . . . . 35

Cleaning

Battery Replacement

Using Different Refrigerants

Specifications . . . . . . . 36

Temperature

Pressure

Deep Vacuum

Wireless Compatibility

Manifold Diagram

Certification and Module IDs . . 39

Limited Warranty . . . . . . 43

32

Page 3

Important Notice

!

This is not a consumer product. Only qualified

personnel trained in service and installation of

A/C and/or refrigeration equipment shall use

this product.

Read and understand this operator’s manual in

its entirety before using your SMAN Refrigerant

Manifold to prevent injury or damage to you or

equipment.

Class A2L/A2/A3 Refrigerant

Safety Notice

Systems using class A2L (mildly flammable),

class A2 (flammable), or class A3 (highly

flammable) refrigerants can be tested safely ONLY

by qualified personnel explicitly trained in the use

and handling of those refrigerants. This manual

is in no way a replacement for proper training.

WARNINGS

Do not apply more than 800 psig to any port of the manifold.

Ground properly when testing A2L/A2/A3 (hydrocarbon) refrigerants.

Do not use in the vicinity of explosive substances.

Inhalation of high concentrations of refrigerant vapor can block oxygen to

the brain causing injury or death.

Refrigerant liquid can cause frostbite.

Follow all equipment manufacturer’s testing procedures above those in

this manual in regards to properly servicing their equipment.

Quick Start

1. Install the included six AA batteries into rear

battery compartment.

2. Press center blue button for 2 seconds to

turn on your new SMAN manifold.

3. Connect your hoses and pipe clamps to the

SMAN manifold and to the system.

4. View live pressures and temperatures.

5. Use arrow buttons to select a refrigerant and

view calculations in real-time!

What’s Included

• SM480V SMAN Refrigerant Manifold (4 Port)

• (2) TC24 Type K Pipe Clamp Thermocouples

• (1) ATA1 Type K Bead Thermocouple w/Clip

• (1) Year Warranty

• Operator’s Manual

54

Page 4

Description

SMAN™ Refrigerant Manifolds give you the

trust needed for doing the job right the first time.

Your new Fieldpiece manifold has been

upgraded for ultimate field protection and

long range wireless communication. The fully

rubberized case seals and protects from dust,

bumps, and light rain. Use the heavy duty hook

to hang it in your work vehicle while protected

by its large padded soft case.

Model SM480V is your testing hub at the jobsite.

In addition to the included thermocouples, you

can connect wirelessly to psychrometers, pipe

clamps, and even a refrigerant scale. For example,

assign one psychrometer (model JL3RH) to

return air and another to supply air to view live

temperature split across the evaporator directly.

View all your measurements and live

calculations on the extra large LCD or from a

distance on your mobile device. A rolling list of

your 10 most recently used refrigerants is stored

at the top of the main refrigerant list for quick

selection.

Verify proper charge by comparing actual

superheat (SH) with target superheat (TSH).

Use the outdoor dry bulb thermocouple and

an optional indoor psychrometer for live TSH

calculations.

Pressure sensors automatically compensate

for altitude and weather changes. Use the

internal vacuum gauge for fast and convenient

monitoring of your evacuations through the full

bore 3/8” VAC port.

Features

Job Link® System Ready

- Long Wireless Range (350 feet/106 meters)

- Connect to Your Mobile Device Directly (page 38)

- Connect Job Link Tools Directly (page 38)

Real-time Calculations

- Superheat and Subcooling

- Vapor Saturation and Liquid Saturation

- Target Superheat (requires model JL3RH for real-time)

- T1-T2

(3) Type K Thermocouple Jacks

- Suction Line

- Liquid Line

- Outdoor Ambient

(4) Ports: (1) 3/8” (3) 1/4”

Built-in Micron Gauge

Tightness Test

Recent Refrigerant List

Sealed Sight Glass

Heavy Duty Rubberized Construction

Rugged Hanging Hook

Operation in the Rain (IP54)

Data Logging with USB Export

7

Page 5

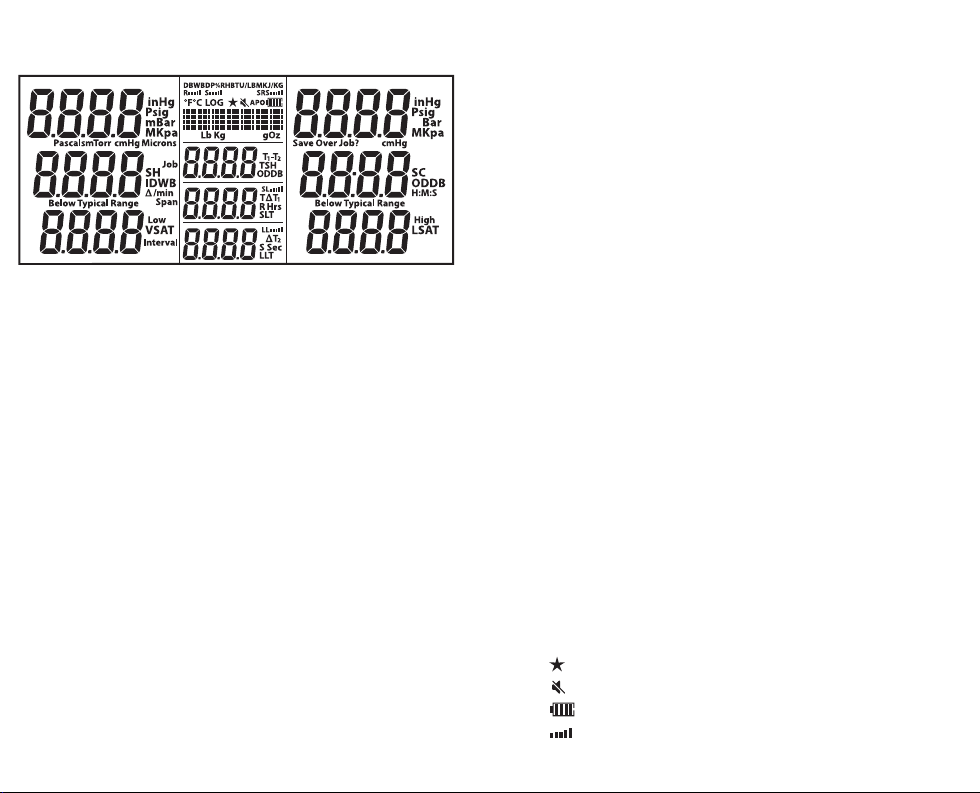

Display

°F: Temperature (Fahrenheit)

