Page 1

SIDEWALL POWER VENTER KIT

Model: SWGII-5,6 AGA and SWG-8*

FOR COMMERCIAL WATER HEATERS

TYPICAL VENTING SYSTEM COMPONENTS:

*Patented

PART

NUMBER

239-81764-00

239-81765-00

239-81766-00

239-81767-00

239-82148-00

DESCRIPTION APPLICATION

SWGII-5 POWER VENTER,

CK-41 24 VOLT CONTROL KIT

SWGII-5 POWER VENTER,

CK-81 MILLIVOLT CONTROL KIT

SWGII-6 POWER VENTER,

CK-41 24 VOLT CONTROL KIT

SWGII-6 POWER VENTER,

CK-81 MILLIVOLT CONTROL KIT

SWG-8 POWER VENTER,

CK-41 24 VOLT CONTROL KIT

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

COMMERCIAL WATER HEATERS WITH 24 VOLT

CONTROLS WITH INPUT RATINGS OF UP TO 290,000

BTU/HR.

COMMERCIAL WATER HEATERS WITH MILLIVOLT

CONTROLS WITH INPUT RATINGS OF UP TO 290,000

BTU/HR.

COMMERCIAL WATER HEATERS WITH 24 VOLT

CONTROLS WITH INPUT RATINGS GREATER THAN

290,000 BTU/HR. UP TO 416,000 BTU/HR.

COMMERCIAL WATER HEATERS WITH 24 VOLT

CONTROLS WITH INPUT RATINGS GREATER THAN

290,000 BTU/HR. UP TO 416,000 BTU/HR.

COMMERCIAL WATER HEATERS WITH 24 VOLT

CONTROLS WITH INPUT RATINGS GREATER THAN

415,000 BTU/HR.

Page 2

CONTROL KITS

Page 2

1. For 24 volt control systems (intermittent pilot ignition): CK-41 control kit with the following components: Junction box

with mounted pressure switch and relay base, 24 volt relay for controlling power venter motor, 1 ft. length of 0.25"

aluminum tubing, 0.25" tubing connector, flexible metal clad conduit, GSK-3 spillage switch, wiring harness (30 ft.

length) to connect power venter control to water heater controls, 3 cable clamps to fasten the harness.

2. For millivolt control systems (standing pilots): CK-81 control kit with the following components: Junction box with

mounted pressure switch, 115V to 24V transformer, and 24 volt relay, 1 ft. length of 0.25" aluminum tubing, 0.25"

tubing connector, flexible metal clad conduit, GSK-3 spillage switch, wiring harness (30 ft. length) to connect power

venter control to water heater controls, 3 cable clamps to fasten the harness.

GENERAL SYSTEM OPERATION

POWER VENTER KITS FOR 24 VOLT CONTROLS (CK-41 CONTROL KIT)

1. The water heater aquastat contacts close and the flue damper (if part of water heater) opens. When the damper

opens all the way, the end switch contacts in the damper motor close, completing the 24 volt circuit to the CK-41

control box causing the motor relay contacts to close and start the power venter motor.

2. When the power venter blower reaches operating speed, the resulting vacuum cause the pressure switch contacts to

close. The 24 volt control circuit flows through the pressure switch contacts in the CK-41 control box and through the

normally closed spillage switch contacts on the draft hood, completing the circuit to the ignition module on the water

heater control box. The ignitor lights the pilot and the main gas valve opens causing the main burners to light.

3. If the venting system becomes disconnected or plugged between the power venter and the water heater vent

connection, the flue products will spill out of the draft hood relief opening, heat up the spill switch temperature disc

and cause the contacts to open and interrupt power to the ignition module causing the gas valve to close and stop the

burners. If the power venter blower fails to operate, the pressure switch contacts will not close and the burners remain

off.

4. When the aquastat is satisfied, the contacts open and stop the power venter, interrupting power to the ignition module

and gas valve, and the flue damper closes.

POWER VENTER KIT FOR MILLIVOLT CONTROLS (CK-81 CONTROL KIT)

1. When the aquastat contacts close, the 24 volt circuit is completed from the transformer, through the wiring harness

and switch contacts, and through the relay coil causing the motor relay contacts to close and start the power venter

blower.

2. When the blower reaches operating speed, the vacuum near the blower causes the pressure switch contacts to close

and complete the millivolt circuit through the normally closed spill switch contacts to the gas valve, allowing main gas

to flow to the burners and ignite from the pilot.

3. If the venting system becomes disconnected or plugged between the power venter and the water heater vent

connection, the flue products will spill out of the draft hood relief opening, heat up the spill switch temperature disc

and cause the contacts to open and interrupt the millivolt circuit to the gas valve and stop all gas flow. If the power

venter blower fails to operate, the pressure switch contacts will not close and the burners remain off. If the pilot

becomes extinguished, the thermopile stops generating millivolt power and the gas valves remain closed until the pilot

is relit.

4. When the aquastat is satisfied, the contacts open and stop the power venter, causing the power to be interrupted to

the ignition module and gas valve, and the flue damper closes.

INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a qualified installer in accordance with the

manufacturer's installation instructions. Appliances should have a minimum of 75%

combustion efficiency or have a maximum measured flue gas temperature of 550EF at the

inlet of the power venter.

1. The power venting system must be installed by a qualified installer. "Qualified Installer"

shall mean an individual who has been properly trained or is a licensed installer. The installer must write or imprint his name, phone number and date of installation on the

installation tag. The tag should be attached to the system control kit box or power

venter unit. Also, the included adhesive "Warning!" label should be attached to the

Control Kit box, as shown in Figure 1, and the installers name be written on it. Recording burner and venting system

initial operational information is strongly recommended as a guide for service or burner tune-up. Enter this on the back

page of this manual. The appropriate wiring diagram for the type of controls on the water heater must be affixed to the

water heater jacket upon completion of the installation.

Figure 1

Page 3

2. Safety inspection of a venting system should be performed before and after installing a power venting system on an

Page 3

existing or new appliance. Procedures to follow are those recommended by the National Fuel Gas Code,

A.N.S.I.Z223.1, or refer to General Installation Inspection section of this manual.

3. Plan the vent system layout before installation to avoid the possibility of accidental contact with concealed wiring or

plumbing inside walls.

4. Single wall vent pipe (refer to Diagram B) may be used to join an appliance to the venting system, but if proper

clearances cannot be maintained from combustible materials, Class B Vent Pipe should be used. Refer to national or

local codes for guidelines.

5. Disconnect power supply before making wiring connections to prevent electrical shock and equipment damage.

6. This equipment is designed to overcome minor negative pressure conditions. To ensure extreme negative pressure

does not exist, follow General Installation Inspection of this manual.

7. The commercial water heaters for the SWGII-5 and 6 power venters have draft hoods and each kit includes a GSK-3

spillage switch which must be installed on the bottom of the draft hood to detect spillage of flue products due to

inadequate venting draft or vent system blockage. In the event of excessive flue spillage from the draft hood, the

spillage switch will interrupt power to the gas valve to stop the burners. Refer to the installation instructions for the

spillage switch in the installation section of these instructions.

