Page 1

PVE SERIES POWER VENTER

SYSTEM MANUAL

Contents Page

I. Typical Venting System Components 2

II. System Operation 3

III. Power Venter Sizing 3,4

IV. Installation Safety Instructions 5,6

V. Installation of Power Venter 6,7

VI. Connecting Power Venter to Appliance 7

VII. General Wiring Instructions 7

VIII. Airflow Adjustments 8

IX. General Installation Inspection 8,9

X. Maintenance 9,10

XI. Replacement Parts List 10

XII. System Operational Information 11

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

Page 2

I. TYPICAL VENTING SYSTEM COMPONENTS:

1 - PVE Series Power Venter

1 - SWH-1 Series Sidewall Vent Hood (Not included)

1 - CK Series Control Kit (Not included)

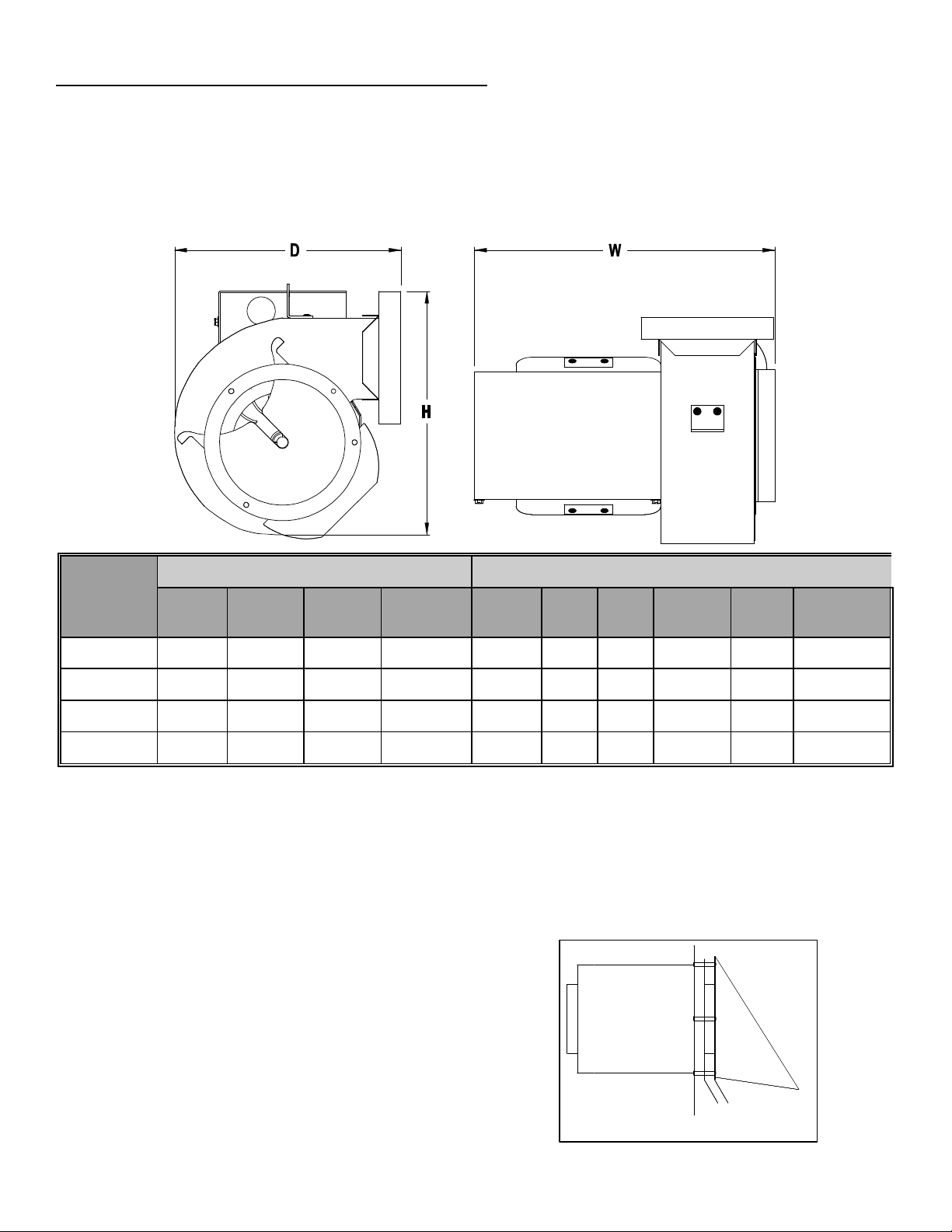

A. DESCRIPTION OF POWER VENTER MODELS

Unit Dimensions (inches) ELECTRICAL DATA

MODEL

"H" "W" "D"

