Page 1

MEDIA AIR CLEANER

Models: FC-1400 & FC-2000

Items Included: 1) Cabinet

1) Media Filter

1) Installation Instruction Manual

NOTE: This device should be installed by a qualified agency* in accordance with the manufacturer’s installation instructions.

*The definition of a qualified agency is: any individual, firm, corporation or company which either in person or through a representative is

engaged in, and is responsible for, the installation and operation of HVAC appliances, who is experienced in such work, familiar with all

the precautions required, and has complied with all the requirements of the authority having jurisdiction.

WARNING: Read the installation instructions carefully and completely before proceeding with the installation.

GENERAL SYSTEM INFORMATION

Field Controls high efficiency series of media air cleaners are designed for installation into heating, ventilation,

air conditioning (HVAC) systems to reduce the amount of airborne particulate (1.0 micron and larger) including

pollen, dust and dander promoting better indoor air quality. The media air cleaner should be installed in the

return air system duct, such that all of the circulated air passes through the filter. For maximum filtering

performance, the air circulation fan should operate continuously.

Model FC - 1400 FC - 2000

Nominal Filter size 16” x 25” x 5” 20” x 25” x 5”

Air flow range 600-1400 CFM 600-2000 CFM

MERV rating 11 11

Filter Replacement P/N 46568500 46568600

Cabinet dimensions 16-1/4” x 24-7/8” x 7-1/8” 20-1/4” x 24-7/8” x 7-1/8”

Cabinet opening dimensions 13-7/8” x 22-1/2” 17-7/8” x 22-1/2”

UL filter media listing Class 2 Class 2

NOTE: FOR OPTIMUM PERFORMANCE, REPLACE THE MEDIA FILTER EVERY 6 TO 12 MONTHS.

DO NOT DESTROY

THESE INSTRUCTIONS MUST REMAIN WITH EQUIPMENT

2630 AIRPORT ROAD · KINSTON, NC 28504

Phone: 252-522-3031· Fax: 252-522-0214

Page 1

www.fieldcontrols.com

Page 2

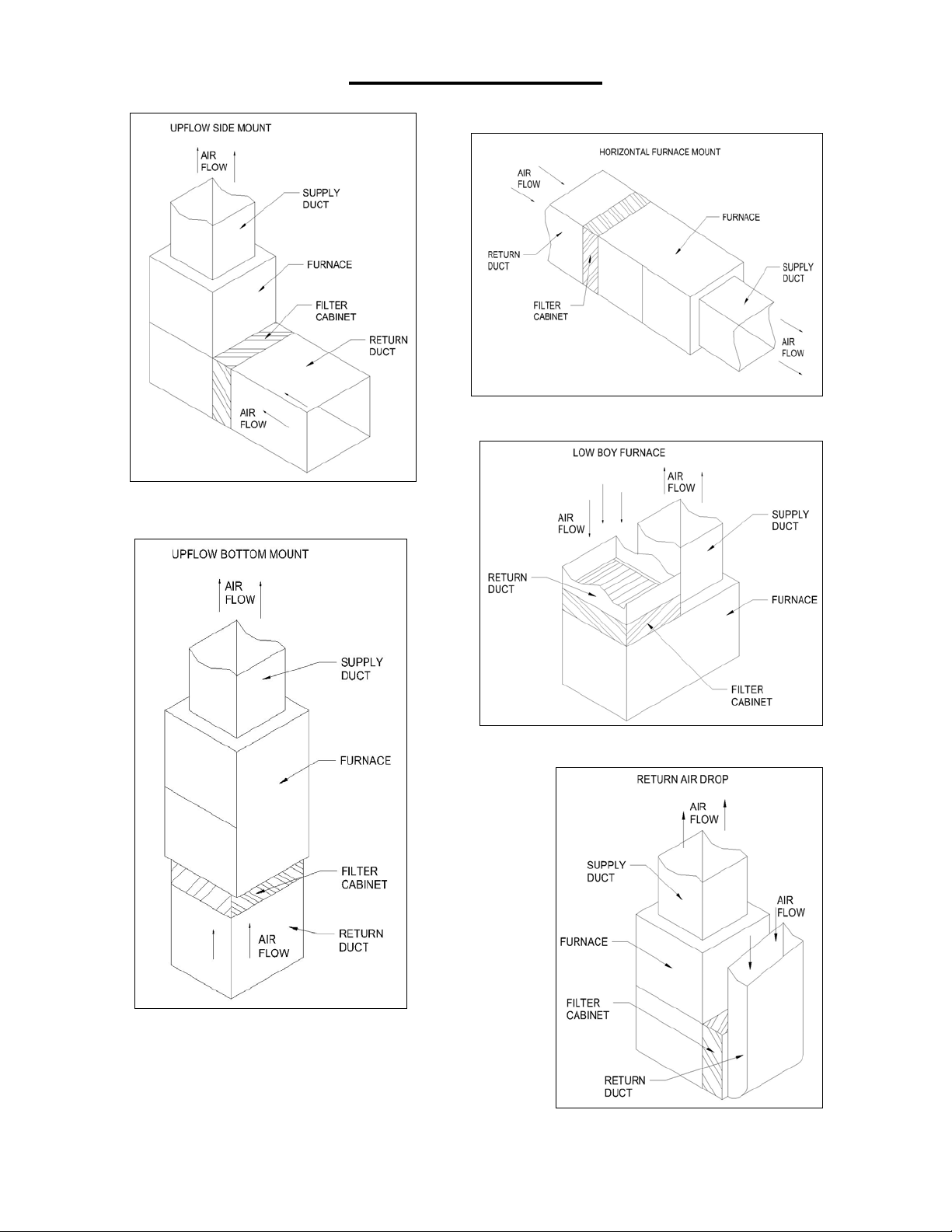

MOUNTING OPTIONS

Figure 1

Figure 3

Figure 2

Figure 4

Figure 5

Page 3

CAUTION:

Before installing a media filter into the HVAC system,

the Qualified Agency must consider the additional

pressure drop being added to the HVAC system.

