Page 1

STARKAP™ CHIMNEY CAP

Model: SK-1

The MODEL SK Starkap™ is designed for terminating gas vents or

metal chimneys for gas or oil heating equipment.

English.......Page 1

Français.....Page 5

Espanõl......Page 8

Page 2

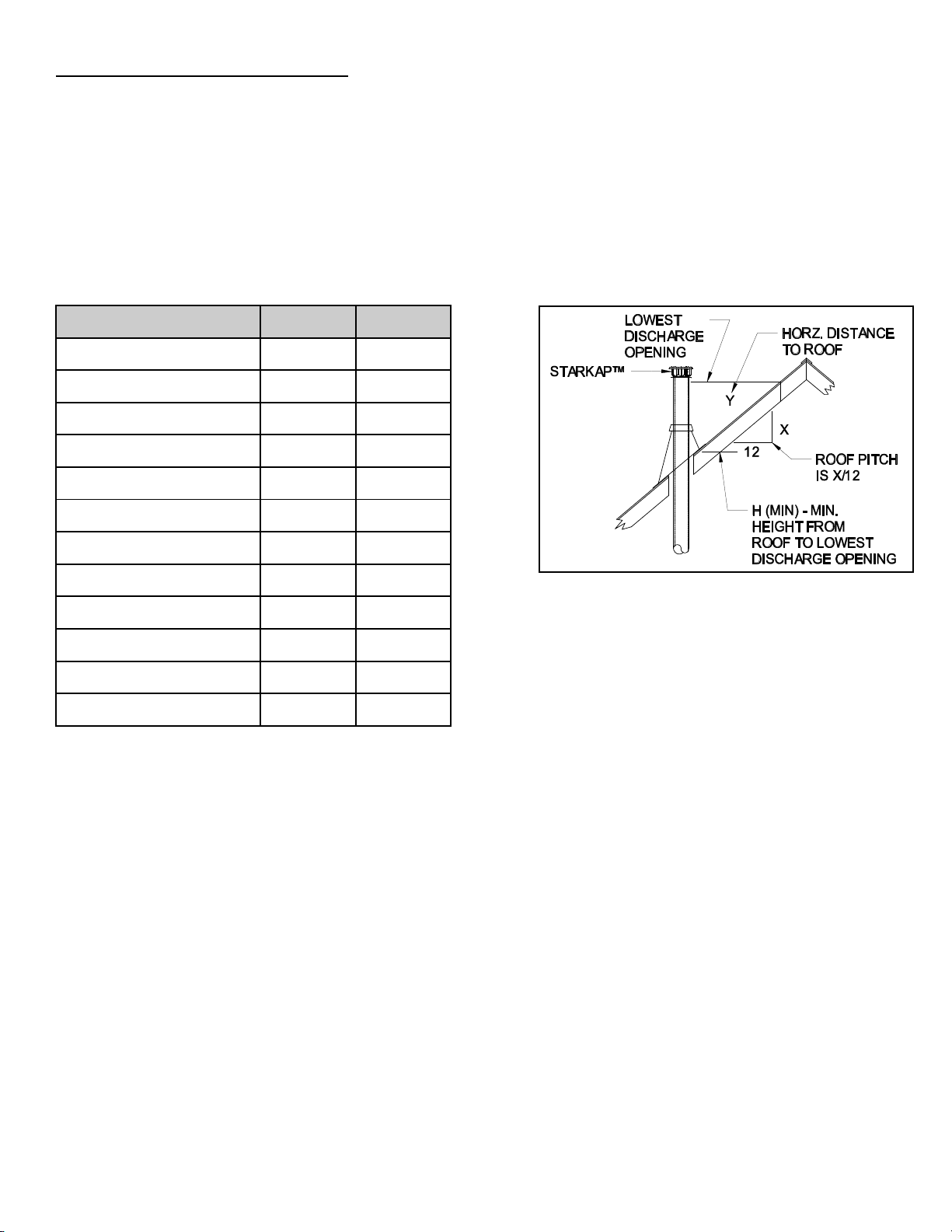

INSTALLATION REQUIREMENTS

1. Install and secure the vertical vent, gas vent or metal chimney according to manufacturer's

instructions or in accordance with NFPA 54 National Fuel Gas code or applicable local codes. The

termination of the vertical vent or metal chimney MUST be installed in accordance with the height

and roof pitch table (See Figure 1 or Table 1 or refer to NFPA 54 for requirements). These

minimum heights may be used if the vertical gas vent is not less than 8 feet from any vertical wall.

