FIELDKING FKDRHD-9, FKDRHD-7, FKDRHD-11 Operator Manual, Service Manual, Part Catalogue

Corporate Office:

Plot No. 235 to 240, Sec-3, HSIIDC, Karnal- 132001 (Haryana), India

+91 184 2221571/ 72/ 73 info@fieldking.com, www.fieldking.com

BERI UDYOG PVT LTD

?Operator Manual Service Manual Part Catalogue? ?

World Class Farm Equipment

Seeding & Plantation

Post Harvest

Harvest

Crop Protection

Landscaping

Tillage

Haulage

Solutions...

Dabbang

Cultivator / Tiller

Multi Row / Double Coil

Cultivator / Tiller

Rigid Cultivator

1.

2.

3.

Models of beri cultivator

Page No.

2 -14

15-28

29-42

Corporate Office:

Plot No. 235 to 240, Sec-3, HSIIDC, Karnal- 132001 (Haryana), India

+91 184 2221571/ 72/ 73 info@fieldking.com, www.fieldking.com

BERI UDYOG PVT LTD

?Operator Manual Service Manual Part Catalogue? ?

World Class Farm Equipment

Seeding & Plantation

Post Harvest

Harvest

Crop Protection

Landscaping

Tillage

Haulage

Solutions...

Dabbang

Cultivator / Tiller

You have invested in one of the best implements of its type in the market today.

The care you give your “FIELDKING” implement will greatly determine your

satisfaction with its performance and its service life. A careful study of this manual

will give you a thorough understanding of your new implement before operating.

If your manual is lost or destroyed, “FIELDKING” will be glad to provide you a new

copy. Visit to nearest dealership & get a copy. Most of our manuals can also be

downloaded from our website at www.fieldking.com.

As an authorized “FIELDKING” dealer, we stock genuine “FIELDKING” parts which

are manufactured with the same precision and skill as our original equipment. Our

trained service persons are well informed on methods required to service

“FIELDKING” equipments and are ready to help you.

Should you require additional information or assistance, please contact us.

CONGRATULATIONS!

YOUR AUTHORIZED

FIELDKING DEALER

BECAUSE “FIELDKING” MAINTAINS AN ONGOING PROGRAMME

OF PRODUCT IMPROVEMENT, WE RESERVE THE RIGHT TO MAKE

IMPROVEMENTS IN DESIGN OR CHANGE IN SPECIFICATION

WITHOUT INCURRING ANY OBLIGATION TO INSTALL THEM ON

UNITS PREVIOUSLY SOLD. BECAUSE OF THE POSSIBILITY THAT

SOME PHOTOGRAPHS IN THIS MANUAL WERE TAKEN OF

PROTOTYPE MODELS, PRODUCTION MODELS MAY VARY IN

SOME DETAIL. IN ADDITION, SOME PHOTOGRAPHS MAY SHOW

SHIELDS REMOVED FOR THE PURPOSE OF CLARITY. NEVER

OPERATE THIS IMPLEMENT WITHOUT ALL SHIELDS IN PLACE.

This manual contains valuable information about your new “FIELDKING” dabbang

cultivator / tiller. It has been carefully prepared to give you helpful suggestions for

operating, adjusting, servicing and ordering spare parts.

Keep this manual in a convenient place for quick and easy reference. Study it

carefully. You have purchased a dependable and sturdy dabbang cultivator / tiller but

only by proper care and operation you can expect to receive the service and long life

designed and built into it.

Sometime in the future your dabbang cultivator / tiller may need new parts to replace

which are worn out or broken. If so, go to your dealer and provide him equipment’s

detail like model and part number.

Name ______________________________________________

Purchased From ______________________________________

Date of Purchase _____________________________________

Model No. ___________________________________________

Serial No. ___________________________________________

TO THE PURCHASER

CUSTOMER INFORMATION

1. Read and understand the information contained in this manual.

2. Operate, lubricate, assemble and maintain the equipment in accordance with all

instructions and safety procedures in this manual.

3. Inspect the equipment and replace or repair any parts that are damaged or worn

out which under continued operation would cause damage, wear to other parts,

or cause a safety hazard.

4. Return the equipment or parts to the authorized “FIELDKING” dealer, from where

it was purchased, for service or replacement of defective parts that are covered

by warranty. (The “FIELDKING” Factory may inspect equipment or parts before

warranty claims are honored.)

5. All costs incurred by the dealer for traveling to or transporting the equipment for

warranty inspection and claims will be borne by the customer.