8. The power venter must be installed downstream of the appliance draft hood.

INSTALLATION OF SWG POWER VENTER

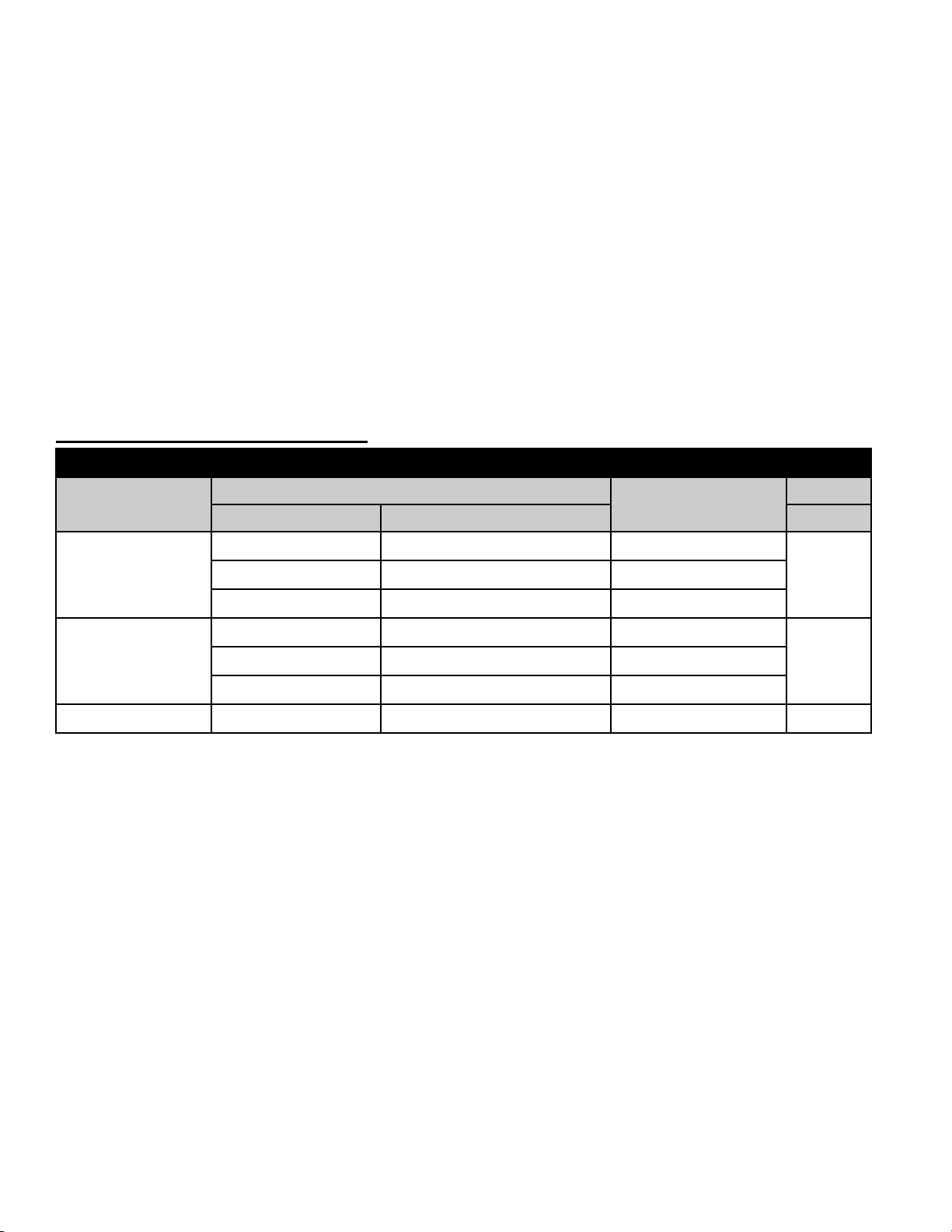

UNIT SIZING CHART

MAXIMUM BTU/HR

INPUT*

MAX. EQUIVALENT FEET OF VENT PIPE MODEL

AT MAXIMUM INPUT AT 60% OF MAXIMUM INPUT

VENTING WITH VENT

PIPE SIZE

16 44 4”

290,000

51 100 5”

95 100 6”

28 78 5”

416,000

68 100 6”

100 100 7”

505,000 65 65 10” SWG-8

*

Do not exceed maximum BTU/HR input rating.

NUMBER

SWGII-5

SWGII-6

Page 4

PROCEDURE FOR CALCULATING TOTAL EQUIVALENT PIPE LENGTH IN FEET

Page 4

1. Calculate the total equivalent feet for each type of fitting used in the venting system from the chart below.

2. Calculate the total amount of feet for the straight lengths of vent pipe.

3. Add the equivalent feet for the fittings with the total amount of feet of straight lengths. This will approximate the total

equivalent feet of the vent system.

