Page 1

METERING AIR SYSTEM

Model: MAS-1

The Field Metering Air System consists of an intake air hood which is installed through the wall to

allow outside air in. The hood is connected via flexible 6” duct or standard duct pipe (not included) to

our metering air device mounted on the return/supply air plenum. This device effectively meters the

air inflow for proper air circulation, combustion and balance.

ITEMS INCLUDED

1) Metering air damper

1) Mounting template

1) 6" intake hood

20) Small washers (2 grams each)

3) Large washers (50 grams each)

English ...... Page 1

Français..... Page 3

Espanõl ..... Page 4

Page 2

INSTALLATION AND ADJUSTMENTS

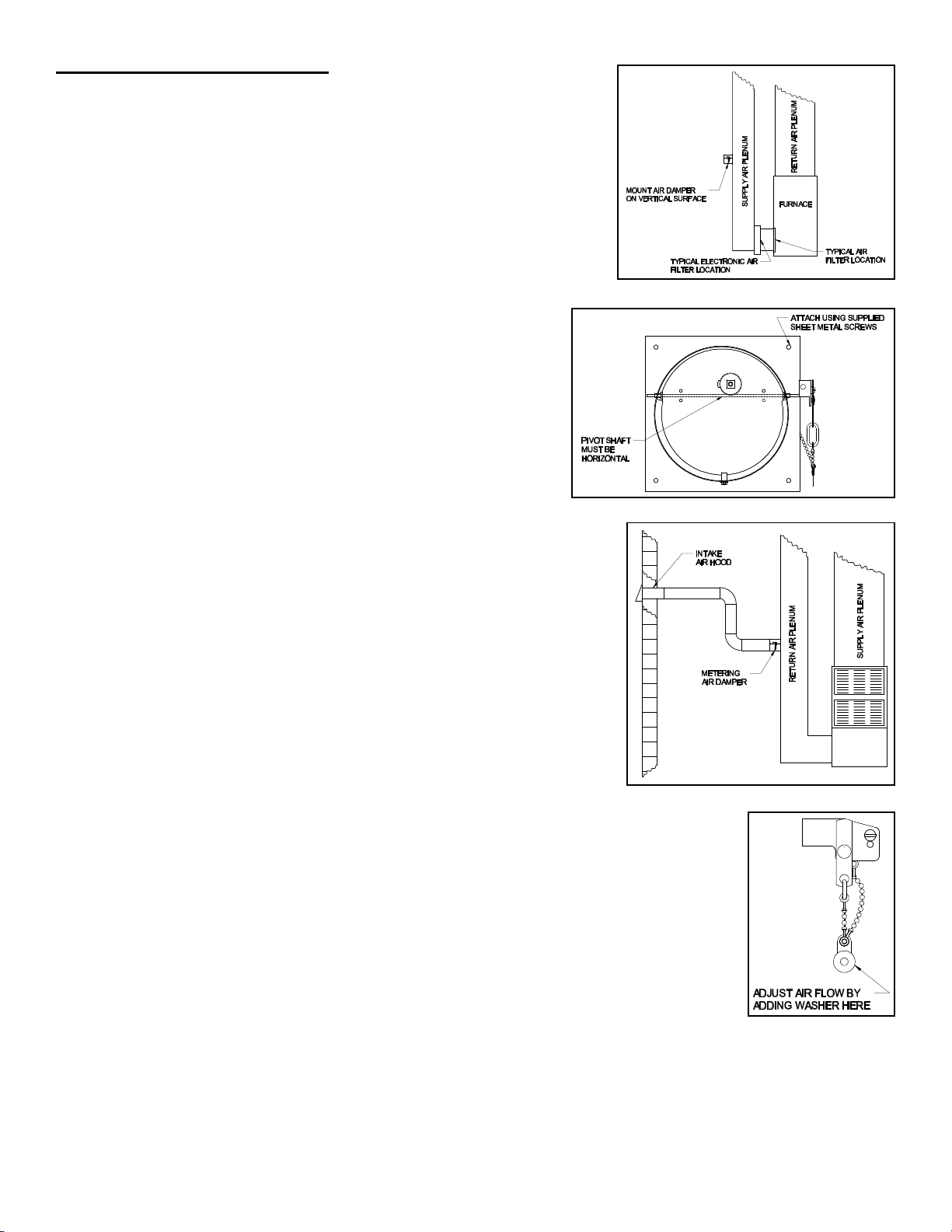

1. Apply mounting template onto the side of the return air plenum of the

furnace. By wetting the back side and applying to any vertical surface of

the return air plenum.

