Page 1

FZS 4003-B

Page 2

FZS 4003-B

2

English .................................................................................................................................................. 7 - 19

Čeština............................................................................................................................................... 21 - 33

Slovenčina ...................................................................................................................................... 35 - 47

Polski ................................................................................................................................................... 49 - 62

Page 3

3

Page 4

FZS 4003-B

4

Page 5

5

Page 6

6

FZS 4003-B

Page 7

7

Gasoline brush cutter

OPERATION MANUAL

Thank you for your purchase of our gasoline brush cutter. Before beginning to use

it, please, read this operation manual carefully and keep it for the case of a further

use.

TABLE OF CONTENTS

APPENDIX OF FIGURES ................................................................................................................. 3

1.

GENERAL SAFETY INSTRUCTIONS ............................................................................................ 8

Important safety warnings

Packaging

Instructions for use

2.

EXPLANATION FOR INSTRUCTION PLATES ON THE MACHINE ................................. 9

3.

MACHINE DESCRIPTION AND DELIVERY CONTENT .................................................... 10

4.

MACHINE ASSEMBLY .................................................................................................................. 11

5.

PUTTING INTO OPERATION ...................................................................................................... 12

Before starting

Fuel filling

Gas lever and main switch (STOP)

Starting

Idle speed setup

6.

INSTRUCTIONS FOR USE .............................................................................................................. 13

Safety instructions

Safety instructions - fuel

Safety instructions – cutting tools

7.

MAINTENANCE AND STORAGE .............................................................................................. 14

Machine maintenance

Service

Storage

8.

TECHNICAL DATA ........................................................................................................................... 16

9.

WHAT TO DO “IF…” ....................................................................................................................... 16

10.

DECLARATION OF CONFORMITY .......................................................................................... 18

11 .

DISPOSAL ........................................................................................................................................... 19

ENTable of contents

WARRANTY CERTIFICATE ......................................................................................................... 64

CONDITION OF GUARANTEE ................................................................................................ 65

OPERATION MANUALGASOLINE BRUSH CUTTER

Page 8

FZS 4003-B

8EN

General safety instructions

1. GENERAL SAFETY INSTRUCTIONS

Important safety warnings

Unpack the product carefully and be sure not to throw away any part of the package before

having found all components of the product.

Keep the product in a dry place out of reach of children.

Read all cautions and instructions. The failure to adhere to warning cautions and instructions

may result in an accident, fire and/or a serious injury.

Packaging

The product is placed in a package preventing damage during transport. This package is a raw

material therefore it can be handed-over for recycling.

Instructions for use

Before beginning to work with the machine, read the following safety rules and instructions for

use. Familiarize with operating elements and the proper use of the device. Keep the manual in a

safe place for future reference. We recommend keeping the original package including the inner

packaging materials, cash voucher and guarantee card for a period of warranty at minimum.

For a case of transportation, pack the machine into the original box from the manufacturer,

thus ensuring a maximum protection of the product during a possible transport (e.g. moving or

sending into a service station).

Note: If you hand the machine over to next persons, hand it over together with the manual.

Adherence to the attached instructions for use is a precondition for the proper use of the

machine. The operation manual includes also instructions for operation, maintenance and

repairs.

The manufacturer does not take any responsibility for accidents or damages

resulting from the failure to adhere to this manual.

Page 9

9

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

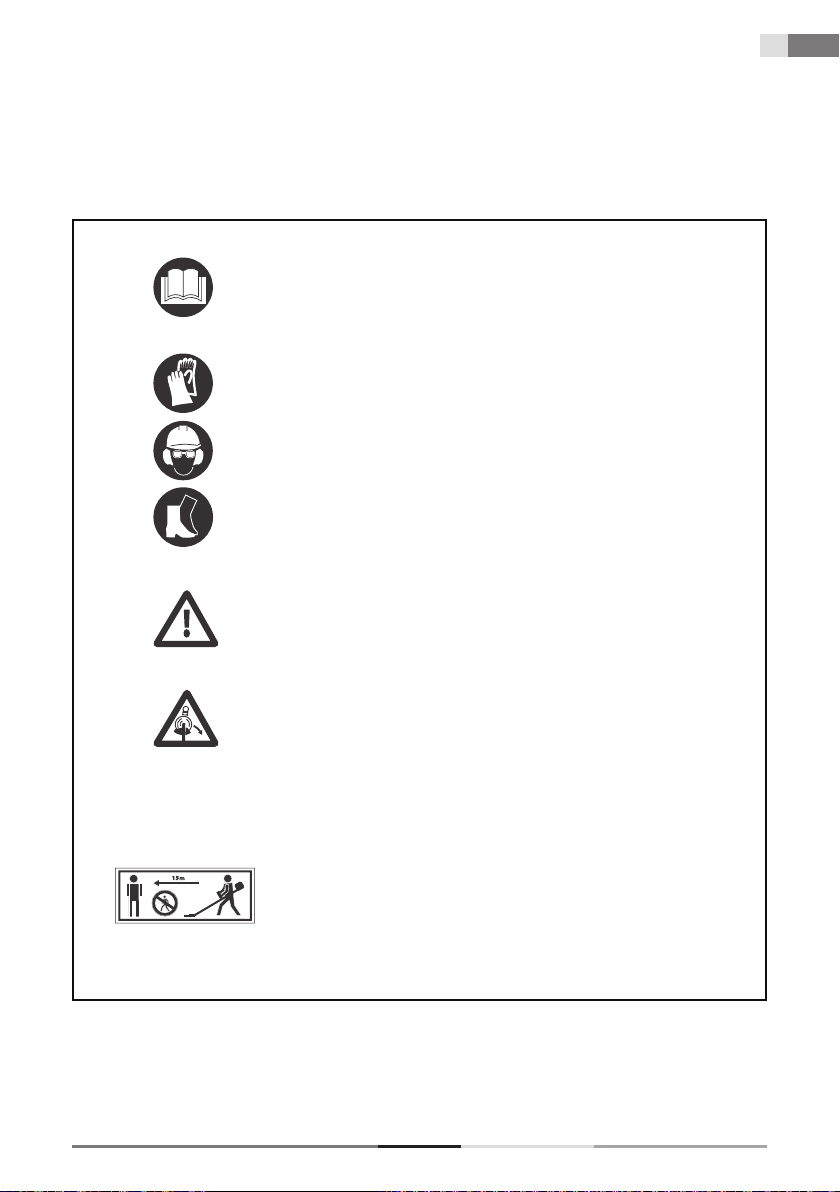

Explanation for instruction plates on the machine

2. EXPLANATION FOR INSTRUCTION

PLATES ON THE MACHINE

Read the manual carefully before the

use

Use protective equipment when

working

General warning of danger!

Watch out, recoil!

Keep other persons (especially

children) and animals min. 15 m out of

the working area.

Page 10

FZS 4003-B

10EN

Machine description and delivery content

3. MACHINE DESCRIPTION AND

DELIVERY CONTENT

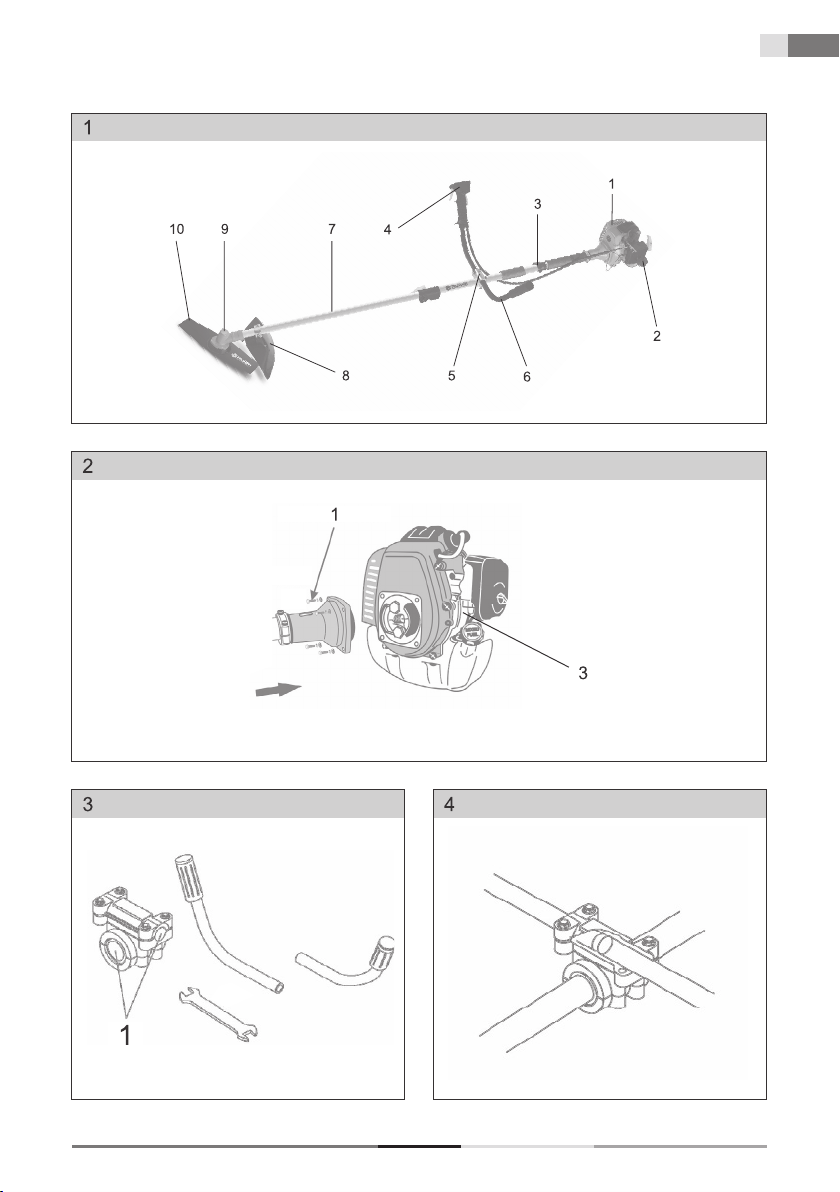

Machine description (see Fig.1)

Motor

1 -

Air cleaner

2 -

Suspension

3 -

Main switch + gas activator

4 -

Handle bar grip holder

5 -

Handle bar

6 -

Shaft

7 -

Use of the product

The brush cutter is only intended for cutting of grass, weed, bush or underbrush. It must not be

used for other purposes, e.g. trimming of lawns or hedges because an injury may occur in this

case.

Machine characteristic

8 -

Housing

9 -

Gearbox body

10 -

Cutting tool

Electronic ignition system

Automatic centrifugal clutch

Spiral transmission

Cardan shaft

WARNING! Sharp blades.

Delivery content

Take the machine carefully out of the package and check whether there are all following

components:

Garden brush cutter

Cord head with a cord of 2.5m length and 2.4mm diameter

Disc head

3-teeth blade

Tubular spanner

Operation manual

In the case of some parts missing or damaged, please, contact the dealer where you’ve bought

the machine.