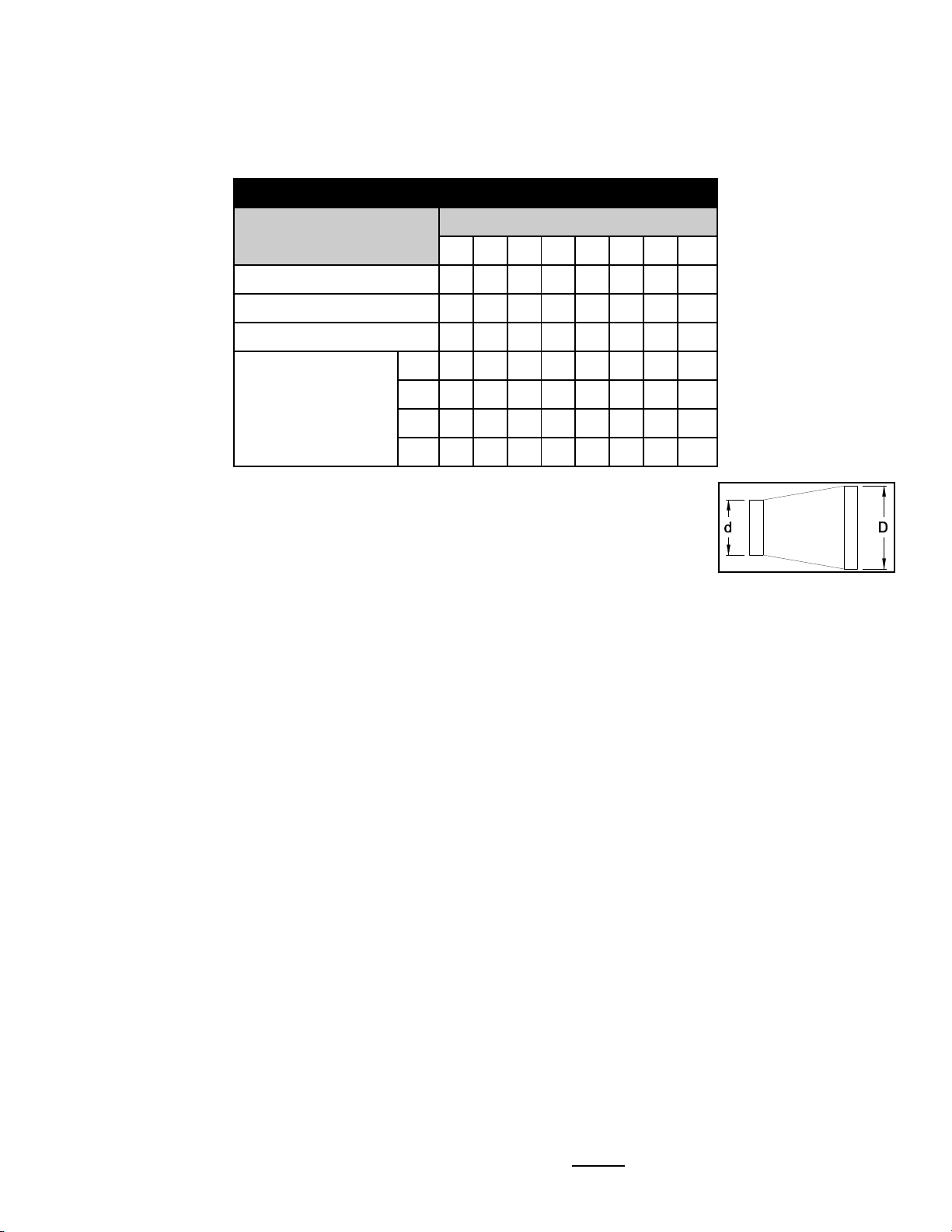

EQUIVALENT LENGTH (FEET) OF VENT PIPE FOR VENT PIPE

VENT PIPE FITTINGS

VENT PIPE DIAMETER

3” 4” 5” 6” 7” 8” 9” 10”

TEE 19 25 31 38 44 50 56 63

90° ELBOW 5 7 9 11 12 14 16 18

45° ELBOW 3 4 4 5 6 7 8 9

d/D

SUDDEN REDUCER

OR INCREASER

FOR THREE

RATIOS* (d/D)

¼ 8 11 14 17 19 22 25 28

½ 5 7 8 10 12 13 15 17

¾ 2 3 3 4 4 5 6 6

*Reducer or increaser ratio (d/D) small diameter divided by the larger diameter. (See Figure

2) Example 4" to 8" reducer: The reducer ratio is d/D = 4/8 = 1/2. To estimate the equivalent

foot length for the fitting, use the smaller pipe diameter for the equivalent length figure.

Example 4" to 8" reducer; the reducer ratio is 1/2 and the smaller pipe diameter is 4". So,

from the chart, the equivalent feet would be 7 feet.

Figure 2

Example 1: System Pipe Size = 4" Example 2: System Pipe Size =

10"

Step 1 Two 4" 90E Elbows @ 7 feet each = 14 Ft. Step 1 Fifteen 2 Foot Lengths of 10” Pipe = 30 Ft.

Step 2 Ten 2 Foot Lengths of 4" Pipe = 20 Ft. Step 2 One 10” 90° Elbow = 18 Ft.

Step 3 Total Equivalent Feet = 14 Ft. + 20 Ft. = 34 Ft. Step 3 One 8” to 10” Reducer (Use ¾) = 5 Ft.

Step 4 Total Equivalent Feet = 30 Ft. + 18 Ft. + 5 Ft. = 53 Ft.

CAUTION: Failure to install, maintain and/or operate the power venting system in accordance with manufacturer's

instructions will result in conditions which may produce bodily injury and/or property damage.

1. Remove power venter from box and inspect unit for damage. If the carton has been crushed or mutilated, check unit

very carefully for damage. Rotate blower wheel to insure that the motor and blower wheel rotate freely. DO NOT

install if any damage is apparent. Refer to unit sizing chart to check proper venting sizing.