PVE-100 7.50 7.75 7.00 4.00 120 60 3000 145 2.1 YES

PVE-300 7.50 9.25 7.00 4.00 120 60 3000 145 2.1 YES

PVE-600 8.75 9.75 8.50 5.00 120 60 3000 167 1.5 YES

PVE-1200 13.75 12.50 13.50 8.00 120 60 1725 280 2.5 YES

INLET/

OUTLET

VOLTS Hz RPM WATTS AMPS

THERMAL

B. SIDEWALL VENT HOODS (SWH-1):

Sidewall vent hoods are available in the following sizes. The vent hood should be chosen

that matches the outlet size of the Power Venter. Note: Different sizes may be used as long

as the reducers and specific size pipe are considered when determining equivalent length of

vent pipe.

SWH-1-3 - 3 inch

SWH-1-4 - 4 inch

PROT.

SWH-1-5 - 5 inch

SWH-1-6 - 6 inch

SWH-1-8 - 8 inch

Typical Side Wall Vent Hood

Page 2

Page 3

C. CONTROL KITS:

The following are the most commonly used Control Kits.

CK-20F: For operation with 30 millivolt or 750 millivolt gas-fired water heaters, gas-fired

space heaters and gas-fired pool or spa heaters with an internally mounted

thermostat. Includes a non-adjustable post purge timer. Use the CK-22 for an

adjustable post purge timer.

CK-21: For operation with gas-fired instantaneous water heaters with a pressure tap port

in the burner manifold.

CK-41: For operation with gas-fired furnaces, boilers, unit heaters and water heaters

operating with a 24 VAC gas valve.

CK-43: For operation with draft induced gas-fired furnaces, boilers, unit heaters and water

heaters operating with a 24 VAC gas valve. Includes an adjustable post purge

relay/timer, and a draft control for draft induced appliances. Use the CK-43F for a

non-adjustable post purge relay/timer. Use the CK-44F for draft hooded

appliances.

CK-61: For operation with all 120 VAC oil-fired systems. Has electronic post purge. Use

the CK-62 for a thermally activated post purge.

CK-81: For operation with 750 millivolt operated boilers, furnaces, water heaters, pool or

spa heaters and gas-fired fireplaces when operating with a remote mounted 24

VAC thermostat. For operation with a 120 VAC thermostat or wall switch, use the

CK-80.

CK-91: For operation with a draft induced gas-fired furnace or boiler and a 30 millivolt

operated water heater. Includes an adjustable post purge relay/timer and a draft

control. Use the CK-92 for draft hooded appliances. Use the CK-91F or 92F for a

non-adjustable post purge relay/timer.

II. SYSTEM OPERATION

A. The thermostat (wall thermostat, or aquastat) calls for heat and energizes a relay which

activates the power venter. After the venter motor has come up to speed, the pressure

switch closes. This completes the circuit to the burner and allows the burner to fire.

B. For millivolt controlled water heaters, the gas pressure switch on the gas valve activates the

power venter at the same time as the burner fires.

C. After the heating requirement has been satisfied, the thermostat circuit will open and de-

activate the burner and power venter circuit.

D. For venting systems equipped with a post purge device, the power venter operates for a

period of time after the burner has shut off to purge remaining flue gases.

