Page 1

,

BLOCKED VENT SWITCH

y

t

r

The WMO-1 Blocked Vent Switch is

Model: WMO-1

recommended for installation with an

oil fired appliance that normall

operates with its vent system under a

I

negative pressure. This device is

intended to detect a blocked ven

system, responds to hot flue gases

backing up through its heat transfe

TEMS SUPPLIED IN THIS KIT:

1-Blocked vent switch assembly

1-Gasket

1-Instruction sheet

tube, and can be wired to shut off the

oil burner. It requires manual resetting.

This device MUST be installed by a qualified agency* in accordance with the manufacturer’s installation instructions.

The definition of a qualified agency is: any individual, firm, corporation or company which either in person or through a

representative is engaged in, and is responsible for, the installation and operation of oil appliances, who is experienced

in such work, familiar with all the precautions required, and has complied with all the requirements of the authority

having jurisdiction.

WARNING: Read the installation instructions carefully and completely before proceeding with the installation.

WARNING:

Do NOT reset the device or restart the appliance unless the cause has been identified and corrected by

a qualified agency. Insure the switch appliance combination has been cleaned by a qualified a gency before placing

back into service. Annual inspection and cleaning by a qualified agency is required.

• Wiring MUST be in accordance with the current Canadian Electric Code and any other applicable federal,

provincial and local code requirements.

• For installations in the USA, all wiring shall be in accordance with the National Electrical Code and applicable local

codes.

• For continued safe operation, the appliance-switch combination is required to be inspected and maintained annually

by a qualified agency. Failure to properly maintain the appliance-switch combination can lead to Death, Personal

Injury and or Property Damage.