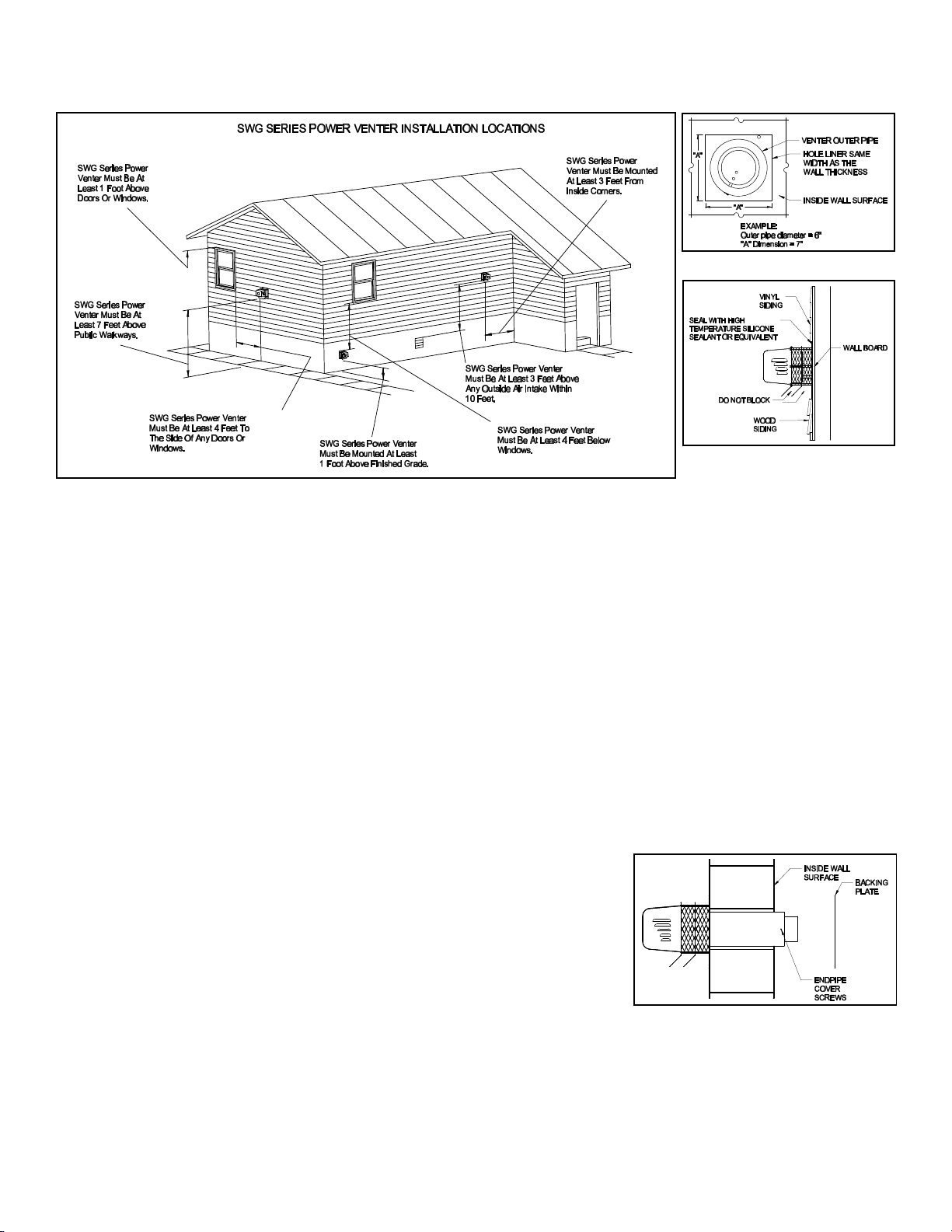

2. Location of the termination of the venting system should be installed in accordance with the National Fuel Gas Code,

A.N.S.I.Z223.1, and/or manufacturer's recommendations which are applicable. See requirements below or refer to

installation location Diagram A for typical locations.

a. The exit termination of mechanical draft systems shall not be less than 7' above grade when located adjacent to

public walkways.

b. A venting system shall terminate at least 3' above any forced air inlet located within 10'.

c. The venting system of other than a direct vent appliance shall terminate at least 4' below, 4' horizontally from, or

1' above any door, window or gravity air inlet into the building.

d. The vent termination of a direct vent appliance with an input of 50,000 BTU's per hour or less, shall be located at

least 9" from any opening through which vented gases could enter the building. With an input over 50,000 BTU's

per hour, a 12" termination clearance shall be required.

e. The vent termination point shall not be installed closer than 3' from an inside corner of an L-shaped structure.

f. The vent termination should not be mounted directly above, or within 3' horizontally from an oil tank vent or gas

meter.

g. The bottom of the vent terminal shall be located at least 12" above finished grade.

Page 5

Diagram A

Page 5

Figure 3

Figure 4

3. After determining the location of the venting system termination point (See Diagram A), cut a square hole through the

wall 1" larger than the outer pipe diameter of the power venter. Mount the power venter through the wall, keeping the

outer pipe centered in the hole. (See Figure 3) Fasten the power venter to the outside wall with appropriate fasteners.

Seal the edges of the power venter base plate to the wall with a high temperature silicone sealant. DO NOT enclose

the spaced plates on the power venter body. This will result in reduced cooling of the power venter body. Galvanized

metal sheets may be installed over surrounding building surfaces to protect building materials for degradation by flue

gases. Brick or tile may be placed on the ground below the power venter to protect the soil and vegetation from the

effects of heated exhaust air. The power venter should be placed so that vegetation and other objects are not in direct

contact with the power venter or blocking the outlet. Snow should be cleared from the outlet area as needed. Wood or

vinyl siding should be cut so that the unit mounts directly on the wall board to provide a stable support. If the siding is

greater than 1/2" thick use a spacer plate or board behind the power venter mounting plate. (See Figure 4)

NOTE: If mounting the power venter through a combustible wall material and the flue gas temperature is above 400EF at

the power venter inlet, line the square hole with a piece of corrosion resistant sheet metal or non-combustible material.

The liner piece should be the same width as the wall section. (See Figure 3) The power venter has maximum flue gas

temperature of 550EF at the power venter inlet. Figure 7 shows how the airflow pattern through an SWG reduces the

required clearances to combustibles. For installation in wall thickness over 8-inches, use an SWG Series Through Wall

Extension Kit, Model PEK.

4. Remove the end pipe cover screws on the sides of the outside pipe and

remove end pipe cover. Then mount the backing plate over the outer pipe and

route the flexible conduit and pressure switch tube through the holes provided

in the backing plate. Fasten the backing plate to the inside wall with appropriate fasteners. (See Figure 5) Re-install end pipe cover and screws.

CONNECTING POWER VENTER TO APPLIANCE

Venting system should be installed and supported in accordance with the National

Flue Gas Code A.N.S.I.Z223.1, or in accordance with any local codes. A vent

pipe connector shall be supported for the design and weight of the material

Figure 5

employed, to maintain clearances, prevent physical damage and separation of joints. A vent pipe increaser or reducer

may be required for connecting the power venter to the vent system. If needed, place the reducer close to the power

venter. Smaller vent pipe sizes than a chimney-vented system may be used for the vent system.