Page 11

11

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

Machine assembly

4. MACHINE ASSEMBLY

Drive shaft parts

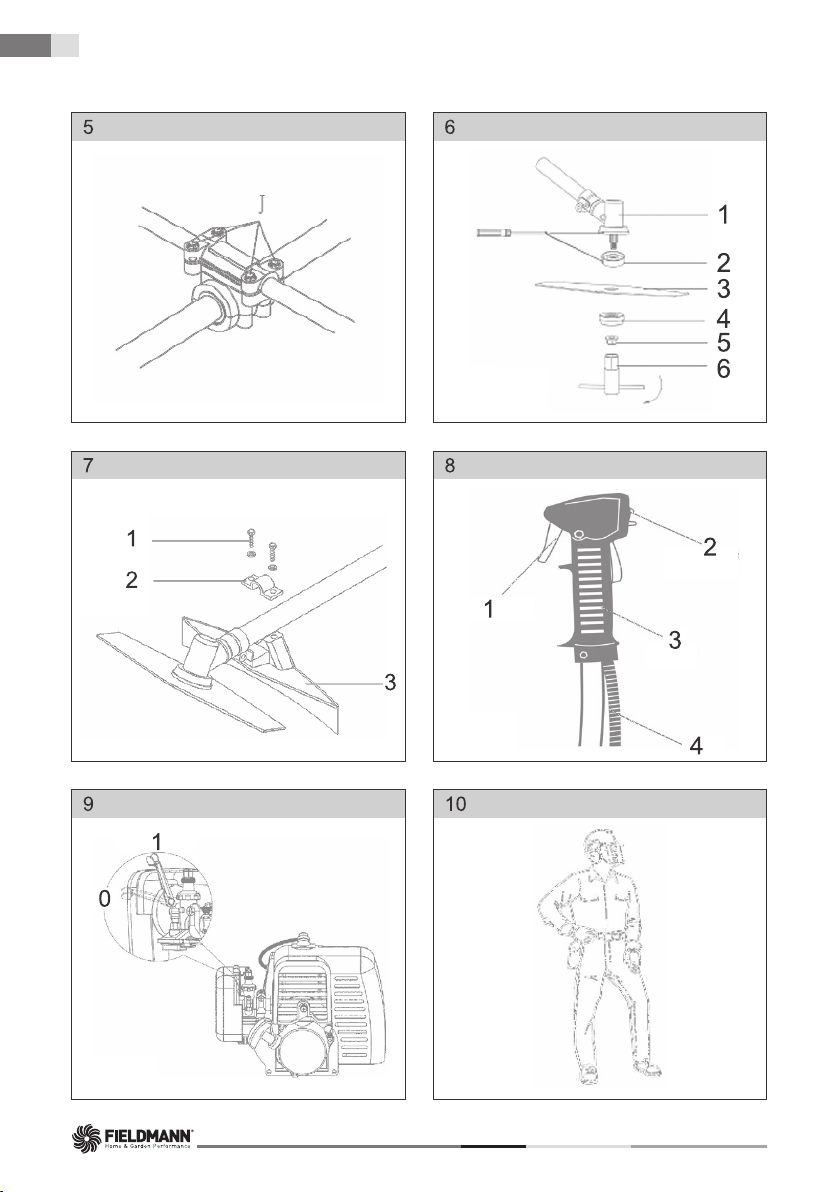

Drive shaft assembly (see Fig.2)

Unscrew hexagonal screws (M6 x 10; Figs. 2, 1) .

Fasten the drive shaft to the engine housing with the help of 4 screws, tighten thoroughly.

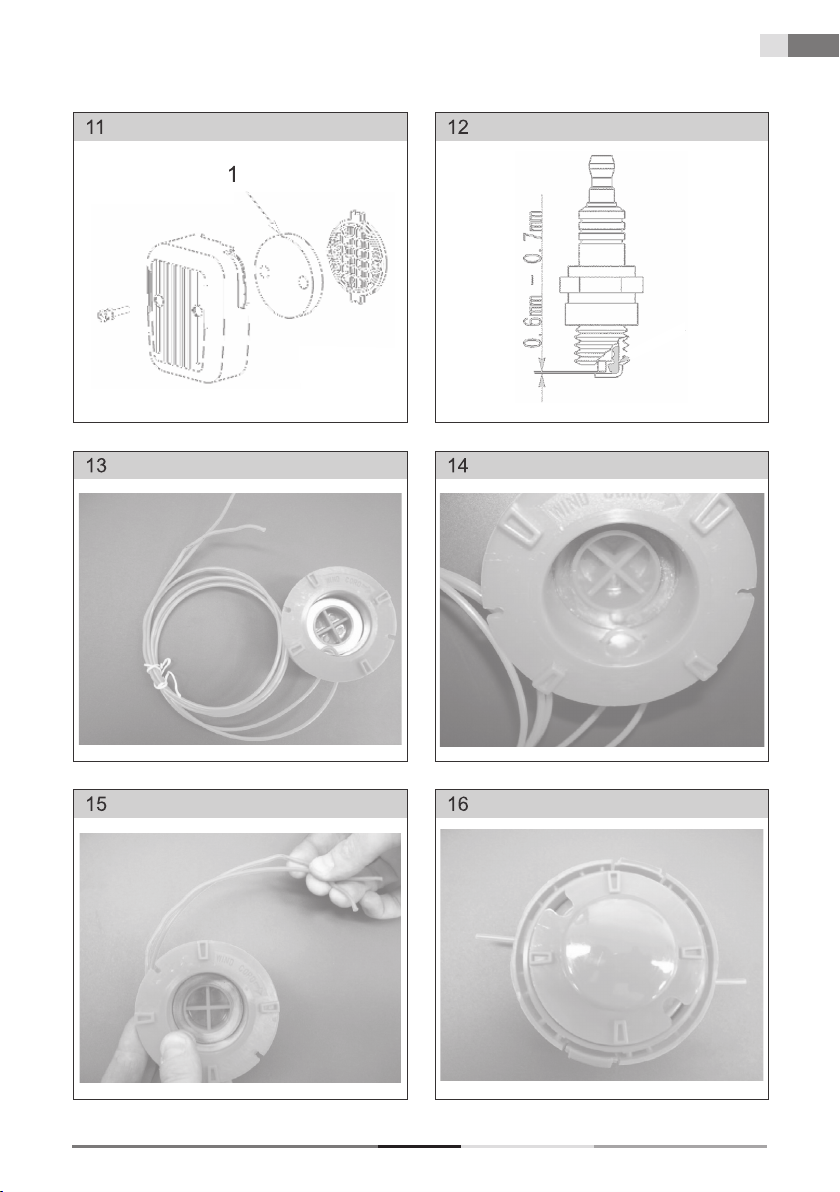

Handle assembly (see Figs. 3, 4, 5)

Unscrew screws (2), put the handle bars to the grip holder (1), select the position according

to your working style (right-handed – the switch on the right side when viewing from the

engine). Pre-screw the upper parts of the grip holder (4 screws) (2), adjust the position of the

handle bars and tighten the screws (2) thoroughly.

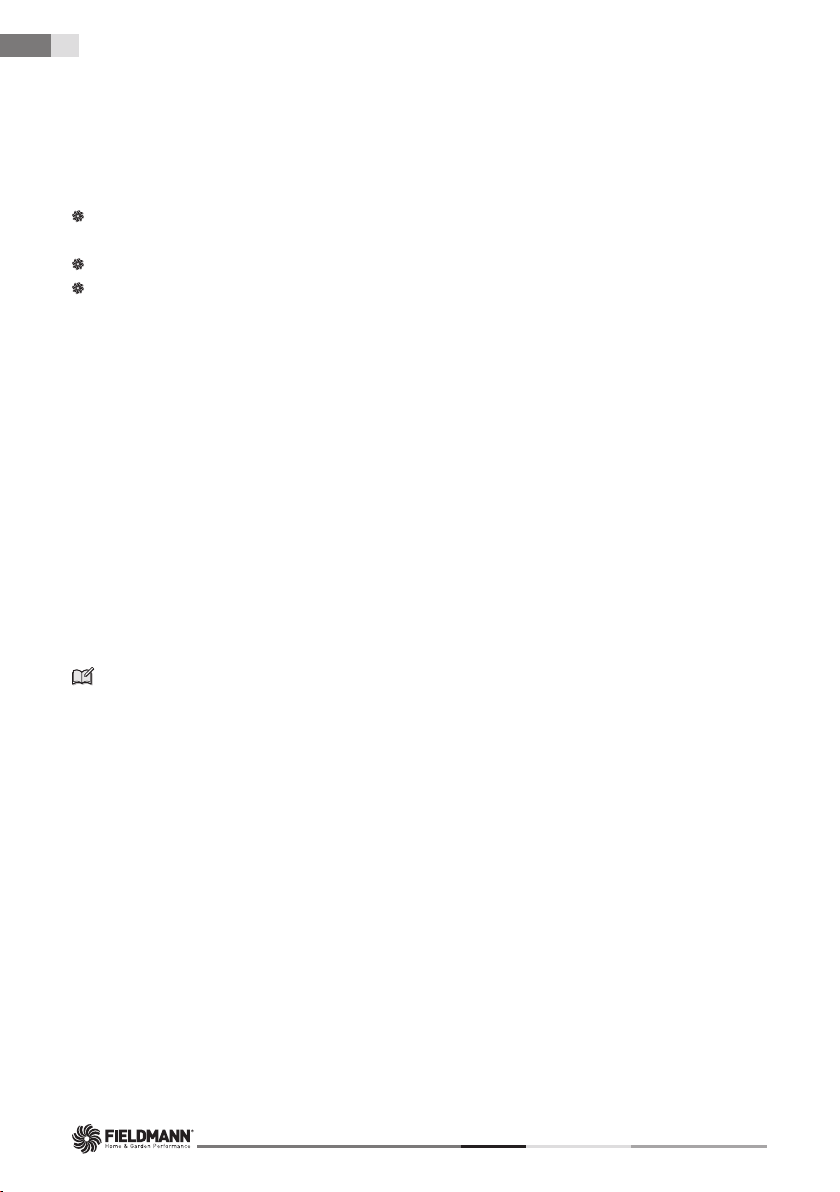

Gearbox parts (see Figs. 6, 7)

Unscrew the locking bolt, mount the cutting tool respectively (see Fig. 6): Gearbox (1) –

Cutting head carrier (2) – Cutting blade (3) – Cover (4) – Fixing nut (5). Insert a screwdriver

to align the gearbox body groove with a hole of the cutting head carrier.Tighten the nut with

the aid of the tubular spanner (6) delivered within the packaging.

Note: Instead of the cutting blade, you can wind the head with the cord on the screw of the

carrier.

Mount the safety cover (3) on the shaft rod with the help of a clamp (2) and screws (1). Be

particular about the proper position (see Fig. 7

Cord replacement (see Figs. 13, 14, 15, 16)

Demount the cord head, take-out the coil with the cord and remove the rest of the cord.

Pull a new cord of the total length c. 2 m through both openings in the inner part of the cord

head (see Fig. 14) so that both ends are of the same length (see Fig. 13).

Wind both ends onto the coil in the direction of the WIND CORD marked arrow (see Fig. 15).

Place the coil with the cord into the head (see Fig. 16), pull both ends of the cord through the

opposite openings in the head and finish the assembly (close up).

Page 12

FZS 4003-B

12EN

Putting into operation

5. PUTTING INTO OPERATION

Before starting

Adjust the shoulder strap length and handle position so that you feel comfortably when

working. Recheck tightening of all screws, bolts and nuts.

Fuel filling

Gasoline – use only unleaded motor gasoline with octane number 95 (NATURAL 95).

Oil – use only high-quality two-cycle engine oil intended for high speed engines.

Mix with gasoline in 1:25 ratio and pour into the tank.

Gas lever and main switch (STOP) (see Fig. 8)

The gas lever (1) with the electrical switch (2) are only partly mounted. Insert the gas cable

(47) into the carburetor drawbar groove and connect the electrical switch wires. The gas

lever is preassembled on the handle from the factory (3).

WARNING! When adjusting the gas lever, be sure not to let the cutting tool rotate while

starting. The cutting tool would start turning at high speed abruptly and could be dangerous.

The gas cable must be adjusted so that the engine is running at idle thrust when releasing the

gas lever (the cutting tool is not rotating).

Starting (see Fig. 9)

Press the gas lever to the ¼ of the gas lock and cage it.

Turn the main switch on.

Set the primer lever to the OFF (0) position.

Pull the starter quickly. If the engine started-up, move the primer lever into the ON (1) position

again. Repeat this procedure, until the engine starts-up and begins to run.

After having started-up, let the engine warm at idle speed 2,500-2,800 rpm for c. 2-3 min

before the load of the machine.

WARNING! The cutting blade may begin rotating just when starting. When starting the

engine, the blade must not be touching anything.

Idle speed setup (see Fig. 2)

If idle speed is too high or low, adjust the idle speed with the aid of the adjusting screw (3).

If the speed is too high, turn the adjusting screw counterclockwise.

If the speed is too low, turn the adjusting screw clockwise.

Page 13

13

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

Instructions for use

6. INSTRUCTIONS FOR USE

Safety instructions

Read carefully!

Always wear safety helmet, safety gloves, protective clothing (trouser-legs against cutting

through), protective gloves and safety shoes (see Fig. 10).

Keep the machine out of the reach of children.

Never work with the engine if there is only gasoline in the fuel tank.

Never fill up fuel while the engine is running or still hot. Fill the service liquids into the engine

only while the engine is cold.

Store fuels in a closed container in a dry and cool place.

Follow safety rules.

Recheck the workspace before each use. Remove objects which may be flung away or get

stuck into the machine.

When working, all other persons have to be out of a range of 15 meters at minimum.

Never use the machine without the protective safety cover (of the cutting blade) on.

Never fill the fuel tank so that it is full up to the top completely.

The fuel tank closing cover must be tightened thoroughly in order to avoid the fuel overflow.

Do not let the machine run at full throttle if the fuel tank is empty.

Never switch-off the machine abruptly if it runs at full throttle.

Do not use the machine if it is damaged in any way. Contact an authorized service station.

When carrying over, grasp the whole device; grasping the fuel tank only is dangerous, the fuel

tank damage and fire may be a result.