°C: Temperature (Celcius)

Psig: Pressure (pounds/in2)

Bar: Pressure

MPa: Pressure (megapascals)

kPa: Pressure (kilopascals)

inHg: Negative Pressure (inches of mercury)

cmHg: Negative Pressure (centimeters of mercury)

Microns: Vacuum (microns of mercury)

Pascals: Vacuum

mBar: Vacuum (millibar)

mTorr: Vacuum (millitorr)

Torr: Vacuum (equivalent to mmHg)

Δ/min: Vacuum Rate (differential per minute)

h:m:s: Hours:Minutes or Minutes:Seconds

SH: Superheat (suction line - vapor saturation)

SC: Subcooling (liquid saturation - liquid line)

VSAT: Vapor Saturation Temperature (from P-T chart)

LSAT: Liquid Saturation Temperature (from P-T chart)

TSH: Target Superheat (calculated from IDWB and ODDB)

T1-T2: Measurement Differential

SLT : Suction Line Temperature (low side)

LLT : Liquid Line Temperature (high side)

ODDB: Outdoor Dry Bulb Temperature

IDWB: Indoor Wet Bulb Temperature

LOG: Data Logging in Progress

Job: Job Slot (1-9) of Data Log

Span: Hours (Hrs) of Data Logging

Interval: Seconds (Sec) Between Logged Measurements

R: Return Psychrometer

S: Supply Psychrometer

DB: Dry Bulb from Psychrometer

WB: Wet Bulb from Psychrometer

DP: Dew Point from Psychrometer

%RH: Relative Humidity from Psychrometer

BTU/LBM: Enthalpy from Psychrometer (BTU per pound mass)

KJ/KG: Enthalpy from Psychrometer (kilojoules per kilogram)

TΔT: Target Dry Bulb Split from Psychrometers

ΔT: Dry Bulb Split from Psychrometers

Lb: Pounds (from wireless scale)

Oz: Ounces (from wireless scale)

Kg: Kilograms (from wireless scale)

g: Grams (from wireless scale)

APO: Auto Power Off Enabled

: Top 10 Refrigerant Selected

: Speaker Turned Off

: Battery Life Remaining

: Wireless Signal Strength

98

Page 6

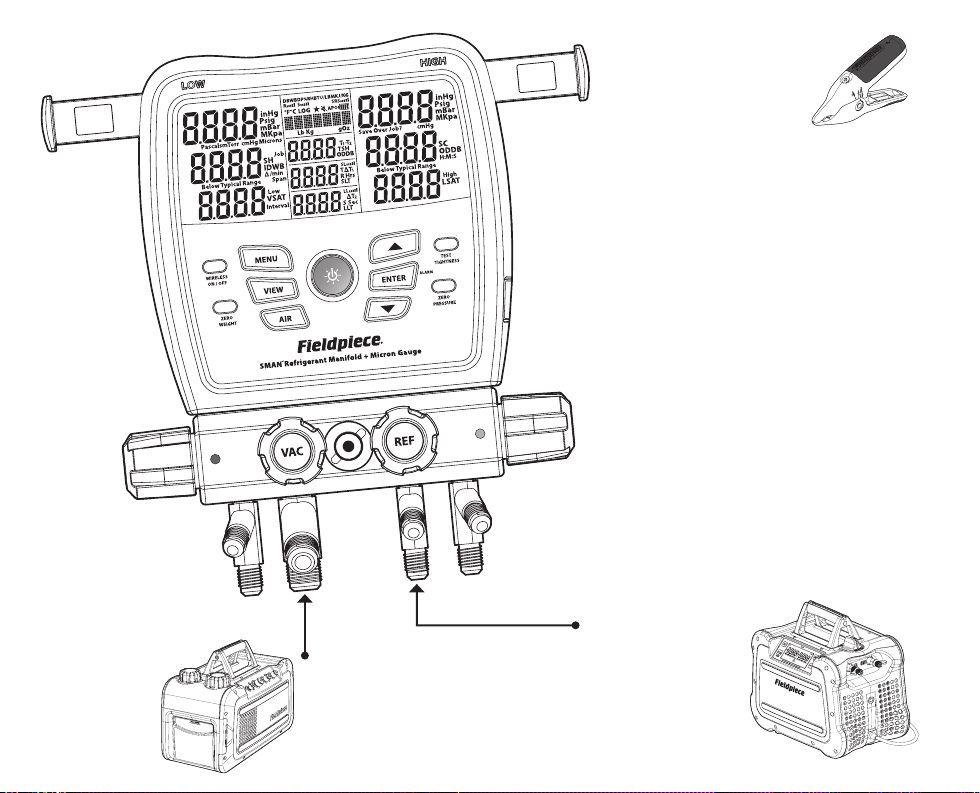

Pipe Clamp Storage Arms

Metal shorting blocks are for

Rapid Rail™ Thermocouple

model JL3PC (sold separately)

Display

Buttons

Suction

Line Port

Sight

Glass

Vacuum Port

Large port matches

perfectly with Fieldpiece

Vacuum Pump models

VP55 and VP85

Front View

Micro USB Port

Removable rubber cover

Liquid

Line Port

Refrigerant Port

Connect to a refrigerant

cylinder directly, or to

a recovery machine like

Fieldpiece model MR45

(LOW)

