Page 1

POWER VENTER SYSTEM

Model: PVU-300

Included is one ETL LISTED power venter to be used for side wall venting of a single 120/24 VAC controlled

furnace, boiler, or water heater which burns natural or LP gas, or oil. The PVU may also be used to vent a

single 24 VAC controlled gas fired furnace or boiler and a 30 millivolt residential gas fired water heate r.

TYPICAL VENTING SYSTEM COMPONENTS

ETL LISTED PVU-300 POWER VENTER with pre-wired integral Universal

Control (24VAC and 120 VAC), factory set Draft Proving Switch, and direct

access Terminal Blocks.

• Side Wall Vent Hood (Not included) • Spill Switches (Not included)

• Barometric Draft Control (Not Included)

C

ONTENTS PAGE

System Operation 2

Power Venter Sizing 2-3

Installation Safety Instructions 3-4

Installation of Power Venter 4-6

General Wiring Instructions 6

PVU Internal Wiring Schematic 6-8

Adjusting Thermostat Anticipator 8

Airflow Adjustments 9

General Installation Inspection 9

System Control Check Procedures 10

Troubleshooting Tips 10

Maintenance 10

Replacement Parts List 10

Multiple Venting Systems 11-13

Venting System Operational Information 15

Installation Information 15

This device MUST be installed by a qualified agency in accordance with the manufacturers installation

instructions.

The definition of a qualified agency is: any i ndividual, fir m, corporation or compa ny which eith er in pers on or through a repr esentative is

engaged in, and is responsible for, the installation and operation of gas ap pliances, who is experienced in such work, familiar with all

the precautions required, and has complied with the requirements of the authority having jurisdiction.

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

2630 Airport Road · Kinston, NC 28504

Phone: 252-522-3031· Fax: 252-522-0214

www.fieldcontrols.com

Page 2

UNIT SPECIFICATIONS

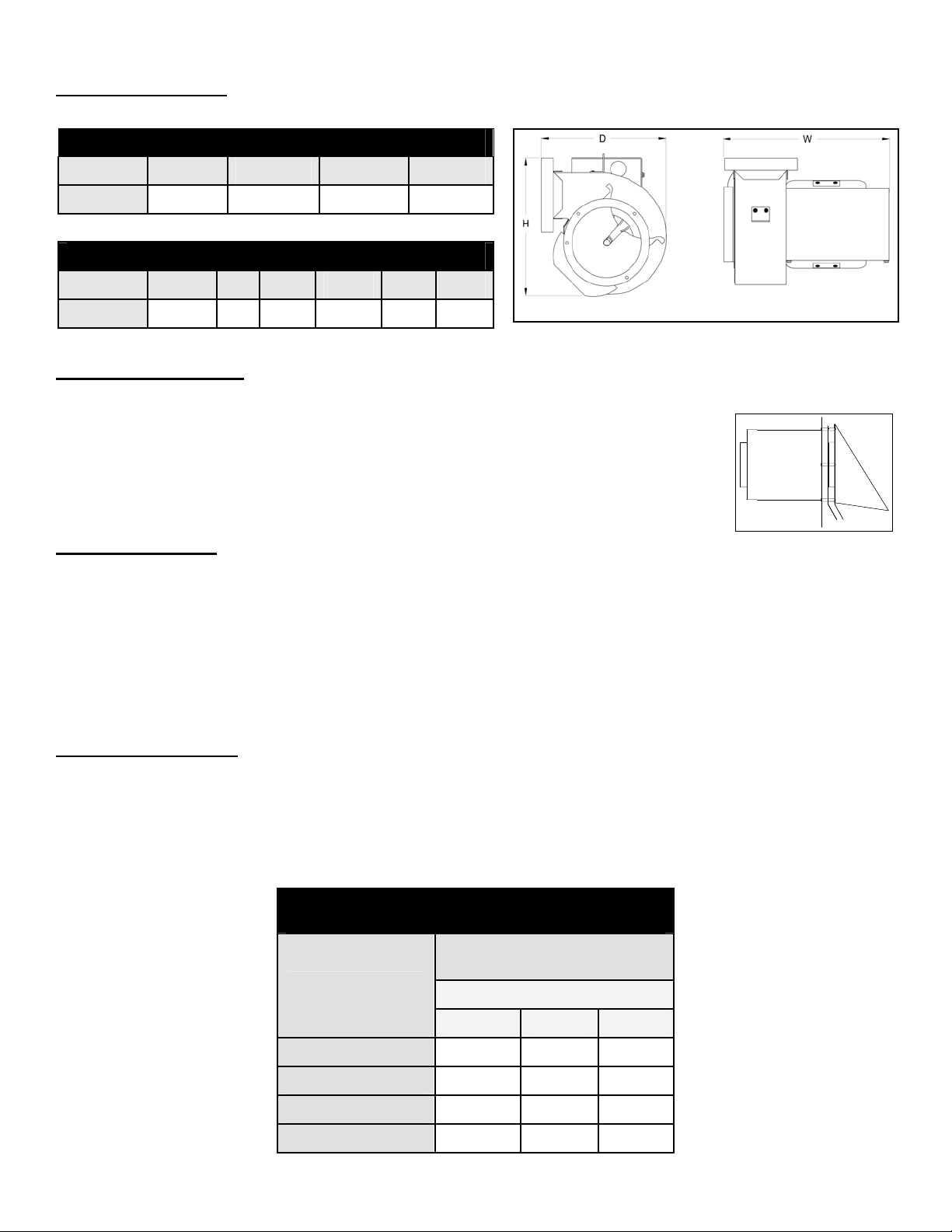

(See Table 1 and Figure 1)

Table 1

UNIT DIMENSIONS (INCHES)

MODEL “H” “W” “D” I/O*

PVU-300

7.5 11.5 7.0 4/4

*

Inlet and outlet diameter.