For other installations, the termination shall be not less than 2 feet above the highest point where

the vertical vent passes through the roof and at least 2 feet higher than any portion of a building

within 10 feet.

TABLE 1

ROOF PITCH H (FEET) Y (FEET)

FLAT TO 6/12 1.0 2.0

6/12 TO 7/12 1.25 2.1

7/12 TO 8/12 1.5 2.3

OVER 8/12 TO 9/12 2.0 2.7

OVER 9/12 TO 10/12 2.5 3.0

OVER 10/12 TO 11/12 3.25 3.5

OVER 11/12 TO 14/12 4.0 4.0

OVER 12/12 TO 14/12 5.0 4.3

Figure 1

OVER 14/12 TO 16/12 6.0 4.5

OVER 16/12 TO 18/12 7.0 4.5

OVER 18/12 TO 20/12 7.5 4.5

OVER 20/12 TO 21/12 8.0 4.5

2. The vent termination MUST be at least 4 feet from or 1 foot above any window or opening into the

building.

3. The Starkap™ is sized to the same diameter as the vent inside diameter (Example: 3" vent uses

a SK-3 Starkap™).

Page 2

Page 3

INSTALLATION

1. Before installation, apply two beads of high temperature

silicone sealant or equivalent around the bottom of the storm

collar and 1 inch above the end of the Starkap™ body. (See

Figure 2)

2. Insert the Starkap™ into the inside of the vent termination

pipe, making sure the Starkap™ is seated against the storm

collar. Fasten the Starkap™ to the vent termination pipe by

using three (3) sheet metal screws. Placement of the screws

should be approximately 1/2 inch from the end of the vent termination pipe. (See Figure 3) The

heads of the screws should be covered with high temperature.