(HIGH)

(VAC)

(REF)

Suction Line Port Valve

Liquid Line Port Valve

Vacuum Port Valve

Refrigerant Port Valve

1110

Page 7

SM480V

1234

0000001234

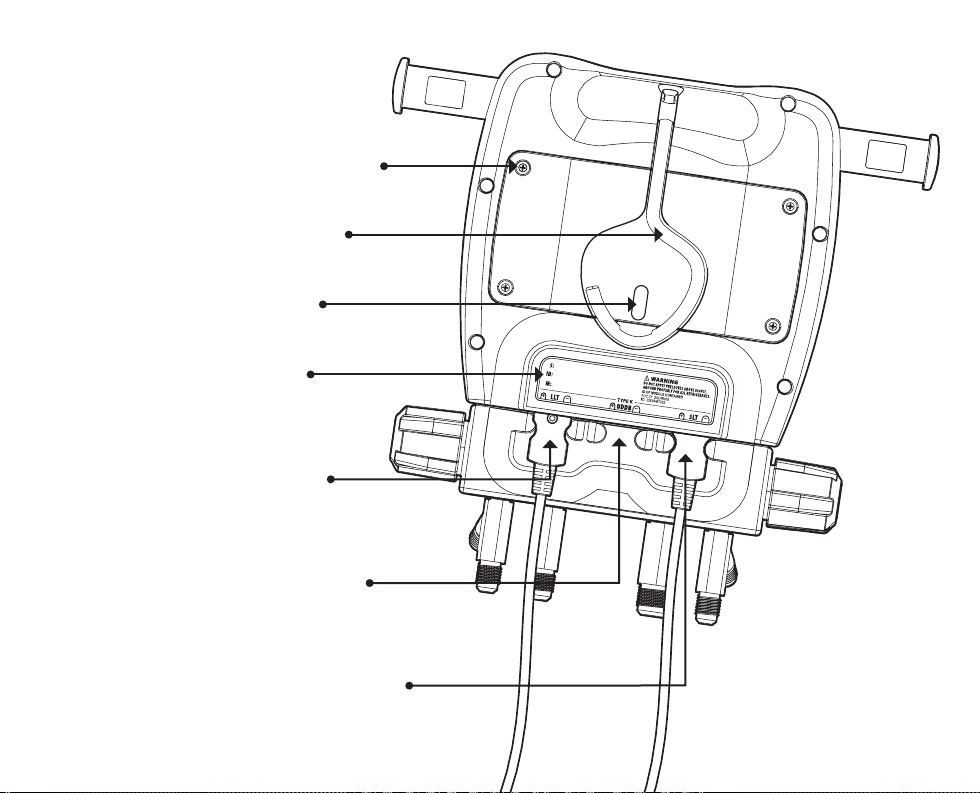

Rear View

Battery Cover Screws

Steel Hanging Hook

Battery Door Finger Pull

4 Digit Job Link® System ID

Use when connecting to the Job Link

Mobile App for testing and reporting

(LLT) Liquid Line

Thermocouple Jack

Shown not inserted enough

(ODDB) Outdoor

Thermocouple Jack

Shown without thermocouple

(SLT) Suction Line

Thermocouple Jack

Shown fully inserted

Thermocouple

Bumpers

Bumpers help secure

thermocouple plugs.

Pipe clamp thermocouples

have indents on the plug

that line up with the bumper

when fully inserted.

1312

Page 8

Operation

Buttons

A beep sounds when a button is pressed. A

double beep sounds when a button is pressed

and the function is not possible at that time. The

speaker can be muted altogether (page 22).

Press 2 sec to toggle power. Press to toggle backlight.

Scroll through refrigerants or change values.

ENTER: Confirm a changed value or activate an ALARM (page 18).

MENU: Enter the menu (page 22) or exit a mode.

VIEW: Display ODDB, TSH, or T1-T2 (page 15).

AIR: Display SLT/LLT or various return and supply air measurements

from optional psychrometers (page 15).

WIRELESS ON/OFF: Toggle wireless communication ON/OFF. Turn

wireless OFF to increase battery life.

ZERO WEIGHT: Press 2 sec to zero (tare) weight from a wireless

scale (page 26).

TEST TIGHTNESS: Enter tightness test setup (page 20).

ZERO PRESSURE: Press 2 sec to zero the displayed pressures.

VIEW Select

Press VIEW to cycle through ODDB (outdoor

dry bulb), TSH (target superheat), and T1-T2

(middle display - bottom display).

ODDB: Live reading of the rear ODDB thermocouple jack. ODDB does

not show if set to manual value (page 27).

TSH: Live target superheat calculated from ODDB and IDWB. Each of

these measurements can be live or manually entered (page 17).

T1-T2: Live simple subtraction of the bottom display (T2) from the

middle display (T1). With SLT and LLT showing, you can check for

a temperature drop across a filter drier. With R and S showing, you

can check the effect of the indoor unit. With TΔT and ΔT showing,

you can see how close the actual ΔT is to the target.

AIR Select

Press AIR to display various calculations

and measurements from Job Link system

psychrometers you’ve assigned (page 26). The

parameter is briefly shown when pressed, then

shown at the top of the LCD.

Press AIR for >1 second to view SLT/LLT.

Recent Refrigerants ( )

A rolling list of your 10 most recent refrigerants,

indicated by a

When you power off your manifold, the current

refrigerant is added automatically to this dynamic

list of 10.

, is stored above the main list.

SLT : Live reading of suction line temperature.

LLT : Live reading of liquid line temperature.

R: Live reading from return air psychrometer.

S: Live reading from supply air psychrometer.

TΔT: Live target dry bulb split from psychrometers.