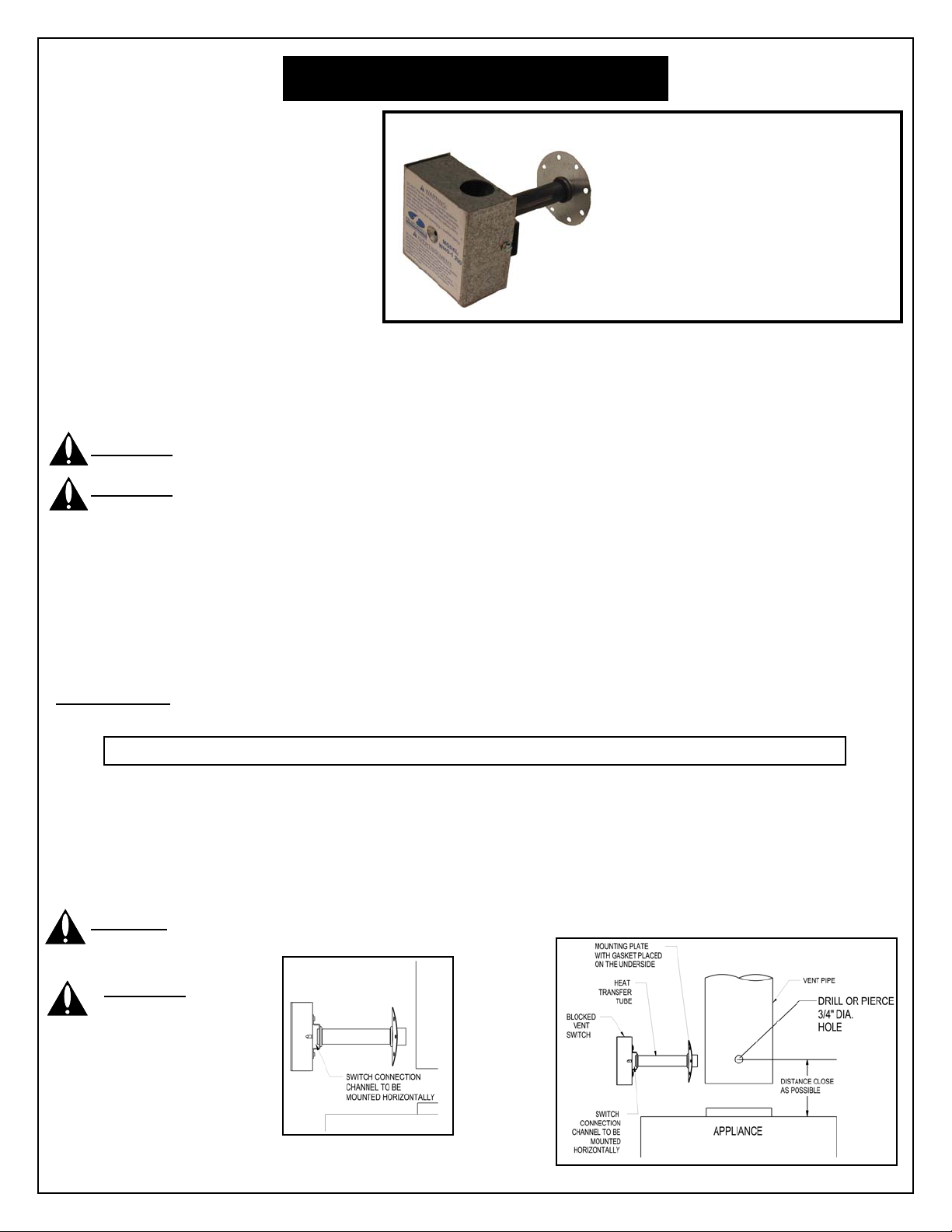

INSTALLATION

M

OUNTING IN THE VENT PIPE

SEE THE APPLIANCE MANUFACTURER’S INSTRUCTIONS FOR THE SPECIFIC LOCATION.

IF THE APPLIANCE MANUFACTURER DOES NOT SPECIFY A LOCATION

REFER TO FIGURE 1.

1. Drill or pierce a clean hole (about 3/4” diameter) in the vent pipe near the appliance outlet. (See Figure 1)

2. The heat transfer tube must have the fiber gasket installed against the mounting plate before attaching the unit to the

vent pipe

3. Insert the heat transfer tube with gasket into the 3/4” diameter hole placed in the vent pipe during step 1.

4. Secure the assembly to the vent pipe with a minimum of 4 sheet metal screws. The channel must be mounted

horizontally, unless specified differently by the appliance manufacturer. (See Figure 1)

CAUTION:

WARNING:

Disconnect electrical power supply to the appliance when wiring the blocked vent switch.

Switch connection

channel must be

mounted horizontally,

unless specified

differently by the

appliance manufacturer.