CAUTION: Unit must be mounted on a vertical surface. Level the template

horizontally by marking a line onto the plenum using a level. Then applying the

edge of the template on this line. (See Figure 1)

2. After allowing template to dry, drill (4) 1/8 inch diameter holes at the

location indicated on the template. Also, drill 4 or 5 holes along the cutting

line of the 6 1/8 inch diameter hole indicated on the template to allow for a

starting hole for cutting. Then cut hole with metal shears.

3. Mount the metering air damper using supplied sheet metal screw. (See

Figure 2)

INSTALLATION OF INTAKE HOOD

1. Locate intake hood at least 10 feet away from any device that

exhaust flue gases.

2. Install the intake hood at least 12 inches above grade.

3. Cut a 6 1/8 inch diameter hole through the wall. Then mount the

intake hood to the wall using suitable fastener. Then seal along the

mounting plate with silicone or equivalent sealant.

Figure 1

4. Connect 6" flex duct or standard 6" duct piping from the intake hood

to the metering air damper. Fasten and support piping, so no

straining of the metering air damper exist. (See Figure 3)

NOTE: Some areas require insulation wrapped around the duct. This will be

required if sweating occurs on the outside of the duct. Seal all duct joints and

seams with duct tape or equivalent.

ADJUSTING METERING AIR DAMPER

1. Determine building square footage. Then refer to the table on the next

page for recommended weighing of air damper.

2. Attach weights to the pendent on weight lever assembly using the supplied

#5 screw and nut. (See Figure 4)