Always hold the brush cutter in both hands.

Never put the warm brush cutter on dry grass.

Do not smoke while working with the machine.

Safety instructions

Fuel

The fuel tank has to be empty during transportation of the brush cutter.

Transport fuels in approved jerry cans.

Check the fuel tank lid regularly. It must be tightened thoroughly and fuel leak must not occur.

Protect the living environment: take care to avoid fuel leakage and soil contamination.

Start-up the machine minimally 3 meters away from the place where you filled fuel.

Never fill up fuel in enclosed areas. Adequate ventilation must be ensured in the room;

explosion hazard.

Do not inhale fuel vapours. Fill up fuel while wearing protective gloves.

Change and clean the protective clothing regularly.

Page 14

FZS 4003-B

14EN

Instructions for use | Maintenance and storage

Safety instructions

Cutting tools

When mounting the cutting tool, check the blade condition. If it is damaged (cracked, bent,

abrupt etc.), eplace it.

After having installed the blade, check whether the hole in the blade is aligned with the arm of

the blade carrier.

Rotate the blade, check whether the blade does not tend to rotate irregularly.

Be sure to install the blade with its cutting edge in the direction of rotation. Never mount it the

other way around.

Check whether the cutting tool has been assembled properly, rotate it without a load

(1 minute is enough).

The blade has to be chosen appropriately for the given material.

Never push the blade against objects while working. Objects must be cut at mild speed.

If you hear an unusual sound or the machine vibrates unusually while working, stop working

and find-out the cause.

Do not stop the machine while the blade is going through the cut object. There is an injury and

machine damage danger.

The cutting tool must be fitted with an appropriate protective cover.

WARNING! The failure to follow instructions may result in serious or fatal

injury of persons!!

Give all persons working with this machine information on the machine operation and safety

instructions.

7. MAINTENANCE AND STORAGE

Machine maintenance

Before each use:

- Recheck tightening of all screws, bolts and nuts.

- Check whether fuel is not escaping from the fuel tank.

After every 20 hours of operation:

- Clean the air cleaner (1) (see Fig. 11).

- Clean the fuel filter.

After every 50 hours of operation:

- Clean the spark plug and adjust a gap between electrodes to 0.6 - 0.7 mm distance

(see Fig.12).

- Clean deposits from the exhaust pipe and the muffler.

- Dismount the shaft and lubricate with quality lubricant.

Page 15

15

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

Maintenance and storage

Lubricate the gearbox.

Recheck the assembly after maintenance and recheck tightening of all screws, bolts and

nuts.

Check carefully whether fuel liquid is not leaking.

Service

In the case you find-out any defect after having purchased the product, contact the service

department. When using the product, follow instructions given in the operation manual.

Your claim will not be taken into consideration if you have modified the product or have not

adhered to instructions given in this operation manual.

Warranty does not cover

Natural wear of functional parts of the machine in consequence of its use

Service interventions relating to the standard maintenance of the machine (e.g. cleaning,

lubricating, adjusting, etc.)

Faults caused by outer influences (e.g. climatic conditions, dustiness, unsuitable use, etc.)

Mechanical damage resulting from a fall of the machine, shock, impact, etc.

Damages resulting from unskilled handling, overloading, the use of improper parts,

unsuitable tools etc. The risk of possible damage of claimed products which have not been

secured against mechanical damage during the transport properly is born exclusively by the

owner.

Storage

WARNING! If not using the machine for a longer time, store it according to the following

instructions. Thus you will prolong the service life of your machine.

Drain fuel from the fuel tank and carburetor completely. Close the primer and pull the starter

3 – 5 times.

Unscrew the spark plug and put a small amount of engine oil into the hole. Pull the starter

2 – 3 times gently.

Clean outer surfaces by a clean cloth. Store the machine in a clean and dry place.

Page 16

FZS 4003-B

16EN

Technical data | What to do “if…”

8. TECHNICAL DATA

Model: ........................................................................................................................................................ FZS 4003-B

Cylinder capacity: ...................................................................................................................................... 42.7 cm3

Maximum engine power: ........................................................................................................................... 1.25 kW

Shaft length: ............................................................................................................................................... 1,500 mm

Engine type: ........................................................................................................................... two stroke, air-cooled

Idling speed: ....................................................................................................................................... 3,000 rev/min

Recommended maximum idling speed: .................................................................................. 9,000 rev/min

Spark plug: ....................................................................................................................................................... L6 (LD)

Fuel tank capacity: ...................................................................................................................................... 1,200 ml

Weight without fuel and sawing tools: ...................................................................................................... 7.5 kg

Sound power level, guaranteed LWA ................................................................................................. 110 dB(A)

Instructions Manual - language version only.

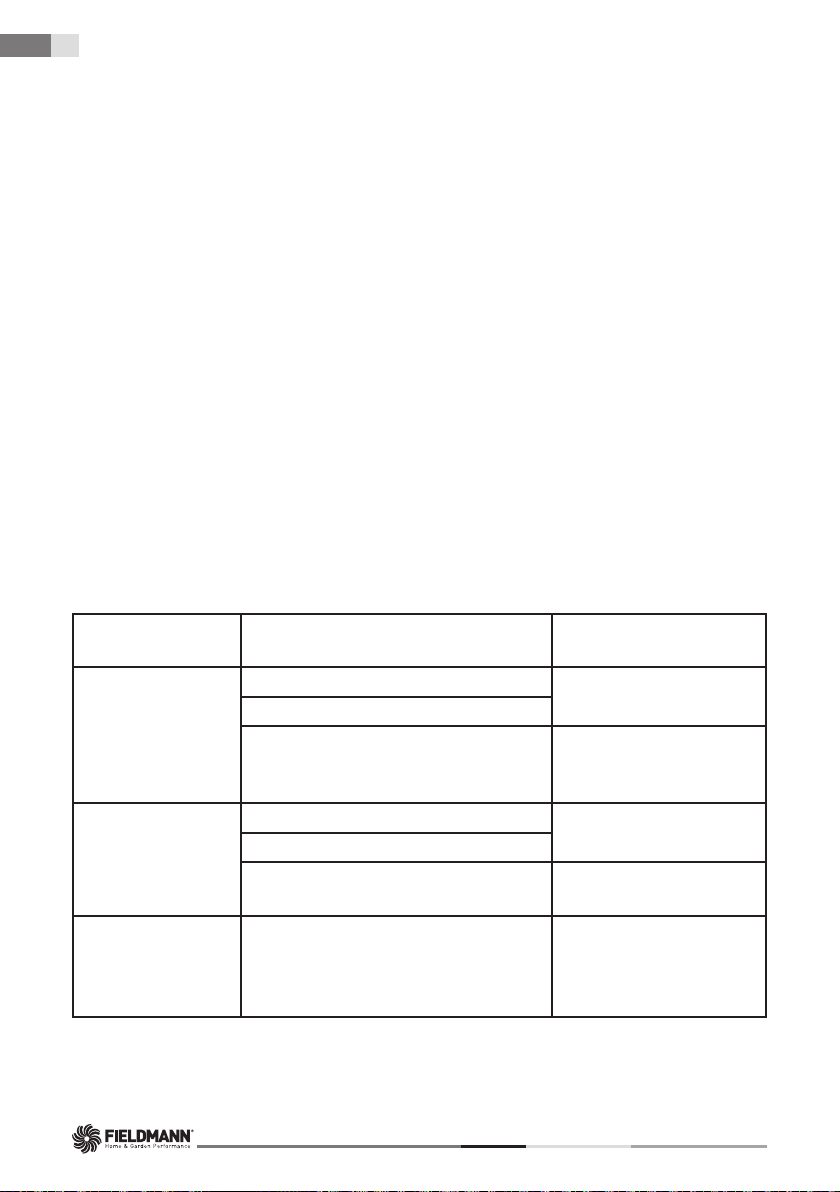

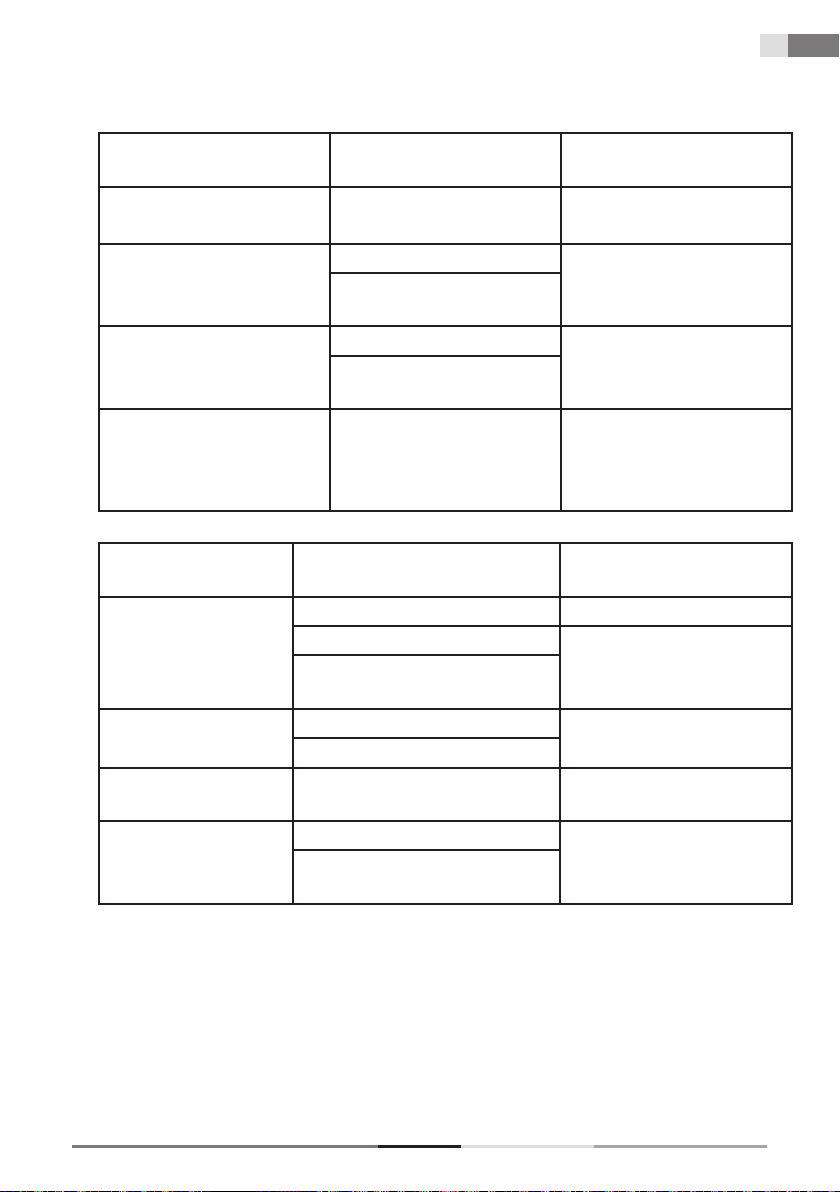

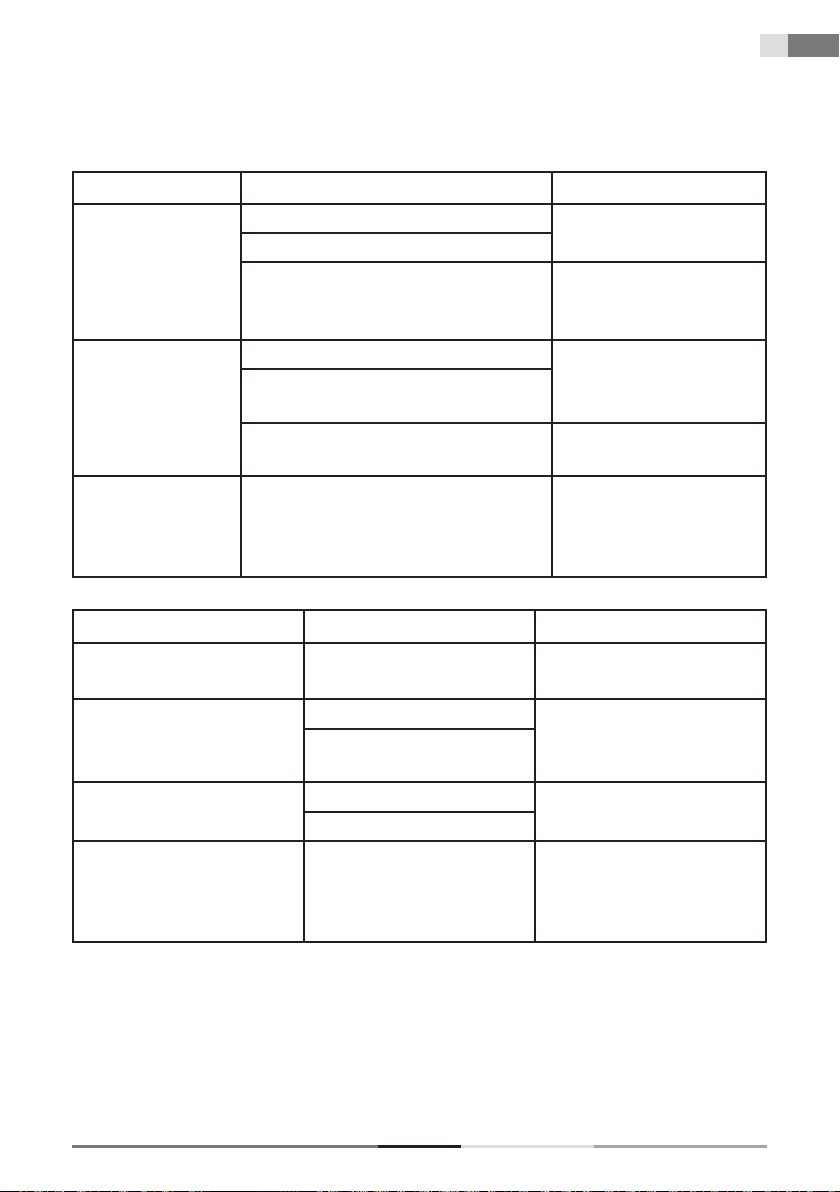

9. WHAT TO DO “IF…”

Engine does not

start

1.Check fuel No fuel in the carburettor or tank. Fill up fuel

2. Take the spark

plug out .