Figure 1

Page 2

,

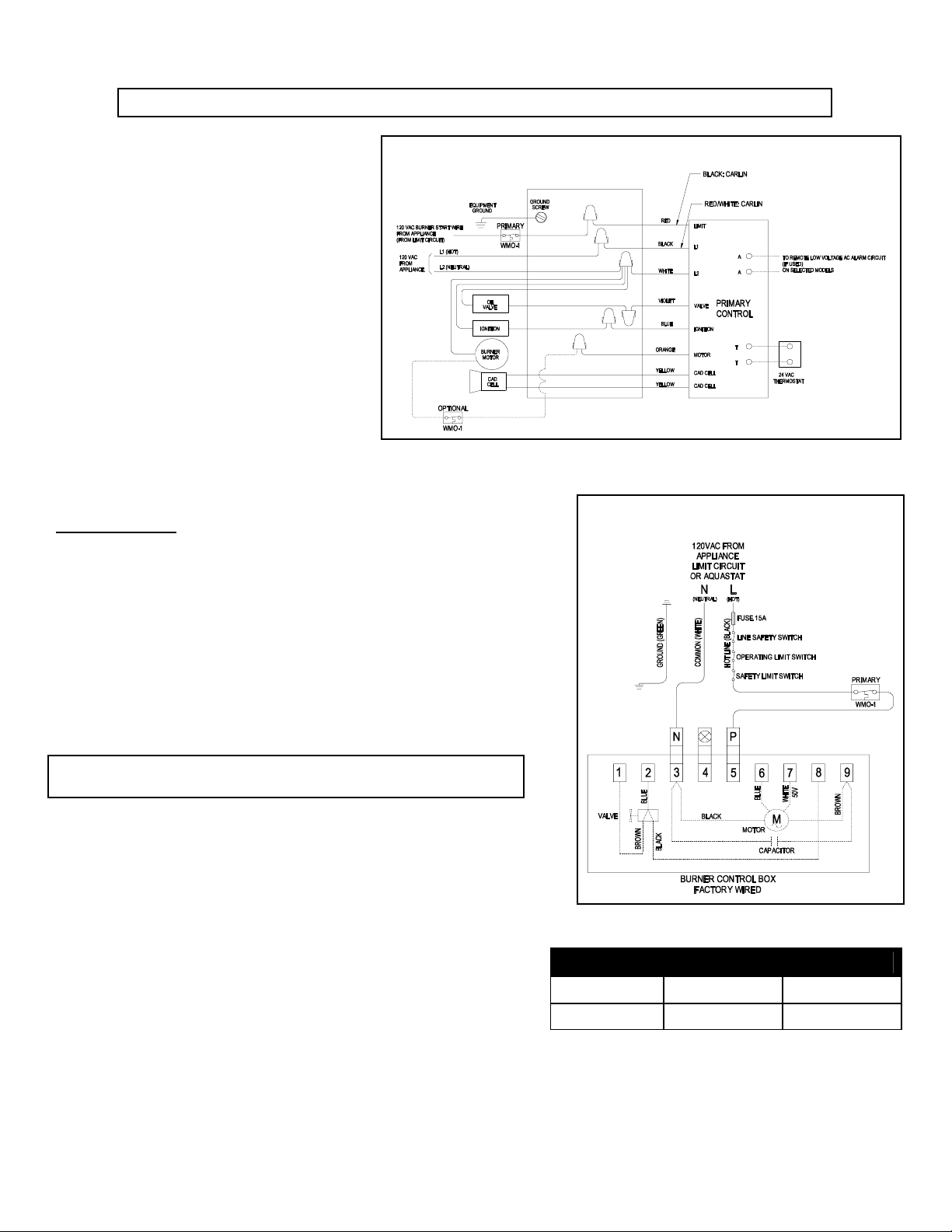

WIRING INSTRUCTIONS

IF THE APPLIANCE MANUFACTURER DOES NOT SUPPLY A WIRING DIAGRAM

FOLLOW THE APPLIANCE MANUFACTURER’S WIRING DIAGRAM.

5. Wire the blocked vent switch in

series with the limit control circuit to

the primary control or as an optional

location in series with the orange

wire from the primary control to the

burner motor. (See Diagram A and

B) Route all wiring with an

acceptable wiring enclosure in

accordance with the current CSA

C22.1 Canadian Electric Code

Part 1 and any other applicable

federal, provincial and local code

requirements. For installations in the

USA all wiring shall be in accordance

with the National Electrical Code

and applicable local codes.

6. The following are typical wiring

diagrams. Read and follow the

appliance manufacturer’s instructions

and wiring diagram.

MAINTENANCE:

REFER TO DIAGRAMS A OR B.

Diagram A

Honeywell R7184B & Carlin 60200-02

Note: For continued safe operation, the appliance-switch

combination is required to be inspected and maintained annually by

a qualified agency.

7. Disconnect power to the appliance.

8. Remove the two screws holding on the WMO-1 blocked vent

switch assembly cover.

9. Remove the cover.

10. Remove the two screws holding the control box to the heat

transfer tube assembly. The control box slides, unlocking it

from the heat transfer tube assembly.

DO NOT DENT OR SCRATCH THE SURFACE OF THE THERMAL SWITCH.

IF THE THERMAL SWITCH IS DAMAGED, REPLACEMENT IS REQUIRED.

11. Carefully remove any buildup from the thermal switch surface.

12. Clear and remove any buildup or obstruction inside the heat

transfer tube.

13. Remount, lock and refasten the control box with the two screws

removed in step 10.

14. Reattach the assembly cover with screws removed in

step 8.

15. Re-establish power to the appliance.

120 VAC

240 VAC

Diagram B

Riello

CURRENT RATING

10 FL AMPS 60 LR AMPS

5 FL AMPS 30 LR AMPS

Page 3

COMMUTATEUR POUR VENTILATION BLOQUÉE

r

r

Il est recommandé d’installer le commutateu

pour ventilation bloquée WMO-1 avec un

appareil au mazout qui fonctionne

normalement avec son système de ventilation

sous dépression. Ce dispositif est prévu pou

détecter un système de ventilation bloqué,

pour répondre aux gaz de cheminée chauds

se formant dans son tube de transfert

thermique et pouvant être câblé pour éteindre

le brûleur à mazout. Il doit être réinitialisé

manuellement.

