Page 1

Fieldpiece

+

INRUSH

Job Link® System

Power

Clamp Meter

OPERATOR'S

MANUAL

Model SC680

11

Page 2

Safety Information

Understand and follow operating instructions

carefully.

A Warning identifies conditions and procedures

that are dangerous to the user. A Caution identifies

conditions and procedures that can cause damage to

the Product or the equipment under test.

! WARNING

To avoid possible electric shock, personal injury or

death, follow these guidelines:

• Use the meter only as specified in this manual;

otherwise, the protection provided by the meter

may be impaired.

• Do not use if meter appears damaged. Visually

inspect the meter to ensure case is not cracked

and back case is securely in place.

• Inspect and replace leads if insulation is damaged,

metal is exposed, or probes are cracked. Pay

particular attention to the insulation surrounding

the connectors.

• Do not use meter if it operates abnormally as

protection maybe impaired.

• Use only correct measurement category (CAT),

voltage, and amperage rated probes, test leads,

and adapters for the measurement.

• Do not use this meter to verify the presence of

hazardous voltages on circuits that may have

voltages generated from frequencies above

1000Hz as the low pass filter limits voltage

measurements to below 1000Hz.

• Do not use during electrical storms or in wet

weather.

• Do not use around explosive gas, dust, or vapor.

• Do not apply more than the rated voltage to,

as marked on the meter, between terminals or

between any terminal and earth ground.

• Do not use without the battery and the back case

properly installed.

• Replace battery as soon as battery indicator

appears to avoid false readings.

• Remove the test leads from the circuit prior to

removing battery cover.

• Do not attempt to repair this unit as it has no

user-serviceable parts.

• Temperature switch prevents leaving

thermocouple plugged in while measuring

voltage.

• Do not measure current while the test leads are

in the input jacks.

• When measuring high frequency AC current,

do not exceed the rated 600AAC of the clamp.

Failure to adhere may cause the clamp to heat

up dangerously.

• Do not use the HOLD function to measure

unknown potentials. When HOLD is turned on,

the display does not change when a different

potential is measured.

• Do not use in CAT III or CAT IV environments with

the protective cap of test probe. The protective

cap decreases the exposed probe metal <4mm.

This decreases the possibility of arc flash from

32

Page 3

short circuits.

!

!

!

• Do not place magnet inside Category IV panel.

Place it outside the panel instead.

CAUTION

To protect yourself, think “Safety First”:

• Voltages exceeding 30VAC or 60VDC pose a shock

hazard so use caution.

• Use appropriate personal protective equipment

such as safety glasses, face shields, insulating

gloves, insulating boots, and/or insulating mats.

• Disconnect circuit power and discharge all highvoltage capacitors before testing resistance,

continuity, diodes, or capacitance.

Before each use:

• Perform a continuity test by touching the test

leads together to verify the functionality of the

battery and test leads.

• Use the 3 Point Safety Method. (1) Verify meter

operation by measuring a known voltage. (2)

Apply meter to circuit under test. (3) Return to

the known live voltage again to ensure proper

operation.

• Use the proper terminals, functions and range for

your measurements.

• Never ground yourself when taking electrical

measurements.

• Connect the black common lead to ground

or neutral before applying the red test lead to

potential voltage. Disconnect the red test lead

from the voltage first.

• Always work with a partner.

• Keep fingers behind the finger guards on the

probes.

All voltage tests: All voltage ranges will

withstand up to 1000VDC/750VAC rms. Do not

apply more than 1000VDC or 750VAC rms.

Symbols used:

Caution, risk of electric shock

Caution, refer to manual.

Ground

Double insulation

WARNINGS

DISCONNECT AND UNPLUG TEST LEADS before opening case.

TEST NCV FUNCTION ON KNOWN LIVE WIRE before using.

DO NOT APPLY VOLTAGE greater than 30VAC/VDC to the

thermocouple or the jacks when the rotary dial is on °F°C. (Use

only Type K thermocouples)

DO NOT APPLY VOLTAGE TO THE JACKS when the rotary dial is on

microamps. Even low voltages can cause a current overload and

potentially harm the meter.

54

Page 4

Description

Your SC680 is the top of the line clamp meter with

wireless functionality for the HVACR professional. Send

your electrical measurements directly to the Job Link®

System mobile app. Leave the meter behind a closed

blower door and view the current measurement on your

mobile device.

Help determine system efficiency by directly

measuring power consumption (W) of the system. Use

this value to inform your customer of energy saving

measures you can take to help them save money on

their energy bills.