3. Bring the engine

to the authorized

service or to the

dealer.

Possible cause Remedy

Fuel contains water.

Improper fuel mixture ratio. Drain the fuel tank and the

carburettor. Fill new fuel

into the tank..

Defective or dirty spark plug. Replace the spark plug.

Wrong gap between electrodes.

Spark plug is damp, affected by gasoline

(flooded engine)..

Clogged fuel filter, carburettor fault,

ignition fault, clogged valves etc.

Dry the spark plug and

reinstall.

Replace or repair defected

parts.

Page 17

17

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

What to do “if…”

Unsufficiently functional

Possible cause Remedy

engine

1. Check the air filter. Dirty air filter Clean or replace the air filter

element.

2. Check fuel. Fuel contains water. Drain the fuel tank and the

Improper fuel mixture ratio.

carburettor. Fill new fuel into

the tank.

3. Check the primer setup and

gas control.

4. Bring the engine to the

authorized service or to the

dealer.

Engine starts-up,

The primer not fully open. Adjust the setup.

Wrongly adjusted gas cable.

Clogged fuel filter, carburettor

fault, ignition fault, clogged

Replace or repair defective

parts.

valves etc.

Possible cause Remedy

conks out immediately

1. Check fuel. Fuel has run out. Fill up fuel

Fuel contains water. Drain the fuel tank and the

Improper fuel mixture ratio.

carburettor. Fill new fuel into

the tank.

2. Take the spark plug

out and check.

Defective or dirty spark plug. Replace the spark plug.

Wrong gap between electrodes.

3. Check the air filter. Dirty air filter. Clogged air filter Clean or replace the air filter

element.

4. Bring the engine to the

authorized service or to

the dealer.

Clogged bleeder valve. Replace or repair defective

Clogged fuel filter, carburettor fault,

parts.

ignition fault, clogged valves etc.

Page 18

FZS 4003-B

18EN

Declaration of conformity

10. DECLARATION OF CONFORMITY

EC Declaration of Conformity

Fast ČR, a.s., Černokostelecká 251 01 Říčany u Prahy, phone: 323204111, declares with binding

effect, that brush cutter Fieldmann FZS 4003-B (the year of manufacture is indicated on a type

label and is followed by a serial number of the machine), complies with the requirements of

DIRECTIVE OF THE COUNCIL:

No. 2006/42/EC, 2006/95/EC, (approval certificate no.: 17704045 001)

No. 2004/26/EC, exhaust emission,

and has been tested in compliance with the following standards:

EN ISO 11806:2008

The company FAST ČR, a.s. is entitled to act on behalf of the manufacturer.

CE label: 13

Říčany, 29 November 2013

name stamp signature

Petr Uher quality manager

Page 19

19

OPERATION MANUALGASOLINE BRUSH CUTTER

EN

11. DISPOSAL

INSTRUCTIONS AND INFORMATION ON USED PACKAGE DISPOSAL

Put the used packaging material to the place designated for waste disposal by a

municipality.

This symbol is valid in the European Union. If you wish to dispose of this

product, ask local authorities or your dealer for necessary information about

the right disposal method.

This product meets all fundamental requirements of applicable EU directives.

Changes of the text, design and technical specifications can be done without prior notice

and we reserve the right for the changes.

Disposal

Page 20

FZS 4003-B

20

Page 21

Obsah

Benzínový křovinořez

NÁVOD K OBSLUZE

Děkujeme vám, že jste si zakoupili tento benzínový křovinořez. Než jej začnete

používat, přečtěte si, prosím, pozorně tento návod k obsluze a uschovejte jej pro

případ dalšího použití.

OBSAH

OBRAZOVÁ PŘÍLOHA ..................................................................................................................... 3

1.

VŠEOBECNÉ BEZPEČNOSTNÍ PŘEDPISY ............................................................................ 22

Důležitá bezpečnostní upozornění

Obal

Návod na použití

2.

VYSVĚTLENÍ ŠTÍTKŮ S POKYNY NA STROJI .......................................................................... 23

3.

POPIS STROJE A OBSAH DODÁVKY .................................................................................... 24

4.

MONTÁŽ STROJE ......................................................................................................................... 25

5.

UVEDENÍ DO PROVOZU .............................................................................................................. 26

Než začnete

Naplnění pohonné hmoty

Plynová páka a hlavní vypínač (STOP

Startování

Nastavení otáček naprázdno

6.

POKYNY K POUŽITÍ ...................................................................................................................... 27

Bezpečnostní instrukce

Bezpečnostní instrukce – palivo

Bezpečnostní instrukce – řezací nástroje

7.

ÚDRŽBA A USKLADNĚNÍ ............................................................................................................ 28

Údržba stroje

Servis

Uskladnění

8.

TECHNICKÉ ÚDAJE ...................................................................................................................... 30

9.

CO DĚLAT „KDYŽ“ .......................................................................................................................... 30

10.

PROHLÁŠENÍ O SHODĚ .............................................................................................................. 32

11 .

LIKVIDACE ......................................................................................................................................... 33

CZ21

ZÁRUČNÍ LIST ................................................................................................................................. 64

ZÁRUČNÍ PODMÍNKY ................................................................................................................ 65

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Page 22

FZS 4003-B

CZ 22

Všeobecné bezpečnostní předpisy | Vysvětlení štítků s pokyny na stroji

1. VŠEOBECNÉ BEZPEČNOSTNÍ PŘEDPISY

Důležitá bezpečnostní upozornění

Výrobek pečlivě vybalte a dejte pozor, abyste nevyhodili žádnou část obalového materiálu

dříve, než najdete všechny součásti výrobku.

Výrobek uchovávejte na suchém místě mimo dosah dětí.

Čtěte všechna upozornění a pokyny. Zanedbání při dodržování varovných upozornění

a pokynů mohou mít za následek úraz elektrickým proudem, požár a/nebo těžká poranění.

Obal

Výrobek je umístěn v obalu bránícím poškozením při transportu. Tento obal je surovinou a lze jej

proto odevzdat k recyklaci.

Návod k použití

Než začnete se strojem pracovat, přečtěte si následující bezpečnostní předpisy

a pokyny k používání. Seznamte se s obslužnými prvky a správným používáním zařízení. Návod

pečlivě uschovejte pro případ pozdější potřeby. Minimálně po dobu záruky doporučujeme

uschovat originální obal včetně vnitřního balicího materiálu, pokladní doklad a záruční list.

V případě přepravy zabalte stroj zpět do originální krabice od výrobce, zajistíte si tak maximální

ochranu výrobku při případném transportu (např. stěhování nebo odeslání do servisního

střediska).

Poznámka: Předáváte-li stroj dalším osobám, předejte jej společně s návodem.

Dodržování přiloženého návodu k obsluze je předpokladem řádného používání stroje. Návod

k obsluze obsahuje rovněž pokyny pro obsluhu, údržbu a opravy.

Výrobce nepřebírá odpovědnost za nehody nebo škody vzniklé následkem

nedodržování tohoto návodu.

Page 23

CZ23

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Vysvětlení štítků s pokyny na stroji

2. VYSVĚTLENÍ ŠTÍTKŮ S POKYNY NA STROJI

Před použitím si pečlivě přečtěte návod

Při práci používejte ochranné pomůcky

Všeobecné upozornění na nebezpečí!

Pozor, zpětný ráz!

Udržujte ostatní osoby (zejména děti)

a zvířata z dosahu min 15 m od

pracovní

plochy.

Page 24

FZS 4003-B

CZ 24

Popis stroje a obsah dodávky

3. POPIS STROJE A OBSAH DODÁVKY

Popis stroje (viz obr. 1)

Motor

1 -

Vzduchový filtr

2 -

Závěs

3 -

Hlavní spínač + ovladač plynu

4 -

Držák tyče rukojeti

5 -

Tyč rukojeti

6 -

Hřídel

7 -

Použití výrobku

Křovinořez je určen pouze pro vyžínání trávy, plevele, křoví nebo podrostu. Nesmí se používat k

jiným účelům, například k zastřihávání trávníků nebo stříhání živých plotů, protože v takovém

případě může dojít k úrazu.

Charakteristika stroje

Elektronický zapalovací systém

Automatické centrifugální uchopení

Spirální převod

Kardanová hřídel

8 -

Kryt

9 -

Těleso převodovky

10 -

Řezný nástroj

POZOR! Ostré nože

Obsah dodávky

Opatrně vyjměte stroj z obalu a zkontrolujte, zda nechybí žádná z níže uvedených součástí:

Zahradní křovinořez

Strunová hlava se strunou o délce 2,5 m a průměru 2,4 mm

Kotoučová hlava

3-zubý nůž

Trubkový klíč

Návod k obsluze

Pokud díly chybí nebo jsou poškozeny, obraťte se prosím na prodejce, kde jste stroj zakoupili.

Page 25

CZ25

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Montáž stroje

4. MONTÁŽ STROJE

Části hnací hřídele

Montáž hnací hřídele (viz obr. 2)

Odšroubujte šestihranné šrouby (M6 x 10; obr. 2, 1).

Připevněte hnací hřídel ke krytu motoru pomocí 4 šroubů, pevně dotáhněte.

Montáž rukojeti (viz obr. 3, 4, 5)

Odšroubujte šrouby (2), vložte tyče rukojeti do držáku (1), zvolte pozici dle Vašeho

pracovního stylu (pravák – spínač na pravé straně při pohledu od motoru). Horní díly držáku

předběžně našroubujte (4 šrouby) (2), upravte pozici tyčí rukojeti a šrouby (2) pevně

dotáhněte.

Části převodovky (viz obr. 6, 7)

Odšroubujte zajišťovací šroub, namontujte řezací nástroj v tomto pořadí (viz obr. 6):

Převodovka (1) – Unašeč řezací hlavy (2 – Řezací nůž (3) – Krytka (4) – Fixační matice. (5)

Pro vyrovnání drážky tělesa převodovky s otvorem unašeče řezací hlavy, vložte šroubovák.

Matici dotáhněte pomocí trubkového klíče (6) dodávaného v balení.

Poznámka: Místo řezacího nože lze na šroub unášeče natočit hlavici se strunou.

Namontujte bezpečnostní kryt (3) na tyč hřídele pomocí svorky (2) a šroubů (1) . Dbejte na

správnou pozici. (viz obr. 7)

Výměna struny (viz obr. 13, 14, 15, 16)

Demontujte strunovou hlavici, vyjměte cívku se strunou a odstraňte zbytek struny

Novou strunu o celkové délce cca 2 metry protáhněte oběma otvory ve vnitřní části strunové

hlavice (viz obr.14), tak aby byly oba konce stejně dlouhé (viz obr. 13)

Oba konce natočte do cívky ve směru šipky s označením WIND CORD (viz obr. 15)

Cívku se strunou umístěte do hlavice (viz obr.16), oba konce struny protáhněte protilehlými

otvory v hlavici a zkompletujte (uzavřete) ji.