Figure 2

Figure 3

Page 3

Page 4

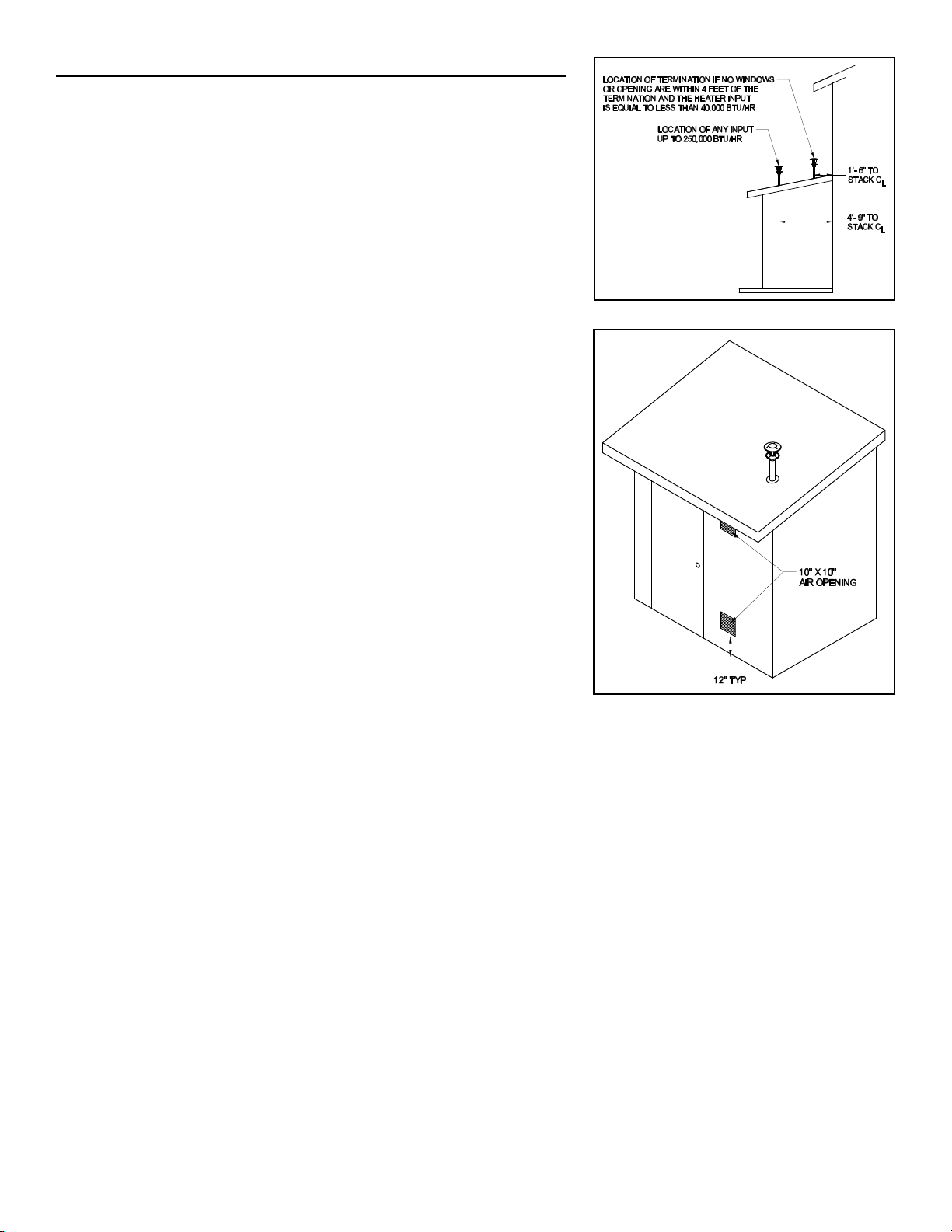

SPECIAL VENTING APPLICATION INSTALLATION SHEET

This sheet covers the requirements for installation of the

Starkap™ for use with attached buildings designed for the

purpose of housing heating equipment outside of the living

space of the structure. These requirements are based on

A.G.A. test reports C-FT-5-90, C-FT-8-90, FT-C-12-93 AND

FT-C-13-93. See Figure 4 and 5.

1. The maximum gas heating appliance (or multiple

appliances ) up to 250,000 BTU/HR input.

2. Each appliance in the building MUST have its own separate

vertical vent and Starkap™.

3. The connecting wall between the attached building and the

main structure MUST be sealed to prevent flow into the

main structure. Example: Attached garages must be

sealed by lining ceiling and any wall adjacent to the living

space with 1/2" thick gypsum board or equivalent.

Openings from an attached garage directly into a room

used for sleeping purposes shall not be permitted. Other

openings between the garage and residence shall be

equipped with either solid wood doors not less than 1-3/8"

in thickness or 20-minute fire-rated doors, or equivalent.

4. Two make up/combustion air openings into the outside

building shall be installed. Size of the openings shall be 10

inch by 10 inch or based on 1 sq. inch per 4000 BTU/HR.

5. Termination location shall have a 4 ft. 9 in. center line

distance from any vertical wall up to 250,000 BTU/HR.

Termination location for up to 40,000 BTU/HR water heaters shall be a minimum 1 ft. 6 in. center

line distance from any vertical wall. A minimum height of 12 inches shall be maintained above the

roof.

Figure 4

Figure 5

6. The vent termination shall be located at least 4 feet from any window or opening into the main

building structure.

Page 4

Page 5

STARKAP™

Model: SK-1

EXIGENCES D’INSTALLATION

1. Installer et fixer l’évent vertical, l’évent à gaz ou la cheminée en métal conformément aux

instructions du fabricant, au code national des gaz combustibles NFPA 54 ou à tout code local

applicable. Le bout d’un évent vertical ou d’une cheminée en métal DOIT être installé

conformément au tableau de hauteur et de pente de toit (Voir Le Schéma 1 ou le TABLEAU 1, ou

se reporter à la NFPA 54 pour les exigences). Ces hauteurs minimales peuvent être utilisées sir

l’évent à gaz vertical n’est pas à moins de 8 pi d’une paroi verticale quelconque. Pour d’autres

installations, le bout ne doit pas être à moins de 2 pi au-dessus du point le plus élevé où l’évent

vertical passe à travers le toit et à au moins 2 pi au-dessus de toute partie d’un bâtiment se

trouvant à dix pieds ou moins de distance.

Tableau 1

PENTE DE TOIT H (PI) Y (PI)

PLAT JUSQU’À 6/12 1.0 2.0

PLUS DE 6/12 À 7/12 1.25 2.1

PLUS DE 7/12 À 8/12 1.5 2.3

PLUS DE OVER 8/12 À 9/12 2.0 2.7

PLUS DE OVER 9/12 À 10/12 2.5 3.0

PLUS DE OVER 10/12 À 11/12 3.25 3.5

PLUS DE OVER 11/12 À 14/12 4.0 4.0

PLUS DE OVER 12/12 À 14/12 5.0 4.3

PLUS DE OVER 14/12 À 16/12 6.0 4.5

Schéma 1

PLUS DE OVER 16/12 À 18/12 7.0 4.5

PLUS DE OVER 18/12 À 20/12 7.5 4.5

PLUS DE OVER 20/12 À 21/12 8.0 4.5

2. Le bout d’évent DOIT être à au moins 4 pi de distance d’une fenêtre ou d’une ouverture dans le

bâtiment, ou à au moins 1 pi au-dessus.