Figure 2

Figure 3

Figure 4

Page 2

Page 3

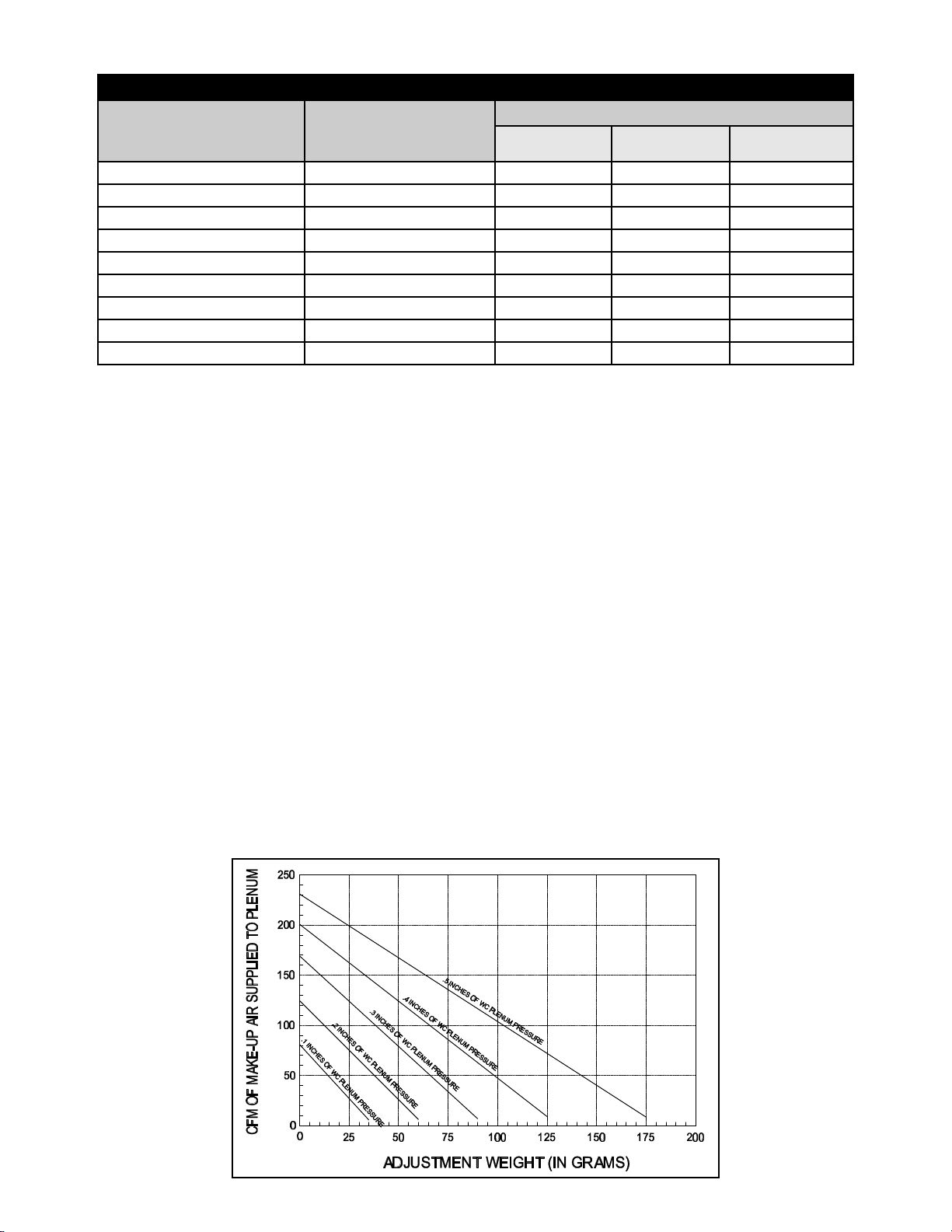

TABLE 1

AIRFLOW CHART

NUMBER OF ADJUSTMENT WEIGHTS ADDED

SMALL LARGE GRAMS

BUILDING SQUARE FEET

APPROXIMATE CFM

OF MAKE-UP

SUPPLIED TO PLENUM

1000 67 19 1 88

1250 83 13 1 76

1500 100 8 1 66

1750 117 2 1 54

2000 133 20 - 40

2250 150 16 - 32

2500 167 11 - 22

2750 183 3 - 6

3000 200 - - -

The cfm of make-up air was based on 1/2 air changes per hour in the building, an average ceiling height of 8

feet and a return air plenum pressure of .4 inches of water column.

CALUCULATE CFM OF MAKE UP AIR

To adjust the metering air damper for different air changes per hour, building volumes or different return air pressures

refer to Table 1.

1. Calculate building volume: Building square feet x average ceiling height.

2. Estimate desired building air change per hour (ACPH).

Typical ACPH for buildings:

Tight construction -.35 to .5

Average construction -.5 to .75

Loose construction .75 to 1.00

3. Calculate required CFM of make up air:

(Building volume x ACPH) ÷ 60.

4. Measure return air plenum pressure. In inches of water column pressure.

5. Refer to chart (or see example)

EXAMPLE: 2,000 sq. ft. building with 8 foot high ceilings required air changes per hour = .5 ACPH. Furnace return air

plenum pressure .3 inch.

1. Building volume = 2,000 sq. ft. x 8 ft. = 16,000 cu. ft.

2. Required CFM = (16,000 cu. ft. x .5) ÷ 60 = 133 CFM. Entering the chart at 133 CFM draw a line horizontally until

it intersects the .3 pressure curve. Then draw a line vertically down to the weight axis. For this example the

amount of weight to add to the weight level assembly would be 20 grams or 10 small washers.

Page 3

Page 4

INSTALLATION

1. Placer le gabarit de montage sur le côté du plenum de retour d’air de la

fournaise. Mouiller le côté arrière et apposer sur toute surface verticale du

plenum de retour d’air.

ATTENTION: L’unité doit être installée sur une surface verticale. Mettre le

gabarit horizontalement de niveau en traçant une ligne sur le plenum au

moyen d’un niveau. Placer ensuite le bord du gabarit sur cette ligne. (Voir Le

Schéma 1)

2. Attendre que le gabarit sèche, puis percer quatre trous de 1/8 po de

diamètre aux endroits indiqués sur le gabarit. Percer aussi quatre ou cinq

trous le long de la ligne de coupe du trou de 6 1/8 po de diamètre

indiqué sur le gabarit pour faire un trou de départ. Découper

ensuite l’ouverture avec des cisailles à tôle.

3. Fixer le registre de dosage d’air au moyen des vis à tôle incluses.

(Voir Le Schéma 2)

INSTALLATION DE LA HOTTE D’ADMISSION

1. Placer la hotte d’admission à au moins 10 pi de tout dispositif

émettant des gaz d’évacuation.