Page 26

FZS 4003-B

CZ 26

Uvedení do provozu

5. UVEDENÍ DO PROVOZU

Než začnete

Upravte délku ramenního popruhu a pozici rukojetí tak, abyste se cítili při práci pohodlně.

Překontrolujte dotažení všech šroubů a matic.

Naplnění pohonné hmoty

Benzín – používejte pouze bezolovnatý motorový benzín s okt. číslem 95 (NATURAL 95).

Olej – používejte pouze kvalitní dvou-cyklový motorový olej , určený pro vysokootáčkové

motory. V poměru 1:25 promíchejte s benzinem a nalijte do nádrže.

Plynová páka a hlavní vypínač (stop) (viz obr. 8)

Plynová páka (1) s elektrickým vypínačem (2) jsou namontovány pouze částečně. Vložte

lanko plynu (4) do drážky táhla karburátoru a připojte dráty elektrického vypínače. Plynová

páka je z továrny předsmontována na rukojeti (3). Při seřízení plynového lanka dbejte na to

aby při startování nedošlo k roztočení řezacího nástroje.

POZOR! Řezací nástroj by se náhle roztočil vysokou rychlostí a mohl by být nebezpečný.

Lanko plynu musí být seřízeno tak, aby při uvolnění plynové páčky motor běžel na volnoběh

(řezací nástroj se neotáčí).

Startování (viz obr. 9)

Stiskněte plynovou páku do 1/4 plyného závěru a zaaretujte

Zapněte hlavní spínač

Nastavte páku sytiče do pozice ZAVŘENO (0).

Rychle zatáhněte za startér. Pokud motor nastartuje, posuňte páku sytiče znovu do pozice

OTEVŘENO (1). Tento postup opakujte, dokud motor nenastartuje a nezačne běžet.

Po nastartování motoru nechte motor před zátěží stroje cca 2–3 minuty zahřát při otáčkách

naprázdno 2500–2800 ot./min.

POZOR! Řezací nůž se již při startování může začít otáčet. Nůž se nesmí ničeho dotýkat,

pokud startujete motor.

Nastavení otáček naprázdno (viz obr. 2)

Pokud jsou otáčky naprázdno příliš vysoké nebo nízké, seřiďte otáčky naprázdno pomocí

seřizovacího šroubu (3).

Pokud jsou otáčky příliš vysoké, otočte seřizovacím šroubem proti směru hodinových ručiček.

Pokud jsou otáčky příliš nízké, otočte seřizovacím šroubem ve směru hodinových ručiček.

Page 27

CZ27

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Pokyny k použití

6. POKYNY K POUŽITÍ

Bezpečnostní instrukce

Čtěte pozorně!

Vždy noste bezpečnostní helmu, bezpečnostní rukavice, ochranný oděv (protiprořezové

nohavice), ochranné rukavice a bezpečnostní obuv. (viz obr. 10)

Stroj uchovávejte z dosahu dětí.

Nikdy nepracujte s motorem, pokud je v palivové nádrži pouze benzín.

Nikdy neplňte pohonné hmoty, pokud motor běží nebo je ještě horký. Motor doplňujte, pouze

pokud je motor studený.

Pohonné hmoty skladujte v uzavřeném obalu na suchém a chladném místě.

Dodržujte bezpečnostní předpisy.

Před každým použitím překontrolujte pracovní prostor. Odstraňte předměty, které by se mohli

odmrštit nebo zaklínit do stroje.

Při práci musí být všechny osoby z dosahu v okruhu minimálně 15 metrů

Nikdy nepoužívejte stroj bez nasazeného ochranného krytu (řezacího nože).

Nikdy nenaplňujte palivovou nádrž, aby byla úplně plná.

Uzávěr palivové nádrže musí být pevně dotažen, aby se zamezilo přetečení pohonné hmoty.

Nenechte běžet stroj na plný plyn, pokud je palivová nádrž prázdná.

Nikdy stroj nevypínejte náhle, pokud běží na plný plyn.

Pokud je stroj jakkoli poškozen, nepoužívejte jej. Kontaktujte kvalifikovaný servis.

Při přenášení uchopte zařízení celé, nošení za palivovou nádrž je nebezpečné, může dojít k

poškození palivové nádrže a požáru.

Křovinořez vždy držte oběma rukama.

Horký křovinořez nikdy nepokládejte do suché trávy.

Při práci se strojem je zakázáno kouřit.

Bezpečnostní instrukce

Palivo

Během přepravy křovinořezu musí být palivová nádrž prázdná.

Pohonné hmoty přepravujte pouze ve schválených kanystrech.

Pravidelně kontrolujte víčko palivové nádrže. Musí být dotažené a nesmí docházet k úniku

palivové hmoty

Chraňte životní prostředí: dávejte pozor, aby nedošlo k úniku palivových hmot a kon-taminaci

půdy.

Stroj startujte minimálně 3 metry od místa, kde jste doplňovali palivo.

Palivo nikdy nedoplňujte v uzavřených místnostech. V místnosti musí být zajištěno

dostatečné větrání, nebezpečí výbuchu.

Page 28

FZS 4003-B

CZ 28

Pokyny k použití | Údržba a uskladnění

Výpary z paliva nevdechujte. Palivo doplňujte v ochranných rukavicích.

Ochranné oblečení pravidelně měňte a čistěte.

Bezpečnostní instrukce

Řezací nástroje

Pokud montujete řezací nástroj, zkontrolujte stav nože. Pokud je poškozen (prasklý, ohlý,

ulomený apod.), vyměňte jej.

Po instalaci nože překontrolujte, zda je díra nože v rovině s ramenem unašeče nože.

Roztočte nůž, překontrolujte, zda nůž nemá tendenci otáčet se nepravidelně.

Překontrolujte, zda montujete nůž s ostřím po směru rotace. Nikdy jej nemontujte obráceně.

Překontrolujte, zda byl řezací nástroj správně smontován, a to otočením bez zátěže (stačí 1

minuta).

Nůž musí být vhodně vybrán pro daný řezací materiál.

Nikdy netlačte nůž na předměty během provozu. Předměty musí být řezány mírnou rychlostí.

Pokud během provozu uslyšíte neobvyklý zvuk nebo se stroj neobvykle třese, ukončete práci a

zjistěte příčinu.

Nezastavujte stroj, pokud je nůž v řezaném objektu. Hrozí nebezpečí úrazu a poškození stroje.

Řezací nástroj musí být opatřen příslušným krytem.

POZOR! Při nedodržení instrukcí hrozí nebezpečí vážného až smrtelného

Zranění osob!

Seznamte všechny osoby pracující s tímto strojem s obsluhou stroje a bezpečnostními

instrukcemi.

7. ÚDRŽBA A USKLADNĚNÍ

Údržba stroje

Před každým použitím:

- Překontrolujte dotažení všech šroubů a matic.

- Překontrolujte, zda nevytéká z palivové nádrže pohonná hmota.

Po každých 20 hodinách provozu:

- Vyčistěte vzduchový filtr (1). (viz obr. 11)

- Vyčistěte filtr paliva.

Po každých 50 hodinách provozu:

- Vyčistěte zapalovací svíčku a seřiďte mezeru mezi elektrodami na vzdálenost 0,6–0,7mm.

(viz obr.12)

- Vyčistěte usazeniny z výfuku a tlumiče výfuku.

- Hřídel znovu odmontujte a promažte kvalitním mazivem.

Page 29

CZ29

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Údržba a uskladnění

Převodovku promažte mazivem.

Překontrolujte montáž po provedení údržby a překontrolujte dotažení všech šroubů a matic.

Pečlivě překontrolujte, zda nevytéká palivová kapalina.

Servis

V případě, že po zakoupení výrobku zjistíte jakoukoli závadu, kontaktujte servisní oddělení. Při

použití výrobku se řiďte pokyny uvedenými v přiloženém návodu k použití.

Na reklamaci nebude brán zřetel, pokud jste výrobek pozměnili či jste se neřídili pokyny

uvedenými v návodu k použití.

Záruka se nevztahuje:

Na přirozené opotřebení funkční částí stroje v důsledku jeho používání

Na servisní zásahy související se standardní údržbou stroje (např. čištění, mazání, seřízení

apod.)

Na závady způsobené vnějšími vlivy (např. klimatickými podmínkami, prašností, nevhodným

použitím apod.)

Na mechanická poškození v důsledku pádu stroje, nárazu, úderu do něj apod.

Na škody vzniklé neodborným zacházením, přetížením, použitím nesprávných dílů,

nevhodných nástrojů apod. U reklamovaných výrobků, které nebyly řádně zabezpečeny proti

mechanickému poškození při přepravě nese riziko případné škody výhradně majitel.

Uskladnění

POZOR! Pokud stroj delší dobu nepoužíváte, přístroj uskladněte dle následujících pokynů.

Prodloužíte tak životnost stroje.

Kompletně vylIjte palivo z palivové nádrže a karburátoru. Zavřete sytič a 3 až 5krát potáhněte

startér.

Vyšroubujte zapalovací svíčku a nalijte do otvoru malé množství motorového oleje. Jemně

potáhněte 2 až 3krát startér.

Čistým hadrem vyčistěte vnější plochy. Stroj uskladněte na čistém a suchém místě.

Page 30

FZS 4003-B

CZ 30

Technické údaje | Co dělat „když“... |

8. TECHNICKÉ ÚDAJE

Model ......................................................................................................................................................... FZS 4003-B

Obsah válce ................................................................................................................................................. 42,7 cm3

Maximální výkon motoru ........................................................................................................................... 1.25 kW

Délka hřídele ............................................................................................................................................... 1500 mm

Typ motoru ................................................................................................................ 2taktní chlazený vzduchem

Otáčky chodu bez zátěže ................................................................................................................. 3000 ot/min

Doporučené maximální otáčky bez zatížení .............................................................................. 9000 ot/min

Zapalovací svíčka .......................................................................................................................................... L6 (LD)

Objem palivové nádrže ............................................................................................................................... 1200 ml

Hmotnost bez paliva a žacích nástrojů .................................................................................................. 7,5 kg

Hladina akustického výkonu, zaručená LWA .................................................................................. 110 dB(A)

Návod k použití v originálním jazyce.

9. CO DĚLAT „KDYŽ“...

Motor nestartuje Možná příčina Odstranění

1. Zkontrolujte palivo. V karburátoru nebo v nádrži není palivo. Doplňte palivo.

Palivo obsahuje vodu.

2. Vyjměte a

zkontrolujte

zapalovací svíčku.

3. Zavezte motor

do kvalifikovaného

servisu, nebo k

prodejci.

Nesprávný poměr směsi pohonné

hmoty.

Vadná nebo znečištěná svíčka. Vyměňte zapalovací svíčku

Nesprávná mezera mezi elektrodami.

Zapalovací svíčka je vlhká, zasažená

benzinem (zahlcený motor).

Ucpaný palivový filtr, porucha

karburátoru, porucha zapalování,

ucpáné ventily apod.

Vypusťte palivovou nádrž

a karburátor. Naplňte nádž

novým palivem.

Vysušte a opět namontujte

zapalovací svíčku.

Vyměňte nebo opravdte

vadné díly.

Page 31

CZ31

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

Co dělat „když“...

Nedostatečně funkční motor Příčina poruchy Oprava

1. Zkontrolujte vzduchový filtr. Znečištění vzduchový filtr. Vyčistěte nebo vyměňte

vložku vzduchového filtru.

2. Zkontrolujte palivo. Palivo obsahuje vodu. Vypustťe palivovou nádrž a

karburátor. Naplňte nádrž

novým palivem.

3. Zkontrolujte nastavení

sytiče a ovládání plynu.

Nesprávný poměr směsi

pohonné hmoty.

Sytič nebyl úplně otevřen. Upravte nastavení.

Špatně seřízené plynové

lanko.

4. Zavezte motor do

kvalifikovaného servisu, nebo

k prodejci.

Ucpaný paivový filtr, porucha

karburátoru, porucha

zapalování, ucpané ventily

Vyměňte nebo opravte vadné

díly.

apod.

Motor nastartuje a hned

Možná příčina Odstranění

zhasne

1. Zkontrolujte palivo. Došlo palivo. Doplňte palivo.

Palivo obsahuje vodu. Vypustťe palivovou nádrž a

karburátor. Naplňte nádrž

noovým palivem.

2. Vyjměte a zkontrolujte

zapalovací svíčku.

Naesprávný poměr směsi pohonné

hmoty.

Vadná nebo znečištěná svíčka. Vyměňte zapalovací svíčku.

Nesprávná mezera mezi

elektrodami.

3. Zkontrolujte

vzduchový filtr.