PURCHASER / OPERATOR’S RESPONSIBILITY

1. TECHNICAL DATA

1.1 Introduction

1.2 Warranty

1.3 When the warranty becomes void

1.4 Warning

2. USAGE INSTRUCTIONS

2.1 Before use & adjustments

2.2 Attaching cultivator/tiller to the tractor

2.3 Safety

3. MAINTENANCE

3.1 Operation, care & maintenance of cultivator/tiller

3.2 Storage of machine after work

4. PARTS CATALOGUE

INDEX

21

1. TECHNICAL DATA

1.1 INTRODUCTION

FIELDKING ‘dabbang cultivator/tiller’ type rigid tiller is designed for tougher

operations. It is suitable for varying hard soil conditions. Dabbang rigid forged tyne

assemblies derive their strength from heavy duty solid bar, new casted Brackets

which once bolted to the immensely strong main frame, cannot move or strain out

of position. Spacing of the tynes is changed simply by slackening the bolts and

sliding the brackets to the desired position. Height of the tynes can aslo be adjusted.

1.2 WARRANTY POLICY FOR FILEKIDNG TILLER/CULTIVATOR

1. Beri Udyog Pvt. Ltd.(“ the company”) warrants to the retail purchase of the

“FIELDKING” tiller/ cultivator that subject to the limitation specified here in

below, the company’s authorised dealer will repair or replace any part there

of found. In its opinion, to be defective in materials of workmanship. The

warranty shall be for a period 1 year from the date of purchase of new

“FIELDKING” agriculture tiller/cultivator by the original purchaser (“retail

purchaser”).

2. This warranty is limited to the delivery to the retail purchaser, free at the

authorized dealer’s workshop or company’s works of the part or parts

whether repaired or replaced in exchange for those acknowledge by the

company to be defective.

3. The purchaser of “FIELDKING” agriculture tiller/cultivator are advised strictly

to follow the instructions given in the operator manual, provided by the

company along with the “FIELDKING” tiller/cultivator at the time of delivery,

changes if any in the “FIELDKING” tiller/cultivator, resulting in improper

usage will not be covered in the warranty, This warrant will a u t oma ti ca l l y

get terminated on the expiry of warrant period even in the “FIELDKING”

tiller/cultivator, may not in use for any time during the warranty period for any

reason whatsoever including any technical reasons, any time for such

repairs/replacements of parts and in transit, whether under this warranty or

otherwise shall not be excluded from the warranty period.

4. Warranty shall apply to following:

• Manufacturing defects: Breaking of any structure & fabrication covered

under warranty.

5. Warranty shall not apply to the following:

• Accidental cases are not covered under warranty.

NOTE: If any kind of breakage and damage is found due to poor handling of

customer that also is not covered under warranty policy.

6. The retail purchaser shall be required to make a thorough examination of

the products prior to the purchase. The authorized dealer are in no way the

legal agent of the company and have no right or authority to give any

warranty or assume any obligation on behalf of the company or bind the

company in any manner whatsoever.

7. For the purpose of this warranty, the term ‘’product” means and includes

only new “FIELDKING” tiller/cultivator, manufactured by or for the company

design and drawing and sold and installed by the authorized dealer.

8. The company’s responsibility is limited to the terms of this warranty and it

shall not be liable for personal injuries or consequential or resulting liability,

damage or loss arising from any defect.

9. The company’s liability under this warranty is depended upon the strict

observance by the retail purchase, of the following provisions.

• The retail purchaser at the time of delivery shall sign complete and return

the authorized warranty and dealer’s delivery report.

• All the parameters should be thoroughly checked as per the scheduled

maintenance in the operator ’s manual. The customers are also bound to

use the genuine spares for “FIELDKING” tiller/cultivator, purchased from

authorized “FIELDKING’ dealers.

• Repairs and replacements will be performed by the facility of the authorized

dealers/its branch dealers.

• This warranty shall not apply if the product or any part there of repaired or

altered not in accordance with our standard repair procedure or by any

person other than an Authorized Dealers/its branch dealers/its authorized

service centre.

• The decision of the company or the concerned authorized dealers in regard

to the warranty shall be final and conclusive and the retail purchaser hereby

agrees to unconditionally accept their decision on all.

• Claims arising from this warranty will be considered only if they are notified

in writing to the concerned authorized dealers after the defect has been

ascertained.

43

12. The court at Karnal shall have exclusive jurisdiction to try, entertain and

dispose of all proceeding relating to any dispute arising between the

company and the retail purchaser on the liability of the company under

this warranty.

1.3 WHEN THE WARRANTY BECOMES VOID

1. Besides the caused specified in the supply agreement, the warranty shall in

any case become void.

2. Should there have been a maneuver error.

3. When following repairs made by the customer without authorization from

the manufacture or owing to the installation of spurious spare parts, the

machine is subject to variations and the damage can be ascribed to these

variations.

4. When the user failed to comply with the instructions in the operator’s

handbook.