2. Installer la hotte d’admission à une élévation d’au moins 12 po.

3. Découper un trou de 6 1/8 po de diamètre dans le mur. Fixer

ensuite la hotte d’admission au mur au moyen d’une fixation

adéquate. Sceller ensuite le long de la plaque de montage avec un scellant

de silicone ou l’équivalent.

Schéma 1

Schéma 2

4. Placer un conduit flexible 6 po ou un tuyau standard 6 po entre la hotte

d’admission et le registre de dosage d’air. Fixer et soutenir le tuyau de

façon à ce qu’il ne s’exerce aucune tension sur le registre de dosage d’air.

(Voir Le Schéma 3)

NOTA: Dans certains endroits, le conduit doit être enveloppé d’isolant.

L’isolation est nécessaire dans les cas où de la condensation se produit à

l’extérieur du conduit. Sceller tous les joints du conduit avec du ruban adhésif

en toile ou l’équivalent.

RÉGLAGE DU REGISTRE DE DOSAGE D’AIR

1. Déterminer la superficie du bâtiment en pieds carrés. Référez-vous à la

table à la prochaine page pour peser recommandé de l'amortisseur d'air.

2. Fixer les poids au pendant de l’assemblage de levier au moyen d’une vis n° 5 et

d’un écrou (inclus). (Voir Le Schéma 4)

Schéma 3

Schéma 4

Page 4

Page 5

TABLEAU 1

DIAGRAMME DE FLUX D'AIR

BÂTIMENT, PIEDS CARRÉS

AIR D’APPOINT EN PI3/MIN

ENVOYÉ AU PLENUM

NOMBRE DE POIDS DE RÉGLAGE AJOUTÉS

PETIT GROS GRAMMES

1000 67 19 1 88

1250 83 13 1 76

1500 100 8 1 66

1750 117 2 1 54

2000 133 20 - 40

2250 150 16 - 32

2500 167 11 - 22

2750 183 3 - 6

3000 200 - - -

L’air d’appoint en pi3/min est calculé selon un demi-changement d’air par heure dans le bâtiment, une hauteur de

plafond moyenne de 8 pi et une pression au plenum de retour d’air de 0,4 po à la colonne d’eau.

CALCULEZ CFM DE COMPOSENT L'AIR

Pour régler le registre de dosage d’air selon différents changements d’air par heure, différents volumes de bâtiment ou

différentes pressions au plenum de retour d’air, se reporter au tableau 1.

1. Calculer le volume du bâtiment: superficie du bâtiment en pieds carrés x hauteur de plafond moyenne.

2. Évaluer le changement d’air par heure (CAPH) désiré pour le bâtiment.

CAPH type pour les bâtiments:

Bâtiment hermétique: -0,35 à 0,5

Bâtiment moyen: -0,5 à 0,75

Bâtiment aléatoire: 0,75 à 1,00

3. Calculer l’air d’appoint en pi3/min requis:

(volume du bâtiment x CAPH) ÷ 60.

4. Mesurer la pression au plenum de retour d’air (pression en pouces à la colonne d’eau).

5. Se reporter au tableau (ou voir l’exemple).

EXEMPLE: Un bâtiment de 2 000 pi2 à plafonds de 8 pi de haut requiert un changement d’air par heure de 0,5. La

pression au plenum de retour d’air de la fournaise est de 0,3 po.

1. Volume du bâtiment: 2 000 pi2 x 8 pi = 16 000 pi3

2. Air d’appoint en pi3/min requis = (16 000 pi3 x 0,5) ÷ 60 = 133 pi3/min. En commençant dans le tableau à 133

pi3/min, tracer une ligne horizontale jusqu’à ce qu’elle rejoigne la courbe de pression 0,3. Tracer ensuite une

ligne verticale pour descendre jusqu’à l’axe de poids. Pour cet exemple, le poids à ajouter à l’assemblage de

levier serait de 20 grammes, ou 10 petites rondelles.

Page 5

Page 6

INSTALACIÓN

1. Aplique la plantilla de montaje del lado del pleno del aire de recuperación

del generador, humedeciendo la parte posterior y aplicándola a una

superficie vertical del pleno de aire de recuperación.

PRECAUCIÓN: La unidad debe colocarse sobre una superficie vertical.