Page 6

If mounting venting system near combustible materials, refer to Diagram B for allowable installation clearances.

Diagram B

Page 6

Clearances are based on an installation using single wall galvanized steel vent pipe. For metal thickness of galvanized

steel pipe connectors, refer to NFPA 211 or NFPA 54 Standards for guidelines. If manufactured double wall vent pipe is

required or used for the installation, clearance should be based on the vent pipes rated clearance. Always check local

code requirements for code restrictions.

Route the vent pipe from the appliance to the power venter using a minimum number of elbows as possible. The

horizontal section of the vent pipe should have a slight upward slope from the appliance to the power venter. For

clearances to combustible materials, multiple appliance venting and other installation requirements, refer to the National

Fuel Gas Code A.N.S.I.Z223.1, and/or any applicable local codes or appliance manufacturer's installation instructions.

INSTALLATION USING SINGLE WALL VENT PIPE

INSTALLATION CLEARANCE WITH SINGLE WALL VENT PIPE

DOUBLE PIPE SYSTEM SINGLE PIPE SYSTEM

ALLOWABLE INLET

TEPERATURE

CLEARANCE (A)

ALLOWABLE INLET

TEMPERATURE

CLEARANCE (B)

400°F OR LESS ½ INCH MINIMUM 400°F OR LESS 3 INCH MINIMUM

400°F TO 550°F 1 INCH MINIMUM 400°F TO 550°F 4 INCH MINIMUM

400°F TO 550°F

½ INCH MINIMUM WITH

SHEET METAL LINER

400°F TO 550°F

3 INCH MINIMUM WITH

SHEET METAL LINER

To install an outer pipe extension to the SWG power venter, the end pipe cover on the power

venter must be removed. Then, cut a 1-inch square notch into the vent pipe extension before

attaching to the power venter. (See Figure 6) This allows clearance for the adjustment damper.

Install the required length of outer pipe extension lengths as needed for clearance to combustible

materials. Terminate the outer pipe extension with the end pipe cover. (See Diagram B) The table

shows minimum allowable clearances when using single or double pipe systems. When the outer

pipe is extended over the inner pipe use the double pipe guidelines when determining clearances.

NOTE: Vent pipe joints should be secured with at least (3) three sheet metal screws.

Figure 6

Figure 7

Page 7

CLASS B AND CLASS L DOUBLE WALL VENT PIPE INSTALLATION

Page 7

(Follow vent pipe manufacturer's listed or recommended clearances from combustible material.)

5. Using a hand crimper or a like device, crimp the inner pipe of the SWG power

venter approximately 1" long. (See Figure 8)

6. Attach the vent pipe over the crimped end of the SWG power venter inner pipe.

7. Secure the vent pipe to the SWG power venter inner pipe with at least (3) three

#8 sheet metal screws. Predrilling the holes through both pipes will allow easier

fastening.

WIRING INSTRUCTIONS

Figure 8

NOTE: Refer to the appropriate wiring diagrams contained in these instructions for the corresponding control system for

the water heater being installed.

Wire the power venter motor and controls in accordance with the National Electric Code and applicable local codes. UNIT

MUST BE GROUNDED. Check ground circuit to make certain that the unit has been properly grounded. The wiring

should be protected by an over-current circuit device rated at 15 amperes. CAUTION MUST be taken to ensure that the

wiring does not come in contact with any heat source. All line voltage and safety control circuits, between the power

venter and the appliance, MUST be wired in accordance with the National Electrical Code for Class 1 wiring or equivalent.

CK-41 CONTROL KIT WIRING FOR 24 VOLT WATER HEATER CONTROLS

1. Remove the wiring harness supplied with the

control kit.

2. Remove the upper left knockout of the control

box. Push the snap bushing supplied over the

knockout hole created to prevent the wires

from being chafed. Insert the end of the

harness with quick connect terminals into the

side of the control box.

3. Disconnect the black wire connected to "TH"

or "24V" on the ignition module and connect to

the fully insulated tab on the black wire from

the wiring harness provided.

4. Connect the yellow wire from the harness

supplied to the "TH" or "24V" terminal on the

ignition module.

5. Connect the red wire from the harness

supplied to the upper terminal block (the

group of terminals opposite the yellow wire

leading to the thermostat).

6. Run the harness supplied along the water

heater jacket and support with the clamps

provided. (See Figure 9)

7.

Figure 9

Page 8

Install the GSK-3 spillage switch on the draft hood with the self-

Figure 10

Page 8

tapping sheet metal screw supplied. The thermal element disc

should hang just below the draft hood relief opening. (See

Figure 10)

8. Run the two (2) yellow wires from the break in the top of the

wiring harness into the spillage switch through the plastic

bushing opening and connect to the switch terminals.

9. Run the harness to the CK-41 junction box, which will be

mounted in a convenient location near the power venter. Use

clamps to support the wire harness to the joists at regular intervals to prevent sagging.