5. When the implement has been used beyond the specified power limit like

(tractor horse power).

6. No warranty will be given if the service is not done on time.

1.4 WARNING

Thoroughly read the instruction manual before proceeding with the various

operations.

Maintain the harrow as per the instructions of this handbook to be entitled for

warranty.

2. USAGE INSTRUCTIONS

2.1 BEFORE USE & ADJUSTMENTS

Before mounting of cultivator make sure that all nuts & bolts are properly secured.

Also determine soil and trash conditions of the field and make the preliminary

adjustments. e.g.

Tyne leveling

To eliminate uneven working and side draft, leveling is done by means of top link.

• This warranty does not cover any applicable taxes payable on any parts

which the company may supply or repairs free of cost of during the warranty

period. This warranty also does not cover the cost of packaging to and fro

freight and transportation charges etc. on the defective “FIELDKING”

tiller/cultivator or other part of the “FIELDKING” tiller/cultivator sent to

“FIELDKING” dealers locations.

• The company reserves the right to make changes in design or introduce

any improvement or add any parts on the products any time without

incurring any obligation to install the same on products previously sold.

10. This contract will be ineffective and incorporative if:

• The dully warranty card is not presented during the repairs.

• The “FIELDKING” agriculture tiller/cultivator or any parts thereof is

subjected to neglect, fire, floods or other acts of god or in the company’s

opinion any damage has caused to be “FIELDKING” agriculture

tiller/cultivator during transportation.

• The original numbers are removed, obliterated or altered from the unit.

• Any attempt is made to have the repairs executed by a person, other than

the company’s or its authorized representatives.

• Any defect if not informed immediately to the company or its authorized

representative, any alterations in the warranty card is made.

• The use of replacement parts not manufactured or supplied by the

company will automatically invalidate this warranty.

This warranty shall not be apply to defect/damages caused by the normal

wear and tear, accident, transportation, misuser or neglect usage in non

agric applications, defect in the products which have been altered outside

the company’s work or which have been let out in hire or the identification

marks in which have been altered or removed. Company’s decisions in this

respect will be final and binding on all.

11. The above warranty is in lieu of all other warranties express or implied, and

no person, agent or representative of the company is authorized to give any

other warranties on the company’s behalf or the assume for it any other

liability in connection, with the product.

65

SAFETY INSTRUCTIONS:

1. All equipment is potentially hazardous. There is no substitute for a safety

conscious operator who recognizes potential hazards and follows reasonable

safety practices.

2. Personal protection equipment including safety glasses, safety shoes, and

gloves are recommended during assembly, installation, operation, adjustment,

maintaining, repairing, removal or moving the implement.

3. Never place yourself between the tractor and implement while implement is in

operation.

4. Do not work under a raised implement unless it is securely blocked or held in

position. Do not depend on the tractor hydraulic system to hold the implement in

place.

5. A heavy load can cause instability of the tractor. Use extreme care during travel.

Slow down on turns and watch out for bumps. The tractor may need front counterweights to counter-balance the weight of the implement.

6. Do not allow others to ride on the tractor with an operator. Riders are subject to

injury such as being struck by foreign objects or being thrown off. Riders obstruct

the operator’s view resulting in unsafe operation. Never allow anyone to ride on

the implement!

7. Do not allow anyone who is not familiar with the safety rules and operation

instructions to use this implement.

8. Keep alert and watch the front as well as the rear when working with equipment.

9. Always be sure the implement is in the fully raised position when in transport.

10. When removing or adjusting equipment, be sure that your feet are never under the

implement.

11. Avoid excessive speed during operation.

12. Before you operate the field cultivator, check over all pins, bolts and connections

to be sure that all are securely in place. Replace any damaged or worn parts

immediately.

13. Make implement adjustments only when the implement is attached to the tractor.

14. Watch for and avoid hidden obstructions, i.e. buried pipes, rocks, uneven

concrete slabs, stumps etc., when operating equipment.

15. Never operate tractor and implement under trees with low hanging limbs.

Operators can be knocked off the tractor and then run over by the implement.

16. Operating rigid cultivator shanks may suddenly fling rocks and clods. Keep all

bystanders 10 meter away and operator must wear safety glasses.

17. Reduce speed when transporting mounted implements to avoid bouncing and

momentary loss of steering control.

18. It may be necessary to raise implement slightly and then lower to desired working

depth when tractor is moving.

Danger:

In operating position the top link must

be higher on the machine side than on

the tractor side!

Depth control

The depth at which the implement is required to work is controlled hydraulically by

raising or lowering the control lever on the tractor.