ELECTRICAL RATINGS

MODEL VAC Hz RPM WATT AMP TP**

PVU-300

115 60 3000 145 2.1 YES

**

Thermally protected motor.

Figure 1

SIDEWALL VENT HOODS (Model SWH-1)

Sidewall vent hoods are available in the following sizes. The vent hood should be chosen that

matches the outlet size of the Power Venter. (See Figure 2) NOTE: When using different sizes

consider reducers and specific size pipe when determining equivalent length of vent pipe.

SWH-1-3 - 3 inch

SWH-1-4 - 4 inch

SWH-1-5 - 5 inch

SWH-1-6 - 6 inch

SWH-1-8 - 8 inch

SYSTEM OPERATION

Figure 2

1. The thermostat (wall thermostat, or aquastat) calls for heat and energizes a relay, which

activates the power venter. After the venter motor has come up to speed, the pressure switch closes. This completes

the circuit to the burner and allows the burner to fire.

2. For millivolt controlled water heaters, the gas pressure switch on the gas valve activates the power venter at the same

time as the burner fires.

3. After the heating requirement has been satisfied, the thermostat circuit will open and de-activate the burner and power

venter circuit.

4. The post purge timer continues to run the power venter for a period of time after the burner has shut off to purge

remaining flue gases.

POWER VENTER SIZING

In order to choose the correct size power venter for a particular installation, the total input firing rate and total equivalent

length of vent pipe to be used must be known. Refer to Table 2 to determine the maximum allowable equivalent feet of

pipe for each model used with the pipe diameters shown. When venting multiple appliances, add the input of each

appliance to determine the total input. Always choose a power venter that is capable of handling more than the system

requires. The choke plate can be adjusted to compensate for the difference.

Table 2

MAXIMUM EQUIVALENT HORIZONTAL PIPE

LENGTH (FEET)

VENTER MODEL NO. AND

VENT PIPE DIAMETER

BTU/HR INPUT

PVU-300

4” 5” 6”