The SC680 is the only meter you’ll need for

troubleshooting mini-split systems. Dual Type K

temperature ports to measure entering/exiting air

temperatures and measure frequency (Hz) directly with

clamp jaw. Reach those cramped mini-split connectors

with the included RCT2 probe tips for voltage and

resistance measurements.

Hang your SC680 clamp meter to any metallic surface

with the heavy-duty magnet. When the job is done, store

your test leads in the back case for tidy and convenient

storage. See both voltage and amperage readings at the

same time on the large dual display.

Easily see your amperage readings no matter how you

clamp around a wire with the swivel head AAC clamp.

Verify the order of 3-phase voltage lines with just two

leads. Capture L1-L2 and L1-L3 to check that motor lines

are correctly installed with Phase Rotation test.

Take more accurate VAC and AAC readings on variable

frequency drives with True RMS sensing technology.

Measure the starting amp draw of a compressor with

Inrush current mode.

Illuminate the way with a powerful LED built into the

clamp jaw. Easily see your measurements with the bright

blue backlight on the display. Safely change functions

with the backlit illuminated dial.

Take measurements more safely with one hand

using the single test lead holder. Test leads come with

removable gold plated tips to reliably connect Fieldpiece

accessory heads.

What’s Included

• SC680 Job Link® System Power Clamp Meter

• ADLS2 Deluxe Test Leads Kit

• ASA2 Alligator Clips

• RCT2 Molex Probe Tips

• 2 ATB1 Type K Thermocouples

• 2 Velcro Straps

• 9V Alkaline Battery (Not installed)

• ANC7 Protective Padded Case

• Operator’s manual

Quick Start

1. For electrical testing, connect test leads to black "COM"

and red "+" jacks.

2. Rotate the dial to your desired measurement.

3. Connect to test points and read measurement.

4. For temperature testing, remove test leads, slide TEMP

switch to the right and connect Type K thermocouples.

76

Page 5

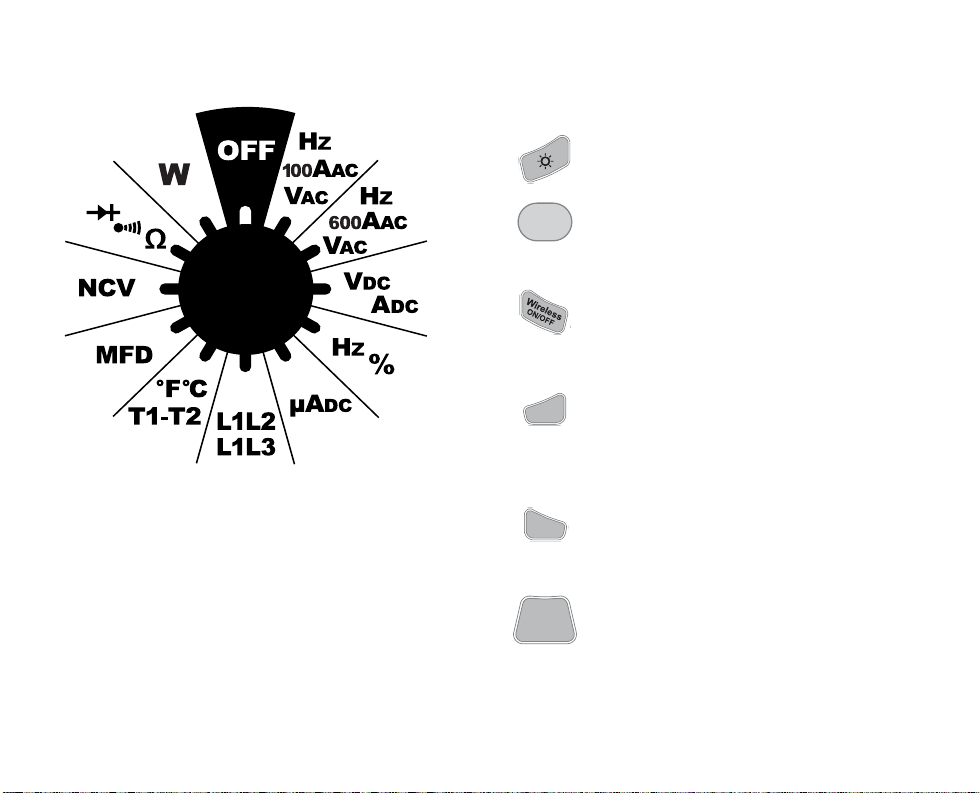

Measurements Dial

ZERO A

DC

INRUSH

H/M/m

DC

INRUSH

OFF

Select

H/M/m

ZERO A

DC

°F °C

INRUSH

Sync

OFF

Range

Select

H/M/m

ZERO A

DC

°F °C

INRUSH

+

INRUSH

Buttons

Illuminate backlight. Press for 1 second to

zero Amps DC

INRUSH

Activate Inrush AAC capture mode

The SC680 is loaded with the measurement

parameters essential for HVACR professionals.