2.2 ATTACHING THE CULTIVATOR/TILLER TO THE TRACTOR

1. Place the cultivator duly leveled on the flat piece of land.

2. Reverse the tractor to the cultivator ( Do not drag the cultivator/tiller up the

tractor)

3. Attach the left arm of the tractor to the cultivator/tiller first.

4. Attach the central arm to the cultivator/tiller. To attach, turn the screws on both

sides to an equal length. If the arm is too short or too long, turn the screw to

adjust both at the same time until aligned with the hole on the central arm.

5. Attach the lower right arm, turn the screw until the mounting pin is at the same

level as the hole on the tractor arm. If the gap between the hole and mounting

pin is too close or too distant, turn the control arm in or pull it away to an

appropriate distance. You may have to adjust both height and distance at the

same time. When the hole at tractor arm and mounting pin are even, insert the

pin in the hole and lock it with the lynch pin.

6. After attaching the cultivator/tiller, lift it and adjust the control arm parallel to

the ground. When you look from both rear or sideways, all shovel should be

touching the ground uniformly.

2.3 SAFETY

REMEMBER SAFETY FIRST

Operator must read the instruction manual before operating the cultivator. Do

not allow anyone to operate this equipment who has not fully read and

comprehended this manual and who has not been properly trained in the safe

operation of the equipment.

87

Non-observance of the above rules shall be considered negligence.

It will rule out any liability of the manufacturer for all possible

damage and / or consequences.

The user is solely responsible for any risk!

ATTENTION

3. MAINTENANCE

3.1 OPERATION, CARE & MAINTENANCE OF CULTIVATOR/ TILLER

1. All the shovels of the tynes should be set at equal depth. To do this, place the

cultivator on level ground and see that all the shovel touch the ground.

2. Before commencing work with a cultivator, check it for loose bolts and nuts and

fasten them properly. After having taken all these precautions, run the cultivator

for one hour and then inspect it once more for any loose parts.

3. Never turn or reverse your tractor while cultivator is ploughed deep in field. This

will twist the assemblies out of alignment and damage them extensively.

4. Reverse or replace the shovel point when worn out. Delay may result in wearing

out of the tynes which will result into expensive repairing/replacements. Avoid use

of extra wide shovels as they do not improve tillage quality but only put extra load

on the tractor and also result into extra fuel consumption.

3.2.STORAGE OF CULTIVATOR/TILLER AFTER WORK

1. Wash the cultivator after work.

2. Replace the worn out nuts & bolts.

3. If cultivator has to remain unused for long time then clean it & apply a layer of used

oil for rust prevention.

4. These steps will enhance the life of your cultivator.

4. PARTS CATALOGUE

19. Use extra care when working on slopes.

20. Never use alcoholic beverages or drugs which can hinder alertness or

coordination while operating this equipment. Consult your doctor about operating

this machine while taking prescription medications.