ΔT: Live actual dry bulb split from psychrometers.

1514

Page 9

Superheat (SH) and Subcooling (SC)

Superheat is the amount of heat added to

refrigerant after changing to a vapor in the

evaporator. Subcooling is the amount of heat

removed from refrigerant after changing to a

liquid in the condenser. View both live at the

same time!

1. Use ARROWS to select the system refrigerant.

2. Close all manifold valves.

3. Connect EPA approved refrigerant hoses to LOW and HIGH side ports.

4. Fully plug pipe clamp thermocouples into SLT and LLT rear jacks.

5. Hand tighten both the LOW side hose to suction line service port and

the HIGH side hose to the liquid line service port.

6. Clamp the SLT thermocouple to the suction line between the

evaporator and compressor, at least 6 inches from the compressor.

7. Clamp the LLT thermocouple to the liquid line between the

condenser and metering device, as close to the service port as

possible.

8. Purge hoses as you open HIGH and LOW manifold valves.

9. View superheat and subcooling in real-time.

• Ensure system has stabilized before using superheat or subcooling to

adjust the charge of the system.

• To add or remove refrigerant connect the tank/cylinder/machine to

the REF port. Use the manifold valves to precisely charge or recover

refrigerant as needed. Follow recommended charging or recovery

practices from equipment manufacturer and training.

• When superheat and/or subcooling cannot be calculated, “- - - - ”

will be displayed. If superheat and/or subcooling is negative, “Below

Typical Range” will show. In rare cases this is normal, but usually a

thermocouple is disconnected or the selected refrigerant is incorrect.

Target Superheat (TSH)

Compare target superheat (TSH) to actual

superheat (SH) when charging fixed orifice

air conditioning systems. TSH is continually

calculated from indoor wet bulb (IDWB) and

outdoor dry bulb (ODDB) temperatures.

IDWB: By default, this is a manually set value of 60.0°F.

For a live measurement, assign the optional model JL3RH wireless

psychrometer (page 26).

ODDB: By default, this is the live measurement of the ODDB

thermocouple jack. If you prefer a static measurement, assign a

manual value (page 27).

1. Connect the included type K bead thermocouple to the ODDB

thermocouple jack. Use the alligator clip to locate the bead in a

shaded area of the condenser to measure the temperature of air

entering the condenser.

2. Press VIEW until ODDB is displayed to verify the measurement.

If you changed ODDB to a manually set value, it will be used to

calculate TSH but will not be displayed.

3. Measure IDWB after the filter, just in front of the indoor coil. If

a psychrometer is assigned, you can press AIR until wet bulb is

displayed to verify the measurement.

4. Press VIEW until TSH is displayed.

1716

Page 10

Deep Vacuum

Follow recommended evacuation practices

from equipment manufacturer and training.

Alarms can be adjusted in the MENU (page 28).

1. Close all manifold valves.

2. Setup your tools and equipment (see diagram).

Connect HIGH port to liquid line service port.

Connect LOW port to suction line service port.

Connect VAC port to vacuum pump.

3. Turn on your vacuum pump.

4. Open VAC valve.

The vacuum sensor is now exposed to your pump, but it will not

display until HIGH/LOW manifold valves are opened. This ensures the

measurement is of the system and not just the manifold.

5. Open HIGH and LOW manifold valves.

6. Press ALARM to activate the low alarm.

The stopwatch starts. The rate of change is displayed in units

per minute. The smaller the rate of change, the closer you are to

stabilization. You may need to improve your setup if rate slows well

before reaching your desired vacuum (see Tips for Better Evacuations).

7. Once the the low alarm level is reached, the backlight blinks and

alarm sounds. Press any button (other than ENTER) to silence alarm.

8. Close VAC valve to block the pump.

Do not close HIGH and LOW valves or you’ll block the system and

measure just the manifold!

9. Turn off your vacuum pump.

10. Press ALARM to activate the high alarm and start the stopwatch.

11. Once the high alarm level is reached, the backlight blinks, alarm

sounds, and the stopwatch stops. Press any button (other than

ENTER) to silence alarm.

12. Close HIGH and LOW manifold valves.

The vacuum sensor is now blocked from the system (page 39).

Tips for Better Evacauations

• Remove schrader cores and depressors with a core removal tool.

• Use shortest vacuum rated hoses with largest diameter available.

• Do not evacuate through hoses with low loss fittings.

• Inspect the rubber seals at both ends of your hoses for damage.

• Change pump oil before and during the job. Change pump oil onthe-fly without losing vacuum with Fieldpiece vacuum pumps.

• When the vacuum pump is blocked, a slow rise that stabilizes may

signify moisture is still present in the system. A continuous rise to

atmosphere indicates a leak. Check hoses, tools, or the system itself.

• Measurements are less representative of the entire system when

the vacuum pump is on because pumping creates a pressure

gradient. Block the pump and allow the system to stabilize before

assuming the measurement is of the entire system.

1918

Page 11

Test Tightness (Pressure Test)

After working on a refrigerant-side component

of an emptied system, it’s a good idea to

pressurize the system with dry nitrogen and

check for pressure drops before evacuation.

1. Pressurize the system with dry nitrogen. Pressure levels vary with

the equipment you’re testing. Always check with the manufacturer.

2. Connect the low side (suction line) port to the system and wait for

the pressure to stabilize. You can connect the high side (liquid line)

as well to help monitor stability, but the pressure differential (P.diF)

calculation is only using the low side sensor.

3. Attach SLT clamp to the pipe you’re going to pressurize.

This temperature is used to compensate for any temperature changes

between the start and end of the test.

To deactivate temperature compensation, unplug or unassign SLT

before starting the test; SLT will not be shown or used.

4. Press TEST TIGHTNESS to prepare test.

5. Press ENTER to start the test.

The stopwatch starts.