Ce dispositif DOIT être installé par une agence qualifiée* conformément aux instructions d’installation du fabricant.

Par agence qualifiée, on entend : tout individu, toute firme, toute corporation ou toute société qui, soit en personne soit par le biais

d’un représentant, engagé dans et responsable de l’installation et du fonctionnement des appareils au mazout, ait une expérience

dans ledit domaine, connaisse toutes les précautions requises et respecte toutes les exigences de l’autorité ayant juridiction.

Modèle : WMO-1

A

RTICLES FOURNIS DANS CE KIT :

1-Ensemble de commutateur pour

ventilation bloquée

1-Joint

1-Fiche d’instructions

AVERTISSEMENT : Lire attentivement et intégralement les instructions relatives à l’installation avant d’entreprendre

l’installation.

AVERTISSEMENT :

NE PAS réinitialiser le dispositif ou remettre l’appareil en marche avant d’avoir identifié la cause

et de l’avoir faite rectifier par une agence qualifiée. S’assurer que la combinaison commutateur-appareil a été

nettoyée par une agence qualifiée avant la remise en service. Une agence qualifiée doit procé der à une inspection et

un nettoyage annuels.

• Le câblage DOIT être conforme aux exigences en cours du Code canadien de l’électricité et de tout autre code

en vigueur aux niveaux fédéral, provincial et local.

• Pour les installations aux États-Unis, tout le câblage sera conforme au Code national de l’électricité et aux codes

locaux en vigueur.

• Pour un fonctionnement continu en toute sécurité, la combinaison appareil-commutateur doit faire l’objet d’une

inspection et d’un entretien, une fois par an, par une agence qualifiée. Un mauvais entretien de la combinaison

appareil-commutateur peut entraîner la mort, des blessures corporelles et/ou des dégâts matériels.

INSTALLATION

M

ONTAGE DANS LE TUYAU DE VENTILATION

VOIR INSTRUCTIONS DU FABRICANT DE L’APPAREIL POUR CONNAITRE L’EMPLACEMENT SPÉCIFIQUE.

SI LE FABRICANT DE L’APPAREIL NE SPÉCIFIE PAS D’EMPLACEMENT, CONSULTER LES FIGURE 1.

1. Percer un trou net [d’environ 1,9 cm (3/4") de diamètre] dans le tuyau de ventilation à proximité de la prise de

l’appareil. (Voir figure 1.)

2. Le tube de transfert thermique doit être muni d’un joint en fibre installé contre la plaque de fixation avant d’attacher

l’unité au tuyau de ventilation.

3. Insérer le tube de transfert thermique avec le joint dans le trou de 1,9 cm (3/4") de diamètre placé dans le tuyau de

ventilation à l’étape 1.

4. Fixer l’ensemble au tuyau de ventilation avec au moins 4 vis auto-taraudeuses. Le canal doit être monté

horizontalement, à moins que ce ne soit indiqué différemment par le fabricant d'appareils. (Voir figure 1.)

ATTENTION :

Débrancher toute alimentation électrique à l’appareil lors du câblage du commutateur pour

ventilation bloquée.

AVERTISSEMENT :

Le canal de connexion

de commutateur doit

être monté

horizontalement, à

moins que ce ne soit

indiqué différemment

par le fabricant

d'appareils.

Figure 1

Page 4

,

INSTRUCTIONS RELATIVES AU CABLAGE

SI LE FABRICANT DE L'APPAREIL NE FOURNIT PAS DE SCHÉMA DE CABLAGE

SUIVRE LES INSTRUCTIONS DU SCHÉMA DE CABLAGE DU FABRICANT DE L'APPAREIL.