109

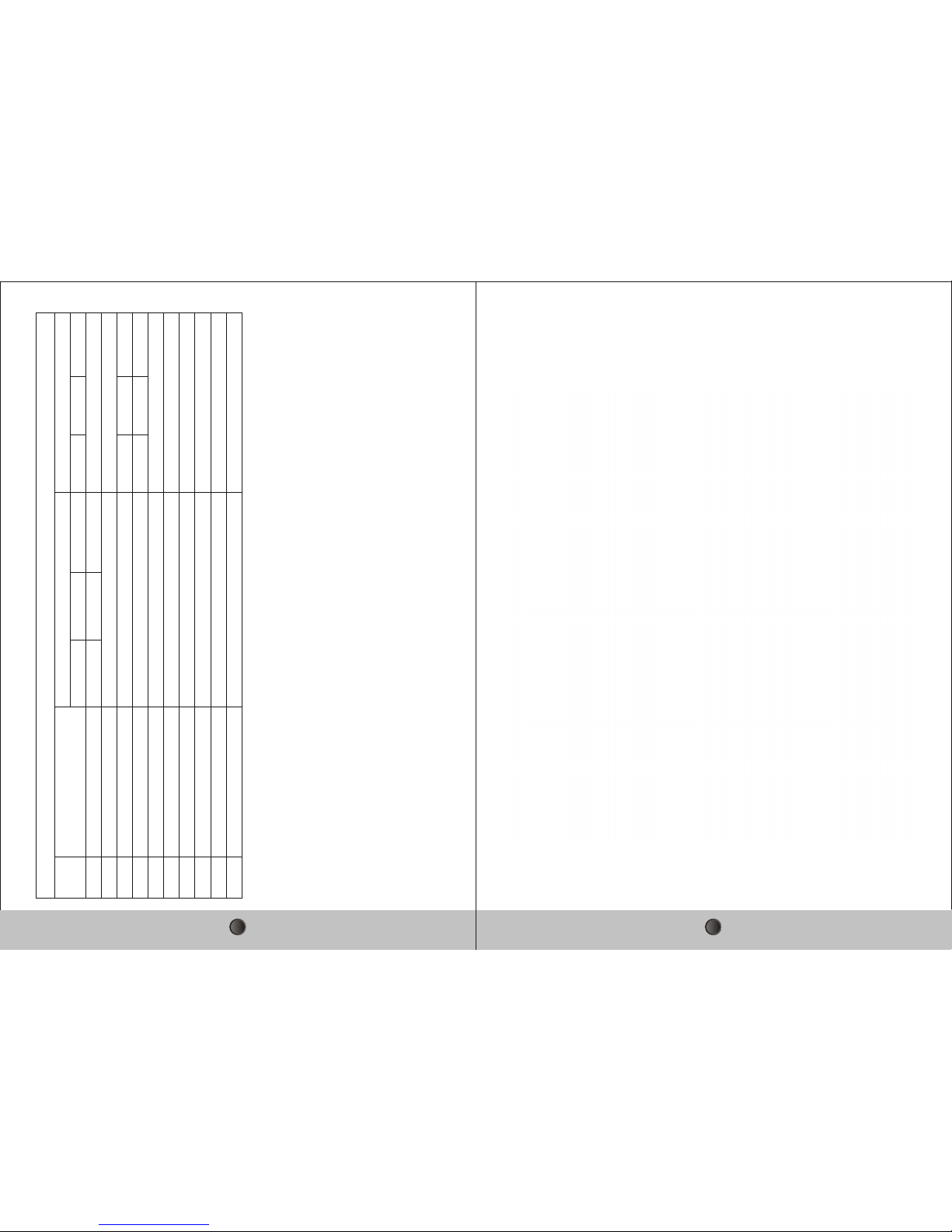

FKDRHD-7 FKDRHD-9 FKDRHD-11 FKDRHD-7 FKDRHD-9 FKDRHD-11

1 FRAME ASSEMBLY FKDRHD-507 FKDRHD-501 FKSLOEHD-508

2 3 POINT LINKAGE ASSEMBLY

3 REAR TYNE ASSEMBLY 4 5 6

4 FRONT TYNE ASSEMBLY 3 4 5

5 HEX. BOLT (M18X65X2P)

6 SPRING WASHER (M18)

7 NYLOCK NUT (M18X2.5P)

8 HITCH PIN

9 SPRING WASHER M25

10 NYLOCK NUT 25MM

FKDRHD-502

FKDRHD-503

DABBANG CULTIVATOR

FKDRHD-504

10270007

10280008

222

2

2

2

QTY

1

1

10260114

10270006

10280020

SR.NO. PARTS DESCRIPTION

PART CODE

10020023

1211

QTY.

111

444

3

111

2

PART NO

FKDRHD-008

FKDRHD-030

FKDRHD-031

10260399

10270004

10280090

10260379

10320007

10260224

10260137

10280033

DESCRIPTION

TYNE 70X25

REAR BRACKET

FRONT BRACKET

HEX HEAD BOLT M14X60

SPRING WASHER 14MM

NYLOCK NUT M14

HEX HEAD BOLT M16X65(FULL THREAD)