Select the parameter on the dial you want to

measure with the rotating selector switch.

Activate wireless to connect to Job Link®

System mobile app

Activate and cycle through Hold, Maximum,

minimum, and real-time measurements

(Press for 1 second to clear and exit)

Deactivate autoranging and select the

range manually

Cycle through displayed values on

applicable switch positions (Press for 1

second to toggle °F and °C)

98

Page 6

Display Icons

Battery Life Monitor

Auto Power Off Enabled

High Voltage Warning (>30VAC/VDC)

Manual Ranging

Data Hold

Maximum

Minimum

Inrush AAC

Wireless ON to Job Link® mobile app

Watts (Active Power)

Power Factor

Reactive Power

Apparent Power

Temperature Inputs

Delta T

Fahrenheit / Celsius

Continuity Test

Diode Test

Frequency (Hertz)

Duty Cycle (percentage)

Resistance Test (Ohms)

Capacitance Test (farads)

Microamps DC

Nano Unit (10−9, one billionth)

Micro Unit (10−6, one millionth)

Milli Unit (10−3, one thousandth)

Kilo Unit (103, one thousand)

Mega Unit (106, one million)

Alternating Current

Direct Current

Easy to Read Display

Easily see your measurements on the large dual

display. You’ll never miss a reading no matter the

lighting with the bright blue backlight to illuminate

the way.

1110

Page 7

Measurement Dial

+

Volts AC (VAC) True RMS (50-400Hz)

Test power lines (120 to 480VAC), test 24VAC going to controls and test

for transformer failure.

Ranges: 1000mV, 10V, 100V, 750V Resolution: 0.1mV

Accuracy: ±(1.5% + 10) 50Hz to 60Hz

±(2.0% + 10) 60Hz to 400Hz

Unspecified at 400Hz and greater

Minimum Input Voltage Range: >20 digits

Low Pass Filter: >1 kHz

Crest Factor: ≤ 3

Audio/Visual Hi-V Indicator: >30VAC/VDC

Input Impedance: 5MΩ

Overload Protection: 1000VDC or 750VAC rms

Volts DC (VDC)

Select VDC and measure DC voltages on circuit boards on more

advanced HVACR systems and logic control boards. In VDC/ADC dial

position, VDC is shown on lower display. Press SELECT button to show ADC

on the top display at the same time.

Ranges: 1000mV, 10V, 100V, 1000V Resolution: 0.1mV

Accuracy: ±(0.5% + 5)

Input Impedance: 5MΩ

Overload Protection: 1000VDC or 750VAC rms

Non Contact Voltage (NCV)

Use NCV to check 24VAC from a thermostat or live voltage up to 600VAC.

Always test a known live source before using. A segment graph and RED

LED will display the presence of voltage. An audible beep increases from

intermittent to continuous as intensity of field (EF) increases.

AC Voltage Detection Range: 24VAC to 600VAC (50-60Hz)

1312

Page 8

Amps AC (AAC) True RMS (50-60Hz)

ZERO A

DC

INRUSH

!

Test isolated power lines. Press SELECT on VAC/100AAC/Hz or

VAC/600AAC/Hz position. Read AAC in upper display and VAC on the lower

display. For AC current <100AAC, select VAC/100AAC/Hz switch position

and for AC current >100AAC, select the VAC/600AAC/Hz switch position.

Range: 100A, 600A Resolution: 0.01A Crest factor: ≤ 3

Accuracy: ±(2.5% + 15) 100A, ±(2.0% + 10) 600A

Minimum Input Current Range: >20 digits

Overload Protection: 600AAC Jaw Opening: 1.2in (30 mm)

Frequency (Hz) Through Clamp

Measure Hz on variable frequency drive motors. Turn dial to either

VAC/100AAC/Hz or VAC/600AAC/Hz position and press SELECT twice. Hz

will show in upper display and VAC on the lower display at the same time.

Range: 10Hz to 400Hz Resolution: 0.1Hz

Accuracy: ±(0.1% + 5)

Minimum current range: >7AAC (10 to 100Hz); >20AAC (100 to

400Hz) on 100AAC range; >25AAC (10 to 400Hz) on 600AAC range.

Overload Protection: 600AAC

Amps DC (ADC)

Measure ADC through the clamp jaw. Press

the ADC value in the top display.