Real-time compensated pressure change is labeled P.diF.

Real-time temperature is labeled SLT.

Real-time temperature change is labeled ΔT.

6. Press ENTER to stop the test.

The stopwatch, P.diF, and ΔT freeze.

If P.diF is negative, there may be a leak in the system.

If P.diF is positive, SLT or nitrogen temperature may be unstable.

High and low side pressures and SLT continue to display, but they are

no longer being used.

7. Press ENTER to exit the test.

Test for Noncondensables

If head pressure seems high even after cleaning

coils, optimizing airflow, and other routine

maintenance, you may have noncondensables

trapped in the system. Noncondensables can

reduce efficiency, performance, and put extra

stress on system components. Noncondensables

can enter the system in many ways, and your initial

system service may be following years of poor

service that introduced the noncondensables.

1. Use ARROWS to select the system refrigerant.

2. Unpower the compressor, but allow the condenser fan to run.

3. Connect high side port to the system to view system pressure.

4. Clamp one thermocouple to the discharge line.

5. Clamp the other thermocouple to the liquid line.

6. Clip the ODDB thermocouple to measure the air entering the

condenser.

7. Monitor all three temperatures until they all stabilize and show the

same value.

8. View the subcooling (SC) calculation on the display.

The closer SC is to 0.0°, the fewer noncondensables are trapped.

Depending on the system, a negative SC may suggest a need to

recover, evacuate, and charge with virgin refrigerant.

• To save battery life, the screen will turn off after 3 hours of testing,

but will continue to test. Press any button to turn the screen on.

2120

Page 12

Menu

Press MENU to enter the menu where most

settings are located. Use arrows to scroll through

the menu and press ENTER to select one of the

below menu items.

LogData: Enter data logging setup mode (page 23).

(StopLog): If data logging, stop the log (page 23).

AutoOff: Enter auto off timer setup mode (page 24).

CalTemp: Enter calibration mode for Type K jacks (page 25).

Wireless Sources: Enter wireless source setup mode (page 26).

TSH Sources: Enter target superheat source setup mode (page 27).

Units: Enter units setup mode (page 28).

Vac Alarms: Enter vacuum alarm setup mode (page 28).

Mute: If unmuted, mute the speaker.

(Unmute): If muted, unmute the speaker.

Backlight Timer: Enter backlight timer setup mode (page 29).

Adv Pressure Cal: Enter advanced calibration mode for pressure

sensors (page 30).

F Ware: Enter firmware view and update mode (page 32).

Restore Settings: Enter restore factory settings mode (page 33).

(Delete Log File): If a log file is saved to the internal flash drive,

enter delete log file mode (page 34).

Format Drive: Enter format drive mode (page 34).

Data Logging

Log measurements and resulting calculations,

such as Superheat, at chosen spans and intervals.

Save up to 9 Jobs (logs) to the internal flash drive.

MENU/LogData

1. Use ARROWS to scroll through Jobs.

The display will alternate between the % free space on the drive and

the % of space the chosen Job uses.

2. Press ENTER to select.

If a Job already exists in that slot, use ARROWS then ENTER to choose

whether or not you want to save over that Job.

3. Use ARROWS to set the Span (total time).

It’s a good idea to use new batteries if setting up a long span. If

batteries run out during a Job, the log will automatically stop and

save, then the SMAN manifold will turn off.

4. Press ENTER to select.

5. Use ARROWS to set the Interval (time between measurements).

6. Press ENTER to select and begin logging data until the Span ends.

LOG will blink to indicate the log is still active.

• Press MENU to exit setup at any time.

• Press MENU and select StopLog to stop the Job and return to

standard operation. The Job will be saved.

• To save battery life, the screen will turn off after 3 hours of logging,

but will continue to log. Press any button to turn the screen on.

• Some buttons and features (including auto power off) are disabled

until the Job ends.

• Jobs are saved as .csv files.

• Connect to your computer via the micro USB port under the

removable rubber cover. View its internal flash drive just like any

other USB drive.

2322

Page 13

Auto Power Off (APO)

To save battery life, your SMAN manifold

automatically powers off after a set time of no

button presses.

MENU/AutoOff

1. Use ARROWS to scroll through times (default is 30 min).

2. Press ENTER to select and exit. If changes were made, choose

whether or not you want to save changes.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• APO is automatically disabled when data logging.

Temperature Calibration

Thermocouples (T/C) are not calibrated

directly. Instead, each T/C jack (ODDB, SLT, LLT)

must be calibrated to the particular T/C that

is plugged into it. Though it’s possible for a

calibration to hold for years, it’s best practice to

calibrate regularly if only to verify accuracy.

Calibration is quick and easy, requiring just a

known temperature to calibrate to. Ice water is

probably the most accurate and readily available

known temperature (32.0°F, 0.0°C) in the field.

MENU/CalTemp

1. Stabilize a large cup of ice water by stirring. Pure, distilled water

will be the most accurate.

2. Immerse the sensing end of the thermocouple in the ice water.

3. Use ARROWS to select the temperature you want to calibrate (SLT,

LLT, or ODDB).

4. Press ENTER to select.

5. Use ARROWS to adjust the temperature to match 32.0°F (0.0°C)

making sure the ice water is continually stirred. The calibration

range is limited to ±7°F (±3.8°C) in order to help prevent mistakes.

6. Press ENTER to save and return to the list of temperatures.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• If you have a wireless thermocouple (model JL3PC) assigned and

wireless is on, calibration is for the wireless thermocouple.

• Calibration of a wireless thermocouple (model JL3PC) does not

override a wired thermocouple calibration. You can switch between

wired and wireless without having to recalibrate.

2524

Page 14

Wireless Measurement Sources

Assign wireless Job Link system tools to

core manifold measurements such as pipe

temperature or to broader measurements such

as refrigerant weights and psychrometrics.