100,000

145,000

220,000

310,000

305 --- --145 247 334

64 100 147

--- 54 74

Page 2

Page 3

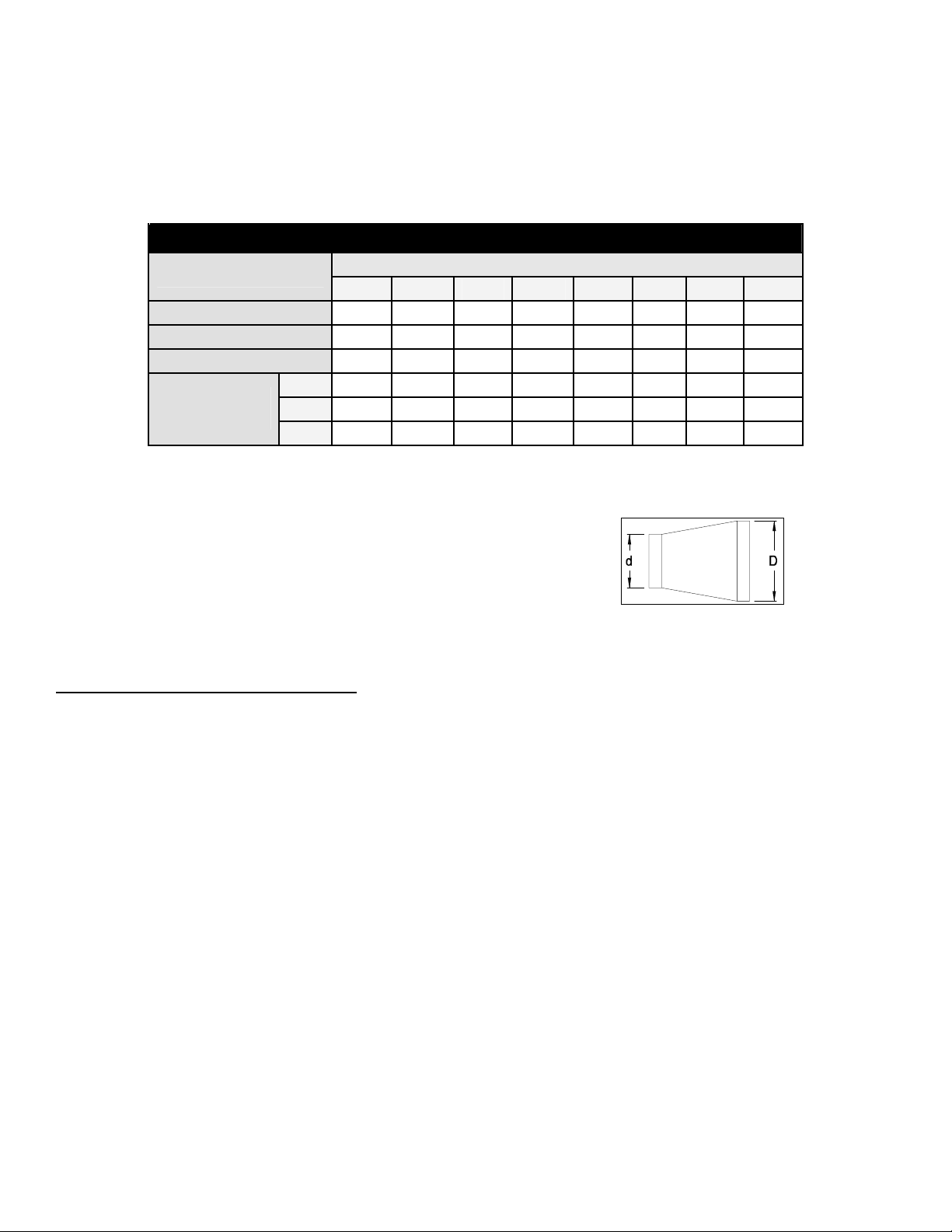

ROCEDURE FOR CALCULATING TOTAL EQUIVALENT PIPE LENGTH IN FEET

P

1. Calculate the total equivalent feet for each type of fitting used in the venting system from the following chart.

2. Calculate the total amount of feet for the straight lengths of vent pipe.

3. Add the equivalent feet for the fittings with the total amount of feet of straight lengths.

Table 3

EQUIVALENT LENGTH (FEET) OF VENT PIPE FOR VENT PIPE FITTINGS

VENT PIPE FITTINGS

VENT PIPE DIAMETER

3” 4” 5” 6” 7” 8” 9” 10”

TEE

90° ELBOW

45° ELBOW

19 25 31 38 44 50 56 63

5 7 9 11 12 14 16 18

3 4 4 5 6 7 8 9

1/4 8 11 14 17 19 22 25 28

REDUCER

(d/D)*

1/2 5 7 8 10 12 13 15 17

3/4 2 3 3 4 4 5 6 6

*

Reducer or increaser ratio (d/D) small diameter divided by the larger diameter. (See Figure 3)

Example: 4" to 8" reducer, the reducer ratio is d/D = 4/8 = 1/2. To estimate the equivalent foot

length for the fitting, use the smaller pipe diameter for the equivalent length figure. Example:

4" to 8" reducer; the reducer ratio is 1/2 and the smaller pipe

diameter is 4". So, from the chart, the equivalent feet would be 7

feet.

Example: System Pipe Size = 4"

Step 1 2 – 90° Elbows (4") = 14 Ft.

Step 2 10 - 2 Ft. Lengths of 4" Pipe = 20 Ft.

Figure 3

Step 3 Total Equivalent Feet = 14 Ft. + 20 Ft. = 34 Ft.

INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a qualified installer in accordance with the manufacturer's installation

instructions. Appliances should have a minimum of 75% combustion efficiency or have a maximum measured flue gas

temperature of 550°F at the inlet of the venter.

1. The power venting system must be installed by a qualified installer. "Qualified Installer" shall mean an individual who

has been properly trained or a licensed installer. The installer must write or imprint his name, phone number and date

of installation on the installation tag. The tag should be attached to the power venter unit. Recording burner and

venting system initial operational information is recommended as a guide for service or burner tune-up. Enter this on

the back page of this manual.

2. Safety inspection of a venting system should be performed before and after installing a power venting system on an

existing or new appliance. Procedures to follow are those recommended by the National Fuel Gas Code,

A.N.S.I.Z223.1 or refer to the "General Installation Inspection" section of this manual.

3. Plan the vent system layout before installation to avoid the possibility of accidental contact with concealed wiring or

plumbing inside walls.

4. Single wall vent pipe may be used to join an appliance to the venting system, but if proper clearances cannot be

maintained from combustible materials, Class B Vent Pipe should be used for gas appliances. Refer to national or

local codes for guidelines. Also, a minimum of 6 inches clearance between the venter housing and combustible

materials must be maintained.

5. Disconnect power supply before making wiring connections to prevent electrical shock and equipment damage.

6. This equipment is designed to overcome minor negative pressure conditions. To ensure extreme negative pressure

does not exist, follow the "General Installation Inspection" section of this manual.

7. Heating appliances equipped with draft hoods, such as boilers or furnaces, LP and natural gas appliances SHOULD

have a secondary spillage switch installed. On appliances without draft hoods, it is recommended that the secondary

safety switch GSK-3 be installed into the system. Gas-fired 30 millivolt power systems MUST be equipped with a

spillage switch.

Page 3

Page 4

8. Air flow adjustment MUST be made to ensure appliance efficiency. This should be done at the appliance exhaust

outlet with a velocity meter, draft gauge or by the "match test procedure". The match test is in accordance with

National Fuel Gas Code A.N.S.I.Z223.1, Section 8.6.

9. On heating appliances not equipped with a draft hood, a barometric draft control MUST be installed to regulate proper

air flow and fluctuations in the system's air flow during operation. Fluctuations can come from wind loads on the outlet

of the venter, house depressurization during windy days and the different house ventilation requirements between

summer and winter operation. Use a Field Controls Type MG-1 Barometric Draft Control. Gas-fired draft induced

systems should have a single-acting or double-acting barometric draft control installed.