DUCKFOOT SHOVEL

SHOVEL BOLT

SHOVEL BOLT

SHOVLE NUT

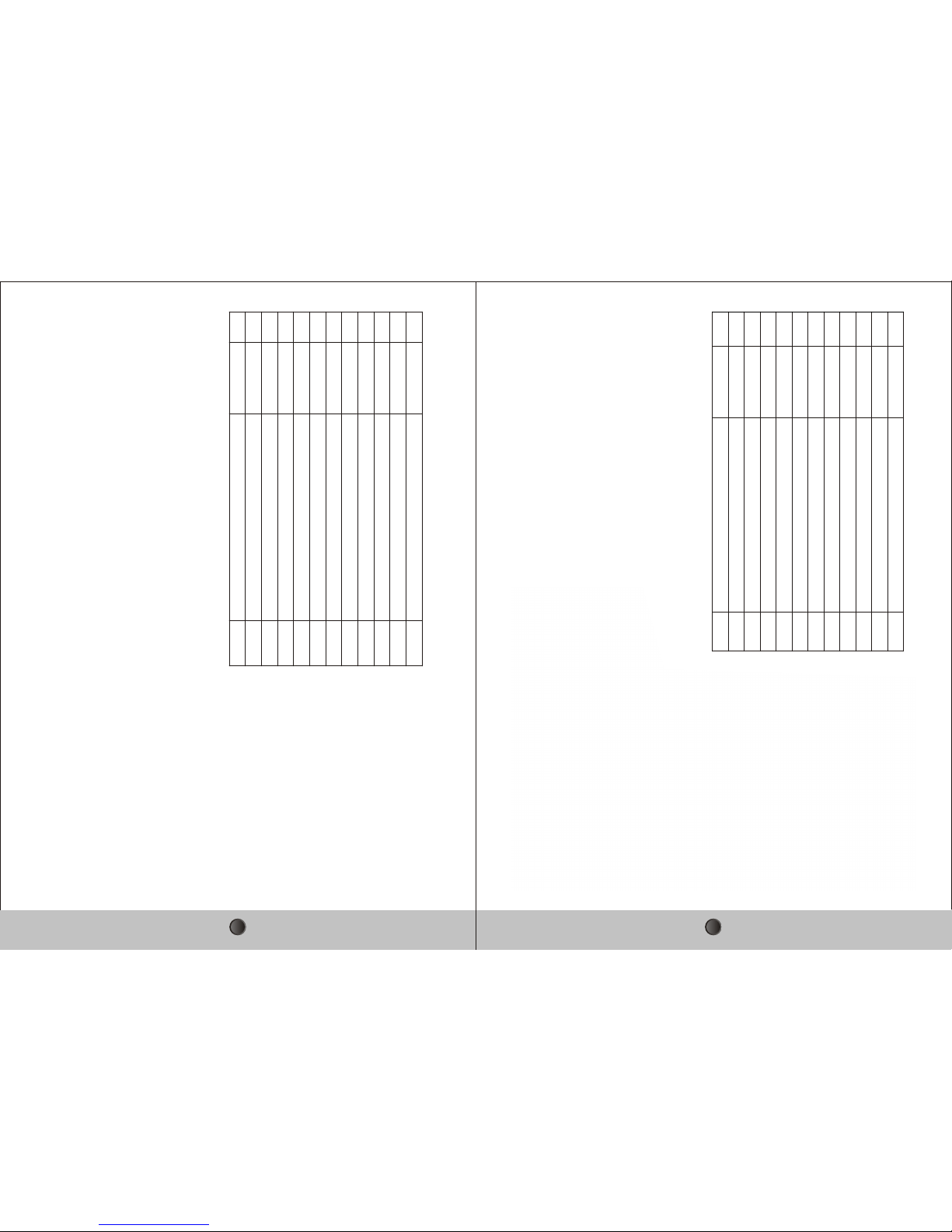

SL. NO.

1

2

3

4

5

6

7

8

9

10

11

SL.NO. DESCRIPTION PART NUMBER QTY.