3. Le Starkap™ a le même diamètre que l’intérieur de l’évent (Exemple: un évent de 3 po requiert le

Starkap™ SK-3).

Page 5

Page 6

INSTALLATION

1. Avant l’installation, appliquer deux cordons de scellant de

silicone à haute température ou l’équivalent autour de la

partie inférieure de la mitre et à 1 po au-dessus de

l’extrémité du Starkap™. (Voir Le Schéma 2)

2. Insérer le Starkap™ à l’intérieur du tuyau de bout d’évent,

en s’assurant qu’il est bien scellé contre la mitre. Fixer le

Starkap™ au tuyau de bout d’évent au moyen de trois vis à

tôle. Les vis devraient être placées à environ 1/2 po de

l’extrémité du tuyau de bout d’évent. (Voir Le Schéma 3)

Les têtes de vis devraient être recouvertes de scellant de

silicone à haute température ou l’équivalent.

Schéma 2

Schéma 3

Page 6

Page 7

FEUILLE D’INSTALLATION POUR ÉVENT SPÉCIAL

Cette feuille traite des exigences d’installation du Starkap™

sur des structures contiguës conçues pour abriter du matériel

de chauffage à l’extérieur de l’espace habitable d’une

structure. Ces exigences sont basées sur les rapports des

tests A.G.A. C-FT-5-90, C-FT-8-90, FT-C-12-93 et FT-C-13-

93. Voir les Schémas 4 et 5.

1. Appareil (ou appareils multiples) de chauffage au gaz à

puissance d’entrée maximale de 250,000 BTU/h.

2. Chaque appareil dans le bâtiment DOIT posséder son

propre évent vertical et son propre Starkap™.

Schéma 4

3. Le mur mitoyen de la structure contiguë et de la structure

principale DOIT être scellé pour éviter le débit dans la

structure principale. Par exemple: on doit sceller un

garage contigu en apposant 1/2 po d’épaisseur de

placoplâtre ou l’équivalent au plafond et sur tout mur

contigu à l’espace habitable. Les ouvertures d’un garage

contigu à une pièce servant de chambre à coucher ne

sont pas permises. D’autres ouvertures entre le garage

et la résidence doivent être dotées soit de portes en bois

massif d’au moins 1-3/8 po d’épaisseur, soit de portes

pare-feu classées 20 minutes, ou l’équivalent.

4. Deux ouvertures d’air d’appoint / de combustion doivent

être faites dans le bâtiment extérieur. Ces ouvertures

doivent mesurer 10 po x 10 po, ou 1 po2 par tranche de

4,000 BTU/h.

5. Le bout doit être à une distance médiane de 4 pi 9 po de

Schéma 5

tout mur vertical pour les appareils jusqu’à 250,000

BTU/h. Pour les chauffe-eau jusqu’à 40,000 BTU/h, le bout doit être à une distance médiane de 1

pi 6 po de tout mur vertical. Une hauteur minimale de 12 po doit être maintenue au-dessus du toit.

6. Le bout d’évent doit être situé à au moins 4 pi de toute fenêtre ou ouverture dans la structure

principale.

Page 7

Page 8

StarKap™

Model: SK-1

REQUISITOS PARA LA INSTALACIÓN

1. Instale y asegure el respiradero vertical, el respiradero de gas o la chimenea metálica según las

instrucciones del fabricante o confirme al código Nacional sobre Gas Combustible, NFPA 54 o

todo código local correspondiente. La terminación del respiradero vertical o de la chimenea

metálica DEBE ser instalada de acuerdo con la gráfica de altura y la inclinación del tejado (Ver

Figura 1 o Tabla 1 o consulte los requisitos de NFPA 54). Estas alturas mínimas se pueden usar

si el respiradero vertical de gas está a menos de 8 pies de distancia de una pared vertical. Para

otras instalaciones, la terminación no estará a menos e 2 pies encima del punto más alto en

donde pasa el respiradero vertical a través del tejado, y por lo menos 2 pies más alto que

cualquier porción de un edificio a 10 pies de distancia.