Ranges: 100A, 600A Resolution: 0.01A Jaw Opening: 1.2in (30 mm)

Accuracy: ±(2.5% + 15) 100A, ±(2.0% + 10) 600A

Overload Protection: 600ADC

for 1 second to zero

+

+

Amps AC (AAC), Frequency (Hz) through the clamp and Inrush AAC current

is measured in the VAC/100AAC/Hz or VAC/600AAC/Hz switch position

shown above.

Inrush AAC Current

Inrush mode captures the starting amp draw of a motor. Starting amp

draw can assist in diagnosing a motor before it fails.

Activate Inrush mode

1 Rotate selector switch to VAC/100AAC/Hz or VAC/600AAC/Hz

2 Press SELECT once to show AAC on upper display. Press INRUSH on the

right side of meter to activate Inrush Mode.

3 Clamp jaw around the motor’s start wire.

4 Turn motor on. The starting amp draw will hold on the upper display.

5 Press INRUSH to clear captured reading. Press INRUSH for 2 seconds to

exit.

Inrush measurement period: 100-milliseconds

Minimum input: >2A on 100AAC range; >20A on 600A range

Note: AAC or Hz through the clamp and VAC through the test leads

can be measured simultaneously. However, if only AAC, Frequency

(Hz), or Inrush AAC is measured through the clamp, test leads and

thermocouples must be unplugged from the meter.

1514

Page 9

MicroAmps DC (µADC)

Test flame rectifier diodes on a heater control. Connect leads between

flame sensor probe and control module. Turn heating unit on. When the

flame is on, there should be a measurable µADC signal, typically under

10µADC. Compare measurement to manufacturer’s specification to

determine if replacement is necessary.

Ranges: 1000µA Resolution: 0.1µA

Accuracy: ±(1.0% + 5) Volts burden: 5V

Overload Protection: 600VDC or 600VAC rms

Frequency (Hz) Through Leads

Check incoming voltages to ensure they are cycling at 60Hz. For

frequency measurements on VFD equipment, use the amp clamp.

Ranges: 100Hz, 1000Hz, 10kHz, 100kHz, 1000kHz Resolution: 0.01Hz

Accuracy: ±(0.1% + 5) Sensitivity: 10Hz to 1000kHz: >3.5Vrms

Minimum PW: >1µs Duty Cycle Limits: >30% and <70%

Overload Protection: 600VDC or 600VAC rms

Duty Cycle (%)

Duty cycle shows the % On Time of a 5V logic signal square wave.

Ranges: 5%-95% (40Hz to 1kHz), 10%-90% (1kHz to 10kHz), 20%-80%

(10kHz to 20kHz)

Accuracy (5V logic): ±(2% + 10) Resolution: 0.1%

Pulse Width: >10µs

Overload Protection: 600VDC or 600VAC rms

Capacitance (MFD)

Test motor start and run capacitors. Capacitors are one of the most

failure prone components in a HVACR system. Disconnect from power and

any resistors found between terminals. Discharge capacitor before testing. If

dIS.C is displayed, the capacitor needs to be fully discharged to test.

Ranges: 10nF, 100nF, 1000nF, 10µF, 100µF, 1000µF, 10mF

Accuracy: ±(3% + 15) 10nF, ±(3% + 5) 100nF to 1000µF, ±(5% + 5) 10mF

Resolution: 0.01nF Overload Protection: 600VDC or 600VAC rms

Discharge Cap First!

1716

Page 10

Resistance (Ω)

DC

SEL

HOLD

INRUSH

HOLD

INRUSH

Used for “ohming out” a compressor. A 0.01Ω resolution is useful to

test the resistance between the terminal poles because the values are

typically very low. For best practice, use a megger (Fieldpiece SMG5) to

measure motor winding insultion to ground.

Ranges: 100Ω, 1000Ω, 10kΩ, 100kΩ, 1000kΩ, 10MΩ, 50MΩ

Resolution: 0.01Ω

Accuracy: ±(1.0% + 15) 100Ω, ±(1.0% + 5) 1000Ω to 100kΩ, ±(1.5%

+ 5) 1000kΩ, ±(3.0% + 5) 10MΩ to 50MΩ

Open circuit volts: -1.1VDC typical, -3.2VDC (100Ω range)

Overload Protection: 600VDC or 600VAC rms

Continuity (

Perfect for checking isolated fuses, use the continuity function to test

whether a circuit is open (no beep, no green LED) or closed (beep and

green LED). Press SELECT once to enter Continuity mode.