Wireless OFF: Line temperatures (SLT and LLT) are automatically

assigned to their type K jacks.

Wireless ON: SLT and LLT type K jacks DO NOT override an

assigned wireless source.

MENU/Wireless Sources

1. Use ARROWS to scroll through the list of measurements.

2. Press ENTER to select.

3. Turn on any wireless sources you want to assign.

If your Job Link system tool has a selector switch, ensure it’s set to

match the measurement.

4. Use ARROWS to scroll through detected measurement sources.

Job Link system tools are displayed by their 4 digit ID, usually found

on the back of the tool.

5. Press ENTER to select and return to the list of measurements.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• Most Job Link system tools have a switch that selects a side of the

system. Set it to match the measurement you’re assigning it to.

• Select Clear to set a source to its factory default source. This is

useful when you want to use a previously assigned tool at the job

site, but do not want to use it with the SMAN manifold.

• A wireless Return psychrometer is assigned to both Return air and

IDWB (page 17) when selected.

Target Superheat (TSH) Sources

Target superheat is calculated from outdoor

dry bulb (ODDB) entering the condenser coil and

indoor wet bulb (IDWB) entering the evaporator

coil. Assign a wireless psychrometer to return air

and plug in a thermocouple to ODDB for real-time

comparison of target vs actual superheat.

MENU/TSH Sources

1. Use ARROWS to toggle between IDWB and ODDB.

2. Press ENTER to select.

3. Use ARROWS to scroll through detected measurement sources.

Job Link system tools are displayed by their 4 digit ID, usually found

on the back of the tool. ODDB cannot be set to wireless.

4. Turn on any wireless sources you want to assign.

If your Job Link system tool has a selector switch, ensure it’s set to

match the measurement.

5. Press ENTER to select and exit or go to next.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• Most Job Link system tools have a switch that selects a side of the

system. Set it to match the measurement you’re assigning it to.

• Select Clear to set a source to its factory default source. This is

useful when you want to use a previously assigned tool at the job

site, but do not want to use it with the SMAN manifold.

• A wireless Return psychrometer is assigned to both Return air (page

15) and IDWB when selected.

• Turning wireless on/off does not change the assigned source.

• If ODDB is set to a manually set value, the thermocouple jack is

deactivated even if a thermocouple is plugged in.

2726

Page 15

Units

Each measurement can have its own unit of

measure.

Backlight Timer

The backlight turns off automatically after a set

time of no button presses.

MENU/Units

1. Use ARROWS to scroll through the list of measurements.

2. Press ENTER to select.

3. Use ARROWS to scroll through units of measure.

4. Press ENTER to select and return to the list of measurements.

• Press MENU to exit at any time. If a change was made before

pressing ENTER, choose whether or not you want to save the change.

Vacuum Alarms

Set high and low vacuum alarms so you know

when you’ve reached an appropriate vacuum

(Low) and time how long it takes to rise after

blocking the pump from the system (High).

MENU/Vac Alarms

1. Use ARROWS to toggle between high and low alarm.

2. Press ENTER to select.

3. Use ARROWS to adjust the alarm trigger.

4. Press ENTER to select and exit or go to next.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• The low alarm cannot go higher than the high alarm.

• The high alarm cannot go lower than the low alarm.

• Press ENTER (ALARM) while in deep vacuum to activate the next

alarm (None >> Low >> High >> None).

MENU/Backlight Timer

1. Use ARROWS to scroll through times (default is 2 min).

2. Press ENTER to select and exit. If changes were made, choose

whether or not you want to save changes.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

2928

Page 16

Advanced Pressure Calibration

Typical HVACR service does not require this

procedure, but you can occassionally calibrate the

pressure sensors to maintain highest accuracy.

It works by measuring the temperature of

virgin refrigerant and applying an offset to match

the pressure to that refrigerant’s P-T chart.

1. Calibrate a beaded thermocouple to the ODDB jack (page 25).

2. Store a virgin refrigerant cylinder, upright and untouched, in the

stable ambient environment for at least 24 hours.

3. Leaving the cylinder in the same place it was left to stabilize,

connect the cylinder to either the HIGH or LOW side port.

4. Close VAC and REF valves and cap the unused port.

If you don’t have caps with seals, you can connect both ends of a

refrigerant hose to the unused ports or hose seats. Some refrigerant

will remain in the hoses which you need to recover after calibration.

5. Use ARROWS to select the refrigerant type in the cylinder.

6. Use tape to attach the ODDB thermocouple bead halfway up the

cylinder to measure the temperature of the refrigerant.

7. Press VIEW if ODDB is not shown.

8. Open both HIGH and LOW side manifold valves.

9. Open the refrigerant cylinder valve.

The pressure inside cylinder should now be displayed on both HIGH

and LOW side pressure sensors.

10. Allow the pressure readings and ODDB temperature to stabilize.

11. Press MENU.

12. Use ARROWS to show Adv Pressure Cal.

13. Press ENTER to initiate calibration of the pressure sensors.

14. Each pressure sensor will briefly display “Good” if successful or “Err”

if unsuccessful, then return to normal operating mode.

Troubleshooting an “Err” message

1. Measured pressure was less than 10 psig.

• Refrigerant cylinder may be nearly empty.

• Valves may be closed.

2. Measured pressure was not within ±3psig of VSAT pressure on

the P-T chart.

• Thermocouple may not have been calibrated properly.

• Thermocouple may not have been attached properly to cylinder.

• Thermocouple may have not been connected to ODDB jack.

• Refrigerant cylinder pressure was unstable.

• Refrigerant cylinder temperature was unstable.

• Refrigerant selected did not match refrigerant in cylinder.

3130

Page 17

Firmware View and Update

Firmware often becomes available as new

refrigerants and features become available.

Before entering this mode, download from

www.fieldpiece.com and transfer from the

computer to the manifold via the micro USB port

on the side.