Tabla 1

INCINACIÓN DEL TEJADO H (PIES) Y (PIES)

PLANO HASTA 6/12 1.0 2.0

MÁS DE 6/12 HASTA 7/12 1.25 2.1

MÁS DE 7/12 HASTA 8/12 1.5 2.3

MÁS DE 8/12 HASTA 9/12 2.0 2.7

MÁS DE 9/12 HASTA 10/12 2.5 3.0

MÁS DE 10/12 HASTA 11/12 3.25 3.5

MÁS DE 11/12 HASTA 14/12 4.0 4.0

MÁS DE 12/12 HASTA 14/12 5.0 4.3

MÁS DE 14/12 HASTA 16/12 6.0 4.5

Figura 1

MÁS DE 16/12 HASTA 18/12 7.0 4.5

MÁS DE 18/12 HASTA 20/12 7.5 4.5

MÁS DE 20/12 HASTA 21/12 8.0 4.5

2. La terminación del respiradero DEBE estar por lo menos a 4 pies de distancia o 1 pie por encima

de cualquier ventana o abertura hacia el edificio.

3. El tamaño del Starkap™ debe tener el mismo diámetro que el diámetro interior del respiradero

(Ejemplo: respiradero de 3” usa un Starkap™ SK-3).

Page 8

Page 9

INSTALACIÓN

1. Antes de la instalación, aplique dos gotas de

compuesto sellador de silicona para altas

temperaturas o un equivalente alrededor del fondo del

collarín y una pulgada encima del extremo del cuerpo

del Starkap™. (Ver Figura 2)

2. Introduzca el Starkap™ en el interior del tubo de

terminación del respiradero, asegurándose de que el

Starkap™ esté bien sellado contra el collarín. Afiance

el Starkap™ al tubo de terminación del respiradero

usando tres (3) tornillos para hoja metálica. La

ubicación de los tornillos debe ser aproximadamente a

½ pulgada del extremo del tubo de terminación del

respiradero. (Ver Figura 3) Las cabezas de los

tornillos deben estar cubiertas con un compuesto

sellador de silicona para altas temperaturas o un

equivalente.

Figura 2

Figura 3

Page 9

Page 10

HOJA DE INSTALACIÓN PARA LA APLICACIÓN

EN SITUACIONES ESPECIALES DE VENTILACIÓN

Esta hoja cubre los requisitos para la instalación del

Starkap™ cuando se usa en edificios contiguos diseñados

con el fin de alojar equipos de calefacción fuera de la

estructura de habitación. Estos requisitos se basan en

informes de prueba A.G.A. C-FT-5-90, C-FT-8-90, FT-C-1293 y FT-C-13-93. Ver Figura 4 y 5.

1. El aparato de calefacción de gas (o aparatos múltiples)

de una entrada máxima de 250,000 BTU/hr.

2. Cada aparato del edificio DEBE tener su propio

respiradero vertical separado y Starkap™.

3. La pared de conexión entre el edificio contiguo y la

estructura principal DEBE estar sellada para evitar el

flujo hacia la estructura principal. Ejemplo: Los garajes

contiguos se deben sellar con revestimiento para techos

y toda pared contigua a las habitaciones debe revestirse

con tablones de yeso de ½” de grosor o equivalentes.

No se permitirán aberturas directas desde el garaje

contiguo hacia una habitación que se use para dormir.

Otras aberturas entre el garaje y la residencia deberán

estar equipadas con puertas de madera sólida de un

grosor no menor de 1-3/8” o con puertas resistentes al

fuego con una clasificación nominal de 20 minutos, o

equivalentes.

4. Se instalarán dos aberturas de aire de

combustión/compensación en el exterior del edificio. El

tamaño de las aberturas será de 10 pulgadas por 10

pulgadas o basadas en 1 pulgada cuadrada por 4,000

BTU/hora.

Figura 4

Figura 5

5. La ubicación de la terminación tendrá una distancia de la línea central de 4 pies 9 pulgadas desde

cualquier pared vertical de hasta 250,000 BTU/hora. La ubicación de la terminación para

calentadores de agua de hasta 40,000 BTU/hora deberá ser por lo mínimo a 1 pie 6 pulgadas de

distancia de la línea central de cualquier pared vertical. Se deberá mantener una altura mínima

de 12 pulgadas encima del tejado.

6. La terminación del respiradero deberá estar ubicada por lo menos a 4 pies desde cualquier

ventana o abertura en la estructura principal de habitación.

Page 10

Page 11

Page 11

Page 12

PN 46263300 Rev C 09/00

Page 12

Loading...

Loading...