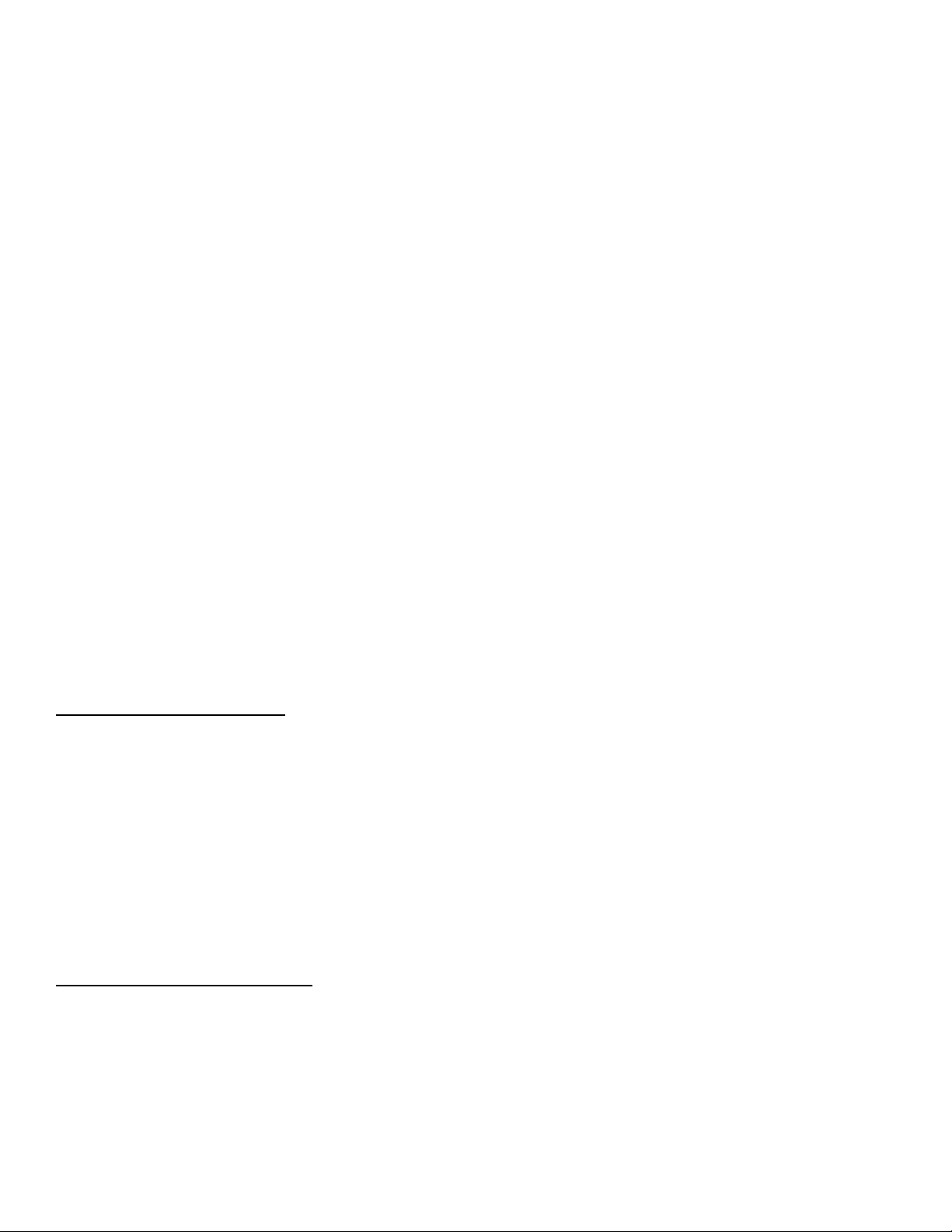

III. POWER VENTER SIZING

In order to choose the correct size power venter for a particular installation, the total input firing

rate and total equivalent length of vent pipe to be used must be known. Refer to the following

sizing chart to determine the maximum allowable equivalent feet of pipe for each model used

with the pipe diameters shown. When venting multiple appliances, add the input of each

appliance to determine the total input. Always choose a power venter that is capable of handling

more than the system requires. The choke plate can be adjusted to compensate for the

difference.