1 TYNE 70X25 FKDRHD-008 1

2 REAR BRACKET FKDRHD-030 1

3 FRONT BRACKET FKDRHD-031 1

4 HEX HEAD BOLT M14X60 10260399 4

5 SPRING WASHER M14 10270004 4

6 NYLOCK NUT M14 10280090 4

7 HEX HEAD BOLT M16X65(FULL THREAD) 10260379 3

8 SHOVEL 10320005 1

9 SHOVLE BOLT 10260224 1

10 SHOVLE BOLT 10260137 1

11 SHOVEL NUT 10280033 2

13 14

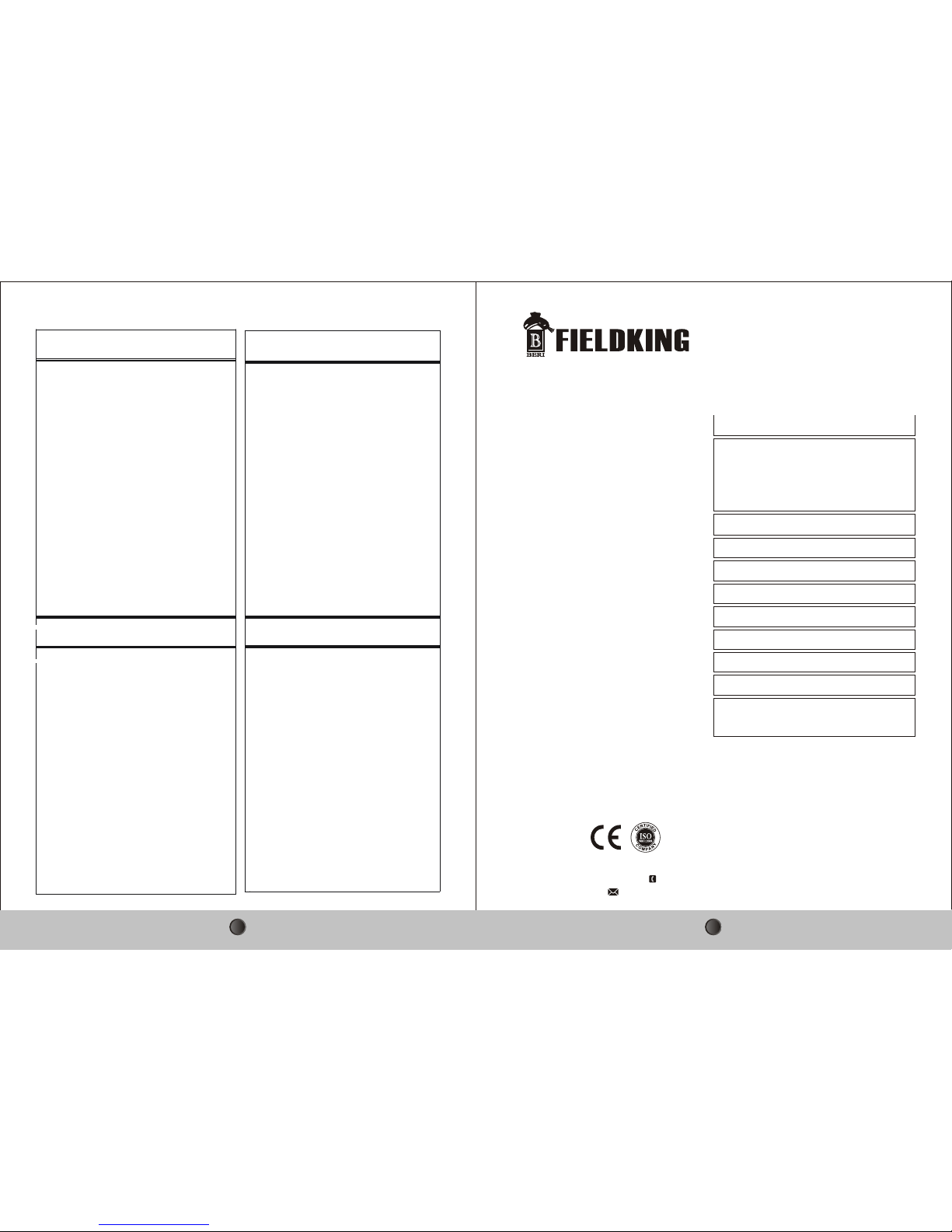

DELIVERY CHECKLIST

Dealer Pre-Delivery (Please Tick)

1. Dealer Pre-Delivery Checklist

1. The customer or person responsible has

been given the operator’s manual.

2. The customer undertakes to read the

co mp le te op erat or ’s m an ua l a nd

understands all aspects of the manual

before operation of the machine.

3. All safety, operational and maintenance

information have been explained and

demonstrated.

4. All greasin g and oil poin ts, stickers,

guarding and ID plate have been identified

and physically pointed out.

5. The c ustomer agre es tha t it is his

responsibility to read and carry out the

safety, maintenance and operation as per

this operator’s manual.

Customer Delivery (Please Tick)

Please Complete all Dealer information Below

Dealer Information

Dealer’s Name..............................................................................

Address........................................................................................

.......................................................................................................

State........................................... Postcode.................................

Phone.......................................... Fax..........................................

Email.............................................................................................

Service Person..............................................................................

I confirm that the pre-delivery service was performed on this machine.

Signature.......................................................................................

Date..............................................................................................

Comments.....................................................................................

.......................................................................................................

.......................................................................................................

Please Complete all Customer Information Below

Customer Information

Customer’s Name.........................................................................

Address........................................................................................

.......................................................................................................

State........................................... Postcode.................................

Phone.......................................... Fax..........................................

Email.............................................................................................

Delivery Person.............................................................................

I confirm that all of the delivery checks were explained and performed.

Signature.......................................................................................

Delivery Date................................................................................

Comments.....................................................................................

.......................................................................................................

.......................................................................................................

2. Customer Delivery Checklist

1. The customer or person responsible has

been given the operator’s manual.

2. The customer undertakes to read the

co mp le te op erat or ’s m an ua l a nd

understands all aspects of the manual

before operation of the machine.

3. All safety, operational and maintenance

information have been explained and

demonstrated.

4. All greasin g and oil poin ts, stickers,

guarding and ID plate have been identified

and physically pointed out.

5. The c ustomer agre es tha t it is his

responsibility to read and carry out the

safety, maintenance and operation as per

this operator’s manual.