4. Zavezte motor do

kvalifikovaného servisu,

nebo k prodejci.

Znečištěný vzduchový filtr. Ucpaný

vzduchový filtr.

Vyčistěte nebo vyměňte

vložku vzduchového filtru.

Ucpaný odvzdušňovací ventil. Veměňte nebo opravte vadné

Ucpaný palivový filtrm porucha

díly.

karburátoru, porucha zapalování,

ucpané ventily apod.

Page 32

FZS 4003-B

CZ 32

Prohlášení o shodě

10. PROHLÁŠENÍ O SHODĚ

ES Prohlášení o shodě

Fast ČR, a.s., Černokostelecká 251 01 Říčany u Prahy, tel.:323204111, závazně prohlašujeme, že

křovinořez Fieldmann FZS 4003 – B (rok výroby je vyznačen na typovém štítku a je následován

výrobním číslem stroje, splňuje předpisy SMĚRNICE RADY:

ES č. 2006/42/EC, 2006/95/IEC, (číslo schvalovacího certifikátu:17704045 001)

ES č.2004/26/ES emise výfukových plynů

a byl testován ve shodě s níže uvedenými normami:

EN ISO 11806:2008

Firma FAST ČR, a.s. je oprávněna jednat jménem výrobce.

CE label: 13

V Říčanech dne 29. 11. 2013

jméno razítko podpis

Petr Uher manažer kvality

Page 33

CZ33

BENZÍNOVÝ KŘOVINOŘEZ NÁVOD K OBSLUZE

11. LIKVIDACE

POKYNY A INFORMACE O NAKLÁDÁNÍ S POUŽITÝM OBALEM

Použitý obalový materiál odložte na místo určené obcí k ukládání odpadu.

Stroj a jeho příslušenství jsou vyrobeny z různých materiálů, např. z kovu a

plastů. Poškozené součástky odevzdejte do tříděného sběru. Informujte se u

příslušného úřadu.

Tento výrobek splňuje veškeré základní požadavky směrnic EU, které se na něj

vztahují.

Změny v textu, designu a technických specifi kací se mohou měnit bez předchozího

upozornění a vyhrazujeme si právo na jejich změnu.

Likvidace

Page 34

34

FZS 4003-B

Page 35

35

Benzínový krovinorez

NÁVOD NA OBSLUHU

Ďakujeme vám, že ste si zakúpili tento benzínový krovinorez. Skôr, než ho začnete

používať, prečítajte si pozorne tento návod na obsluhu a uschovajte ho na ďalšie

použitie.

OBSAH

OBRAZOVÁ PRÍLOHA ..................................................................................................................... 3

VŠEOBECNÉ BEZPEČNOSTNÉ PREDPISY ........................................................................... 36

1.

Dôležité bezpečnostné upozornenia

Obal

Návod na použitie

VYSVETLENIE ŠTÍTKOV S POKYNMI NA STROJI ................................................................. 37

2.

POPIS STROJA A OBSAH DODÁVKY .................................................................................... 38

3.

MONTÁŽ STROJA .......................................................................................................................... 39

4.

UVEDENIE DO PREVÁDZKY ....................................................................................................... 40

5.

Kým začnete

Doplnenie pohonnej hmoty

Plynová páka a hlavný vypínač (STOP)

Štartovanie

Nastavenie otáčok naprázdno

POKYNY NA POUŽITIE .................................................................................................................. 41

6.

Bezpečnostné inštrukcie

Bezpečnostné inštrukcie – palivo

Bezpečnostné inštrukcie – rezacie nástroje

ÚDRŽBA A USKLADNENIE ......................................................................................................... 42

7.

Údržba stroja

Servis

Uskladnenie

TECHNICKÉ ÚDAJE ...................................................................................................................... 44

8.

ČO ROBIŤ „KEĎ“ ............................................................................................................................. 44

9.

VYHLÁSENIE O ZHODE .............................................................................................................. 46

10.

LIKVIDÁCIA ....................................................................................................................................... 47

11 .

SKObsah

ZÁRUČNÝ LIST ............................................................................................................................... 64

ZÁRUČNÉ PODMIENKY ............................................................................................................ 65

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

Page 36

FZS 4003-B

36SK

Všeobecné bezpečnostné predpisy

1. VŠEOBECNÉ BEZPEČNOSTNÉ PREDPISY

Dôležité bezpečnostné upozornenia

Výrobok opatrne vybaľte a dajte pozor, aby ste nevyhodili žiadnu časť obalového materiálu

skôr, než nájdete všetky súčasti výrobku.

Výrobok skladujte na suchom mieste mimo dosahu detí.

Prečítajte si všetky upozornenia a pokyny. Nedodržanie varovných upozornení a pokynov

môže mať za následok úraz, požiar alebo ťažké poranenie.

Obal

Výrobok je umiestnený v obale, ktorý zabraňuje poškodeniu pri preprave. Tento obal je surovina a

preto sa dá použiť na recykláciu.

Návod na použitie

Skôr, než začnete so strojom pracovať, prečítajte si nasledujúce bezpečnostné predpisy a návod

na použitie. Zoznámte sa s obslužnými prvkami a správnym používaním zariadenia. Návod

starostlivo uschovajte na neskoršie použitie. Minimálne počas záruky odporúčame uschovať

originálny obal, vrátane vnútorného baliaceho materiálu, pokladničný doklad a záručný list. V

prípade prepravy zabaľte stroj späť do originálnej škatule od výrobcu, zaistíte si tak maximálnu

ochranu výrobku pri prípadnej preprave (napr. pri sťahovaní alebo odoslaní do servisného

strediska).

Poznámka: Ak predávate stroj ďalším osobám, odovzdajte ho spoločne s návodom.

Dodržiavanie priloženého návodu na použitie je predpokladom riadneho používania stroja.

Návod na použitie obsahuje aj pokyny na obsluhu, údržbu a opravy.

Výrobca nepreberá zodpovednosť za nehody alebo škody vzniknuté

následkom nedodržiavania tohto návodu.

Page 37

37

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

Vysvetlenie štítkov s pokynmi na stroji

2. VYSVETLENIE ŠTÍTKOV S POKYNMI NA

STROJI

Pred použitím si dôkladne prečítajte

návod

Pri práci používajte ochranné pomôcky

Všeobecné upozornenia na

nebezpečenstvo!

Pozor, spätný ráz!

Udržujte ostatné osoby (najmä deti)

a zvieratá z dosahu min. 15 m od

pracovnej plochy.

Page 38

FZS 4003-B

38SK

Popis stroja a obsah dodávky

3. POPIS STROJA A OBSAH DODÁVKY

Popis stroja (pozri obr. 1)

Motor

1 -

Vzduchový filter

2 -

Záves

3 -

Hlavný spínač + ovládač plynu

4 -

Držiak tyče rukoväti

5 -

Tyč rukoväti

6 -

Hriadeľ

7 -

Použitie výrobku

Krovinorez je určený len na vyžínanie trávy, buriny, krovia alebo podrastu. Nesmie sa používať

na iné účely, napríklad na zastrihávanie trávnikov alebo strihanie živých plotov, pretože v takom

prípade môže dôjsť k úrazu.

Charakteristika stroja

Elektronický zapaľovací systém

Automatické centrifugálne uchopenie

Špirálový prevod

Kardanový hriadeľ

8 -

Kryt

9 -

Teleso prevodovky

10 -

Rezný nástroj

POZOR! Ostré nože.

Obsah dodávky

Opatrne vyberte stroj z obalu a skontrolujte, či nechýba žiadna z uvedených súčastí:

Záhradný krovinorez

Strunová hlava so strunou s dĺžkou 2,5 m a priemerom 2,4 mm

Kotúčová hlava

3-zubý nôž

Trubkový kľúč

Návod na obsluhu

Ak diely chýbajú alebo sú poškodené, obráťte sa prosím na predajcu, od ktorého ste stroj kúpili.

Page 39

39

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

Montáž stroja

4. MONTÁŽ STROJA

Časti hnacieho hriadeľa

Montáž hnacieho hriadeľa (pozri obr. 2)

Odskrutkujte šesťhranné skrutky (M6 x 10; obr. 2, 1).

Pripevnite hnací hriadeľ ku krytu motora pomocou 4 skrutiek, pevne dotiahnite.

Montáž rukoväti (pozri obr. 3, 4, 5)

Odskrutkujte skrutky (2), vložte tyče rukoväti do držiaka (1), zvoľte pozíciu podľa vášho

pracovného štýlu (pravák - spínač na pravej strane pri pohľade od motora). Horné diely

držiaka predbežne naskrutkujte (4 skrutky) (2), upravte pozíciu tyčí rukoväti a skrutky (2)

pevne dotiahnite.

Časti prevodovky (pozri obr. 6, 7)

Odskrutkujte bezpečnostnú skrutku, namontujte rezací nástroj v tomto poradí (pozri obr. 6):

Prevodovka (1) - Unášač rezacej hlavy (2) - Rezací nôž (3) - Krytka (4) - Fixačná matica. (5)

Na vyrovnanie drážky telesa prevodovky s otvorom unášača rezacej hlavy vložte skrutkovač.

Maticu dotiahnite pomocou rúrkového kľúča (6) dodávaného v balení.

Poznámka: Namiesto rezacieho noža sa dá na skrutku unášača natočiť hlavica so

strunou.

Namontujte bezpečnostný kryt (3) na tyč hriadeľa pomocou svorky (2) a skrutiek (1). Dbajte

na správnu pozíciu (pozri obr. 7).

Výmena struny (pozri obr. 13, 14, 15, 16)

Demontujte strunovú hlavicu, vyberte cievku so strunou a odstráňte zvyšok struny.

Novú strunu s celkovou dĺžkou cca 2 metre pretiahnite oboma otvormi vo vnútornej časti

strunovej hlavice (pozri obr. 14) tak, aby boli oba konce rovnako dlhé (pozri obr. 13).

Oba konce natočte do cievky v smere šípky s označením WIND CORD (pozri obr. 15).

Cievku so strunou umiestnite do hlavice (pozri obr. 16), oba konce struny pretiahnite

protiľahlými otvormi v hlavici a skompletizujte (uzavrite) ju.

Page 40

FZS 4003-B

40SK

Uvedenie do prevádzky

5. UVEDENIE DO PREVÁDZKY

Kým začnete

Upravte dĺžku ramenného popruhu a pozíciu rukovätí tak, aby ste sa cítili pri práci pohodlne.

Skontrolujte dotiahnutie všetkých skrutiek a matíc.

Doplnenie pohonnej hmoty

Benzín - používajte len bezolovnatý motorový benzín s okt. číslom 95 (NATURAL 95).

Olej - používajte len kvalitný dvojcyklový motorový olej, určený na vysokootáčkové motory. V

pomere 1:25 premiešajte s benzínom a nalejte do nádrže.

Plynová páka a hlavný vypínač (stop) (pozri obr. 8)

Plynová páka (1) s elektrickým vypínačom (2) sú namontované len čiastočne. Vložte lanko

plynu (4) do drážky tiahla karburátora a pripojte drôty elektrického vypínača. Plynová páka je

z továrne vopred namontovaná na rukoväti (3).

POZOR! Pri nastavení plynového lanka dbajte na to, aby pri štartovaní nedošlo k roztočeniu

rezacieho nástroja. Rezací nástroj by sa náhle roztočil vysokou rýchlosťou a mohol by byť

nebezpečný. Lanko plynu musí byť nastavené tak, aby pri uvoľnení plynovej páčky motor

bežal na voľnobeh (rezací nástroj sa neotáča).

Štartovanie (pozri obr. 9)

Stlačte plynovú páku do 1/4 plynového uzáveru a zaaretujte.

Zapnite hlavný spínač.

Nastavte páku sýtiča do pozície ZATVORENÉ (0).

Rýchlo zatiahnite za štartér. Ak sa motor naštartuje, posuňte páku sýtiča znova do pozície

OTVORENÉ (1). Tento postup opakujte, kým sa motor nenaštartuje a nezačne bežať.

Po naštartovaní motora nechajte motor pred záťažou stroja cca 2-3 minúty zahriať pri

otáčkach naprázdno 2500-2800 ot./min.

POZOR! Rezací nôž sa už pri štartovaní môže začať otáčať. Keď štartujete motor, nôž sa

nesmie ničoho dotýkať.

Nastavenie otáčok naprázdno (pozri obr. 2)

Ak sú otáčky naprázdno príliš vysoké alebo nízke, nastavte otáčky naprázdno pomocou

nastavovacej skrutky (3).

Ak sú otáčky príliš vysoké, otočte nastavovacou skrutkou proti smeru hodinových ručičiek.