Page 3

Page 4

MAXIMUM EQUIVALENT HORIZONTAL PIPE LENGTH (FEET)

BTU/HR

INPUT

3" 4" 4" 5" 6" 5" 6" 8" 8" 10"

25,000 270 455 - - - - - - - 55,000 100 169 - - - - - - - 70,000 - 144 - - - - - - - -

100,000 - 100 305 - - - - - - 145,000 - - 145 247 334 413 - - - 220,000 - - 64 100 147 181 - - - 310,000 - - - 54 74 91 146 216 - 400,000 - - - - - 54 87 134 - 520,000 - - - - - - 52 86 443 610,000 - - - - - - - 66 313 390

700,000 - - - - - - - - 227 330

900,000 - - - - - - - - 180 290

PVE-100 PVE-300 PVE-600 PVE-1200

VENTER MODEL AND VENT PIPE DIAMETER

1,000,000 - - - - - - - - 125 190

1,250,000 - - - - - - - - - 80

A. PROCEDURE FOR CALCULATING TOTAL EQUIVALENT PIPE LENGTH IN FEET:

1) Calculate the total equivalent feet for each type of fitting used in the venting system from

the chart below.

2) Calculate the total amount of feet for the straight lengths of vent pipe.

3) Add the equivalent feet for the fittings with the total amount of feet of straight lengths.

EQUIVALENT LENGTH (FEET) OF VENT PIPE FOR VENT PIPE FITTINGS

VENT PIPE

FITTINGS

TEE 19 25 31 38 44 50 56 63

90° ELBOW 5 7 9 11 12 14 16 18

45° ELBOW 3 4 4 5 6 7 8 9

1/4 8 11 14 17 19 22 25 28

REDUCER

(d/D)*

1/2 5 7 8 10 12 13 15 17

3/4 2 3 3 4 4 5 6 6

3" 4" 5" 6" 7" 8" 9" 10"

VENT PIPE DIAMETER

Page 4

Page 5

*

Reducer or increaser ratio (d/D) small diameter divided by the larger

diameter. Example 4" to 8" reducer, the reducer ratio is d/D = 4/8 = 1/2.

To estimate the equivalent foot length for the fitting, use the smaller pipe

diameter for the equivalent length figure. Example 4" to 8" reducer; the

reducer ratio is 1/2 and the smaller pipe diameter is 4". So, from the

Typical Pipe Fitting

chart, the equivalent feet would be 7 feet.

Example:

System Pipe Size = 4"

Step 1: 2 - 90° Elbows (4") = 14 Ft.

Step 2: 10 - 2 Ft. Lengths of 4" Pipe = 20 Ft.

Step 3: Total Equivalent Feet = 14 Ft. + 20 Ft. = 34 Ft.

IV. INSTALLATION SAFETY INSTRUCTIONS

CAUTION: This device must be installed by a qualified installer in accordance with the

manufacturer's installation instructions. Appliances should have a minimum of 75% combustion

efficiency or have a maximum measured flue gas temperature of 550°F at the inlet of the venter.

A. The power venting system must be installed by a qualified installer. "Qualified Installer" shall

mean an individual who has been properly trained or a licensed installer. The installer must

write or imprint his name, phone number and date of installation on the installation tag. The

tag should be attached to the power venting system control kit box or venter unit. Recording

burner and venting system initial operational information is recommended as a guide for

service or burner tune-up. Enter this on the back page of this manual.

B. Safety inspection of a venting system should be performed before and after installing a

power venting system on an existing or new appliance. Procedures to follow are those

recommended by the National Fuel Gas Code, A.N.S.I.Z223.1 or refer to the "General

Installation Inspection" section of this manual.

C. Plan the vent system layout before installation to avoid the possibility of accidental contact

with concealed wiring or plumbing inside walls.

D. Single wall vent pipe may be used to join an appliance to the venting system, but if proper

clearances cannot be maintained from combustible materials, Class B Vent Pipe should be

used for gas appliances and Class L Type Vent Pipe for oil appliances. Refer to national or

local codes for guidelines.

E. Disconnect power supply before making wiring connections to prevent electrical shock and

equipment damage.

F. This equipment is designed to overcome minor negative pressure conditions. To ensure

extreme negative pressure does not exist, follow the "General Installation Inspection" section

of this manual.