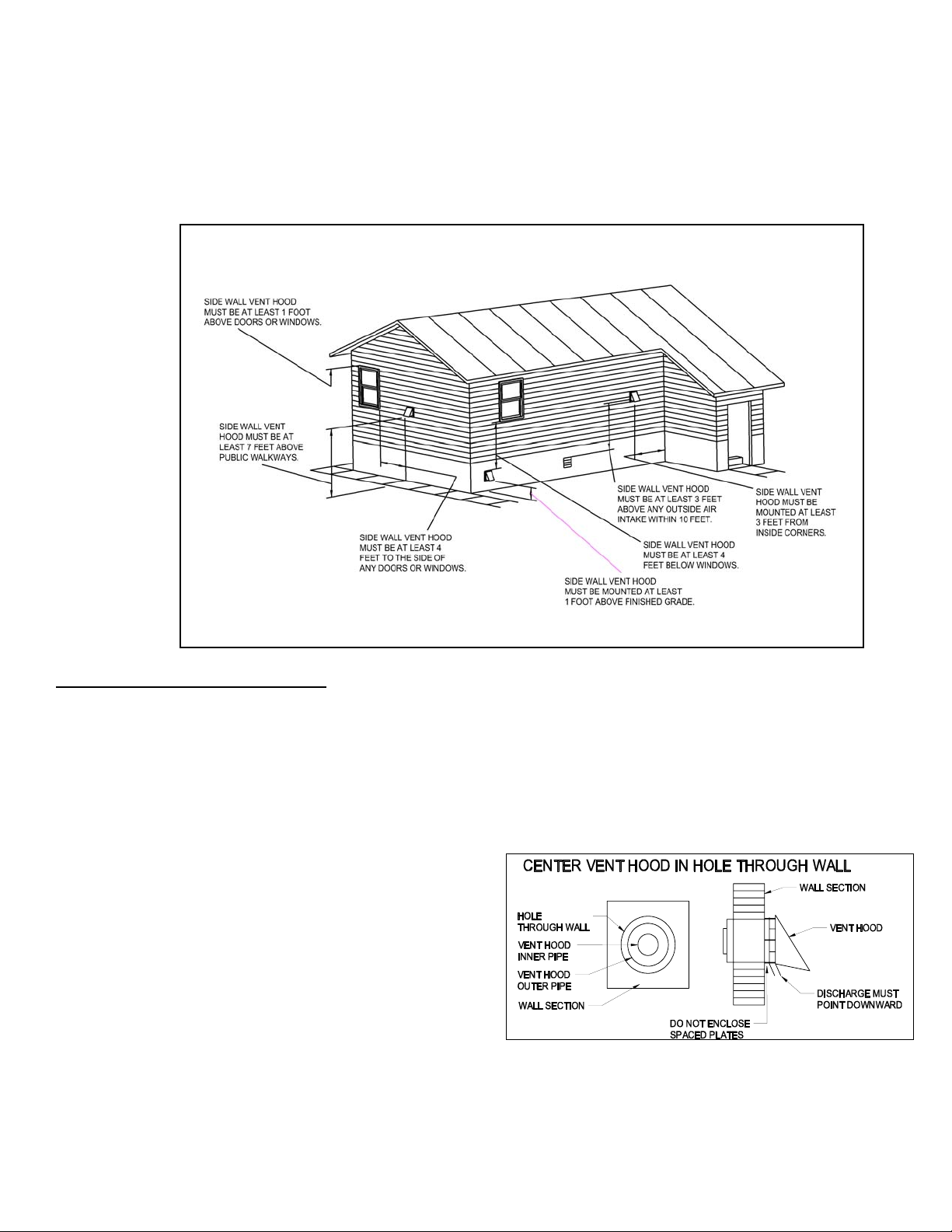

Diagram A

INSTALLATION OF POWER VENTER

CAUTION: Failure to install, maintain and/or operate the power venting system in accordance with manufacturer's

instructions will result in conditions which may produce bodily injury and/or property damage.

1. Remove power venter from box and inspect unit for damage. If the carton has been crushed or mutilated, check unit

very carefully for damage. Rotate venter wheel to insure that the motor and venter wheel rotate freely. DO NOT install

if any damage is apparent. Refer to unit sizing chart to check proper venting sizing.

2. Location of the termination of the venting system should be installed in accordance with the National Fuel Gas Code,

A.N.S.I.Z233.1, manufacturer's recommendations, and/or local codes which are applicable. See the following

requirements or refer to Diagram A for typical locations.

a. The exit termination of mechanical draft systems shall

not be less than 7' above grade when located

adjacent to public walkways.

b. A venting system shall terminate at least 3' above any

forced air inlet located within 10'.

c. The venting system of other than a direct vent

appliance shall terminate at least 4' below, 4'

horizontally from, or 1' above any door, window, or

gravity air inlet into the building.

d. The vent termination of a direct vent appliance with an

input of 50,000 BTU/Hr or less, shall be located at

least 9" from any opening through which vented gases

Figure 4

could enter the building. With an input over 50,000

BTU/Hr, a 12" termination clearance shall be required.

e. The vent termination point shall not be installed closer than 3' from an inside corner of an L-shaped structure.

f. The vent termination should not be mounted directly above or within 3' horizontally from an oil tank vent or gas

meter.

g. The bottom of the vent terminal shall be located at least 12" above finished grade.

Page 4

Page 5

SIDE WALL VENT HOOD INSTALLATION

1. Use the inside wall plate as a template to mark the hole location. Cut a hole 1 inch larger than the marked hole to

facilitate easy installation (See Figure 4)

2. Center vent hood through the hole from outside. Fasten the vent hood to the outside wall with the appropriate type of

mounting screws.

3. Fasten the wall end plate to the inside wall with the appropriate type of

mounting screws. NOTE: Apply sealant to the outside mounting plate of

the vent hood to prevent leakage.

4. Connect the venter outlet or a properly sized section of vent pipe onto

the inner pipe of the vent hood. Fasten the connection with three sheet

metal screws or equivalent fastening method.