Ak sú otáčky príliš nízke, otočte nastavovacou skrutkou v smere hodinových ručičiek.

Page 41

41

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

Pokyny na použitie

6. POKYNY NA POUŽITIE

Bezpečnostné inštrukcie

Čítajte pozorne!

Vždy noste bezpečnostnú helmu, bezpečnostné rukavice, ochranný odev (protiprerezové

nohavice), ochranné rukavice a bezpečnostnú obuv (pozri obr. 10).

Stroj uchovávajte mimo dosahu detí.

Nikdy nepracujte s motorom, ak je v palivovej nádrži iba benzín.

Nikdy nedopĺňajte pohonné hmoty, kým motor beží alebo je ešte horúci. Napĺňajte iba

studený motor.

Pohonné hmoty skladujte v uzavretom obale na suchom a chladnom mieste.

Dodržiavajte bezpečnostné predpisy.

Pred každým použitím skontrolujte pracovný priestor. Odstráňte predmety, ktoré by sa mohli

odmrštiť alebo zakliniť do stroja.e.

Pri práci musia byť všetky osoby z dosahu v okruhu minimálne 15 metrov.

Nikdy nepoužívajte stroj bez nasadeného ochranného krytu (rezacieho noža).

Nikdy nenapĺňajte palivovú nádrž doplna.

Uzáver palivovej nádrže musí byť pevne dotiahnutý, aby pohonná hmota nepretiekla.

Nenechajte bežať stroj na plný plyn, ak je palivová nádrž prázdna.

Nikdy stroj nevypínajte náhle, ak beží na plný plyn.

Ak je stroj akokoľvek poškodený, nepoužívajte ho. Kontaktujte kvalifikovaný servis.

Pri prenášaní uchopte zariadenie celé, nosenie za palivovú nádrž je nebezpečné, môže dôjsť

k poškodeniu palivovej nádrže a požiaru.

Krovinorez vždy držte oboma rukami.

Horúci krovinorez nikdy neukladajte do suchej trávy.

Pri práci so strojom je zakázané fajčiť.

Bezpečnostné inštrukcie

Palivo

Počas prepravy krovinorezu musí byť palivová nádrž prázdna.

Pohonné hmoty prepravujte len v schválených kanistroch.

Pravidelne kontrolujte viečko palivovej nádrže. Musia byť dotiahnuté a nesmie dochádzať k

úniku palivovej hmoty.

Chráňte životné prostredie: dávajte pozor, aby nedošlo k úniku palivových hmôt a

kontaminácii pôdy.

Stroj štartujte minimálne 3 metre od miesta, kde ste dopĺňali palivo.

Palivo nikdy nedopĺňajte v uzavretých miestnostiach. Miestnosť musí byť dostatočne vetraná,

inak hrozí nebezpečenstvo výbuchu.

Page 42

FZS 4003-B

42SK

Pokyny na použitie | Údržba a uskladnenie

Výpary z paliva nevdychujte. Palivo dopĺňajte v ochranných rukaviciach.

Ochranné oblečenie pravidelne vymieňajte a čistite.

Bezpečnostné inštrukcie

Rezacie nástroje

Ak montujete rezací nástroj, skontrolujte stav noža. Ak je poškodený (prasknutý, ohnutý,

odlomený a pod.), vymeňte ho.

Po inštalácii noža skontrolujte, či je diera noža v rovine s ramenom unášača noža.

Roztočte nôž, prekontrolujte, či nôž nemá tendenciu otáčať sa nepravidelne.

Skontrolujte, či montujete nôž s ostrím v smere rotácie. Nikdy ho nemontujte obrátene.

Skontrolujte, či bol rezací nástroj správne zmontovaný, a to otočením bez záťaže

(stačí 1 minúta).

Vždy je nutné vybrať nôž vhodný na daný rezací materiál.

Počas prevádzky nikdy netlačte nôž na predmety. Predmety musia byť rezané pri pomalej

rýchlosti.

Ak počas prevádzky počujete neobvyklý zvuk alebo sa stroj neobvykle trasie, ukončite prácu

a zistite príčinu.

Stroj nezastavujte, ak je nôž v rezanom objekte. Hrozí nebezpečenstvo úrazu a poškodenia

stroja.

Rezací nástroj musí mať príslušný kryt.

VAROVANIE! Pri nedodržaní inštrukcií hrozí nebezpečenstvo vážneho až smrteľného

zranenia osôb!

Zoznámte všetky osoby pracujúce s týmto strojom s obsluhou stroja a bezpečnostnými

inštrukciami.

7. ÚDRŽBA A USKLADNENIE

Údržba stroja

Pred každým použitím:

- Skontrolujte dotiahnutie všetkých skrutiek a matíc.

- Skontrolujte, či nevyteká z palivovej nádrže pohonná hmota.

Po každých 20 hodinách prevádzky:

- Vyčistite vzduchový filter (1) (pozri obr. 11).

- Vyčistite filter paliva.

Po každých 50 hodinách prevádzky:

- Vyčistite zapaľovaciu sviečku a nastavte medzeru medzi elektródami na vzdialenosť

0,6 - 0,7 mm (pozri obr. 12).

Page 43

43

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

Údržba a uskladnenie

- Vyčistite usadeniny z výfuku a tlmiče výfuku.

- Hriadeľ znova odmontujte a premažte kvalitným mazivom

Prevodovku premažte mazivom.

Skontrolujte montáž po vykonaní údržby a skontrolujte dotiahnutie všetkých skrutiek a matíc.

Dôkladne skontrolujte, či nevyteká palivová kvapalina.

Servis

V prípade, že po zakúpení výrobku zistíte akúkoľvek poruchu, kontaktujte servisné oddelenie.

Pri použití výrobku sa riaďte pokynmi uvedenými v priloženom návode na použitie.

Na reklamáciu nebude braný ohľad, ak ste výrobok upravili alebo ste sa neriadili pokynmi

uvedenými v návode na použitie.

Záruka sa nevzťahuje:

Na prirodzené opotrebenie funkčných častí stroja v dôsledku jeho používania,

Na servisné zásahy súvisiace so štandardnou údržbou stroja (napr. čistenie, mazanie,

nastavenie a pod.),

Na poruchy a kazy spôsobené vonkajšími vplyvmi (napr. klimatickými podmienkami,

prašnosťou, nevhodným používaním a pod.),

Na mechanické poškodenie v dôsledku pádu stroja, nárazu, úderu do neho a pod.,

Na škody vzniknuté neodborným zaobchádzaním, preťažením, použitím nesprávnych

dielov, nevhodných nástrojov a pod. V prípade reklamovaných výrobkov, ktoré neboli riadne

zabezpečené proti mechanickému poškodeniu pri preprave, nesie riziko prípadnej škody

výhradne majiteľ.

Uskladnenie

POZOR! Ak stroj dlhšiu dobu nepoužívate, uskladnite ho podľa nasledujúcich pokynov.

Predĺžite tak životnosť stroja.

Kompletne vylejte palivo z palivovej nádrže a karburátora. Zatvorte sýtič a 3 až 5-krát

potiahnite štartér.

Vyskrutkujte zapaľovaciu sviečku a nalejte do otvoru malé množstvo motorového oleja.

Jemne potiahnite 2 až 3-krát štartér.

Čistou handrou vyčistite vonkajšie plochy. Stroj uskladnite na čistom a suchom mieste.

Page 44

FZS 4003-B

44SK

Technické údaje | Čo robiť „keď“...

8. TECHNICKÉ ÚDAJE

Model .......................................................................................................................................................... FZS 4003-B

Obsah valca ................................................................................................................................................ 42,7 cm3

Maximálny výkon motora .......................................................................................................................... 1,25 kW

Dĺžka hriadeľa ............................................................................................................................................ 1500 mm

Typ motora ............................................................................................................. 2-taktný chladený vzduchom

Otáčky chodu bez záťaže ................................................................................................................. 3000 ot/min

Odporúčané maximálne otáčky bez zaťaženia ........................................................................ 9000 ot/min

Zapaľovacia sviečka ..................................................................................................................................... L6 (LD)

Objem palivovej nádrže .............................................................................................................................. 1200 ml

Hmotnosť bez paliva a žacích nástrojov .................................................................................................. 7,5 kg

Hladina akustického výkonu, zaručená LWA ................................................................................. 110 dB (A)

Návod na použitie – len jazyková mutácia.

9. ČO ROBIŤ „KEĎ“...

Motor neštartuje Možná príčina Odstránenie

1. Skontrolujte palivo. V karburátore alebo v nádrži nie je palivo. Doplňte palivo.

Palivo obsahuje vodu.

2. Vyberte a skon-

trolujte zapaľovaciu

sviečku.

3. Zavezte motor

do kvalifikovaného

servisu alebo k

predajcovi.

Nesprávny pomer zmesi pohonnej

hmoty.

Pokazená alebo znečistená sviečka. Vymeňte zapaľovaciu

Nesprávna medzera medzi elektródami.

Zapaľovacia sviečka je vlhká, znečistená

benzínom (zahltený motor).

Upchaný palivový filter, porucha

karburátora, porucha zapaľovania,

upchané ventily a pod.

Vypusťte palivovú nádrž a

karburátor. Naplňte nádrž

novým palivom.

sviečku.

Vysušte a opäť namontujte

zapaľovaciu sviečku.

Vymeňte alebo opravte

pokazené diely.

Page 45

45

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

Čo robiť „keď“...

Nedostatočne funkčný motor Príčina poruchy Oprava

1. Skontrolujte vzduchový

filter.

Znečistený vzduchový filter. Vyčistite alebo vymeňte

vložku vzduchového filtra.

2. Skontrolujte palivo. Palivo obsahuje vodu. Vypusťte palivovú nádrž a

karburátor. Naplňte nádrž

novým palivom.

3. Skontrolujte nastavenie

sýtiča a ovládanie plynu.

Nesprávny pomer zmesi

pohonnej hmoty.

Sýtič nebol úplne otvorený. Upravte nastavenie.

Nesprávne nastavené plynové

lanko.

4. Zavezte motor do

kvalifikovaného ser-visu alebo

k predajcovi.

Upchaný palivový filter,

porucha karburátora,

porucha zapaľovania,

Vymeňte alebo opravte

pokazené diely

upchané ventily a pod.

Motor naštartuje, ale

Možná príčina Odstránenie

hneď zhasne

1. Skontrolujte palivo. Došlo palivo. Doplňte palivo.

Palivo obsahuje vodu. Vypusťte palivovú nádrž a

karburátor. Naplňte nádrž

novým palivom.

Vymeňte zapaľovaciu

sviečku.

2. Vyberte a skontrolujte

zapaľovaciu sviečku.

Nesprávny pomer zmesi pohonnej

hmoty.

Pokazená alebo znečistená

sviečka.

Nesprávna medzera medzi

elektródami.

3. Skontrolujte

vzduchový filter.

4. Zavezte motor do

kvalifikovaného servisu

alebo k predajcovi.

Znečistený vzduchový filter.

Upchaný vzduchový filter.

Vyčistite alebo vymeňte

vložku vzduchového filtra.

Upchaný odvzdušňovací ventil. Vymeňte alebo opravte

Upchaný palivový filter, porucha

pokazené diely.

karburátora, porucha zapaľovania,

upchané ventily a pod.

Page 46

FZS 4003-B

46SK

Vyhlásenie o zhode

10. VYHLÁSENIE O ZHODE

ES Vyhlásenie o zhode

Fast ČR, a.s., Černokostelecká 251 01 Říčany u Prahy, tel.: 323204111, závzne vyhlasujeme, že

krovinorez Fieldmann FS 4003- (rok výroby je vyznačený na typovom štítku a je nasledovaný

výrobným číslom stroja, splňuje predpisy SMERNICE RADY:

ES č. 2006/42/ES, 2006/95/ES, (číslo schvaovacieho certifikátu: 17704045 001)

ES č. 2004/26/ES emisie výfukových plynov

a bol testovaný v zhode s nižšie uvedenými normami:

EN ISO 11806:2008

Firma FAST ČR, a.s. je oprávnená kona menom výrobcu.

CE label: 13

V Říčanoch dňa 29. 11. 2013

meno pečiatka podpis

Petr Uher manažér kvality

Page 47

47

NÁVOD NA OBSLUHUBENZÍNOVÝ KROVINOREZ

SK

11. LIKVIDÁCIA

POKYNY A INFORMÁCIE O ZAOBCHÁDZANÍ S POUŽITÝM OBALOM

Použitý obalový materiál odložte na miesto určené obcou na ukladanie odpadu.