10. Run the low voltage wires into the control box (through hole with plastic bushing) and connect the wires as follows:

Connect the black wire to terminal T1, the red wire to T2, and the yellow wire to T3. (See Figures 11 and 12)

11. Follow the National Electrical Code and or applicable local codes for running high voltage wires to the CK-41 control

box an wire according to the diagram. Unit must be grounded. Check ground circuit to make sure the unit has been

properly grounded. Connect the flexible conduit from the blower to the control box and wire according to the diagram.

12. Attach the appropriate self-adhesive wiring diagram label to the water heater jacket.

Page 9

Figure 11

Page 9

Page 10

Figure 12

Page 10

Page 11

CK-81 CONTROL KIT WIRING FOR MILLIVOLT WATER HEATER CONTROLS

Figure 13

Page 11

1. Remove wiring harness from control kit

box.

2. Remove top knockout from the thermostat.

Push the snap bushing supplied over the

knockout hole created to prevent the wires

from being chafed. Insert wire harness

through bushing hole in thermostat top.

3. Disconnect the white jumper lead, the

white, and red leads from the thermostat

terminals. Reconnect the white wire from

the gas valve to terminal #3 (lower left) on

the thermostat. Cut the tongue terminal

from the end of the red wire to the

thermostat and strip 0.5" of insulation to

expose bare wire. Connect to bare end of

red wire from harness using wire nut or

crimp butt connector to join wires inside

thermostat housing.

4. Connect the black and yellow 24 volt wires

from the harness to the two (2) top

terminals of the thermostat.

5. Run the harness supplied along the water

heater jacket and support with the clamps

provided.

6. Install the GSK-3 spillage switch on the

draft hood with the self-tapping sheet metal

screw supplied. The thermal element disc

should hang just below the draft hood relief

opening. (See Figure 10)

7. Run the two (2) red wires from the break in

the top of the harness into the spillage

switch through the plastic bushing opening

and connect to the switch terminals.

8. Run the harness to the CK-81 junction box, which will be mounted in a convenient location near the power venter.

Use clamps to support the wire harness to the joists ar regular intervals to prevent sagging.

9. Run the harness wires through the hole with the plastic bushing in the control box and connect the wires as follows:

Connect the black wire to terminal T1, the yellow wire to T2, the blue wire to T3, and the red wire to T4. (See Wiring

Diagram, Figure 14)

10. Follow the National Electrical Code and or applicable local codes for running high voltage wires to the CK-81 control

box and wire according to the diagram. Unit must be grounded. Check ground circuit to make sure the unit has been

properly grounded. Connect the flexible conduit from the blower to the control box and wire according to the diagram.

11. Attach the appropriate self-adhesive wiring diagram label to the water heater jacket.

Page 12

PRESSURE SWITCH ADJUSTMENT

Figure 14

Figure 15

Page 12

Important: Both the CK-41 and CK-81 power vent control systems

have a pressure switch which must be properly set before the

water heater can be started. The pressure switches are set so that

the contacts will not close until properly set by the installer. Failure

to carefully follow the procedure below for setting the pressure

switch will either prevent the water heater from operating properly

of defeat the safety feature of the control which could allow a

hazardous condition to occur in the event the power venter

operates with a venting malfunction.

1. Attach the 0.25" tubing connector on the pressure tube on the

SWG venter. Connect the supplied 0.25" aluminum tubing to

the tubing connector. Route the tubing to the power venter

control box and connect the tubing to the pressure switch.

When routing the tubing, avoid kinking the tubing by bending

the tubing too sharply.

2. Follow the lighting instructions and light the pilot (millivolt

models). Turn thermostat to the highest setting and turn on

sufficient water flow to keep the burners on continually. The

power venter should start, but the main burners will not come

on until the pressure switch is adjusted.

3. Slowly rotate the pressure switch adjustment screw

counterclockwise until the contacts close and the burners fire,

then rotate the screw 1/4 turn counterclockwise. (See Figure

15) Cycle the thermostat a couple of times to insure proper

operation.

4. Follow the "General Installation Inspection " below to make

sure the pressure switch and venting system operates properly

with all gas appliances and exhaust fans operating.

GENERAL INSTALLATION INSPECTION

Recommended procedures for safety inspection of an appliance in accordance

with the National Fuel Gas Code A.N.S.I.Z223.1. The following procedure will

help evaluate the venting system. It is intended as a guide to aid in determining

that the venting system is properly installed and is in a safe condition for

continuous use. This procedure should be recognized as a generalized

procedure which cannot anticipate all situations. Accordingly, in some cases,

deviation from this procedure may be necessary to determine safe operation of

the equipment. If it is determined that a condition exists which could result in

unsafe operation, the appliance should be shut off and the owner advised of the

unsafe condition. Corrections must be made before the appliance is put into

continuous operation. The following steps should be followed in making a safety

inspection.

1. Visually inspect the venting system for proper size and determine that there is no flue gas spillage, blockage, restriction, leakage, corrosion, or other deficiency which could cause an unsafe operation.