G. Heating appliances equipped with draft hoods, such as boilers or furnaces, LP and natural

gas appliances SHOULD have a secondary spillage switch installed. On appliances without

draft hoods, it is recommended that the secondary safety switch WMO-1 be installed into the

system. Gas-fired 30 millivolt power systems MUST be equipped with a spillage switch.

H. Air flow adjustment MUST be made to ensure appliance efficiency. This should be done at

the appliance exhaust outlet with a velocity meter, draft gauge or by the "match test

procedure". The match test is in accordance with National Fuel Gas Code A.N.S.I.Z223.1,

Section 8.6.

Page 5

Page 6

I. On oil-fired and gas-fired heating appliances not equipped with a draft hood, a barometric

draft control MUST be installed to regulate proper air flow and fluctuations in the system's air

flow during operation. Fluctuations can come from wind loads on the outlet of the venter,

house depressurization during windy days and the different house ventilation requirements

between summer and winter operation. For gas appliances use a Field Controls Type MG-1

Barometric Draft Control. For oil appliances use a Field Controls Type M or RC Barometric

Draft Control. Gas-fired draft induced systems should have a single-acting or double-acting

barometric draft control installed.

V. INSTALLATION OF POWER VENTER

CAUTION: Failure to install, maintain and/or operate the power venting system in accordance

with manufacturer's instructions will result in conditions which may produce bodily injury and/or

property damage.

A. Remove power venter from box and inspect unit for damage. If the carton has been crushed

or mutilated, check unit very carefully for damage. Rotate venter wheel to insure that the

motor and venter wheel rotate freely. DO NOT install if any damage is apparent. Refer to

unit sizing chart to check proper venting sizing.