Nivele la plantilla horizontalmente marcando una línea sobre el pleno usando

un nivel. Luego aplique el borde de la plantilla sobre esta línea. (Ver Figura 1)

2. Después de dejar que la plantilla se seque, perfore 4 orificios de 1/8 de

pulgada de diámetro en el lugar indicado en la plantilla. Además perfore 4

o 5 orificios a lo largo de la línea de corte del orificio de 6 1/8” de diámetro

indicado en la plantilla para obtener un orificio inicial para el corte. Luego

corte el orificio con tijeras para metal.

3. Coloque el regulador de aire de dosificación usando el tornillo para

hoja metálica provisto. (Ver Figura 2)

INSTALACIÓN DE LA CAMPANA DE ADMISIÓN

1. Ubique la campana de admisión por lo menos a 10 pies de

distancia desde cualquier dispositivo que deje escapar los gases

de combustión.

2. Instale la campana de admisión por menos a 12 pulgadas por

encima del nivel del suelo.

3. Corte un orificio de 6 1/8 pulgadas de diámetro a través de la

pared. Luego coloque la campana de admisión sobre la pared

usando un sujetador adecuado. Luego selle a lo largo de la plancha de

montaje con silicona o un compuesto sellador equivalente.

Figura 1

Figura 2

4. Conecte 6 " conducto de la flexión o tubería del conducto del estándar 6 "

de la capilla del producto con el apagador medidor del aire. Sujete y utilice

la tubería, así que el ningún filtrar del apagador medidor del aire existe.

(Ver Figura 3)

AJUSTE DEL REGULADOR DE AIRE DE DOSIFICACIÓN

1. Determine los pies cuadrados del edificio. Refiera al vector en la

paginación siguiente para pesar recomendado del apagador del aire.

2. Coloque los pesos en el colgante de la unidad de palanca de peso usando

el tornillo #5 y la tuerca suministrados. (Ver Figura 4)

Figura 3

Figura 4

Page 6

Page 7

Tabla 1

DIAGRAMME DE FLUX D'AIR

PIES CUADRADOS DEL

EDIFICIO

PIES CÚBICOS POR MINUTO (CFM)

APROXIMADOS DE COMPENSACIÓN

SUMINISTRADOS AL PLENO

NÚMERO DE PESOS DE AJUSTE

AGREGADOS

PEQUEÑAS GRANDES GRAMOS

1000 67 19 1 88

1250 83 13 1 76

1500 100 8 1 66

1750 117 2 1 54

2000 133 20 - 40

2250 150 16 - 32

2500 167 11 - 22

2750 183 3 - 6

3000 200 - - -

Los pies cúbicos por minuto de aire de compensación se basan en la mitad de cambios de aire por hora en el edificio, una

altura promedio del techo de 8 pies y una presión del pleno de aire de recuperación de 0,4 pulgadas de columna de agua.

CALCULE CFM DE HACEN PARA ARRIBA EL AIRE

Para ajustar el regulador de aire de dosificación para diferentes cambios de aire por hora, volúmenes del edificio o

diferentes presiones del aire de recuperación, consulte Tabla 1.

1. Calcule el volumen del edificio: pies cuadrados del edificio x altura promedio del techo.

2. Estime el cambio de aire deseado del edificio por hora (“CAPH”).

ACPH típico para los edificios:

Construcción apretada - 35 al 5

Construcción media - 5 al 75

Construcción floja - 75 a 1.00

3. Calcule requirió CFM de hacen para arriba el aire:

(volumen x ACPH del edificio) ÷ 60.

4. Presión de vuelta del pleno del aire de la medida. En pulgadas de presión de la columna del agua.

5. Refiera a la carta (o vea el ejemplo)

EJEMPLO: Edificio de 2.000 pies cuadrados con un techo de 8 pies de altura requiere cambios de aire por hora = 0.5

CAPH. Presión del pleno de aire de recuperación del generador 0,3 pulgadas.

1. Volumen del edificio = 2.000 pies cuadrados x 8 pies = 16.000 pies cúbicos.

2. CFM requeridos = (16.000 pies cúbicos x 0,5) ÷ 60 = 133 CFM. Vaya a la gráfica a 133 CVM, trace una línea

horizontal hasta que se entrecruce con la curva de presión de 0,3. Luego trace una línea vertical por el eje de

peso hacia abajo. Para este ejemplo, la cantidad de peso que se debe agregar a la unida de nivel de peso sería

de 20 gramos o 10 arandelas pequeñas.

Page 7

Page 8

Page 8

P/N 46233500 Rev A 11/00

Loading...

Loading...