5. Seal the vent hood inlet connection and any other vent pipe joints on the

outlet side of the venter with an approved high temperature silicone

adhesive sealant or equivalent material.

NOTE: Do not enclose the space between the plates on the outside of the

Figure 5

vent hood or between the inner and outer pipe of the vent hood. This might

cause overheating of the wall structure. Local codes might require

fencing around the vent hood outlet.

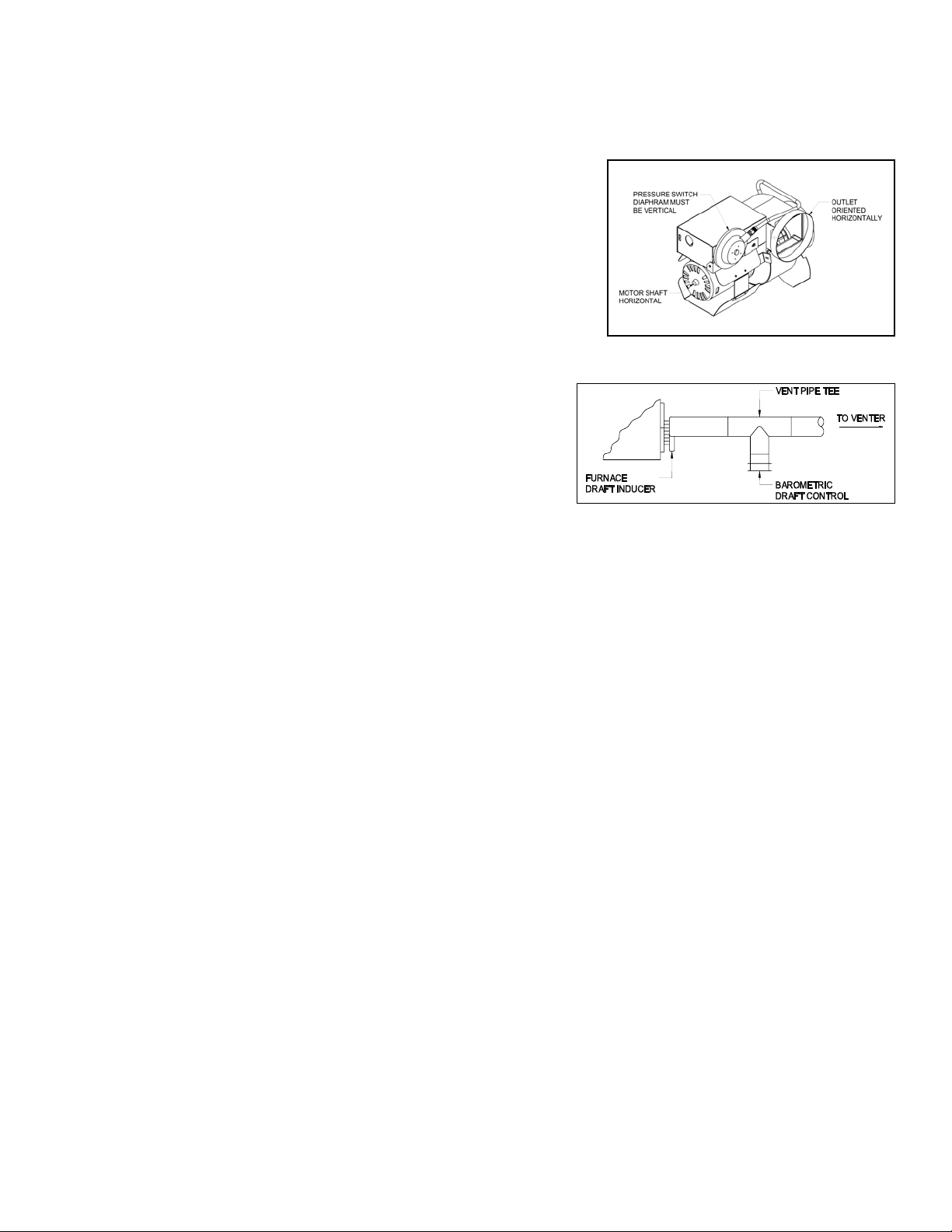

V

ENTER LOCATION

Install the power venter onto the vent hood inlet or as close to the vent

hood inlet as possible. Always install the venter such that the motor

shaft is horizontal and the pressure switch diaphragm is vertical (See

Figure 5) When venting a draft induced gas fired heating appliance a

Figure 6

barometric draft control must be installed on the vent system between

the appliance outlet and the venter inlet. (See Figure 6)

CAUTION: The power venter should never be installed with the motor shaft in the vertical position. This could allow heat

to be trapped in the venter housing and radiate through the motor possibly causing motor deterioration and premature

failure. Never attach the venter inlet directly to the outlet of the heating appliance. Also, a minimum of 6 inches clearance

between the venter housing and combustible materials must be maintained.

C

ONNECTING VENTER TO THE FLUE PIPE

NOTE: The power venter should be supported in accordance with National Fuel Gas Code Z223.1, Section 7.910 as

follows; A vent connector shall be supported for the design and weight of the material employed to maintain clearances

and to prevent physical damage and separation of joints.

NOTE: For gas fired heating appliances not equipped with a draft hood, a barometric draft control must be installed

between the heating appliance exhaust outlet and the power venter inlet to regulate any draft fluctuations during

operation.

1. Use approved vent connectors to join the heating appliance outlet to the venter inlet securing each joint with sheet

metal screws or equivalent means of fastening when required.