Tento symbol je platný v Európskej únii. Ak chcete tento výrobok zlikvidovať,

vyžiadajte si potrebné informácie o správnom spôsobe likvidácie od miestnych

úradov alebo od svojho predajcu.

Tento výrobok spĺňa všetky základné požiadavky smerníc EÚ, ktoré sa naň

vzťahujú.

Zmeny v texte, dizajne a technických špecifikáciách sa môžu meniť bez predošlého

upozornenia a vyhradzujeme si právo na ich zmenu.

Likvidácia

Page 48

48

FZS 4003-B

Page 49

49

Kosa spalinowa

INSTRUKCJA OBSŁUGI

Dziękujemy za zakup naszego produktu. Przed rozpoczęciem pracy należy zapoznać

się z niniejszą instrukcją obsługi. Instrukcje obsługi należy zachować w celu jej

późniejszego wykorzystywania.

SPIS TREŚCI

ZDJĘCIA I RYSUNKI .......................................................................................................................... 3

OGÓLNE PRZEPISY BEZPIECZEŃSTWA ................................................................................. 50

1.

Ważne uwagi dotyczące bezpieczeństwa

Opakowanie

Instrukcja obsługi

OBJAŚNIENIA DO TABLICZEK INFORMACYJNYCH NA URZĄDZENIU ................... 51

2.

OPIS URZĄDZENIA I ZAWARTOŚĆ OPAKOWANIA ......................................................... 52

3.

MONTAŻ URZĄDZENIA ................................................................................................................ 53

4.

EKSPLOATACJA ............................................................................................................................... 54

5.

Zanim zaczniesz

Uzupełnienie paliwa

Dźwignia gazu i wyłącznik główny (STOP)

Uruchomienie

Ustawienie obrotów na biegu jałowym

INSTRUKTAŻ ....................................................................................................................................... 55

6.

Instrukcja bezpieczeństwa

Instrukcja bezpieczeństwa – paliwo

Instrukcja bezpieczeństwa – urządzenia tnące

KONSERWACJA I PRZECHOWYWANIE ............................................................................... 57

7.

Konserwacja urządzenia

Serwis

Przechowywanie

DANE TECHNICZNE ....................................................................................................................... 58

8.

USUWANIE USTEREK ...................................................................................................................... 59

9.

DEKLARACJA ZGODNOŚCI .................................................................................................... 61

10.

UTYLIZACJA....................................................................................................................................... 62

11 .

PLSpis treści

KARTA GWARANCYJNA .......................................................................................................... 64

WARUNKI GWARANCJI ............................................................................................................ 65

INSTRUKCJA OBSŁUGIKOSA SPALINOWA

Page 50

FZS 4003-B

50PL

Ogólne przepisy bezpieczeństwa

1. OGÓLNE PRZEPISY BEZPIECZEŃSTWA

Ważne uwagi dotyczące bezpieczeństwa

Produkt należy starannie rozpakować, należy zwrócić uwagę na wyjęcie z opakowania

wszystkich części produktu.

Produkt należy przechowywać w miejscu suchym, zabezpieczyć przed dostępem dzieci.

Przeczytać wszelkie uwagi i instrukcje. Zaniedbania w stosunku do uwag i instrukcji mogą

być powodem urazu, pożaru i/lub ciężkiego zranienia.

Opakowanie

Produkt jest zapakowany do opakowania chroniącego go przed uszkodzeniem w czasie

transportu. Opakowanie jest surowcem wtórnym i należy poddać je recyklingowi.

Instrukcja obsługi

Przed rozpoczęciem korzystania z urządzenia należy zapoznać się z poniższymi przepisami

bezpieczeństwa i instrukcją obsługi. Należy zapoznać się z elementami obsługi i właściwym

korzystaniem z urządzenia. Instrukcje należy przechowywać w celu późniejszego z niej

korzystania. Przez okres trwania gwarancji zaleca się przechowanie oryginalnego opakowania

wraz z materiałami opakunkowymi, dokument zakupu i kartę gwarancyjną. Przechowanie

opakowania ułatwi w przyszłości ewentualny transport urządzenia (przeprowadzka, odesłanie

do naprawy).

Uwaga: Jeżeli nastąpi przekazanie urządzenia innym użytkownikom, należy przekazać

również instrukcję obsługi. Stosowanie się do zaleceń zawartych w instrukcji zapewni

właściwe użytkowanie urządzenia. Instrukcja obsługi zawiera również instrukcje

konserwacji urządzenia i napraw.

Producent nie ponosi odpowiedzialności za wypadki lub szkody powstałe w

wyniku nie stosowania się do niniejszej instrukcji obsługi.

Page 51

51

INSTRUKCJA OBSŁUGIKOSA SPALINOWA

PL

Objaśnienia do tabliczek informacyjnych na urządzeniu

2. OBJAŚNIENIA DO TABLICZEK

INFORMACYJNYCH NA URZĄDZENIU

Przed użytkowaniem należy zapoznać

się z instrukcją.

W czasie pracy używać środków

ochrony osobistej.

Uwaga niebezpieczeństwo!

Uwaga odrzut!

Obecność ludzi (zwłaszcza dzieci) i

zwierząt w odległości mniejszej niż 15

m od miejsca pracy jest niedozwolona.

Page 52

FZS 4003-B

52PL

Opis urządzenia i zawartość opakowania

3. OPIS URZĄDZENIA I ZAWARTOŚĆ

OPAKOWANIA

Opis urządzenia (zobacz rys. 1)

Silnik

1 -

Filtr powietrza

2 -

Zaczep

3 -

Włącznik główny + dźwignia gazu

4 -

Zaczep uchwytu

5 -

Uchwyt kosy

6 -

Rura nośna

7 -

Przeznaczenie

Używaj kosę spalinową tylko do celów, do których została zaprojektowana: ścinanie trawy,

chwastów, zarośli lub podszycia. Nie używaj kosy do innych celów, na przykład koszenia

trawników lub strzyżenia żywopłotów. Użycie maszyny w innym celu może stanowić zagrożenie

dla operatora i osób postronnych.

Charakterystyka urządzenia

8 -

Osłona

9 -

Obudowa przekładni

10 -

Urządzenie tnące

Elektroniczny system uruchamiania

Automatyczny uchwyt odśrodkowy

Przekładnia spiralna

Wał Cardana

UWAGA! Ostre noże.

Zawartość opakowania

Delikatnie wyjąć urządzenie z opakowania i sprawdzić, czy są wszystkie z wymienionych

poniżej części:

Kosa ogrodowa

Głowica do żyłki, z żyłką o długości 2,5 m i średnicy 2,4 mm

Głowica tarczowa

Nóż 3-zębny

Klucz rurkowy

Instrukcja obsługi

Jeżeli stwierdzą Państwo brak elementów lub ich uszkodzenie, prosimy o interwencję u

sprzedawcy, u którego dokonano zakupu urządzenia.

Page 53

53

INSTRUKCJA OBSŁUGIKOSA SPALINOWA

PL

Montaż urządzenia

4. MONTAŻ URZĄDZENIA

Części wału napędowego

Montaż wału napędowego (zobacz rys. 2)

Odkręć śruby sześciokątne (M6 x 10; rys. 2, 1).

Przymocuj wał napędowy do odsłony silnika używając 4 śrub. Dobrze dokręć.

Montaż uchwytu kosy (zobacz rys. 3, 4, 5)

Odkręć śruby (2), zamontuj rurę uchwytu w punkcie zaczepienia uchwytu na wysięgniku

(1), wyważ kosę tak, aby uzyskać najkorzystniejsze i najwygodniejsze ustawienie (osoba

praworęczna włącznik/wyłącznik po prawej stronie patrząc od silnika). Przykręć wstępnie

górne elementy uchwytu ( 4 śruby) (2), sprawdź ponownie wyważenie i jeśli będzie to

konieczne – jeszcze raz popraw. Następnie dokręć śruby (2) mocujące uchwyt.

Elementy przekładni (zobacz rys. 6, 7)

Odkręć śrubę zabezpieczającą, załóż narzędzie tnące montując elementy tnące w

następującej kolejności (zobacz rys. 6): Przekładnia (1) – Zabierak głowicy tnącej (2 ) Ostrze (3) – Osłona ostrza (4) – Nakrętka mocująca (5). Użyj śrubokrętu, żeby rowki wału

przekładni wpasowały się w otwór zabieraka głowicy tnącej. Dokręć nakrętkę przy pomocy

klucza rurkowego (6) będącego na wyposażeniu.

Uwaga: Zamiast noża można na śrubę zabieraka wkręcić głowicę z żyłką.

Załóż osłonę zabezpieczającą (3) osłonę wału używając zacisku (2) i śrub (1) . Należy

zwrócić uwagę na poprawne zamontowanie osłony. ( zobacz rys. 7)

Wymiana żyłki (zobacz rys. 13, 14, 15, 16)

Zdemontować głowicę, wyjąć cewkę z żyłką i usunąć resztki żyłki.

Nową żyłkę o długości około 2 metrów przełożyć przez dwa otwory znajdujące się w

wewnętrznej części głowicy (zobacz rys.14) tak, aby oba wystające końce żyłki miały

jednakową długość (zobacz rys. 13).

Oba końce żyłki nawinąć na cewkę zgodnie z kierunkiem strzałki oznaczonej WIND CORD

(zobacz rys. 15).

Cewkę z nawiniętą żyłką umieścić w głowicy (zobacz rys. 16), dwa końce żyłki przeciągnąć

przez przeciwległe otwory głowicy i zamknąć głowicę.

Page 54

FZS 4003-B

54PL

Eksploatacja

5. EKSPLOATACJA

Zanim zaczniesz

Wyreguluj długość paska naramiennego i pozycję uchwytu kosy, tak aby można było

wygodnie operować kosą. Sprawdź dokręcenie wszystkich śrub i nakrętek.

Uzupełnianie paliwa

Benzyna – używaj wyłącznie bezołowiowej 95 oktanowej benzyny silnikowej (NATURAL 95).

Olej – używaj wyłącznie dobrej jakości oleju silnikowego przeznaczonego do silników

dwusuwowych, przystosowanego dla silników wysokoobrotowych. Olej z benzyną zmieszać

w stosunku 1:25 i wlać do zbiornika.

Dźwignia gazu i wyłącznik główny (stop) (zobacz rys. 8)

Dźwignia gazu (1) z elektrycznym wyłącznikiem (2) jest zamontowana tylko częściowo.

Włóż linkę gazu (4) do wpustu cięgła gaźnika i podłącz przewody wyłącznika elektrycznego.

Dźwignia gazu jest zamontowana fabrycznie na uchwycie (3).

OSTERZEŻENIE! Regulując linkę gazu uważaj, żeby podczas uruchamiania silnika ostrze

nie zaczęło się obracać. Ostrze mogłoby się nagle zacząć obracać z wysoką prędkością

i mogłoby spowodować sytuację niebezpieczną. Linka gazu musi być tak wyregulowana,

żeby przy zwolnieniu dźwigni gazu silnik pracował na wolnych obrotach ( urządzenie tnące

nie obraca się).

Uruchomienie (zobacz rys. 9)

Wprowadzić dźwignię gazu w położenie na 1/4 regulacji gazu

Włączyć włącznik główny

Ustawić dźwignię ssania w pozycji ZAMKNIĘTE (0).

Szybko pociągnąć za rączkę startera. Jeżeli silnik zastartuje, przesunąć dźwignię ssania

znowu w położenie OTWARTE (1). Powtarzaj, aż silnik zacznie pracować.

Po uruchomieniu silnika, pozostaw silnik, przed obciążeniem urządzenia przez około

2 – 3 minuty na obrotach 2500 – 2800 obrotów/minutę w celu zagrzania silnika.

UWAGA! Podczas rozruchu ostrze tnące może zacząć się obracać. Zanim uruchomisz

silnik upewnij się, że elementy tnące nie dotykają podłoża ani innych przedmiotów.

Regulacja obrotów bez obciążenia (zobacz rys. 2)

Jeżeli obroty silnika są zbyt wysokie lub niskie, wyreguluj obroty za pomocą śruby

regulującej (3), bez obciążania silnika.

Jeżeli obroty są zbyt wysokie, obróć śrubę regulacyjną w kierunku przeciwnym do ruchu

wskazówek zegara.

Page 55

55

INSTRUKCJA OBSŁUGIKOSA SPALINOWA

PL

Eksploatacja | Instrukcja użytkowania

Jeżeli obroty są zbyt niskie, obróć śrubę regulacyjną w kierunku zgodnym z ruchem

wskazówek zegara.

6. INSTRUKCJA UŻYTKOWANIA

Instrukcja bezpieczeństwa

Przeczytaj dokładnie!