Range: 100Ω Resolution: 0.01Ω Response time: 100ms

Audible beep: <30Ω

Visual Indicator: Green LED

Overload Protection: 600VDC or 600VAC rms

Diode Test (

Test diodes for proper forward and reversed-biased functions. A

voltage will display in forward-bias and “OL” in reversed-bias. Press SELECT

twice to enter Diode mode.

Test current: 0.8mA (Approx.) Accuracy: ±(1.5% + 5)

Open circuit volts: 3.2VDC typical Audible beep: <0.05V

Visual Indicator: Green LED

Overload Protection: 600VDC or 600VAC rms

)

)

1918

Page 11

Dual Temperature (T1, T2, T1-T2)

Plug any Type K thermocouple directly into the meter to measure

temperature. Test for proper airflow across the evaporator coil by

measuring delta T with the dual temperature inputs.

Insulated cold junction is located inside the meter and allows for

accurate measurements even in rapidly changing ambient temperatures

(going from rooftop to freezer). No adapter is required.

By default, T1 will show on top display and T2 on bottom display. Press

SELECT button once to display T1 on top and T1-T2 on the bottom. Press

SELECT button again to display T2 on top and T1-T2 on the bottom.

Range: -58°F to 2372°F, (-50°C to 1300°C) Resolution: 0.1°

Accuracy: ±(1°F)* 32°F to 120°F, ±(1°C) 0°C to 49°C

±(1%+2°F) 32°F to 932°F, ±(1%+1°C) 0°C to 500°C

±(2%+6°F) -58°F to 32°F, ±(2%+3°C) -50°C to 0°C

±(2%+6°F) 932°F to 2372°F, ±(2%+3°C) 500°C to 1300°C

Sensor type: Type K thermocouple *After field calibration

Overload protection: 30 VDC or 30VAC rms

COM

Unplug Leads and Slide

TEMP Switch to the Right

Change Units (°F or °C)

By default, temperature units are set to Fahrenheit (°F). In

Temperature dial position, press SELECT button for 1 second to toggle

between Fahrenheit (°F) and Celsius (°C).

Temperature Calibration

Thermocouples (T/C) are not calibrated directly. Instead, each T/C jack

(T1 and T2) must be calibrated to the particular T/C that is plugged into it.

Though it’s possible for a calibration to hold for years, it’s best practice to

calibrate regularly if only to verify accuracy. Labelling your T/C, T1 or T2,

will help ensure using the same T/C for T1 and T2 ports.

Calibration is quick and easy, requiring just a known temperature to

calibrate to. Ice water is probably the most accurate and readily available

known temperature (32.0°F, 0.0°C) in the field.

1. Rotate dial to the °F °C, T1-T2

position.

2. Plug one thermocouple to be

calibrated into the T1 Type K jack.

3. Unscrew A and B and remove the

battery cover.

4. Stabilize a large cup of ice water.

Stir the ice with the water until

temperature stays at a stable value.

5. Immerse the T1 thermocouple

probe and let it stabilize.

Keep stirring water to prevent

thermocouple from direct contact

with ice.

6. Use a small screwdriver to adjust

calibration T1 Temp Cal pot below

the battery as close to 32°F(0°C) as

you would like.

7. Repeat step 2-6 and replace T2 for

T1 for T2 thermocouple.

Note: J1-J2 switch is for factory

calibration purposes only. Do not

switch from J2.

A

DO NOT SWITCH

FROM J2

TEMP

T1

CAL

T2

B

2120

Page 12

Power (Watts, VAr, VA, WDC, PF)

!

Help determine system efficiency by measuring the power exerted

by the system. The actual power consumed by the system is called Active

Power and is measured in watts (W or kW). Reactive loads, inductors

and capacitors, dissipate zero power, but they drop voltage and draw

current giving the deceptive impression they do dissipate power. This is

called Reactive Power and is measured in Volt-Amps-Reactive (VAr). The

combination of reactive and real power is called Apparent Power and

is the product of a system’s voltage and current, without phase angle

consideration. Apparent Power is measured in Volt-Amps (VA).

Power Factor (PF) is the ratio of the power the system draws from

the main power supply and the power the system actually consumes. An

ideal PF is 1, meaning the system consumes all the power it draws. Due to

inductive and capacitive loads of the system however, this is not possible.

To take the power reading you need to measure both voltage and

amperage simultaneously. Connect test leads to main power supply

terminals and secure amp clamp around the same line that the positive

(red) test lead is connected to.

See Power Factor in top display and Power in bottom display. Press

SELECT to toggle Active Power (W), Reactive Power (VAr), Apparent Power

(VA) and DC Power (W).

CAUTION! DO NOT MEASURE VOLTAGE LINES OR EXPOSE THE METER TO

LIVE POWER LINES EXCEEDING 750VAC/1000VDC NOMINAL VOLTAGE.