2. Seal all pipe joints on the outlet side of the venter with a high temperature silicone adhesive or equivalent. Test the

vent connections for leaks by using a soap solution as recommended by the National Fuel Gas Code, A.N.S.I. Z223.1,

Section 4.1.1.

Page 5

Page 6

OPTIONAL GSK-3 EXHAUST GAS SPILLAGE DETECTOR SWITCH INSTALLATION

NOTE: Installation of the GSK-3 secondary safety switch is recommended

for LP and Natural gas fired appliances with a draft hood. This switch will

detect exhaust gas spillage out of the draft hood due to a blocked vent

system and/or inadequate draft during operation. When this switch senses

spillage it interrupts the power supply to the gas valve which terminates the

burner operation.

1. Mount the GSK-3 on the lower edge of the draft hood with the exposed

thermal disk directed into the draft hood (See Figure 7)

2. Route the electrical wires along the heating appliance cabinet within an

accepted wiring enclosure in accordance with the National Electrical

Code and any applicable local codes. Keep the wires away from any

HOT surfaces.

3. Wire the switch into the low voltage thermostat circuit. Refer to the

appropriate wiring diagram in this manual.

Figure 7

4. After installation, check the amperage through the thermostat circuit and adjust the anticipator if necessary.

CAUTION: The GSK-3 is a manual reset switch. Investigate the system thoroughly for the cause of any shut down and

correct the problem before resetting the GSK-3 and restarting the system.

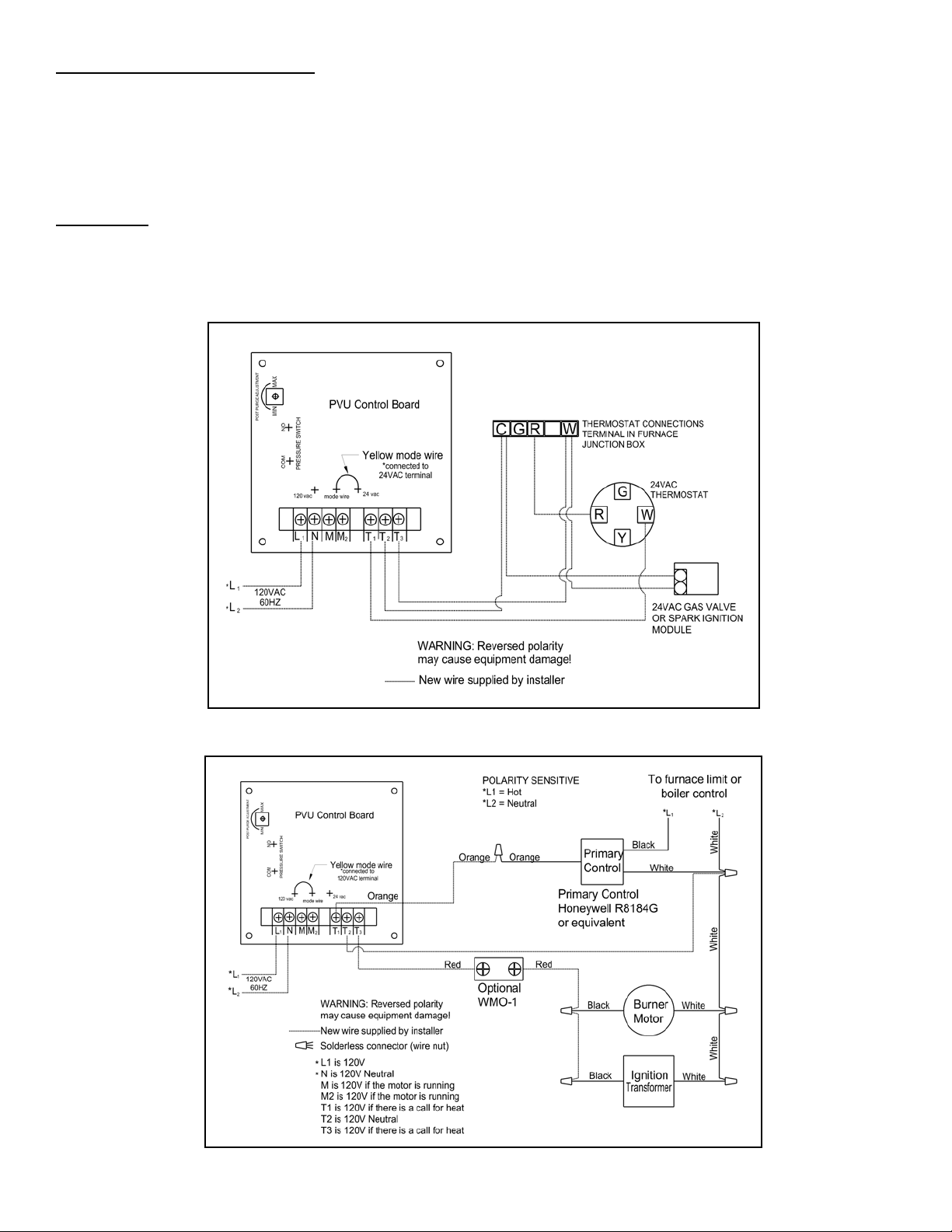

Diagram B – Internal Wiring Schematic for PVU-300

Page 6

Page 7

GENERAL WIRING INSTRUCTIONS

CAUTION: Disconnect electrical power before wi ring power venter!