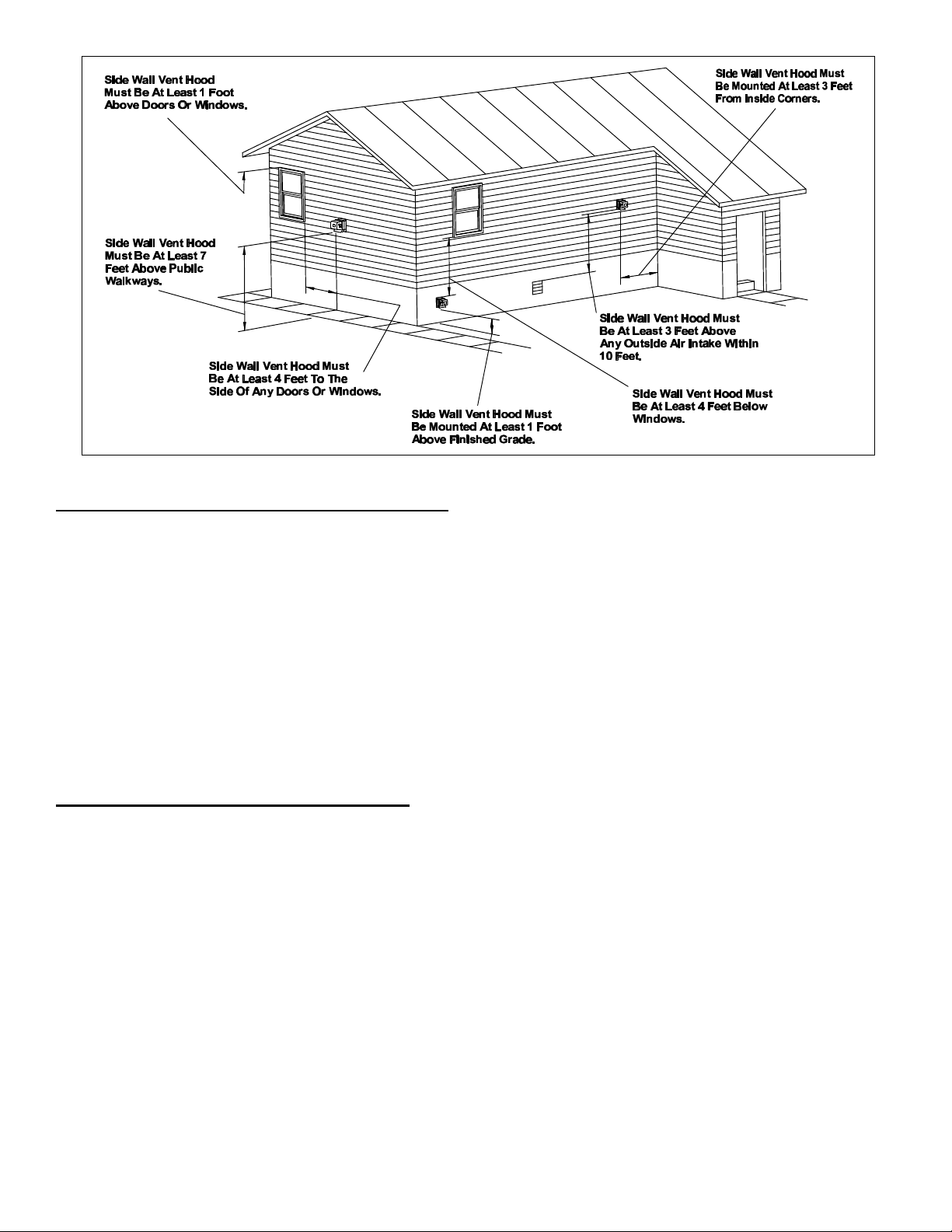

B. Location of the termination of the venting system should be installed in accordance with the

National Fuel Gas Code, A.N.S.I.Z233.1, manufacturer's recommendations, and/or local

codes which are applicable. See the following requirements or refer to installation location

Diagram A for typical locations.

1. The exit termination of mechanical draft systems shall not be less than 7' above grade

when located adjacent to public walkways.

2. A venting system shall terminate at least 3' above any forced air inlet located within 10'.

3. The venting system of other than a direct vent appliance shall terminate at least 4'

below. 4' horizontally from or 1' above any door, window or gravity air inlet into the

building.

4. The vent termination of a direct vent appliance with an input of 50,000 BTU/Hr or less,

shall be located at least 9" from any opening through which vented gases could enter

the building. With an input over 50,000 BTU/Hr, a 12" termination clearance shall be

required.

5. The vent termination point shall not be installed closer than 3' from an inside corner of

an L-shaped structure.

6. The vent termination should not be mounted directly above or within 3' horizontally from

an oil tank vent or gas meter.

7. The bottom of the vent terminal shall be located at least 12" above finished grade.

C. The power venter should never be installed with the venter motor in the vertical position.

This could lead to premature motor failure. The venter outlet can be oriented at any angle,

from horizontal to vertical. The power venter should be installed as close to the outside wall

as possible.

Page 6

Page 7

Diagram A PVE Side Wall Vent Termination Locations

VI. CONNECTING VENTER TO APPLIANCE:

The venting system should be installed and supported in accordance with the National Fuel Gas

Code A.N.S.I.Z223.1, or in accordance with any local codes. A vent pipe connector shall be

supported for the design and weight of the material employed, to maintain clearances, prevent

physical damage and separation of joints. A vent pipe increaser or reducer may be required for

connecting the venter to the vent system. Smaller vent pipe sizes than a chimney-vented system

may be used for the vent system.

Route the vent pipe from the appliance to the venter using a minimum number of elbows as

possible. The horizontal section of the vent pipe should have a slight upward slope from the

appliance to the venter. For clearances to combustible materials, multiple appliance venting and

other installation requirements, refer to the National Fuel Gas Code A.N.S.I.Z223.1, and/or any

applicable local codes or appliance manufacturer's installation instructions.

VII. GENERAL WIRING INSTRUCTIONS:

The PVE-100, 300, 600, and 1200 are designed to be used with either millivolt, 24 VAC, or 120

VAC appliances when used with the appropriate controls. For use on a millivolt controlled

system a Field Controls HWK-6 or an appropriate Control Kit is required. For use on a 24 VAC

or 120 VAC controlled system a Control Kit must be used. Refer to the installation manuals for

the HWK-6 and individual Control Kits for wiring instructions. The small steel tube mounted on

the inlet to the PVE power venter must be connected to the air pressure switch on the Control

Kit. This enables the primary safety feature of the PVE power venter system.