+

Power (Watts, VAr, VA, WDC, PF)

Accuracy: Stated accuracy @ 73°F±9°F (23°C±5°C), <75%RH

Effective Current Range: 2AAC/ADC to 600AAC/ADC

Effective Voltage Range: 80VAC to 750VAC, 80VDC to 1000VDC

Effective Frequency Response: 50Hz to 60Hz

Power accuracies unspecified for non-sinusoidal current waveforms

Active Power (W)

Ranges: 1000W, 10kW, 100kW, 450kW

Resolution: 0.1W

Accuracy: ±(5.0% + 5) >10A

±(10.0% + 5) 2A to 10A on 450kW range

Reactive Power (VAr)

Ranges: 1000VAr, 10kVAr, 100kVAr, 450kVAr

Resolution: 0.1VAr

Accuracy: ±(5.0% + 5) >10A on 1000VAr range

±(10.0% + 5) 2A to 10A

Apparent Power (VA)

Ranges: 1000VA, 10kVA, 100kVA, 450kVA

Resolution: 0.1VA

Accuracy: ±(5% + 5) >2A

DC Power (W)

Ranges: 1000W, 10kW, 100kW, 600kW

Resolution: 0.1W

Accuracy: ±(5% + 5) > 10A, ±(10.0% + 5) 2A to 10A

Power Factor (PF)

Ranges: -1.00 to +1.00

Resolution: 0.01 PF

Accuracy: ±(5.0% + 5) >10A, ±(10.0% + 5) 2A to 10A

PF readings will be displayed on upper display

2322

Page 13

Phase Rotation Test (L1L2, L1L3)

Connect 3-phase power lines in the correct order to the terminals of

a motor to ensure the motor turns in the intended direction. Incorrect

wiring can damage some equipment. The terminals on the motor are

usually marked L1, L2, and L3; however, the wires supplying power

usually are not. Perform a simple phase rotation test with two test leads

to quickly identify the order of 3-phase power lines.

Range: 80±5 VAC to 600VAC (50Hz to 80Hz) Resolution: 0.1V

Accuracy: ±(1.5% rdg + 10 dgts)

Overload Protection: 600VDC or AC rms

Step 2: Connect Leads

Connect both black and red

test leads to any two of the three

phase voltage lines in question.

The line voltage will hold on the

bottom display. Blinking L1 and

L2 disappear. L3 will blink on top

display to indicate test is ready for

Step 2.

How to Perform a Phase Rotation Test

Set 1: Select Function

Switch to . Plug black test lead

into the COM (L1) port and red test lead

to the VΩ (L2 L3) port on the SC680.

You will see “L1L2” blinking

to indicate phase rotation test

is ready to begin.

Important: Step 2 must

be performed within

5 seconds of completing Step 1 or “Err” will

show and Step 1 must

be repeated.

Step 3: Move Red Lead

With the black lead still on

“L1”, move the red test lead to the

third 3-phase voltage line. The line

voltage will hold on the bottom

display. The top display will show

L123 indicating forward or L321

indicating reversed.

Simply swap any two lines to

change the direction. You can verify

this by performing the test again.

2524

Page 14

Phase Rotation Testing Tips

1 The measured voltage during phase rotation test

must be >80.0±5VAC. If not, the phase rotation

test can not be performed and “Err” will show on

the top display.

2 After phase rotation test is complete, press SELECT

button to begin a new phase rotation test.

3 Be sure to connect test leads to 3-phase voltage

lines for at least 2 seconds until voltage reading

holds on the bottom display

4 Phase rotation test cannot be performed on Hi-

frequency voltage signals. Be sure voltage lines

are within 50-80Hz to perform the phase rotation

test.

Modular

Expandability

Your SC680 is compatible with Fieldpiece

Accessory Heads. With Fieldpiece Accessory Heads,

you can measure any available parameter, and read

the measurement on your new meter’s display in

real-time, Hold, Max, and min.

Rotate the selector to VDC and stay in mV range.

Remove the probe tips of your test leads, and

connect your accessory head (model AAV3 shown).

+

LCDX

100

ON

READLOBATT

AirVelocity

&Temperature

Average

English

(16sec)

Head

Real

Metric

time

English Metric

Ft/min M/s

KM/hrMPH

ºF ºC

OFF

AUTOOFF

AAV3

Visit www.fieldpiece.com to see all of the

different Accessory Heads that Fieldpiece offers.

2726

Page 15

Works with Job Link® System

Do More with the Job Link® System

Directly document critical electrical

measurements at the job site, and add them to

professional PDF reports. No separate transmitter

required.