WARRANTY CARD

Customer Copy

Customer`s Signature Dealer`s Signature

CUSTOMER NAME Mr./ Mrs :

ADDRESS :

MOBILE NO. :

Email :

NAME OF IMPLEMENT :

MODEL NO. :

YEAR OF Mfg. :

SERIAL NO. :

REGISTRATION NO. :

DATE OF PURCHASING :

NAME OF DEALER :

Corporate Office:

Plot No. 235 to 240, Sec-3, HSIIDC, Karnal- 132001 (Haryana), India

+91 184 2221571/ 72/ 73

info@fieldking.com, www.fieldking.com

BERI UDYOG PVT LTD

15 16

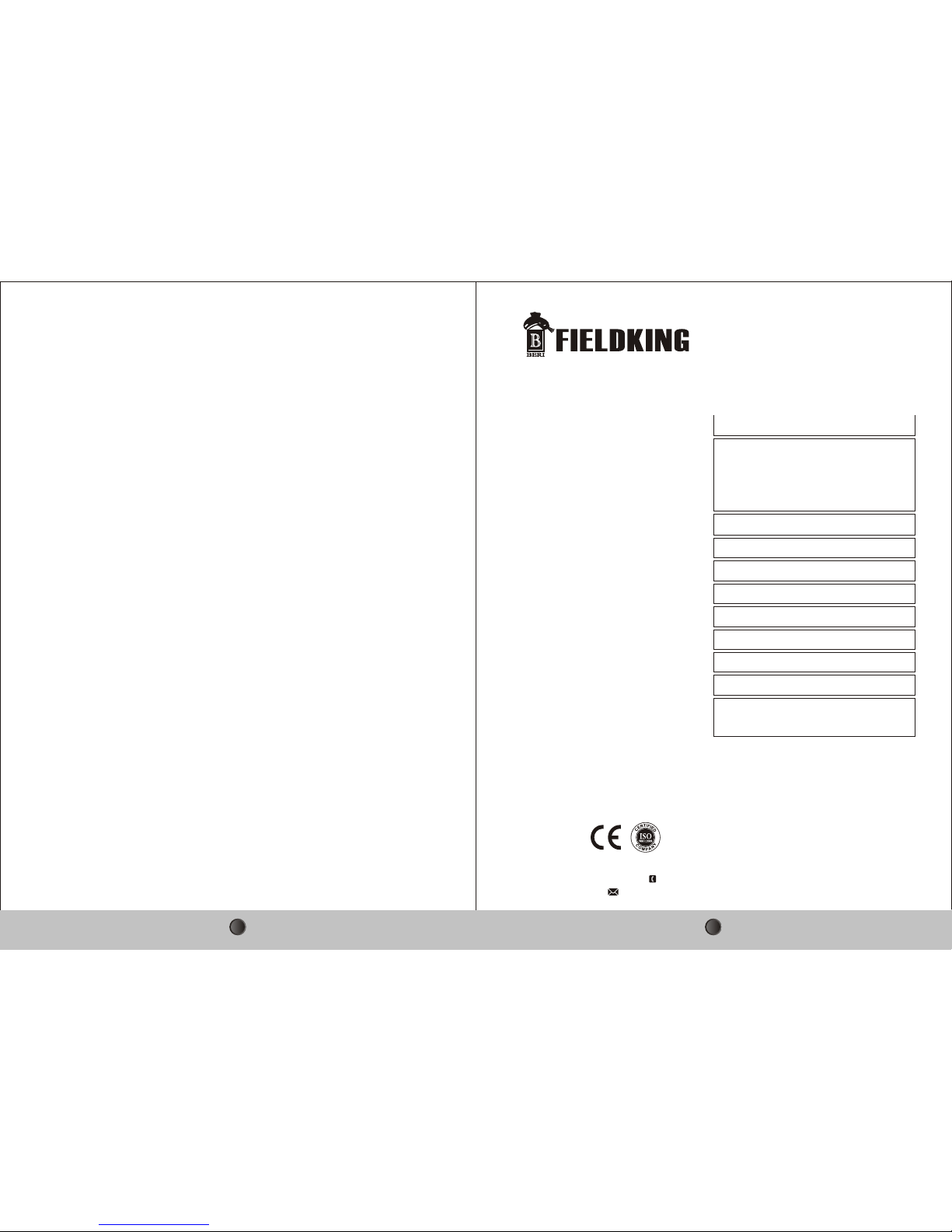

WARRANTY CARD

Company Copy

Customer`s Signature Dealer`s Signature

CUSTOMER NAME Mr./ Mrs :

ADDRESS :

MOBILE NO. :

Email :

NAME OF IMPLEMENT :

MODEL NO. :

YEAR OF Mfg. :

SERIAL NO. :

REGISTRATION NO. :

DATE OF PURCHASING :

NAME OF DEALER :

Corporate Office:

Plot No. 235 to 240, Sec-3, HSIIDC, Karnal- 132001 (Haryana), India

+91 184 2221571/ 72/ 73

info@fieldking.com, www.fieldking.com

BERI UDYOG PVT LTD

Loading...

Loading...