Connect line voltage (110/120 VAC) through junction box access hole labeled "120 VAC Only". Connect low voltage

control wiring through junction box access hole labeled "24 VAC Control Wiring Only". VENTER MUST BE

GROUNDED! Check ground circuit to make certain that venter has been properly grounded. The wiring must be

protected by an over current protection circuit such as a fuse or circuit breaker rated at 15 amperes. Prevent wiring

contact with any heat source.

IMPORTANT

: The PVU-300 is shipped with the yellow mode wire connected to the 120VAC terminal. This is correct for

120VAC control (typical oil-fired). For 24VAC control (typical gas fired) the yellow mode wire must be disconnected from

the 120VAC terminal and reconnected to the 24VAC terminal (see wiring diagrams).

NOTE: Wire the venter in accordance with the National Electrical Code and applicable local codes. Refer to Diagrams C

and D for proper wiring specifications for a 24VAC Gas or 120VAC Oil fired appliance.

Diagram C – Wiring with 24 VAC Gas Valve

Diagram D – Wiring with a 120 VAC Oil Fired Primary Control

Page 7

Page 8

r

NOTE: A CK-20FV or CK-20FG control kit MUST be added to the system to properly control the venter with the operation

of a 30mV water heater. Refer to Diagram E for proper wiring specifications.

Diagram E – Wiring with a 30mV Water Heate

ADJUSTING THERMOSTAT ANTICIPATOR

If connecting the Power Venter system to a gas appliance with a

thermostat anticipator, refer to the following to make adjustments.

Disconnect one side of the thermostat circuit at the gas valve or burner

control, and connect an ampere meter into the circuit. With the system

running, take an amperage reading on the circuit. Check the nameplate or

instructions for the thermostat to obtain the proper amperage level. Adjust

amperage level by moving the anticipator lever. Reconnect the thermostat

to the gas valve and start the system operating. Time the burn cycles and

adjust as follows; To make the cycle time longer, increase the amount on

the anticipator (Example: .45 to .5 Amps); to decrease cycle time, reduce

the amount on the anticipator. (Example: .45 to .3 Amps) (See Figure 8)

Figure 8

Page 8

Page 9

AIR FLOW ADJUSTMENTS

1. To properly adjust the venter air flow, loosen the inlet ring screws and open the

choke plate approximately 1/2 to 3/4 open. (See Figure 9) Start the heating

appliance following the manufacturer specified procedure, and set the

thermostat to call for heat.

2. After the system has operated for several minutes to stabilize the exhaust gas

temperature, check for air flow at the draft hood or the heating appliance outlet

using a velocity meter, draft meter, or match test procedure.

3. Adjust the venter choke plate inward or outward to obtain the minimum draft

necessary to maintain venting. Then increase the draft slightly (Approximately

10% over minimum flow rate) to ensure proper venting during any variations in

venter performance, such as wind load or house depressurization.

Figure 9

4. Secure the choke plate into position by tightening the screws on the inlet collar

(See Figure 9)

GENERAL INSTALLATION INSPECTION

Follow recommended procedures for safety inspection of a heating appliance in accordance with the National Fuel Gas

Code A.N.S.I. Z223.1. The following procedure will help in evaluation of the venting system. It is intended as a guide to

aid in determining that the appliance is properly installed and is in a safe condition for continuous use. This is a

generalized procedure, which cannot anticipate all situations. Accordingly, in some cases deviation from this procedure

may be necessary to determine safe operation of the equipment. If it is determined that a condition which could result in

unsafe operation exists, the appliance should be shut off and the owner advised of the unsafe conditions. Corrections

must be made prior to allowing continuous operation. The following steps should be taken in making a safety inspection.

1. Visually inspect the venting system for proper size and determine that there is no blockage, restriction, leakage,

corrosion, or other deficiencies, which could cause unsafe operation.

2. To the extent possible, close all building doors, windows, and all doors to the room in which the heating appliance is

located. Turn on clothes dryers and any exhaust fans so that they operate at maximum speed. Do not operate a

summer exhaust fan. Also close all fireplace dampers. If after completing steps 3 through 7 it is believed that sufficient

combustion air is not available, refer to the National Fuel Gas Code A.N.S.I. Z223.1 or any local codes for proper

guidelines.

3. Place the appliance being inspected into operation. Follow the lighting instructions and adjust the thermostat so that

the heating appliance will operate continuously.

4. Determine that the burner is operating properly and that the main burner ignition functions satisfactorily, by

interrupting the electrical power of the appliance in any safely convenient manner. Test the burner safety device to

determine if it is operating properly by extinguishing the pilot or disconnecting the flame safety circuit.

5. Visually determine that the main burner is burning properly, i.e. no floating, lifting, or flashbacks. Adjust the primary air

shutter as required by the appliance manufacturer. If the appliance is equipped with high and low flame control or

flame modulation, check for proper main burner operation at both flame levels.

6. Test for exhaust gas spillage at the draft hood or the barometric draft control after approximately 5 minutes of main

burner operation. Use a draft meter or flame or smoke from match, candle or cigarette.

7. Turn on all fuel burning appliances within the same room so that they operate at their maximum capacity. Then repeat

Steps 5 and 6.

8. Return all doors, windows, exhaust fans, fireplace dampers, and any other fuel burning appliances to their previous

condition.

Page 9

Page 10

SYSTEM CONTROL CHECK PROCEDURES

1. Adjust the thermostat to call for heat and observe the power venting system for proper operation sequence. Repeat as

necessary.

a. Thermostat calls for heat.

b. Venter relay is energized which starts venter motor.

c. Pressure switch closes which allows burner to fire.

d. Thermostat is satisfied, burner stops operation.

e. Venter continues to operate for up to 2 minutes during the post purge cycle.