Combine your new clamp meter with other Job

Link System tools to create seamless reports. Show

customers what needs to be done (Pre-work) and

prove how that work helped (Post-work).

Other Job Link® System Tools

• SM480V Refrigerant Manifold + Micron Gauge (4 Port)

• SM380V Refrigerant Manifold + Micron Gauge (3 Port)

• JL3KH6 Wireless Charge and Air Test Kit

• JL3KR4 Wireless Charge Test Kit

• SRS3 Wireless Refrigerant Scale

Go to www.fieldpiece.com for all Job Link® System options.

Wireless Mode

Send electrical measurements wirelessly from

SC680 directly to the Job Link® mobile app. No JL2

transmitter required.

Sending Wireless Measurements

1 Select any switch position other than L1L2 and NCV

on SC680.

2 Press WIRELESS ON/OFF button on meter.

3 Favorite your SC680 by going to the measurement

screen in the Job Link app.

4 Tap on Electrical tab in the Job Link measurement

screen.

Note: By default, wireless is OFF when powering on

the SC680. Press WIRELESS ON/OFF buton to turn

wireless ON.

Wireless Specifications

Wireless range: Up to 115 feet (35m) line of sight. Distance decreases

through obstructions.

Wireless frequency: 2.4 GHz

Wireless Compatibility

Minimum Device Requirement:

BLE 4.0 devices running iOS® 7.0 or Android™ 5.0

(Latest compatibility at www.fieldpiece.com)

2928

Page 16

Functions

Sync

OFF

Range

Select

H/M/m

ZERO A

DC

°F °C

INRUSH

Sync

OFF

Range

Select

H/M/m

ZERO A

DC

°F °C

INRUSH

H/M/m

DC

INRUSH

H/M/m

DC

INRUSH

H/M/m

DC

INRUSH

ZERO A

DC

INRUSH

ZERO A

DC

INRUSH

Sync

OFF

Range

Select

H/M/m

ZERO A

DC

°F °C

INRUSH

Auto Power Off

Auto power off or APO will automatically turn off

your meter after 30 minutes of inactivty. By default

it is activated and APO will show on the display. To

disable, turn meter off. Hold

the meter by turning the selector dial to any range.

Release

after the beep. APO will no longer

display over the battery icon.

and power on

Battery Replacement

When your meter’s battery is low, the battery icon

will appear empty and blink for 30 seconds. “bAtt”

will display and meter will power off.

Turn dial to OFF position, disconnect test leads

and remove the battery cover with magnet strap

on the back of your meter. Remove old battery and

replace with a standard 9V battery only. Be sure to

re-insert the magnet strap before re-installing the

battery cover.

Hold/Max/min

Press

minimum, or real-time measurements. When

MAXMIN is displayed, you are seeing the real-time

measurement, but Max and min values are still

being recorded. Press

and exit. Press

in Job Link mobile app. See Wireless Section for Job

Link compatibility details.

High Voltage Warning

The symbol will display when measuring

>30VAC/VDC. An audible beep will be heard and

red LED will be shown.

to cycle through Hold, Maximum,

for 1 second to clear

to log an SC680 measurement

Backlight Illumination

See your measurements in dark environments.

Press

to illuminate the display and the selector

dial. Illumination will stay on for 5 minutes before

turning off automatically. Illumination can be

turned off at any time by pressing

.

Manual Ranging

Press

clamp meter to a specific range. Manual ranging

applies to VAC, VDC, Hz, MFD, W and resistance

(Ω). Press for 1 second to exit manual ranging and

return to auto-ranging.

to disable auto-ranging and set your

3130

Page 17

Certifications and

Module IDs

UL 61010-1, Third Edition

EN61010-1, EN61010-2-032

EN61010-2-033, EMC EN61326-1

FCC ID: 2ALHR005

RCM (N22675)

WEEE

Restriction of Hazardous

Substances Compliant

IC: Industry Canada IFETEL: Federal Telecom Institute

22518-BT005 RCPFI2A19-0287

CATIV 600V, CATIII 1000V or above. Included test leads are gold-plated and

have removable safety caps.

CATIII 1000V, CATIV 600 class II and pollution degree 2 indoor use comply

with CE, RoHS compliant.

CATIII is designated for measurements performed in the building

installation.

CATIV is for measurements performed at the source of the low-voltage

installation.