Wire the venter motor and controls in accordance with the National Electric Code, and/or

applicable local codes. UNIT MUST BE GROUNDED. Check ground circuit to make certain that

the unit has been properly grounded. The wiring should be protected by an over-current circuit

device rated at 15 amperes. CAUTION MUST be taken to ensure that the wiring does not come

in contact with any heat source. All line voltage and safety control circuits, between the venter

and the appliance, MUST be wired in accordance with the National Electrical Code for Class 1

wiring, or equivalent methods.

Page 7

Page 8

A. ADJUSTING THERMOSTAT ANTICIPATOR:

If connecting the Power Venter system to a gas appliance with a thermostat anticipator, refer

to the following to make adjustments. Disconnect one side of the thermostat circuit at the

gas valve or burner control, and connect an ampere meter into the circuit. With the system

running, take an amperage reading on the circuit. Check the nameplate or instructions for

the thermostat to obtain the proper amperage level. Adjust amperage level by moving the

anticipator lever. Reconnect the thermostat to the gas valve and start the system operating.

Time the burn cycles and adjust as follows; To make the cycle time longer, increase the

amount on the anticipator (Example: .45 to .5 Amps); to decrease cycle time, reduce the

amount on the anticipator (Example: .45 to .3 Amps) (See Figure 1.)

VIII. AIR FLOW ADJUSTMENTS:

To adjust the power venter air flow, open the choke plate 1/2 to

3/4 of the way open (See Figure 2.) Follow appliance

manufacturer's procedures for starting the heating appliance.

Then adjust the thermostat to call for "Heat". After the system

has operated for several minutes to stabilize flue gas

temperatures, check for negative draft or up-draft at the heating

appliance outlet or air flow into the draft hood. Use a draft

gauge, velocity meter, or match test procedure. Adjust the inlet

choke damper on the power venter in or out to obtain the

minimum air flow required to maintain draft. Then increase air

flow slightly (10% over minimum air flow rate) to ensure proper

venting. For oil-fired or gas-fired power burners, adjust draft to

proper over-fired draft. If using a barometric draft control, use

the draft control to fine tune the system draft. If proper draft has

been established, secure the choke plate by tightening the

screws on the inlet collar. For gas-fired systems, shut off

thermostat and check for residual heat spilling from the draft

hood. If this occurs, a post purge system may be required. If

so, use a Field Controls PPC-5 Electronic Post Purge. Before

installing, refer to the General Installation Inspection to check for

negative pressure problems in the building. Refer to the

appropriate control kit installation instructions for pressure

switch adjustment procedure and system checkout procedures

before operating continuously.

Figure 1

NOTE: After proper venting has been established, it is

recommended that a combustion test on gas and oil units, a

check for CO levels on gas units, and a smoke test on oil

Figure 2

systems be performed to ensure maximum burner efficiency.

Oil burner air adjustments should be set at a zero to a trace

smoke at the highest or recommended CO2% setting set by

heating equipment manufacturer.

IX. GENERAL INSTALLATION INSPECTION:

Recommended procedures for safety inspection of an appliance in accordance with the National

Fuel Gas Code A.N.S.I.Z223.1. The following procedure will help evaluate the venting system. It

is intended as a guide to aid in determining that the venting system is properly installed and is in

a safe condition for continuous use. This procedure should be recognized as a generalized

procedure which cannot anticipate all situations. Accordingly, in some cases, deviation from this

Page 8

Page 9

procedure may be necessary to determine safe operation of the equipment. If it is determined

that a condition exists which could result in unsafe operation, the appliance should be shut off

and the owner advised of the unsafe condition. Corrections must be made before the appliance

is put into continuous operation. The following steps should be followed in making a safety

inspection.

1. Visually inspect the venting system for proper size and determine that there is no flue

gas spillage, blockage or restriction, leakage, corrosion and other deficiencies which

could cause an unsafe operation.

2. Insofar as practical, close all building doors, fireplace dampers, windows, and all doors

in area in which the appliance is located. Turn on clothes dryers, any exhaust fans,

such as range hoods and bathroom exhausters so they operate at maximum speed. Do

not operate a summer exhaust fan. If, after completing Steps 3 through 7 it is believed

sufficient combustion air is not available, refer to the National Fuel Gas Code

A.N.S.I.Z223.1, or any applicable local codes for guidance.