2. While the system is in operation, disconnect the draft tube from the air pressure switch. The pressure switch should

open and interrupt burner operation. Re-connect the draft tube to the air pressure switch, which should allow the

burner re-light.

3. If a GSK-3 secondary safety switch is installed, allow the vent pipe to cool and disconnect the vent pipe between the

appliance outlet and venter inlet. Block the vent connected to the appliance with a non-combustible material. Activate

the heating system main burner and verify that the GSK-3 shuts down the burner within a few minutes or less. Reset

the GSK-3 and repeat.

TROUBLESHOOTING TIPS

1. Burner does not fire when thermostat calls for heat.

a. Make sure draft tube is securely fastened to the air pressure switch, and is not blocked.

b. Check for continuity across pressu re switch te rminals when venter is operating.

c. Check wiring connections between air pressure switch, appliance, relay, yellow mode wire connection

and PVU control board.

d. Relay should “click” when pressure switch closes.

2. Venter does not activate when thermostat calls for heat.

a. Check to see if relay closes when thermostat calls for heat.

b. Check wiring connections, including yellow mode wire connection.

c. Check motor for unrestricted shaft rotation.

3. Exhaust gas odor.

a. Check system draft level during operation.

b. Check vent system on outlet side of venter for leakage.

c. Check for negative pressure in building.

MAINTENANCE

1. Motor: Inspect the motor once a year - motor should rotate freely. The PVU’s motor has sealed ball bearings,

therefore, should not need oiling.

2. Blower Wheel: Inspect the blower wheel annually to clear any soot, ash or coating, which inhibits either rotation or

airflow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion and for flue gas leakage.

Replace, seal, or tighten pipe connections if necessary. Check the power venter choke plate to insure it is secured in

place. Check the barometric draft control, if installed, to insure the gate swings freely.

4. System Safety Devices: With the heating system operating disconnect the pressure sensing tube from the pressure

switch on the venter. This should stop the burner operation. Re-connecting the tube will relight the burner. For 30

millivolt operating systems, disconnect one lead of the spill switch circuit from the thermocouple junction block. This

should shut off the pilot and the burner. Re-connection will allow re-lighting of the pilot.

REPLACEMENT PARTS LIST

The following items are available for replacement, if necessary.

REPLACEMENT PARTS LIST

DESCRIPTION

PVU-300

Motor 46512900

Blower Wheel 46513100

24 VAC Relay 46257300

Pressure Switch 46513200

CK-63/PVU Circuit Board 46399200

Page 10

Page 11

r

MULTIPLE VENTING SYSTEMS

1. To vent a 24 VAC controlled boiler or furnace and a 30

millivolt residential water heater using one PVU power

venter refer to the following.

a. Follow the instructions for safe and proper venting

previously specified in this manual. Make sure that the

combined gross BTU/Hr input and equivalent vent pipe

length does not exceed the maximum venting capacity

of the venter selected.

b. A CK-20FV or CK-20FG control kit MUST be added to

the system to properly control the venter during

operation of the water heater. Refer to Figure 10 and

Diagram F for vent pipe arrangement and wiring

information.

Figure 10

Diagram F – Multiple Wiring with 24 VAC Furnace and 30mV Water Heate

Page 11

Page 12

2. To vent two 24 VAC appliances using one PVU power venter refer to the following.

a. Follow the instructions for safe and proper venting previously specified in this manual. Make sure that the

combined gross BTU/Hr input and equivalent vent pipe length does not exceed the maximum venting capacity of

the venter selected.

b. A CK-41 Control Kit must be added to the system to properly control the venter when common venting an

additional 24 VAC furnace or boiler. Tee the draft tube on the PVU unit to connect to the air pressure switch on

the Control Kit. Refer to Diagram G for wiring instructions.

Diagram G – Multiple Wiring with two 24 VAC Appliances

Page 12

Page 13

3. To vent two 120 VAC appliances using one PVU power venter refer to the following.

c. Follow the instructions for safe and proper venting previously specified in this manual. Make sure that the

combined gross BTU/Hr input and equivalent vent pipe length does not exceed the maximum venting capacity of

the venter selected.

d. A CK-61, 62, or 63 Control Kit must be added to the system to properly control the venter when common venting

an additional 120 VAC furnace or boiler. Tee the draft tube on the PVU unit to connect to the air pressure switch

on the Control Kit. Refer to Diagram H for wiring instructions.

Diagram H – Multiple Wiring with two 120 VAC Appliances

Page 13

Page 14

PV SERIES POWER VENTER: VERTICAL VENTING OPTION

Natural gas, lp gas or #2 fuel oil appliance rated at 75% or greater non-condensing type of appliance.

Maximum input temperature at power venter: 575°f

Diagram I – Vertical Venting Option

Page 14

Page 15

VENTING SYSTEM OPERATIONAL INFORMATION

Date:

Heating appliance BTU/Hr input

Gas valve operation pressure

Vent system draft above draft hood or

below barometric draft control

CO2 measurement

CO measurement

Appliance outlet flue gas temperature

INSTALLATION INFORMATION

MODEL NO.:____________________________________________________________

INSTALLER'S NAME:_____________________________________________________

PVU-300

INSTALLER'S COMPANY:_________________________________________________

INSTALLER'S PHONE NO.:________________________________________________

DATE OF INSTALLATION:_________________________________________________

Page 15

Page 16

Page 16

P/N 46517200 Rev B 11/06

Loading...

Loading...