Specifications

Display: 10000 count dual display

Backlight: 5 minute duration with auto-off, blue color

Overrange: “OL” or “-OL” is displayed

Measurement rate: 3.3 times per second, nominal

Zero: Automatic

Operating environment: 32°F to 122°F (0°C to 50°C) at <70%RH

Storage temperature: -4°F to 140°F (-20°C to 60°C), 0 to 80%RH (with

battery removed)

Accuracy: Stated accuracy @ 73°F±9°F (23°C±5°C), <75%RH

Temperature coefficient: 0.1 x (specified accuracy) per °C [0°C to 19°C

(32°F to 66°F), 28°C to 50° C (82°F to 122°F)]

APO (Auto Power Off): Approx. 30 minutes

Power: Single standard 9-volt battery, NEDA 1604, JIS 006P, IEC 6F22

Battery life: 100 hours typical alkaline (No wireless, no backlight)

Low battery indication: Battery icon blinks and "batt" is displayed

when the battery voltage drops below the operating level

Dimensions: 301.5mm(H) x 79.5mm(W) x 50.0mm(D)

Weight: Approx. 480g including battery

Altitude: Up to 6562 ft (2000m)

Overload protection: 1000VDC or 750VAC rms unless otherwise stated

Test leads: Use UL listed test leads that comply to UL61010-031 rated

CATIV 600V, CATIII 1000V or above. Included test leads are gold-plated

and have removable safety caps.

Please operate the instrument following all instructions of

the operator's manual to avoid impairing the safety of

the product.

3332

Page 18

FCC Statement

This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will

not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

1. Reorient the receiving antenna.

2. Increase the separation between the equipment and receiver.

3. Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

4. Consult the dealer or an experienced radio/TV technician for help.

FCC Caution:

Any changes or modifications not expressly approved by the party

responsible for compliance could void the user’s authority to operate this

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This device and its antenna(s) must not be co-located or operating in

conjunction with any other antenna or transmitter.

IMPORTANT NOTE: FCC Radiation Exposure Statement:

This equipment complies with FCC radiation exposure limits set forth

for an uncontrolled environment. This equipment should be installed and

operated with minimum distance 20cm between the radiator & your body.

IC Statement

This device contains licence-exempt transmitter(s)/receiver(s) that

comply with Innovation, Science and Economic Development Canada’s

licence-exempt RSS(s). Operation is subject to the following two

conditions:

1. This device may not cause interference.

2. This device must accept any interference, including interference

that may cause undesired operation of the device.

L’émetteur/récepteur exempt de licence contenu dans le présent

appareil est conforme aux CNR d’Innovation, Sciences et Développement

économique Canada applicables aux appareils radio exempts de licence.

L’exploitation est autorisée aux deux conditions suivantes :

1. L’appareil ne doit pas produire de brouillage;

2. L’appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d’en compromettre le

fonctionnement.

IMPORTANT NOTE: IC Radiation Exposure Statement:

This equipment complies with IC RSS-102 radiation exposure limits set

forth for an uncontrolled environment. This equipment should be installed

and operated with minimum distance 20cm between the radiator & your

body.

Cet équipement est conforme aux limites d’exposition aux

rayonnements IC établies pour un environnement non contrôlé. Cet

équipement doit être installé et utilisé avec un minimum de 20cm de

distance entre la source de rayonnement et votre corps

3534

Page 19

IFETEL Statement

La operación de este equipo está sujeta a las siguientes dos

condiciones: (1) es posible que este equipo o dispositivo no cause

interferencia perjudicial y (2) este equipo o dispositivo debe aceptar

cualquier interferencia, incluyendo la que pueda causar su operación no

deseada.

The operation of this equipment is subject to the following two

conditions: (1) this device or device may not cause harmful

interference, and (2) this device or device must accept any interference,

including interference that may cause undesired operation.

Limited Warranty

This product is warranted against defects in material or

workmanship for one year from date of purchase from an authorized

Fieldpiece dealer. Fieldpiece will replace or repair the defective unit, at

its option, subject to verification of the defect.

This warranty does not apply to defects resulting from abuse,

neglect, accident, unauthorized repair, alteration, or unreasonable use

of the machine.

Any implied warranties arising from the sale of a Fieldpiece product,

including but not limited to implied warranties of merchantability and

fitness for a particular purpose, are limited to the above. Fieldpiece

shall not be liable for loss of use of the machine or other incidental or

consequential damages, expenses, or economic loss, or for any claim of

such damage, expenses, or economic loss.

State laws vary. The above limitations or exclusions may not apply

to you.

Obtaining Service

Visit www.fieldpiece.com/rma for the latest information on how

to obtain service. Warranty for products purchased outside of the U.S.

should be handled through local distributors. Visit our website to find

your local distributor.

3736

Page 20

SC680

© Fieldpiece Instruments, Inc 2019; v10

38

Loading...

Loading...