1. The filter must be installed on the return side of

the HVAC system, between the return air duct

and the intake of the system blower. NEVER

install on the supply side of the HVAC system.

2. The filter access panel MUST be installed where

there is at least twenty-six (26) inches in front of it.

This allows clearance for the replacement of the

media filter.

3. Some installations may require a duct transition.

Transitions may be needed to reduce pressure

drop and maintain appliance efficiency. The

appliance must operate within the manufacturer’s

recommended temperature and pressure drop

requirements.

4. Check the flow capacity and pressure drop

(Figure 6) to determine the filter is properly sized.

Figure 6

INSTALLATION:

WARNING: Always shut off the electrical power supply before working on the appliance.

1. Refer to the typical mounting positions (Figures 1 to 5) for proper placement of the filter cabinet.

2. Remove the metal filter cabinet from the carton and plastic bag.

3. Remove the access panel door and pull the media filter (in plastic bag) out of the cabinet. DO NOT install the media

filter with the plastic bag around it.

4. Position cabinet so access panel is available for easy media filter replacement The access panel MUST be accessible

to remove and replace the media filter. (Note: Minimum of twenty-six (26) inches for front clearance).

5. Position the filter cabinet onto return air side of the appliance (Figures 1 to 5). Duct transitions may be required to

properly mount the filter cabinet.

6. When the filter cabinet is mounted directly to the appliance or existing duct, mark the inside opening of the filter cabinet

and all 12 mounting screw locations.

7. Drill the marked mounting holes with a 1/8 inch diameter drill bit. Remove the marked filter opening with metal cutting

shears or equivalent.

8. Attach filter cabinet to the appliance or duct work using #8 X 1/2 inch long sheet metal screws or pop rivets. Seal the

housing connections with aluminum duct tape or equivalent.

9. Remove media filter from the plastic bag and discard the plastic bag. TIP: Write the installation date on filter next to

directional arrow for future filter replacement reference. The media filter MUST be installed WITHOUT the plastic bag.

10. Install media filter into the filter cabinet.

11. Install the filter cabinet access panel.

12. Place appliance back into service. Appliance must operate within the appliance manufacturer’s recommended

temperature and pressure drop requirements.

Page 4

MAINTENANCE:

b

t

The media filter MUST be replaced periodically. The

reason is to maintain appliance operating efficiency

by minimizing pressure drop through the HVAC

system. The frequency of filter media replacement

depends on the operational environment. The need

for replacement is easily determined by a visual

inspection. Note: For optimum performance, replace

the media filter every 6 to 12 months.

EDIA FILTER REPLACEMENT PROCEDURE:

M

1. Turn off electrical power to the HVAC system.

2. Remove the filter cabinet access panel.

Note: “AIR FLOW” directional arrow, located on

existing media filter (Figure 6).

3. Remove the existing filter media.

4. Remove the new media filter from the plastic bag.

Tip: Re-use plastic bag to discard the used

media filter.

5. Check media filter directional arrow (→)! The

directional arrow MUST point in the direction of

air flow.

Tip: Write the installation date on media filter

next to directional arrow for future filter

replacement reference.

6. Install the new media filter.

7. Install the filter cabinet access panel.

8. Turn on electrical power to the HVAC system.

R

EPLACEMENT PARTS LIST:

Figure 7

Air cleaner Model Replacement filter size

FC - 1400 16 x 25 x 5

FC - 2000 20 x 25 x 5

Replacement filter

part number

46568500

46568600

Number of filters per carton

3

3

Limited Warranty

Field Controls, L.L.C. warrants that the following Field Controls, L.L.C. products sold hereunder, shall be free from defects in material and workmanship

under normal use for eighteen (18) months from date of manufacturing by the consumer excepting the provisions numbered below.

Provisions:

1. Field Controls shall have no obligation in the event the customer is unable to provide receipt showing the date the customer purchased the

product(s) or accurate date code information.

2. The product must be properly installed, maintained and operated under normal conditions.

3. Field Controls shall not be liable for any consequential and incidental damages, resulting from failure of a Field Controls, L.L.C. product, failure to

deliver, delay in delivery, delivery in nonconforming condition, or for any breech of contract or duty

customer.

4. Field Controls, L.L.C. products are often intended for use in specific applications. Field Controls, L.L.C. makes no warranty if a Field Controls,

L.L.C. product is used in applications other than intended.

5. Field Controls, L.L.C. makes no warranty of any kind in regard to any other manufacturer’s products distributed by Field Controls, L.L.C. Field

Controls, L.L.C. will pass on all warranties made by the manufacturer and where possible, will expedite the claim on behalf of the customer, bu

ultimately, responsibility for disposition of the warranty claim lies with the manufacturer.

etween Field Controls, L.L.C. and the

P/N 46567000 11/08

Loading...

Loading...