Or you can initiate an update over the air from

your mobile device running the Job Link system

mobile app while the version is displayed.

MENU/F Ware

1. View the firmware version on the top line, P/T chart on the

second line, and radio region on the bottom line.

2. If a new firmware file is found on the internal flash drive the new

versions will be shown. Choose whether or not you want to update.

3. Once installation begins you will see a bar moving across the

screen. “donE” will appear and your SMAN manifold will turn off

when finished.

• Press MENU to exit at any time before installation begins.

• During installation, buttons are disabled.

• User settings are not deleted.

• Log files are not deleted.

Restore User Settings

Restore factory default user settings when you

want a fresh start.

MENU/Restore Settings

1. Use ARROWS to select Yes or No.

2. Press ENTER to select and exit.

• Press MENU to exit at any time. If changes were made, choose

whether or not you want to save changes.

• If you choose to restore, it may take a few seconds before returning

to standard operation.

3332

Page 18

Delete Log File

Clear up space by deleting old logs or just view

free space available.

MENU/Delete Log File

1. Use ARROWS to scroll through Jobs (logs). The display will alternate

between the % free space on the drive and the % of space the chosen

Job uses.

2. Press ENTER to select a Job to delete. Choose whether or not you

want to delete that Job.

3. If you choose to delete, it may take a few seconds to finish. If no

more Jobs are found, the manifold returns to standard operation.

• Press MENU to exit at any time.

Format Internal Flash Drive

Quickly clear up maximum space by

reformatting the internal flash drive. This deletes

everything on the drive including log files,

firmware update files, and any other files added

manually.

MENU/Format Drive

1. Use ARROWS to select Yes or No.

2. Press ENTER to select and exit.

Maintenance

Cleaning

Wipe with damp cloth to clean the exterior.

Do not use solvents.

Battery Replacement

The batteries must be replaced when the

battery life indicator is empty. Once the batteries

are drained beyond operating voltage, “Low Bat”

briefly appears and the manifold turns off.

Unscrew the 4 cover screws and pull out the

rear battery cover. Replace the 6 AA batteries and

properly dispose of the old ones.

Using Different Refrigerants

You can use different refrigerants, but be

sure to purge your manifold with nitrogen

before connecting to a system with a different

refrigerant. Contamination can hurt system

performance and cause damage.

Temperature Calibration

See page 25.

• Press MENU to exit at any time.

• If you choose to format, it may take a few seconds before returning

to standard operation.

• User settings are not deleted.

Advanced Pressure Calibration

See page 30.

3534

Page 19

Specifications

Display: LCD (5 inches diagonal)

Backlight: Blue (adjustable duration)

Low Battery Indication: is displayed when the battery voltage

drops below the operating level.

Over Range Display: OL for pressure, - - - - for temperature

Auto Power Off: 30 minutes of inactivity (adjustable)

Maximum Manifold Pressure: 800 Psig (5500 kPa)

Battery Type: 6 x AA alkaline

Battery Life: 350 hours typical

(without vacuum, backlight, and wireless)

Radio Frequency: 2.4 GHz

Wireless Range: 350 feet (106 meters) line of sight.

Distance decreases through obstructions.

Data Port: Micro USB (for extracting data logs or updating firmware)

Operating Environment: 32°F to 122°F (0°C to 50°C) at <75% RH

Storage Environment: -4°F to 140°F (-20°C to 60°C) at <80% RH

(with battery removed)

Temperature Coefficient: 0.1 x (specified accuracy) per °C (0°C to

18°C, 28°C to 50°C), per 1.8°F (32°F to 64°F, 82°F to 122°F)

Weight: 4.03 lbs (1.83 kg)

Water Resistant: Designed to IP54

US Patent: www.fieldpiece.com/patents

Refrigerants: New refrigerants are continually being added so be

sure to visit www.fieldpiece.com for the latest firmware.

R448A

R422B

R414B

R407A

R290

R115

R11

R12

R13

R22

R23

R32

R113

R114

R116

R123

R124

R125

R134A

R236FA

R245FA

R401A

R401B

R402A

R402B

R403B

R404A

R406A

R407C

R407F

R408A

R409A

R410A

R413A

R414A

R416A

R417A

R417C

R420A

R421A

R421B

R422A

*Maximum pressure: 580 Psig (4000 kPa)

R422C

R422D

R424A

R427A

R428A

R434A

R438A

R449A

R450A

R452A

R452B

R453A

R454B

R458A

R500

R501

R502

R503

R507A

R508B

R513A

R600

R600A

R601

R601A

R744*

R1233ZD

R1234YF

R1234ZE

Temperature

Sensor Type: Type K thermocouple

(nickel chromium/nickel aluminum)

Jack Type: (3) Type K thermocouple

Range: -50°F to 257°F (-46°C to 125°C), limited by the thermocouple

specification. Display range is -95°F to 999.9°F (-70°C to 537.0°C).

Resolution: 0.1°F (0.1°C)

Accuracy: Shown accuracies are after field calibration.