5. Câbler le commutateur pour ventilation

bloquée en série, le circuit limiteur à

l’appareil de commande ou comme

emplacement facultatif en série avec le

fil orange de l’appareil de commande

au moteur du brûleur. (Voir Schémas A

et B.) Acheminer tout le câblage muni

FIL DE DÉM ARRAGE D E 12 0

V c.a. DU BRÛL EUR, À

PARTIR D E L’APPAREIL

(DU CIRC UIT D U LIM ITEUR)

L1 (CHAUD )

120 V c.a.

DE

L2 (NEUTRE)

L’APPARE IL

TERRE DE

L’ÉQUIPEMENT

PRIMAI RE

WMO-1

VIS DE

TERRE

d’une gaine de câble acceptable

conformément aux exigences en cours

de la norme CSA C22.1 Code

canadien de l’électricité Partie 1 et de

tout autre code en vigueur aux niveaux

fédéral, provincial et local. Pour les

installations aux États-Unis, tout le

câblage sera conforme au Code

national de l’électricité et aux codes

locaux en vigueur.

EN OPTION

WMO-1

SOUPAPE DE

MAZOUT

ALLUMAGE

MOTEUR DU

BRÛLEUR

CELLULE

AU CdS

6. Les schémas suivants sont des

schémas de câblage types. Lire et

Honeywell R7184B et Carlin 60200-02

suivre les instructions et le schéma

de câblage du fabricant de l’appareil.

ENTRETIEN :

Remarque : Pour un fonctionnement continu en toute sécurité, la

combinaison appareil-commutateur doit faire l’objet d’une inspection et

d’un entretien, une fois par an, par une agence qualifiée.

7. Débrancher toute alimentation à l’appareil.

8. Dévisser les deux vis qui maintiennent le couvercle de l’ensemble

de commutateur pour ventilation bloquée WMO-1.

9. Retirer le couvercle.

10. Retirer les deux vis qui maintiennent le boîtier de commande à

l’ensemble du tube de transfert thermique. Le boîtier de commande

coulisse, en le débloquant de l’ensemble du tube de transfert

thermique.

NE PAS BOSSELER NI RAYER LA SURFACE DU COMMUTATEUR THERMIQUE.

SI LE COMMUTATEUR THERMIQUE EST ENDOMMAGÉ, IL FAUT LE

REMPLACER.

11. Retirer avec soin tout dépôt de la surface du commutateur

thermique.

12. Dégager et éliminer tout dépôt ou toute obstruction à l’intérieur du

tube de transfert thermique.

13. Remonter, verrouiller et refixer le boîtier de commande à l’aide des

deux vis qui avaient été retirées à l’étape 10.

14. Remonter et fixer le couvercle de l’ensemble à l’aide des

vis qui avaient été retirées à l’étape 8.

15. Rebrancher toute alimentation à l’appareil.

CONSULTER LE SCHÉMA A OU B.

NOIR : CARLI N

ROUGE/BLANC : CARLIN

ROUGE

LIMITEUR

NOIR

BLANC

MAUVE

SOUPAPE

COMMANDE

ALLUMAGE

MOTEUR

CELLULE

AU CdS

CELLULE

AU CdS

PRINCIPALE

BLEU

ORANGE

JAUNE

JAUNE

Schéma A

SOUPAP E

BRUN

120 V c. a. DU CIRCUIT

LIMITEUR OU DE

(NEUTRE)

TERRE (VERT)

BLEU

NOIR

BOÎTIER DE COMMANDE DU

BRÛLEUR, CÂBLÉ À L’USINE

L’AQUASTAT

(CHAUD)

(NOIR)

LIGNE SOUS TENSION

COMMUN (BLANC)

NOIR

Schéma B

Riello

COURANT NOMINAL

120 c.a.

240 c.a.

10 FL A 60 LR A

5 FL A 30 LR A

VERS L E CIRC UIT À D IST ANCE D E

L’ALARM E c.a. DE FAIBLE TE NSION (S I

UTILISÉ )

SUR CERT AINS M ODÈ LES

THERMOSTAT

DE 24 V c.a.

FUSIBLE 15 A

CONT ACTE UR DE S ÉCURIT É

DE LIGNE

CONT ACTE UR DE L IMIT EUR E N

FONCT IONNE MENT

CONT ACTE UR DE L IMIT EUR D E

SÉCURITÉ

BLEU

BLANC

MOTEUR

CONDENSATEUR

PRIMAIRE

WMO-1

BRUN

For Technical Support

call…

1-800-742-VENT

Pour le service technique,

appeler …

1 800 742-VENT

2630 Airport Road, Kinston, NC 28504

www.fieldcontrols.com

P/N 46086800 Rev D 07/06

Loading...

Loading...