2. Insofar as practical, close all building doors, fireplace dampers, windows, and all doors in area in which the appliance

is located. Turn on clothes dryers, any exhaust fans, such as range hoods and bathroom exhausters so they operate

at maximum speed. Do not operate a summer exhaust fan. If, after completing Steps 3 through 6 it is believed

sufficient combustion air is not available, refer to the National Fuel Gas Code A.N.S.I.Z223.1, or any applicable local

codes for guidance.

3. Place in operation the appliance being inspected. Follow the lighting instructions and adjust thermostat so appliance

will operate continuously.

4. Determine that the pilot or burner is operating properly and that the main burner ignition operates satisfactorily, by

interrupting and re-establishing the electrical power of the appliance in any convenient manner. Test the pilot or

burner safety device to determine if it is operating properly by extinguishing the pilot or disconnecting the flame safety

circuit and pressure switch sensing tube from the pressure switch.

5. Visually determine that the main burner is burning properly; i.e., no floating, lifting, or flashbacks.

Page 13

SWGII-5,6 Repair Motor Kit SWG-8 Repair Motor Kit Blower Wheel

Page 13

6. Test for spillage at draft hood opening and burner inlet air location after 5 minutes of main burner operation. Use a

draft gauge, flame of a match or candle, smoke from a cigarette, cigar or pipe. If spillage occurs, adequate air is not

available. Shut off heating appliance thermostat and check for spillage around the draft hood and burner inlet air

location after power venter has stopped operation. If a flow reversal is noticed, house depressurization is occurring

and make up air is required.

7. Turn on all fuel burning appliances within the same room so that they will operate at their maximum input. Then repeat

Steps 5 through 6.

8. Return doors, windows, exhaust fans, fireplace dampers and any other fuel-burning appliances to their previous

condition of use.

MAINTENANCE

NOTE: The installer must notify the owner/user of the device of the maintenance requirements listed below. This

instruction sheet must also be left with the owner/user.

1. Motor: Inspect the motor once a year - motor should rotate freely. To prolong the life of the motor, it should be

lubricated with six drops of SWG Superlube, Part # 46226200, annually.

2. Wheel: Inspect the power venter wheel annually to clear any soot, ash or coating which inhibits either rotation or air

flow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion and for flue gas leakage.

Replace, seal, or tighten pipe connections if necessary.

4. System Safety Devices: With the heating system operating disconnect the pressure sensing tube from the pressure

switch on the CK Kit. This will stop the burner operation. Re-connecting the tube will relight the burner. For millivolt

operating systems, disconnect one lead of the spill switch. This will shut off the pilot and the burner. Re-connection

will allow relighting the pilot.

Should the motor or blower wheel need replacing, the following replacement items are available. The Repair Motor

Assembly contains the Motor and Blower Wheel factory assembled to a mounting bracket.

FIELD CONTROLS PART NUMBERS

MODEL REPAIR MOTOR KIT BLOWER WHEEL ONLY

SWG11-5 46234900 46150700

SWGII-6 46235000 46154600

SWG-8 46160101 46154800

REMOVAL AND INSTALLATION OF THE MOTOR ASSEMBLY

REMOVAL

1. Shut down appliance and turn off electrical supply.

2. Remove the motor enclosure cover by loosening the four screws. (See Figure 16)

3. Open the electrical box on the motor and disconnect the conduit and wires from the motor. (See Figure 17)

Page 14

4. Remove the four nuts securing the motor assembly, and pull the motor assembly straight off of the unit. (See Figure

Page 14

18)

5. Clean off any build-up inside the blower wheel housing and the blower wheel. CAUTION: Avoid applying excess pressure on the blower wheel when cleaning off any build-up of material. This will cause an imbalance of the blower wheel

which will result in excessive vibration and premature motor failure.

INSTALLATION

1. Align the holes in the circular cover plate with the holes in the motor mount bracket on the motor assembly. (See

Figure 17)

2. Slide the motor assembly onto the protruding threaded studs on the venter body with the exhaust chute pointing

downward, and replace the four nuts securely to the threaded studs.

3. Reattach the flexible conduit and wires to the motor and secure the cover on the electrical box.

4. Install the motor cover with the side louvers pointing downward.

INITIAL BURNER AND VENTING SYSTEM OPERATIONAL INFORMATION

List the following for each operating appliance on the sidewall venting system, as a guide for tune-up or service

information annually.

DATE:

Heating Appliance BTU/HR Input

Gas Valve Operation Pressure

Vent System Draft Above Draft Hood

CO2 Measurement

CO Measurement

Equipment Outlet Flue Gas Temperature

Page 15

Page 15

INSTALLATION INFORMATION

MODEL NO.:_____________________________________________________________

INSTALLER’S NAME: _____________________________________________________

INSTALLER’S COMPANY:__________________________________________________

INSTALLER’S PHONE NO.:_________________________________________________

DATE OF INSTALLATION: _________________________________________________

Page 16

PN 46256400 Rev B 7/00

Loading...

Loading...