3. Place in operation the appliance being inspected. Follo w the lighting instructions and

adjust thermostat so appliance will operate continuously.

4. Determine that the pilot or burner is operating properly and that the main burner ignition

operates satisfactorily, by interrupting and re-establishing the electrical power of the

appliance in any convenient manner. Test the pilot or burner safety device to determine

if it is operating properly by extinguishing the pilot or disconnecting the flame safety

circuit and pressure switch sensing tube from pressure switch.

5. Visually determine that the main burner is burning properly; i.e., no floating, lifting or

flashbacks. Perform a smoke test on oil-fired system; the burner should operate at a

zero to a trace smoke. This can indicate reduced available combustion air to burner.

6. If appliances are equipped with high and low flame control or flame modulation, check

for proper main burner operation at low flame.

7. Test for spillage at draft hood or barometric draft control opening and burner inlet air

location after 5 minutes of main burner operation. Use a draft gauge, flame of a match

or candle, smoke from a cigarette, cigar or pipe. If spillage occurs, adequate air is not

available. Shut off heating appliance thermostat and check for spillage around the draft

hood, barometric draft control or burner inlet air location after power venter has stopped

operation. If a flow reversal is noticed, house depressurization is occurring and make

up air is required. For oil-fired systems, this may be noticed by oil fume smell after post

purge cycle.

8. Turn on all fuel burning appliances within the same room so that they will operate at

their maximum input. Then repeat Steps 5 through 7.

9. Return doors, windows, exhaust fans, fireplace dampers and any other fuel-burning

appliances to their previous condition of use.

X. MAINTENANCE:

1. Motor: Inspect the motor once a year - motor should rotate freely.

2. Wheel: Inspect the venter wheel annually to clear any soot, ash or coating which inhibits

either rotation or air flow. Remove all foreign materials before operating.

3. Vent System: Inspect all vent connections annually for looseness, for evidence of corrosion

and for flue gas leakage. Replace, seal, or tighten pipe connections if necessary. Check the

power venter choke plate to insure it is secured in place. Check the barometric draft control,

if installed, to insure the gate swings freely.

Page 9

Page 10

10

4. System Safety Devices: With the heating system operating disconnect the pressure sensing

tube from the pressure switch on the CK kit. This should stop the burner operation. Reconnecting the tube will relight the burner. For 30 millivolt operating systems, disconnect

one lead of the spill switch circuit from the thermocouple junction block. This should shut off

the pilot and the burner. Re-connection will allow relighting the pilot.

XI. REPLACEMENT PARTS

The following items are available for replacement, if necessary.

Replacement Parts List

Part Number Description

46032000 PVE-100 Motor

46032000 PVE-300 Motor

46083300 PVE-600 Motor

46226500 PVE-1200 Motor

46080100 PVE-100 Blower Wheel

46033400 PVE-300 Blower Wheel

46089400 PVE-600 Blower Wheel

46124000 PVE-1200 Blower Wheel

Page

Page 11

11

XII. INITIAL BURNER AND VENTING SYSTEM OPERATIONAL INFORMATION

List for each operating appliance on the sidewall venting system, as a guide for tune-up or service

information.

FOR GAS-FIRED EQUIPMENT

Heating Appliance BTU-HR Input ___________________________________________________

Gas Valve Operation Pressure _____________________________________________________

Vent System Draft Above Draft Hood ________________________________________________

or below Barometric Draft Control___________________________________________________

CO2 Measurement ______________________________________________________________

CO Measurement _______________________________________________________________

Equipment Outlet Flue Gas Temperature_____________________________________________

FOR OIL-FIRED EQUIPMENT

Oil Burner Nozzle Size ___________________________________________________________

Oil Burner Operating Pressure _____________________________________________________

Pump Operating Vacuum Pressure _________________________________________________

Smoke Number_________________________________________________________________

Over-fire Draft__________________________________________________________________

Equipment Outlet Flue Gas Temperature_____________________________________________

CO2 Measurement ______________________________________________________________

Page

Page 12

12

P/N 46115300 Rev. D

Page

Loading...

Loading...