±(1.0°F) -95°F to 200°F, ±(2.0°F) 200°F to 999.9°F;

±(0.5°C) -70°C to 93°C, ±(1.0°C) 93°C to 537.0°C

Pressure

Sensor Type: Absolute pressure sensors

Port Type: (1) 3/8” and (3) 1/4” standard NPT male flare fittings

Pressure Range and Units: 580 Psig (English), 40.00 Bar (Metric),

4.000 MPa (Metric), and 4000 kPa (Metric)

Negative Pressure Range and Units:

29 inHg (English), 74 cmHg (Metric)

Resolution: 0.1 Psig; 0.01 Bar; 0.001 MPa; 1 kPa; 0.1 inHg; 1 cmHg

Negative Pressure Accuracy:

29 inHg to 0 inHg: ±0.2 inHg;

74 cmHg to 0 cmHg: ±1 cmHg

Pressure Accuracy:

0 Psig to 200 Psig: ±1 Psig;

200 Psig to 580 Psig: ±(0.3% of reading + 1 Psig);

0 Bar to 13.78 Bar ±0.07 Bar;

13.78 Bar to 40.00 Bar: ±(0.3% of reading + 0.07 Bar);

0 MPa to 1.378 MPa: ±0.007 MPa;

1.378 MPa to 4.000 MPa: ±(0.3% of reading + 0.007 MPa);

0 kPa to 1378 kPa: ±7 kPa;

1378 kPa to 4000 kPa: ±(0.3% of reading + 7 kPa)

37

Page 20

Deep Vacuum

Low Pressure Sensor High Pressure SensorDeep Vacuum Sensor

Sensor Type: Thermistor

Port Type: (1) 3/8” and (3) 1/4” standard NPT male flare fittings

Range and Units:

50 to 9999 microns of mercury (English),

6 to 1330 Pascals (Metric),

0.06 to 13.3 mBar (Metric),

50 to 9999 mTorr (Metric),

0.05 to 10 Torr (Metric, equivalent to mmHg)

Best Resolution:

1 micron of mercury (below 2000 microns),

1 Pascal (below 250 Pascals),

0.001 mBar (below 2.5 mBar),

1 mTorr (below 2000 mTorr),

0.001 Torr (below 2.5 Torr)

Accuracy @ 77°F (25°C):

±(5% of reading + 5 microns of mercury), 50 to 1000 microns

±(5% of reading + 1 Pascal), 7 to 133 Pascal

±(5% of reading + 0.01 mBar), 0.067 to 1.33 mBar

±(5% of reading + 5 mTorr), 50 to 1000 mTorr

±(5% of reading + 0.005 Torr), 0.067 to 1 Torr

Manifold Diagram

LOW

Port

LOW

Valve

VAC

Valve

VAC

Port

Valve

HIGH

Valve

REF

REF

Port

Certifications and

Module IDs

HIGH

Port

Wireless Compatibility

Latest compatibility at www.fieldpiece.com

Job Link System Minimum Device Requirement:

BLE 4.0 devices running iOS 7.1 or AndroidTM Kitkat 4.4

Wireless Measurement Source Assignments:

Suction line temperature: Fieldpiece model JL3PC (set to blue)

Liquid line temperature: Fieldpiece model JL3PC (set to red)

Supply air psychrometer: Fieldpiece model JL3RH (set to blue)

Return air psychrometer: Fieldpiece model JL3RH (set to red)

Refrigerant weight scale: Fieldpiece models SRS3, SRS3P

EN 300 328

2ALHR005

IC: Industry Canada

22518-BT005

Regulatory Compliance Mark

Waste Electrical and

Electronic Equipment

Restriction of Hazardous

Substances Compliant

IFETEL: Federal Telecom Institute

RCPFI2A19-0287

3938

Page 21

FCC Statement

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or

more of the following measures:

1. Reorient the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

FCC Caution:

Any changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate

this equipment.

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

This device and its antenna(s) must not be co-located or operating

in conjunction with any other antenna or transmitter.

IMPORTANT NOTE: FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set

forth for an uncontrolled environment. This equipment should be

installed and operated with minimum distance 20cm between the

radiator & your body.

IC Statement

This device contains licence-exempt transmitter(s)/receiver(s) that

comply with Innovation, Science and Economic Development Canada’s

licence-exempt RSS(s). Operation is subject to the following two

conditions:

1. This device may not cause interference.

2. This device must accept any interference, including

interference that may cause undesired operation of the

device.

L’émetteur/récepteur exempt de licence contenu dans le

présent appareil est conforme aux CNR d’Innovation, Sciences et

Développement économique Canada applicables aux appareils radio

exempts de licence. L’exploitation est autorisée aux deux conditions

suivantes :

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d’en compromettre le

fonctionnement.

IMPORTANT NOTE: IC Radiation Exposure Statement:

This equipment complies with IC RSS-102 radiation exposure limits

set forth for an uncontrolled environment. This equipment should be

installed and operated with minimum distance 20cm between the

radiator & your body.

Cet équipement est conforme aux limites d’exposition aux

rayonnements IC établies pour un environnement non contrôlé. Cet

équipement doit être installé et utilisé avec un minimum de 20cm de

distance entre la source de rayonnement et votre corps

4140

Page 22

IFETEL Statement

La operación de este equipo está sujeta a las siguientes dos

condiciones: (1) es posible que este equipo o dispositivo no cause

interferencia perjudicial y (2) este equipo o dispositivo debe aceptar

cualquier interferencia, incluyendo la que pueda causar su operación no

deseada.

The operation of this equipment is subject to the following

two conditions: (1) this device or device may not cause harmful

interference, and (2) this device or device must accept any interference,

including interference that may cause undesired operation.

Limited Warranty

This product is warranted against defects in material or

workmanship for one year from date of purchase from an authorized

Fieldpiece dealer. Fieldpiece will replace or repair the defective unit, at

its option, subject to verification of the defect.

This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable use

of the machine.

Any implied warranties arising from the sale of a Fieldpiece product,

including but not limited to implied warranties of merchantability and

fitness for a particular purpose, are limited to the above. Fieldpiece

shall not be liable for loss of use of the machine or other incidental or

consequential damages, expenses, or economic loss, or for any claim of

such damage, expenses, or economic loss.

State laws vary. The above limitations or exclusions may not apply

to you.

Obtaining Service

Visit www.fieldpiece.com/rma for the latest information on how

to obtain service. Warranty for products purchased outside of the U.S.

should be handled through local distributors. Visit our website to find

your local distributor.

4342

Page 23

SM480V

© Fieldpiece Instruments, Inc 2019; v18

Loading...

Loading...